Plastic Testing Equipment

Standards

DIN ISO 7619, DIN EN ISO 868, NF EN ISO 868, ASTM D 2240, SRIS 0101

Certified

Main Unit

HPE III is R&D's latest development of the next generation HPE testing systems. The system offers cutting edge features above and beyond the standard HPEII model. The system is capable of taking a hardness value while a temperature sensor mounted on the bottom of the device is taking a temperature value. Equipped with aluminum casing alloy offers the end user the optimal combination of robust structure and light weight. The display will indicate the hardness value, the temperature as well as the humidity values. The system has an intuitive user Interface. This advanced shore durometer is designed for one-handed operation. A large hand grip will assist the user to approach the specimen perpendicularly and minimizing incorrect measuring angle and ensuring the right force is applied.

The unit is equipped with a large LCD display with 102 x 64 pixels with selectable information to display and now comes standard with a USB connection for the BSA test stand and battery charging purposes. The patented hand grip designed to achieve correct measuring angle and correct force amount are all standard features on HPE III. Historical measurements can be displayed for the hardness values and date/time when each measurement was taken. Excellent solution for automotive industry, rubber and plastic industry, defense and aerospace industry, and more

-

Shore-hardness

-

Specimen-/environment

-

Temperature Humidity

Test Method

Shore A / A0 / B / 0 / C / D / D0 / 00 / 000 / 000S / E / L/c

Portable Advanced Shore Hardness Testing System

Automatic Shore Hardness Testing System

Features

| HPE ||| | Available Methods |

|---|---|

| Temperature/humidity | DIN ISO 48-2/DIN ISO 7619 |

| Sample Temperature | Shore A |

| Date and Time | Shore A0 |

| Lithium Battery | Shore D |

| Display with backlight | ASTM D 2240 |

| Auto-Power-Off | Shore 0 / Shore 00 |

| Contact pressure acc. standards | Shore 000 / Shore 000S |

| Peak Value | Shore E / Shore B |

| USB Interface | Shore C / Shore D0 |

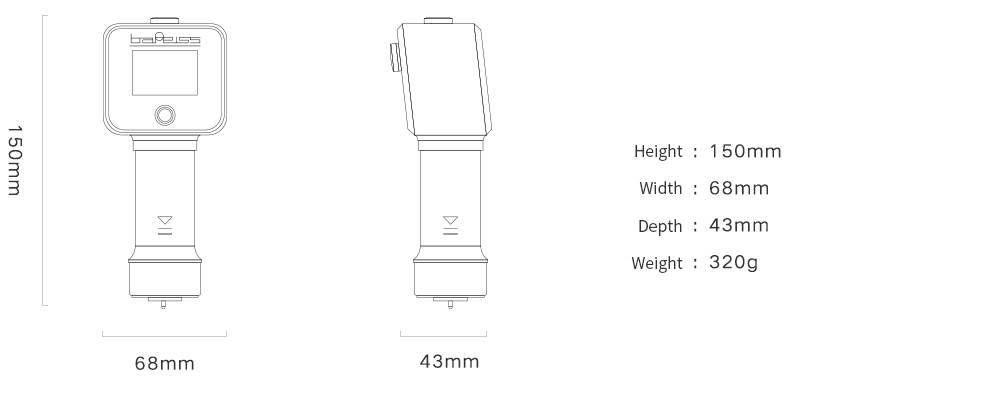

Size And Weight

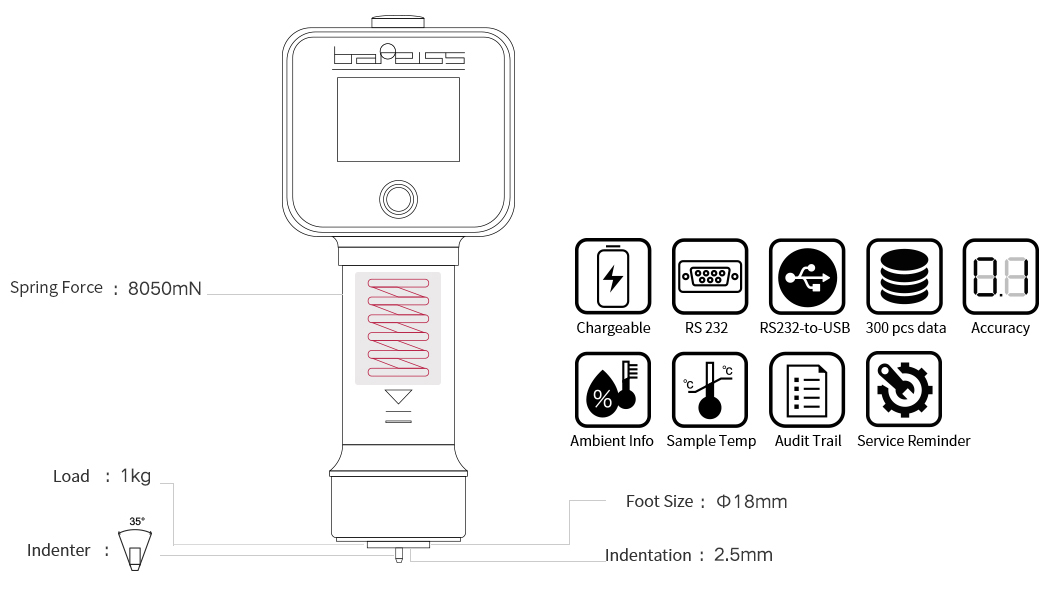

Method A

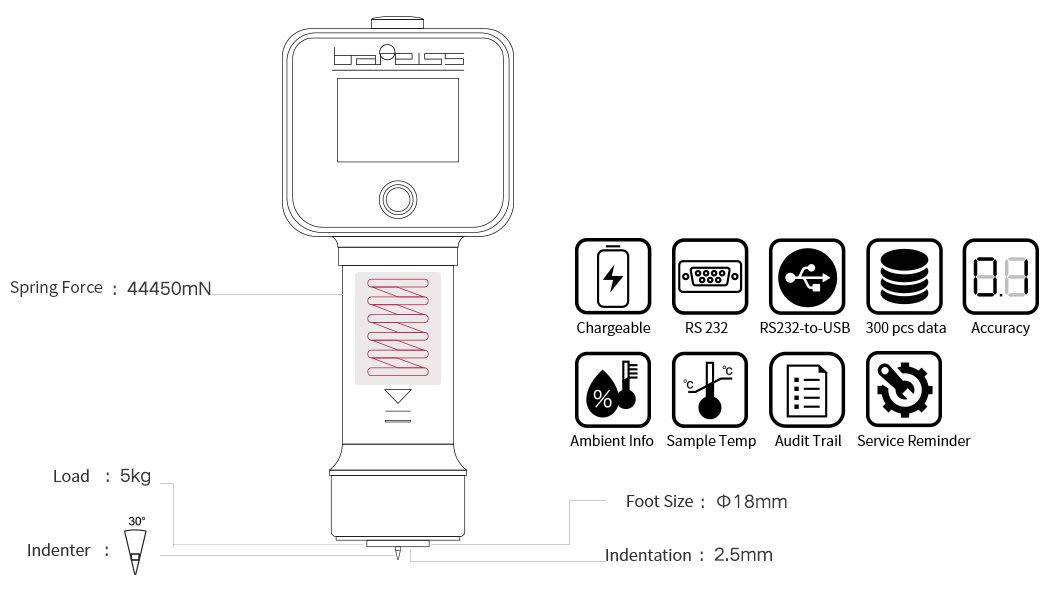

Method D

Calibration

As a national accredited DAkkS/DKD laboratory, our partners are officially authorized to perform repair and recalibration services on all types of hardness testers in accordance with specified standards and to issue the DAkkS/DKD certificate.

Loaner Program for Testing Heads

Avoid service interruptions by getting a tester head on loan. Contact us today to ask how.

Sample Preparation Service

We welcome you to send your specimens to our facility to confirm that our equipment's accuracy is perfectly in line with your expectations. Contact us today to learn more.

Training

We stand behind our product. Should you require additional training support, please contact us and we would be happy to assist your most suitable remote communication method.

BSA test stand

This Automatic test stand is perfectly compatible with our HP and HPEIII units allowing for hardness measurements in accordance with ASTM D2240 Shore standards. It is designed to help eliminate the human error factor creating consistent measuring results operator-to-operator. The pick-up device found on the test stand allows for quick and easy clamping of the hardness tester. Manual test stand option is also available.

Calibration device for HP and HPE II

In compliance with ISO 9000 the operator should perform a periodical equipment calibration. With this calibration device the accuracy of the Shore hardness tester is controlled. It allows for a quick control of the spring force in increments of ten for the measuring ranges including Shore A/B/0/C/D/DO and L, L/c.

DIN 53 505, EN ISO 868, NF EN ISO 868, ASTM D2240, JIS K 6253.

Shore Reference Test Blocks

Standard rubber blocks are used to ensure the metrological capability of the measuring device according to the Shore standard during the frequency of recalibration. The rubber blocks are embedded in a holder made of stainless steel.

The calibration stands can come with single, 3, 5 or 6 plates including DAkkS/DKD calibration certificate

Shore Control Ring

Control of the measuring distance with DAkkS/DKD / WKS Certificate

- 20 Shore

- 40 Shore

- 60 Shore

- 80 Shore

Hardtest – Software

Hardtest is one of the most prominent accessories applicable to both the DigiTest and the HPE line of equipment. It comes standard with a serial interface. The software designed to eliminate all human and other error factors.

DAkkS/DKD Calibration Certificate

The purpose of the hardness tester calibration is to determine the unit's measure output against the standard reference. Once the unit is confirmed to meet the testing criteria, a calibration certificate is then issued indicating the measuring results and the corresponding measurement uncertainties and the instrument is marked as calibrated.

All supplied corresponding documentation offered with the calibration certificate provides traceability in accordance to national standards./p>

FAQs

ISO 868 is an international standard that defines the characteristics of thermoplastic materials used in engineering. This standard covers specifications for unplasticized polyvinyl chloride (uPVC), polycarbonate (PC), acrylonitrile-butadiene-styrene (ABS), and other thermoplastic materials, including their dimensional stability, strength, and temperature resistance. Manufacturers and designers of plastic products primarily use it to ensure consistent quality and performance across different products and applications.

DIN EN ISO 868 is the German national adoption of the international ISO 868 standard. It specifies the requirements and test methods for thermoplastics used in engineering applications and covers the same material characteristics as the ISO 868 standard. The "DIN EN" designation indicates that it is a European standard harmonized across the European Union (EU) countries. This standard ensures that plastic products manufactured in Germany or other EU countries meet the same basic requirements for quality, performance, and safety.

NextGen’s Advanced Portable Shore Durometer System complies with DIN EN ISO 868 standard.

Click here to request a personalized quote from our team!

ASTM D 2240 is a standard test method published by the American Society for Testing and Materials (ASTM) for measuring the hardness of rubber products. Rubber hardness is defined as its resistance to permanent indentation. You measure it using a durometer, a type of instrument that applies a standardized force to the surface of the rubber. The durometer used in this test method measures the hardness on a scale ranging from 0 to 100, where higher values indicate a harder material. The ASTM D 2240 standard is widely used in various industries, including automotive, aerospace, and construction, to ensure consistent and reliable measurements of rubber hardness. ASTM D 2240 covers type A and type D durometer scales used to measure different rubber products. The type A scale is used for softer rubbers, while type D is used for harder ones.

NextGen’s Advanced Portable Shore Durometer System complies with ASTM D 2240 standard.

Click here to request a personalized quote from our team!

ISO 7619 is an international standard that defines the methods for measuring vibration and shock on equipment and machines. The standard provides guidelines for determining the vibration and shock resistance of various types of equipment, including machinery, vehicles, and buildings. Methods for evaluating their ability to withstand vibration and shock are provided. The standard is used in various industries, including automotive, aerospace, and construction, to ensure that equipment and machines meet minimum performance requirements and provide consistent and reliable vibration and shock resistance measurements. The standard covers sinusoidal, random vibration, and shock and defines the frequency ranges and measurement procedures for each type. The purpose of ISO 7619 is to provide a consistent and reliable method for evaluating the performance of equipment and machines in environments where they may be subjected to vibration and shock.

The "DIN ISO" designation indicates that it is an international standard adopted by Germany. The standard ensures that equipment and machines meet minimum performance requirements and provide consistent and reliable vibration and shock resistance measurements.

NextGen’s Advanced Portable Shore Durometer System complies with DIN ISO 7619 standard.

Click here to request a personalized quote from our team!

JIS K 6253 is a Japanese Industrial Standard (JIS) that specifies the method for rubber hardness testing using a type A durometer (Shore hardness tester). The standard provides guidelines for performing hardness measurements on rubber materials, including the type of durometer used, the measurement procedure, and the calculation of the hardness value. The JIS K 6253 standard is widely used in the rubber and plastics industries for quality control and materials testing. The Shore A scale is widely used for soft rubber and elastomers, while the Shore D is used for harder rubber materials.

JIS K 6253 provides detailed information on performing accurate and consistent hardness tests on rubber materials using a type A durometer. This includes specifications for the durometer, such as the shape, size, and materials used in the penetrator and the scale. The standard also provides guidelines for sample preparation, including the thickness and surface finish of the sample, as well as the test conditions, such as temperature, humidity, and loading time.

NextGen’s Advanced Portable Shore Durometer System complies with JIS K 6253 standard.

Click here to request a personalized quote from our team!

Temperature can affect the hardness of rubber, plastic and other materials, so it is important to know and control the temperature when performing a Shore Hardness Test. The hardness of rubber can change with temperature due to changes in its molecular structure, causing it to expand or contract. Suppose the temperature of the rubber is not controlled during the hardness test. In that case, it can affect the accuracy of the test results and make it difficult to compare the hardness of different samples or assess changes in hardness over time.

To ensure accurate and consistent results, the temperature of the rubber sample being tested and the testing environment should be maintained within a specified range, usually defined by the relevant industry standard or specification. This can be achieved by using temperature-controlled testing equipment or by ensuring that the sample and testing environment are stable before the test is performed. Knowing and controlling the temperature during a Shore Hardness Test helps to ensure that the results are accurate and meaningful and can provide valuable information about the performance and durability of rubber products.

Click here to request a personalized quote for NextGen’s Advanced Portable Shore Durometer System from our team!

The Shore test is a method for measuring the hardness of rubber, plastic and other flexible materials. Usually, a durometer is used: a device that applies a standardized force to the surface of the material and measures the depth of the indentation. The hardness is then reported on a scale ranging from 0 to 100, with higher numbers indicating a harder material.

There are two main types of Shore hardness tests: Shore A and Shore D. The Shore A test measures the hardness of soft to medium-hard rubbers and other flexible materials. In contrast, the Shore D test measures the hardness of harder rubbers and other materials.

The Shore test is important because hardness is a key property of rubber, plastic and other flexible materials and is directly related to their performance and durability. Hardness affects the material's resistance to wear, abrasion, and other forms of degradation, as well as its ability to maintain its shape and mechanical properties under various loads and conditions. Shore hardness test allows manufacturers and engineers to determine the hardness of plastic products and ensure that they meet the required performance and durability standards.

NextGen’s Advanced Portable Shore Durometer System can perform the following Shore test methods:

Shore A / A0 / B / 0 / C / D / D0 / 00 / 000 / 000S / E / L/c

Click here to request a personalized quote from our team!

When it comes to plastic hardness testing, the most commonly used test is the Shore D test. The Shore D test uses a type D durometer, such as NextGen's Advanced Portable Shore Durometer System - designed to measure the hardness of many plastics.

The Shore D test method applies a standardized force to the surface of the plastic. It measures the depth of the indentation, which is then reported on a scale ranging from 0 to 100, with higher numbers indicating a harder material. The Shore D test is widely used in various industries, including automotive, aerospace, and construction, to evaluate the performance and durability of plastic products.

Not all plastics can be tested with the Shore D test, as some plastics may be too soft or too flexible to be accurately measured with this method. In these cases, alternative methods, such as the Rockwell hardness test or the Barcol hardness test, may be used to determine the hardness of the plastic. The choice of test method depends on the type of plastic, its thickness, and other factors and should be determined based on the relevant industry standards and specifications.

Click here to request a personalized quote for NextGen’s Advanced Portable Shore Durometer System from our team!

ISO 48-2 is an international standard that defines the method for determining the hardness of rubber and plastic materials using a durometer. It specifies the requirements for the apparatus, the test conditions, the procedure for measuring the hardness of the material, as well as the expression of results.

This version is part of the ISO 48 series of standards for determining the hardness of rubber and plastic materials, which provides guidelines for various hardness testing methods, including the Shore A and Shore D test methods. The ISO 48-2 standard covers the Shore A test method, which measures the hardness of soft to medium-hard rubbers and other flexible materials.

The ISO 48-2 standard is widely used in various industries, including automotive, aerospace, and construction, to evaluate the performance and durability of rubber and plastic products. By following the requirements specified in this standard, manufacturers and engineers can ensure that the hardness measurements of their products are accurate, reliable, and consistent.

NextGen’s Advanced Portable Shore Durometer System complies with DIN ISO 48-2 standard.

Click here to request a personalized quote from our team!

What is the spring force of NextGen’s Advanced Portable Shore Durometer System during Test Method D?

The spring force in the Shore Test Method D refers to the force applied to the material being tested during the hardness measurement. The Shore D test method is used to measure the hardness of hard plastics and rubber-like materials, and it involves applying a standardized force to the surface of the material and measuring the indentation depth.

The spring force in the Shore D test method is generated by a type D durometer, which consists of a spring-loaded plunger that is pressed against the material being tested. The force applied by the plunger is proportional to the compression of the spring and is standardized to ensure consistent and accurate measurements.

The exact value of the spring force used in the Shore D test method is defined by the relevant industry standards and specifications. It can vary depending on the type of material being tested and the desired level of precision. The spring force is typically expressed in newtons (N) units or pounds-force (lbf).

It is important to ensure that the spring force in the Shore D test method is consistent and within the specified tolerance range, as variations in the spring force can impact the accuracy of the hardness measurement. The consistency of the spring force can be verified through regular calibration and maintenance of the durometer.

The spring force of NextGen’s Advanced Portable Shore Durometer System during Test Method D is 44450 mN.

Click here to request a personalized quote from our team!

What is the spring force of NextGen’s Advanced Portable Shore Durometer System during Test Method A?

The spring force in the Shore Test Method A refers to the force that is applied to the material being tested during the hardness measurement. The Shore A test method is used to measure the hardness of soft to medium-hard rubbers and other flexible materials, and it involves applying a standardized force to the surface of the material and measuring the depth of the indentation.

The spring force in the Shore A test method is generated by a type A durometer, such as NextGen’s Advance Shore Hardness Testing System, which consists of a spring-loaded plunger that is pressed against the material being tested. The force applied by the plunger is proportional to the compression of the spring and is standardized to ensure consistent and accurate measurements. The spring force is typically expressed in units of newtons (N) or pounds-force (lbf).

The spring force of NextGen’s Advanced Portable Shore Durometer System during Test Method A is 8050 mN.

Click here to request a personalized quote from our team!

Indentation in Shore Hardness Testing refers to the deformation or mark made in the material being tested by the durometer plunger when a standardized force is applied. The indentation depth is then used to determine the hardness of the material.

In Shore hardness testing, the material being tested is placed on a flat and stable surface, and a durometer plunger is pressed against the material with a standardized force. The plunger makes an indentation in the material, and the depth of the indentation is measured. The hardness of the material is then calculated based on the depth of the indentation, the spring force of the durometer, and the type of Shore hardness test method being used (e.g., Shore A, Shore D).

NextGen’s Advanced Portable Shore Durometer System indentation depth during test method A is 2.5mm.

Click here to request a personalized quote from our team!

The indentation depth is an essential factor in determining the hardness of the material. It reflects the material's resistance to deformation under a given force. A material with a high hardness value will have a smaller indentation depth than a material with a lower hardness value, which will have a larger indentation depth.

The indentation depth also depends on various other factors. Such factors are the surface finish, the material's temperature, and the degree of homogeneity of the material. Consistent and accurate hardness measurements can be ensured by following the industry standards and specifications for the Shore hardness testing method.

The Indentation depth of NextGen’s Advanced Portable Shore Durometer System during Shore Test Method D is 2.5mm.

Click here to request a personalized quote from our team!

Reference plates in Shore Hardness Testing are calibrated plates used as a reference standard to verify the accuracy and consistency of the hardness measurement equipment (durometer). The reference plates have a known hardness value. They are used to check the durometer's performance and ensure that the hardness measurement results are accurate and within the specified tolerance range.

The reference plates are usually made of materials with a hardness value similar to the tested materials. They are designed to use specific Shore hardness testing methods (e.g., Shore A, Shore D). The reference plates are usually supplied by the manufacturer of the durometer or by a third-party calibration laboratory, and they are typically made to high standards of accuracy and consistency.

Quality control process in hardness testing should be done using reference plates. It helps to ensure that the hardness measurements are accurate, reliable, and consistent over time. Regular use of reference plates is recommended to maintain the accuracy and performance of the hardness testing equipment.

NextGen’s Advanced Portable Shore Durometer System can be supplied with reference plates.

Click here to request a personalized quote from our team!

DAkkS/DKD calibration certificate is a calibration certificate issued by the German Accreditation Body (Deutsche Akkreditierungsstelle, DAkkS) or the German Calibration Service (Deutsches Kalibrierdienst, DKD). The DAkkS/DKD is a recognized accreditation body in Germany and is responsible for the accreditation of calibration laboratories, testing laboratories, and inspection bodies.

The DAkkS/DKD calibration certificate formally recognizes the measurement equipment's accuracy and traceability. It ensures that the testing equipment has been calibrated and verified to meet specified standards and requirements. The certificate provides a record of the measurement results and the measurement uncertainty, and the conditions and methods used during the calibration process.

The DAkkS/DKD calibration certificate is a valuable tool for ensuring that the measurement equipment is functioning correctly, is accurate and reliable, and is suitable for specific applications. It is recommended to calibrate the measurement equipment regularly and to keep the DAkkS/DKD calibration certificate up-to-date to ensure the quality and accuracy of the measurement results.

Click here to request a personalized quote from our team!

The most recent version of the HPE testing systems for the next generation is called HPE III. In addition to the regular HPEII model, the system has cutting-edge functionality. While a temperature sensor installed on the device's bottom measures temperature, the system can measure hardness. The end user is provided with the ideal blend of a sturdy structure and lightweight thanks to the aluminum casing alloy. The temperature, humidity, and hardness data will all be displayed on the screen. The system's user interface is simple to use. The one-handed operation of this sophisticated shore durometer is intended. To approach the specimen perpendicularly, minimize the wrong measuring angle, and ensure the proper force is delivered, the user will benefit from a large hand grip.

NextGen’s Advanced Portable Shore Durometer System is DAkkS/DKD certified and comes with a calibration certificate when purchasing.

Click here to request a personalized quote from our team!

HPE III is R&D's latest development of the next generation HPE testing systems. The system offers cutting edge features above and beyond the standard HPEII model. The system is capable of taking a hardness value while a temperature sensor mounted on the bottom of the device is taking a temperature value.

Here are the features of NextGen’s Advanced Portable Shore Durometer System:

|

HPE ||| |

Available Methods |

|

Temperature/humidity |

DIN ISO 48-2/DIN ISO 7619 |

|

Sample Temperature |

Shore A |

|

Date and Time |

Shore A0 |

|

Lithium Battery |

Shore D |

|

Display with backlight |

ASTM D 2240 |

|

Auto-Power-Off |

Shore 0 / Shore 00 |

|

Contact pressure acc. standards |

Shore 000 / Shore 000S |

|

Peak Value |

Shore E / Shore B |

|

USB Interface |

Shore C / Shore D0 |

Click here to request a personalized quote from our team!

BSA Test Stand:

This Automatic test stand is perfectly compatible with our HP and HPEIII units allowing for hardness measurements under ASTM D2240 Shore standards.

It is intended to reduce human error and produce consistent measurement results from operator to operator. The hardness tester may be clamped quickly and easily using the pick-up device on the test stand. There is also the option of a manual test stand.

Calibration device for HP and HPE II:

To comply with ISO 9000, the operator should regularly calibrate the equipment to ensure the accuracy of the Shore hardness tester. The calibration device allows for a quick check of the spring force, which can be adjusted in increments of ten for the different measuring ranges, including Shore A/B/0/C/D/DO and L, L/c.

DIN 53 505, EN ISO 868, NF EN ISO 868, ASTM D2240, JIS K 6253.

Shore Reference Test Blocks:

To maintain the accuracy of the measuring device according to the Shore standard, standard rubber blocks are utilized during frequent recalibrations. These blocks are securely held in a stainless steel holder.

The calibration sets are available with various plates, including single, 3, 5, or 6 plates, and can be accompanied by a DAkkS/DKD calibration certificate.

Shore Control Ring:

Control of the measuring distance with DAkkS/DKD / WKS Certificate

- 20 Shore

- 40 Shore

- 60 Shore

- 80 Shore

Hardtest – Software

Hardtest is one of the most prominent accessories applicable to both the DigiTest and the HPE line of equipment. It comes standard with a serial interface. The software designed to eliminate all human and other error factors.

Click here to request a personalized quote from our team!

A portable plastic hardness durometer is a handheld device used to measure the hardness of plastic materials. It is designed for use in the field and provides a convenient means of measuring the hardness of plastic samples without the need for laboratory testing. Durometers work by using a penetrator, typically a metal or diamond stylus, to indent the surface of a sample. The hardness of the material is determined based on the depth of the indentation and the force required to produce it.

NextGen’s Advanced Portable Shore Durometer System has the following size and weight:

Height: 150mm;

Width: 68mm;

Depth: 43mm;

Weight: 320g.

Click here to request a personalized quote from our team!

Calibration

Our partners are officially qualified to provide repair and recalibration services on all varieties of hardness testers in compliance with predetermined requirements and to issue the DAkkS/DKD certificate as a national recognized DAkkS/DKD laboratory.

Loaner Program for Testing heads

Get a tester head on loan to prevent service interruptions. Call us right away to learn how.

Sample service preparation

Sending samples to our facility is welcome if you want to ensure our tools' accuracy meets your standards. To find out more, call us right away.

Training

We support our offering. Contact us if you need more training support, and we'll recommend the best remote connection strategy for you.

Click here to request a personalized quote from our team!

A Shore control ring is a reference tool used in Shore hardness testing to help ensure that the hardness tester performs accurately. The control ring is made of a material with a known hardness, and it is used to check the performance of the hardness tester periodically. The ring is placed on the tester, and the hardness measurement is taken. Having the measurements within the specified tolerance means the tester is working correctly. If the measurement is outside the tolerance, it may indicate that the tester needs to be calibrated or repaired. Using a control ring, the accuracy of the hardness tester can be monitored and maintained, ensuring that the hardness measurements are accurate and reliable.

A Shore Control Ring is available for NextGen’s Advanced Portable Shore Durometer System as part of product accessories.

Click here to request a personalized quote from our team!

Related Products

Melt Flow Indexer

Our melt flow indexer is a highly precise instrument designed for the measurement of melt flow rate (MFR)/(MI) or melt volume rate (MVR) in quality control and research applications.

NG-ImpactFall – Falling Weight Impact Tester

Our falling weight impact tester finds extensive application in conducting external impact strength tests on plastic and non-metal materials.

High Energy Elemendorf

Measure the tearing strength of plastic materials with the NG-HE Elemendorf, a versatile tester with advanced potential energy calculation.

NextGen Environmental Chambers NG-EC 100,150,225,408,1000

The temperature and humidity NextGen Environmental Chambers features a sturdy cabinet made of cold-rolled steel and stainless steel.

HDA 120 - Hardness and Density Automation Test System

The HDA 120 test system is a versatile solution for semi-automatic detection of sample hardness and density.

Automatic Shore, IRHD and VLRH Hardness Testing System

NextGen is proud to present our German line of fully-automatic Shore, IRHD and VLRH hardness testing system for plastic materials, plastic and foam compounds for the ultimate precision, accuracy and repeatability, exceptional ease-of-use and maintenance. Experience the industry leader for specimen testing including rubbers, plastics, foams, composites, o-rings, and more.

Classic Analogue Shore Durometer with Test Stand Options

This German-manufactured system has been the global benchmark of Shore hardness testing systems since 1954. With ever enhanced ergonomic design, the HP Shore Hardness Tester is both visually appealing and precise rubber and plastic testing system as it has been for nearly 50 years.

Automatic Capsule and Soft Gel Hardness Tester

Gelomat is an automatic capsule hardness tester designed for regular and soft gel capsule testing. This state of the art system is developed by the latest R&D technology to meet and exceed the highest quality standards for gelatin capsule testing. The system comes standard with your desired testing head and can be upgraded to optional accessories for maximum efficiency.

Fruit Firmness Tester

This German manufactured fruit firmness and fruit hardness testing device is designed specification for the determination of the pulp hardness of a given fruit. This state-of-the-art device is invaluable for trading companies serious about their quality control procedures. The unit helps identify the harvest date of the specific fruits relative to the time of transpirations and storage.

Ball Rebound Tester

Ball Rebound Tester is designed for measuring the rebound resilience of polymer foams.

Pendulum Rebound Resilience Tester

Manual and Fully-Automatic Pendulum Rebound Resilience Tester. These rebound testers will determine the dynamic behavior of various materials and supply the differentiation of these materials' qualities. It will also identify material changes after aging and fatigue. The Pendulum Rebound Tester is out there with an adjustable heater for sample temperatures up to 100 ℃. It can simulate the effect of heat on the elasticity of samples with different formulations.

Pusey & Jones Tester

Pusey & Jones is a rubber and rubber like material testing system. The unit is designed for testing rubber rollers in the paper industry. The system can test specimens with flat surfaces and thickness of 13 mm.