Plastic Testing Equipment

Standards

ISO 1133, ASTM D1238, ASTM D3364, BS 2782, DIN 53735, JIS K7210

Description

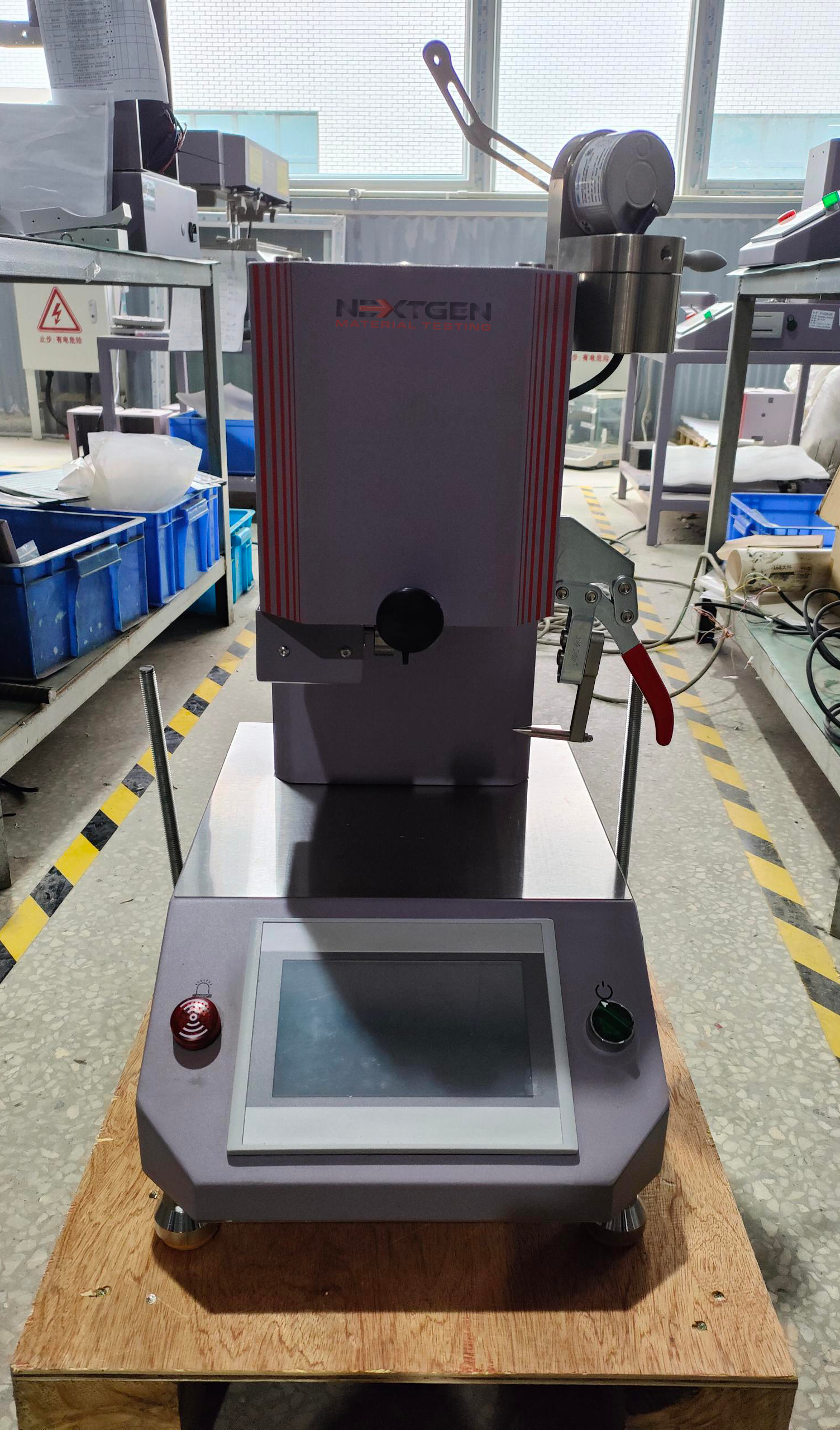

Our melt flow indexer is a highly precise instrument designed for the measurement of melt flow rate (MFR)/(MI) or melt volume rate (MVR) in quality control and research applications. The testing results obtained from the model MFR450 can effectively distinguish the viscous flow performance of thermoplastic materials. This model exhibits advantages suitable for various industries, including factories, product quality testing stations, scientific and research institutes, as well as related sectors.

The MFR450 features a broad measuring range, convenient cleaning, a compact size, and comes with a range of accessories to meet diverse testing conditions. The equipment's measuring range spans from 0.1g/10min to 2000g/10min, providing versatility for different testing requirements. The mouth part incorporates a funnel-shaped design, facilitating a straightforward feeding process. Additionally, the detachable die support plate mitigates the risk of sample accumulation, effectively preventing jams during operation. Learn more in our newest mega blog!

Melt Flow Indexer Features

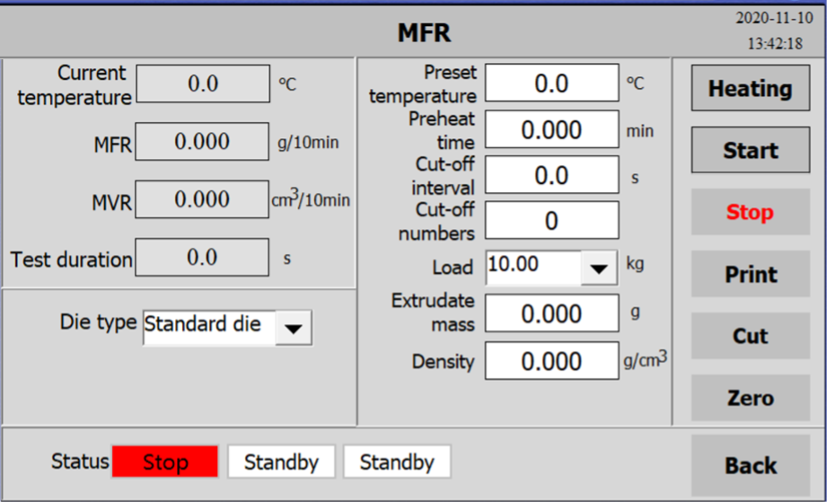

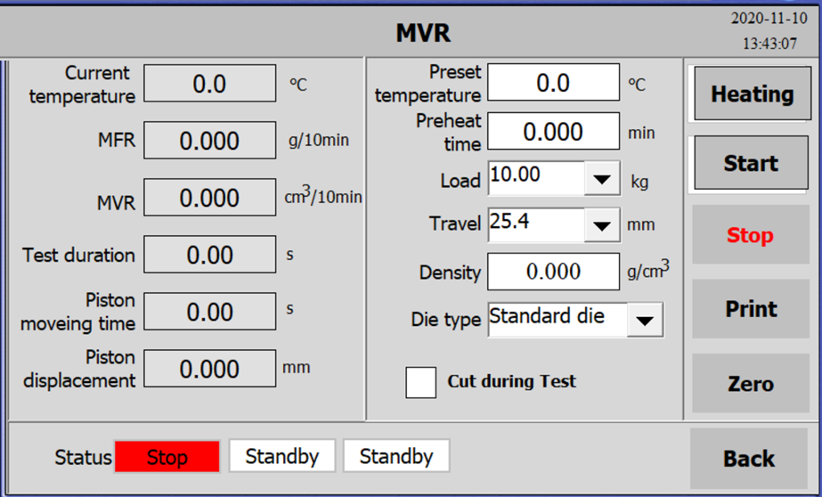

- User-Friendly Interface: The operation interface is designed for user convenience, allowing easy switching between Chinese and English displays to reduce testing complexity.

- Method Flexibility: The equipment offers free switching between the mass method and volume method. The intuitive test interface significantly minimizes operational challenges.

- High-Quality Construction: Key components such as the cylinder and piston are constructed from high-temperature-resistant, low-expansion-coefficient alloy materials. These parts undergo special surface heat treatment, ensuring resistance to high-temperature deformation, high hardness, and prolonged durability.

- Precision Temperature Control: The oven temperature control system employs an Omron temperature control meter, providing accurate temperature control. This system ensures maximum temperature accuracy while maintaining temperature fluctuations within a minimal range.

- Optical Displacement Measuring Device: An optical high-precision displacement measuring device is incorporated to ensure precise and reliable data.

- Automatic Cutting Device: The equipment features an automatic cutting device driven by a miniature motor. Users can set the cutting time, allowing the rotating electric machine to cut at specified intervals. This feature provides accurate time control and minimal errors. Additionally, the cutting device can be manually operated for simplicity and convenience.

- Microcomputer Controller: Equipped with a microcomputer controller, the system can manage the entire testing process, including data processing and printing. The microprinter allows for the easy output of test results.

- Preheating Alarm: After reaching the pre-set preheating time, the device automatically alarms, prompting the user to place weights.

- Special Weight Box: The equipment includes a dedicated weight box with individual grooves to prevent accessory loss, ensuring efficient and organized testing procedures.

Melt Flow Indexer Structure

-

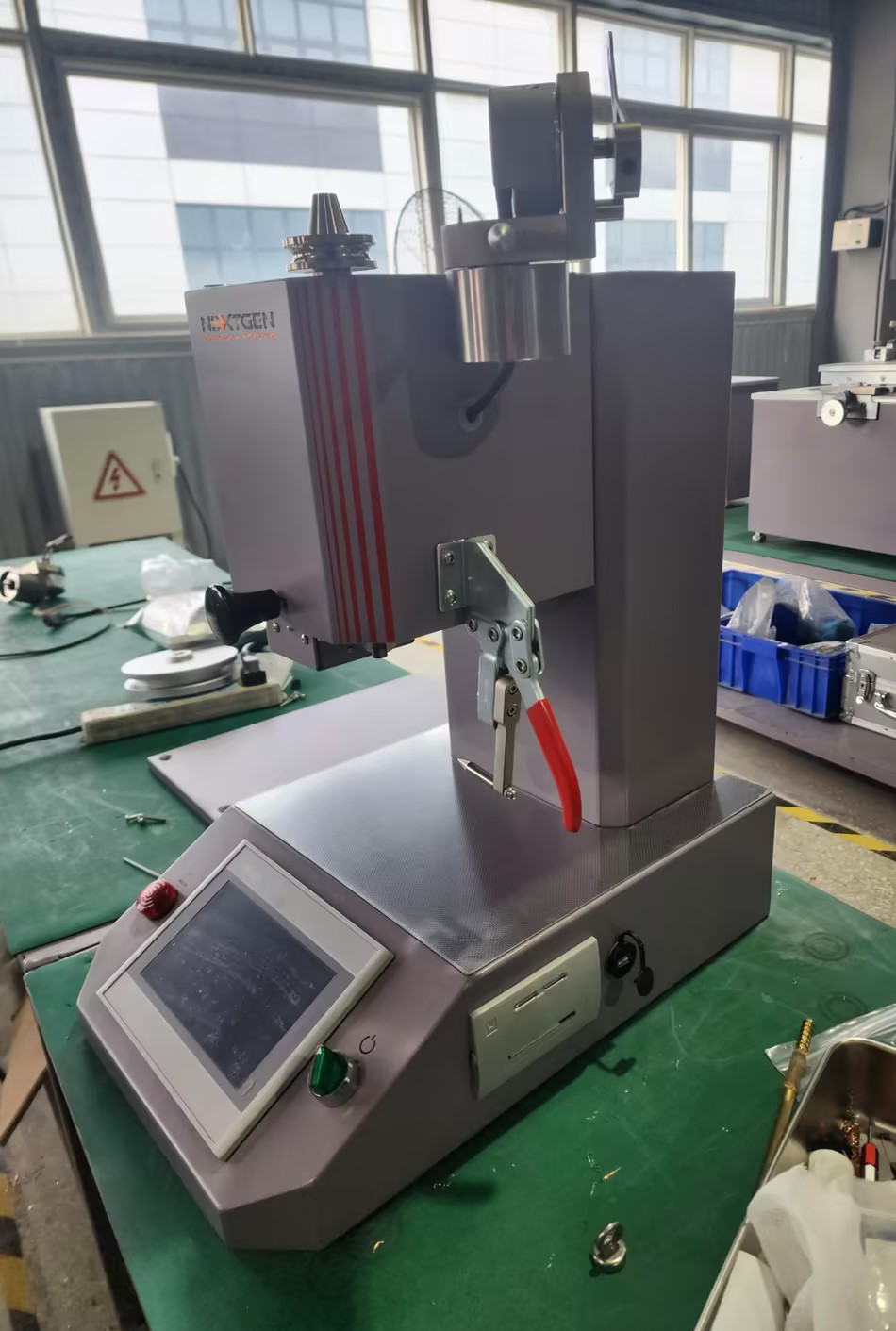

Robust Construction: The equipment’s main body is constructed from high-quality alloy with a thickness of 1.5mm, providing durability. It features a 7-inch color display with a user-friendly interface that allows seamless switching between Chinese and English. The interface displays real-time test parameters for enhanced user interaction.

-

Temperature Uniformity: The oven, cast as a single body from red copper, ensures good temperature uniformity and stability within the test area.

-

Precision Measurement: The measurement component’s core element is an imported Baumer encoder, renowned for its high measurement accuracy and consistent data reliability.

-

Specialized Die Plug: The equipment is equipped with a die plug, specifically designed for materials with high melt flow rates.

-

Micro Printer: Featuring a built-in micro printer, the equipment allows direct printing of test parameters or results immediately after the test is completed.

-

Cutting Motor Reliability: The cutting motor exhibits high repeatability, and a self-locking function is integrated into the program to prevent external interference from affecting test results.

-

Stable Base Structure: The wide base structure ensures stability during operation, contributing to the overall reliability and accuracy of the equipment.

Piston

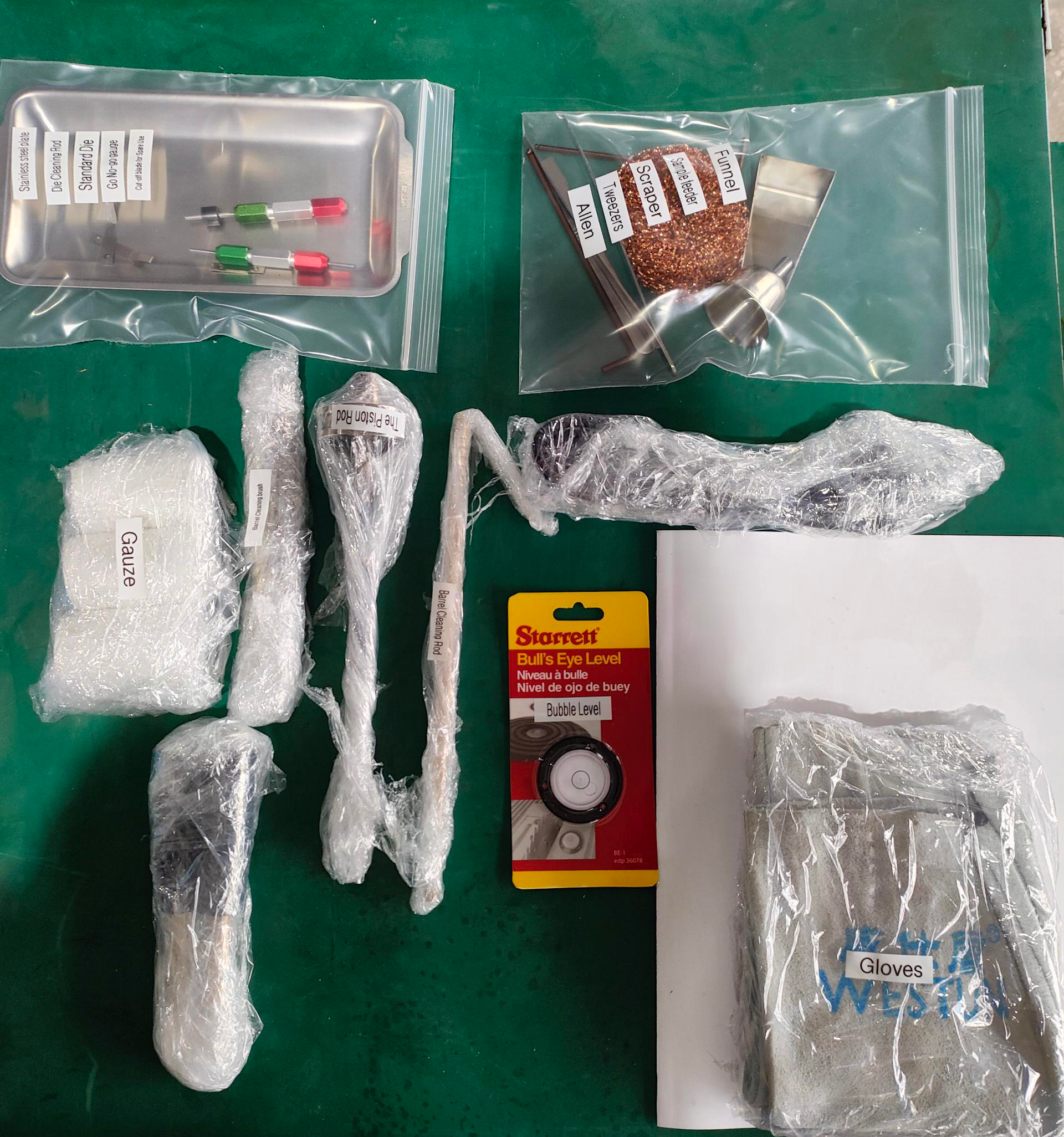

The piston rod, weighing 325g, is nitrided to achieve exceptionally high hardness. Additionally, it exhibits self-guided performance, enhancing the precision of test results and ensuring the safety of the testing process.

The piston rod, weighing 325g, is nitrided to achieve exceptionally high hardness. Additionally, it exhibits self-guided performance, enhancing the precision of test results and ensuring the safety of the testing process.

Melt Flow Indexer Test Load

Loading is accomplished by combining the piston with weights. The load is the result of the assembly of the piston and dead weights, ensuring a comprehensive and accurate testing procedure.

|

Load (g) |

Combination of dead weight (g) |

||||

|

325 |

Piston |

||||

|

1200 |

325+875 |

||||

|

2160 |

325+875+960 |

||||

|

3800 |

325+875+960+1640 |

||||

|

5000 |

325+875+960+1640+1200 |

||||

|

10000 |

325+875+960+1640+1200+5000 |

||||

|

21600 |

325+875+960+1640+1200+1600+2500+2500+5000+5000+5000+1600 |

||||

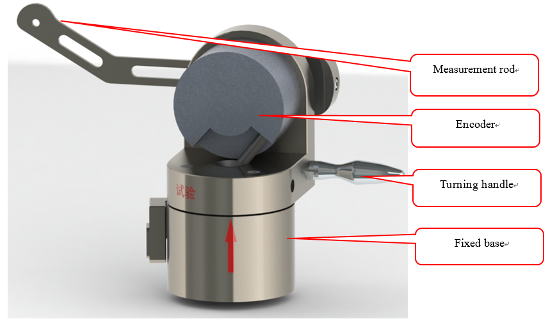

Melt Flow Indexer Optional Encoder

The encoder serves as an optional accessory for MVR tests. Positioned at the top of the measuring rod, it makes direct contact with the piston rod, transmitting real-time displacement data. The primary function of the encoder is to measure the vertical displacement of the piston rod, converting it into signal pulses in real time. Following processing by the Programmable Logic Controller (PLC), the encoder outputs the instantaneous displacement of the piston rod.

For added versatility, the encoder can be switched into different positions according to distinct test methods, ensuring flexibility to meet varying requirements across different testing procedures.

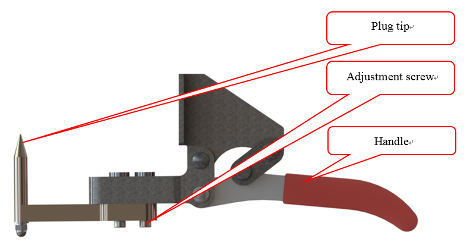

Die Plug

Situated on the side of the oven, the die plug is a component designed to aid in the testing of samples with high melt flow rates. By utilizing the red handle, the die outlet can be efficiently obstructed, preventing rapid sample loss. This feature allows for swift movement of the die plug before the commencement of the test, ensuring precise control over the sample and testing conditions.

Touch Screen

Melt Flow Indexer Technical Specifications

|

Model |

Unit |

MFI452 |

|

Type |

|

B |

|

Temperature range |

℃ |

50~450 |

|

Temperature variation in 4 hours |

℃ |

≤±0.5 |

|

Maximum permitted deviation from the required test temperature: 75mm above the top surface of the standard die |

℃ |

≤0.25 |

|

Temperature Resolution |

℃ |

0.1 |

|

Measurement range |

g/10min |

Method A: 0.1~50 Method B: 0.1~2000 |

|

Displacement error |

mm |

≤±0.02 |

|

Displacement resolution |

mm |

0.003 |

|

Displacement measurement range |

mm |

25.5 |

|

Interval of temperature recovering after changing testing samples |

minute |

≤3 |

|

Resolution of timing |

second |

0.01 |

|

Inner diameter of die |

mm |

Φ2.095±0.005 |

|

Inner diameter of cylinder |

mm |

Φ9.550±0.007 |

|

Weights accuracy |

|

≤±0.5% |

|

Possible Combination of the Standard Weights |

g |

325, 1200, 2160, 3800, 5000 10000, 21600 |

|

Dimension |

in / mm |

13.78x17.13x25.98 / 350x435x660 |

|

Weight |

lbs. / kg |

71 / 35 |

|

Power Supply |

|

220V±10%, AC, 50Hz,1.5kW |

Standard Configurations

- Main machine (with built-in 7” touch screen, micro-printer, cylinder, temperature controller, heater, cutting blade) - 1 set

- Piston Head is Nitriding treatment, Vickers hardness≥600HV - 1 set

- Standard die of Φ2.095±0.005mm Length: 8±0.025mm, Nitriding treatment, Vickers hardness≥700HV - 1 set

- Combined weight -325g, 1200g, 2160g, 3800g, 5000g - 1 set for each

- Compressing rod, barrel cleaning brush, barrel cleaning rod Die cleaning tool, Sample feeder, Funnel, Bubble level Scraper, Tweezers, Cutting blade, Fuse, Go No-go gauge - 1 set for each

Optional Accessories

- Encoder for MVR test

- 10kg load (one more 5000g dead weight weight)

- 21.6kg load (three more 5000g, and one more 1600g dead weight)

- Φ1.05 die

- Φ1.18 die

FAQs

Yes, the Melt Flow Indexer is designed to comply with the ISO 1133 standard, which specifies the method for determining the melt mass-flow rate (MFR) and melt volume-flow rate (MVR) of thermoplastic materials. Compliance with this standard makes certain that the Melt Flow Indexer can accurately measure how easily a material can flow under specific conditions, which is essential for assessing plastic processability and quality.

By adhering to ISO 1133, the Melt Flow Indexer provides manufacturers, researchers, and quality control labs with a reliable tool for evaluating the melting characteristics of different thermoplastic materials. This capability is crucial for ensuring consistent quality in plastic production and for developing materials with desired properties for specific applications. The precision and compliance of the Melt Flow Indexer with international standards like ISO 1133 make it an invaluable asset in the plastics industry, facilitating the advancement of material science and manufacturing practices.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Melt Flow Indexer is designed to comply with the ASTM D3364 standard, which outlines the methods for determining melt flow rates of thermoplastic compounds, including filled and reinforced materials, using an extrusion plastometer. This standard is particularly relevant for materials that have additives or fillers, which can significantly affect their flow characteristics during the melting process.

ASTM D3364 provides a specific protocol for measuring the flow properties of these more complex thermoplastic materials, ensuring that the data obtained is accurate and reflective of the material's behavior in real-world processing scenarios. Compliance with this standard allows the Melt Flow Indexer to offer valuable insights into the processability of a wide range of thermoplastics. This includes those used in high-performance and specialized applications.

By meeting ASTM D3364 requirements, the Melt Flow Indexer demonstrates its versatility and precision in handling diverse materials, making it an essential tool for quality control, research and development, and material formulation in the plastics industry. This capability supports the optimization of material properties and processing conditions, leading to high-quality plastic products that meet specific application needs.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Melt Flow Indexer is designed to adhere to the BS 2782 standard, which specifies methods for testing and assessing thermoplastic materials properties. This British Standard encompasses a range of tests, including those for determining the melt flow rate (MFR) of thermoplastics, similar to ISO 1133 and ASTM D1238. Compliance with BS 2782 ensures that the Melt Flow Indexer can accurately evaluate the flow characteristics of thermoplastic materials under specified conditions, providing vital information for material selection, quality control, and research purposes.

The alignment with BS 2782 highlights the Melt Flow Indexer's versatility and capability to meet the rigorous requirements of the plastics industry, both in the UK and internationally. By conducting tests by this standard, users can ensure that their thermoplastic materials conform to recognized quality and performance benchmarks.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Melt Flow Indexer can perform tests in compliance with the DIN 53735 standard. This standard is specific to the plastics industry, detailing the method for determining the melt mass-flow rate (MFR) and melt volume-flow rate (MVR) of thermoplastic materials. DIN 53735 is critical for ensuring that materials meet precise requirements for high-quality plastic production and application.

The standard's focus on providing a uniform method for melt flow testing ensures that materials can be evaluated for their processing and flow characteristics under controlled conditions. By adhering to DIN 53735, the Melt Flow Indexer offers manufacturers and researchers a reliable tool for assessing the viscosity and fluidity of thermoplastics, which are pivotal factors in injection molding, extrusion, and other plastic manufacturing processes.

Compliance with DIN 53735 not only underscores the accuracy and reliability of the Melt Flow Indexer but also enhances its utility across the global plastics industry. It allows for consistent comparison of materials and ensures that plastic products are manufactured to meet stringent quality standards.

Click here to learn more about the product or here to receive a personalized quote.

The Melt Flow Indexer is designed to align with the JIS K7210 standard, which is a crucial benchmark in the plastics industry for assessing the melt flow rate (MFR) of thermoplastic materials. This Japanese Industrial Standard specifies methods for determining the ease with which molten thermoplastic polymers can flow, providing a measure of the material's processing behavior.

Compliance with JIS K7210 ensures that the Melt Flow Indexer can accurately evaluate the viscosity and fluidity of plastics under controlled conditions, which are indicative of the material's quality and suitability for various manufacturing processes. The standard is particularly critical for ensuring consistency and reliability in plastic product production, facilitating international trade and communication within the industry.

The Melt Flow Indexer's adherence to JIS K7210 highlights its capability to support manufacturers, researchers, and quality control laboratories in developing and verifying thermoplastic materials' performance. By providing precise and standardized measurements of melt flow rate, the Melt Flow Indexer plays a pivotal role in advancing material science, optimizing manufacturing processes, and enhancing product quality.

Click here to learn more about the product or here to receive a personalized quote.

The Melt Flow Indexer is a highly precise instrument specifically designed for measuring the melt flow rate (MFR) or melt index (MI) and melt volume rate (MVR) of thermoplastic materials. Its primary purpose in both quality control and research applications is to assess plastic viscosity, flowability, and processing behavior under specific conditions. These measurements are crucial for ensuring plastic materials' consistency and quality before shaping them into final products.

In quality control contexts, the Melt Flow Indexer plays a pivotal role in verifying that incoming raw materials and finished products meet the required standards and specifications. This ensures that production materials are of consistent quality, leading to reliable and high-quality end products.

In research and development settings, the Melt Flow Indexer facilitates the exploration of novel plastic formulations and modifications to existing materials. By accurately measuring how materials flow under heat and pressure, researchers can better understand material behavior. They can also develop plastics that are easier to process, more durable, or have other desired properties.

Click here to learn more about the product or here to receive a personalized quote.

The MFR450 Melt Flow Indexer model is exceptionally effective at distinguishing thermoplastic materials' viscous flow performance. This precision instrument is designed to measure the melt flow rate (MFR) and melt volume rate (MVR), which are critical indicators of the material's viscosity and flow characteristics under heat and pressure. By providing accurate and reliable testing results, the MFR450 allows users to assess and compare the flow performance of different thermoplastic materials with a high degree of precision.

This capability is particularly valuable in quality control processes, where ensuring material consistency is essential, and in research and development, where understanding the flow properties of materials can lead to innovations in plastic formulations. The MFR450's ability to effectively characterize thermoplastic viscous flow performance supports the optimization of processing conditions and the development of materials with targeted properties, enhancing product quality and manufacturing efficiency in the plastics industry.

Click here to learn more about the product or here to receive a personalized quote.

The MFR450 model of the Melt Flow Indexer offers a range of advantages that make it particularly suitable for use in a variety of industries, including manufacturing plants, product quality testing stations, scientific research institutes, and other related sectors. Its ability to effectively distinguish the viscous flow performance of thermoplastic materials allows for precise quality control and material characterization, which is necessary for ensuring plastic products' reliability and performance.

For factories, the MFR450 enhances production efficiency and material consistency by providing accurate measurements of melt flow rates, aiding in the selection of suitable materials and optimization of processing conditions. Product quality testing stations benefit from the instrument's precision and reliability, enabling them to uphold high standards of quality and compliance with international norms.

In scientific and research environments, the MFR450's detailed analysis capabilities support the development of innovative materials and improvement of existing formulations. Its accurate testing results contribute to a deeper understanding of material properties and behavior, facilitating breakthroughs in polymer science and engineering.

Click here to learn more about the product or here to receive a personalized quote.

The funnel-shaped design of the mouth part of the Melt Flow Indexer significantly enhances the equipment's operation by facilitating a straightforward and efficient feeding process. This design feature is particularly advantageous in making sure that thermoplastic materials are easily and accurately introduced into the instrument for testing. The funnel shape naturally guides the material into the barrel, reducing the potential for spillage or misalignment that could affect the precision of the test results.

This design improvement streamlines the preparation phase of melt flow rate testing, making it quicker and more user-friendly. It is especially beneficial in a high-volume testing environment or when handling materials with challenging physical properties. Feeding ease directly impacts the overall efficiency and reliability of the testing process, allowing for smoother operation and consistent test outcomes.

Moreover, the funnel-shaped mouth part minimizes operator error risk and enhances safety by reducing the need for direct contact with the heated parts of the instrument.

Click here to learn more about the product or here to receive a personalized quote.

The detachable die support plate in the Melt Flow Indexer is vital to increasing efficiency and reliability. By mitigating the risk of sample accumulation, this innovative feature effectively prevents jams during operation, providing a smooth and continuous testing process. The ability to detach the support plate for cleaning and maintenance means that any residual or excess material can be quickly removed, reducing downtime and maintaining the precision of subsequent tests.

This design consideration is particularly important when working with a wide range of thermoplastic materials, each with its own flow characteristics and potential for clogging. The detachable nature of the die support plate allows for easy adaptation to different testing requirements. It simplifies the switch between materials, further enhancing the versatility of the Melt Flow Indexer.

The inclusion of a detachable die support plate underscores the commitment to user-friendly operation and maintenance, minimizing potential operational issues and supporting consistent, accurate measurements of melt flow rates.

Click here to learn more about the product or here to receive a personalized quote.

The Melt Flow Indexer's user-friendly interface significantly enhances its usability by simplifying the testing process. Designed with user convenience in mind, it features the capability to easily switch between Chinese and English displays. This caters to a larger number of operators by reducing language barriers. This bilingual interface ensures that users can navigate the system more intuitively, making it easier to set up tests, input parameters, and interpret results without language-induced complications.

The straightforward design of the interface streamlines operation, from initial setup to final analysis, facilitating a smoother workflow that can contribute to increased testing efficiency. It allows for quick adjustments and modifications to test settings, helping users optimize their testing procedures with minimal effort.

By prioritizing ease of use, the Melt Flow Indexer becomes more accessible to personnel of varying skill levels and backgrounds, promoting accurate and reliable testing across different environments.

Click here to learn more about the product or here to receive a personalized quote.

The method flexibility feature of the Melt Flow Indexer significantly increases its testing capabilities by offering users the ability to freely switch between the mass method (measuring melt flow rate, MFR) and the volume method (measuring melt volume rate, MVR). This flexibility allows for comprehensive analysis and characterization of thermoplastic materials under different testing conditions. This caters to the specific requirements of different standards and applications.

The intuitive test interface that facilitates this switching process minimizes operational challenges, making it easier for users to select the most appropriate testing method for their needs. This adaptability is particularly beneficial in a research and quality control context, where different materials may require different assessment approaches to accurately determine their properties.

By incorporating method flexibility into the equipment, the Melt Flow Indexer becomes a more versatile tool. It is capable of accommodating a wider range of testing scenarios and providing more detailed insights into material behavior.

Click here to learn more about the product or here to receive a personalized quote.

The high-quality construction of the Melt Flow Indexer's key components, including the cylinder and piston made from high-temperature-resistant, low-expansion-coefficient alloy materials, significantly improves its performance and durability. These critical parts are subjected to special surface heat treatment, which guarantees they maintain resistance to high-temperature deformation, possess high hardness, and offer prolonged durability.

This robust construction is vital for the accurate and reliable measurement of melt flow rates over extended periods, even under the demanding conditions typical of the high-temperature operations involved in testing thermoplastic materials. Resistance to high-temperature deformation ensures that measurements are precise and consistent, critical factors for quality control and research applications where even slight variations can lead to significant differences in material characterization.

Furthermore, the enhanced hardness and durability of these components reduce the need for frequent replacements and maintenance, contributing to lower operational costs and increased testing efficiency. The use of high-quality materials and specialized treatments ensures that the Melt Flow Indexer can withstand continuous use, making it an invaluable tool for industries reliant on thorough and dependable materials testing.

Click here to learn more about the product or here to receive a personalized quote.

The precision temperature control system in the Melt Flow Indexer, featuring an Omron temperature control meter, plays a crucial role in maintaining melt flow rate accuracy. This advanced control system maintains the oven temperature with maximum accuracy, keeping temperature fluctuations within minimal limits. Such precise temperature regulation is essential for consistent and reliable thermoplastic materials testing, as melt flow properties are highly sensitive to temperature variations.

Accurate temperature control guarantees that each test is conducted under optimal conditions, mirroring the standards required for quality assessment and research into thermoplastic materials. This fidelity to testing conditions allows the Melt Flow Indexer to produce accurate and repeatable results, facilitating comparative analyses and quality control processes.

Moreover, the minimal range of temperature fluctuations enhances the Melt Flow Indexer's ability to simulate real-world processing conditions, providing valuable insights into how materials will behave during manufacturing and end-use.

Click here to learn more about the product or here to receive a personalized quote.

The incorporation of an optical high-precision displacement measuring device into the Melt Flow Indexer guarantees its accuracy and reliability. This advanced device precisely measures the displacement of the thermoplastic material as it flows through the indexer, providing exact measurements that are crucial for calculating the melt flow rate (MFR) and melt volume rate (MVR) of the material under test.

The use of optical technology for displacement measurement offers several advantages over traditional mechanical methods. It provides high sensitivity and accuracy, capable of detecting minute changes in the material's position. This precision is essential for evaluating thermoplastic flow characteristics, where even slight variations can significantly impact processability and performance.

Furthermore, the optical displacement measuring device ensures consistent and repeatable measurements, vital for quality control and research applications. By delivering precise and reliable data, the device enhances the Melt Flow Indexer's capability to assess material properties accurately, supporting the development of high-quality thermoplastic products.

Click here to learn more about the product or here to receive a personalized quote.

The automatic cutting device, driven by a miniature motor in the Melt Flow Indexer, significantly enhances the equipment's functionality by providing precise control over the cutting process. Users can set the cutting time according to their specific testing requirements, allowing the rotating electric machine to cut the extruded thermoplastic material at predetermined intervals. This feature ensures accurate time control and minimizes errors in the measurement of melt flow rate (MFR) or melt volume rate (MVR), which are critical for assessing thermoplastic materials' viscosity and processability.

The precision afforded by the automatic cutting device contributes to test results' repeatability and reliability, which is essential for quality control, research, and development purposes. By automating the cutting process, the Melt Flow Indexer reduces the potential for human error and enhances the efficiency of the testing procedure.

Furthermore, the inclusion of a manual operation mode for the cutting device adds versatility and convenience. This option allows users to perform cuts manually when desired, providing flexibility for various testing scenarios or when specific adjustments are needed.

Click here to learn more about the product or here to receive a personalized quote.

The integration of a microcomputer controller into the Melt Flow Indexer significantly enhances its operation by managing the entire testing process, from initiating tests to processing data and even printing results. This advanced controller automates various functions, making testing more efficient, accurate, and user-friendly.

One of the key advantages of microcomputer controllers is its ability to streamline data processing. It quickly analyzes the collected data, calculating melt flow rates and other relevant parameters with precision. This automation reduces human error in data interpretation, resulting in reliable and consistent results.

Additionally, the inclusion of a micro printer as part of the system offers the convenience of printing the test results directly from the Melt Flow Indexer. This feature facilitates immediate documentation and review of results, enhancing workflow in quality control and research settings. The ability to print results on-site eliminates manual record-keeping and simplifies sharing and discussing findings.

Click here to learn more about the product or here to receive a personalized quote.

The pre-heating alarm feature of the Melt Flow Indexer significantly enhances the testing process's operation and reliability. Once the device reaches the pre-set pre-heating time, it automatically activates an alarm. This alert prompts the user to place weights on the machine, indicating that the indexer is ready to commence the melt flow rate test.

This automatic notification ensures that the material inside the indexer has been adequately preheated to the optimal temperature for testing, which is crucial for accurate and consistent results. The preheating phase is essential to ensure that the thermoplastic material reaches a uniform temperature throughout, minimizing any potential discrepancies caused by temperature variations.

By reminding the user to place the weights at the correct time, the preheating alarm helps maintain the integrity of the testing protocol. This reduces the possibility of operator error. This feature contributes to a more efficient workflow, as it minimizes the chances of starting a test without proper preheating.

Click here to learn more about the product or here to receive a personalized quote.

The inclusion of a special weight box in the Melt Flow Indexer significantly contributes to its efficiency and organization. This thoughtfully designed box features individual grooves for each weight, effectively preventing accessory loss and ensuring that the necessary components are always readily available for testing. By safeguarding against accessory misplacement, the weight box streamlines the preparation process, allowing users to quickly and accurately set up the equipment for each test.

This organizational tool not only enhances workflow by minimizing time spent searching for the correct weights. It also reduces the risk of using incorrect weights, which could compromise test accuracy. The dedicated storage solution ensures that weights are kept in optimal condition, free from damage or contamination.

The special weight box exemplifies the Melt Flow Indexer's commitment to user convenience and operational efficiency. By simplifying the management of testing components, the box supports a smooth, uninterrupted testing process, enabling users to focus on analyzing material properties and ensuring quality control in thermoplastic manufacturing and research applications.

Click here to learn more about the product or here to receive a personalized quote.

The Melt Flow Indexer is distinguished by its robust construction and user-friendly design, incorporating several key features to increase durability, accuracy, and ease of use. The equipment's main body is constructed from high-quality alloy with a 1.5mm thickness, ensuring durability and long-term reliability. This sturdy construction is complemented by a 7-inch color display that provides a user-friendly interface. The interface also displays real-time test parameters, significantly enhancing user interaction and monitoring during testing.

Temperature uniformity within the test area is achieved through the oven, which is cast as a single body from red copper, known for its excellent temperature uniformity and stability. Precision in measurement is guaranteed by the core element of the measurement component, an imported Baumer encoder.

The equipment also includes a specialized die plug designed for materials with high melt flow rates, addressing the specific needs of various thermoplastic materials. Additionally, a built-in micro printer allows direct printing of test parameters or results immediately after completion.

The cutting motor's high repeatability and the integration of a self-locking function into the program prevent external interference from affecting test results. Furthermore, the wide base structure of the Melt Flow Indexer provides stability during operation, contributing to equipment reliability and accuracy.

Click here to learn more about the product or here to receive a personalized quote.

The piston rod in the Melt Flow Indexer, weighing 325g and treated with a nitriding process, is integral to optimizing equipment performance. The nitriding treatment significantly increases the rod's hardness, making it exceptionally durable and resistant to wear and deformation. Durability is crucial for maintaining measurement precision over repeated use and under varying test conditions.

Furthermore, the piston rod is designed to perform in a self-guiding manner. This feature ensures smooth and precise movement within the cylinder, maintaining proper alignment and minimizing friction. The precision movement of the piston rod directly impacts the reliability of melt flow rate measurements, as it provides consistent application of force to the thermoplastic material being tested.

The combination of high hardness and self-guided performance improves test results precision and safety of the testing process. By ensuring smooth operation and reducing the potential for mechanical failure, the piston rod helps protect users and the integrity of the testing environment.

Click here to learn more about the product or here to receive a personalized quote.

The optional encoder significantly improves the functionality of the Melt Flow Indexer for melt volume rate (MVR) tests by providing precise and real-time measurement of the vertical displacement of the piston rod. Positioned at the top of the measuring rod and making direct contact with the piston rod, the encoder meticulously captures every minute movement. It converts these movements into signal pulses. These pulses are then processed by the Programmable Logic Controller (PLC), which outputs the instantaneous displacement data essential for calculating MVR.

The primary advantage of incorporating an encoder into MVR tests is its high measurement accuracy and consistent data reliability. This precision is crucial for ensuring the quality and consistency of thermoplastic materials, as it allows for the detailed analysis of their flow properties under specific conditions.

Moreover, the encoder's design provides the flexibility to switch positions according to different test methods. This adaptability ensures that the Melt Flow Indexer can accommodate a wide range of testing requirements and procedures, making it a versatile tool for laboratories and manufacturers working with various thermoplastic materials.

Click here to learn more about the product or here to receive a personalized quote.

The die plug, strategically situated on the side of the oven in the Melt Flow Indexer, assists in enhancing the testing of samples with high melt flow rates. Designed to obstruct the die outlet efficiently by using a red handle, the die plug prevents the premature loss of the sample. This makes sure that the material does not flow out too quickly before the test officially begins. This capability is crucial for materials that exhibit high flowability under heat and pressure, as it allows for more accurate measurement and control of the material's flow rate.

The feature enables swift movement of the die plug, allowing operators to manage testing conditions and sample handling precisely. By controlling the flow of highly fluid materials, the die plug provides accurate and consistent test results, reflecting the true melt flow characteristics of the sample under standardized conditions. Precision control over sample and testing conditions is essential for quality control, research, and development applications. Understanding the flow behavior of thermoplastic materials is key to assessing their suitability for different manufacturing processes and applications.

Click here to learn more about the product or here to receive a personalized quote.

The standard configurations of the Melt Flow Indexer are designed to maximize its functionality and provide comprehensive testing capabilities. The main machine comes equipped with a built-in 7” touch screen, micro-printer, cylinder, temperature controller, heater, and cutting blade, providing a user-friendly interface and the essential components for conducting melt flow rate tests.

The piston head, undergoing Nitriding treatment with a Vickers hardness of ≥600HV, provides durability and precision in applying force to the thermoplastic sample. Similarly, the standard die, with dimensions of Φ2.095±0.005mm in diameter and 8±0.025mm in length, also receives Nitriding treatment to achieve a Vickers hardness of 700HV.

The inclusion of combined weights (325g, 1200g, 2160g, 3800g, 5000g) allows for flexible adjustment of the testing load, accommodating different standards and material characteristics. Additional tools and accessories, such as the compressing rod, barrel cleaning brush and rod, die cleaning tool, sample feeder, funnel, bubble level, scraper, tweezers, cutting blade, fuse, and a Go-No-go gauge.

Click here to learn more about the product or here to receive a personalized quote.

The Melt Flow Indexer is equipped with a range of optional accessories designed to enhance its capability and adaptability to different testing requirements. These optional accessories include:

- Encoder for MVR Test: Positioned at the top of the measuring rod, the encoder makes direct contact with the piston rod, transmitting real-time displacement data essential for melt volume rate (MVR) tests. It offers added versatility by allowing for adjustments in positioning according to different test methods, ensuring flexibility in different testing procedures.

- 10kg Load: This accessory includes one additional 5000g dead weight, enabling the Melt Flow Indexer to handle tests with higher load applications up to 10kg. This is particularly useful for materials that require greater force to achieve accurate melt flow measurements.

- 21.6kg Load: For even more demanding test conditions, this accessory package includes three more 5000g and one additional 1600g dead weight, allowing the machine to apply a total load of 21.6kg. This capability is essential for testing a broad range of materials under specific conditions that require higher-load applications.

- Φ1.05 Die and Φ1.18 Die: These specialized die plugs are designed for testing samples with particular melt flow rates, customizing the testing process further and providing precise control over the sample and testing conditions.

Click here to learn more about the product or here to receive a personalized quote.

The MFI452 Melt Flow Indexer model offers an extended temperature range from 50°C to 450°C. This extensive temperature capability allows for the testing of a broad range of thermoplastic materials. Each material requires specific conditions to accurately measure its melt flow rate (MFR) or melt volume rate (MVR). The ability to adjust the temperature within such a wide range ensures that the equipment can accommodate materials with low melting points. In addition, it can accommodate those requiring high temperatures to reach a molten state.

This temperature flexibility is crucial for manufacturers, researchers, and quality control laboratories that work with a diverse array of plastics. These plastics range from common polymers like polyethylene and polypropylene to engineering plastics that require higher processing temperatures. The MFI452's precise temperature control and high range facilitate the accurate evaluation of plastic materials under varying conditions, supporting the development of new materials and ensuring the consistency and quality of existing products.

Click here to learn more about the product or here to receive a personalized quote.

The maximum permitted deviation from the required test temperature of ≤0.25°C, measured 75mm above the top surface of the standard die in the MFI452 model of the Melt Flow Indexer, signifies the instrument's exceptional accuracy in maintaining a precise testing environment. This stringent temperature control ensures that the conditions under which melt flow rate (MFR) or melt volume rate (MVR) tests are conducted remain consistent and accurate to the set parameters.

This level of temperature precision is particularly important in the plastics industry, where even minor variations in temperature can significantly impact the properties of the thermoplastic material being tested. The ability to limit temperature deviation to such a narrow range demonstrates MFI452's advanced engineering and quality. This makes it ideal for applications requiring high precision, such as material development, quality assurance, and research.

By making sure that the test temperature remains stable with minimal deviation, the MFI452 model provides confidence to users that thermoplastic materials are being evaluated under optimal conditions.

Click here to learn more about the product or here to receive a personalized quote.

The temperature resolution of 0.1°C in the MFI452 model of the Melt Flow Indexer indicates the instrument's ability to adjust and display temperature changes with high precision. This level of resolution allows for very fine control over the testing environment, enabling users to set and monitor the temperature of thermoplastic materials with exceptional accuracy.

This fine temperature resolution is necessary for conducting melt flow rate (MFR) and melt volume rate (MVR) tests, where slight differences in temperature can significantly impact the material's flow properties and, consequently, the test results. By providing such precise control, the MFI452 guarantees that each test is performed under conditions that closely match the intended parameters, leading to reliable and consistent outcomes.

The high-temperature resolution of the MFI452 model increases its functionality in research, development, and quality control settings, where understanding and replicating specific processing conditions are essential for the accurate characterization of materials and the development of new plastics with desired properties.

Click here to learn more about the product or here to receive a personalized quote.

The MFI452 Melt Flow Indexer offers two distinct measurement ranges to accommodate different testing needs for thermoplastic materials. For Method A, the measurement range is 0.1 to 50 g/10min, which is suited to materials with lower melt flow rates, providing precise data for substances that exhibit less fluidity under heat. Method B expands the measurement capacity significantly, with a range of 0.1 to 2000 g/10min, catering to materials that demonstrate a higher flow rate when melted.

These diverse measurement ranges ensure that the MFI452 can accurately assess a range of thermoplastic materials, from those requiring delicate handling due to low flow rates to those with high melt flow characteristics. The flexibility to switch between Method A and Method B enables users to tailor the testing process to the specific properties of the material under examination.

This adaptability makes the MFI452 an invaluable tool in quality control laboratories, research institutes, and manufacturing settings, where understanding the melt flow properties of plastics is essential for material selection, process optimization, and product development.

Click here to learn more about the product or here to receive a personalized quote.

The displacement error of ≤±0.02 mm in the MFI452 model of the Melt Flow Indexer signifies the instrument's exceptional precision in measuring thermoplastic materials displacement during melt flow rate tests. This tight margin of error ensures that the movements of the piston rod, which exerts pressure on the molten plastic to flow through the die, are measured with high accuracy, leading to more reliable and consistent test results.

When it comes to determining melt flow rates (MFRs) and melt volume rates (MVRs) of plastics, such precision is crucial for accurate calculation, since even some tiny variations in displacement can have a big impact on the calculated values. By minimizing displacement error, the MFI452 provides users with confidence in the accuracy of their measurements, facilitating the detailed analysis of material properties required for quality control, research, and development in the plastics industry.

Click here to learn more about the product or here to receive a personalized quote.

The displacement resolution of 0.003mm in the MFI452 model of the Melt Flow Indexer signifies the instrument's exceptional ability to detect and measure very fine movements with high precision. This level of resolution is crucial for accurately determining thermoplastic materials' flow behavior during melt flow rate (MFR) and melt volume rate (MVR) tests.

Such precise displacement measurement allows for a detailed analysis of material viscosity and processing characteristics. This is essential for quality control, research, and development in the plastics industry. The ability to capture subtle displacement changes ensures that the MFI452 can provide reliable and accurate data, supporting the development of materials with specific properties and the optimization of processing conditions.

This high displacement resolution enhances the MFI452's capability to conduct detailed evaluations of thermoplastic materials. This contributes to its effectiveness as a tool for advancing material science and ensuring product quality.

Click here to learn more about the product or here to receive a personalized quote.

In the MFI452 Melt Flow Indexer model, the displacement measurement range is 25.5 mm, which is a generous amount of measurement range. A range such as this indicates the extent to which the instrument is able to measure the piston rod movement during a test of melt flow rate (MFR) or melt volume rate (MVR). The 25.5 mm range is designed to accommodate typical displacement as thermoplastic materials are extruded through the die under specified conditions.

This measurement range is essential for accurately assessing the flow properties of a wide variety of thermoplastic materials, providing flexibility to test materials with different viscosities and flow characteristics. By covering a broad range of displacements, the MFI452 ensures comprehensive testing capabilities, supporting precise evaluations of material behavior essential for quality control, research, and development in the plastics industry.

Click here to learn more about the product or here to receive a personalized quote.

The interval of temperature recovered after changing testing samples, specified as less than or equal to 3 minutes for the MFI452 model of the Melt Flow Indexer, indicates the instrument's rapid response and efficiency in returning to the required test temperature after a sample change. This quick recovery time is essential for maintaining high throughput in testing environments, allowing for minimal downtime between tests and guaranteeing that the testing process remains efficient and productive.

This feature demonstrates the MFI452's capability to swiftly stabilize the testing temperature, ensuring that each new sample is tested under consistent and accurate conditions. Such efficiency is particularly valuable in quality control and research settings, where time is often critical, and the accuracy of temperature conditions directly impacts the reliability of melt flow rate (MFR) and melt volume rate (MVR) measurements.

The MFI452's rapid temperature recovery after sample changes underscores its design for high-performance operation, catering to busy laboratories and production facilities in the plastics industry.

Click here to learn more about the product or here to receive a personalized quote.

The timing resolution of 0.01 seconds in the MFI452 model of the Melt Flow Indexer indicates the instrument's exceptional precision in measuring time intervals during testing. This high-resolution timing allows for the accurate measurement of how long the thermoplastic material takes to flow through the indexer, which is crucial for determining the melt flow rate (MFR) or melt volume rate (MVR) with precision.

This level of temporal accuracy ensures that the MFI452 can capture even the slightest variations in flow behavior, contributing to the reliability and consistency of the test results. Such precision in timing is essential for assessing the viscosity and processability of different thermoplastic materials, where even minor differences can significantly impact their performance and suitability for different applications.

The 0.01-second timing resolution highlights the MFI452's capability to support detailed and rigorous analysis in both quality control and research contexts, offering insights into materials' properties that are necessary for developing high-quality plastic products.

Click here to learn more about the product or here to receive a personalized quote.

The precise inner diameter specification of Φ2.095±0.005mm for the die in the MFI452 model of the Melt Flow Indexer is crucial for guaranteeing the accuracy and consistency of melt flow rate (MFR) and melt volume rate (MVR) tests. This specification indicates the instrument's ability to provide a highly controlled environment for assessing thermoplastic materials flow properties. The tight tolerance of ±0.005mm underscores the MFI452's precision engineering so that the flow path through which the melted material is extruded remains consistent across tests.

Such precision in the die diameter is essential for producing reliable and reproducible test results, which are vital for material characterization, quality control, and research. It allows manufacturers and researchers to accurately compare the flow behavior of different materials or the same material under different conditions, supporting the development of plastics with desired properties and processing characteristics.

The specific diameter measurement complies with industry standards. This facilitates compliance and guarantees that tests conducted using the MFI452 are valid and recognized globally in the plastics industry.

Click here to learn more about the product or here to receive a personalized quote.

The inner diameter specification of Φ9.550±0.007mm for the cylinder in the MFI452 model of the Melt Flow Indexer is critical for improving the precision and accuracy of melt flow tests. This specification demonstrates the instrument's high level of manufacturing precision, guaranteeing that the space through which the thermoplastic material is extruded is consistent and adheres to stringent standards.

The tight tolerance of ±0.007mm is necessary for maintaining uniform pressure and temperature conditions across the material during testing. Such consistency is vital for accurately measuring the melt flow rate (MFR) or melt volume rate (MVR) of thermoplastic materials, as even minor deviations in cylinder dimensions could significantly impact the test results.

This precise control over the testing environment enables the MFI452 to produce reliable, repeatable results, crucial for material characterization, quality control, and research. By meeting such exacting specifications, the MFI452 facilitates the comparison of materials and the assessment of their suitability for various applications, supporting the development of plastics with optimal processing and performance characteristics.

Click here to learn more about the product or here to receive a personalized quote.

The weight accuracy specification of ≤±0.5% for the MFI452 model of the Melt Flow Indexer significantly impacts its performance by ensuring that the force applied during melt flow rate (MFR) and melt volume rate (MVR) tests is precise and consistent. This level of accuracy in the weights used to apply pressure to the thermoplastic material being tested is crucial for reliable and reproducible results.

Accurate weight measurements are fundamental to the integrity of the testing process, as even slight deviations can alter the material's flow behavior and lead to inaccuracies in flow property determination. By maintaining weight accuracy within ±0.5%, the MFI452 ensures that each test is performed under conditions that closely match the intended parameters, facilitating accurate comparisons between different materials or the same material under various conditions.

This specification highlights the MFI452's commitment to precision and reliability, essential qualities for quality control labs, research institutions, and manufacturers seeking to assess and verify thermoplastic materials' performance characteristics.

Click here to learn more about the product or here to receive a personalized quote.

The range of possible standard weights for the MFI452 model of the Melt Flow Indexer, which includes 325g, 1200g, 2160g, 3800g, 5000g, 10000g, and 21600g, indicates a high level of versatility and adaptability to testing capabilities. This extensive range allows for precise adjustment of the applied force to match the requirements of various melt flow rate (MFR) and melt volume rate (MVR) tests, accommodating the many types of thermoplastic materials with different viscosities and flow properties.

The availability of such a diverse set of weights ensures that the MFI452 can accurately assess the behavior of materials under conditions that closely simulate their processing environments or end-use applications. It enables researchers and quality control professionals to customize testing parameters to specific standards or research objectives, providing valuable insights into the materials’ processability, quality, and performance characteristics.

Click here to learn more about the product or here to receive a personalized quote.

The MFI452 Melt Flow Indexer model measures 13.78 inches by 17.13 inches by 25.98 inches. This translates to 350 mm by 435 mm by 660 mm in metric units. These dimensions reflect the compact and efficient design of the instrument, making it suitable for various laboratory settings without excessive space.

The MFI452's design balances the need for a robust structure capable of accommodating the advanced features necessary for precise melt flow testing with the practical considerations of laboratory space. Its size ensures that it can be easily integrated into existing workflows, providing researchers and quality control professionals with a powerful tool for assessing thermoplastic materials flow properties.

This careful consideration of size and functionality underscores the MFI452's role in supporting the plastics industry's needs for material characterization and quality assurance. This ensures it can meet the rigorous demands of both research and production environments.

Click here to learn more about the product or here to receive a personalized quote.

The MFI452 model of the Melt Flow Indexer weighs 71 pounds (approximately 35 kilograms). This weight reflects the instrument's solid construction and durable materials used in its manufacturing, essential for ensuring its reliability and longevity in demanding laboratory environments. The weight of the MFI452 is a critical factor in its design, contributing to its stability during operation and reducing vibrations that could affect melt flow measurement accuracy.

As a result of its robust build, the weight of the MFI452 has been optimized in order to balance durability with ease of handling and installation. At 35 kilograms, the instrument is relatively easy to move and install in different laboratory settings, allowing it to be adapted to a variety of testing configurations and requirements irrespective of the setting in which it is being used. This level of portability is especially beneficial in multi-use laboratories where space and testing demands change frequently.

Click here to learn more about the product or here to receive a personalized quote.

The power supply requirements for the MFI452 Melt Flow Indexer model are 220V±10%, AC, 50Hz, with a power consumption of 1.5kW. These specifications indicate that the instrument is designed for efficient operation within a standard electrical infrastructure, particularly suited to regions with a 220V power supply. The allowance for a ±10% voltage variation provides some flexibility, accommodating minor fluctuations in the power supply without impacting the instrument's performance.

Considering the advanced features and capabilities of the MFI452, the MFI452's 1.5kW power consumption is a reflection of the MFI452's energy-efficient design. As a result of this level of power, it is possible to maintain precise control of the melt temperature, as well as power the mechanical components, such as the cutting device and the displacement measuring system, making sure that this measurement of melting flow rate is accurate and reliable.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

Class J - Charpy and Izod Automatic Impact Testing System - 1J - 50J

Class J is widely used for lzod and Charpy impact test on softer metals, plastics and rubber specimens. Equipped with tensile impact pendulum and fixtures, it can carry on tests on plastic film and sheet. The newly enhanced design offers the most cost-effective configuration to address Charpy test from 1J to 50J (0.7 - 37 ft/lbs), and lzod test from 1J to 22J (0.7 - 16 ft/lbs).

NG-ImpactFall – Falling Weight Impact Tester

Our falling weight impact tester finds extensive application in conducting external impact strength tests on plastic and non-metal materials.

Advanced Motorized Multi-Specimen Notching and Broaching Machine for Impact Testing on Plastic Specimens GenNotch 3000

Description The GenNotch 3000 machine is designed for creating notches in plastic specimens for Charpy impact testing. It has a capacity to hold 20 samples simultaneously and can process 60 samples within a 10-minute timeframe. With its high processing accuracy, […]

High Energy Elemendorf

Measure the tearing strength of plastic materials with the NG-HE Elemendorf, a versatile tester with advanced potential energy calculation.

NextGen Environmental Chambers NG-EC 100,150,225,408,1000

The temperature and humidity NextGen Environmental Chambers features a sturdy cabinet made of cold-rolled steel and stainless steel.

HDA 120 - Hardness and Density Automation Test System

The HDA 120 test system is a versatile solution for semi-automatic detection of sample hardness and density.

NG-EML Series B – Dual Column Bench Top Universal Testing Machine (100 N – 10 kN)

The NG-EML Series B is a high-precision dual-column benchtop universal testing machine engineered for tensile, compression, and flexural testing in the 0.1 kN to 10 kN range. It features Class 0.5 accuracy, a rigid FEM-optimized frame, and a direct-drive servo system with advanced closed-loop control, making it ideal for testing rubber, plastics, metals, composites, and high-performance polymers in both R&D and quality assurance settings.

NG-EML Series C – Dual Column Bench Top and Floor Standing Universal Testing Machine (5 kN – 50 kN)

The NG-EML Series C is a precision-engineered dual-column universal testing machine for tension, compression, and flexural testing of metals, composites, rubbers, and polymers. Available in both bench-top and floor-standing formats, with force capacities from 5 kN to 50 kN and Class 0.5 accuracy.

NG-EML Series D – Floor Standing Universal Testing Machine (50 kN – 1000 kN)

The NG-EML Series D – Floor Standing Universal Testing Machine (50 kN–1000 kN) is a dual-column system for tensile, compression, flexural, shear, and cyclic testing of high-strength metals, composites, polymers, and advanced materials. Available in single-space and dual-space configurations, it meets ASTM E8, ISO 6892-1, ISO 527, and GB/T 228 standards. With closed-loop control, 1200 Hz sampling, ultra-low speeds (0.00005 mm/min), and waveform generation, it is ideal for aerospace, automotive, construction, and research labs.

GenTest Data Acquisition Software - Advanced Universal Testing Machine Software

Upgrade to GenTest, the latest data acquisition software for universal testing machines. Ensure precise, repeatable material testing with an intuitive interface, powerful analysis tools, and full compliance with ASTM, ISO, DIN, and more.

Automatic Shore, IRHD and VLRH Hardness Testing System

NextGen is proud to present our German line of fully-automatic Shore, IRHD and VLRH hardness testing system for plastic materials, plastic and foam compounds for the ultimate precision, accuracy and repeatability, exceptional ease-of-use and maintenance. Experience the industry leader for specimen testing including rubbers, plastics, foams, composites, o-rings, and more.

Advanced Portable Shore Durometer System with Test Stand Options

HPEIII is NextGen's advanced German line of equipment that is the new generation of HPE systems ideal for various plastic and plastic compound testing. The new system enhancements offer advantages including temperature sensor, reading values of ambient temperature and humidity, historical hardness value display, larger LCD display, standard USB connection and much more. These advanced portable systems can be paired up with either manual or automatic motorized test stands to help eliminate the human error factor and maximize accuracy and repeatability between test when switching from one operator to the next.

Classic Analogue Shore Durometer with Test Stand Options

This German-manufactured system has been the global benchmark of Shore hardness testing systems since 1954. With ever enhanced ergonomic design, the HP Shore Hardness Tester is both visually appealing and precise rubber and plastic testing system as it has been for nearly 50 years.

Automatic Capsule and Soft Gel Hardness Tester

Gelomat is an automatic capsule hardness tester designed for regular and soft gel capsule testing. This state of the art system is developed by the latest R&D technology to meet and exceed the highest quality standards for gelatin capsule testing. The system comes standard with your desired testing head and can be upgraded to optional accessories for maximum efficiency.

Fruit Firmness Tester

This German manufactured fruit firmness and fruit hardness testing device is designed specification for the determination of the pulp hardness of a given fruit. This state-of-the-art device is invaluable for trading companies serious about their quality control procedures. The unit helps identify the harvest date of the specific fruits relative to the time of transpirations and storage.

Ball Rebound Tester

Ball Rebound Tester is designed for measuring the rebound resilience of polymer foams.

Pendulum Rebound Resilience Tester

Manual and Fully-Automatic Pendulum Rebound Resilience Tester. These rebound testers will determine the dynamic behavior of various materials and supply the differentiation of these materials' qualities. It will also identify material changes after aging and fatigue. The Pendulum Rebound Tester is out there with an adjustable heater for sample temperatures up to 100 ℃. It can simulate the effect of heat on the elasticity of samples with different formulations.

Pusey & Jones Tester

Pusey & Jones is a rubber and rubber like material testing system. The unit is designed for testing rubber rollers in the paper industry. The system can test specimens with flat surfaces and thickness of 13 mm.

Specimen Notching and Broaching Machine for Impact Testing on Plastic Specimens

GenNotch 2000 is the industry leading motorized lzod and Charpy impact test notching and broaching system for plastic specimens.