Metal Testing Equipment

Description

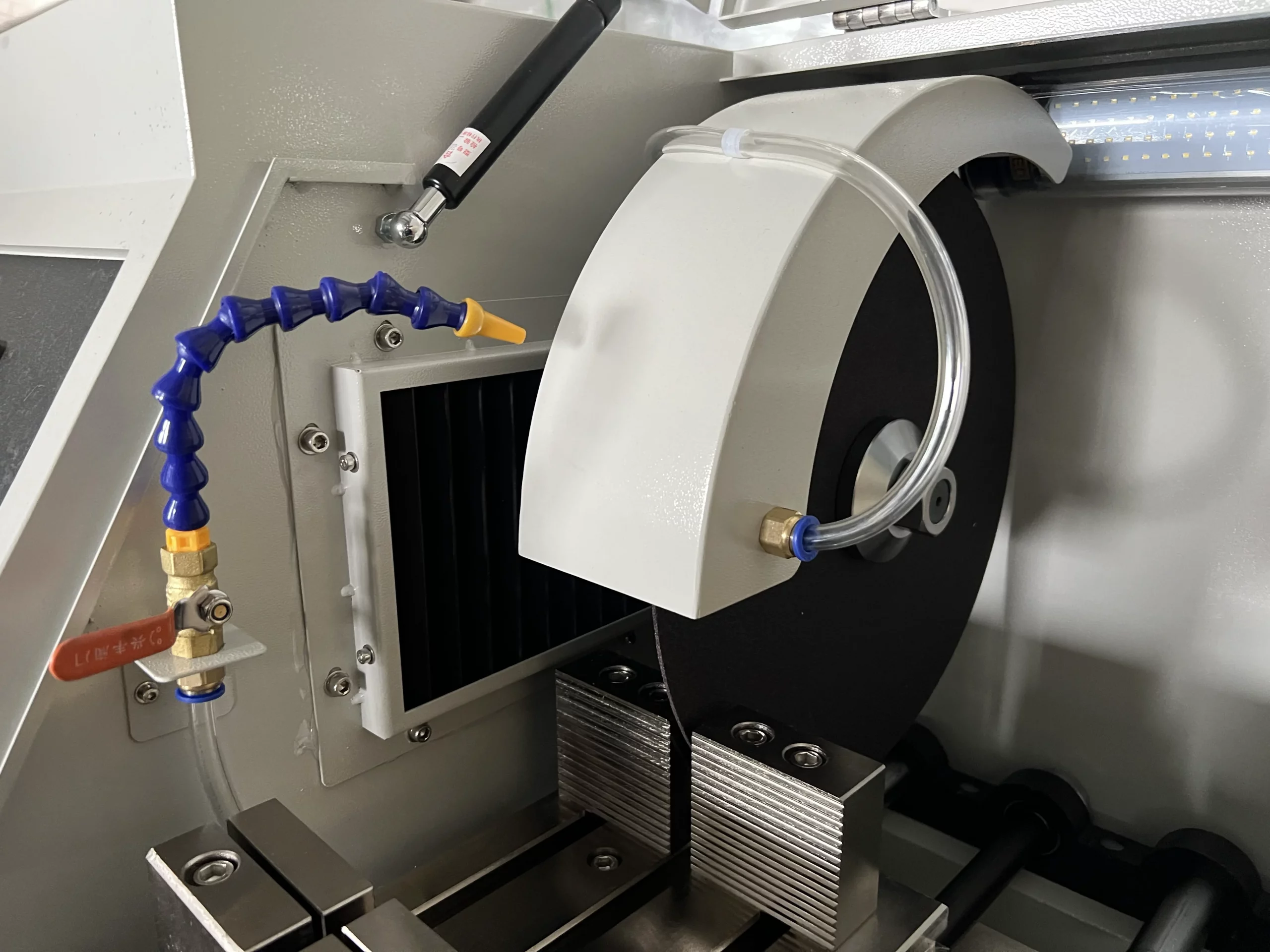

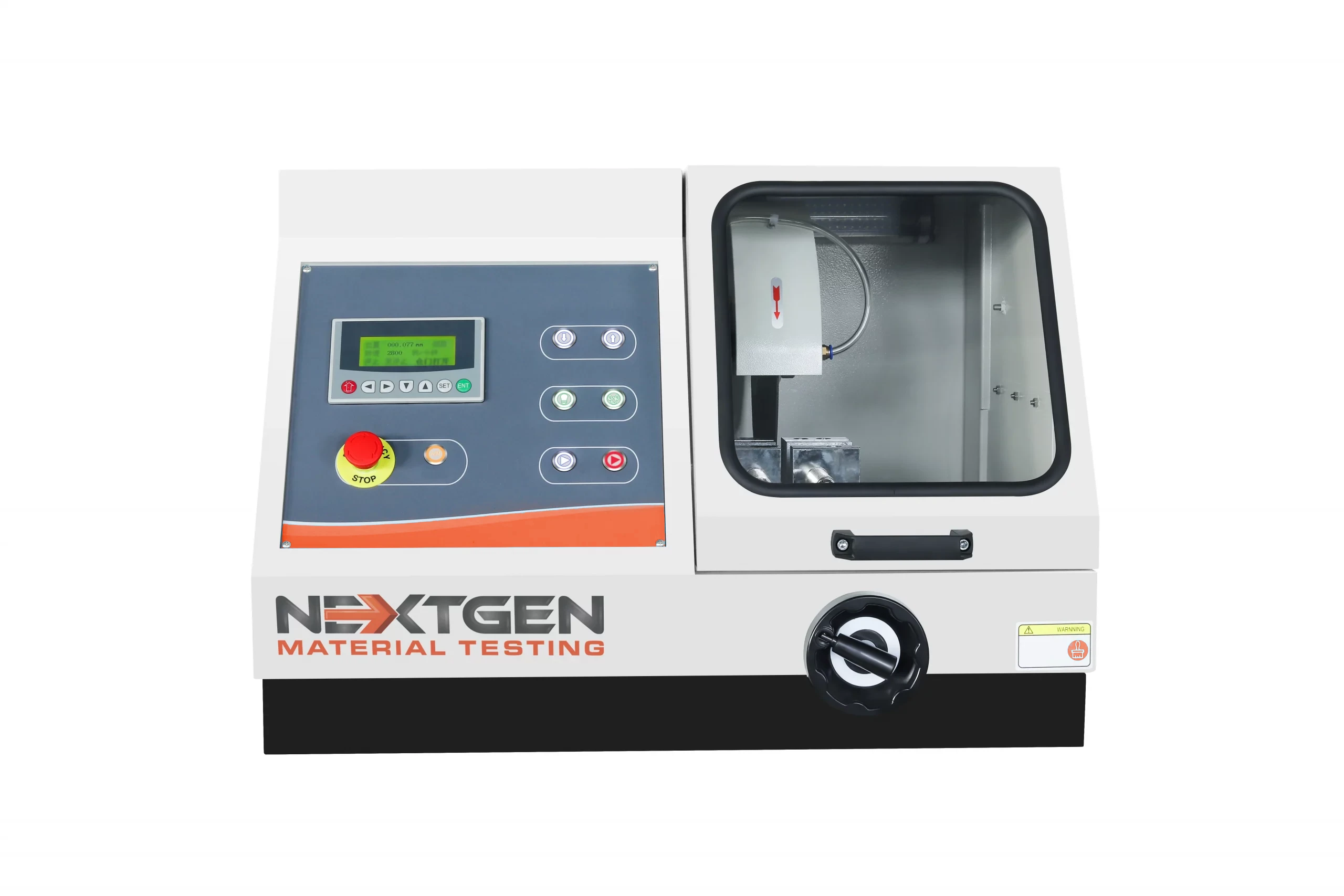

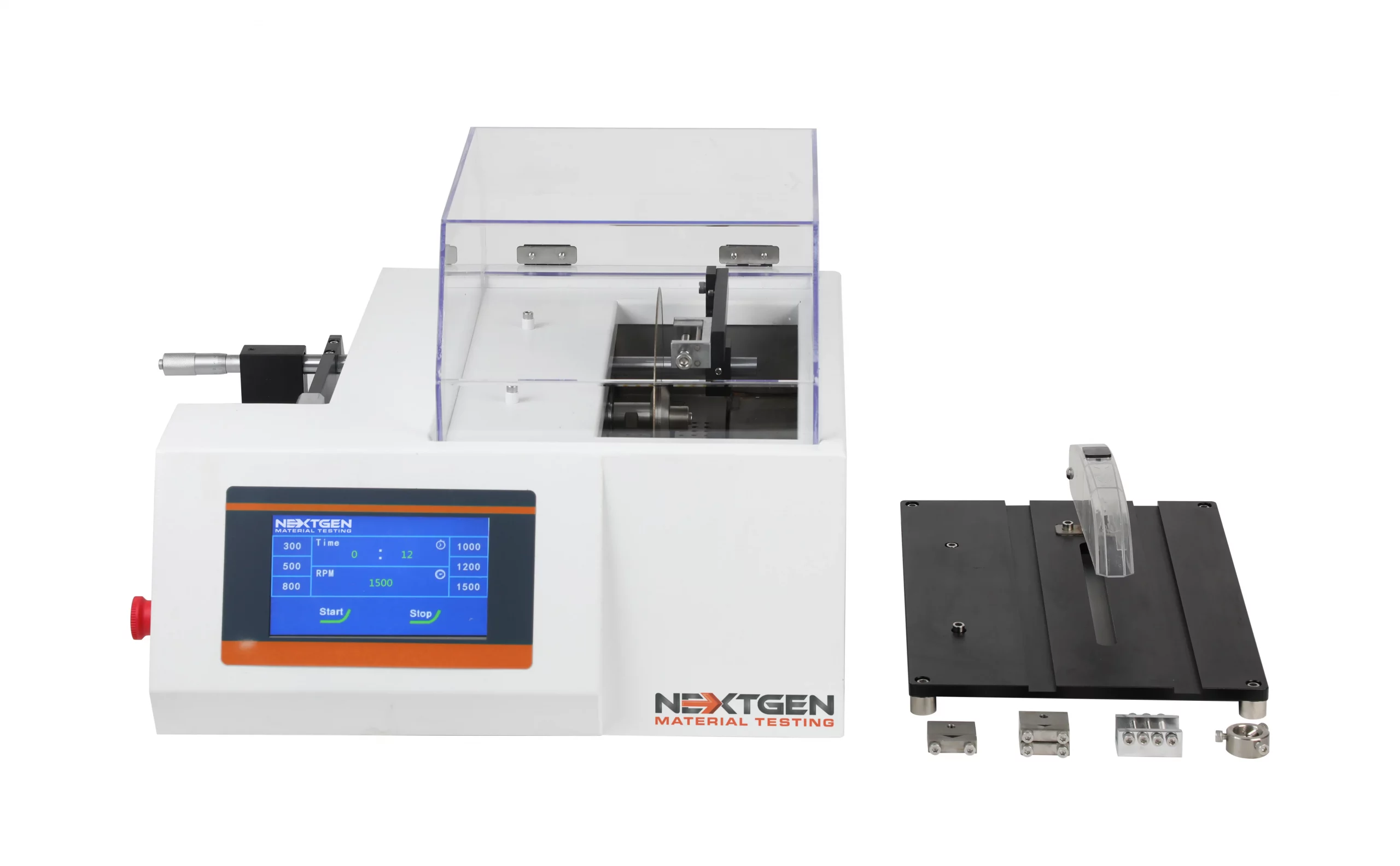

The GenCut GL350 is a cutting-edge high precision cutting machine equipped with advanced features and capabilities. It offers both automatic and manual work modes, providing flexibility for various cutting tasks. With components such as the body, electric control box, cutting room, motor, cooling system, and cutting wheel, this machine is designed to deliver exceptional performance.

One of the remarkable features of the GenCut GL350 is its ability to cut circular workpieces with a diameter of less than 100mm, as well as rectangular samples with a height of 100mm and a depth of less than 200mm. To ensure the safety of the samples and prevent tissue burning, the machine incorporates a robust cooling system.

This cutting-edge machine allows users to customize the cutting speed within a range of 1-40mm/min, enabling them to achieve high-quality cutting results. With a closed structure design and a large observation window, the GenCut GL350 prioritizes safety and user convenience. It also features a quick clamping mechanism for swift and effortless sample fixation, while key components like the jaw and work surface are constructed from durable stainless materials for a long service life. Additionally, the inclusion of an emergency stop button ensures secure operation, giving users peace of mind during their cutting tasks.

Metallographic Precision / Abrasive Cutting System Operational Video

Technical Specifications

|

Model |

GenCut GL350 |

|

Cutting Wheel |

Φ350×2.5×Φ32mm |

|

Maximum Cutting Section |

Φ100mm |

|

Automatic Cutting Stroke |

125mm |

|

Max. Movement of the Table |

275mm |

|

Spindle Speed |

300-3000rpm |

|

Feed Speed |

1-40mm/min |

|

Work Table Size |

310 x 280 mm |

|

Motor Power |

3.3kW |

|

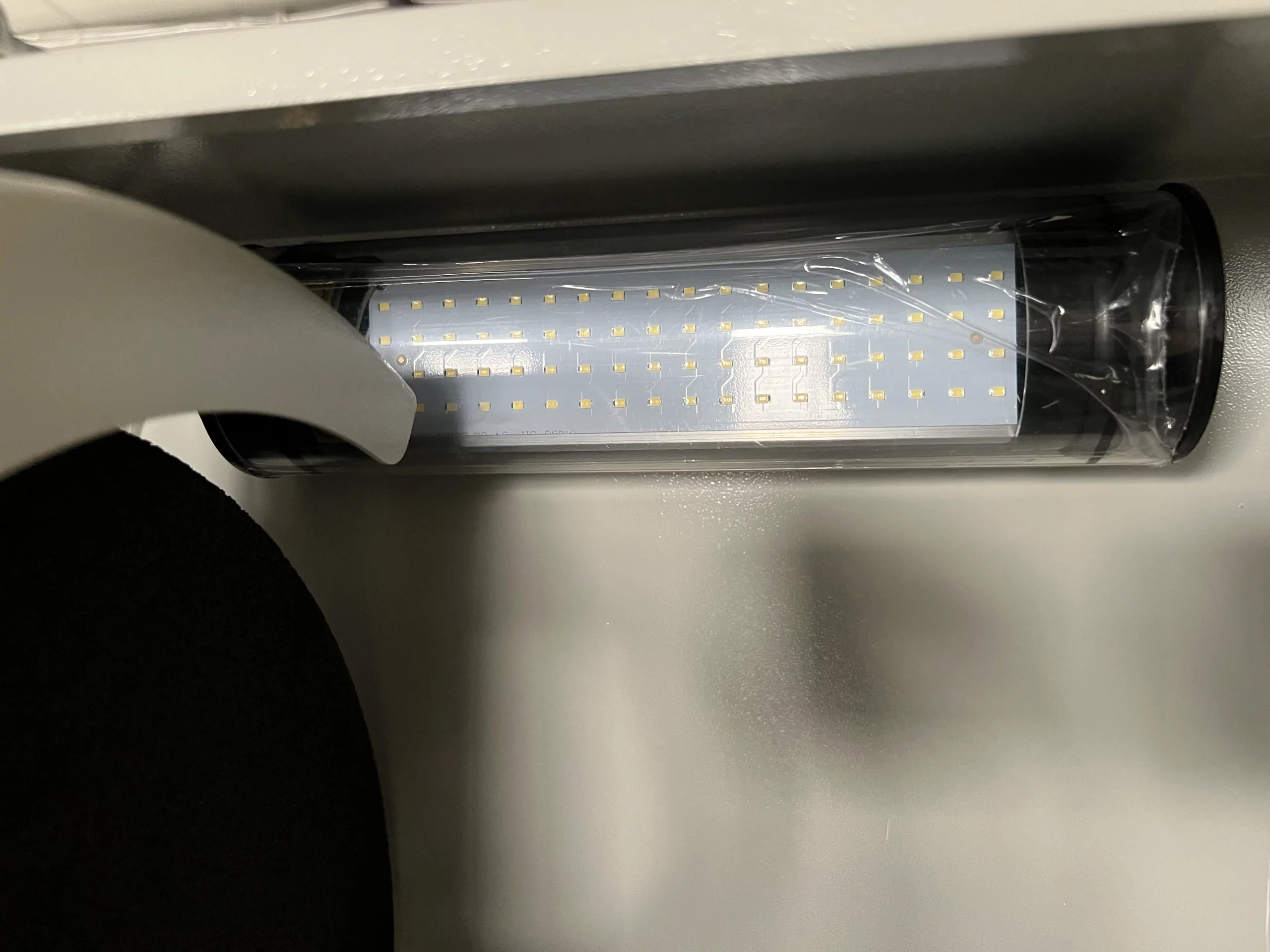

Cutting Room Light |

Low Voltage DC Led Lighting |

|

Voltage |

220V / 60Hz / 3 Phase |

|

Dimensions |

33" x 33.5" x 63.75" / 835x850x1620 mm |

|

Weight |

Cutter - 396lbs / 180kg Tank - 55lbs / 25kg |

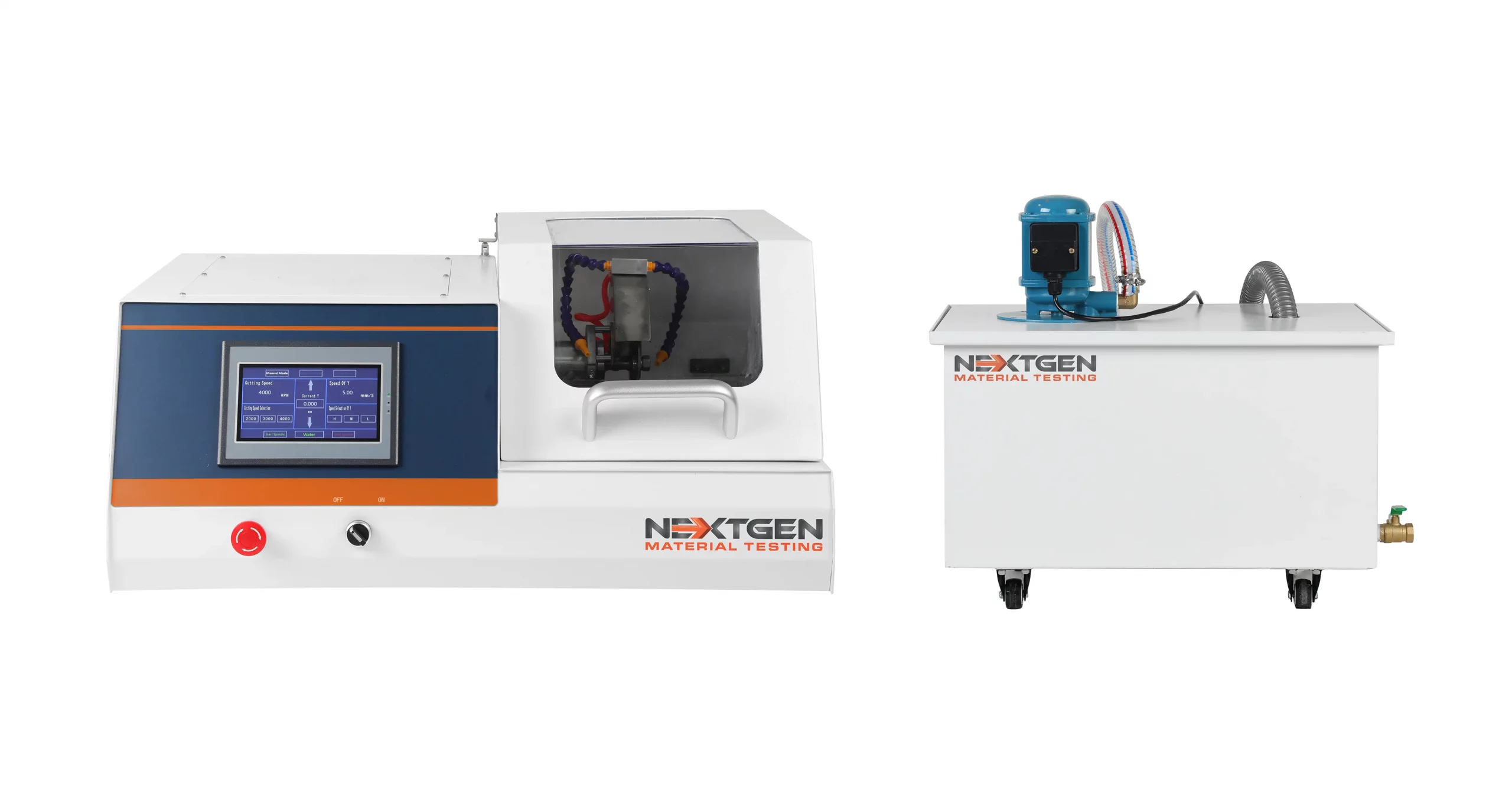

GenCut GL350 Standard Configuration

-

GenCut GL350 Cutting Saw

-

Coolant Tank

-

Coolant Pump

-

Wrench 13#-15#

-

Wrench 17#-19#

-

Water Inlet Tube

-

Drain Pipe

-

Cutting Wheel

-

Φ350 x 2.5 x Φ32mm

-

Fast Clamps and Operation Manual

Features

-

Introducing the GenCut GL350 - a cutting machine that sets the standard for high precision. With its versatile automatic work mode and manual work mode, it offers unparalleled flexibility in operation.

-

The GenCut GL350 is expertly constructed with essential components including a durable body, an efficient electric control box, a well-designed cutting room, a powerful motor, a reliable cooling system, a precision-engineered cutting wheel, and other integral elements.

-

Pushing boundaries, the GenCut GL350 excels at cutting both circular workpieces with a diameter under 100mm and rectangular samples with a height of 100mm and a depth below 200mm.

-

To ensure optimal sample preservation, the GenCut GL350 incorporates a highly effective cooling system, effectively preventing overheating and minimizing the risk of tissue burning during the cutting process.

-

Boosting cutting precision and quality, this remarkable machine allows users to precisely set the cutting speed within a range of 1-40mm/min, catering to diverse sample requirements.

-

The GenCut GL350 showcases a closed structure design with a large observation window, prioritizing user safety while maintaining a secure working environment.

-

With its quick clamping mechanism, the GenCut GL350 enables easy and efficient sample fixation, streamlining the workflow.

-

Durability is key, and the GL350 employs stainless materials for crucial components such as the jaw and work surface, ensuring a prolonged service life.

-

Safety is paramount, and the GL350 is equipped with an emergency stop button, further enhancing operational security and peace of mind.

GenCut GL350 Typical Applications

-

φ100mm pipe material, wall thickness 6mm

-

Solid bar material: Diameter≤φ100mm, hardness≤HRC30, material: iron base metal

-

Diameter≤φ60mm, hardness≤HRC60, material: iron base metal

-

100mm×100mm Angle steel

-

100mm×100mm Channel-Section steel

Important note: Additional Blades available upon request. Please advise your material type and we can suggest the most suitable blades.

FAQs

The main purpose of the GenCut GL350 – Precision Metallographic Sample Cutting Machine is to provide high-precision cutting of metal samples for metallographic analysis. This advanced machine is designed to deliver exceptional performance through its combination of automatic and manual work modes, enabling users to achieve precise and consistent cuts for different sample types.

Equipped with a powerful 3.3kW motor, the GenCut GL350 supports an array of spindle speeds from 300 to 3000 RPM. Its cutting capacity includes the ability to handle circular workpieces up to 100mm in diameter and rectangular samples with a height of 100mm and a depth of up to 200mm. This flexibility makes it ideal for a broad range of metallographic applications.

The machine also features a robust cooling system that prevents overheating and minimizes tissue burning. This preserves the integrity of the samples. Additionally, the customizable cutting speed, ranging from 1 to 40mm per minute, allows for high-quality cuts customized to specific needs.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL350 – Precision Metallographic Sample Cutting Machine offers both automatic and manual cutting modes. This dual-mode functionality provides users with the flexibility to choose the best mode based on their specific needs.

In automatic mode, the machine can perform repetitive and complex cutting tasks with consistent precision, ideal for high-volume sample preparation. This mode reduces manual intervention and provides uniformity and efficiency. The automatic cutting stroke of 125mm and adjustable cutting speed from 1 to 40mm per minute allow precise control over the cutting process.

In manual mode, the GenCut GL350 allows users to control the cutting operation. This mode is particularly useful for tasks that require fine adjustments and meticulous handling, enabling operators to manage intricate or delicate cuts with high precision. The handwheel operation for Y-axis control increases this capability, providing precise sample positioning.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL350 – Precision Metallographic Sample Cutting Machine is composed of several important components that collectively contribute to its exceptional performance. These components include the body, electric control box, cutting room, motor, cooling system, and cutting wheel.

The GenCut GL350 body provides a robust and stable framework for the machines. Its sturdy construction minimizes vibrations and maintains sample integrity.

The electric control box houses the machine’s electronic controls and circuitry. This component is crucial for managing machine operations, allowing users to easily set and adjust cutting parameters such as speed and mode.

The cutting room is designed with a closed structure and a large observation window. This design prioritizes user safety by enclosing the cutting area.

The GL350's motor is a powerful 3.3kW unit that drives the cutting wheel. It supports an array of spindle speeds from 300 to 3000 RPM.

The cooling system is integrated to prevent overheating and minimize tissue burning risk during cutting. This system circulates cooling liquid, maintaining optimal temperatures and preserving sample integrity.

The cutting wheel (Φ350×2.5×Φ32mm) is precision-engineered to deliver accurate and clean cuts. Its size and specifications are designed to handle a range of sample dimensions.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL350 – Precision Metallographic Sample Cutting Machine offers impressive cutting capabilities. This includes the ability to cut circular workpieces with diameters of less than 100mm and rectangular samples with a height of 100mm and a depth of less than 200mm. The versatility of the machine allows it to work with different types of sample types and sizes, making it an ideal tool for many different types of metallographic analysis.

To guarantee the safety of the samples and prevent tissue burning during the cutting process, the GenCut GL350 incorporates a robust cooling system. This cooling system efficiently circulates coolant liquid around the cutting area, maintaining optimal temperatures and preventing samples from overheating. By keeping the samples cool, the machine preserves their structural integrity and makes sure that microstructural properties remain intact.

The cooling system also contributes to the longevity and performance of the cutting wheel and other components. By preventing excessive heat buildup, the cooling system reduces cutting wheel wear and tear. This feature is particularly helpful in maintaining the machine's quality and reliability in high-volume or demanding cutting applications.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL350 – Precision Metallographic Sample Cutting Machine allows users to achieve high-quality cutting results by customizing the cutting speed within a range of 1 to 40mm per minute. This adjustable cutting speed is a key feature that provides flexibility and precision in processing an extensive variety of metal samples.

By offering a range of cutting speeds, the GenCut GL350 allows users to tailor the cutting process to specific material and sample requirements. For instance, slower speeds can be used for harder materials or samples that require meticulous precision. Conversely, faster speeds can be applied to softer materials or when a quicker cutting process is needed.

The ability to precisely control cutting speed is necessary for maintaining sample integrity. It minimizes the risk of excessive heat, which can lead to thermal damage or tissue burning. This control provides assurance that the microstructural properties of the samples are preserved.

Additionally, the customizable cutting speed further increases the machine's adaptability, making it suitable for a broad range of applications in both laboratory and industrial settings. Whether dealing with small, delicate samples or larger, more robust specimens, the GenCut GL350 can adapt to your specific cutting needs.

Click here to learn more about the product or here to receive a personalized quote.

The design of the GenCut GL350 – Precision Metallographic Sample Cutting Machine focuses on safety and user convenience through its closed structure and large observation window. Through this thoughtful design, the machine operates safely while providing users with a clear view of the cutting process.

The closed structure of the GenCut GL350 encloses the cutting area, significantly reducing the risk of exposure to moving parts, flying debris, and other potential hazards. This feature protects users from accidental contact with the cutting wheel and other dangerous elements. The enclosed design also contains sparks or fragments produced during cutting.

The large observation window integrated into the closed structure allows users to monitor the cutting process in real time without compromising safety. This window provides a clear view of the work area. By allowing users to observe the cutting operation closely, the observation window helps maintain accuracy and quality in sample preparation.

Additionally, the GenCut GL350 is equipped with user-friendly features such as a quick clamping mechanism, which makes it easy to hold samples swiftly and securely. This mechanism increases operational efficiency and reduces setup time, allowing users to concentrate more on cutting tasks rather than securing samples.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL350 – Precision Metallographic Sample Cutting Machine features several key elements that contribute to its efficiency and durability. These elements include a quick clamping mechanism and the use of durable stainless materials for key components such as the jaw and work surface.

The quick clamping mechanism provides swift and easy sample fixation. This feature allows users to secure samples quickly and securely, optimizing operational efficiency and reducing setup time. The ease of sample fixation guarantees sample stability during cutting. This mechanism simplifies the workflow, making cutting more efficient and less time-consuming.

Additionally, the GenCut GL350 jaw and work surface are constructed from high-quality stainless materials. Stainless steel is known for its strength, corrosion resistance, and durability, making these components exceptionally durable. The robust construction of the jaw and work surface means they can withstand frequent use in demanding environments without degradation.

The durability provided by stainless steel components provides consistent performance over time, even under challenging conditions. This reliability reduces the need for frequent maintenance and replacement of parts, making the GenCut GL350 a cost-effective solution for metallographic sample preparation.

Click here to learn more about the product or here to receive a personalized quote.

The cutting wheel used in the GenCut GL350 – Precision Metallographic Sample Cutting Machine has specific dimensions designed for high precision and efficiency. The cutting wheel measures 350 millimeters in diameter, 2.5 millimeters in thickness, and has a central bore diameter of 32 millimeters (Φ350×2.5×Φ32mm).

It is through these specifications that the cutting wheel is able to handle different types of metal samples with precision. The 350mm diameter allows for significant cutting depth, making it suitable for cutting larger samples. The 2.5mm thickness guarantees that the wheel can make clean and precise cuts without compromising its structural integrity. The 32mm diameter of the central bore provides a secure fit onto the machine's spindle, providing stability during operation.

The cutting wheel’s size and design are integral to the machine’s ability to deliver accurate and smooth cuts, which are necessary for preparing samples for detailed metallographic analysis. Despite frequent use in demanding laboratory and industrial environments, the robust construction of this instrument provides durability and longevity.

Click here to learn more about the product or here to receive a personalized quote.

The maximum cutting section capacity of the GenCut GL350 – Precision Metallographic Sample Cutting Machine is 100 millimeters in diameter (Φ100mm). This capacity indicates the largest diameter of a circular metal workpiece that the machine can effectively cut.

This significant cutting capacity allows the GenCut GL350 to accept a wide selection of sample sizes. This machine can accommodate both small and large samples of different sizes due to its ability to cut samples up to 100mm in diameter.

The precise cutting capability, combined with the robust construction of the GenCut GL350, guarantees that even at its maximum cutting section, the machine delivers clean, accurate, and high-quality cuts. For detailed microscopic examinations and other metallurgical assessments, such accuracy is a requirement for maintaining the integrity of the samples.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL350 – Precision Metallographic Sample Cutting Machine has a 125-millimeter automatic cutting stroke capacity. This feature allows the machine to automatically advance the cutting wheel through the sample up to a depth of 125mm.

The automatic cutting stroke enhances the GenCut GL350's efficiency and ease of use. By automating the cutting process, it reduces the need for continuous manual intervention, allowing for more consistent and accurate cuts. This is especially useful for high-volume sample preparation, where uniformity and precision are extremely important.

With a 125mm automatic cutting stroke, the machine can cut an array of sample sizes and shapes, allowing it to be used in a number of metallographic applications. It allows users to achieve high-quality cuts with minimal effort, thus enhancing productivity and accuracy, due to its capabilities.

Click here to learn more about the product or here to receive a personalized quote.

The table on the GenCut GL350 - Precision Metallographic Sample Cutting Machine can move 275 millimeters. This means that the work table can move up to 275mm, allowing for precise positioning and maneuvering of the samples during the cutting process.

This range of movement increases the versatility of the GenCut GL350, enabling it to handle larger and more complex samples easily. The ability to move the table over a distance of 275mm ensures that users can accurately align and position their samples for optimal cutting.

The extended table movement capability also allows for better handling of irregularly shaped or oversized samples that require additional space for proper placement and cutting. This flexibility makes the GenCut GL350 suitable for a broad range of metallographic applications, accommodating diverse sample dimensions and configurations.

Click here to learn more about the product or here to receive a personalized quote.

The spindle speed range of the GenCut GL350 – Precision Metallographic Sample Cutting Machine is from 300 to 3000 revolutions per minute (rpm). This comprehensive range of speeds provides the ability to work with different materials and cutting requirements with precision.

The lower end of the speed range, 300 RPM, is ideal for cutting harder materials or when slower, more controlled cuts are necessary to maintain the integrity of the sample. This setting prevents overheating and potential damage to both the sample and the cutting wheel.

The higher end of the speed range, 3000 RPM, allows for faster cutting of soft materials or when a quick cut is needed. This capability increases the machine’s efficiency, enabling it to handle high-volume sample preparation without compromising cut quality.

The ability to adjust the spindle speed within this range means that the GenCut GL350 can be optimized for a variety of cutting tasks, providing precise control over the cutting process. This flexibility is a key requirement for achieving high-quality results in metallographic sample preparation, where different materials and sample sizes may require different cutting approaches.

Click here to learn more about the product or here to receive a personalized quote.

The feed speed range of the GenCut GL350 – Precision Metallographic Sample Cutting Machine is from 1 to 40 millimeters per minute (mm/min). This adjustable feed speed allows users to customize the cutting process to meet the specific requirements of different materials and sample sizes.

A lower feed speed, such as 1 mm/min, is suitable for cutting harder materials or when high precision is required. Slower feed speeds prevent overheating and provide smooth, accurate cuts, maintaining samples' structural integrity.

Conversely, a higher feed speed, up to 40 mm/min, is ideal for softer materials or when faster cutting is desired. This higher speed optimizes the efficiency of the cutting process, making it suitable for high-volume sample preparation without compromising the quality of the cuts.

The ability to adjust the feed speed within this range provides significant flexibility and control over the cutting operation. It ensures that the GenCut GL350 can deliver high-quality cutting results in a broad range of metallographic applications, catering to different material properties and sample requirements.

Click here to learn more about the product or here to receive a personalized quote.

The work table size of the GenCut GL350 – Precision Metallographic Sample Cutting Machine is 310 millimeters by 280 millimeters (310 x 280 mm). This ample work table size provides a stable and spacious platform for positioning and securing samples during cutting.

The work table can be adjusted to accept a wide range of sample sizes and shapes, offering maximum flexibility for different metallographic cutting tasks. The generous surface area allows that samples can be easily positioned and manipulated, providing enough space for precise alignment and secure clamping.

The size of the work table also contributes to the overall stability and accuracy of the cutting operation. A larger table helps minimize vibrations and movement, which is necessary for maintaining samples' integrity and achieving clean, precise cuts.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL350 - Precision Metallographic Sample Cutting Machine has 3.3 kilowatts (kW). This substantial motor power provides the machine with the necessary strength and efficiency to perform precise and clean cuts through different types of metal samples.

A 3.3kW motor guarantees that the GenCut GL350 can handle demanding cutting tasks easily, delivering consistent and reliable performance. This high power output enables the cutting wheel to maintain steady speed and torque, even when cutting through tougher or thicker materials.

The powerful motor also contributes to the machine's overall efficiency. With 3.3kW of power, the GenCut GL350 can complete cutting operations faster, reducing sample preparation time. This efficiency is particularly useful in high-throughput environments where large numbers of samples need to be processed on time.

Moreover, the motor's power assures that the machine operates reliably over extended periods, minimizing the risk of mechanical failures or interruptions. Durability and reliability make the GenCut GL350 an ideal choice for laboratories and industrial settings where precision and efficiency are vital to success.

Click here to learn more about the product or here to receive a personalized quote.

The cutting room of the GenCut GL350 – Precision Metallographic Sample Cutting Machine uses low voltage DC LED lighting. This type of lighting provides bright and clear illumination of the cutting area.

Low voltage DC LED lighting is chosen for efficiency and safety. LEDs consume less power compared to traditional lighting options, which makes them more energy-efficient and cost-effective. Moreover, the low voltage requirement ensures that the lighting system is safe to operate, minimizing the risk of electrical shock.

LED lights also have a long lifespan, reducing frequent replacements and maintenance. This durability aligns with the robust design of the GenCut GL350, which provides consistent and reliable performance over an extended period of time. The clear and bright light provided by LEDs allows operators to closely monitor the cutting process.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL350 – Precision Metallographic Sample Cutting Machine operates on a voltage requirement of 220 volts (V) with a frequency of 60 hertz (Hz) and uses a 3-phase power supply. These specifications are standard for industrial-grade equipment, guaranteeing that the machine receives a stable and sufficient power supply for high-performance operations.

The 220V, 60Hz, 3-phase power setup provides several advantages. Firstly, it makes certain that the machine can deliver consistent power to its 3.3kW motor. This supports the robust performance needed for precise and efficient metal sample cutting. The 3-phase power supply is particularly beneficial for industrial applications as it provides a more balanced and reliable flow of electricity, reducing the risk of power fluctuations that could affect machine performance.

Using a 3-phase power system also increases the efficiency of the GenCut GL350, as it allows the machine to operate more smoothly and with greater stability. This type of power supply is known for its ability to handle high power loads, making it suitable for demanding tasks that require continuous and intensive operation.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL350 - Precision Metallographic Sample Cutting Machine measures 33 inches wide, 33.5 inches deep, and 63.75 inches high. In metric units, these dimensions are 835 millimeters in width, 850 millimeters in depth, and 1620 millimeters in height.

These dimensions provide a substantial and robust exterior, which houses the machine's advanced features and components. The machine's considerable height and footprint guarantee that there is ample space for cutting operations, including the large work table and various mechanical parts.

The GenCut GL350's substantial size allows it to be used for a wide array of metallographic samples. Despite its large size, the machine fits into standard laboratory and industrial setups.

The generous dimensions also contribute to the machine’s overall stability during operation, minimizing vibrations and movements that could affect cutting precision.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL350 – Precision Metallographic Sample Cutting Machine has a total weight divided into two main components: the cutter and the tank. The cutter itself weighs 396 pounds, equivalent to 180 kilograms. The cooling system tank weighs 55 pounds, or 25 kilograms.

The cutter's substantial weight reflects its robust construction and high-quality materials. This weight provides stability during operation, minimizing vibrations and movements that could affect cut precision. Stable machines are vital for producing clean and accurate cuts that are necessary in order to prepare samples for detailed metallographic analyses, which is why such machines are essential.

As a result of the additional weight of the tank, the overall stability and functionality of the cooling system is increased, necessary for maintaining optimal cutting temperatures and preventing overheating of the tool.

Click here to learn more about the product or here to receive a personalized quote.

The standard configuration of the GenCut GL350 – Precision Metallographic Sample Cutting Machine includes key components that contribute to its efficiency and accuracy. These components are:

-

GenCut GL350 Cutting Saw: The main unit of the machine, designed for high precision cutting of metallographic samples.

-

Coolant Tank: This tank holds cooling liquid, providing optimum temperatures during the cutting process and preventing overheating.

-

Coolant Pump: The pump circulates the cooling liquid from the coolant tank to the cutting area.

-

Wrenches (13#-15# and 17#-19#): These wrenches are provided for assembly, maintenance, and adjustment of the machine.

-

Water Inlet Tube: This tube connects the coolant system to a water supply, allowing for a consistent flow of cooling liquid.

-

Drain Pipe: Used for draining the cooling liquid from the machine, facilitating easy maintenance and cleaning of the cooling system.

-

Cutting Wheel (Φ350 x 2.5 x Φ32mm): The cutting wheel, with 350mm diameter, 2.5mm thickness, and 32mm central bore.

-

Fast Clamps: These clamps securely hold samples in place during cutting.

-

Operation Manual: A comprehensive guide providing detailed instructions on GenCut GL350 setup, operation, and maintenance.

Click here to learn more about the product or here to receive a personalized quote.

Designed to meet a broad range of metallographic sample cutting applications, GenCut GL350 - Precision Metallographic Sample Cutting Machine is suitable enough for different materials and sample types. Some typical applications include:

-

Pipe Material: The machine can cut pipe materials with a diameter of up to 100mm and a wall thickness of 6mm. This capability is necessary for preparing tubular samples for metallographic analysis.

-

Solid Bar Material: The GenCut GL350 can cut solid bar materials with a diameter of up to 100mm and a hardness of up to HRC30, specifically iron base metals. It is particularly useful for preparing samples from solid cylindrical materials.

-

Harder Solid Bar Material: The machine is also capable of cutting solid bar materials with a diameter of up to 60mm and a hardness of up to HRC60, again for iron base metals. This makes it suitable for handling hard materials that require precise cutting.

-

Angle Steel: The GenCut GL350 can cut angle steel up to 100mm x 100mm. This application is valuable for preparing samples of L-shaped structural steel components.

-

Channel-Section Steel: The machine can handle channel-section steel with dimensions of 100mm x 100mm. For the preparation of samples from U-shaped structural steel sections, this capability is indispensable.

Click here to learn more about the product or here to receive a personalized quote.

Yes, additional blades are available for the GenCut GL350 – Precision Metallographic Sample Cutting Machine. Users can request specific blades best suited to their particular material types and cutting requirements.

In order to make sure that users select the most appropriate blades for their needs, it is recommended to provide detailed information about the material to be cut. This includes the type of material, its hardness, thickness, and any other relevant properties. Based on this information, the manufacturer or supplier can suggest the best blades that deliver optimal cutting performance.

This option for customization makes it possible that the GenCut GL350 can be adapted to a broad range of applications and materials. Users can achieve precise and high-quality cuts by using blades specifically designed for their material types.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

GenCut GL100M – Precision Manual Metallographic Sample Cutting Machine with Simple User-Friendly Operation and Large Cutting Capacity Φ100mm

Introducing the GenCut GL100M Manual Cutting Machine, expertly designed for precision metal sample cutting.

GenCut GL80A – Precision Metallographic Sample Cutting Machine with Simple User-Friendly Operation and Large Cutting Capacity Φ80mm

Introducing the GenCut GL80A, a highly precise cutting machine offering both automatic and manual work modes.

GenCut GL200E – High Speed Automatic Precision Metallographic Cutter with User-Friendly Touch Screen Interface with max. cutting diameter of 60mm

GenCut GL 200E precision cutting machine includes a touch screen and PLC control, with stable performance and real-time display parameters.

GenCut GL100E – Low Speed Precision Metallographic Automatic Cutter with User-Friendly Touch Screen Interface with max. cutting diameter of 25mm

GenCut GL100E low speed series metallographic precision cutter has variable speed control from 50-1000 rpm.

Metallography Consumables

Learn about the full scope of NextGen's cutting, polishing & grinding, mounting and etching metallography consumables. Our consumables are compatible with virtually all global brands, offering a rare combination of exceptional quality, longevity and affordability.