Plastic Testing Equipment

Standards

DIN ISO 48, ISO 2781, ISO 1183

Certified

Description

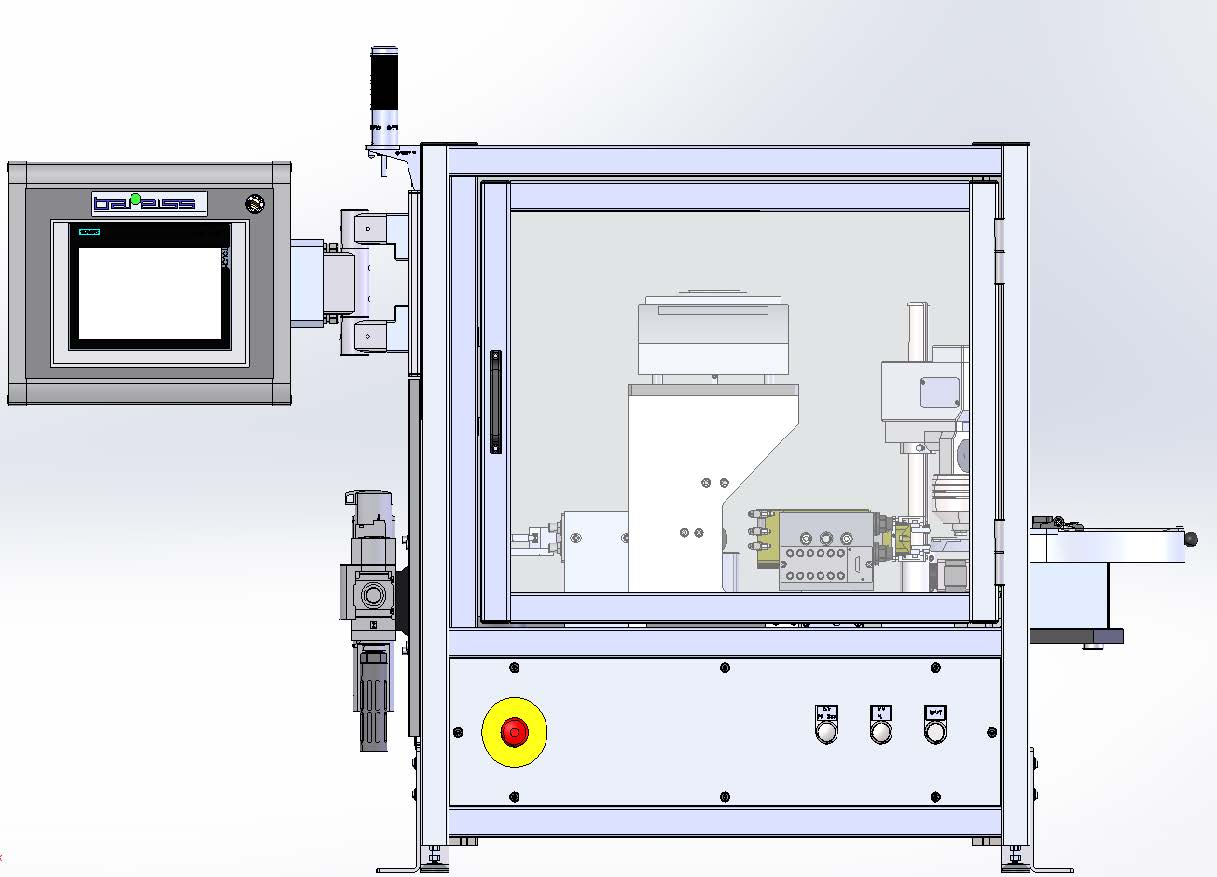

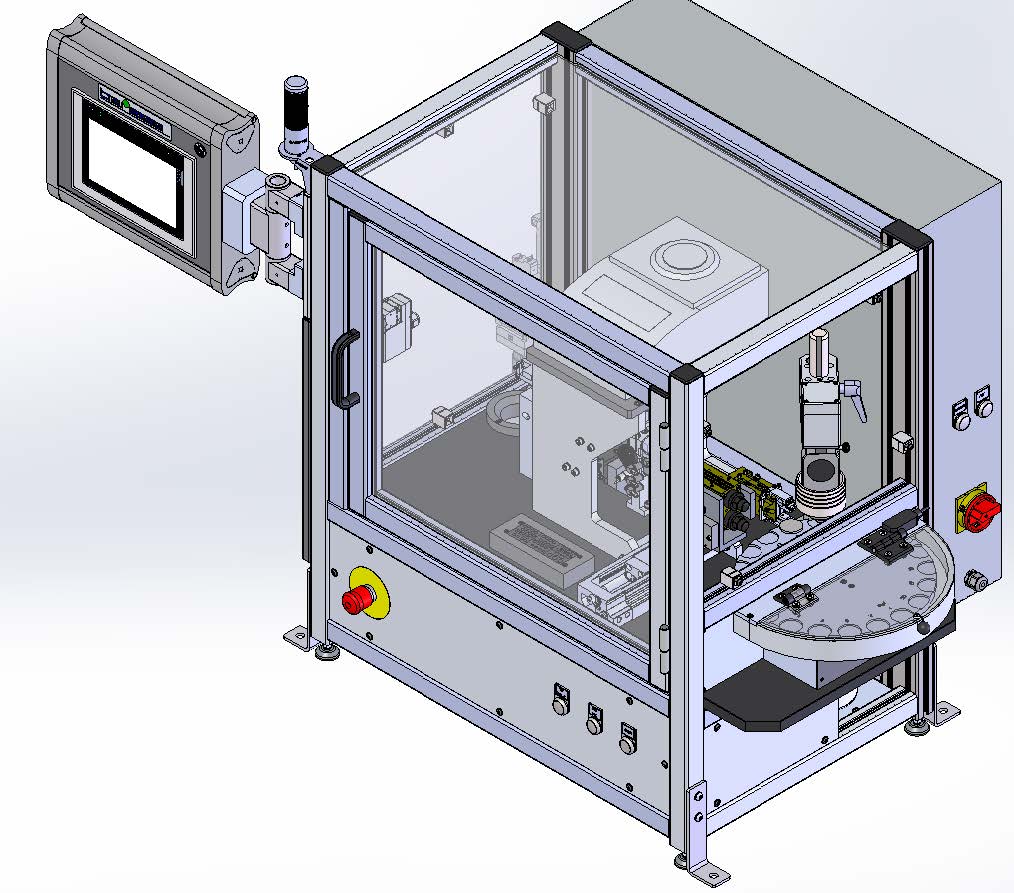

The HDA 120 test system is a versatile solution for semi-automatic detection of sample hardness and density. The HDA 120 can be fully integrated into existing laboratory systems and processes using a data interface, allowing for the exchange of sample-specific information such as batch, compound, operator, and production date before a series of measurements is started. Ethernet interface in a defined protocol is available to then transmit this data and store it in the PLC.

With the ability to load up to 20 samples, the HDA 120 offers a built-in rotating table for hardness testing with an emphasis on process stability. During the three hardness measurements, samples are securely held on the rotary indexing table by a hold-down, ensuring reliable results even with strongly adhering samples. Lear more about HDA 120 - Hardness and Density Automation Test System in our blog.

Hardness and Density Automation Test System Features

-

Consists of a built-in rotating table that provides great process stability during measurements and can handle up to 20 samples at a time.

-

User-friendly and can be operated via touchscreen and has a pneumatic gripping system for density determinations along with a force ejection mechanism making it a more competitive device in the market.

-

Hardness testing optionally with IRHD N (DIN ISO 48-2) or Shore A (DIN ISO 48-4)

-

Density measurement acording to ISO 2781, DIN EN ISO 1183-1, ASTM D1817

-

ISO/IEC 17025 certified

HDA 120 Input-Output Data

|

HDA 120 - Hardness and Density Automation Test System |

|

|

Input data Which data can be transferred to the HDA? |

Operator |

|

Compound Folder |

|

|

Compound |

|

|

Production Date |

|

|

Output Data What Data Does the HDA Provide? |

Sample Counter |

|

Operator |

|

|

Compound Folder |

|

|

Compound |

|

|

Production Date |

|

|

Hardness 1 |

|

|

Hardness 2 |

|

|

Hardness 3 |

|

|

Timestamp |

|

|

Weight in Air |

|

|

Weight in Water |

|

|

Temperature of the water |

|

|

Density |

|

All measurement data, together with the sample-specific information, can be fetched via the interface and processed further in downstream analysis systems. With its wide range of features, the HDA 120 is an ideal choice for those looking for accurate and reliable semi-automatic detection of hardness and density in their samples.

HDA 120 Sample Operation

The samples are transported to a transfer point by a pneumatic gripping system for the subsequent density determination after the hardness measurement. In order to determine the density, the weight of the sample is first determined in air. Next, the sample is transported with the gripping system to another station and deposited there. A cylinder moves up a container filled with distilled water and immerses the sample completely under water. The water level is checked and, if necessary, corrected for each measurement, and the current water temperature is recorded and taken into account. The cylinder moves the water bath up at least twice to eliminate possible air bubbles. You can also increase the number of weightings in water, which leads to a more accurate result. Further, the density is determined using the highest wet weight.

The gripping system used for the density determination has a forced ejection, which prevents the sample from sticking to the gripper. Once the density has been determined, the sample is picked up and ejected by a separate gripping system, further avoiding any potential carryover of water. This gripping system is also equipped with a forced ejector, ensuring that no sample gets stuck.

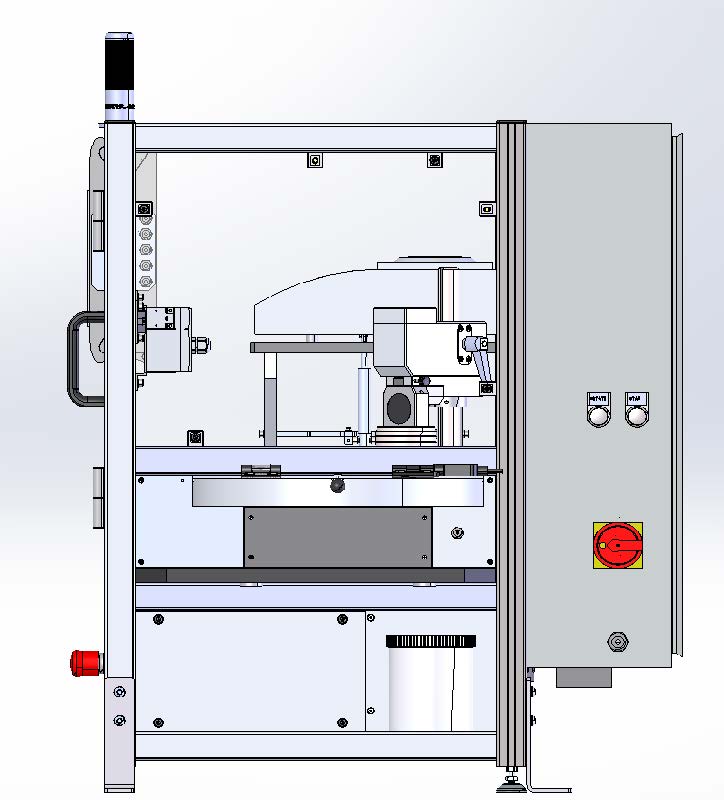

HDA 120 Technical Specifications

|

HDA 120 - Hardness and Density Automation Test System |

|

|

W x L x H |

1625 x 825 x 1065mm |

|

Weight |

ca. 175kg |

|

Impress Protection |

IP 21 |

|

Power Supply |

100-240VAC; 50/60Hz; 10A |

|

Air Pressure |

4-6bar |

|

Operating Temperature |

23±2°C |

|

Specimen Geometry |

Ø 35-38 mm, d=6 ± 0,5 mm / Ø 39-42mm, d=6 ± 0,5mm |

|

Density range of the samples |

>1kg/dm3 |

|

Number of samples |

20 |

|

Communication interface |

Ethernet |

|

Data communication |

Specific Software / Web server |

|

Data format |

* .csv |

|

Resolution hardness measurement |

0,1 |

|

Resolution density measurement |

0,001kg/dm3 |

|

Error analysis of the complete system |

Value < 1 |

FAQs

The DIN ISO 48 standard outlines the procedure for performing a Shore A hardness test, which measures the resistance of a rubber material to indentation. The test involves applying a defined force to a standardized indenting tool and measuring the depth of the resulting indentation. The Shore A hardness value is then calculated based on the depth of the indentation. The specimen should be a flat and uniform piece of rubber or elastomer material. The specimen thickness should be at least 6 mm (0.24 in) and should be sufficient to allow the indenting tool to penetrate the surface without bottoming out on the support surface. The Shore A durometer used for testing should be calibrated before the test to ensure accurate and consistent results. The hardness value is reported in Shore A units, which range from 0 to 100. A higher Shore A value indicates a harder material, while a lower value indicates a softer material.

NextGen’s HDA 120 – Hardness and Density Automation Test System complies with DIN ISO 48 standard.

Click here to learn more about the product or here to receive a personalized quote.

The ISO 2781 test method involves measuring the mass of a test specimen and its volume. The mass of the specimen is determined using a balance, while the volume is determined by either measuring the displacement of a liquid or by measuring the dimensions of the specimen and calculating the volume using geometric formulas.

The ISO 2781 standard outlines the specific test conditions and requirements for performing the density test, including specific test equipment and procedures for specimen preparation, handling, and testing. The test specimen should be a representative material sample, free from air bubbles or voids, and have a known weight. You also need to weigh the specimen on a balance of suitable accuracy and record the weight. To calculate the specimen's density, divide its weight by its volume. The density is usually expressed in grams per cubic centimetre (g/cm3) or kilograms per cubic meter (kg/m3).

NextGen’s HDA 120 – Hardness and Density Automation Test System complies with ISO 2781 Standard.

Click here to learn more about the product or here to receive a personalized quote.

The ISO 1183 standard has been adopted by many countries around the world, including the United States, Canada, and the EU. The test method involves measuring the mass of a test specimen and its volume. The mass of the specimen is determined using a balance, while the volume is determined by either measuring the displacement of a liquid or by measuring the dimensions of the specimen and calculating the volume using geometric formulas.

The ISO 1183 standard outlines the specific test conditions and requirements for performing the density test, including the use of specific test equipment and procedures for specimen preparation, handling, and testing. It also provides guidelines for reporting test results and includes information on calculating the test results' uncertainty.

The volume of the specimen can be determined using one of two methods:

- Liquid displacement: Submerge the specimen in a liquid of known density and measure the volume of the displaced liquid using a graduated cylinder or other suitable equipment.

- Dimensional measurement: Measure the dimensions of the specimen using a suitable instrument, such as a micrometre or calliper, and calculate the volume using geometric formulas.

NextGen’s HDA 120 – Hardness and Density Automation Test System complies with ISO 1183 Standard.

Click here to learn more about the product or here to receive a personalized quote.

The HDA-120 Hardness and Density Automation Test System is designed to measure the hardness and density of rubber and elastomer materials. This system utilizes automation as its advantage, providing consistent and accurate test results

The HDA-120 system can perform two different tests: the Shore A hardness and density tests. The Shore A hardness test measures the resistance of a rubber material to indentation, providing a measure of the material's hardness. The density test measures the mass of a material relative to its volume, providing a measure of the material's density.

One of the key advantages of the HDA-120 system is its high level of automation. The system is capable of performing tests automatically, reducing the need for manual intervention and increasing the consistency and accuracy of test results. There is also a range of safety features to protect operators and ensure safe operation of the equipment.

Click here to learn more about the product or here to receive a personalized quote.

The HDA-120 Hardness and Density Automation Test System accurately measures the hardness and density of rubber and plastic materials. The testing range of the HDA-120 depends on the test that is being conducted, thus, can vary.

For hardness testing, the HDA-120 can measure the Shore A and Shore D hardness of materials within a range of 0 to 100 units. The tester can accurately measure the hardness of very soft materials, such as foam rubber, and very hard materials, such as dense plastics.

For density testing, the HDA-120 can measure the density of materials within a range of 0.01 to 2.00 g/cm3. This covers a range of plastic and rubber materials, including solid and cellular ones.

Click here to learn more about the product or here to receive a personalized quote.

The HDA-120 is designed to provide highly accurate and repeatable hardness and density testing results.

For hardness testing, the HDA-120 has a measurement accuracy of ±0.5 Shore A and ±1 Shore D. One of the main advantages of our tester is that it is also equipped with an automatic correction function, which compensates for any deviations caused by the surface condition of the material being tested.

For density testing, the HDA-120 has a measurement accuracy of ±0.0005 g/cm3, which is highly precise and ensures that the results are accurate and repeatable.

Moreover, the HDA-120 is designed with advanced automation features, eliminating the potential for human error and increasing the test results' accuracy and repeatability. The tester is equipped with a motorized drive system, which provides consistent and precise pressure during testing.

Click here to learn more about the product or here to receive a personalized quote.

The duration of a test using the HDA-120 Hardness and Density Automation Test System depends on the type of test being conducted and thus can vary.

For hardness testing, the HDA-120 can perform a single test in as little as 10 seconds, with a maximum testing time of 60 seconds. This rapid testing time is made possible by the instrument's advanced automation features, which include a motorized drive system that provides consistent and precise pressure during testing.

The HDA-120 can perform a single test in as little as 10 minutes for density testing, with a maximum testing time of 60 minutes. Density testing takes longer because the instrument needs to reach thermal equilibrium with the test material before the measurement is taken. On top of that, the HDA-120 is equipped with advanced features, such as automatic temperature compensation, which ensures that the density measurements are accurate even in fluctuating temperatures.

Click here to learn more about the product or here to receive a personalized quote.

ASTM D1817 is a standard test method for rubber products. It specifies the determination of the specific gravity of raw or unvulcanised rubber.

The specific gravity of a rubber material is a physical property that provides valuable information about the composition and quality of the material. It is the ratio of the mass of a given volume of the material to the mass of an equal volume of distilled water at a specified temperature.

What is the procedure? ASTM D1817 involves measuring the mass of a sample of rubber material and then determining the volume of the sample by immersing it in a liquid displacement medium, typically water. The specific gravity is then calculated by dividing the mass of the sample by the volume displaced by the sample.

The test method specifies several variables that must be controlled during the test. These variables are the temperature and timing of the measurements, the cleanliness and temperature of the liquid displacement medium, and the size and shape of the sample.

HDA 120 complies with ASTM D1817 Standard.

Click here to learn more about the product or here to receive a personalized quote.

|

HDA 120 - Hardness and Density Automation Test System |

|

|

W x L x H |

1625 x 825 x 1065mm |

|

Weight |

ca. 175kg |

|

Impress Protection |

IP 21 |

|

Power Supply |

100-240VAC; 50/60Hz; 10A |

|

Air Pressure |

4-6bar |

|

Operating Temperature |

23±2°C |

|

Specimen Geometry |

Ø 35-38 mm, d=6 ± 0,5 mm / Ø 39-42mm, d=6 ± 0,5mm |

|

Density range of the samples |

>1kg/dm3 |

|

Number of samples |

20 |

|

Communication interface |

Ethernet |

|

Data communication |

Specific Software / Web server |

|

Data format |

* .csv |

|

Resolution hardness measurement |

0,1 |

|

Resolution density measurement |

0,001kg/dm3 |

|

Error analysis of the complete system |

Value < 1 |

Click here to learn more about the product or here to receive a personalized quote.

The HDA-120 Hardness and Density Automation Test System is designed with several advanced features that ensure accurate and safe testing of materials:

- Automation: The HDA-120 has a motorized drive system that provides consistent and precise pressure during hardness testing. This automation reduces the need for manual manipulation of the testing process, improving accuracy and reproducibility.

- Versatility: The HDA-120 can perform both hardness and density measurements. Hence, providing a comprehensive characterization of the physical properties of materials.

- High throughput: The HDA-120 can perform multiple tests in a single operation, allowing for high throughput and increased efficiency.

- User-friendly interface: The HDA-120 features an intuitive and easy-to-use interface providing easy access to new and experienced users.

- Automatic temperature compensation: The HDA-120 is equipped with automatic temperature compensation for density measurements, ensuring accurate and consistent results even in fluctuating temperatures.

- Safety features: The HDA-120 has emergency stop buttons, overload protection, and interlocks, which prevent the instrument from operating under unsafe conditions.

- Calibration and verification: The HDA-120 is equipped with calibration and verification routines to provide the highest test results accuracy.

Click here to learn more about the product or here to receive a personalized quote.

After the hardness measurement, a pneumatic gripping system transports the samples to a transfer point for density determination. Initially, the weight of the sample is determined in the air to calculate density. Subsequently, the gripping system transfers the sample to another station where it is deposited. A cylinder immerses the sample entirely underwater in a container filled with distilled water, and the water level is checked and adjusted if needed for each measurement. The cylinder moves the water bath up at least twice to eliminate air bubbles, and the current water temperature is recorded. The number of weightings in water can be increased to obtain more precise results. The highest wet weight is used to calculate the density.

The gripping system for density determination is designed with a forced ejection feature to prevent samples from sticking to the gripper. Once the density is determined, a separate gripping system picks up and ejects the sample, preventing potential water carryover. This gripping system also has a forced ejector feature to ensure no sample gets stuck.

Click here to learn more about the product or here to receive a personalized quote.

|

HDA 120 - Hardness and Density Automation Test System |

|

|

Input data Which data can be transferred to the HDA? |

Operator |

|

Compound Folder |

|

|

Compound |

|

|

Production Date |

|

|

Output Data What Data Does the HDA Provide? |

Sample Counter |

|

Operator |

|

|

Compound Folder |

|

|

Compound |

|

|

Production Date |

|

|

Hardness 1 |

|

|

Hardness 2 |

|

|

Hardness 3 |

|

|

Timestamp |

|

|

Weight in Air |

|

|

Weight in Water |

|

|

Temperature of the water |

|

|

Density |

|

The HDA 120 offers the flexibility to obtain all measurement data and sample-specific information through its interface, allowing for further processing in downstream analysis systems. The system's extensive range of features makes it an ideal choice for those seeking precise and dependable semi-automatic detection of hardness and density in their samples.

Click here to learn more about the product or here to receive a personalized quote.

ISO/IEC 17025 standard establishes a framework for the quality management of laboratories, including the management system, technical competence, and the validity of the results. The standard applies to all types of laboratories, regardless of the size or complexity of the operations.

The procedures outlined in ISO/IEC 17025 include several elements. The standard requires laboratories to establish and maintain a quality management system. You have to document a set of procedures for testing and calibration activities. The procedures should cover sample handling, test methods, equipment calibration, and reporting of results. The laboratory should also have a plan for ongoing training and development of its personnel, as well as appropriate documentation and records management systems.

The standard also includes requirements for the technical competence of laboratory personnel, including education, training, and experience. Laboratories must use validated test methods and calibrated equipment to ensure reliable results.

NextGen’s HDA 120 complies with ISO/IEC 17025 standard.

Click here to learn more about the product or here to receive a personalized quote.

The Impress Protection of HDA 120 is IP21.

IP21 (Ingress Protection 21) is a rating system that defines the level of protection provided by an enclosure against the ingress of solid objects and dripping water. The IP rating system is a standard defined by the International Electrotechnical Commission (IEC).

In the case of IP21, the first digit "2" indicates that the enclosure provides protection against the ingress of solid objects larger than 12.5mm, such as fingers or small tools. The second digit, "1," indicates that the enclosure provides protection against vertically dripping water.

In practical terms, IP21 is a relatively low level of protection and is often found in indoor environments where the equipment is not exposed to harsh conditions. Enclosures with IP21 protection are not sealed against dust or water spray and may not be suitable for use in dusty or wet environments.

The Impress Protection of HDA 120 is IP21.

Click here to learn more about the product or here to receive a personalized quote.

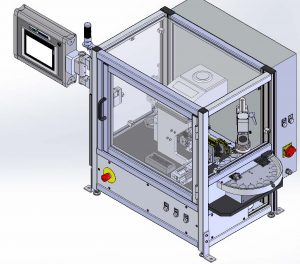

The HDA 120 is a highly adaptable solution for semi-automatic sample hardness and density detection. By utilizing a data interface, the HDA 120 can be seamlessly integrated into existing laboratory systems and processes, enabling the exchange of essential sample-specific information, such as batch number, compound, operator, and production date, before a measurement sequence is initiated. This information can then be transmitted via an Ethernet interface with a defined protocol and stored in the PLC.

With a capacity of up to 20 samples, the HDA 120 includes a built-in rotating table that provides exceptional process stability during hardness testing. A hold-down mechanism holds samples securely on the rotary indexing table, ensuring reliable results even with strongly adhering samples.

Furthermore, the HDA 120 is equipped with an array of user-friendly features, such as a pneumatic gripping system and forced ejectors for easy handling of samples and an automated transfer station for density determination after hardness measurement. The system also has built-in safety features, such as the IP21 protection class, which protects against foreign objects and water ingress.

HDA 120 Weight & Dimensions:

|

W x L x H |

1625 x 825 x 1065mm |

|

Weight |

ca. 175kg |

Click here to learn more about the product or here to receive a personalized quote.

Related Products

Melt Flow Indexer

Our melt flow indexer is a highly precise instrument designed for the measurement of melt flow rate (MFR)/(MI) or melt volume rate (MVR) in quality control and research applications.

NG-ImpactFall – Falling Weight Impact Tester

Our falling weight impact tester finds extensive application in conducting external impact strength tests on plastic and non-metal materials.

High Energy Elemendorf

Measure the tearing strength of plastic materials with the NG-HE Elemendorf, a versatile tester with advanced potential energy calculation.

NextGen Environmental Chambers NG-EC 100,150,225,408,1000

The temperature and humidity NextGen Environmental Chambers features a sturdy cabinet made of cold-rolled steel and stainless steel.

Automatic Shore, IRHD and VLRH Hardness Testing System

NextGen is proud to present our German line of fully-automatic Shore, IRHD and VLRH hardness testing system for plastic materials, plastic and foam compounds for the ultimate precision, accuracy and repeatability, exceptional ease-of-use and maintenance. Experience the industry leader for specimen testing including rubbers, plastics, foams, composites, o-rings, and more.

Advanced Portable Shore Durometer System with Test Stand Options

HPEIII is NextGen's advanced German line of equipment that is the new generation of HPE systems ideal for various plastic and plastic compound testing. The new system enhancements offer advantages including temperature sensor, reading values of ambient temperature and humidity, historical hardness value display, larger LCD display, standard USB connection and much more. These advanced portable systems can be paired up with either manual or automatic motorized test stands to help eliminate the human error factor and maximize accuracy and repeatability between test when switching from one operator to the next.

Classic Analogue Shore Durometer with Test Stand Options

This German-manufactured system has been the global benchmark of Shore hardness testing systems since 1954. With ever enhanced ergonomic design, the HP Shore Hardness Tester is both visually appealing and precise rubber and plastic testing system as it has been for nearly 50 years.

Automatic Capsule and Soft Gel Hardness Tester

Gelomat is an automatic capsule hardness tester designed for regular and soft gel capsule testing. This state of the art system is developed by the latest R&D technology to meet and exceed the highest quality standards for gelatin capsule testing. The system comes standard with your desired testing head and can be upgraded to optional accessories for maximum efficiency.

Fruit Firmness Tester

This German manufactured fruit firmness and fruit hardness testing device is designed specification for the determination of the pulp hardness of a given fruit. This state-of-the-art device is invaluable for trading companies serious about their quality control procedures. The unit helps identify the harvest date of the specific fruits relative to the time of transpirations and storage.

Ball Rebound Tester

Ball Rebound Tester is designed for measuring the rebound resilience of polymer foams.

Pendulum Rebound Resilience Tester

Manual and Fully-Automatic Pendulum Rebound Resilience Tester. These rebound testers will determine the dynamic behavior of various materials and supply the differentiation of these materials' qualities. It will also identify material changes after aging and fatigue. The Pendulum Rebound Tester is out there with an adjustable heater for sample temperatures up to 100 ℃. It can simulate the effect of heat on the elasticity of samples with different formulations.

Pusey & Jones Tester

Pusey & Jones is a rubber and rubber like material testing system. The unit is designed for testing rubber rollers in the paper industry. The system can test specimens with flat surfaces and thickness of 13 mm.