Metal Testing Equipment

Description

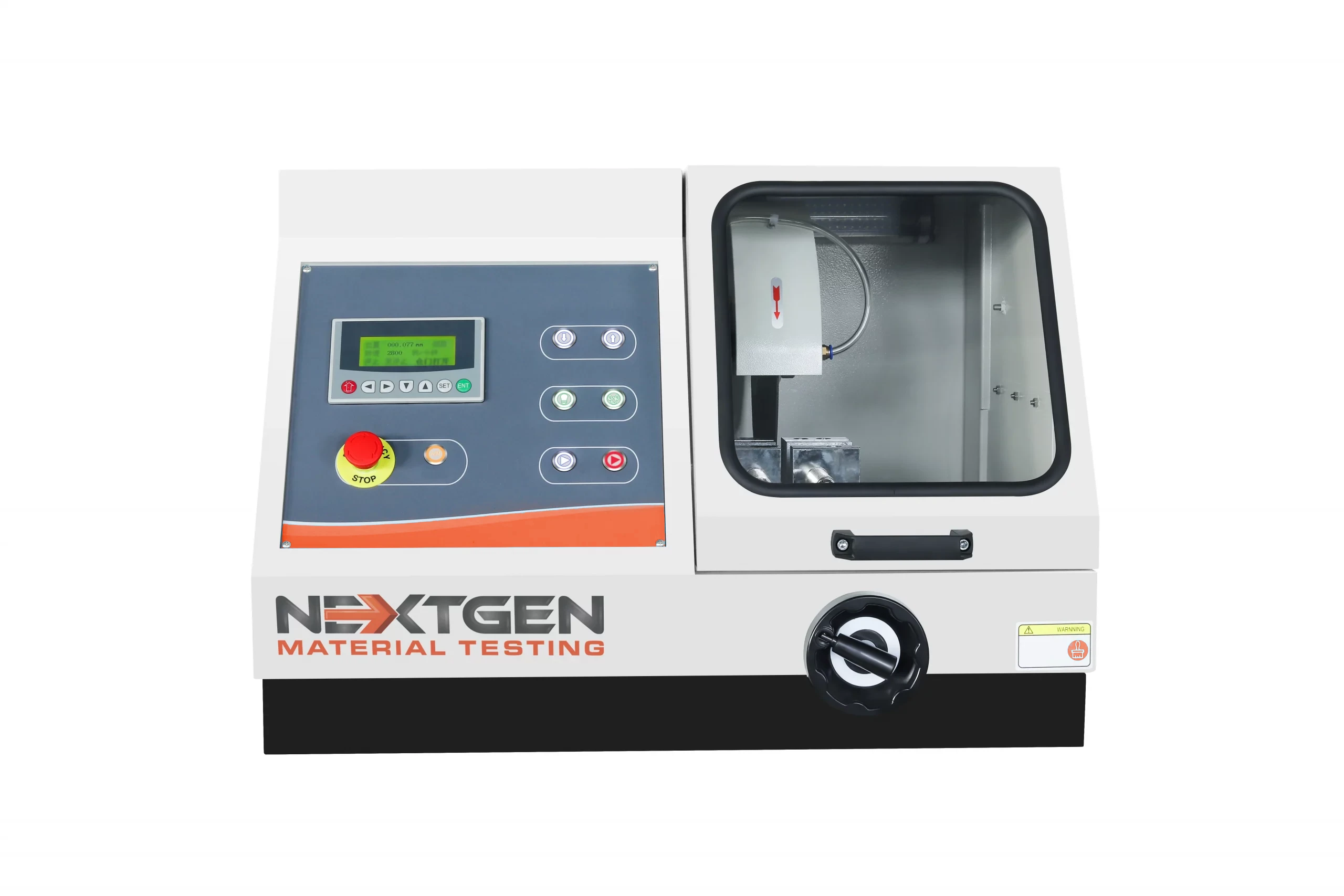

Introducing the GenCut GL80A, a highly precise cutting machine offering both automatic and manual work modes. Comprising essential components such as the body, electric control box, cutting room, motor, cooling system, cutting wheel, and more, this machine is a comprehensive solution for your cutting needs.

With the GenCut GL80A, you can effortlessly cut circular workpieces with a diameter of under 80mm, as well as rectangular samples with a height of 80mm and a depth of less than 200mm. Its versatility ensures it meets various cutting requirements.

To safeguard your samples from overheating and tissue damage during the cutting process, the machine features an efficient cooling system. This technology guarantees optimal cutting results while maintaining the integrity of your materials. Read more in our MEGA BLOG!

Standard Configuration

-

GenCut GL80A Cutting Saw

-

Coolant Tank 50L

-

Coolant Pump

-

Wrench 12-14mm

-

Wrench 24-27mm

-

Wrench 36mm

-

Water Inlet Tube

-

Drain Pipe

-

Cutting Wheel

-

Φ350 x 2.5 x Φ32mm

-

Fast Clamps (Left and Right) and Operation Manual

Designed with a closed structure and a large observation window, the GenCut GL80A prioritizes user safety without compromising visibility. You can work confidently knowing that precautions have been taken to create a safe and secure environment.

With its quick clamping mechanism, sample clamping becomes a breeze, saving you time and effort. The GenCut GL80A streamlines your workflow, enabling you to focus on the task at hand.

For enhanced durability, the machine's main components are constructed using stainless materials, ensuring a long service life. You can rely on the GenCut GL80A to withstand frequent use and deliver consistent performance.

The GenCut GL80A offers high precision cutting capabilities with automatic and manual work modes. Its robust construction, user-friendly features, and safety mechanisms (emergency stop) make it a reliable choice for a wide range of cutting applications.

GenCut GL80A Technical Specifications

|

Model |

GenCut GL80A |

|

Cutting Wheel |

Φ350×2.5×Φ32mm |

|

Maximum Cutting Section |

Φ80mm |

|

Max. Movement of the Table in the Y Axis |

275mm |

|

Spindle Speed |

Constant Speed 2100rpm |

|

Cutting Speed |

0.01 - 1mm/s |

|

Cutting Table Size |

310 x 280 mm |

|

Clamping |

Fast Action Left and Right Vise (Included) |

|

Feeding Modes |

Automatic mode: Cutting wheel moves automatically in the Y axis (forward - backward), and automatically returns to the original position after cutting is done. Manual mode: Rotate handwheel to move the work table forward/backward in Y direction |

|

Automatic Cutting Mode |

Intermittent Cutting (Metal Workpieces) and Continuous Cutting (Non-Metal Workpieces) |

|

Reset Mode |

Automatic Reset |

|

Cooling System |

Automatic Water Cooling with 2 Nozzles |

|

Water Tank |

50L |

|

Data Display |

LCD Digital Display |

|

Cutting Chamber Housing |

Steel Plating |

|

Cutting Light |

Low Voltage DC Led Lighting |

|

Motor Power |

3kW |

|

Voltage |

220V 50/60Hz 3 Phase |

|

Dimensions & Weight |

35” x 31.25” x 23.625”; 462lbs / 887 x 795 x 600 mm; 210kg |

FAQs

The GenCut GL80A - Precision Metallographic Sample Cutting Machine offers both automatic and manual work modes to meet diverse cutting requirements. In automatic mode, the cutting wheel moves automatically along the Y axis (forward and backward), and the machine returns to its original position once the cutting is complete. This mode is ideal for consistent, precise cuts with minimal manual intervention.

In manual mode, users can operate the machine by rotating a handwheel to move the work table forward and backward along the Y axis. This manual control allows for greater precision and customization during the cutting process, making it suitable for more intricate or specific cutting tasks. The combination of these two modes provides flexibility, allowing the GenCut GL80A to accommodate a broad spectrum of cutting applications. This dual-mode functionality increases the machine's versatility and reliability when it comes to preparing metallographic samples for analysis.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL80A - Precision Metallographic Sample Cutting Machine comprises key components that make it a comprehensive solution suitable for a wide range of cutting applications. Key components include the main body, which houses the machine’s structure, and the electric control box, which manages operational settings and controls.

The cutting room is where the actual cutting process takes place, equipped with a powerful motor that drives the cutting wheel. The cooling system, featuring automatic water cooling with two nozzles and a 50-liter coolant tank, is crucial for preventing overheating and ensuring optimal cutting conditions. The cutting wheel itself, with dimensions Φ350 x 2.5 x Φ32mm, is designed to handle precise cuts on various materials.

Additionally, the GenCut GL80A includes components like fast action vises for quick and secure sample clamping, a cutting table for stable sample placement, and an LCD digital display for monitoring and adjusting settings. Together, these components provide the machine with reliable and efficient performance for precision metallographic sample cutting.

Click here to learn more about the product or here to receive a personalized quote.

What types of samples can the GenCut GL80A - Precision Metallographic Sample Cutting Machine handle?

The GenCut GL80A - Precision Metallographic Sample Cutting Machine is designed to handle various types of sample types, showcasing its adaptability and capability in precision cutting. It can effortlessly cut circular workpieces with a diameter of under 80mm, making it suitable for numerous round samples used in metallographic analysis.

Additionally, the GenCut GL80A can cut rectangular samples with a height of up to 80mm and a depth of less than 200mm. This flexibility allows it to accommodate different shapes and sizes of samples, making sure that it meets various cutting requirements. Whether working with circular or rectangular specimens, the GenCut GL80A provides precise and efficient cutting performance.

The machine’s ability to handle diverse sample types makes it an essential tool for laboratories and industries involved in metallographic sample preparation. Its versatility means that users can rely on the GenCut GL80A to perform an array of cutting tasks with ease and accuracy.

Click here to learn more about the product or here to receive a personalized quote.

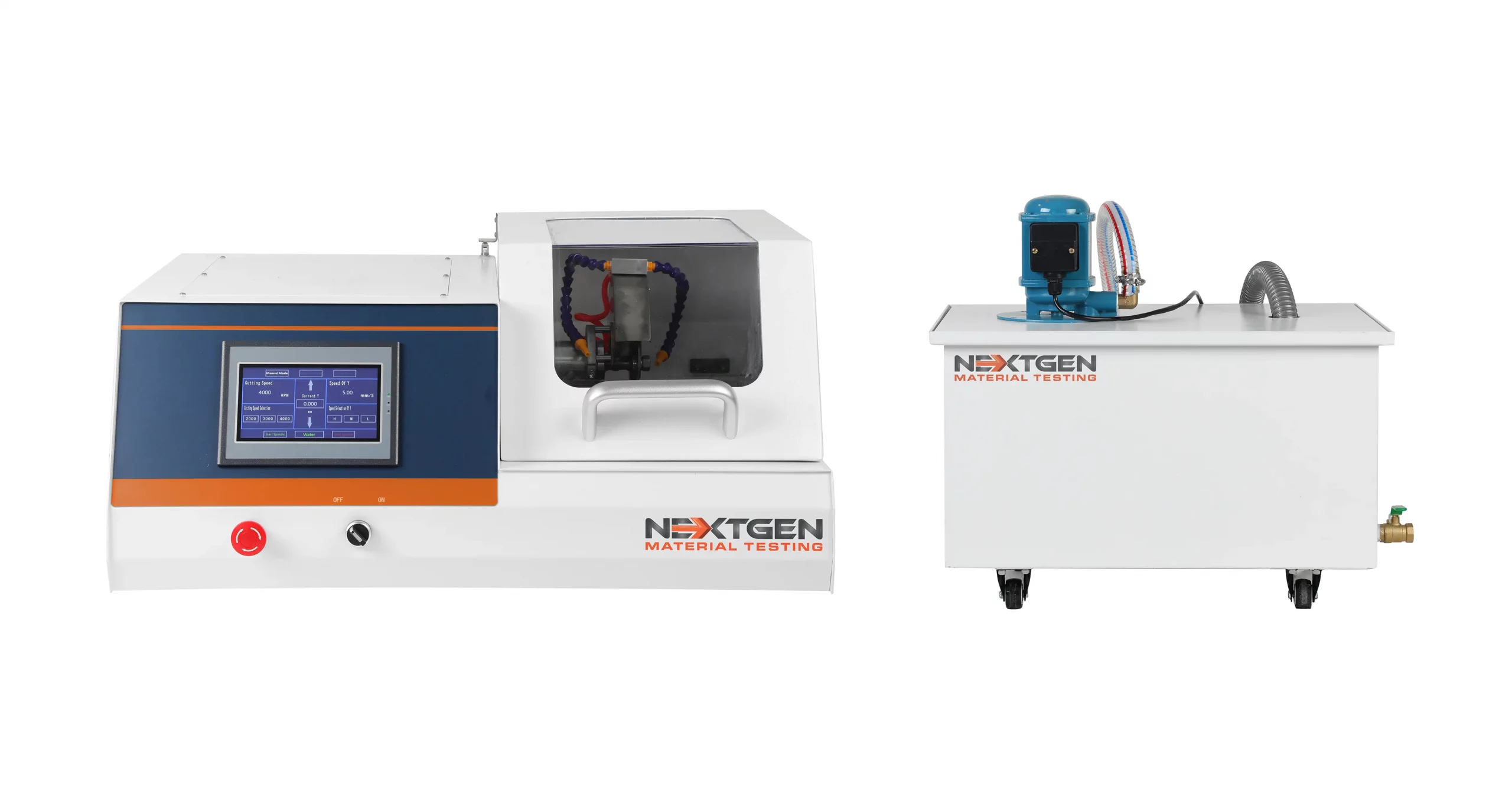

To protect your samples from overheating and tissue damage during the cutting process, the GenCut GL80A - Precision Metallographic Sample Cutting Machine features an efficient cooling system. This advanced technology assures that the cutting area remains at an optimal temperature, preventing heat buildup that could compromise the integrity of the samples.

The cooling system includes automatic water cooling with two nozzles, providing continuous and effective cooling directly to the cutting area. It also comes with a 50-liter coolant tank and a coolant pump, maintaining a steady flow of coolant to keep samples cool during cutting operations. This setup is necessary for precise cuts without damaging the material being processed.

By effectively managing heat, the cooling system guarantees that the GenCut GL80A delivers optimal cutting results while preserving your materials' quality and structural integrity. This feature is particularly important when working with sensitive or heat-sensitive materials.

Click here to learn more about the product or here to receive a personalized quote.

The standard configuration of the GenCut GL80A - Precision Metallographic Sample Cutting Machine includes all the key components needed for optimal operation and precision cutting. This comprehensive setup guarantees that users have everything they need to start cutting tasks quickly.

The standard package includes the GenCut GL80A Cutting Saw, which is the main unit of the machine. It comes with a 50-liter coolant tank and a coolant pump, which are required for the machine's efficient cooling system. Additionally, the package includes wrenches (sizes 12-14mm, 24-27mm, and 36mm) for assembly and maintenance tasks.

Also included are a water inlet tube and a drain pipe, facilitating the connection and management of the cooling system. The cutting wheel provided has dimensions of Φ350 x 2.5 x Φ32mm, suitable for precise cutting tasks. Fast clamps (left and right) are also part of the configuration, providing secure sample clamping during cutting operations. Users are guided through setup, operation, and maintenance procedures.

This complete configuration of the GenCut GL80A ensures that users have everything they need to perform precise and efficient metallographic sample cutting from the very beginning of their project.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL80A - Precision Metallographic Sample Cutting Machine is designed with a closed structure and a large observation window, prioritizing user safety without compromising visibility. The closed structure provides assurance that all cutting operations are contained within a secure environment, minimizing exposure to moving parts and debris.

The large observation window allows users to monitor the cutting process in real time, providing clear visibility of the operation while maintaining a safe distance. This design feature makes it possible to observe and control the cutting process without opening the machine, which increases safety by preventing accidental contact with the cutting wheel or other components.

By combining these safety features, the GenCut GL80A provides a secure and user-friendly environment for precision cutting. Users can work confidently, knowing that the machine's design includes essential safety precautions to protect them during operation. This thoughtful design makes the GenCut GL80A an ideal choice for laboratories and industries that require both safety and efficiency in metallographic sample preparation.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL80A - Precision Metallographic Sample Cutting Machine improves workflow efficiency with its quick clamping mechanism. This feature allows for fast and secure clamping of samples, significantly reducing the time and effort required to set up each cutting task. By simplifying the clamping process, users can quickly prepare samples and proceed with cutting, thus simplifying the overall workflow.

The quick clamping mechanism of the GenCut GL80A ensures samples are held firmly in place, preventing movement during cutting and precise results. This improves the efficiency, accuracy, and reliability of the cutting process. Users can focus more on the actual cutting tasks and less on setup procedures, leading to increased productivity and better use of time.

By including a quick clamping system, the GenCut GL80A makes sample preparation more straightforward and efficient, enabling users to maintain a steady workflow and achieve consistent cutting results. This feature is particularly beneficial in busy laboratory environments where time management and precision are critical.

Click here to learn more about the product or here to receive a personalized quote.

The main components of the GenCut GL80A - Precision Metallographic Sample Cutting Machine are made of stainless materials. There are many advantages to this type of construction, including excellent durability and resistance to wear, corrosion, and other forms of degradation. A stainless steel component is renowned for its strength, durability, and resistance to corrosion, making it an ideal choice for components in demanding laboratory environments in which they must withstand frequent and rigorous use.

By using stainless materials for its key parts, the GenCut GL80A is designed to offer long service life and reliable performance. This robust construction reduces the need for frequent maintenance and replacements, guaranteeing that the machine remains a valuable tool for precision cutting tasks over time. The durability of these materials ensures consistent and accurate results, making the GenCut GL80A a dependable choice for metallographic sample preparation.

Click here to learn more about the product or here to receive a personalized quote.

The cutting wheel used in the GenCut GL80A - Precision Metallographic Sample Cutting Machine has specific dimensions designed for precision and efficiency. The cutting wheel measures Φ350mm in diameter, with a thickness of 2.5mm and a central hole diameter of Φ32mm. These dimensions provide assurance that the cutting wheel can handle a broad range of materials with precision.

The large 350mm diameter allows for deep and thorough cuts. This makes it suitable for both circular workpieces up to 80mm in diameter. It is also suitable for rectangular samples with a height of 80mm and a depth of up to 200mm. The 2.5mm thickness provides an excellent balance between cutting strength and finesse, ensuring clean and accurate cuts without excessive material removal. The 32mm central hole diameter provides a secure attachment to the machine, providing stability and safety during operation.

Click here to learn more about the product or here to receive a personalized quote.

There is a maximum cutting section of 80mm available on the GenCut GL80A - Precision Metallographic Sample Cutting Machine. Based on this specification, it can be concluded that the machine is capable of cutting through circular workpieces with a diameter of up to 80 mm with great efficiency. As a result of these capabilities, the machine is suitable for the preparation of metallographic samples of various sizes, providing precise and accurate cuts for the purpose of analysis.

The ability to handle a maximum cutting section of Φ80mm allows the GenCut GL80A to be versatile in its applications, accommodating a range of sample sizes typically encountered in metallographic studies. This guarantees that users can rely on the machine for consistent and high-quality cutting performance, making it one of the most valuable tools for the preparation of metallographic samples in laboratories and industrial settings.

Click here to learn more about the product or here to receive a personalized quote.

The maximum movement of the table in the Y axis for the GenCut GL80A - Precision Metallographic Sample Cutting Machine is 275mm. The wide range of motion makes it possible for the table to move forward and backward in a significant amount of space. In this way, the user is able to handle larger samples with greater ease and achieve precise positioning during the cutting process.

The 275mm maximum movement means that the GenCut GL80A can accommodate various sample sizes and shapes, increasing its flexibility and usability in different cutting applications. This feature is particularly beneficial for accurate cuts on longer samples or when multiple cuts are required on a single piece. The substantial Y-axis movement capability makes the GenCut GL80A a reliable and adaptable tool for precision metallographic sample preparation, meeting the needs of diverse laboratory and industrial environments.

Click here to learn more about the product or here to receive a personalized quote.

The spindle speed of the GenCut GL80A - Precision Metallographic Sample Cutting Machine is constant at 2100 revolutions per minute (rpm). This consistent and high spindle speed guarantees that the cutting wheel operates at an optimal rate for precise and efficient cutting of different materials.

Maintaining a constant speed of 2100rpm allows the GenCut GL80A to deliver smooth and accurate cuts. This reduces the likelihood of imperfections and ensures a high-quality finish on the samples. This speed is particularly effective for metallographic sample preparation, where precision and consistency are crucial for reliable results.

GenCut GL80A is a dependable choice for laboratories and industries requiring precise cutting capabilities for metallographic analysis in order to improve their efficiency and productivity. The constant spindle speed of 2100rpm increases the machine's performance and reliability.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL80A - Precision Metallographic Sample Cutting Machine offers a cutting speed range from 0.01 to 1 millimeter per second. This adjustable speed range allows users to select the best cutting speed for different materials and sample types. For instance, a slower speed of 0.01 mm/s might be chosen for delicate or heat-sensitive materials to ensure precision and avoid damage, while a faster speed of 1 mm/s can be used for tougher materials that require quicker processing.

As a result of this versatility in cutting speed, the GenCut GL80A is capable of performing a wide range of cutting tasks efficiently, providing optimal results for both simple and complex samples, regardless of their complexity. It is particularly useful in metallographic sample preparation to fine-tune the speed of cutting because different materials and sample conditions necessitate different cutting methods.

Click here to learn more about the product or here to receive a personalized quote.

The cutting table on the GenCut GL80A - Precision Metallographic Sample Cutting Machine measures 310 x 280 millimeters. This ample table size provides a stable and spacious platform for securing and cutting a variety of samples. Whether dealing with large or small workpieces, the 310 x 280 mm cutting table accommodates an array of sample sizes, allowing them to be held firmly during the cutting process despite their large size.

Due to the generous dimensions of the cutting table, the machine has a great deal of versatility, allowing for precision and efficient handling of a variety of different materials when preparing metallographic samples. It is ideal for accurate cuts and for maintaining the integrity of samples in both laboratories and industrial settings, making the GenCut GL80A a reliable tool that can be used in both environments.

Click here to learn more about the product or here to receive a personalized quote.

With the GenCut GL80A - Precision Metallographic Sample Cutting Machine, you will get a fast action mechanism for clamping the left and right vises. With the help of this clamping system, it is possible to position samples on the cutting table in a quick and secure manner. The fast action vises provide assurance that samples are held firmly in place, reducing setup time and enhancing cutting efficiency.

The left and right vises provide strong and reliable clamping from both sides, providing stability during cutting operations. This type of clamping mechanism is particularly useful for maintaining precise alignment and minimizing movement, which is necessary for accurate and consistent cuts. The inclusion of these fast action vises makes the GenCut GL80A a practical and user-friendly choice for metallographic sample preparation, facilitating quick setup and reliable performance.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL80A - Precision Metallographic Sample Cutting Machine offers two feeding modes: automatic and manual. In automatic mode, the cutting wheel moves automatically along the Y axis (forward and backward) and returns to its original position once the cutting process is complete. This mode is ideal for consistent and precise cuts with minimal manual intervention.

In manual mode, users can rotate a handwheel to move the work table forward and backward along the Y axis. This allows greater control over the cutting process, making it suitable for more intricate or customized cutting tasks. Manual mode is beneficial when precise adjustments are needed, enabling users to fine-tune sample positioning.

These dual feeding modes provide flexibility, allowing the GenCut GL80A to accommodate an array of cutting requirements and user preferences. Whether you need the precision of automatic mode or the control of manual mode, this machine provides optimal performance for different metallographic sample preparation tasks.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL80A - Precision Metallographic Sample Cutting Machine offers two automatic cutting modes: intermittent cutting for metal workpieces and continuous cutting for non-metal workpieces. In intermittent cutting mode, the machine periodically pauses the cutting process, allowing for controlled and precise metal materials cutting. This helps manage heat and reduces the risk of damage.

In continuous cutting mode, the machine performs a constant, uninterrupted cut. This is ideal for non-metal materials that do not require the same heat management. This mode allows for faster processing of plastics or composites, improving efficiency without compromising cut quality.

These automatic cutting modes enhance the versatility of the GenCut GL80A, allowing it to handle a variety of materials with the appropriate cutting approach. This provides optimal performance and precision across different sample types in metallographic sample preparation.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenCut GL80A - Precision Metallographic Sample Cutting Machine has an automatic reset mode. Using this feature, the machine will automatically return to its original starting position after every single cutting operation is completed. This automatic reset feature enhances the efficiency of the machine by preparing it for the next cutting job without requiring manual intervention on the operator's part.

As a result of the automatic reset mode, workflow is simplified, and downtime between cuts is reduced, making it easier for operators to move seamlessly from one operation to another. This can be especially useful in busy laboratory environments where time management is of utmost importance. With the GenCut GL80A, you can ensure a smooth and efficient cutting process by making sure the machine is always ready to cut the next sample.

Click here to learn more about the product or here to receive a personalized quote.

With the GenCut GL80A - Precision Metallographic Sample Cutting Machine, you will be able to view the sample information on the LCD display. As a result of this modern and user-friendly interface, users can easily read out key operational data in a clear and accurate manner, enabling them to monitor and then adjust the cutting parameters as needed.

Its LCD digital display provides real-time information on settings such as cutting speed, spindle speed, and other operational parameters, allowing the user to make precise adjustments as necessary according to the need. As a result, all the relevant information is easily accessible and easy to interpret, thus increasing the accuracy and efficiency of the cutting process.

As the GenCut GL80A integrates a digital LCD display, it offers operators a more intuitive and streamlined user experience that will greatly assist them in getting optimal results when it comes to cutting metallographic samples in a streamlined manner.

Click here to learn more about the product or here to receive a personalized quote.

The cutting chamber housing of the GenCut GL80A - Precision Metallographic Sample Cutting Machine is made from steel plating. This robust material provides excellent durability and protection, guaranteeing that the machine can withstand frequent use in demanding laboratory environments.

Steel plating not only enhances the structural integrity of the cutting chamber but also offers resistance to wear and corrosion. This makes certain that the cutting chamber remains in optimal condition over time, maintaining its protective function and contributing to the overall longevity of the machine.

By using steel plating for the cutting chamber housing, the GenCut GL80A provides a secure and reliable environment for precision cutting operations. This protects both the machine and the samples being processed. This durable construction makes it an ideal choice for metallographic sample preparation tasks.

Click here to learn more about the product or here to receive a personalized quote.

In order to achieve precision metallographic sample cutting results, GenCut GL80A - Precision Metallographic Sample Cutting Machine is equipped with low voltage DC LED lighting. A type of lighting that provides bright and consistent illumination of the cutting area makes it easier for users to clearly see the cutting process and ensure that it is done accurately.

LED lighting is energy-efficient and generates less heat than traditional lighting options, making it ideal for use in a cutting machine where temperature control is crucial. The low-voltage DC aspect ensures safety and efficiency, reducing electrical hazards while providing sufficient light for detailed work.

By incorporating low-voltage DC LED lighting, the GenCut GL80A enhances visibility and accuracy during cutting operations. This helps users achieve high-quality cuts with confidence. This feature contributes to the machine’s overall user-friendly design and reliable performance in metallographic sample preparation.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL80A - Precision Metallographic Sample Cutting Machine is equipped with a powerful 3kW motor. Due to the robust design of this motor, the machine is able to handle demanding cutting tasks efficiently, meaning that different types of materials can be cut with ease by this machine.

This machine is equipped with a motor of 3kW which contributes to its ability to deliver consistent and precise cuts every time. Because of this, it can be used for a broad range of metallographic sample preparation applications. This level of motor power ensures that the GenCut GL80A can maintain high performance even under continuous use, providing reliable and efficient operation in laboratories and industrial settings.

Click here to learn more about the product or here to receive a personalized quote.

In order to operate the GenCut GL80A - Precision Metallographic Sample Cutting Machine, you will need a 220V, 50/60Hz, three-phase power supply. It is important to note that this is a standard industrial power requirement to guarantee reliable and consistent performance.

The 220V three-phase power supply is common in many laboratory and industrial settings, providing the necessary power to support the machine's robust 3kW motor and other operational components. This configuration helps maintain stable and efficient cutting operations, enabling the GenCut GL80A to handle demanding metallographic sample preparation tasks effectively.

The GenCut GL80A not only adheres to this voltage and power configuration, but it is also compatible with the standard electrical setups in professional environments, therefore allowing for easy integration and cost-effective operation in a wide range of applications.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL80A - Precision Metallographic Sample Cutting Machine has dimensions of 35 inches in length, 31.25 inches in width, and 23.625 inches in height. In metric units, these dimensions are 887 mm in length, 795 mm in width, and 600 mm in height. The machine weighs 462 pounds, equivalent to 210 kilograms.

These dimensions and weight reflect the robust construction of the GenCut GL80A, providing stability and durability during operation. The substantial size provides a solid foundation for precise cutting tasks, capable of accommodating a wide range of sample sizes and guaranteeing consistent performance. The weight and dimensions make it suitable for placement in laboratory and industrial environments, where space and structural support can support its footprint.

This sturdy build is crucial for maintaining the machine's accuracy and reliability, making the GenCut GL80A an excellent choice for detailed and high-quality metallographic sample preparation.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

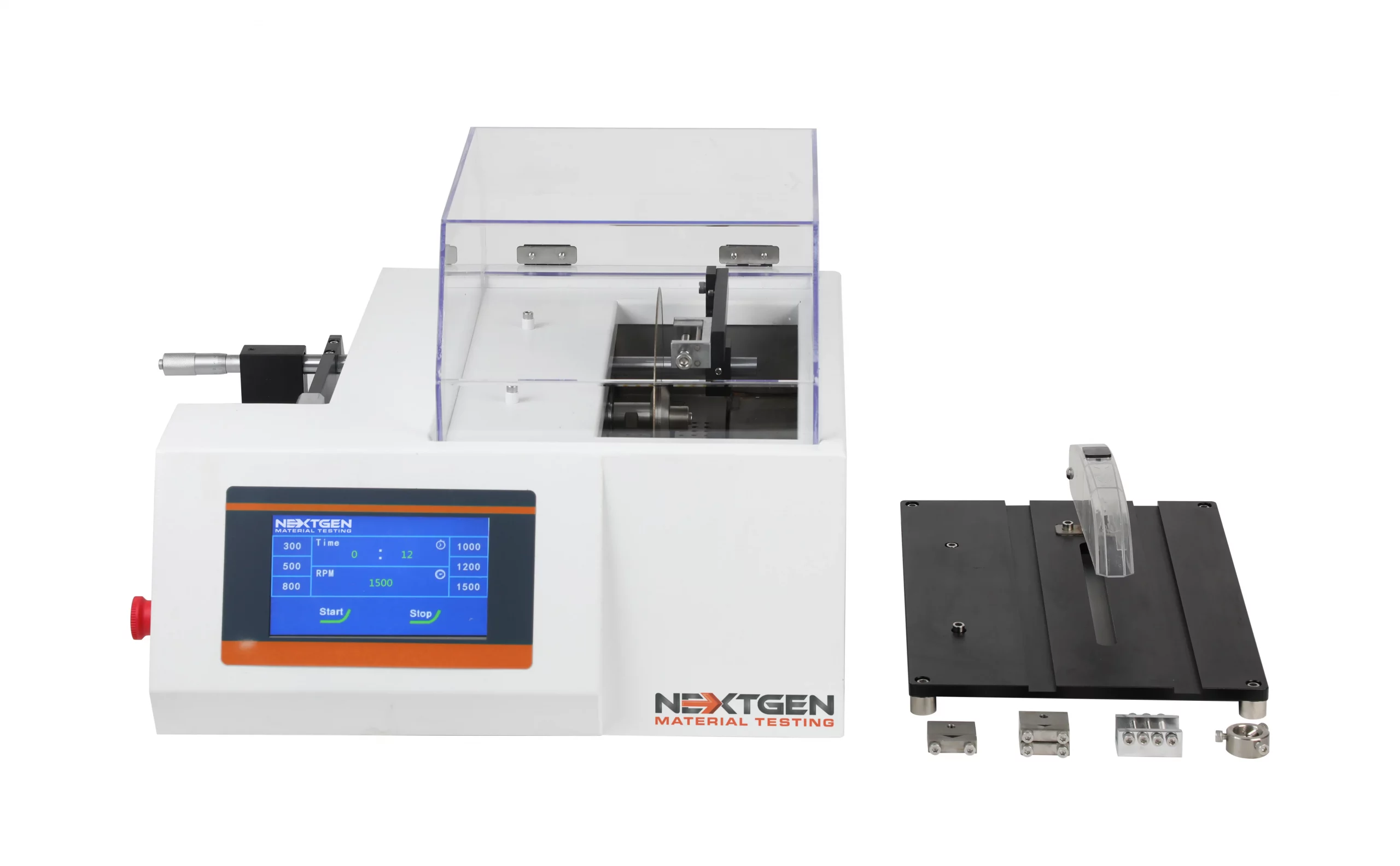

GenCut GL100M – Precision Manual Metallographic Sample Cutting Machine with Simple User-Friendly Operation and Large Cutting Capacity Φ100mm

Introducing the GenCut GL100M Manual Cutting Machine, expertly designed for precision metal sample cutting.

GenCut GL350 – Precision Metallographic Sample Cutting Machine with Simple User-Friendly Operation and Large Cutting Capacity Φ100mm

The GenCut GL350 is a cutting-edge high precision cutting machine equipped with advanced features and capabilities

GenCut GL200E – High Speed Automatic Precision Metallographic Cutter with User-Friendly Touch Screen Interface with max. cutting diameter of 60mm

GenCut GL 200E precision cutting machine includes a touch screen and PLC control, with stable performance and real-time display parameters.

GenCut GL100E – Low Speed Precision Metallographic Automatic Cutter with User-Friendly Touch Screen Interface with max. cutting diameter of 25mm

GenCut GL100E low speed series metallographic precision cutter has variable speed control from 50-1000 rpm.

Metallography Consumables

Learn about the full scope of NextGen's cutting, polishing & grinding, mounting and etching metallography consumables. Our consumables are compatible with virtually all global brands, offering a rare combination of exceptional quality, longevity and affordability.