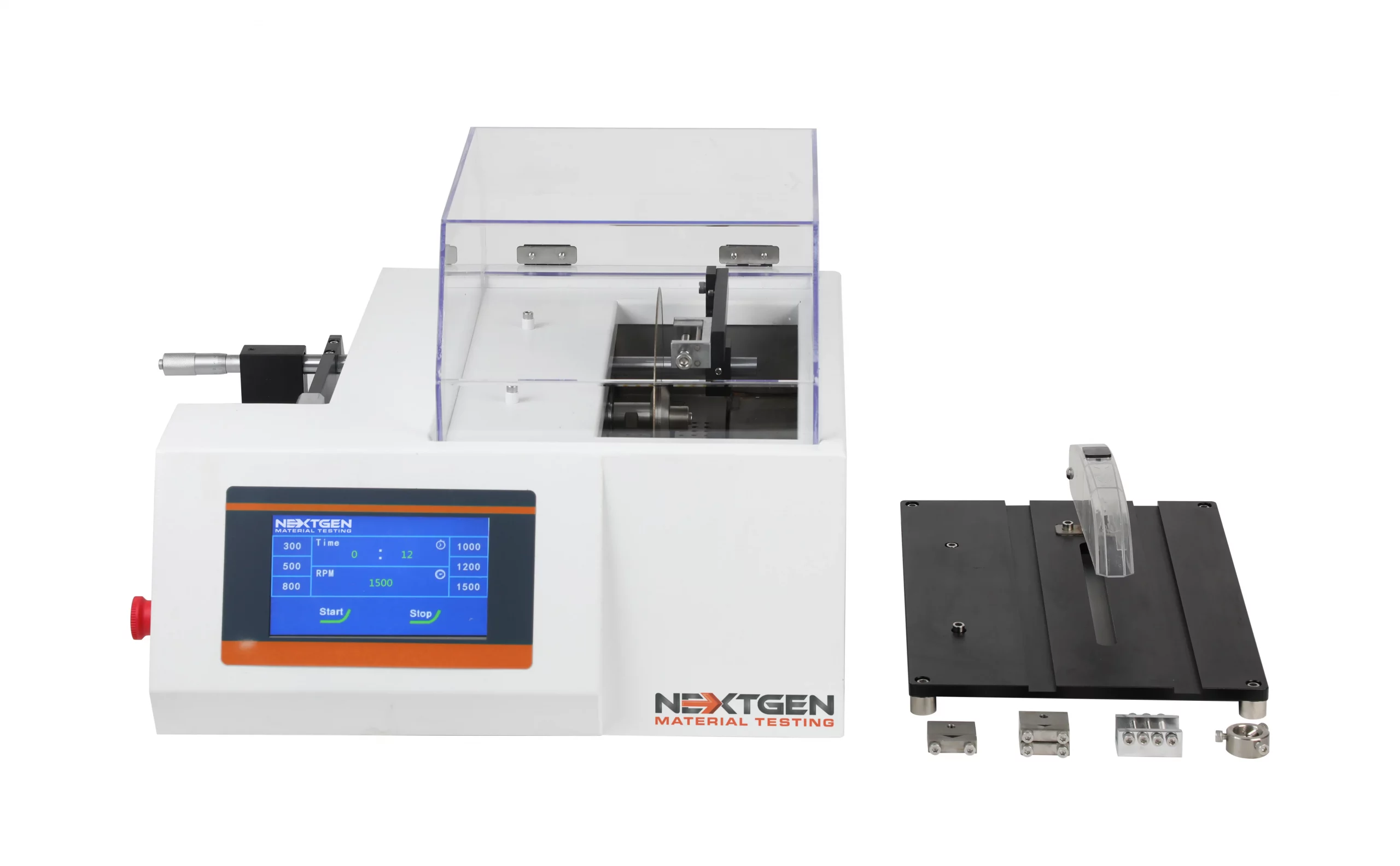

The NG-AutoPol system integrates multiple advanced functions that make it exceptionally efficient for preparing tensile and fatigue testing specimens. Here are some of its key highlights:

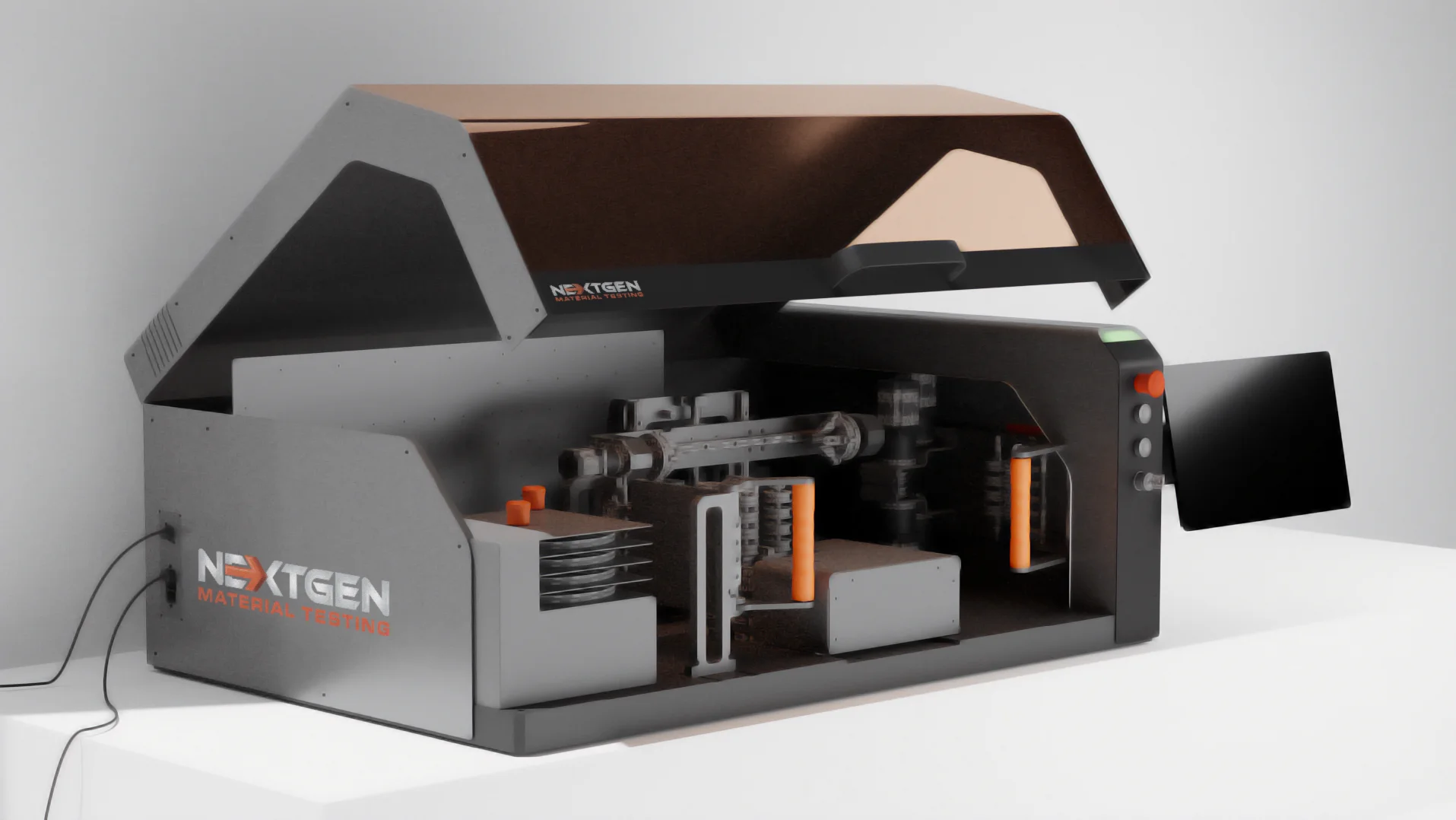

- Automatic Longitudinal Polishing: Provides consistent, repeatable surface results with controlled single-contact polishing.

- Customizable Parameters: Adjust rotation, force, speed, and polishing length directly from the touchscreen interface.

- Multi-Grit Sandpaper Switching: Automatically transitions between up to four sandpaper types within one polishing cycle.

- Integrated Cleaning System: Keeps the sandpaper clean for longer service life and uniform performance.

- Stable Mechanical Design: Maintains polishing accuracy and uniform pressure across all sample types.

- Process Memory Function: Saves polishing configurations for identical repeat runs and standardized workflows.

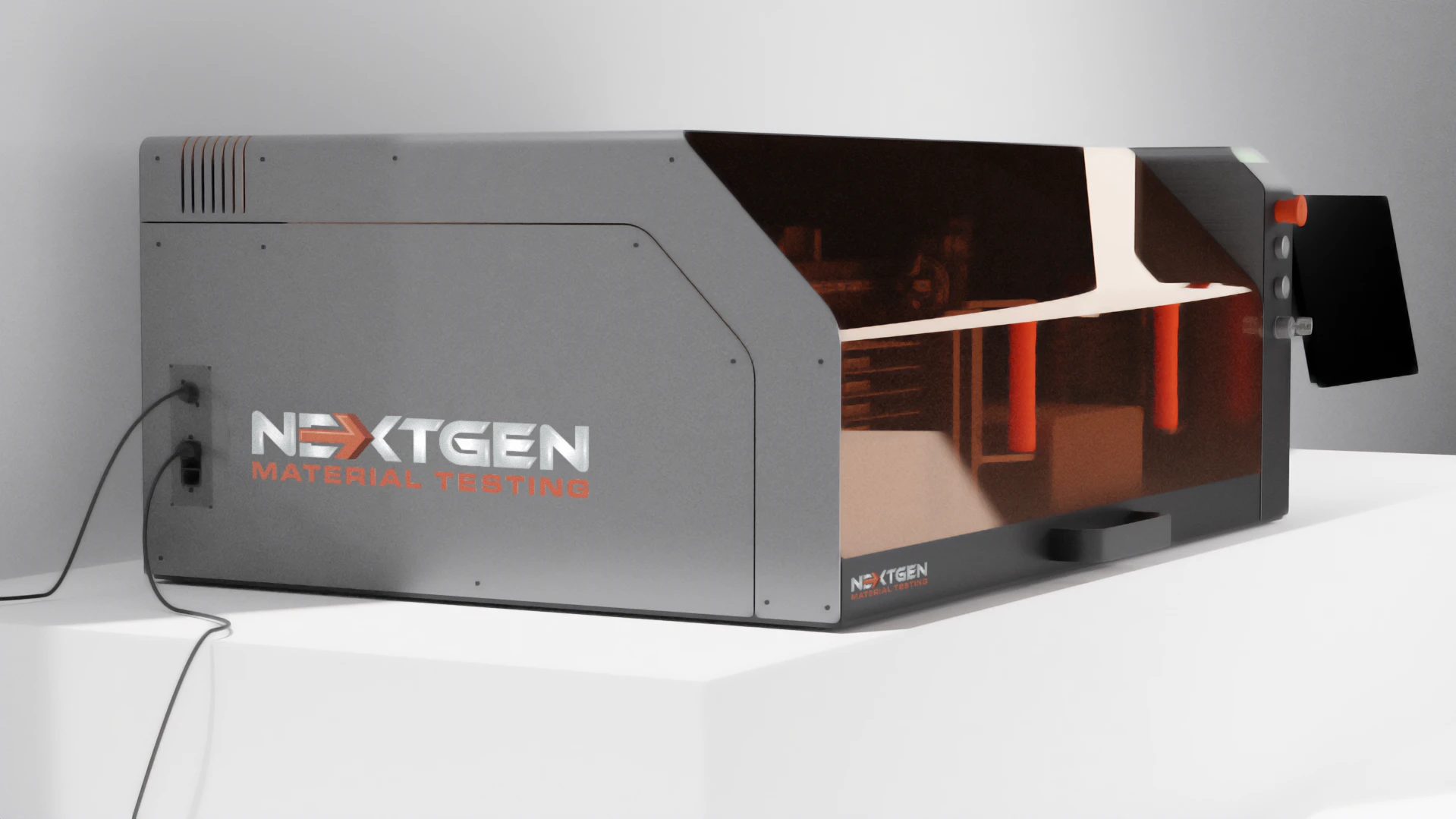

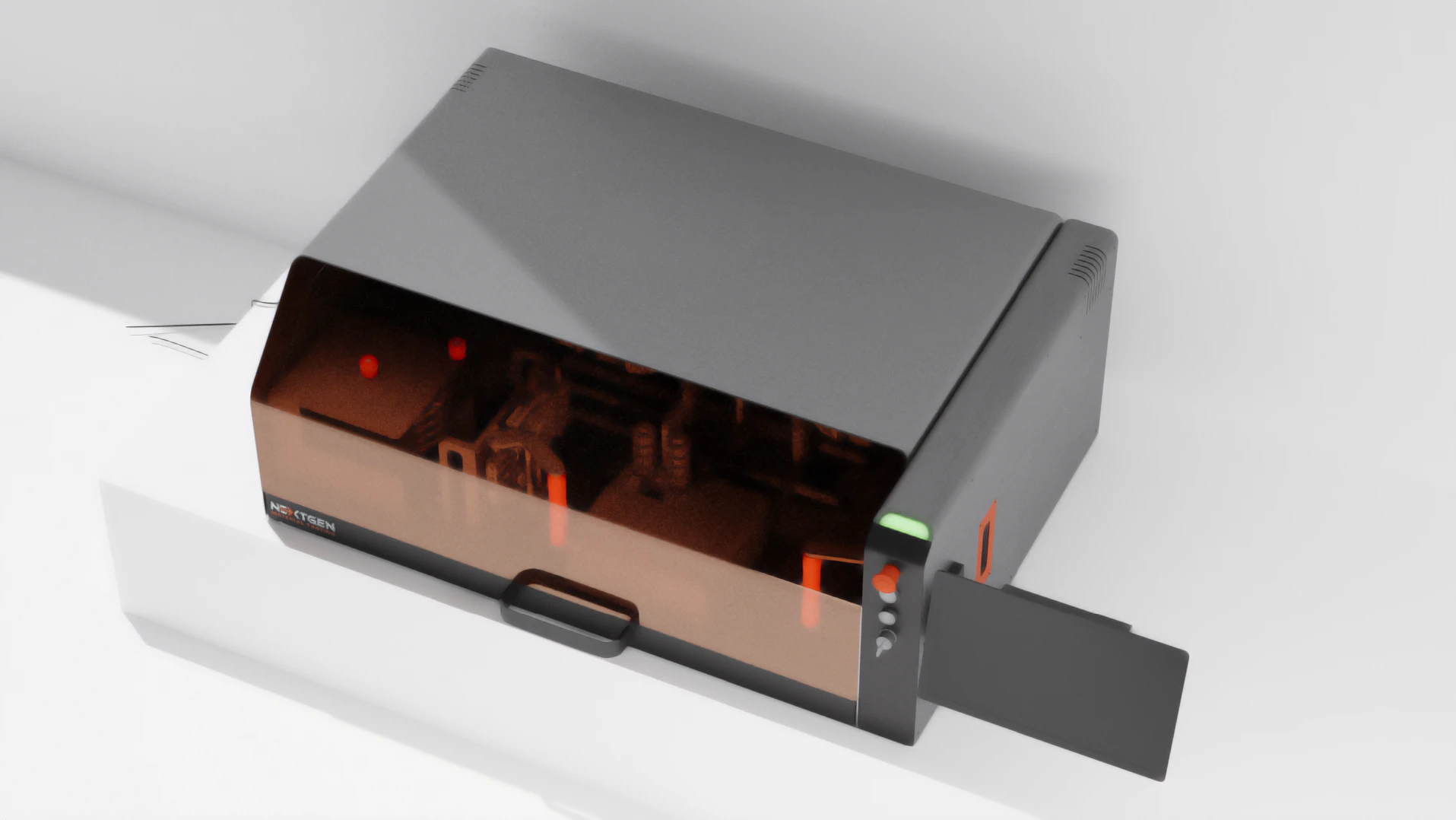

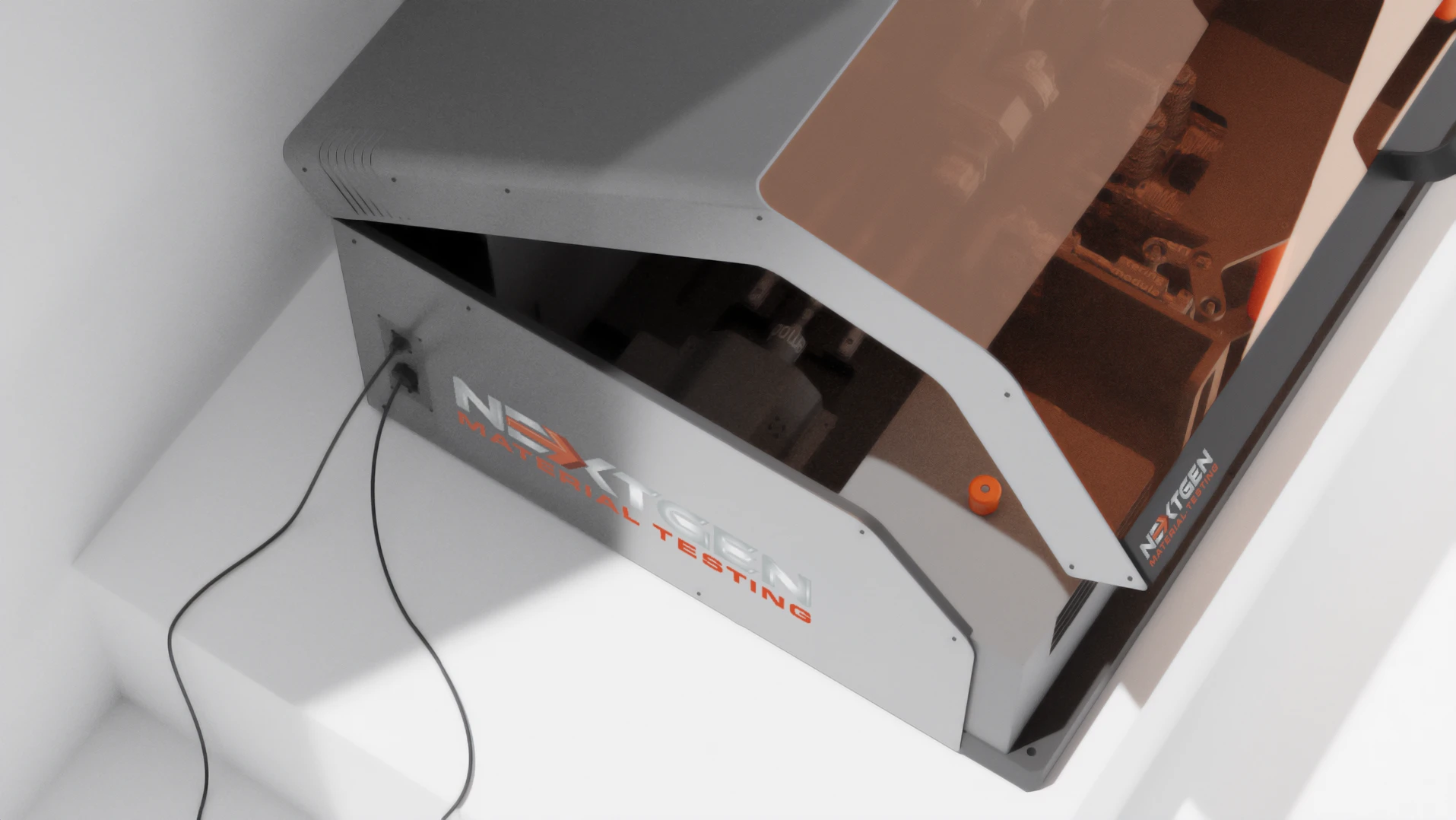

- Compact, Low-Maintenance Setup: Space-efficient design ideal for busy laboratories with limited floor area.

- Low-Stress Surface Finishing: Uses precise pressure control and linear motion to minimize residual stress and preserve specimen integrity.

- Multi-Geometry Compatibility: Quickly adapts to cylindrical, flat, small, and large specimens with interchangeable fixtures.

- NADCAP Compliance Option: Available in NADCAP-ready configuration for certified aerospace and high-precision testing environments.

NG-AutoPol Model Configurations

The NG-AutoPol machine is available in several configurations to accommodate different sample geometries and laboratory requirements. Each model maintains full compliance with EN 6072 and supports stress-free surface finishing for tensile and fatigue testing applications.

| Model | Description |

| SCS – Standard Cylindrical Specimen | Designed for polishing cylindrical specimens of various diameters and lengths in full compliance with EN 6072. |

| ESCS – Extremely Small Cylindrical Specimen | Optimized for polishing micro-sized cylindrical specimens that require precise control and delicate surface finishing. |

| ELCS – Extremely Large Cylindrical Specimen | Engineered to handle oversized cylindrical samples while maintaining uniform polishing quality and stability. |

| FS – Flat Specimen | Developed for polishing flat tensile specimens, ensuring a consistent longitudinal surface finish across the entire sample area. |

| C – Customized Configuration | Tailor-made solution available to meet specific laboratory or industrial polishing requirements. |

System Configuration

The NG-AutoPol comes as a complete, ready-to-operate machine. Each unit includes:

- NG-AutoPol main unit — automatic longitudinal polishing system with integrated touchscreen control.

- Interchangeable specimen fixtures — compatible with cylindrical, extremely small or large, and flat specimen types.

- Comprehensive sandpaper roll set — multiple grit sizes for progressive surface finishing.

- Operation and training package — detailed user manual and step-by-step instructional videos for smooth setup and use.

Technical Specifications

The NG-AutoPol combines intelligent automation with precise mechanical control. Below are the key technical specifications that define its performance and flexibility:- Suitable for cylindrical and flat specimens of various diameters and lengths.

- Fully automatic longitudinal polishing process for consistent surface finish.

- Controlled single-contact motion — each paper area interacts with the specimen only once to prevent over-polishing.

- Adjustable sandpaper force: 5 – 50 N.

- Adjustable linear speed: 10 – 100 mm/s, in 10 mm/s increments.

- Adjustable active polishing length: 5 – 280 mm.

- Compatible with multiple sandpaper grits (e.g., 200, 400, 600, 800).

- Overall dimensions (W × L × H): 33.07" × 48.82" × 19.69" (840 × 1240 × 500 mm).

- Weight: 485 lbs (220 kg).

- Automatic switching between up to four sandpaper grades in one cycle.

- All parameters controlled via touchscreen interface with process visualization.

- Optional data logging and calibration modes available for advanced testing workflows.

Global Testing Standards Compliance

To operate on a global scale, the NG-AutoPol system supports multiple industry standards. This means that your lab results are internationally recognized and comparable across testing facilities in North America, Europe, Asia, and beyond. Below are the standards that NG-AutoPol complies with:

To operate on a global scale, the NG-AutoPol system supports multiple industry standards. This means that your lab results are internationally recognized and comparable across testing facilities in North America, Europe, Asia, and beyond. Below are the standards that NG-AutoPol complies with:

- ASTM E466 – Force-Controlled Constant Amplitude Axial Fatigue

Defines the procedure for fatigue testing of metallic samples under a constant axial load amplitude, where strains remain mostly elastic. It is used to assess fatigue life under repeat loading. - ASTM E606 – Strain-Controlled Fatigue Testing

Covers fatigue tests where the strain (rather than the stress) is controlled across cycles. It is used to study low-cycle fatigue and the plastic deformation that occurs during repeated loading. - EN 6072 – Metallic Materials — Constant Amplitude Fatigue Testing (S-N method)

European standard equivalent for S-N fatigue data under constant amplitude loading, aligning specimen geometry and testing methods across labs. - NADCAP (Materials Testing Accreditation)

An accreditation program used in aerospace and related industries to validate that testing, preparation, and inspection processes meet rigorous quality and traceability standards. NG-AutoPol can be used in a NADCAP-ready configuration.

Specimen Compatibility

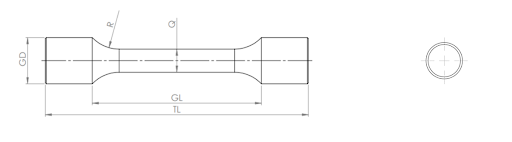

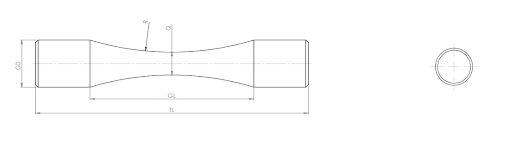

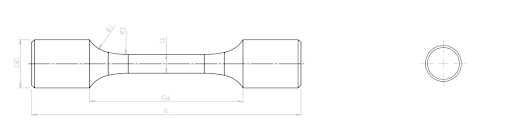

The NG-AutoPol achieves outstanding surface finish on both round and flat specimens, meeting the highest preparation standards. Below are the sample geometry references supported by the NG-AutoPol system:Cylindrical Specimens

|

| Standard Cylindrical Specimen |

|

| Continuous Radius Cylindrical Specimen |

|

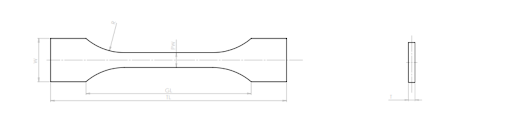

| Double Radius Cylindrical Specimen |

Flat Specimens

|

| Standard Flat Specimen |

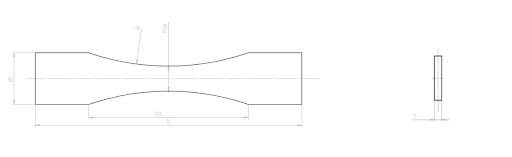

|

| Continuous Radius Flat Specimen |

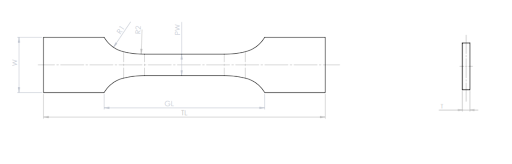

|

| Double Radius Flat Specimen |