Plastic Testing Equipment

Standards

ASTM A 194, ASTM C 157, ASTM C 367, ASTM D 1151, ASTM D 1183

Description:

The temperature and humidity NextGen Environmental Chambers feature a sturdy cabinet made of cold-rolled steel and stainless steel, with an insulation layer to prevent frost and dew. The cabinet includes independent temperature control, circulating air ducts, heaters, and cooling systems. It also has a manual, single-opening door with a constant temperature heating belt and a viewing window with moisture-proof lighting fixtures. The chamber uses mechanical compression refrigeration and high-quality refrigeration accessories. It has a 7" TFT colour touch screen controller with an extensive program capacity and various protection features. The equipment provides two stainless steel sample racks with adjustable spacing and a maximum load of 100kg.

NextGen Environmental Chambers Standard Features

| Item | NG-EC100 | NG-EC150 | NG-EC225 | NG-EC408 | NG-EC1000 |

|

Internal Dimensions (W x H x D) |

20" x 20" x 16" | 20" x 24" x 20" | 24" x 30" x 20" | 31.5" x 33.5" x 24" | 39" x 39" x 39" |

|

External Dimensions (W x H x D) |

25" x 68" x 52" | 28" x 72" x 56" | 35.5" x 75" x 60" | 42.5" x 82" x 65" | 51" x 91" x 81" |

| Temperature Range | -40°C to +150°C | ||||

| Temperature Fluctuations | ≤±0.5℃ (w/o anything in chamber) | ||||

| Temperature Uniformity | ≤4℃ (w/o anything in chamber) | ||||

| Temperature Deviation | ≤±2℃ (w/o anything in chamber) | ||||

| Heating Rate | +25°C to +150°C ≥40min(without load) | ||||

| Cooling Rate | +25°C to -70°C ≥80min (without load) | ||||

| Power Requirements | 1 phase, AC220V, 50/60Hz, Approx. 4.5kW | 1 phase, AC220V, 50/60Hz, Approx. 5kW | 3 phase, AC380V, 50/60Hz, Approx. 9kW | 3 phase, AC380V, 50/60Hz, Approx. 9.5kW | 3 phase, AC380V, 50/60Hz, Approx. 14kW |

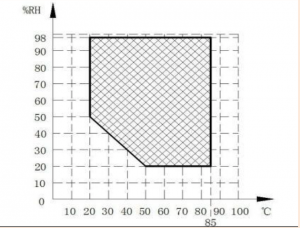

| Humidity Range |

Temperature : +20°C to +85°C,Humidity: 20% to 98% RH

|

||||

| Humidity Deviation |

1、≥75%RH : ≤±3%RH 2、≤75%RH:≤±5%RH |

||||

| Noise |

≤75db - Measured 3 feet in front of the chamber door, at 4 feet in height |

||||

NextGen Environmental Chambers Structure Features

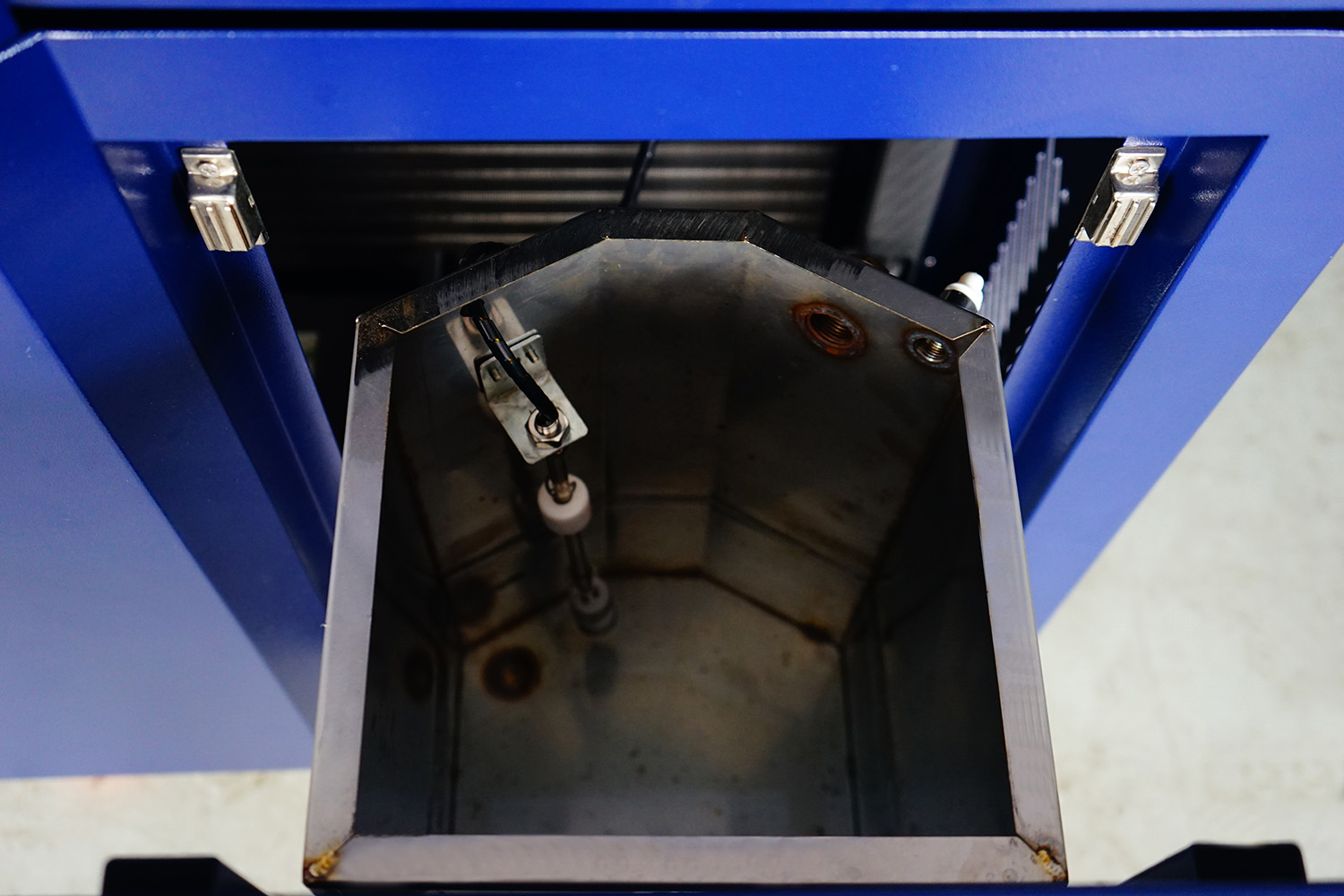

Cabinet

- The cabinet includes independent temperature control with circulating air ducts, heaters, cooling systems, etc.

- Outer Wall: 0.059” cold-rolled steel plate with plastic-sprayed surface

- Insulation layer: 4” polyurethane foam + ultra-fine glass wool, to ensure that the outer surface of the test chamber does not frost or dew;

- Inner wall: 0.047” Stainless 304 #4 Stainless Steel Sheet;

Circulation Ducting

- The circulating air duct is set at the back on the interior of the chamber

- Motor, impeller, heater and evaporator are installed in order from top to bottom inside the air duct

Door

- Manual, single-opening door is set on the front of the chamber with quality hinges and door locks.

- A constant temperature heating belt is installed around the door. The heating belt is automatically turned on for defrosting depending on the ambient temperature.

Viewing Window

- Each door is equipped with a three-layer hollow electric vacuum glass observation window. The observation window automatically turns on the defogging function according to the ambient temperature to ensure a clear observation at any state.

Lighting

- The observation window is equipped with a set of moisture-proof lighting fixtures to ensure that the test pieces in the box can be clearly observed under any working conditions. The lamp has the function of automatically turning off to prolong the life of the bulb.

Test Hole

- 2” test hole with Side Access on the Chamber

- Test holes are equipped with custom accessories and flexible silicone rubber seals.

Sample rack

- The equipment provides 2 stainless steel sample racks with adjustable spacing and a max load of 100Kg.

- To maintain air pressure balance between the interior of the chamber and the external environment during the test, the box is provided with a set of air pressure balance windows.

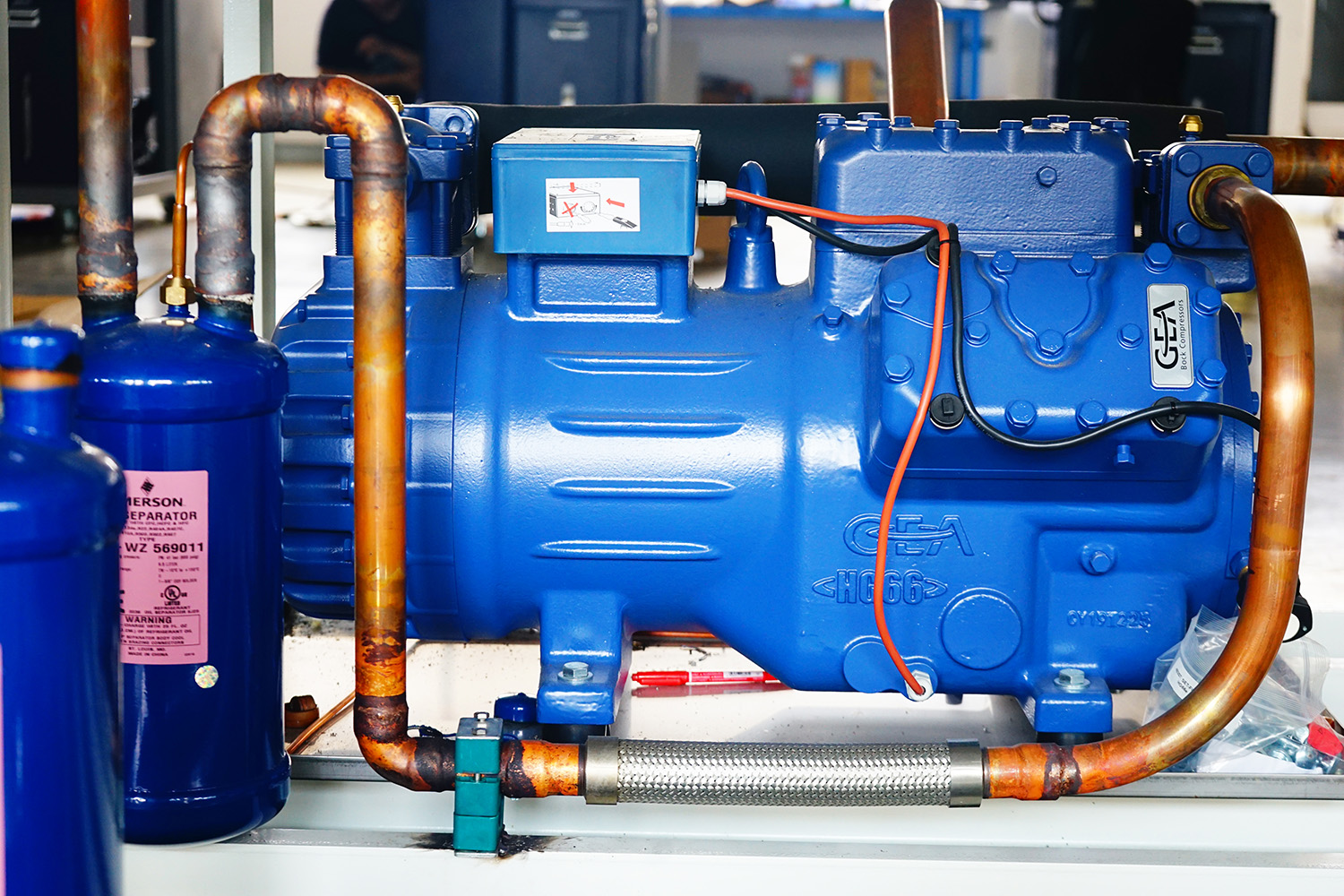

NextGen Environmental Chambers Cooling System

Refrigeration Method

- Mechanical Compression Refrigeration;

- Compressor starts as needed and at a specific time if desired

- The controller works together with the solenoid valve to control the on and off refrigerant flow for cold balance control. This prevents cooling during heating, and heating during cooling cycles.

Cooling method

- Air-cooled

- Refrigerant

- High temperature class: R404A / R23, DuPont

- The above refrigerants are all environmentally friendly that meet international environmental protection requirements.

Reliability

The main refrigeration accessories are assembled with internationally recognized brands including France Tecumseh compressors, Denmark DANFOSS pressure controller, American EMERSON oil separator, American EMERSON or Italian CASTEL solenoid valve, etc. NextGen Material Testing is dedicated to providing a long-lasting solution and uses quality components on the chamber from top to bottom.

NextGen Environmental Chambers Temperature Control

Temperature

- Temperature measurement: High-precision A-class PT100 platinum resistance sensor

- Temperature control

The controller collects the temperature sensor signal and automatically adjusts the heating power or refrigerant flow through the PID + SSR output to ensure that the air temperature in the chamber reaches a dynamic equilibrium.

- Heater: High-quality nickel-cadmium alloy wire heater driven by a non-contact zero-cross triggering solid state controller.

The water vapor condensation on the surface of the evaporator is achieved by the cooling capacity of the previous stage compressor. When the dew point temperature of the air in the chamber is lower than the surface temperature of the dehumidification evaporator, the water vapor in the air will condense on the surface of the evaporation coil.

NextGen Environmental Chambers Control System

Environmental Chambers Controller

- 7” TFT color touch screen controller

- Controller parameters:

- Accuracy: temperature ± 0.1°C + 1 digit, humidity ± 1% R.H + 1 digit

- Resolution: temperature ± 0.01°C, humidity ± 0.1% R.H

- Temperature slope: 0.1 to 9.9 (Can be set)

- Temperature input signal PT100x1 SensorP.I.D control parameters: 9 sets of PID control parameters are automatically calculated

- Screen functions

- Touch input, display temperature and humidity set value and measured value, various parameters of program operation, operation timing, equipment operation curve and history curve, fault prompt screen, with a adjustable screen brightness

Program Capacity

Available program groups: up to 250 saved patterns

Usable memory capacity: Up to 12500 segments

- Program editing adopts conversational style, with functions such as editing, clearing, inserting, etc.

- SEGMENTS time setting 0 ~ 540Hour59Min

- Record function

The controller can save the setting values, sampling values and sampling time of the equipment up to 90 days.

- Data stored in the controller can be called, analyzed, and processed using office programs such as Microsoft Excel

- Communication function

The control system can export the data saved by the device operation through the USB interface

- The control system can communicate with your computer through an RS232 connection or with the optional Ethernet interface.

NextGen Environmental Chambers Protection

- Chamber Over-Temperature Protection

- Heater Short Circuit Protection

- Humidifier Short Circuit Protection

- Fan Overload Protection

- Compressor Overpressure Protection

- Compressor Overload Protection

- Water Cut/Shortage Protection

- Electrical Ground Protection.

FAQs

NextGen Environmental Chambers uses R134a refrigerant, which is a hydrofluorocarbon (HFC) refrigerant that has become a popular replacement for the older R-12 refrigerant in automotive air conditioning systems. R134a has a much lower ozone depletion potential than R-12, which makes it a more environmentally friendly option. It is also less flammable than other refrigerants, making it a safer choice for use in air conditioning systems.

R134a refrigerant is commonly used in air conditioning systems for both vehicles and buildings. It has good thermodynamic properties and is able to provide efficient cooling. It also has a lower toxicity level compared to other refrigerants, making it a safer option for use in various applications. However, R134a is a greenhouse gas, which means that it has the potential to contribute to climate change if it is not properly contained and disposed of.

Click here to learn more about the product or here to receive a personalized quote.

Rubber hardness testing is a critical aspect of evaluating the quality of rubber products. Hardness refers to the resistance of rubber to indentation or deformation under the application of a certain force. It is a key property that determines the performance of rubber products in various applications.

The NextGen Environmental Chambers NG-EC is designed to operate within a wide temperature range of -70°C to +180°C, providing flexibility for testing materials at extreme temperatures.

Our chamber uses an advanced control system to maintain temperature stability and uniformity, ensuring accurate and consistent results. The control system features a programmable temperature controller and a high-precision sensor to maintain the desired temperature within a tolerance of ± 0.5°C.

The temperature range of the NG-EC makes it an ideal choice for a range of industries, including plastics, rubber, electronics, and aerospace. It can be used to test the performance of products in extreme environmental conditions, helping manufacturers to develop high-quality and reliable products.

Click here to learn more about the product or here to receive a personalized quote.

The NextGen Environmental Chambers NG-EC is designed to meet the needs of rubber and plastic manufacturers who require a reliable and efficient way to perform environmental testing. The chamber is equipped with a spacious interior that can accommodate multiple sample racks.

Each NG-EC chamber comes with one sample rack included in the package. However, additional sample racks can be purchased separately depending on the customer's needs. The sample rack is specifically designed to securely hold samples during testing and ensure consistent exposure to the environmental conditions inside the chamber.

The number of samples that can be tested at once depends on the sample size and the chamber size. The NG-EC chamber has a capacity of 100 litres, which allows for the testing of a significant number of samples at once. The chamber's advanced temperature and humidity control systems ensure accurate and stable conditions for each sample, enabling precise and repeatable results.

Click here to learn more about the product or here to receive a personalized quote.

The NextGen Environmental Chambers NG-EC features a precise and reliable temperature control system that ensures the internal temperature of the chamber is maintained within the desired range. The chamber uses a microprocessor-based PID controller that constantly monitors and adjusts the temperature to within ±0.2°C of the set point.

The temperature control system in the NG-EC works by circulating chilled air through a refrigeration system that uses R134a refrigerant. The refrigeration system is designed to remove heat from the chamber and maintain the temperature at the desired level. The temperature sensor located inside the chamber sends a signal to the controller, which adjusts the amount of refrigerant flowing through the system to maintain the set temperature.

Our chamber also features a fan system that ensures uniform temperature distribution throughout the chamber. The fan circulates the air, ensuring that the temperature is consistent across all sample racks. Moreover, the NG-EC features a safety thermostat that cuts off the power to the heater and compressor if the temperature exceeds the set limit.

Click here to learn more about the product or here to receive a personalized quote.

The NextGen Environmental Chambers NG-EC has an automatic defrosting function that is designed to remove ice build-up on the evaporator coils. This is necessary to ensure that the unit operates efficiently and maintains consistent temperature control. The defrost cycle is controlled by a microprocessor-based controller that monitors the temperature of the evaporator coils and initiates defrosting when necessary.

The defrosting function is initiated when the controller detects that the evaporator coils have reached a pre-set temperature. When this occurs, the refrigeration cycle is temporarily suspended, and the unit's electric heaters are turned on to melt the ice on the coils. Once the ice has melted, the controller will then turn off the electric heaters and resume the refrigeration cycle. The frequency of defrost cycles is determined by the amount of frost accumulation on the coils, which can be influenced by factors such as humidity levels and the number of door openings.

Click here to learn more about the product or here to receive a personalized quote.

The NextGen Environmental Chambers come with a defrosting function to ensure that frost accumulation does not affect the accuracy of the testing process. The defrosting function is controlled by an automatic system that senses the amount of ice buildup on the evaporator and initiates the defrost cycle as needed. The system uses a programmed microprocessor-based controller to monitor the chamber's temperature and humidity levels and control the defrost cycle.

During the defrost cycle, the system temporarily stops the cooling and heating functions and activates the defrost heater to melt the ice. The water produced from the defrost cycle is then collected in a drain pan and removed from the chamber. The defrost cycle is timed and varies depending on the amount of ice buildup, typically 30 to 45 minutes.

The automatic defrosting function is designed to minimize the need for manual intervention, reducing the risk of errors and ensuring test results' accuracy. The user can also manually initiate the defrost cycle if necessary. Additionally, the system includes a defrost heater safety limit switch to prevent overheating and ensure safe operation.

Click here to learn more about the product or here to receive a personalized quote.

The NextGen Environmental Chambers NG-EC features a high-precision temperature measurement system with a resolution of 0.1°C. The temperature measurement system uses a platinum resistance thermometer (PRT). PRTs are a type of temperature sensor that is known for their excellent accuracy and long-term stability.

A microprocessor-based temperature controller controls the temperature measurement system, which continuously monitors and adjusts the temperature inside the chamber to maintain the set temperature within a tight tolerance range. The temperature controller uses feedback from the PRT to adjust the heating and cooling systems to maintain the set temperature.

The NG-EC also features an optional data logger system that can record temperature and humidity data at user-defined intervals. The data logger system uses a high-precision thermistor sensor with a resolution of 0.01°C to provide accurate temperature measurements, which can be downloaded to a computer for analysis.

Click here to learn more about the product or here to receive a personalized quote.

The NextGen Environmental Chambers NG-EC-100/150 series have a highly precise humidity sensor with a resolution of 0.1%RH. The high resolution of the humidity sensor allows users to make precise adjustments to the humidity levels within the test chamber to achieve the desired testing conditions.

The humidity measurement is performed using a capacitive sensor, which operates based on the principle that the electrical capacitance of the sensor varies as a function of the relative humidity. The sensor's built-in microprocessor uses an algorithm to convert the capacitance measurement to a digital signal, which can be read and displayed on the chamber's control panel.

The NG-EC-100/150 series also features a humidity range of 10% to 98%RH, allowing users to test various products under various humidity conditions. The chamber is designed to provide consistent and uniform humidity distribution throughout the test area, ensuring that all samples are subjected to the same testing conditions.

Click here to learn more about the product or here to receive a personalized quote.

The insulation material used in the cabinet of this environmental chamber is a critical component that determines its energy efficiency and temperature stability. This product insulates the cabinet with high-quality polyurethane foam that provides excellent thermal insulation properties. Polyurethane foam insulation is widely used in environmental chambers due to its low thermal conductivity, high strength-to-weight ratio, and excellent dimensional stability. The foam insulation is applied to all sides of the cabinet walls, including the doors, to ensure that there are no thermal leaks.

Polyurethane foam insulation has a high R-value, which is a measure of its thermal resistance. The higher the R-value, the better the insulation properties. The R-value of the insulation used in this product is designed to maintain a consistent temperature inside the chamber even when the temperature outside fluctuates. The insulation also helps reduce energy consumption, as the cooling system does not have to work as hard to maintain the desired temperature.

Click here to learn more about the product or here to receive a personalized quote.

Yes, you can export data from the controller of this product. The NextGen Environmental Chambers has a user-friendly touchscreen controller that allows easy data logging and exporting. The controller allows exporting data via USB, Ethernet, or RS-485. This feature allows for the easy transfer of test data to a computer or other device for further analysis and documentation.

The touchscreen controller also has a built-in data logging function that can record and store test data over an extended period. This data can be exported in CSV format, which is easily readable by most spreadsheet software. The controller also allows for inputting test parameters, such as temperature and humidity set points, as well as the test duration.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

Class J - Charpy and Izod Automatic Impact Testing System - 1J - 50J

Class J is widely used for lzod and Charpy impact test on softer metals, plastics and rubber specimens. Equipped with tensile impact pendulum and fixtures, it can carry on tests on plastic film and sheet. The newly enhanced design offers the most cost-effective configuration to address Charpy test from 1J to 50J (0.7 - 37 ft/lbs), and lzod test from 1J to 22J (0.7 - 16 ft/lbs).

Melt Flow Indexer

Our melt flow indexer is a highly precise instrument designed for the measurement of melt flow rate (MFR)/(MI) or melt volume rate (MVR) in quality control and research applications.

NG-ImpactFall – Falling Weight Impact Tester

Our falling weight impact tester finds extensive application in conducting external impact strength tests on plastic and non-metal materials.

Advanced Motorized Multi-Specimen Notching and Broaching Machine for Impact Testing on Plastic Specimens GenNotch 3000

Description The GenNotch 3000 machine is designed for creating notches in plastic specimens for Charpy impact testing. It has a capacity to hold 20 samples simultaneously and can process 60 samples within a 10-minute timeframe. With its high processing accuracy, […]

High Energy Elemendorf

Measure the tearing strength of plastic materials with the NG-HE Elemendorf, a versatile tester with advanced potential energy calculation.

HDA 120 - Hardness and Density Automation Test System

The HDA 120 test system is a versatile solution for semi-automatic detection of sample hardness and density.

NG-EML Series B – Dual Column Bench Top Universal Testing Machine (100 N – 10 kN)

The NG-EML Series B is a high-precision dual-column benchtop universal testing machine engineered for tensile, compression, and flexural testing in the 0.1 kN to 10 kN range. It features Class 0.5 accuracy, a rigid FEM-optimized frame, and a direct-drive servo system with advanced closed-loop control, making it ideal for testing rubber, plastics, metals, composites, and high-performance polymers in both R&D and quality assurance settings.

NG-EML Series C – Dual Column Bench Top and Floor Standing Universal Testing Machine (5 kN – 50 kN)

The NG-EML Series C is a precision-engineered dual-column universal testing machine for tension, compression, and flexural testing of metals, composites, rubbers, and polymers. Available in both bench-top and floor-standing formats, with force capacities from 5 kN to 50 kN and Class 0.5 accuracy.

NG-EML Series D – Floor Standing Universal Testing Machine (50 kN – 1000 kN)

The NG-EML Series D – Floor Standing Universal Testing Machine (50 kN–1000 kN) is a dual-column system for tensile, compression, flexural, shear, and cyclic testing of high-strength metals, composites, polymers, and advanced materials. Available in single-space and dual-space configurations, it meets ASTM E8, ISO 6892-1, ISO 527, and GB/T 228 standards. With closed-loop control, 1200 Hz sampling, ultra-low speeds (0.00005 mm/min), and waveform generation, it is ideal for aerospace, automotive, construction, and research labs.

GenTest Data Acquisition Software - Advanced Universal Testing Machine Software

Upgrade to GenTest, the latest data acquisition software for universal testing machines. Ensure precise, repeatable material testing with an intuitive interface, powerful analysis tools, and full compliance with ASTM, ISO, DIN, and more.

Automatic Shore, IRHD and VLRH Hardness Testing System

NextGen is proud to present our German line of fully-automatic Shore, IRHD and VLRH hardness testing system for plastic materials, plastic and foam compounds for the ultimate precision, accuracy and repeatability, exceptional ease-of-use and maintenance. Experience the industry leader for specimen testing including rubbers, plastics, foams, composites, o-rings, and more.

Advanced Portable Shore Durometer System with Test Stand Options

HPEIII is NextGen's advanced German line of equipment that is the new generation of HPE systems ideal for various plastic and plastic compound testing. The new system enhancements offer advantages including temperature sensor, reading values of ambient temperature and humidity, historical hardness value display, larger LCD display, standard USB connection and much more. These advanced portable systems can be paired up with either manual or automatic motorized test stands to help eliminate the human error factor and maximize accuracy and repeatability between test when switching from one operator to the next.

Classic Analogue Shore Durometer with Test Stand Options

This German-manufactured system has been the global benchmark of Shore hardness testing systems since 1954. With ever enhanced ergonomic design, the HP Shore Hardness Tester is both visually appealing and precise rubber and plastic testing system as it has been for nearly 50 years.

Automatic Capsule and Soft Gel Hardness Tester

Gelomat is an automatic capsule hardness tester designed for regular and soft gel capsule testing. This state of the art system is developed by the latest R&D technology to meet and exceed the highest quality standards for gelatin capsule testing. The system comes standard with your desired testing head and can be upgraded to optional accessories for maximum efficiency.

Fruit Firmness Tester

This German manufactured fruit firmness and fruit hardness testing device is designed specification for the determination of the pulp hardness of a given fruit. This state-of-the-art device is invaluable for trading companies serious about their quality control procedures. The unit helps identify the harvest date of the specific fruits relative to the time of transpirations and storage.

Ball Rebound Tester

Ball Rebound Tester is designed for measuring the rebound resilience of polymer foams.

Pendulum Rebound Resilience Tester

Manual and Fully-Automatic Pendulum Rebound Resilience Tester. These rebound testers will determine the dynamic behavior of various materials and supply the differentiation of these materials' qualities. It will also identify material changes after aging and fatigue. The Pendulum Rebound Tester is out there with an adjustable heater for sample temperatures up to 100 ℃. It can simulate the effect of heat on the elasticity of samples with different formulations.

Pusey & Jones Tester

Pusey & Jones is a rubber and rubber like material testing system. The unit is designed for testing rubber rollers in the paper industry. The system can test specimens with flat surfaces and thickness of 13 mm.

Specimen Notching and Broaching Machine for Impact Testing on Plastic Specimens

GenNotch 2000 is the industry leading motorized lzod and Charpy impact test notching and broaching system for plastic specimens.