Metal Testing Equipment

Standards

ISO 179, ISO 180, ASTM D6110, ISO 13802, ISO 8256, ISO 9854.1, ASTM D256, ASTM D1822, ASTM E74 (Class AA), ISO 376

Function

Class J Impact Testing System is widely used for lzod and Charpy impact test on plastics and rubber specimens. Equipped with tensile impact pendulum and fixtures, it can carry on tests on plastic film and sheet. The newly enhanced design offers the most cost-effective configuration to address Charpy test from 1J to 50J (0.7 - 37 ft/lbs), and lzod test from 1J to 22J (0.7 - 16 ft/lbs). Learn more about the full scope of plastic impact testing procedure.

Features

High Resolution

Using a shaftless encoder allows angle resolution of 0.045 °

Energy Losses

Shaftless encoder for angle measurement rotates without friction, thereby offering the lowest energy loss.

Touch Screen Display

Touch screen provides easy setup of specimen dimensions, pendulum energy, units and calibration data. The unit can also intuitively display test results such as absorbed energy and impact toughness

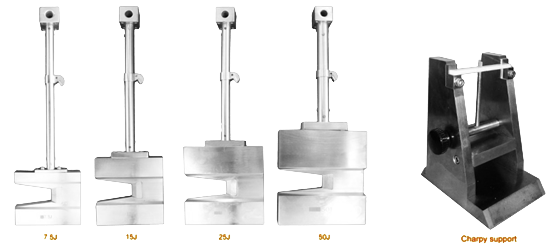

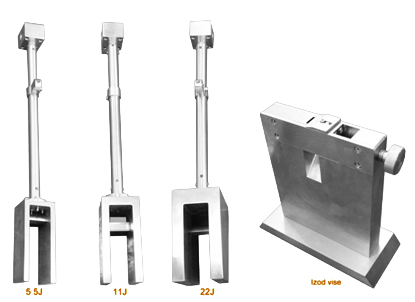

Interchangeable Pendulum

Simply change the pendulum to satisfy Charpy, Izod and tensile impact tests

Center Alignment

Rotating design allows for a quick and accurate specimen center alignment for the Charpy test

Supports and Anvils

Supports are firmly tightened and only require the remove of two bolts to change the supports

Broader Test Space

Single column structure offers broad test space. The machine allows for easy installation of low temperature impact test accessories in the future

Machine Dimensions and Specifications

1. Capacity

| Test type | Standard | Pendulum |

|---|---|---|

| Charpy for plastics | ISO179, GB/T 1043 | 1J (0.7 ft/lbs), 2J (1.5 ft/lbs), 4J (2.95 ft/lbs), 7.5J (5.5 ft/lbs), 15J (11 ft/lbs), 25J (18 ft/lbs), 50J (37 ft/lbs) |

| ASTM D6110 | 2.7J (2 ft/lbs), 5.4J (4 ft/lbs), 10.8J (8 ft/lbs), 21.6J (16 ft/lbs) | |

| Charpy for plastic pipe | ISO 9854.1 | 15J (11 ft/lbs), 50J (37 ft/lbs) |

| Izod | ISO 179, GB/T1843, GB/T1844 | 2.75J (2 ft/lbs), 5.5J (4 ft/lbs), 11J (8 ft/lbs), 22J (16 ft/lbs) |

| ASTM D256 | 2.7J (2 ft/lbs), 5.4J (4 ft/lbs), 10.8J (8 ft/lbs), 21.6J (16 ft/lbs) | |

| Tensile impact | ISO 8256, GB/T 13525 | 7.5J (5.5 ft/lbs), 15J (11 ft/lbs), 25J (18 ft/lbs) |

| ASTM D1822 | 7.5J (5.5 ft/lbs), 15J (11 ft/lbs), 25J (18 ft/lbs) |

2. Pendulum Movement

| Charpy | 1J (0.7) | 0.5358983 Nm | Izod | 1J (0.7) | 0.5358983 Nm |

|---|---|---|---|---|---|

| 2J (1.4) | 1.0717967 Nm | 2.75J (2) | 1.4737205 Nm | ||

| 4J (3) | 2.1435935 Nm | 5.5J (4) | 2.94744 Nm | ||

| 7.5J (5.5) | 4.0192 Nm | 11J (8) | 5.8949 Nm | ||

| 15J (11) | 8.0385 Nm | 22J (16) | 11.7898 Nm | ||

| 25J (18.5) | 13.397 Nm | ||||

| 50J (37) | 26.795 Nm | ||||

| Tensile impact | 7.5J (5.5) | 4.01923 Nm | |||

| 15J (11) | 8.03847 Nm | ||||

| 25J (18.5) | 13.39745 Nm |

3. Angle of striking: 150°

4. Angle resolution: 0.045°

Reading resolution of digital display: 0.01J

5. Power supply: AC220V, 50Hz, 0.3kW

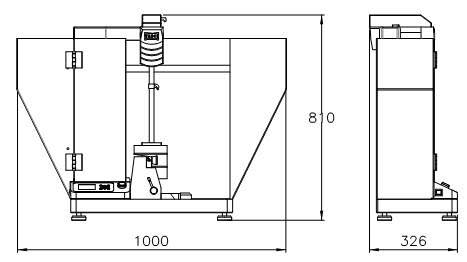

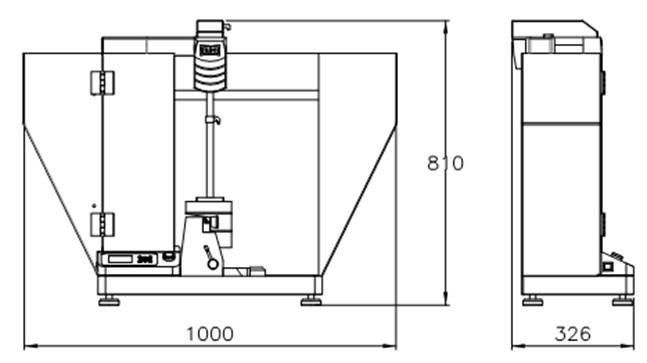

6. Machine dimension (LxWxH): 40" x 12" x 30" / 1000x300x760mm

7. Weight: 310lbs. / 140kg

8. Charpy Test for Plastics

| Items | ISO 179, GB/T 1043 | ASTM D6110 |

|---|---|---|

| Angle of striking | 150° | 150° |

| Velocity of striking | 2.9m/s (≤5J - 3.7 ft/lbs), 3.8m/s (>5J - 3.7 ft/lbs) | 3.46m/s |

| Distance from the axis of support to the center of percussion | 230mm(≤5J - 3.7 ft/lbs), 395mm(>5J - 3.7 ft/lbs) | 327mm |

| Span | 40mm, 60mm, 70mm (can be adjusted by span block) | 95.3mm |

| Radius of striker edge | 2±0.5mm | 3.17±0.12mm |

| Specimen dimension (LxWxH) | 80x10x4mm | 127x12.7x(3~12.7)mm |

9. Charpy Test for plastic pipe

| Standard | ISO 9854.1 |

|---|---|

| Angle of striking | 150° |

| Velocity of striking | 3.8m /s |

| Distance from the axis of support to the center of percussion | 395mm |

| Span | 40mm, 60mm, 62mm, 70mm |

| Radius of striker edge | 3.17±0.12mm |

| Specimen dimension Length x width x thickness (mm) |

Type | Length | Width | Thickness | Support span |

|---|---|---|---|---|---|

| 1 | 100±2 | Whole pipe | 70±0.5 | ||

| 2 | 50±1 | 6±0.2 | e | 40±0.5 | |

| 3 | 120±2 | 15±0.5 | e | 70±0.5 | |

| Note: e is the machining pipe thickness | |||||

10. Izod Test

| Standard | ISO 180 | ASTM D256 |

|---|---|---|

| Angle of striking | 150° | 145.2° |

| Velocity of striking | 3.5m/s | 3.46m/s |

| Distance from the axis of support to the center of percussion | 335 | |

| Striking knife center to vice upper surface | 22±0.2mm | |

| Radius of striker edge | 0.8±0.2mm | |

| Specimen dimension (LxWxH) | 80×10×4mm, 63.5×12.7×12.7mm 63.5×12.7×6.4mm, 3.5×12.7×3.3mm |

|

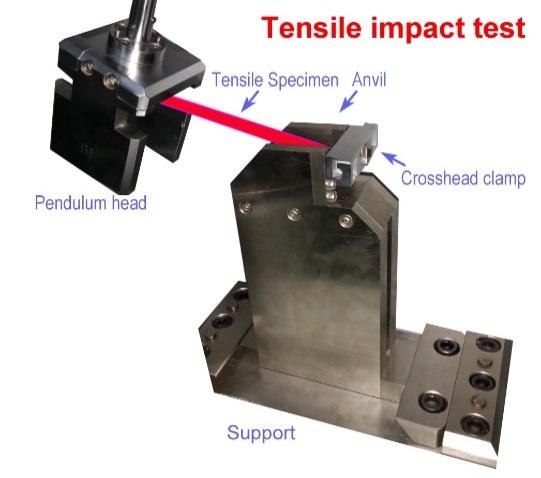

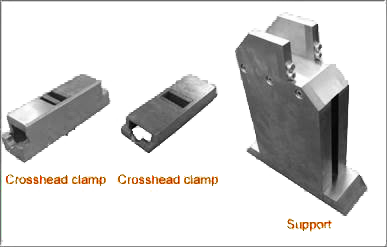

11. Tensile Impact Test

| Standard | ASTM D1822 | ISO 8256 |

|---|---|---|

| Angle of striking | 150° | 150° |

| Velocity of striking | 3.46m/s | 3.8m/s |

| Distance from the axis of support to the center of percussion | 327mm | 395mm |

| Crosshead mass | 60±1g, 120±1g | |

| Maximum specimen thickness | 4mm | |

Standard Accessories

| Model | NGI-501J | |

|---|---|---|

| Type | J-2 | J-3 |

| Main machine | 1 set | 1 set |

| Angle encoder (shaftless) | 1 set | 1 set |

| Controller with digital display | 1 set | 1 set |

| Electromagnetic hook | 1 set | 1 set |

| Maintenance tools | 1 set | 1 set |

| Half protection shield | 1 set | 1 set |

| Software | N/A | 1 set |

| Micro-printer | 1 set | N/A |

Optional Accessories

| Test | Type | Description |

|---|---|---|

| NGI-501J | ||

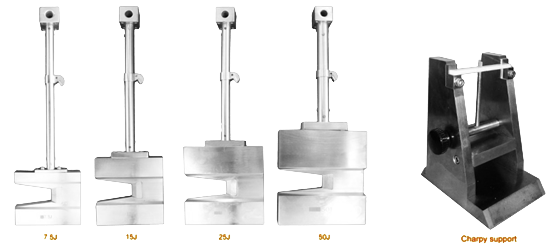

| Charpy (Plastics) | Chapry pendulum (ISO 179) | 1J (0.7 ft/lbs), 2J (1.5 ft/lbs), 4J (2.95 ft/lbs), 7.5J (5.5 ft/lbs), 15J (11 ft/lbs), 25J (18 ft/lbs), 50J (37 ft/lbs) |

| Chapry pendulum (ASTM D6110) | 2.7J (2 ft/lbs), 5.4J (4 ft/lbs), 10.8J (8 ft/lbs), 21.6J (16 ft/lbs) | |

| Charpy support | ||

| Charpy span block | ||

| Charpy notch centering block | ||

| Charpy (Plastic pipes) | Chapry pendulum (ISO179) | 15J (11 ft/lbs), 50J (37 ft/lbs) |

| Supports for convex test piece | ||

| Supports for bar specimen | ||

| Charpy span block (40mm, 70mm) | ||

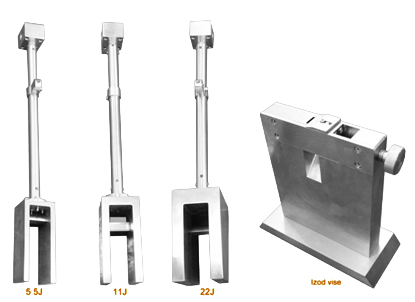

| Izod | Izod pendulum (ISO180) | 2.75J (2 ft/lbs), 5.5J (4 ft/lbs), 11J (8 ft/lbs), 22J (16 ft/lbs) |

| Izod pendulum (ASTM D256) | 2.7J (2 ft/lbs), 5.4J (4 ft/lbs), 10.8J (8 ft/lbs), 21.6J (16 ft/lbs) | |

| Izod vise jaw | ||

| Izod notch centering block | ||

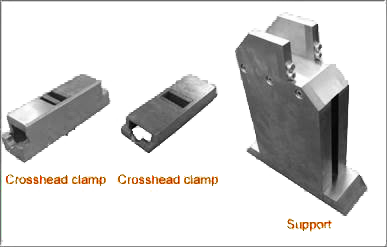

| Tensile impact | Tensile impact pendulum (ISO 8256) | 7.5J (5.5 ft/lbs), 15J (11 ft/lbs), 25J (18 ft/lbs) |

| Tensile impact pendulum (ASTM D1822) | 7.5J (5.5 ft/lbs), 15J (11 ft/lbs), 25J (18 ft/lbs) | |

| Tensile impact anvil | ||

| Tensile impact crosshead | 60g, 120g |

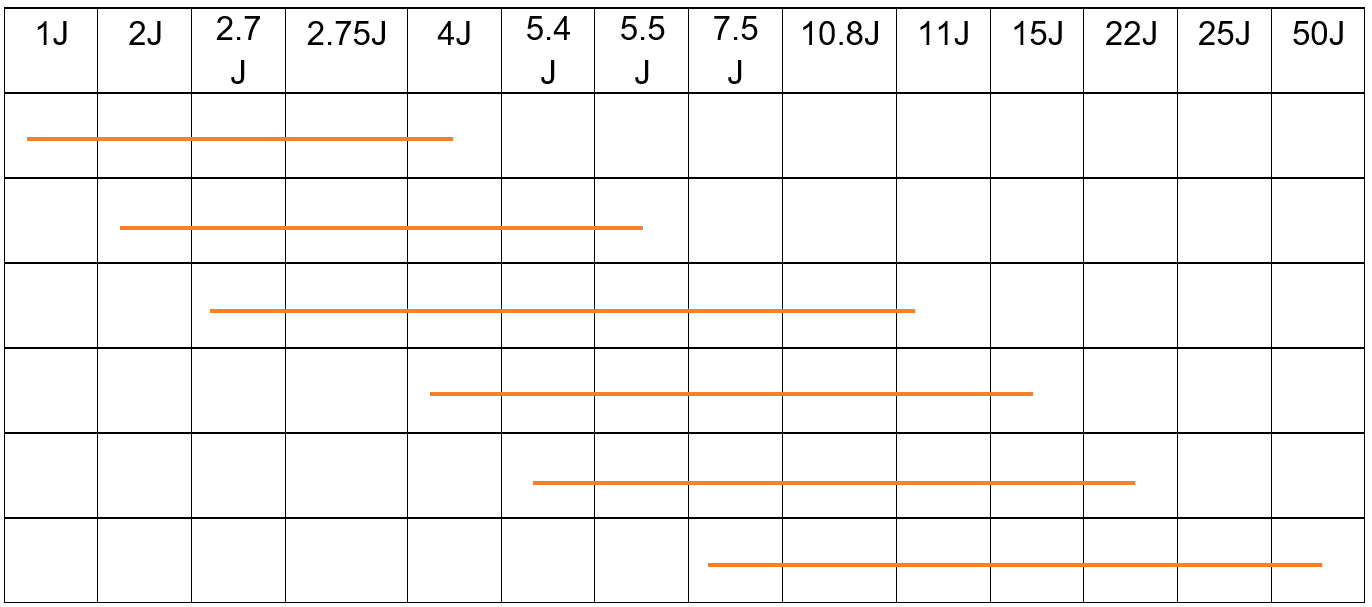

Test Method vs. Pendulum Energy

| No. | Standard | Type | Velocity(m/s) | Energy - J (ft/lbs) |

|---|---|---|---|---|

| 1 | GB/T 1043 | Charpy | 2.9 | 1 (0.7), 2 (1.5), 4 (3) |

| 2 | GB/T 1043 | Charpy | 3.8 | 7.5 (5.5), 15 (11), 25 (18.4), 50 (37) |

| 3 | ISO 179 | Charpy | 2.9 | 1 (0.7), 2 (1.5), 4 (3) |

| 4 | ISO 179 | Charpy | 3.8 | 7.5 (5.5), 15 (11), 25 (18.4), 50 (37 |

| 5 | GB/T 1843 | Izod | 3.5 | 2.75 (2), 5.5 (4) |

| 6 | GB/T 1844 | Izod | 3.5 | 5.5 (4), 11 (8), 22 (16) |

| 7 | ISO180 | Izod | 3.5 | 2.75 (2), 5.5 (4) |

| 8 | ISO180 | Izod | 3.5 | 5.5 (4), 11 (8), 22 (16) |

| 9 | GB/T 13525 | Tensile | 3.8 | 7.5 (5.5), 15 (11), 25 (18.4) |

| 10 | ISO8256 | Tensile | 3.8 | 7.5 (5.5), 15 (11), 25 (18.4) |

| 11 | ASTM D6110 | Charpy | 3.46 | 2.7 (2), 5.4 (4), 10.8 (8), 21.6 (16) |

| 12 | ASTM D256 | Izod | 3.46 | 2.7 (2), 5.4 (4), 10.8 (8), 21.6 (16) |

| 13 | ASTM D1822 | Tensile | 3.46 | 7.5 (5.5), 15 (11), 25 (18.4) |

Pendulum Range Selection

One machine is recommended to be equipped with less than 5 pendulums. More than 5 pendulums result in a more complicated calibration procedure.

FAQs

The Class J Impact Testing System for Charpy and Izod is designed with a measuring accuracy range of 10% to 80%. This means that if you are using a 22J hammer, your accurate testing range will be from 2.2J to 22J. If you require accuracy down to 1J, it is suggested to include the 2.75J pendulum hammer in the solution. This ensures that your testing needs are covered across the entire Izod testing range, from 22J down to 1J.

ISO 179 is a standard published by the International Organization for Standardization (ISO). It is titled "Plastics - Determination of Charpy Impact Properties" and provides guidelines and procedures for evaluating plastic materials' impact properties using the Charpy impact test.

The Charpy impact test is commonly used to assess plastics' toughness and impact resistance. It involves subjecting a standardized specimen to the impact of a swinging pendulum, causing a fracture. By measuring the amount of energy absorbed during fracture, the test provides valuable insights into the material's ability to withstand sudden impacts.

ISO 179 establishes a standardized procedure for conducting the Charpy impact test, ensuring consistency and enabling test comparison. The standard covers various aspects, including specimen preparation, test conditions, and test outcomes calculation and reporting.

By complying with ISO 179, manufacturers, researchers, and regulatory bodies can conduct reliable and consistent evaluations of plastic materials' impact properties. This standard plays a crucial role in material selection, quality control, and ensuring plastic products' performance and safety across various industries.

Class J – Charpy and Izod Automatic Impact Testing System complies with ISO 179 standard.

You can also learn more about the product or receive a personalized quote.

ISO 180 is an internationally recognized standard published by the International Organization for Standardization (ISO) under the title "Plastics -- Determination of Izod Impact Strength." It provides comprehensive guidelines for evaluating plastic impact strength using the Izod impact test.

The Izod impact test is a widely used method for measuring plastics' ability to withstand impact forces. It involves striking a standardized specimen with a pendulum, which causes a fracture. The energy absorbed during fracture is then measured to assess the material's impact resistance.

This standard specifies the procedures and parameters necessary to accurately perform the Izod impact test. It covers key aspects such as specimen preparation, test conditions, and test results calculation and reporting. The standard allows for testing notched and unnotched specimens, enabling the evaluation of different plastic materials.

Class J – Charpy and Izod Automatic Impact Testing System complies with ISO 180 standard.

You can also learn more about the product or receive a personalized quote.

ASTM D6110 is a standard published by the American Society for Testing and Materials (ASTM) that focuses on evaluating the impact resistance of plastics using the Charpy impact test. This widely recognized test evaluates plastics' toughness and ability to withstand sudden impacts by subjecting notched specimens to a swinging pendulum. The amount of energy absorbed during impact is measured, providing valuable information about the material's resistance to impact and its suitability for different applications.

ASTM D6110 provides a comprehensive framework for conducting the Charpy impact test, covering important aspects such as specimen preparation, test conditions, and results calculation and reporting. Following this standard ensures consistent and reliable testing practices across different laboratories, allowing for meaningful comparisons of different plastic materials.

Class J – Charpy and Izod Automatic Impact Testing System complies with ASTM D6110 standard.

You can also learn more about the product or receive a personalized quote.

ISO 13802 is an international standard that sets forth guidelines for verifying the accuracy and reliability of pendulum impact-testing machines used for the Charpy impact test, Izod impact test, and tensile impact test. This standard establishes the frequency and methods for conducting the verification process.

This standard specifically focuses on non-instrumented impact machines, providing guidance on verifying their geometrical and physical properties. However, it does not encompass force/work verification of instrumented impact machines.

By following ISO 13802, testing laboratories and facilities can ensure that their impact-testing machines are properly calibrated and functioning correctly. This adherence promotes consistent and comparable test results, enabling accurate evaluations of different materials' impact resistance.

Class J – Charpy and Izod Automatic Impact Testing System complies with ISO 13802 standard.

You can also learn more about the product or receive a personalized quote.

ISO 8256 is an ISO standard that is focused determining the tensile-impact strength of plastics. It provides a standardized testing procedure to evaluate how plastics perform when subjected to combined tensile stress and impact loads.

The standard outlines a detailed process for conducting a tensile-impact test. This involves applying controlled tensile forces to plastic specimens while measuring fracture energy. By quantifying the absorbed energy, the test provides valuable insights into the material's ability to withstand sudden impacts while under tension.

ISO 8256 ensures consistency and reliability by establishing uniform test conditions, specimen dimensions, and calculation methods. Adhering to this standard enables meaningful comparisons of tensile-impact strength across different plastic materials. This allows manufacturers, researchers, and quality control professionals to make informed decisions about material selection based on their specific application requirements.

Class J – Charpy and Izod Automatic Impact Testing System complies with ISO 8256 standard.

You can also learn more about the product or receive a personalized quote.

ISO 9854.1 is an internationally recognized standard that focuses on pendulum impact strength determination using the Charpy method. This is for unnotched test pieces from thermoplastic pipes used in fluid transportation. This standard provides a general test method for assessing the impact strength of these test pieces.

While ISO 9854.1 is not intended to be used as a reference test method for evaluating the impact strength of complete pipes, it finds applicability in scientific research, materials testing, or situations where measurements according to the reference method are impractical.

The standard outlines detailed procedures for conducting a pendulum impact test on the test pieces, measuring the energy absorbed when a swinging pendulum strikes the specimen. The test results offer valuable insights into the material's ability to withstand sudden impacts.

Class J – Charpy and Izod Automatic Impact Testing System complies with ISO 9854.1 standard.

You can also learn more about the product or receive a personalized quote.

ASTM D256 is a standard published by ASTM (the American Society for Testing and Materials) titled "Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics." This standard serves as a comprehensive guide for performing the Izod impact test, which is widely used to assess plastic impact resistance.

In the Izod impact test, a notched plastic specimen is subjected to a swinging pendulum hammer, and the energy absorbed during fracture is measured. This test helps evaluate the material's ability to withstand sudden impact loads and provides essential insights into its toughness and resistance to brittle fracture.

ASTM D256 establishes standardized procedures for preparing test specimens, defining test conditions, and accurately calculating and reporting test results. By adhering to this standard, consistent and reliable testing can be achieved across different laboratories, facilitating meaningful comparisons among various plastic materials.

Class J – Charpy and Izod Automatic Impact Testing System complies with ASTM D256 standard.

You can also learn more about the product or receive a personalized quote.

ASTM D1822 is a standard published by the American Society for Testing and Materials (ASTM) titled "Standard Test Method for Tensile-Impact Energy to Break Plastics and Electrical Insulating Materials." This standard provides guidelines for determining the tensile-impact energy required to fracture plastics and electrical insulating materials.

ASTM D1822 test method involves subjecting a notched test specimen to combined tensile and impact load until a fracture occurs. The energy required to break the specimen is measured, providing valuable information about the material's ability to withstand both tensile and impact forces.

This standard establishes specific procedures for specimen preparation, test conditions, and results calculation and reporting. By following this standard, consistent and reliable testing can be achieved, allowing for meaningful comparisons of different materials.

Class J – Charpy and Izod Automatic Impact Testing System complies with ASTM D1822 standard.

You can also learn more about the product or receive a personalized quote.

The Class J – Charpy and Izod Automatic Impact Testing System is a versatile solution equipped with a wide range of pendulum options, enabling precise testing across various energy levels. With a testing range of 1J to 50J for Charpy tests and 1J to 22J for Izod tests, this system ensures an accurate evaluation of materials' impact strength. Its advanced design enhances performance and cost-effectiveness.

This user-friendly system features intuitive controls, a high-resolution display, and interchangeable pendulums, delivering consistent and reliable results. Its robust construction guarantees durability, making it a trusted choice for research laboratories, quality control departments, and material testing facilities.

By utilizing the Class J – Charpy and Izod Automatic Impact Testing System, professionals can efficiently assess materials' impact properties. This critical information empowers informed decision-making in industries where product reliability and safety are paramount.

You can also learn more about the product or receive a personalized quote.

The Class J – Charpy and Izod Automatic Impact Testing System is equipped with a shaftless encoder that enables an exceptional angle resolution of 0.045°. This advanced encoder technology precisely measures the pendulum's angular displacement during impact testing.

The absence of a shaft in the encoder provides distinct advantages. It eliminates potential mechanical limitations and interferences, ensuring highly accurate pendulum movement measurements. The impressive 0.045° angle resolution signifies the encoder's ability to detect even the smallest angular changes with exceptional precision.

The angle resolution of the system allows for the detection of subtle variations in tested materials' impact behaviour. This level of precision empowers researchers and quality control professionals to gather detailed data and make informed decisions regarding material properties.

You can also learn more about the product or receive a personalized quote.

An important advantage of this machine is its shaftless encoder for angle measurement. A key benefit of this technology is the reduction of energy loss during rotation. In contrast to traditional encoders, shaftless encoders operate without friction, resulting in minimal energy loss.

By eliminating the need for a shaft, the encoder reduces mechanical resistance, enabling smoother and more efficient rotation. This streamlined operation enhances the accuracy and precision of angle measurement, ultimately improving the overall performance of the testing system.

Moreover, the reduced energy loss contributes to enhanced energy efficiency and cost-effectiveness. The Class J – Charpy and Izod Automatic Impact Testing System optimizes resource utilization, minimizing waste and prolonging the lifespan of the equipment.

You can also learn more about the product or receive a personalized quote.

The touchscreen interface on the Class J – Charpy and Izod Automatic Impact Testing System offers convenient features for efficient operation. With this intuitive interface, users can easily set up specimen dimensions, pendulum energy, units, and calibration data. The touch screen enables quick and hassle-free input of parameters, eliminating complex manual adjustments.

Furthermore, the touch screen provides a clear and concise display of test results, including absorbed energy and impact toughness. Users can effortlessly access and interpret the data, enabling prompt analysis and evaluation of material properties.

The user-friendly interface enhances the overall usability of the testing system, simplifying the testing process and reducing error risk. Touchscreen's responsive nature ensures swift navigation and smooth interaction, promoting a seamless testing experience.

You can also learn more about the product or receive a personalized quote.

Certainly! The Class J – Charpy and Izod Automatic Impact Testing System offers the convenience of a replaceable and interchangeable pendulum. This unique feature enables users to easily switch pendulums to accommodate different types of impact tests. Whether conducting Charpy, Izod, or other relevant impact tests, the system can be adapted by selecting the appropriate pendulum.

The versatility of the replaceable and interchangeable pendulum enhances the flexibility of the testing system, making it suitable for a wide range of materials and testing requirements. It simplifies the testing process and ensures accurate and reliable results, regardless of the material being evaluated. With the ability to tailor the pendulum to specific testing needs, the Class J system proves to be highly adaptable and efficient in meeting the demands of various applications and industries.

You can also learn more about the product or receive a personalized quote.

The rotating design of the Class J - Charpy and Izod Automatic Impact Testing System enables quick and accurate specimen center alignment for the Charpy test. This innovative feature simplifies the setup process and ensures precise positioning of the specimen.

By incorporating a rotating mechanism, the system allows for easy adjustment of the specimen's position, ensuring that it is aligned precisely at the center. This alignment is crucial for conducting accurate Charpy tests, as it ensures consistent and reliable results.

With the rotating design, users can swiftly and efficiently align the specimen without the need for complex manual adjustments. This saves time during testing and minimizes the risk of errors caused by misalignment.

You can also learn more about the product or receive a personalized quote.

Certainly! The supports on the Class J - Charpy and Izod Automatic Impact Testing System are securely fastened in place to ensure stability and reliability during impact tests. They are tightened firmly to minimize any potential movement or instability that could impact the accuracy of the results. The durable construction of the supports enables them to withstand the forces exerted during testing.

When it comes to changing the supports, the process is designed to be convenient and efficient. By removing just two bolts, the supports can be easily replaced or reconfigured. This streamlined process reduces downtime and allows for smooth transitions between different support configurations, catering to a variety of testing requirements.

You can also learn more about the product or receive a personalized quote.

Yes, the Class J - Charpy and Izod Automatic Impact Testing System is designed to allow for easy installation of low-temperature impact test accessories in the future. Its single column structure provides a broad test space, allowing flexibility for incorporating additional accessories and attachments.

The machine is engineered to support the seamless integration of low-temperature impact test accessories, enabling users to expand the testing capabilities of the system. This feature is particularly advantageous for industries that require testing at sub-zero temperatures to assess the impact performance of materials under extreme conditions.

The design of the Class J system prioritizes adaptability and future-proofing, recognizing the evolving needs of material testing. By offering the option to incorporate low-temperature impact test accessories, the machine ensures that users can enhance their testing capabilities without the need for extensive modifications or additional equipment.

You can also learn more about the product or receive a personalized quote.

Class J - Charpy and Izod Automatic Impact Testing System meets ISO179, GB/T 1043, and ASTM D6110 standards for charpy testing of plastics. The pendulum options enable precise impact testing of plastics and provide valuable insight into their mechanical properties.

GB/T 1043 and ISO179 standards specify pendulum options of 1J, 2J, 4J, 7.5J, 15J, 25J, and 50J. An impact test measures the amount of energy absorbed. It depends on the plastic and the standard of whether a pendulum is appropriate.

Additional pendulum options are specified in ASTM D6110. There are four levels of energy: 2.7J, 5.4J, 10.8J, and 21.6J. The ASTM standard specifies these energy levels for the testing of certain types of plastics.

You can also learn more about the product or receive a personalized quote.

The Class J - Charpy and Izod Automatic Impact Testing System offers specific pendulum options for Charpy testing of plastic pipes. These pendulum options are designed to meet the testing requirements of plastic pipe specimens. The system provides two main standards for Charpy testing of plastic pipes: ISO 9854.1 and ASTM D6110.

For ISO 9854.1, the system offers pendulum options of 15J and 50J. These pendulums are suitable for conducting Charpy tests on plastic pipe specimens according to this standard.

For ASTM D6110, the system provides pendulum options of 2.7J, 5.4J, 10.8J, and 21.6J. These pendulums are specifically designed for performing Charpy tests on plastic pipe specimens in accordance with this standard.

You can also learn more about the product or receive a personalized quote.

The Class J - Charpy and Izod Automatic Impact Testing System offers multiple pendulum options for Izod testing. For Izod testing according to ISO 179, GB/T1843, and GB/T1844 standards, the system provides pendulums with energy levels of 2.75J, 5.5J, 11J, and 22J. These pendulums are specifically designed to meet these standards' requirements and ensure accurate and high-quality impact tests on specimens.

Moreover, for Izod impact testing in accordance with the ASTM D256 standard, the system offers pendulums with energy levels of 2.7J, 5.4J, 10.8J, and 21.6J for Izod impact testing in accordance with this standard. In accordance with the ASTM D256 standard specifications, these pendulum options are calibrated and configured in accordance with the specifications needed to perform precise Izod impact testing on materials using these pendulums.

You can also learn more about the product or receive a personalized quote.

The Class J - Charpy and Izod Automatic Impact Testing System complies with the standards ISO 8256, GB/T 13525, and ASTM D1822, and offers energy levels of 7.5J, 15J, and 25J for tensile impact testing. The use of these energy levels allows the testing of the impact resistance and performance of materials to be accurate and reliable.

A variety of specimens can be handled by the system and precise results can be generated for a variety of applications utilizing the system. Its ability to carry out tests at multiple energy levels means that it provides flexibility and meets the requirements of different testing standards since it is able to perform tests at different levels of energy.

A Class J - Charpy and Izod Automatic Impact Testing System ensures reliable and consistent results regardless of whether you are evaluating the tensile impact properties of metals, plastics, or other materials in accordance with the specified energy levels.

You can also learn more about the product or receive a personalized quote.

The following are the energy levels for the Charpy and Izod tests in the Class J - Charpy and Izod Automatic Impact Testing System:

Charpy Test:

- 1 J: 0.5358983 Nm

- 2 J: 1.0717967 Nm

- 4 J: 2.1435935 Nm

- 5 J: 4.0192 Nm

- 15 J: 8.0385 Nm

- 25 J: 13.397 Nm

- 50 J: 26.795 Nm

Izod Test:

- 1 J: 0.5358983 Nm

- 75 J: 1.4737205 Nm

- 5 J: 2.94744 Nm

- 11 J: 5.8949 Nm

- 22 J: 11.7898 Nm

These energy levels indicate the amount of impact energy applied to specimens during testing. The values are measured in Newton-meters (Nm) and are crucial for assessing materials' impact resistance and toughness. The Class J - Charpy and Izod Automatic Impact Testing System offers a range of energy levels to accommodate different testing requirements and ensure a comprehensive evaluation of material properties.

You can also learn more about the product or receive a personalized quote.

The Class J - Charpy and Izod Automatic Impact Testing System offers different energy levels for the Tensile Impact test. The available energy levels and their corresponding values in Newton-meters (Nm) are as follows:

- 5 J: This energy level corresponds to 4.01923 Nm.

- 15 J: 15 J's energy level is equivalent to 8.03847 Nm.

- 25 J: At 25 J, the corresponding value is 13.39745 Nm.

These energy levels represent the amount of energy applied during the Tensile Impact test. The higher the energy level, the greater the impact force experienced by the specimen. By offering multiple energy levels, the testing system allows for a range of impact forces to be applied, which is critical for assessing materials' performance and mechanical properties under different conditions.

You can also learn more about the product or receive a personalized quote.

The Class J - Charpy and Izod Automatic Impact Testing System has an angle of striking 150°. This refers to the angle at which the pendulum strikes the specimen during the impact testing process. The 150° angle is a standardized measurement used in Charpy and Izod impact testing methods.

The angle of striking is a critical parameter as it determines the direction and force of impact applied to the specimen. By striking the specimen at a specific angle, the testing system ensures consistency and reproducibility of test results. The 150° angle is widely accepted in various standards and regulations governing impact testing procedures.

By using the Class J - Charpy and Izod Automatic Impact Testing System, you can confidently perform impact tests on various materials, including plastics and rubber specimens, with the assurance that the specified striking angle will be maintained. This will allow for accurate and reliable impact property measurement.

You can also learn more about the product or receive a personalized quote.

The reading resolution of the digital display on the Class J - Charpy and Izod Automatic Impact Testing System is 0.01J. Meaning that the digital display can show impact energy values with 0.01 joules precision.

The reading resolution of the digital display is a vital feature as it allows for accurate and precise measurement of the impact energy absorbed by the specimen during testing. With a resolution of 0.01J, the system provides detailed and reliable data, enabling precise analysis and comparison of impact properties.

This high reading resolution ensures that even small changes in impact energy can be accurately captured and recorded. It enhances the sensitivity and accuracy of the testing system, enabling researchers, engineers, and quality control professionals to obtain precise impact test results and make informed decisions based on the data generated by the Class J - Charpy and Izod Automatic Impact Testing System.

You can also learn more about the product or receive a personalized quote.

The power supply specification for the Class J - Charpy and Izod Automatic Impact Testing System is AC220V, 50Hz, 0.3kW.

The system operates on an alternating current (AC) power supply with 220 voltage. The power supply frequency is 50 hertz, which is the standard frequency in many regions. The system consumes 0.3 kilowatts (kW).

Having a specific power supply specification is essential for maintaining the testing system's proper functioning and reliability. The AC220V voltage requirement ensures that the system receives the necessary electrical power to operate effectively. The 50Hz frequency ensures synchronization with the power grid frequency, preventing power fluctuations.

The 0.3kW power consumption indicates the amount of electrical power the system requires during operation. This information is helpful for power management and understanding system energy requirements.

By adhering to the specified power supply, users can ensure the stable and efficient operation of the Class J - Charpy and Izod Automatic Impact Testing System.You can also learn more about the product or receive a personalized quote.

The Class J - Charpy and Izod Automatic Impact Testing System has dimensions of 1000x300x760mm (Length x Width x Height).

The machine's length is 1000mm, its width is 300mm, and its height is 760mm. These measurements indicate the testing system's physical size and space requirements. The length dimension refers to the horizontal extent of the machine, the width dimension represents the side-to-side measurement, and the height dimension indicates the vertical height of the system.

Considering machine dimensions is imperative for several reasons. It helps determine the amount of space required for installation and operation, ensuring that the testing system fits comfortably in the designated area. Additionally, knowing the dimensions can help plan the layout of the testing laboratory or facility, optimizing workflow and accessibility.

The 1000x300x760mm dimensions provide a compact and space-efficient design, making the Class J - Charpy and Izod Automatic Impact Testing System suitable for various testing environments while maintaining its functionality and performance.

You can also learn more about the product or receive a personalized quote.

The Class J - Charpy and Izod Automatic Impact Testing System weighs 140kg. The weight of the testing system is a crucial specification to consider as it provides information about the machine's stability and transportability. A weight of 140kg indicates that the testing system is relatively heavy, which contributes to its stability during operation, minimizing vibrations and ensuring accurate test results.

Additionally, weight affects transportation and installation. A machine of this weight may require proper equipment or assistance during setup. It is crucial to ensure that the testing system is placed on a stable and secure surface to prevent accidents or damage.

Considering the weight of 140kg, it is advisable to make appropriate arrangements for the transportation and positioning of the Class J - Charpy and Izod Automatic Impact Testing System to ensure its safe and efficient use in the desired testing environment.

You can also learn more about the product or receive a personalized quote.

The specified velocities of striking for the Class J - Charpy and Izod Automatic Impact Testing System are as follows:

ISO 179, GB/T 1043:

- For impact energies ≤5J: The velocity of striking is 2.9m/s.

- For impact energies >5J: The velocity of striking is 3.8m/s.

ASTM D6110:

- The velocity of striking is 3.46 m/s.

These velocities indicate the speed at which the pendulum strikes the specimen during impact testing. Impact velocity is an essential parameter that affects the energy absorbed by the specimen and influences the test results. Different standards may specify different velocities to ensure standardized testing conditions.

It is critical to adhere to the specified velocities of striking when conducting impact tests to ensure accurate and comparable results. The Class J - Charpy and Izod Automatic Impact Testing System provides the capability to adjust and control the striking velocity based on the specified requirements of ISO 179, GB/T 1043, and ASTM D6110 standards.

You can also learn more about the product or receive a personalized quote.

The specified distances from the axis of support to the center of percussion for the Class J - Charpy and Izod Automatic Impact Testing System are as follows:

ISO 179, GB/T 1043:

- For impact energies ≤5J: The distance from the axis of support to the center of percussion is 230mm.

- For impact energies >5J: The distance from the axis of support to the center of percussion is 395mm.

ASTM D6110:

- The distance from the axis of support to the center of percussion is 327mm.

The distance from the axis of support to the center of percussion is a critical parameter in impact testing. It represents the effective lever arm length, which influences the moment of inertia and the energy transferred to the specimen during impact. Different standards may specify different distances to ensure consistent and reliable test results.

The Class J - Charpy and Izod Automatic Impact Testing System offers the capability to adjust the distance from the axis of support to the center of percussion based on the specific requirements of ISO 179, GB/T 1043, and ASTM D6110 standards, enabling accurate and standardized impact testing procedures.

You can also learn more about the product or receive a personalized quote.

The specified spans for the Class J - Charpy and Izod Automatic Impact Testing System are as follows:

ISO 179, GB/T 1043:

- The system offers flexibility to adjust the span using span blocks. The available span options are 40mm, 60mm, and 70mm. This means that the user can select the desired span by using the appropriate span block.

ASTM D6110:

- Specifies 95.3mm.

The span is a critical parameter in impact testing as it determines the specimen support width during testing. Different test standards may specify different spans to accommodate various types of specimens and ensure consistent testing conditions.

With the Class J - Charpy and Izod Automatic Impact Testing System, users can adjust the span according to ISO 179, GB/T 1043, and ASTM D6110. This versatility allows precise and accurate testing of a wide range of materials and specimens.

You can also learn more about the product or receive a personalized quote.

The specified radius of striker edge values for the Class J - Charpy and Izod Automatic Impact Testing System are as follows:

ISO 179, GB/T 1043:

- The specified radius of striker edge is 2±0.5mm. This means that the striker edge radius should be within 1.5mm to 2.5mm.

ASTM D6110:

- The specified radius of striker edge is 3.17±0.12mm. This means that the striker edge radius should be within the range of 3.05mm to 3.29mm.

The radius of the striker edge is a crucial parameter in impact testing as it determines the striking surface geometry. It affects the stress distribution and fracture behaviour of the tested specimens. The specified values ensure consistency and standardization in impact testing according to the respective standards.

With the Class J - Charpy and Izod Automatic Impact Testing System, users can ensure compliance with the specified radius of striker edge values for ISO 179, GB/T 1043, and ASTM D6110. This facilitates accurate and reliable impact testing results.

You can also learn more about the product or receive a personalized quote.

The specified specimen dimensions for the Class J - Charpy and Izod Automatic Impact Testing System, as per ISO 179 and GB/T 1043, are 80mm in length (L), 10mm in width (W), and 4mm in height (H). Based on these dimensions, it can be concluded that the specimen should have a rectangular shape with a length of 80mm, a width of 10mm, and a height of 4mm, all of which indicate a rectangular shape.

Contrary to ASTM D6110, the specimen dimensions are 127mm long, 12.7mm wide, and 3mm to 12.7mm high. As a result, specimens can vary in height within the range of 3mm to 12.7mm, while maintaining the specified length and width.

It is crucial to adhere to the specified specimen dimensions to ensure accurate and consistent testing results. By following the prescribed dimensions according to ISO 179, GB/T 1043, and ASTM D6110, users can conduct impact testing in accordance with the respective standards, enabling reliable comparisons and compliance with international testing requirements.

You can also learn more about the product or receive a personalized quote.

The Class J - Charpy and Izod Automatic Impact Testing System, a sophisticated and versatile machine meticulously engineered for impact tests on plastic pipes, employs an angle of striking 150 degrees during the Charpy test. The angle of striking is a crucial parameter in the test, determining the direction and force with which the pendulum strikes the plastic pipe specimen. By precisely controlling the angle of striking, the testing system ensures a consistent and accurate evaluation of the material's impact resistance properties.

The choice of 150 degrees as the striking angle is not arbitrary; rather, it is based on standardized testing procedures and industry specifications. This specific angle has been carefully determined and validated to provide meaningful and reliable results in assessing the performance and durability of plastic pipes under impact loads. By subjecting the pipes to controlled impacts at this defined angle, the Charpy test allows for a comprehensive evaluation of their ability to withstand sudden impacts and potential damage. This provides valuable insights for design, manufacturing, and quality control processes.

You can also learn more about the product or receive a personalized quote.

The Class J - Charpy and Izod Automatic Impact Testing System, when used to perform the Charpy Test on plastic pipes in accordance with the ISO 9854.1 standard, requires a specified velocity of striking of 3.8m/s. The striking velocity refers to the speed at which the pendulum impacts the plastic pipe specimen during the test. It is a crucial parameter that determines the energy transferred to the specimen and influences its fracture behaviour.

By complying with ISO 9854.1 standard and utilizing the Class J - Charpy and Izod Automatic Impact Testing System with the specified striking velocity of 3.8m/s, accurate and standardized testing can be conducted to evaluate the impact resistance and overall performance of plastic pipes. This information ensures a reliable and consistent assessment of plastic pipe materials in accordance with the specified test requirements.

You can also learn more about the product or receive a personalized quote.

As per the ISO 9854.1 standard, the Class J - Charpy and Izod Automatic Impact Testing System specifies a distance of 395mm between the axis of support and the center of percussion. This measurement denotes the precise distance between the support point for the plastic pipe specimen and the exact location on the pendulum where the impact force is applied during testing. Adhering to this specified distance is crucial for ensuring a standardized and accurate assessment of plastic pipes' impact resistance characteristics.

By maintaining consistency in the distance between the support and the center of percussion, manufacturers, researchers, and quality control personnel can obtain reliable test results. This will enable them to evaluate plastic pipes' performance and durability in different applications. The prescribed distance plays a significant role in ensuring test performance comparability and reliability, enabling effective quality assurance and product evaluation.

You can also learn more about the product or receive a personalized quote.

The Class J - Charpy and Izod Automatic Impact Testing System offers span options of 40mm, 60mm, 62mm, and 70mm for the purpose of conducting Charpy tests on plastic pipes in compliance with ISO 9854.1. With these span options, it is possible to choose the right distance between the supports for a test specimen based on the distance between the supports. There is a wide range of span sizes to meet the needs of a variety of pipe sizes and to ensure accurate and reliable test results.

As a result of the system's adjustable span feature, users are able to customize the setup of the testing based on the specific requirements they have, ensuring compliance with the ISO standard at all times. The testing system can be adjusted with a variety of span options, so that it is suitable for a wide range of plastic pipe applications, enhancing its versatility.

You can also learn more about the product or receive a personalized quote.

In accordance with the ISO 9854.1 standard, the radius of the striker edge on the Class J - Charpy and Izod Automatic Impact Testing System for the Charpy Test of plastic pipes according to this standard is 3.17±0.12mm. As the name implies, this parameter refers to the curvature of the striking edge of the striker that was used in the test. It is the precise radius specification that assures accurate and consistent results by maintaining the intended impact conditions during the testing process.

As part of the impact testing process, the striker edge radius plays a crucial role in determining how much energy is absorbed by the plastic pipe and how it fractures under impact. By adhering to the specified radius, the testing system can effectively evaluate the impact resistance and mechanical properties of plastic pipes according to the ISO 9854.1 standard.

You can also learn more about the product or receive a personalized quote.

The specified dimensions of the first type specimen for the Charpy Test of plastic pipe in the Class J - Charpy and Izod Automatic Impact Testing System are as follows:

- Length: 100±2mm

- Width: Whole pipe

- Thickness: 70±0.5mm

The specimen length is controlled within a 2mm tolerance to ensure measurement consistency. The width of the specimen, in the case of a whole pipe, is not specified in a specific measurement. This indicates that the entire pipe width is used. The specimen thickness is maintained within a 0.5mm tolerance to adhere to standardized dimensions. These specifications ensure that the testing process is conducted on a consistent and representative sample of plastic pipe.

You can also learn more about the product or receive a personalized quote.

The specified dimensions of the second type specimen for the Charpy Test of plastic pipe in the Class J - Charpy and Izod Automatic Impact Testing System are as follows:

- Length: 50±1mm

- Width: 6±0.2mm

- Thickness: e (machining pipe thickness)

- Support span: 40±0.5mm

In the case of the second type specimen, the length is controlled within a 1mm tolerance, ensuring consistent measurement. The width is specified as 6±0.2mm, which determines the specimen width. The thickness is denoted by an "e," representing the machining pipe thickness, which may vary depending on the specific requirements of the testing process. The support span, which is the distance between supports during testing, is maintained at 40±0.5mm. These dimensional specifications ensure standardized testing conditions for the second type specimen in the Charpy Test of plastic pipe.

You can also learn more about the product or receive a personalized quote.

The specified dimensions of the third type specimen for the Charpy Test of plastic pipe in the Class J - Charpy and Izod Automatic Impact Testing System are as follows:

- Length: 120±2mm

- Width: 15±0.5mm

- Thickness: e (machining pipe thickness)

- Support span: 70±0.5mm

In the case of the third type specimen, the length is controlled within a 2mm tolerance, ensuring consistent measurement. The width is specified as 15±0.5mm, which determines the specimen width. The thickness is denoted by an "e," representing the machining pipe thickness, which may vary depending on the specific requirements of the testing process. The support span, which is the distance between the supports during testing, is maintained at 70±0.5mm. These dimensional specifications ensure standardized testing conditions for the third type specimen in the Charpy Test of plastic pipe.

You can also learn more about the product or receive a personalized quote.

The Izod Test in the Class J - Charpy and Izod Automatic Impact Testing System follows the following standards and angles of striking:

- Standard: ISO 180, ASTM D256

- Angle of striking: 150° (ISO 180), 145.2° (ASTM D256)

The ISO 180 standard specifies the test method for plastic impact strength determination using the Izod test. In this test, the striking angle is set at 150°, which refers to the angle at which the pendulum strikes the specimen.

Similarly, the ASTM D256 standard also describes the test method for determining plastic impact resistance using the Izod test. However, in this case, the striking angle is slightly different, namely 145.2°.

You can also learn more about the product or receive a personalized quote.

A standard striking specification and speed defined by ISO 180 and ASTM D256 is followed when carrying out the Izod Test using the Class J - Charpy and Izod Automatic Impact Testing System.

In accordance with ISO 180, a standard that outlines the method for determining plastic impact strength through the Izod test is an international standard. In this test, the angle of impact is set at 150°, and the strike velocity is maintained at 3.5 m/s.

According to ASTM D256, the Izod test, developed by ASTMA for evaluating plastics' impact resistance, may also be used to evaluate plastic's impact resistance. The angle of strike in this standard differs slightly from the one in the previous standard, which is 145.2°, as well as the velocity of strike which is specified as 3.46 m/s.

You can also learn more about the product or receive a personalized quote.

The Class J - Charpy and Izod Automatic Impact Testing System for the Izod Test provides a specified distance from the axis of support to the center of percussion, which is measured at 335 mm. This distance is a critical parameter in the Izod Test as it determines the leverage and moment of the pendulum when it strikes during impact. By setting the distance to 335 mm, the testing system ensures consistent and reliable test results for assessing materials' impact resistance and strength.

The distance from the axis of support to the center of percussion is a critical factor in properly simulating real-world impact scenarios and evaluating materials' ability to withstand sudden external forces. It plays a significant role in determining the energy transfer and fracture behaviour of test specimens. Therefore, by maintaining a precise distance of 335 mm, the Class J - Charpy and Izod Automatic Impact Testing System ensures accurate and standardized Izod Test measurements.

You can also learn more about the product or receive a personalized quote.

The Class J - Charpy and Izod Automatic Impact Testing System for the Izod Test provides a specified distance from the striking knife center to the vice upper surface, which is measured at 22±0.2 mm. This distance is a crucial parameter in the Izod Test as it determines the position of the striking knife in relation to the vice upper surface during impact. By setting the distance to 22 mm with a tolerance of ±0.2 mm, the testing system ensures precise and consistent positioning for reliable test results.

The distance from the striking knife center to the vice upper surface is crucial for accurately aligning the test specimen and ensuring proper contact between the striking knife and the specimen during impact. It affects the transfer of energy and the resulting fracture behaviour, thus influencing the measured impact strength of the material. Therefore, maintaining a precise and specified distance of 22 mm is essential for conducting standardized and reliable Izod Tests.

You can also learn more about the product or receive a personalized quote.

The Class J - Charpy and Izod Automatic Impact Testing System for the Izod Test provides a specified radius of the striker edge, which is measured at 0.8±0.2 mm. This radius refers to the curvature of the striker edge used in the test. By setting the radius to 0.8 mm with a tolerance of ±0.2 mm, the testing system ensures consistency and accuracy in the impact test results.

The radius of the striker edge is an important parameter as it affects the way the striker contacts and interacts with the test specimen during impact. A precise and specified radius ensures that the force is applied uniformly and consistently across the specimen, leading to reliable and comparable test results. The radius also influences the stress concentration at the point of impact, which can affect fracture behaviour and the measured impact strength of the material.

Therefore, maintaining a specified radius of 0.8 mm with a tolerance of ±0.2 mm is crucial for conducting standardized Izod Tests and obtaining accurate and reliable impact test data.

You can also learn more about the product or receive a personalized quote.

Related Products

Class D Single-Column Charpy Impact Tester – High-Precision Pendulum Testing Machine

NextGen’s Class D Single-Column Charpy Impact Testing System is built for high rigidity and dependable specimen testing across a wide energy range. It supports impact energies from around 150 J (111 ft-lbs) up to around 750 J (553 ft-lbs), covering most standard metal testing needs. The unit includes a digital display and offers a software upgrade option for data plotting. Additional features, such as automated specimen feeding and integrated cooling or heating systems, are available as optional enhancements.

Class G Single-Column Charpy & Izod Impact Tester – High-Precision Pendulum Testing Machine

NextGen's Class G – Single Column Charpy and Izod Impact Testing system provides a high level of rigidity and specimen testing capacity. This Charpy and Izod Impact tester has a minimum capacity of 150 J (111 ft/lbs) and a maximum capacity of 750 J (553 ft/lbs). The system comes standard with a digital display with software upgrade function for data plotting. The Class G impact system can also include automatic specimen feeding, cooling and heating systems as optional upgrades.

Class H - Servo-Motor Dual Column Charpy Impact Tester - 300J, 450J, 600J or 750J

NextGen's Class H – Servo-Motor Dual Column Charpy Impact Testing system offers of an exceptional combination of versatility and robust build. This impact system provides our most durable options designed with a dual column configuration. The system offers the ultimate versatility of testing 300J (212 ft/lbs), 450J (332 ft/lbs), 600J (442 ft/lbs) and a maximum of 750J (553 ft/lbs) capacities based on both Charpy and Izod test methods. The unit comes standard equipped with a servo motor and is designed to test at any preset angle. The unit comes standard with all the functions of our Class G tester as well as enhanced functionality upgrade of a force transducer inside the strikerwhich enables the determination of characteristic force, energy and displacement parameters such as pre-maximum force energy (Wm), the post maximum force energy, the general yield force (Fgy), the force at brittle fracture initiation (Fbf) and the arrest force (Fa).

Triple Specimen Chamber Motorized Charpy Notch Making Machine

The GenNotch 4000UPG Series is a motorized Charpy & Izod Notch Making Machine with a triple specimen chamber.

Specimen Notching/Broaching Machine

NextGen offers an economical solution for Specimen notching and broaching for Charpy and Izod specimens. This certified system complies with ASTM ISO148, EN10045, ASTM E23, DIN 50115 standards. This automated, motorized solution is capable of preparing two specimens at any one given time up to 46 HRC. A variety of broaches are available for different geometries of notches.

Impact Specimen Cooling and Heating Temperature Chamber – GenChamber

NextGen offers a full range of impact specimen cooling and heating chamber designed to meet virtually all Charpy, Izod and Tensile Impact Testing requirements. NextGen's temperature chambers are a combination of user-friendliness, compact and robust build, offering the ultimate versatility of cooling and heating requirements.

Charpy/Izod Notch Verification Projector System NG-NPS-CIS

Enhance your material testing accuracy with our advanced Charpy/Izod Notch Verification Projector System NG-NPS-CIS.

DWT-1800 Computer Controlled Drop Weight Impact Testing Machine

DWT-1800 Impact Testing Machine is specifically designed for determining the non-plastic transformation temperature of ferritic steel.

Low-capacity Vertical Drop Weight Testers Up To 2000J NG-FWT1 & NG-FWT2

Discover NextGen's NG-FWT1 & NG-FWT2 low-capacity drop weight testers up to 2000J (1475 ft/lbs), designed for precise impact resistance testing of metals & non-metals.