Rubber Testing Equipment

Standards

Description

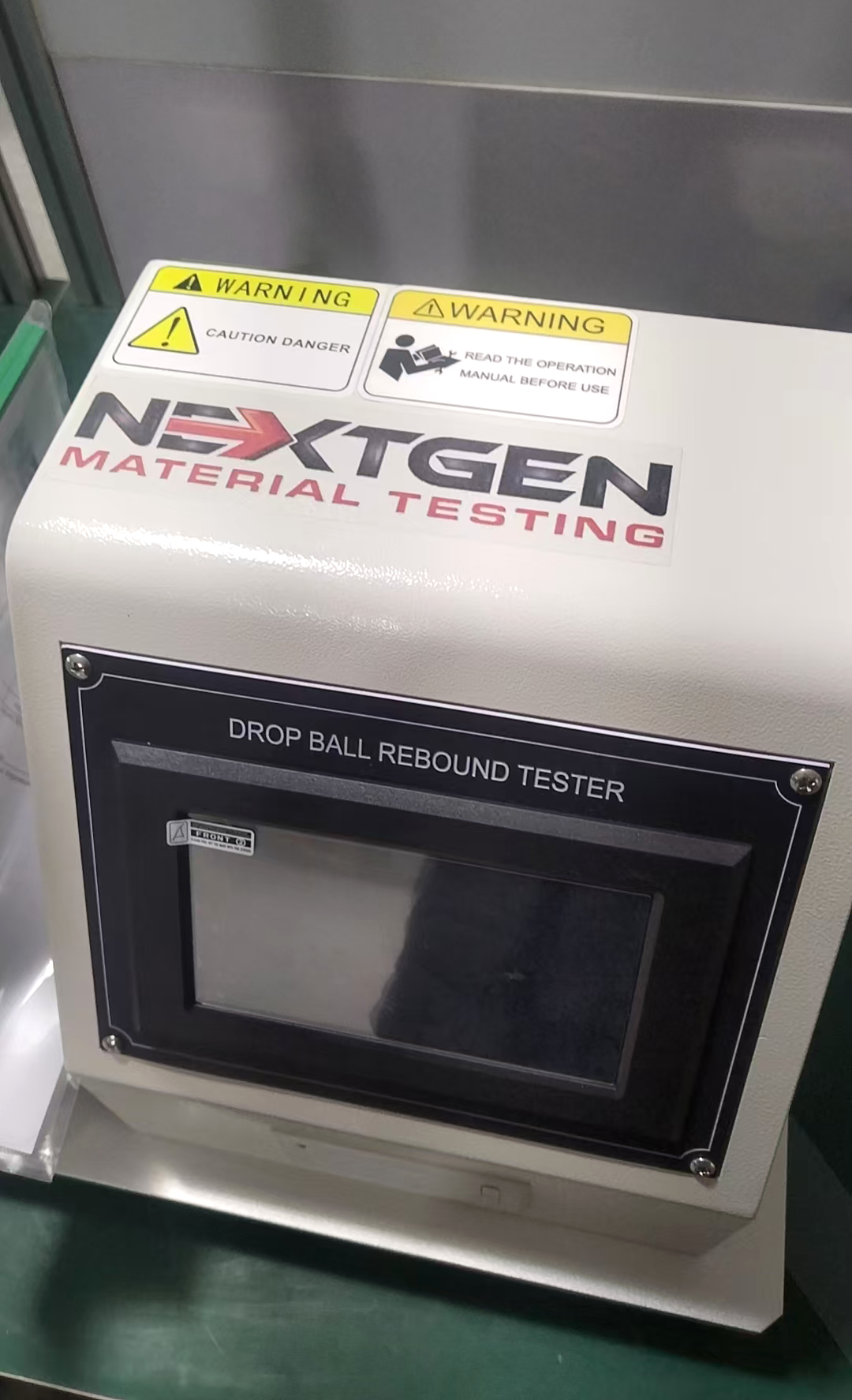

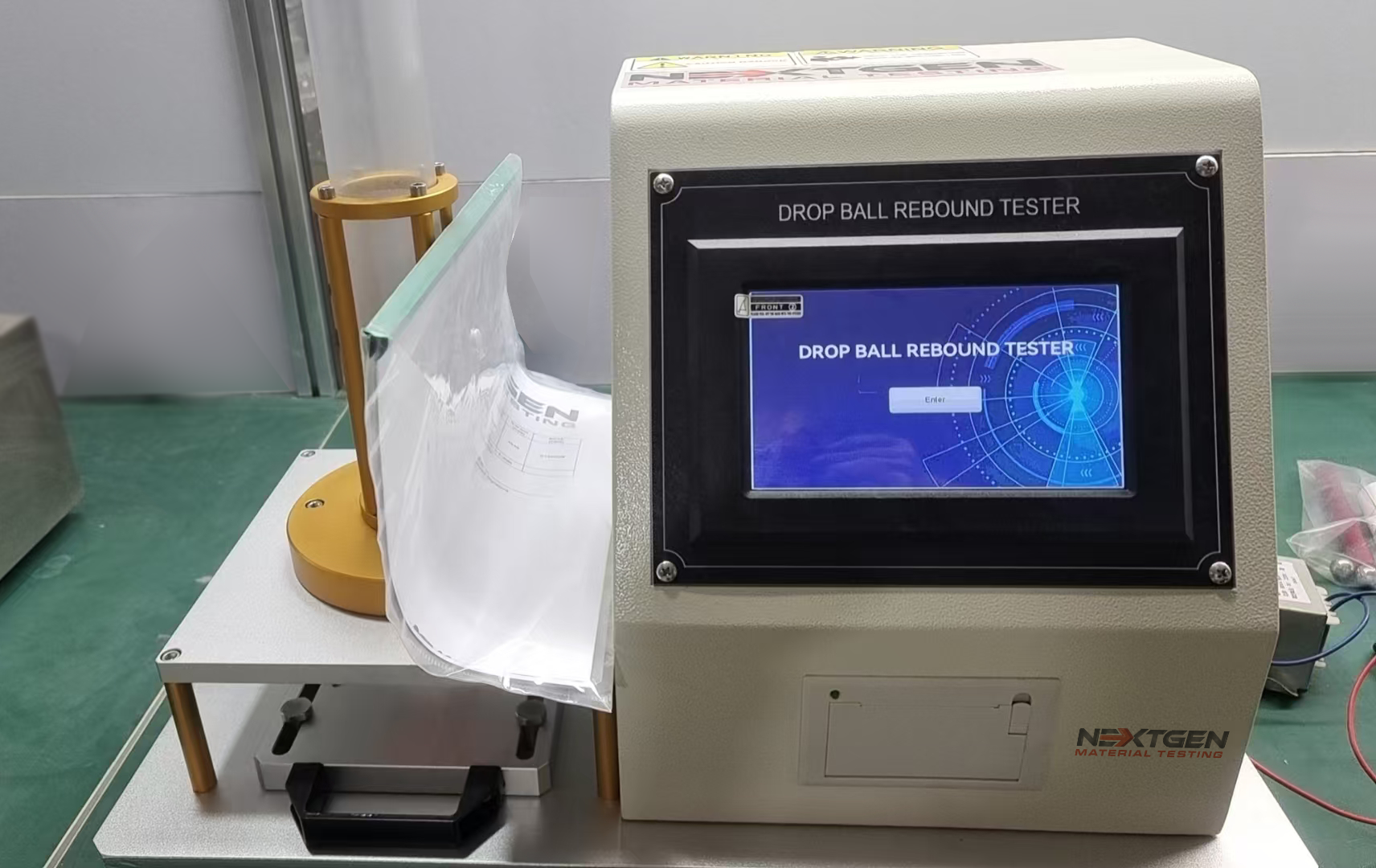

Digital Ball Vertical Rebound Resilience Tester

Vertical Rebound Resilience Tester is a device designed to test resilience of materials such as foam, polyurethane and other similar materials. The unit comes certified in accordance with ASTM D3574 industry standards. The test consists of a 16mm magnetic ball dropping freely onto a sample from a specified height of 500mm. The electronic console unit that comes standard with this instrument will show the measured value and calculate the proportion of the average value in %. After the test completion, a sensor placed close to the holder ensures that the ball is returns to the home position.

Digital Ball Rebound Resilience Tester Features

- Plug-n-Play System

- Extremely Easy to Learn to Operate

- Short Measuring Cycle

- USB Port

- Test cycle, measured values, median value in %, status and operating instructions output to 4-line LCD

- No Calibration Requirements

GenRebound - Vertical Rebound Resilience Tester Video

Digital Ball Rebound Resilience Tester Technical Specifications

| Drop Distance of Steel ball |

ISO 8307 ASTM D357: 500mm GB/T6670: 460+0.5%mm |

| Diameter of steel ball | Ф16-0.1mm |

| Steel ball quality | 16.7g |

| Accuracy of rebound rate of falling ball | <1.5% |

| Sample Size | 100mm×100mm×50mm |

| Power Supply | 1∮,AC220V/50HZ |

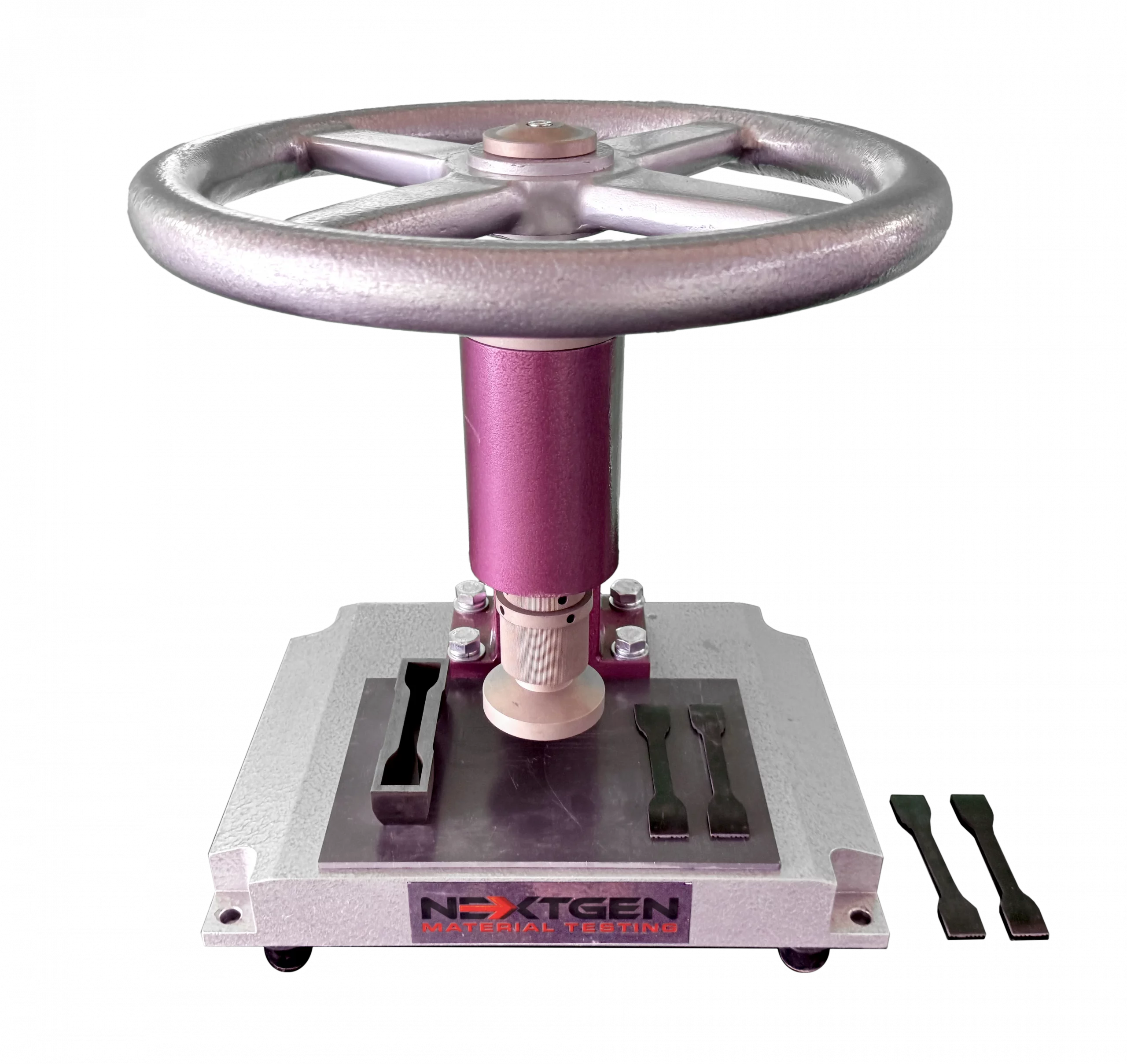

Analogue Ball Rebound Resilience Tester

GenRebound tests the resilience of rubber compounds. The machine must be adjusted in a horizontal position and the plunger raised at a specific height. The plunger is then released onto the specimen for a given number of impacts. The measurements are based on the 4th, 5th, and 6th impacts. The average of the three (3) measurements is then calculated for the test result. The machine is highly useful in production of compounds designed to absorb vibration or shock according to the ASTM standards.

The Operating Process Of Analogue Ball Rebound Resilience Tester

The resiliometer is based on the vertical free-fall hammer method to test the elasticity of rubber materials. First adjust the tester level the elevation degree of drop hammer. Place the test films 14mm from the edge of the specimen. The first three tests are not used for record. Use only the average reading of the fourth, fifth and sixth tests.

Analogue Ball Rebound Resilience Tester Technical Specifications

| Drop Height | 40 cm |

| Hammer Weight | 28 g |

| Dimensions (W x D x H) | 8.3" x 5.9" x 20.7" / 21x15x52.5 cm |

| Weight | 18 bs / 8 kg |

FAQs

|

Sample thickness |

12.5mm |

|

Sample Diameter |

¢28mm |

|

Falling height |

400mm |

|

Hammer weight |

(28g±0.5)g |

|

Volume |

250x150x525mm |

|

Machine weight |

8kg |

This test apparatus was created using ASTM-D2632, ISO-10012, and other standard papers, and it is primarily used to measure the rebound height of hard rubber materials. It cannot be used to measure the rebound height of soft rubber or glued leather.

Installation:

- Operating environment conditions: The required temperature is (23 ± 2) ° C, and the humidity is (65 ± 5) RH%

- The instrument should be placed on a flat platform of 25cm x 15cm or more.

Click here to obtain a personalized quote.

The ISO standard known as ISO 10012:2003, Measurement management systems - Requirements for measurement processes and measuring equipment, lays out general requirements and offers instructions for the management of measurement processes and metrological confirmation of measuring equipment used to support and demonstrate compliance with metrological requirements. In order to ensure that metrological standards are met, it describes the quality management requirements of a measurement management system that can be utilized by an organization that performs measurements as part of its overall management system.

It is not intended for ISO 10012:2003 to be used as a prerequisite for proving compliance with ISO 9001, ISO 14001, or any other standard. The use of ISO 10012:2003 as input for fulfilling the needs of measurement management systems in certification operations is open to interested parties.

There are further standards and guidelines for specific factors influencing measurement outcomes, such as the specifics of testing procedures, staff competency, and interlaboratory comparisons.

The requirements of ISO/IEC 17025 are not to be replaced or supplemented by ISO 10012:2003.

NextGen’s Vertical Rebound Resilience Tester – GenRebound complies with ISO 10012 standard

Click here to obtain a personalized quote.

This test instrument was created using ASTM-D2632, ISO-10012, and other standard documents, and it is primarily used to measure the rebound height of hard rubber materials. It cannot be used to measure the rebound height of soft rubber or glued leather. In units are the test results. Although the test method can be used to identify and research materials, it cannot directly assess final performance.

Adaptive Vertical Rebound Using the free fall weight method, the tester evaluates the rubber materials' elasticity. Adjust the instrument's horizontal position first, and only after that elevate the drop weight to the desired height. Make sure the drop point is 14 millimetres from the test piece's edge when you set it down. The average of the fourth, fifth, and sixth rebound heights was recorded; the first three trials were not used.

NextGen's Vertical Rebound Resilience Tester machine uses the vertical free fall hammer method to observe its rebound height.

Click here to obtain a personalized quote.

Rubber compound resiliency is examined via GenRebound. The machine must be positioned horizontally, with the plunger lifted to a predetermined height. The measurements are based on hits four, five, and six. The test result is then determined by taking the average of the three (3) measurements. The equipment is very helpful in producing compounds that meet ASTM criteria for vibration or shock absorption.

Function of each component:

- Scale, index: The rebound height of the main inspection materials.

- Adjustable Handle: Adjust the position of the pointer.

- Slider: The steering hammer acts as a guide.

- Punching: Impact on the test piece.

- Pole: Support the entire machine.

- Pull rod: Start the hammer to test.

- Horizontal foot: Adjust the level of the machine. When the bubble in the horizontal ball is in the center, the machine is in a level state.

- Fixing screw: Adjust the height of the test piece holder to place the test piece.

Click here to obtain a personalized quote.

Rubber compound resiliency is examined via GenRebound. The machine must be positioned horizontally, with the plunger lifted to a predetermined height. After that, the plunger is let go onto the sample for a specific amount of impact.

Here is how you properly maintain NextGen’s Vertical Rebound Resilience Tester – GenReboun:

- Check the verticality of the hammer guide before the test.

- Check if the machine is level before the test.

- The instrument can't be lubricated, otherwise, it will affect its performance.

- Keep the appearance of the machine clean and organized.

- Please operate and maintain by professionals only.

Click here to obtain a personalized quote.

- Prepare the test piece:

- Determination of the position of the test piece: Select the test piece from the dispersed position of the same batch of materials.

- Test piece production: Cut the test piece into two pieces of standard disc core test piece with a thickness of 12.5mm and a diameter of 28mm.

- Operation steps:

- Confirmation before operation:

- Check if the machine is level. If the machine is not in the horizontal state, adjust the machine to the level through the adjustable feet.

- Confirm that the slider is vertical.

- Clamp the test piece: Loosen the fixing screw of the machine stand and move the test piece up to the position where the rubber test piece can be placed. After pressing the rubber, lock the fixing screw.

- Confirmation before operation:

- Start the test:

- Move the hammer along the slide bar to the highest point, use the trigger to fix the hammer.

- Press the lever, the hammer will naturally fall to the test piece along the slide bar and the height will be the rubber rebound height.

Note:

- The same test piece is tested six times, the first three times are predicted first, no need to record the value, and then the adjustment handle is locked.

- After predicting three times, test again three times and record the rebound heights h1, h2, h3.

- Only when the test piece is clamped, the test can be carried out, otherwise the hammer and the base will be damaged.

- Recording method: The bounce height is read from the scale.

Note:

- When reading, the line of sight should be perpendicular to the scale to avoid errors in the test results.

- When reading a value, generally retain 1 decimal place, and the second digit is rounded.

- The scale next to the slide bar of the machine, each scale is 4mm.

- Results Processing Take the average of the first three test results

Rubber Rebound Height (W)= (h1 + h2 + h3)/3

Click here to obtain a personalized quote.

The relationship or ratio between the energy that is returned and the energy that is impacted between a force, such as a dropped hammer, and the test specimen is known as rebound resilience. In order to determine whether your material is ready for its intended application, the energetic reaction to an impact, often caused by a hammer, is measured and then assessed in accordance with the goals and quality control requirements.

By measuring the vertical rebound of a dropped plunger with a specified mass and shape, the ASTM D2632 test determines the impact resilience of solid rubber. Then, resilience is calculated as the difference between the hammer's drop height and rebound height. Again, variations in temperature and the depth of the plunger's entry are sensitive to the resilience measurement.

Although ASTM D2632 is used to create and compare materials, it is frequently inapplicable to the testing of end-use performance. Additionally, it does not apply to the testing of coated fabrics or cellular rubbers, yet it is suited for those types of tests.

NextGen’s Vertical Rebound Resilience Tester – GenReboun complies with ASTM D2632 standard

Click here to obtain a personalized quote.

Standard test method for Rubber Property Standard Test Method—Resilience By Vertical Rebound

This test procedure entails measuring the vertical rebound of a dropped mass in order to determine the impact resilience of solid rubber.

Cellular rubbers and coated fabrics cannot be tested using this test procedure.

Test Method D1054 provides a description of a common test procedure for rubber impact resilience and penetration using a rebound pendulum.

The values given in SI units should be taken as the norm. Parenthetical values are provided only for informational purposes.

If there are any safety concerns, they are not all claimed to be addressed by this standard. The user of this standard is responsible for establishing suitable safety and health procedures and determining whether any regulatory restrictions apply prior to using.

NextGen’s Vertical Rebound Resilience Tester – GenReboun complies with ASTM D2632 standard

Click here to obtain a personalized quote.

The scale on the Vertical Rebound tester is based on 4mm intervals (per section). This scale also indicates the percentage of height post bounce.

For example, if it bounces up to 30, the result is 30%.

Related Products

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

ICI / Mace Snag Tester

Discover the Fabric Textile ICI / Mace Snag Tester, a reliable tool for assessing fabric snagging under normal wear conditions.

Moving Die Rheometer (MDR)

Introducing the NG-MDR Moving Die Rheometer, your solution for accurately assessing the curing and processing characteristics of vulcanized rubber compounds. Designed for precision, this state-of-the-art rheometer captures the characteristic curve and parameters of rubber vulcanization by measuring the torque applied to the oscillating die.

Aging Oven – High-Temperature Chamber – NG-AGOV-ADV

The NG-AGOV-ADV Aging Oven is designed for high-temperature testing of rubber, plastics, and insulating materials. It features programmable PID control, uniform airflow, and forced convection for stable and repeatable aging cycles. This system supports global testing standards including ISO 188, ASTM D573, and IEC 60216-4-1. With its durable stainless-steel chamber and user-friendly interface, it’s ideal for R&D, quality control, and certification labs.

NG-T-Press M Series - Manual Cutting Press System for Rubber Tensile Specimens

Our newest manual cutting press system is suitable for laboratories to create specimens from rubber, tape, and special materials.

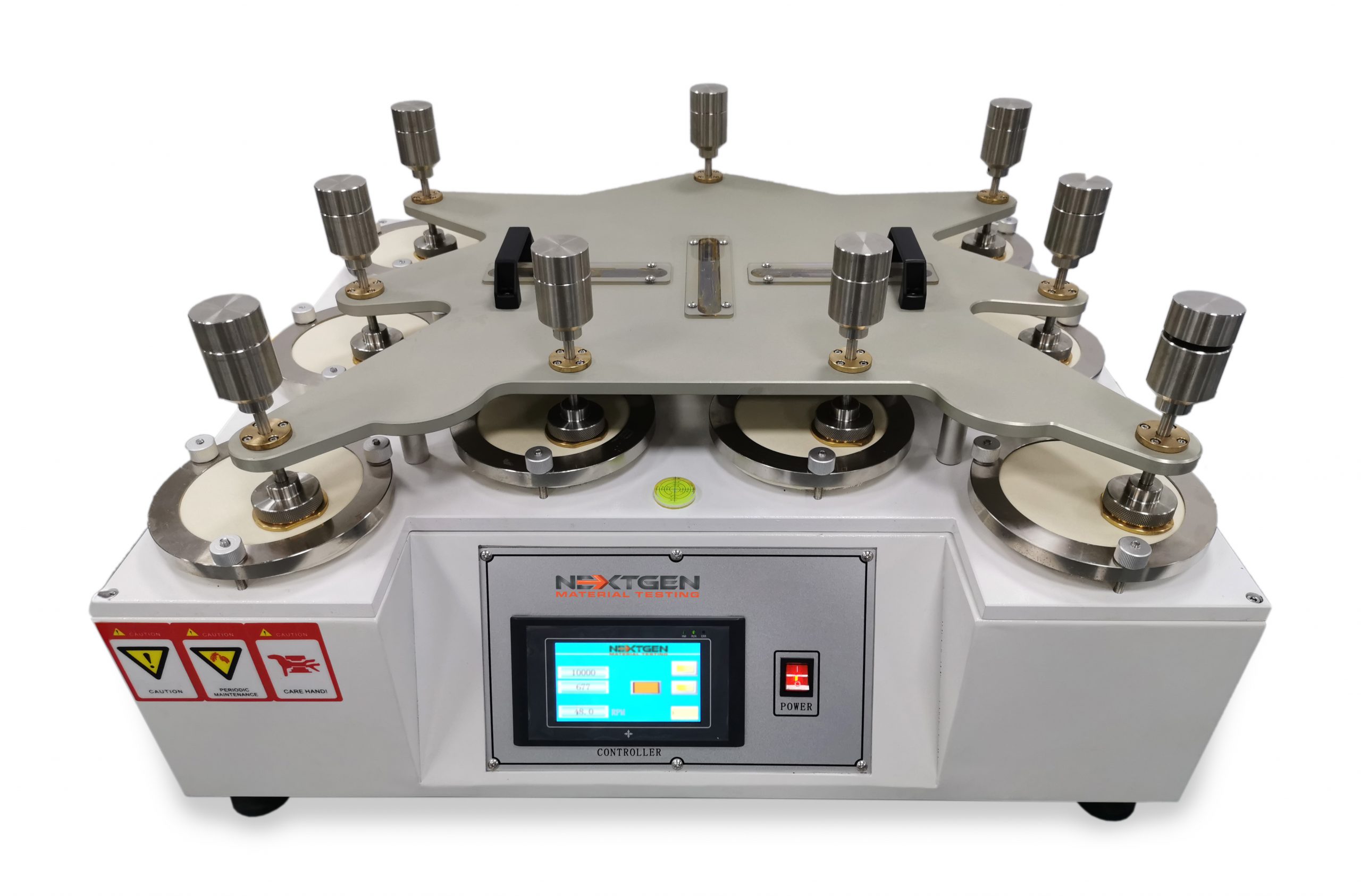

Rotary Abrasion Tester Single & Dual Wheel

GenRotary used evaluate abrasion resistance. It can conduct tests on a wide range of materials such as: cloth, paper, paint, plywood, leather, tile, glass, rubber etc. It tests the specimen by rotating it while in contact with the grinding wheel and applying the required pressure. The Joss of weight reflects on the change in weight of the specimen. The unit also has an intelligent power failure recovery function.

9-Station Martindale Abrasion Tester

The GenDale - Martindale Abrasion Tester is mainly used to test shoe fabric, shoe lining, and many other types of shoe related materials.

GenRoss-CH - Ross Flex Tester with Low Temperature Chamber

GenRoss-CH is an advanced Ross Flex Tester designed for assessing the cold resistance of materials in low temperature environments.

Linear Abrasion Tester

NextGen's linear abrasion meters evaluate the abrasion and scratch resistance of products, along with color transmission.

NextGen Environmental Chambers NG-EC 100,150,225,408,1000

The temperature and humidity NextGen Environmental Chambers features a sturdy cabinet made of cold-rolled steel and stainless steel.

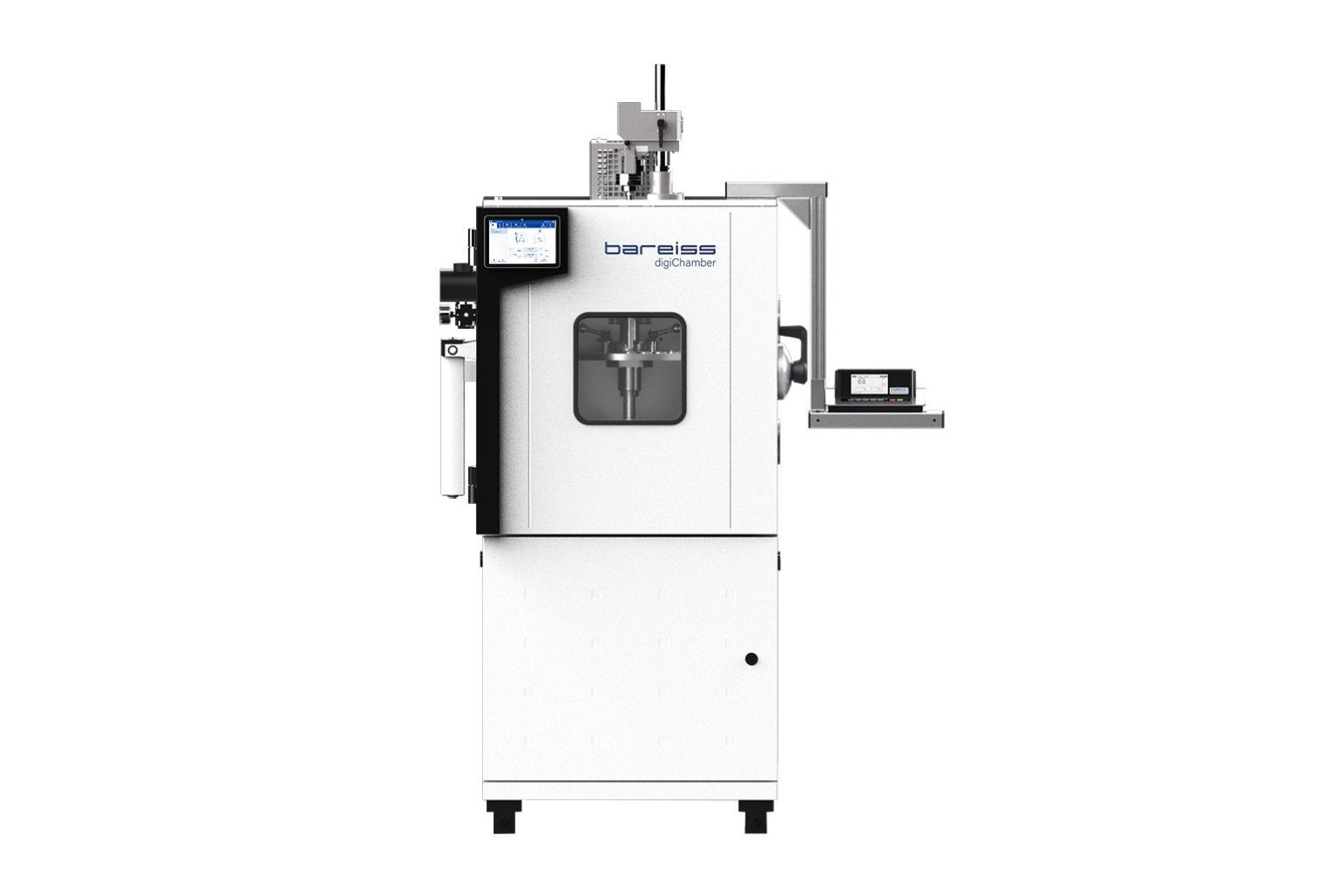

digiChamber - Temperature Controlled Hardness Testing

Discover digiChamber from NextGen Material Testing, the advanced temperature-controlled hardness tester developed by Bareiss.

HDA 120 - Hardness and Density Automation Test System

The HDA 120 test system is a versatile solution for semi-automatic detection of sample hardness and density.

RPA Ultra - Advanced Rubber Process Analyzer Rheometer

RPA Ultra is an advanced rubber process analyzer rheometer that measures the dynamic and static characteristics of raw rubber compounds

NG-EML Series B – Dual Column Bench Top Universal Testing Machine (100 N – 10 kN)

The NG-EML Series B is a high-precision dual-column benchtop universal testing machine engineered for tensile, compression, and flexural testing in the 0.1 kN to 10 kN range. It features Class 0.5 accuracy, a rigid FEM-optimized frame, and a direct-drive servo system with advanced closed-loop control, making it ideal for testing rubber, plastics, metals, composites, and high-performance polymers in both R&D and quality assurance settings.

NG-EML Series C – Dual Column Bench Top and Floor Standing Universal Testing Machine (5 kN – 50 kN)

The NG-EML Series C is a precision-engineered dual-column universal testing machine for tension, compression, and flexural testing of metals, composites, rubbers, and polymers. Available in both bench-top and floor-standing formats, with force capacities from 5 kN to 50 kN and Class 0.5 accuracy.

NG-EML Series D – Floor Standing Universal Testing Machine (50 kN – 1000 kN)

The NG-EML Series D – Floor Standing Universal Testing Machine (50 kN–1000 kN) is a dual-column system for tensile, compression, flexural, shear, and cyclic testing of high-strength metals, composites, polymers, and advanced materials. Available in single-space and dual-space configurations, it meets ASTM E8, ISO 6892-1, ISO 527, and GB/T 228 standards. With closed-loop control, 1200 Hz sampling, ultra-low speeds (0.00005 mm/min), and waveform generation, it is ideal for aerospace, automotive, construction, and research labs.

GenTest – Advanced UTM Testing Software

GenTest Software provides test control and data acquisition for universal testing machine workflows used in quality control and materials testing. It combines method templates, step-based sequencing, live curve monitoring, and built-in calculations in one environment. The software supports standards-based testing programs aligned with ASTM, ISO, DIN, EN, and BS. Results and reports remain linked to the method and specimen inputs for consistent review, auditing, and customer documentation.

Automatic Shore, IRHD and VLRH Hardness Testing System

NextGen is proud to present our German line of fully-automatic Shore, IRHD and VLRH hardness testing system for plastic materials, plastic and foam compounds for the ultimate precision, accuracy and repeatability, exceptional ease-of-use and maintenance. Experience the industry leader for specimen testing including rubbers, plastics, foams, composites, o-rings, and more.

Advanced Portable Shore Durometer System with Test Stand Options

HPEIII is NextGen's advanced German line of equipment that is the new generation of HPE systems ideal for various plastic and plastic compound testing. The new system enhancements offer advantages including temperature sensor, reading values of ambient temperature and humidity, historical hardness value display, larger LCD display, standard USB connection and much more. These advanced portable systems can be paired up with either manual or automatic motorized test stands to help eliminate the human error factor and maximize accuracy and repeatability between test when switching from one operator to the next.

Classic Analogue Shore Durometer with Test Stand Options

This German-manufactured system has been the global benchmark of Shore hardness testing systems since 1954. With ever enhanced ergonomic design, the HP Shore Hardness Tester is both visually appealing and precise rubber and plastic testing system as it has been for nearly 50 years.

Akron Abrasion Tester

GenKron is used together with a special balance for testing the abrasive consumption of materials. The measurements are done through volumetric loss of a rotating specimen exposed to the action of a standard grinding wheel. It is especially suited for testing harder materials such as shoe soles, tires and other rubber materials.

Burst Strength Tester for Fabric

GenBurst is the Burst Strength Tester designed to test anti-rupture strength of variety of materials such as leather, paper and fabric.

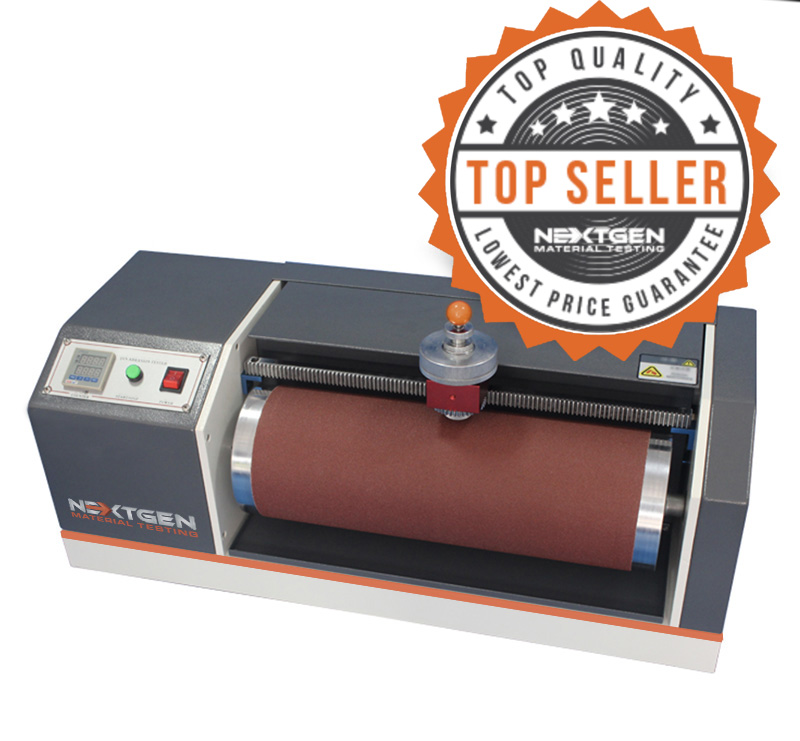

DIN Abrasion Tester

GenDin, is designed to conform to the ASTM D5963 and IS0 4649 standards. This top quality and highly popular abrasion tester will allow you to measure the abrasion resistance of rubbers (vulcanized thermo set rubbers and thermoplastic elastomers) that are subject to abrasive/frictional wear on their actual service. Since wear is always a result of abrasion, different test methods have been developed for the simulation of long term wear.

Demattia Flex Cracking Tester

GenFlex tests the ability of rubber products to withstand repeated flexing without developing cracks is of prime importance where such products are used in conditions undergoing repeated flexing. Flexing endurance of rubber products is determined by simulating in laboratory the action of flexing repeatedly under standard conditions of speed, mode, and degree of flexing.

Discoloration Meter

The machine is used to simulate an environment of sunlight radiation on a specimen to identify the resistance of fabric to discoloration.

Electric Crocking Tester - GenCrock

The machine is used to test the dyeing of the fabric, and the fade degree of the leather after dry or wet rubbing. The test method involves the specimen to be fastened to the base of the crocking meter and rubbed with an abrasive hammer attached to a wet or a dry cloth under controlled conditions. The transfer of colour is then measured using a scale to evaluate the rating of the specimen's dyeing grade.

Freezing Tester - GenFreeze

GenFreeze is specially designed to test the characteristics of various materials in a cold environment to ensure suitability for use in a cold climate. Based on the testing demand, adjust the beater and flexing grip, then load to the desired position. It can be used to test rubbers, leather, and plastics, PU leather etc. The unit can be adjusted to meet different requirements.

Martindale Abrasion Tester - GenDale

GenDale is mainly used to test shoe fabric, shoe lining, and many other types of shoe related materials. The unit can test up to four specimens at the same time for abrasion. The fabric specimen is measured by having rubbing applied on it via a complex direction of back and forth motion. The accuracy of abrasion strength is determined by the specific number of cycles conducted until a hole appears in the test area of the fabric specimen.

Mooney Viscosity Testing Machine - GenMooney

GenMooney is a viscosity testing machine is applied to measure the viscosity of the unmixed or mixed unvulcanized natural rubber, synthetic rubber and regenerated rubber .This tester has many functions such as fast warming, maintaining temperature, data stability, etc. It is equipped with an automated calibration feature for a simple data calibration of each experiment.

NBS Rubber Abrasion Tester - GenNBS

GenNBS is used to test the abrasion resistance of vulcanized rubber or other rubber compounds. It is commonly used for the soles and heels of footwear. It has an intelligent power failure recovery system. The unit conducts measurements through volumetric loss of specimens exposed to the action of a normalized abrasive medium secured to a rotations cylinder.

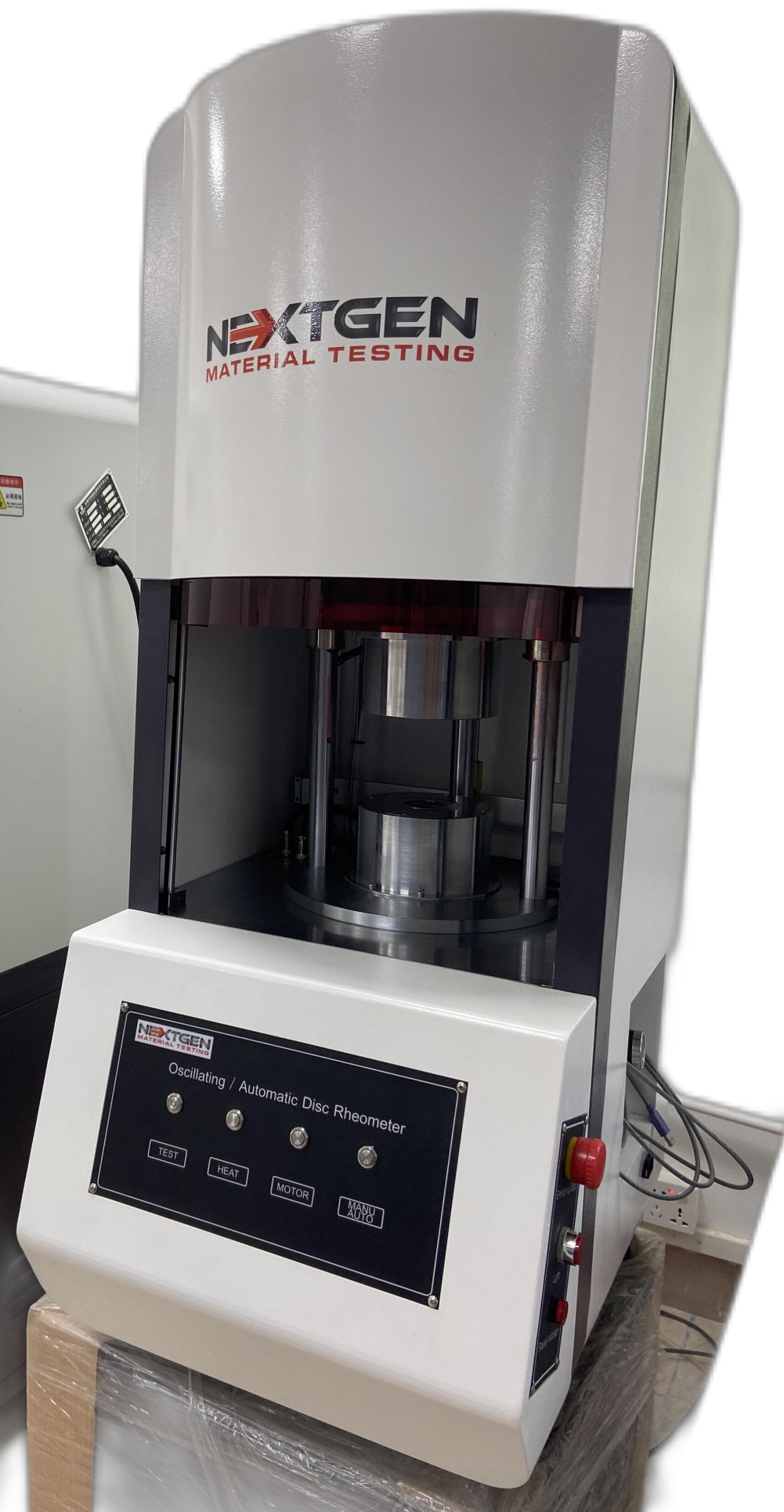

Oscillating / Automatic Disc Rheometer (ODR)

This machine is designed to get the characteristic curve and characteristic parameters of rubber vulcanization by measuring the applied moment of rubber to the oscillating dye body. NG-ODR rotor-free vulcameter has an excellent stability of results. The data and diagrams can be used as a reference for development, research and production quality.

Salt Spray Tester - GenSalt

GenSalt is designed to test the surface of different materials for resistance to corrosion. The unit is commonly used to test coated materials of a metallic nature in a controlled corrosive environment. The test can be used on rust-proof painting, anodizing, electroplating and rust-proof of grease. The machine imitates expedited corrosion process via salt spraying on a given test sample to identify the corrosion (oxides) resistance. Test results are based on the longevity of time a material can resist visible corrosion on the test sample.

Wyzenbeek Abrasion Tester - GenWyze

The machine is designed to test the abrasion resistance of fabrics and metals. The abrasion of fabrics is tested when the specimen is pulled over the frame and rubbed against an abradant over a curved surface. The number of cycles, also known as double rubs, conducted on the specimen before the fabric shows visible wear is used to determine the rating of abrasion.

Digital Densimeter Systems

Description The NG-DM-A Series offers high-accuracy digital Densimeters designed for a wide variety of material testing needs. These elegant and compact densimeter systems offer capacity ranges from 150g to 3000g with accuracy of 0.001g/cm3 down to 0.0002g/cm3. Advanced Densimeter System […]

Ross Flex Tester

Ross Flex Tester is designed to determine the resistance of vulcanized or synthetic elastomers to cut growth. The system does so under continuously bend flexing in 90°.