Metal Testing Equipment

Standards

UL 651, UL1, UL360, UL1660, UL797, UL6, UL1242

Description

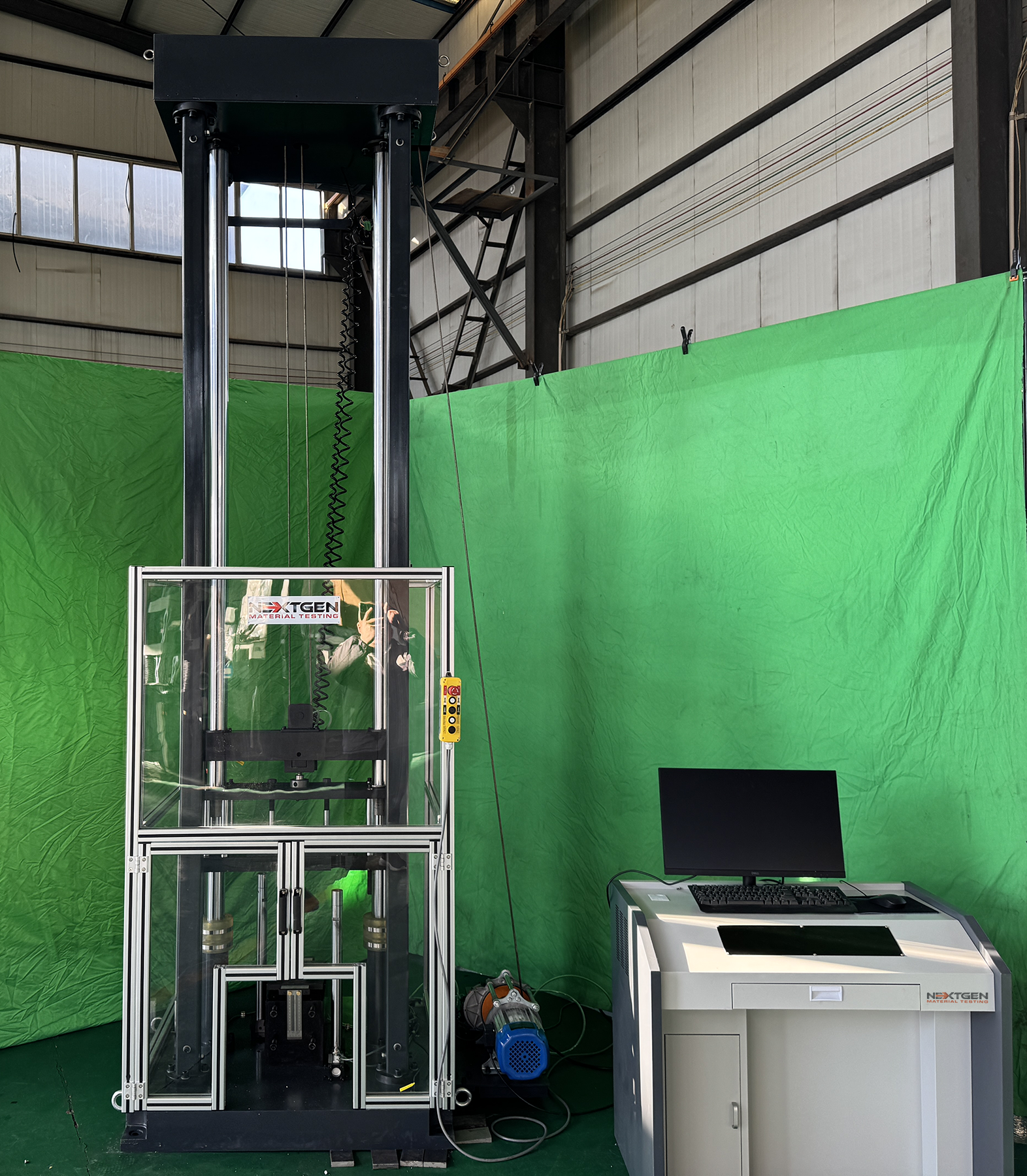

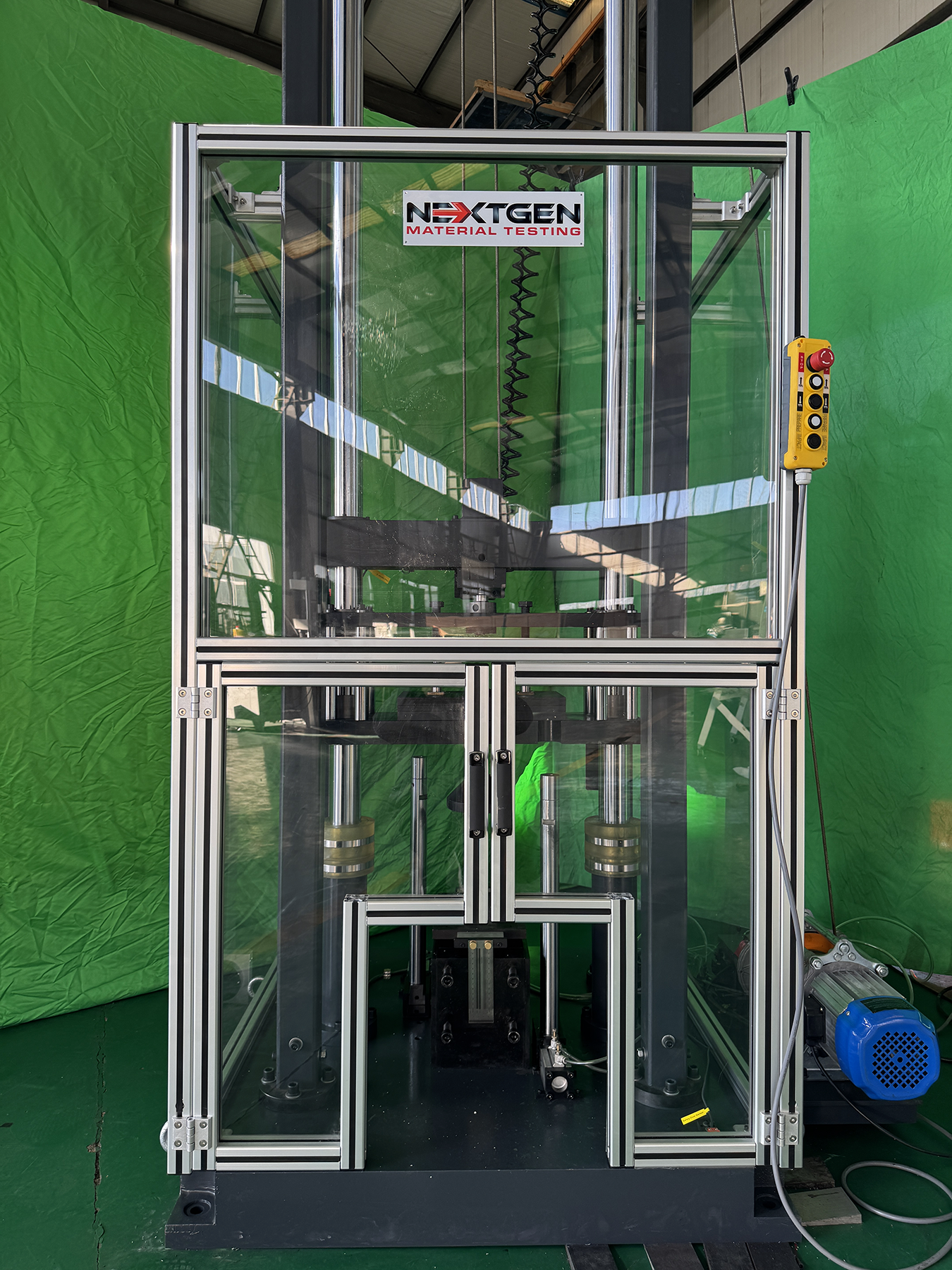

The DWT-1800 Computer Controlled Drop Weight Impact Testing Machine is a high-performance, PLC-driven system that is designed to assess the impact resistance of a diverse array of metal and non-metal materials. The DWT-1800 is an extremely versatile tool for product validation, quality assurance, and material certification processes, as it is capable of performing high-energy impact tests up to 1800 joules and low-energy tests as small as 3.72 joules.

This drop weight impact tester is commonly used to assess the nil-ductility transition (NDT) temperature of ferritic steel, which includes plates, profiles, forged steel, and cast components. It is also equally effective in testing materials such as rigid PVC conduits, metal conduits, electrical tubing, cable support hardware, and flush-mounted electrical enclosures. The machine is fully compliant with an extensive number of UL impact testing standards, such as UL651, UL1, UL360, UL1660, UL797, UL6, UL1242, UL1569, UL514C, UL514D, and UL2239. This allows laboratories and manufacturers to conduct certified impact resistance testing within a range of industrial applications.

The DWT-1800's intuitive software interface enables users to pre-set hammer weight, target energy, and drop height with its advanced computer-controlled system. Through the use of a precision wire encoder, touchscreen controls, and photoelectric sensors, the system executes and calculates test sequences automatically, guaranteeing real-time monitoring and highly accurate energy readings. The hammer lift, release, and grasp functions are fully automated to guarantee a safe and efficient operation.

The machine's frame is robust and includes a heavy-duty base, an adjustable sample seat (with a height tolerance of up to 50 mm), guidance columns, and multiple interchangeable impact hammers and anvils that can handle an array of specimen geometries. The testing integrity is guaranteed by a built-in anti-secondary impact device, which prevents rebound strikes. Additionally, the adjustable locking rings support an effortless shift between high-energy and UL-specific low-energy tests. More context and real-world applications are covered in our blog.

The DWT-1800 was built for long-term durability, low maintenance, and installation on a stable concrete foundation, and is constructed from industrial-grade 45# steel. The modular components of the system, such as hammers, anvils, and protective elements, are easily serviceable or replaceable, thereby guaranteeing long-term performance and minimal downtime in rigorous testing environments.

Technical Specifications of the DWT-1800 Impact Testing Machine

| Specification | Values |

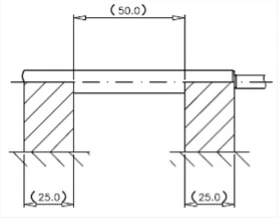

| Sample Length Specification |

Standard UL651 |

| Sample Length |

6 inches (152.4 mm) |

| Sample Size |

16 mm – 152.4 mm |

| Anvil Size |

13 mm steel plate |

| Test Temperature |

23°C ±2°C |

| Impact Hammer – Heavy Hammers | 397 lb (180 kg), 600 lb (272 kg) |

|

Impact Hammer – Light Hammers

|

9.1 kg, 34 kg, 1.36 kg, 4.54 kg, 22.7 kg, 2.72 kg |

|

UL Standard Impact Hammers

|

Right Cylindrical (Flat Face): Diameter: 1″, 1-1/8″, 2″, 6″

Rectangular: ¾″ × 6″ (Width: 3/8″) (Polyurethane), 2″ × 6″, 3″ × 6″ |

|

Sample Seat

|

According to customer requirements in compliance with UL standards

|

|

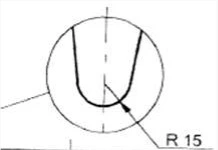

Impact Hammer Knife Radius

|

R25 mm or R50 mm (Produced according to customer requirements)

|

| Deviation Between Central Line of Drop Hammer and Sample Seat |

≤ ±2.5 mm

|

| Lifting Height of Falling Weight | 3.94″ – 131.9″ (100 mm – 3350 mm) |

| Precision of Falling Weight Lifting Height | ±0.5% |

| Rockwell Hardness of the Drop Hammer Blade and Supporting Table | HRC ≥ 50 |

| Machine Size | 50.4″ × 51.2″ × 177.2″ (1280 × 1300 × 4500 mm) |

| Machine Weight | Approx. 5512 lb (2500 kg) |

Specification Comparison: Low vs High Impact Hammer

| Specification | DWT-1800 LIH (Low Impact Hammer) | DWT-1800 HIH (High Impact Hammer) |

| Hammer Size | Diameter: 2″ (50.8 mm) | Diameter: 6″ (152.4 mm) |

| Hammer Weight | 20.1 lb (9.1 kg) | 74.9 lb (34 kg) |

| Impact Height | 3.94″ – 131.9″ (100 mm – 3350 mm) | 3.94″ – 83.9″ (100 mm – 2130 mm) |

| Impact Energy | 6.57 – 220.3 ft-lbf (8.9 J – 298.7 J) | 24.6 – 523.3 ft-lbf (33.3 J – 709.7 J) |

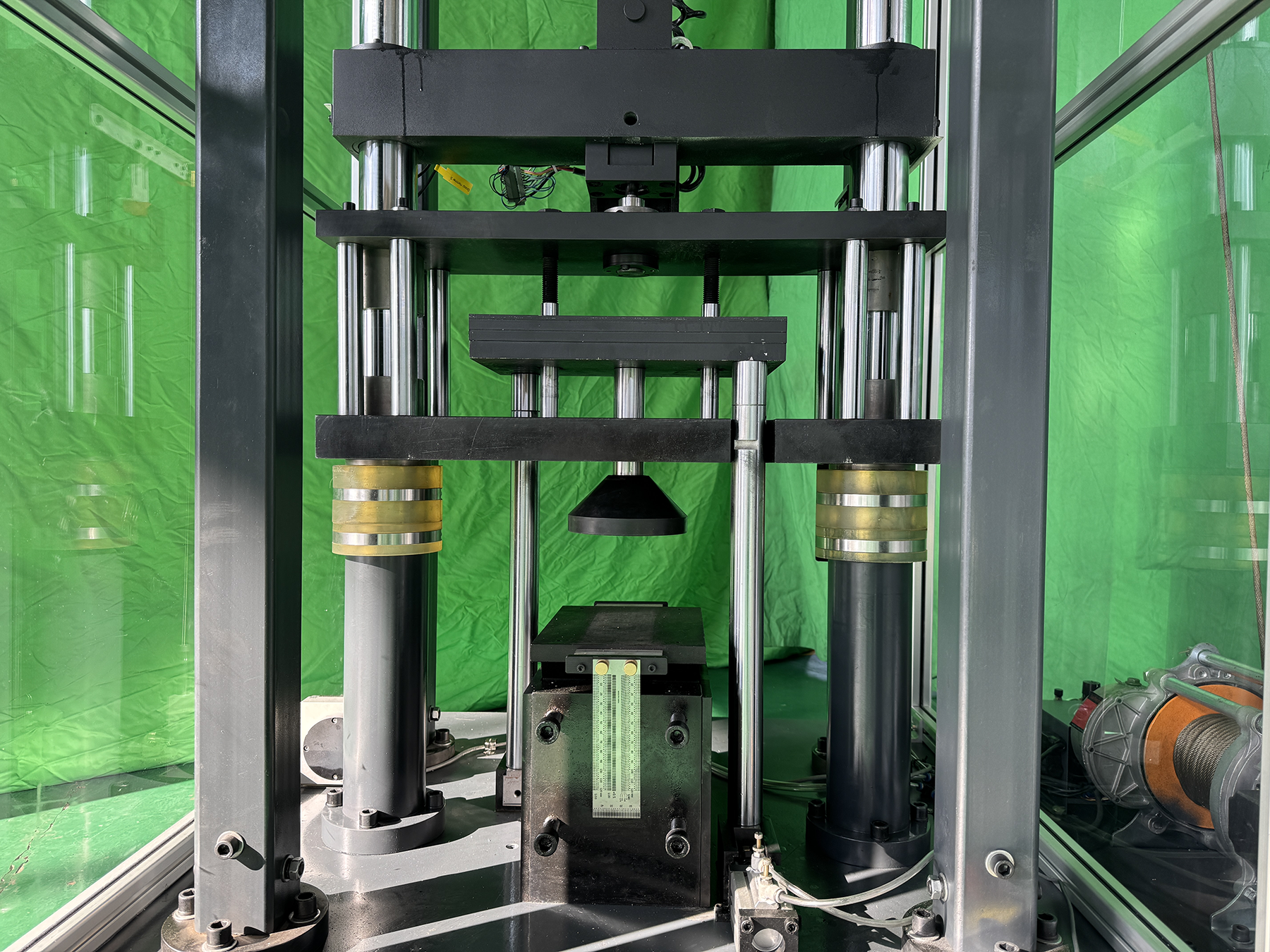

Working Principle and Structural Overview

The DWT-1800 Drop Weight Impact Testing Machine was built with a focus on durability, safety, and precision. A steel-reinforced base, dual guide columns, a configurable hammer assembly, and a dependable lifting mechanism comprise the system's robust mechanical structure. The hammer is dropped along a strictly controlled linear path by the vertical guide rail, which is perfectly aligned with the base.

The crossbeam can be raised or lowered by an anchor chain mechanism to adjust the testing height. The hammer body is equipped with a mechanical locking block and reinforced side protection to prevent debris projection in the event of specimen failure. This feature is required for the safety of the operator.

The microcomputer-controlled pre-set system is a critical functional component that enables users to program precise hammer weights and impact energy values. The machine achieves consistent test conditions by automatically lifting the hammer to the calculated height before initiating the drop once the parameters have been defined.

The DWT-1800 is equipped with an integrated electric winding engine that is mounted to the side of the frame for better operational efficiency. The total vertical footprint of the equipment is reduced, structural stability is improved, and routine maintenance procedures are simplified by this compact motorized system.

How to Operate the DWT-1800 Impact Testing Machine

Operating the DWT-1800 Computer Controlled Drop Weight Impact Testing Machine is a streamlined process, combining automation with high precision. The system is equipped with an intuitive touchscreen interface and a PLC-driven measurement and control unit that manages the entire test cycle — from pre-setting parameters to capturing final energy readings.

To begin, the operator inputs key test parameters into the control software, including the hammer weight, target impact energy, and local gravitational acceleration. The system automatically calculates the required drop height based on these settings. The hammer is then raised by the motorized winding engine, with its position monitored by a wire encoder and photoelectric sensors to guarantee precise height alignment. Once the hammer reaches the programmed height, it pauses automatically. With the specimen in place, a single click of the “Impact” button releases the hammer to execute the test.

Throughout the test cycle, impact energy values are calculated and displayed in real time, while the anti-secondary impact device prevents rebound errors. Safety is reinforced by features such as a lockable safety pin for setup phases, an enclosed impact zone, and automatic grasping of the hammer post-impact via pneumatic control.

The DWT-1800 also supports multiple UL test setups. Operators can easily swap hammer types and anvils, adjust sample seat height up to 50 mm with built-in leveling gauges, and reconfigure locked ring positions for high- or low-energy tests. Detailed guidance is provided in the software interface, and first-time users are prompted to perform a blank drop to calibrate the system.

Please note that custom solutions with varying impact energy, hammer weights, and lift heights are available and customizable to match your specific testing requirements.

Who Can Benefit from the DWT‑1800 Drop Weight Impact Testing Machine

Many sectors rely on drop weight impact testing to evaluate how materials behave under real-world conditions. The DWT‑1800 is particularly useful in:

-

Metal manufacturing and steel processing, where it’s used to determine the nil-ductility transition (NDT) temperature of ferritic steels such as plates, profiles, cast steel, and forged components.

-

Electrical and cable conduit production, where manufacturers test PVC and metallic/non-metallic conduits for compliance with UL standards like UL 651, UL 1, UL 360, and others.

-

Electrical enclosure and hardware industries, where the impact resistance of device boxes, outlet covers, and support fittings must meet requirements such as UL 514C, UL 514D, and UL 2239.

-

Construction and infrastructure, where conduit systems, cable supports, and related components are expected to maintain integrity under mechanical stress or impact.

-

Automotive and aerospace sectors, which require in-depth analysis of how structural and shielding materials perform under dynamic loading and crash-like conditions.

-

Packaging and logistics, where drop impact tests help evaluate packaging materials and designs for strength and shock resistance under ASTM-related standards.

The DWT‑1800 is also built to serve testing labs, R&D teams, and production environments. It’s regularly used by:

-

Materials engineers and lab technicians, to gather reliable data on impact energy absorption and fracture behavior.

-

Quality assurance and regulatory professionals, to confirm product compliance with standardized testing methods.

-

Designers and product developers, who use test results to improve material selection, safety margins, and long-term performance.

-

Independent testing laboratories, which provide certified test results for manufacturers and regulatory bodies.

FAQs

For your maintenance and installation team, we provide a detailed Maintenance and Set Up FAQ document, which includes foundation specs, electrical setup, air supply requirements, and calibration steps.

This guide ensures smooth installation, safe operation, and proper long-term care of the system. Contact us for further assistance or training options.

Click here to learn more about the product or here to receive a personalized quote.

Minimal maintenance is needed. Key tasks include:

-

Monthly inspection of the air pump

-

Regular checks of bolts, nuts, and sensors

-

Occasional lubrication and cleaning of guidance columns

The machine is designed for low wear and long-term use, with easily replaceable modular parts like anvils, pads, and encoders. Simple upkeep keeps the system fully reliable.

Click here to learn more about the product or here to receive a personalized quote.

Yes — multiple safety features are built in. The DWT‑1800 includes a lockable safety pin, protective shields, automatic hammer grasping, and a software-controlled anti-rebound device.

During setup or maintenance, users can lock the hammer in place. All high-impact tests are performed within an enclosed zone, and impact sequences cannot begin until all safety conditions are met.

Click here to learn more about the product or here to receive a personalized quote.

Precision and repeatability are central to the DWT‑1800’s performance. The system uses a wire encoder, photoelectric sensors, and automated drop height calculations to maintain consistent impact energy.

With a height control accuracy of ±0.5% and built-in anti-secondary impact protection, it delivers highly repeatable test results under consistent conditions, crucial for certification, research, and compliance.

Click here to learn more about the product or here to receive a personalized quote.

Yes — full adaptability. The DWT‑1800 supports sample diameters from 16 mm to 152 mm and beyond, depending on the selected hammer and anvil.

Its adjustable sample seat allows precise height positioning with the help of built-in rulers and level indicators. This makes it suitable for ferritic steel plates, PVC conduits, castings, enclosures, and more — even with custom geometries.

Click here to learn more about the product or here to receive a personalized quote.

UL standards compliance is a core function of the DWT‑1800. The machine supports a wide range of UL specifications, including UL 651, UL 1, UL 360, UL 1660, UL 797, UL 6, UL 1242, UL 514C, UL 514D, UL 1569, and UL 2239. It is specifically designed for UL-certified impact resistance testing in conduit, cable, and enclosure-related applications.

Click here to learn more about the product or here to receive a personalized quote.

A key factor in ensuring the longevity and sustained performance of the DWT-1800 Computer Controlled Drop Weight Impact Testing Machine is the availability of stocked consumables and spare parts. It is essential that these essential components are available on a timely basis to maintain consistency in testing and operational reliability.

Maintaining a well-stocked inventory of consumables and spares serves two purposes: first, to prevent unforeseen disruptions in the machine's operation due to wear or malfunction of components, and second, to ensure that DWT-1800 users can access the necessary parts promptly whenever they are needed, thus reducing possible delays in testing.

To maintain the accuracy and reliability of impact testing, consumables, such as impact blades and other wear-prone components, are kept in ready stock. Consumables are manufactured to exact specifications, ensuring seamless integration and maintaining the integrity of test results.

Furthermore, spare parts necessary for the machine's operation are readily available. The DWT-1800 can thus be quickly repaired or replaced in the event of wear or failure, maintaining its operational continuity and safeguarding ongoing research or quality control activities.

Click here to learn more about the product or here to receive a personalized quote.

The Trusted After Sales Technical Support is a valuable resource for users to rely on following the purchase of the DWT-1800 Computer Controlled Drop Weight Impact Testing Machine. This is more than a service. It is a commitment to ongoing reliability and consistency for users navigating impact resistance testing complexities.

Through this support, machine operators and technicians can navigate through operational hurdles with expert advice and guidance. Assuring minimal downtime and maintaining testing efficiency is the goal of after-sales support, whether it is troubleshooting, software updates, or spare parts requisitions.

Additionally, DWT-1800 users have access to a team of expert technicians and specialists who can offer nuanced, application-specific advice, ensuring DWT-1800 longevity and reliability. The support infrastructure safeguards your investment but also ensures that every test, and every result, maintains the highest levels of accuracy and reliability at all times.

Click here to learn more about the product or here to receive a personalized quote.

As part of the Lifetime Product Support Advantage, the DWT-1800 Computer Controlled Drop Weight Impact Testing Machine is committed to providing optimal functionality and support throughout its operational lifetime. We guarantee that users of the DWT-1800 will receive the highest level of assistance and technical support, protecting their investment and ensuring seamless operation for years to come.

In terms of technical support, users have access to a team of expert technicians and specialists who can assist with troubleshooting, maintenance, and operational questions. By providing enduring support, the DWT-1800 continues to deliver precise and reliable results, maintaining its operational integrity and effectiveness over time.

Moreover, the Lifetime Product Support Advantage includes a variety of elements in addition to technical support, such as software updates, component replacements, and access to a repository of resources and documentation. As a result, users can expect a comprehensive set of support features designed to safeguard their operations, extend the life of the machine, and ensure continuous excellence of the DWT-1800 throughout its lifecycle.

Click here to learn more about the product or here to receive a personalized quote.

There is a high level of adaptability provided by the DWT-1800 Computer Controlled Drop Weight Impact Testing Machine, providing customized solutions according to the unique requirements of each user. There are several aspects of this system that can be modified, including the impact energy, weight, and lift height, which can be precisely adjusted to meet specific testing requirements.

The customization process is guided by your unique testing requirements. To produce meaningful and relevant data, different materials and test procedures may require varying impact energies, weights, and lift heights. By establishing a clear understanding of these needs, custom solutions can be developed to ensure that the DWT-1800 provides the most accurate and relevant data possible based on the materials and conditions of your particular test.

Users can leverage the advanced capabilities of the DWT-1800 to meet specific testing challenges and scenarios, enhancing the scope and reliability of the results obtained. Thus, the DWT-1800 is characterized not only by its precision and reliability but also by its ability to adapt to a wide range of testing requirements across multiple application areas.

Click here to learn more about the product or here to receive a personalized quote.

It is easy to operate the DWT-1800 Computer Controlled Drop Weight Impact Testing Machine due to its user-friendly design. To begin, the user should enter critical parameters into the computer display menu or utilize the command button to ensure that the machine is configured for the particular testing needs.

There are several key parameters that must be inputted, including drop weight, the weight of the hammer that will be dropped, local gravitational acceleration, which varies with geography and is crucial for calculating impact energy, and preset energy, a predetermined energy level for which the test is designed. Parameters such as these are crucial since they directly affect the testing environment and, as a consequence, the results obtained.

As soon as these parameters are entered, the computer automatically calculates the required impact height based on the correlation between the input data and the intrinsic algorithms. The following test is then conducted accurately, adheres to the specified conditions, and provides reliable and reproducible results. In this way, the DWT-1800 offers both precision in testing and ease of operation, making it an efficient tool for diverse testing scenarios.

Click here to learn more about the product or here to receive a personalized quote.

The DWT-1800 Computer Controlled Drop Weight Impact Testing Machine is constructed of several crucial components that, collectively, ensure accurate and reliable operation throughout the testing process. The system includes an encoder that converts motion into an electronic signal, ensuring accurate positional data during testing.

Also, it is equipped with an A/D (Analog-to-Digital) data acquisition system, which converts analog signals obtained during testing into digital data for further analysis and processing. It is further provided with a data analysis system that analyzes the acquired data, ensuring that the results of the impact tests are precisely evaluated and interpreted.

DWT-1800's combination of systems ensures not only the accuracy of data acquisition and analysis, but also the reliability of test results. Due to the detailed architecture and strategic alignment of these components, the machine is able to deliver exact and reproducible results, which is important for comprehensive impact analysis of the materials being tested.

Click here to learn more about the product or here to receive a personalized quote.

DWT-1800 Computer Controlled Drop Weight Impact Testing Machine features a specially designed measurement and control system that is crucial to ensuring the accuracy and reliability of the displayed impact energy during tests. In this state-of-the-art system, many aspects of the testing process are meticulously controlled and monitored, with particular attention being paid to the hammer's lifting height and the display of impact energy. This ensures that the test data is accurate and reliable.

The ability of the system to control the lifting height of the falling hammer is directly correlated with its ability to manage and dictate the impact energy generated during a test. With the ability to precisely control the height from which the hammer is dropped, the system is able to accurately modulate the potential energy, and consequently, the kinetic energy upon impact, so that the tests can be conducted under conditions that are strictly controlled and reproducible.

After an impact, the system's ability to display the resultant energy levels is crucial for providing operators with accurate, real-time information. By systematically capturing the data post-impact, it provides insights into the material's resilience and impact resistance, which are necessary for analysis and subsequent decision-making.

Click here to learn more about the product or here to receive a personalized quote.

By primarily reducing the overall height of the DWT-1800 Computer Controlled Drop Weight Impact Testing Machine, the electric lifting mechanism greatly enhances its stability and ease of maintenance. Low stature provides a more stable foundation, minimizing the possibility of tilting or wobbling during operation and ensuring that impact tests are as accurate and consistent as possible.

In addition to stabilizing the machine's physical structure, reducing its height promotes its ergonomic design. With a compact and stable frame, operators can interact with the machine more easily and safely, which is particularly important during the setup, testing, and maintenance phases. During testing procedures, such a design reduces the risk of accidents or misalignments.

Moreover, the strategic placement and design of the electric lifting mechanism enhance the machine's maintainability. Having easy access to the machine's critical components facilitates straightforward servicing and ensures that any required maintenance can be performed with the least amount of hassle and downtime. As a result, this careful design consideration significantly enhances the machine's operational lifespan, reliability, and overall performance in carrying out precise impact resistance tests.

Click here to learn more about the product or here to receive a personalized quote.

An electric lifting mechanism is strategically located at the bottom right of the frame of the DWT-1800 Computer Controlled Drop Weight Impact Testing Machine. Testing procedures are streamlined and efficient due to this location that aligns with the machine's operational workflow.

In order to achieve the precision and consistency for which the DWT-1800 is renowned, the electric lifting mechanism plays an integral role in managing the hammer's motion. Located at the bottom right, the mechanism ensures that the hammer is lifted smoothly and efficiently, preparing it for the drop and ensuring repeatability and reliability of the test.

Furthermore, the location of the electric lifting mechanism adheres not only to ergonomic considerations, but also enhances the machine's overall safety and efficiency. It is located at the bottom right of the frame, which makes it easy for operators and maintenance personnel to access and service the machine.

Click here to learn more about the product or here to receive a personalized quote.

With safety being a top priority, the DWT-1800 Computer Controlled Drop Weight Impact Testing Machine incorporates an array of safety protection devices that are constantly monitored throughout the testing procedure to ensure maximum safety.

The inclusion of safety protection devices and the continuous monitoring of these devices are integral to protecting the operator and maintaining a secure testing environment. The devices continuously monitor various aspects of the machine's operation, looking for anomalies or potential safety breaches that may compromise the integrity of the test or put the operator at risk.

Further, this proactive monitoring system functions proactively, designed to halt operations as soon as any irregularities are detected, thus mitigating any potential risks. Continual inspection of safety mechanisms ensures the physical safety of the operator as well as the reliability and integrity of the test results by maintaining a stable and controlled operational environment.

Click here to learn more about the product or here to receive a personalized quote.

An integral part of the DWT-1800 Computer Controlled Drop Weight Impact Testing Machine is a pre-set impact energy system controlled by a microcomputer to facilitate precise and accurate testing with the DWT-1800.

By using this sophisticated microcomputer-controlled system, the impact energy can be meticulously pre-set, ensuring that each test is conducted under controlled and consistent conditions. It is due to the use of such advanced technology that the impact energy can be calibrated and maintained accurately throughout the testing process, adding an additional level of precision to the results.

With the use of a microcomputer-controlled system, operators are offered a streamlined and straightforward user interface that contributes greatly to the overall efficiency and effectiveness of the machine. This innovative technology is embedded in the DWT-1800, ensuring that not only can the machine conduct highly accurate tests but is also user-friendly, reducing the potential for human error, and ensuring reproducible results across multiple tests.

Click here to learn more about the product or here to receive a personalized quote.

How Does the DWT-1800 Computer Controlled Drop Weight Impact Testing Machine Ensure Operator Safety?

With the DWT-1800 Computer Controlled Drop Weight Impact Testing Machine, operator safety is prioritized, employing robust mechanisms to reduce potential risks during testing procedures. First of all, the hammer body is equipped with a manual iron block safety insurance mechanism. As a result of this feature, the hammer is prevented from moving inadvertently during operation, thereby safeguarding against unintended accidents and improving operator safety.

Additionally, the machine is equipped with protective devices to prevent flying debris from entering the work area when the specimen breaks, thereby protecting the operator from potential harm. The strategic inclusion of these devices emphasizes not only the machine's compliance with safety protocols but also the effort to minimize risks and ensure a secure environment during testing.

By implementing these safety measures, the machine demonstrates a significant commitment to operational security and, at the same time, reinforces its credibility in the execution of accurate, reliable impact tests without compromising user safety. Operators and technicians can therefore use the DWT-1800 with confidence, knowing that safety has been integrally incorporated into its design and operation.

Click here to learn more about the product or here to receive a personalized quote.

The DWT-1800 Computer Controlled Drop Weight Impact Testing Machine combines several pivotal components for seamless testing of impact resistance on a variety of materials.

By anchoring the operation, the sturdy guide rail ensures an accurate path for the dropping hammer, preventing any lateral deviation and making sure the impact is accurate. A robust construction ensures that the hammer follows a consistent trajectory, thereby ensuring the repeatability of results.

Directly connected to this, the base provides unwavering stability to the entire system, while the anvil, carefully placed, directs the force from the hammer to the test sample. By coupling the energy to the material under test, it is ensured that it will be efficiently transferred and absorbed by the material, permitting an accurate evaluation of the material's impact resistance.

The lifting mechanism lifts and drops the hammer, a key player in generating the impact. As well as determining the falling height of the hammer and thus its potential energy, it also plays a crucial role in adjusting the severity of the impact, allowing the tests to be adapted to different material properties.

Click here to learn more about the product or here to receive a personalized quote.

In terms of weight, the DWT-1800 Computer Controlled Drop Weight Impact Testing Machine has an approximate weight of 2500kg. In order for the machine to perform high-impact tests, this significant mass is critical in providing the machine with stability.

With an approximate weight of 2500kg, the DWT-1800 is designed to effectively stabilize itself during testing processes, preventing generated impact forces from being dissipated through unnecessary vibrations or movement of the machine itself. By minimizing any potential disturbances or deviations during the impact testing process, its substantial weight is critical to producing accurate and reliable test results.

Its weight also indicates that the machine has been constructed from robust and durable materials, ensuring that it is capable of withstanding the rigorous conditions associated with impact testing. As a result of its substantial weight, the DWT-1800 provides a fundamentally reliable apparatus in laboratories and testing environments, ensuring consistent and accurate results over extended periods of time thanks to its assurance of stability and durability.

Click here to learn more about the product or here to receive a personalized quote.

The DWT-1800 Computer Controlled Drop Weight Impact Testing Machine provides precise and reliable impact resistance testing with dimensions of approximately 1280×1300×4500mm. During the rigorous impact tests that it conducts, this size is determined scientifically in order to ensure accuracy and stability.

The machine has a relatively compact footprint of 1280 mm by 1300 mm and a height of 4500 mm, which facilitates precise control and generation of impact forces. As a result of this strategic sizing, the apparatus is able to accommodate the intricate mechanical and electronic systems that are crucial to delivering accurate, repeatable, and reliable results while maintaining physical stability.

In addition, the machine's defined dimensions make it suitable for use in a wide range of laboratory and industrial environments without requiring excessive space. Throughout the testing process, each millimeter is measured to verify that impact forces are applied accurately and effectively. This ensures the collection of reliable data concerning the impact resistance of the materials being examined. This strategic design ensures optimal functionality.

Click here to learn more about the product or here to receive a personalized quote.

DWT-1800 is a computer-controlled drop weight impact testing machine that has been meticulously designed to ensure robustness and reliability in its operation. The drop hammer blade and the supporting table are maintained at HRC≥50. As a result of this considerable hardness level, consistent testing procedures can be conducted over an extended period of time without degradation or wear.

A Rockwell hardness of 50 or higher indicates a significant level of hardness, ensuring that the machine's components are not only resistant to wear and deformations, but can also deliver precise and consistent results over a long period of time. A high level of hardness ensures that the machine components are able to endure repeated stress without wearing away, thus maintaining the integrity of the testing process.

Therefore, the noteworthy hardness level of these critical components within the DWT-1800 ensures that users can reliably assess the impact resistance of various materials, with confidence in the durability and consistency of the machine’s performance across numerous tests and applications due to its notable hardness level. The resultant data, therefore, can be used for material analysis and decision-making with unwavering confidence.

Click here to learn more about the product or here to receive a personalized quote.

In addition to achieving a stringent precision in the lifting height of the falling weight, the DWT-1800 Computer Controlled Drop Weight Impact Testing Machine maintains a precision of ±0.5%. This meticulous level of accuracy underscores its capability to deliver consistent and reliable testing results, which are crucial for understanding the complex behaviors of materials under impact stress.

The impact energy is precisely controlled and highly reproducible with a precision of +0.5%, thereby minimizing the possibility of variations between individual tests. An accurate understanding of the material's characteristics and performance under impact conditions requires accurate control over the lifting height and, subsequently, the impact energy.

In impact testing, precision is essential because minor variations can have a significant impact on the resulting data, affecting the conclusions drawn regarding the material's durability and resilience. Especially when considering materials for critical applications, such as aerospace or automotive industries, where safety and reliability are paramount, precise and accurate testing is imperative.

Click here to learn more about the product or here to receive a personalized quote.

Drop Weight Impact Testing Machine DWT-1800 offers a number of options for lifting height for falling weight, ranging from 100 mm to 3350 mm. With such a broad range of options, impact tests can be performed in a variety of conditions and with different materials, which makes it suitable for a wide range of applications and industries.

The ability to explore different levels of energy during impact testing requires a wide range of lifting heights. In order to assess the material's strength and integrity under different stress levels, the impact energy can be precisely adjusted by adjusting the falling height. This allows an in-depth analysis and evaluation of the material's behavior and resilience under diverse impact energies, enabling a thorough evaluation of its properties and potential uses.

It is also possible to perform testing on materials of different thicknesses and densities since the impact energy can be meticulously calibrated for each material depending on the specific test conditions. The range from 100mm to 3350mm ensures that tests are not only accurate but also adaptable to the unique requirements of each material, enhancing the machine's utility and applicability across a wide range of research and industrial settings.

Click here to learn more about the product or here to receive a personalized quote.

With the DWT-1800 Computer Controlled Drop Weight Impact Testing Machine, there is a minimum deviation between the central line of the drop hammer and the sample seat, which is ≤±2.5mm. When conducting impact testing, extreme precision is crucial to achieving accurate and reliable results.

A minimal deviation from the alignment is important since even a slight misalignment could result in variation in the data, resulting in misinterpretations about the material's properties and performance under impact stress in a research or industrial context. With a deviation of 2.5mm, the impact force is directed appropriately and consistently during testing, providing reliable data upon which to make critical decisions related to materials and their application.

A precise alignment also safeguards the integrity of the test samples and the machine itself, preventing undue wear and tear or damage that may result from misaligned impact forces. This diligence in maintaining alignment contributes not only to the quality of the test data but also to the longevity and performance of the DWT-1800 over its operational lifetime.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the DWT-1800 Computer Controlled Drop Weight Impact Testing Machine produces Impact Hammer Knives with specified radii according to customer requirements. This ensures a customized impact testing approach.

The impact hammer knives can be produced with a radius of either R25mm or R50mm, depending on the specific requirements of the client and the parameters of the material being tested. Different materials and products may interact differently with different impact shapes and sizes, making these specific radii adaptations critical to conducting accurate and relevant tests.

In order to simulate various real-world impact scenarios, the impact hammer knives must be designed with specified radii. A wide range of radii may simulate different types of impacts, such as those caused by rounded or pointed objects, which would provide vital information regarding the material's resistance and behavior under such conditions.

Click here to learn more about the product or here to receive a personalized quote.

In compliance with UL Standards, the DWT-1800 Computer Controlled Drop Weight Impact Testing Machine offers a customized Sample Seat, tailored rigorously to the customer's requirements and rigorously adapted to meet specific testing requirements. In order to ensure that diverse testing protocols and requirements are met accurately and reliably, the sample seat must be customized.

Engineering considerations are taken into consideration when a customer specifies requirements for the Sample Seat to ensure that dimensions, material properties, and supporting structures are closely aligned with the intended testing requirements. It may be necessary to adjust the seat dimensions, shape, material, and support mechanisms in order to accommodate different samples and their respective impact testing parameters.

As a result of this customization, the machine does not simply perform generic tests but is finely tuned to simulate the actual conditions under which the materials will be used in the real world. Therefore, the DWT-1800 not only becomes a tool for impact resistance testing but also a robust instrument that enables a deeper understanding of how materials will behave under specific impact conditions, providing valuable information that can serve as a basis for future design, manufacturing, and utilization decisions across multiple industries.

Click here to learn more about the product or here to receive a personalized quote.

Drop Weight Impact Testing Machine DWT-1800 uses UL Standard Impact Hammers, offering precisely engineered hammers designed to meet stringent testing requirements. It is important to note that these impact hammers are available in a variety of shapes and dimensions to cater to a wide range of testing requirements. This ensures adaptability and precision when generating accurate impact resistance values.

- Right Cylindrical (Flat Face) Hammers are available in diameters of:

- 1"

- 1-1/8"

- 2"

- 6"

- Rectangular Hammers feature dimensions of:

- ¾” x 6” with a width of 3/8” (crafted from Polyurethane)

- 2” x 6”

- 3” x 6”

With this selection of hammers, each with distinctive physical characteristics, users are able to navigate through different testing scenarios, ensuring that materials are evaluated under appropriate conditions. These cylindrical and rectangular configurations are intended to simulate various real-world impact scenarios, providing reliable and valid data regarding materials' performance in practical applications.

The addition of polyurethane to specific hammers contributes to the improvement of testing parameters by enhancing resilience and impact absorption. Therefore, the DWT-1800 provides not only diverse testing capabilities but also aligns closely with UL Standards, ensuring the robustness and reliability of impact testing outcomes across a variety of materials and products.

Click here to learn more about the product or here to receive a personalized quote.

DWT-1800 Computer Controlled Drop Weight Impact Testing Machine provides an array of specialized light impact hammers, each designed to meet specific testing requirements. Featuring six unique light impact hammers, each with a specific weight, it is designed to accommodate a variety of testing needs in a precise and accurate manner. Specifically:

- 9.1 kg

- 34 kg

- 1.36 kg

- 4.54 kg

- 22.7 kg

- 2.72 kg

Diverse weights enable a broad range of impact tests to be conducted on a variety of materials. With this range of weights, the DWT-1800 is capable of simulating a wide range of real-world impact conditions to enable the testing of different materials under varied conditions.

As a result of its versatility, the DWT-1800 has become a valuable tool across a wide range of industries that require precise impact testing capabilities, enhancing its versatility and applicability in a variety of settings.

Click here to learn more about the product or here to receive a personalized quote.

DWT-1800 Computer Controlled Drop Weight Impact Testing Machine is equipped with heavy impact hammers that ensure accurate and reliable impact testing on various materials. In particular, there are two heavy hammers, each distinguished by its own weight:

- A hammer weighing 180 kg

- Another hammer with a weight of 272 kg or approximately 600 lb

These hammers are pivotal in performing precise impact tests, providing quantifiable data on a material's impact resistance by delivering a predetermined force upon the test specimen.

In practical applications, the precise mass of the hammers allows the use of a specific, controlled impact energy during tests, allowing operators to reproduce a wide range of impact scenarios. There are a number of hammer weights available, which provide flexible testing capabilities to accommodate a variety of materials and testing requirements. As a result, the DWT-1800 not only adheres to but can also be adapted to, a wide range of industrial standards and testing protocols.

The inclusion of these hammers augments the machine’s functionality, providing the technical ability to acquire precise and varied data across numerous testing scenarios. Consequently, this enhances the DWT-1800’s utility in material testing labs and related environments.

Click here to learn more about the product or here to receive a personalized quote.

In order to accommodate various testing requirements, the DWT-1800 Computer Controlled Drop Weight Impact Testing Machine has been specially engineered to handle significant measurements and forces. Specifically:

- The Maximum Impact Energy that can be applied using the machine is 1800 Joules (J). The maximum energy that can be applied to a test sample during a single impact test provides a meaningful measurement range for evaluating the impact resistance of materials.

- Regarding Weight, the DWT-1800 can manage a Maximum Weight of 600 pounds (lb), enabling the testing of materials that may experience substantial force or mass during real-world applications, ensuring accurate assessment of diverse materials.

- The Testing Machine has a Hammer Lifting Height of 3.35 meters (m). It is important to pay attention to this height parameter when determining the potential energy (and therefore the kinetic energy) that can be used for the impact test since it allows a wide range of energy levels to be tested according to the specific requirements of each sample material.

These specifications illustrate the machine's capability to conduct thorough and robust impact tests on a wide range of materials, which facilitates a wide range of industrial and research applications. Furthermore, these parameters indicate the machine's ability to simulate various real-world impact scenarios, meeting the diverse and often demanding testing requirements found across a wide variety of industries and sectors.

Click here to learn more about the product or here to receive a personalized quote.

The DWT-1800 Computer Controlled Drop Weight Impact Testing Machine complies with a variety of standards, demonstrating its ability to generate accurate and consistent test results and establishing its credibility as a competent testing tool. A standard, such as that issued by Underwriters Laboratories (UL) or another recognized entity, is the result of in-depth research and the collection of industry best practices.

As a result of adhering to these standards, the DWT-1800 is aligned with the stringent criteria and protocols which are mandated for impact testing, ensuring accurate and repeatable results. In other words, the machine's testing methodologies, control mechanisms, and data output have been evaluated and calibrated against recognized benchmarks.

Therefore, materials tested using the DWT-1800 are subjected to rigorous and reliable evaluation, which ensures the integrity of the test data. Due to this, organizations and professionals relying on the DWT-1800 can be confident that the insights derived from its testing are dependable and reproducible, aligned with industry-validated standards.

Click here to learn more about the product or here to receive a personalized quote.

With the DWT-1800 Computer Controlled Drop Weight Impact Testing Machine, you can conduct impact resistance tests with enhanced reliability, versatility, adaptability, and extensibility. Computer-controlled processes are fully automated, precision-guided processes, which minimize manual error and enhance repeatability across multiple tests.

DWT-1800's reliability comes from its ability to perform tests with a high level of accuracy, resulting in the correct results. Through the use of a computerized control system, variables such as the height from which weights are dropped can be precisely calibrated, ensuring that test results are accurate and standardized.

Also, the DWT-1800's strong expansibility, enabled by computer control, enables the machine to seamlessly integrate into evolving testing environments. It may be necessary to modify or update the machine as new testing methods or methodologies are introduced as a result of technological advancements.

Click here to learn more about the product or here to receive a personalized quote.

The DWT-1800 Computer Controlled Drop Weight Impact Testing Machine is particularly designed to determine the non-plastic transformation temperature of ferritic steel, which is a crucial parameter in understanding its phase transformation behaviors under dynamic loading conditions.

Various forms of ferritic steel, including plates, profiles, cast steel, and forged steel, undergo significant physical changes when subjected to varying temperatures and impact forces. It is important to understand the non-plastic transformation temperature since it defines the threshold at which the steel transitions from being ductile to becoming brittle.

Engineers and materials scientists can optimize manufacturing processes and enhance the overall quality of final products by understanding the non-plastic transformation temperature in practical applications, such as the fabrication of plates or the casting of steel. The process may involve manipulating heating or cooling rates during processing or altering the compositional alloying elements to control the steel's behavior under dynamic stress conditions.

This makes the DWT-1800 a quintessential tool in identifying this temperature threshold with precision, thereby providing a solid foundation upon which strategic material and processing decisions can be calibrated for applications that require strict adherence to safety and material integrity requirements.

Click here to learn more about the product or here to receive a personalized quote.

The DWT-1800 Computer Controlled Drop Weight Impact Testing Machine is a versatile and essential device designed to evaluate the impact resistance of a wide array of materials, spanning both metal and non-metal categories.

In terms of testing metal materials, the DWT-1800 is capable of testing alloys of iron, aluminum, copper, and various other metals, proficiently determining their strength against impact forces. These materials are subjected to assessments related to their behavior when suddenly applied forces are applied, their energy absorption capabilities, and their ability to deform or fail under high strain rates.

When evaluating non-metal materials, the machine demonstrates its adaptability by testing polymers, ceramics, and composite materials, among others. As a result, it provides invaluable data regarding the durability, breakage pattern, and overall robustness of these materials when exposed to a variety of dynamic loading scenarios.

By using the DWT-1800, industries and research laboratories are able to assess the impact resilience of various materials, ultimately enabling them to make informed decisions regarding material selection and design considerations in a variety of applications.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the DWT-1800 Computer Controlled Drop Weight Impact Testing Machine adheres to a wide range of industry standards, including UL 514D, for consistent, accurate, and safe impact testing across a variety of materials and products.

According to UL 514D, cover plates for flush-mounted wiring devices must meet specified safety and performance criteria. The DWT-1800 Computer Controlled Drop Weight Impact Testing Machine is designed to perform rigorous tests in order to determine whether the product meets these safety and performance requirements.

The DWT-1800, with its advanced computer-controlled operations, provides a rigorous and reliable testing methodology that ensures that cover plates and similar products adhere to the rigorous safety and performance criteria defined in UL 514D, as well as comply with the UL 514D evaluation standards. In this way, manufacturers can ensure that their products will have the ability to resist specific impact energies, ensuring that their functionality and integrity are safeguarded throughout the life cycle of their products.

Click here to learn more about the product or here to receive a personalized quote.

Yes, this computer-controlled drop weight impact testing machine complies with a number of high standards, including UL 514C, which ensures the accuracy, reliability, and safety of testing various materials, particularly when it comes to impact resistance and durability.

By working with the DWT-1800, manufacturers, researchers, and quality assurance professionals will be able to gain a better understanding of the material characteristics and likely performance of their products during the operational life. As a result, these products can be validated for structural and functional integrity under specific impact energies under which they were impact tested.

When it comes to electrical conduits and cabling systems, the DWT-1800 is an essential tool for industries that prioritize safety and reliability, as well as those that prioritize electrical conduits and cabling systems, in order to ensure that their products meet the stringent safety and performance criteria set out in the UL 514C standard, as well as to exceed them.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the DWT-1800 Computer Controlled Drop Weight Impact Testing Machine complies with numerous industry standards, including UL 2239, ensuring it provides robust, precise, and reliable testing capabilities across an array of applications. UL 2239 outlines standards related to hardware for conduit, tubing, and cable. It is used to determine and validate the mechanical and impact-resistance properties of such hardware.

Ensuring compliance with UL 2239, the DWT-1800 has been designed and optimized to validate that the products being tested can handle specified impact energies. It also ensures that they maintain structural integrity and functionality when subjected to stresses and impacts defined within the standard. This is particularly vital in maintaining cable support hardware safety and reliability, especially in applications where mechanical stability and safety are a priority.

For industries and labs focused on ensuring their cable, conduit, and tubing support hardware adheres to recognized safety and performance standards, the DWT-1800 serves as an invaluable tool, assuring that tested products meet UL 2239 criteria.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the DWT-1800 Computer Controlled Drop Weight Impact Testing Machine is precisely designed to comply with many industry standards, including UL 1569. The UL 1569 standard, established by Underwriters Laboratories (UL), defines the requirements for metal-clad cables and cable glands, focusing on their safety and reliability, especially electrical and fire safety in their applications.

This conformance to UL 1569 indicates that the DWT-1800 can proficiently facilitate testing to validate the safety, reliability, and performance of metal-clad cables and cable glands, ensuring that they are capable of withstanding the expected impact, mechanical stresses, and other related factors outlined in the standard.

The DWT-1800, with its precise control and reliable testing capabilities, offers manufacturers and testing laboratories a robust tool to thoroughly validate their products against the stringent criteria set out by UL 1569, thereby ensuring that they provide safe, durable, and high-performing products to the market.

For those who prioritize safety and quality through stringent testing of metal-clad cables and cable glands, utilizing a tool like the DWT-1800, which aligns with recognized standards like UL 1569, provides an essential tool for achieving and maintaining those standards.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the DWT-1800 Computer Controlled Drop Weight Impact Testing Machine meets various industry standards, including UL 1242. The UL 1242 standard, established by Underwriters Laboratories (UL), outlines the criteria for Intermediate Metal Conduit (IMC) and its associated joints, couplings, and nipples, focusing on ensuring consistent quality and safety of these electrical conductor components.

Compliance with UL 1242 implies that the DWT-1800 is capable of rigorously testing products to the high safety and performance levels detailed in the standard. Therefore, manufacturers and testing laboratories in the electrical conduit industry can leverage the DWT-1800 to validate that their IMC and associated fittings meet or exceed the safety and performance requirements set out by UL 1242, ensuring their applicability and durability in safeguarding electrical wiring within the conduits.

Understanding the significance of ensuring product quality and user safety in electrical installations, the DWT-1800 provides a robust and reliable solution for verifying the impact resistance and integrity of materials and products. This facilitates the development and testing of superior, safe, and reliable IMC products.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the DWT-1800 Computer Controlled Drop Weight Impact Testing Machine conforms to numerous industry standards, one of which is UL 6. The UL 6 standard, developed by Underwriters Laboratories (UL), specifies the requirements for both material and construction quality of rigid metal conduit, including aluminum, red brass, and stainless steel conduit.

UL 6 sets strict guidelines related to safety, material robustness, and reliability for these conduits, ensuring they serve their purpose of safeguarding and routing electrical wiring effectively and securely, especially in environments that demand high structural integrity.

The compliance of the DWT-1800 with UL 6 signifies that it is expertly engineered to assess the impact resistance of materials and products adhering to this standard, thereby ensuring their quality and durability in real-world applications. Consequently, manufacturers, and testers of rigid metal conduit, especially in electrical installation and infrastructure, can trust the DWT-1800 to provide accurate and reliable data. This will verify that their products meet the stringent safety and quality requirements specified in UL 6.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the DWT-1800 Computer Controlled Drop Weight Impact Testing Machine is certified according to various industry standards, including UL 797. UL 797 is a standard established by Underwriters Laboratories (UL), which specifies the safety requirements for electrical metallic tubing (EMT) and its associated materials and manufacturing processes. It provides guidelines regarding the material's structural integrity and safety, ensuring it can securely protect electrical and telecommunication wires under different physical and environmental conditions.

By complying with UL 797, the DWT-1800 showcases its capability to test EMT materials for impact resistance, ensuring they maintain physical integrity and safety under specific impact conditions. This is critical for verifying that EMT materials can withstand potential impacts throughout their service life, safeguarding the electrical components housed within from potential damage.

Entities in the electrical and construction industries, particularly those producing or utilizing EMT, will find the DWT-1800’s compliance with UL 797 instrumental. It assures that the testing machine will provide robust, reliable data that verifies the materials' impact resistance, ensuring they meet the necessary safety and quality benchmarks.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the DWT-1800 Computer Controlled Drop Weight Impact Testing Machine adheres to numerous industry standards, including UL 1660. The UL 1660 standard, established by Underwriters Laboratories (UL), specifies the guidelines for Liquid-Tight Flexible Nonmetallic Conduits, ensuring that they safely and effectively perform in their designed applications, particularly in resisting environmental factors such as liquids.

The DWT-1800, in compliance with UL 1660, demonstrates its capacity to provide precise and reliable impact testing for materials used in liquid-tight flexible nonmetallic conduits. This adherence to established standards ensures that the materials tested can withstand specified levels of impact. This is crucial for maintaining integrity in various industrial applications, particularly where electrical conduit materials are exposed to rigorous conditions and need to preserve their protective qualities.

For professionals and entities, especially in the electrical and construction sectors, the DWT-1800’s compliance with UL 1660 provides reassurance of its capacity to provide accurate and trustworthy data, validating the durability and safety of materials in practical applications. This assures that the materials used in producing nonmetallic conduits can successfully withstand potential impacts without compromising their liquid-tight properties.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the DWT-1800 Computer Controlled Drop Weight Impact Testing Machine adheres to a variety of industry standards, including UL 360. The UL 360 standard, defined by Underwriters Laboratories (UL), establishes the requirements and specifications for Liquid-Tight Flexible Metal Conduits, ensuring optimal safety and functionality across an array of applications.

Conforming to the UL 360 standard, the DWT-1800 demonstrates its capacity to accurately test impact resistance in a broad range of materials. This includes those involved in the manufacture of flexible metal conduits that need to be liquid-tight. The reliable and verifiable results provided by the DWT-1800 machine are crucial in numerous industry sectors, particularly where materials are required to withstand certain levels of impact while preserving their structural integrity and ensuring safety in electrical applications.

Professionals and organizations, especially those operating within industries such as electrical systems and infrastructure, who prioritize recognized testing standards will find the DWT-1800 an invaluable tool. This is due to its capability to assure that the materials used, especially in the production of liquid-tight flexible metal conduits, have been tested for impact resistance in compliance with a widely acknowledged safety standard.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the DWT-1800 Computer Controlled Drop Weight Impact Testing Machine complies with numerous industry standards, including UL 1. The UL 1 standard, developed by Underwriters Laboratories (UL), defines the specifications for metallic electrical conduits, ensuring that these products meet the necessary safety and reliability criteria for their intended use.

Ensuring compliance with UL 1, the DWT-1800 assures users that its testing processes for impact resistance in various materials, both metallic and non-metallic, conform to a recognized safety and performance standard. Given that the UL 1 standard is crucial for materials used in electrical systems, it demonstrates the DWT-1800's capability to generate precise and reliable testing results. It is particularly important for materials used in metallic electrical conduits.

The DWT-1800's alignment with the UL 1 standard underscores its capability and reliability in professional testing scenarios, notably those requiring dependable impact testing of materials in the electrical industry. Clients and organizations that value proven precision and robustness in their testing practices will find the DWT-1800 to be a significant asset in assuring the impact resistance of their materials.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the DWT-1800 Computer Controlled Drop Weight Impact Testing Machine is specifically engineered to conform to a number of industry standards, including UL 651. The UL 651 standard outlines the specific requirements and guidelines for Schedule 40 and 80 Rigid PVC Conduit and Fittings, ensuring that products made according to this standard are safe and reliable for their intended applications.

Its compliance with UL 651 demonstrates the DWT-1800's commitment to maintaining the highest standards of quality, safety, and reliability. In the manufacturing and construction industries, impact resistance testing is indispensable when testing a variety of materials, both metal and non-metal. Using a machine that complies with the rigorous standards established by UL 651, users of the DWT-1800 can be confident that their results will be accurate and consistent.

The machine's adherence to such a widely accepted and respected standard enhances its applicability and trustworthiness in professional settings, especially those that call for precise and dependable materials impact testing. Users and organizations that place a high priority on validated accuracy and robustness in their testing mechanisms will find the DWT-1800 Computer Controlled Drop Weight Impact Testing Machine to be indispensable.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

Alignment Device

(NADCAP-Ready Precision Fixture)

NextGen Material Testing’s Alignment Device is a precision-engineered fixture designed to ensure perfect axial alignment in universal testing machines.

G-800E Trinocular Metallurgical Microscope

This inverted metallurgical trincoular microscope is ideal for both industrial or educational metallurgy applications.

HDT/VICAT Testing Machine – Thermal Analysis for Plastics NG-HDT

Description The HDT/VICAT testing machine offers high precision, reliability, and efficiency for the thermal analysis of thermoplastics and polymers. Engineered with advanced sensors and high-temperature-resistant components, it ensures minimal deformation, fast response, and precise data transmission, delivering consistent and accurate […]

Class J - Charpy and Izod Automatic Impact Testing System - 1J - 50J

Class J is widely used for lzod and Charpy impact test on softer metals, plastics and rubber specimens. Equipped with tensile impact pendulum and fixtures, it can carry on tests on plastic film and sheet. The newly enhanced design offers the most cost-effective configuration to address Charpy test from 1J to 50J (0.7 - 37 ft/lbs), and lzod test from 1J to 22J (0.7 - 16 ft/lbs).

Class D Single-Column Charpy Impact Tester – High-Precision Pendulum Testing Machine

NextGen’s Class D Single-Column Charpy Impact Testing System is built for high rigidity and dependable specimen testing across a wide energy range. It supports impact energies from around 150 J (111 ft-lbs) up to around 750 J (553 ft-lbs), covering most standard metal testing needs. The unit includes a digital display and offers a software upgrade option for data plotting. Additional features, such as automated specimen feeding and integrated cooling or heating systems, are available as optional enhancements.

Class G Single-Column Charpy & Izod Impact Tester – High-Precision Pendulum Testing Machine

NextGen's Class G – Single Column Charpy and Izod Impact Testing system provides a high level of rigidity and specimen testing capacity. This Charpy and Izod Impact tester has a minimum capacity of 150 J (111 ft/lbs) and a maximum capacity of 750 J (553 ft/lbs). The system comes standard with a digital display with software upgrade function for data plotting. The Class G impact system can also include automatic specimen feeding, cooling and heating systems as optional upgrades.

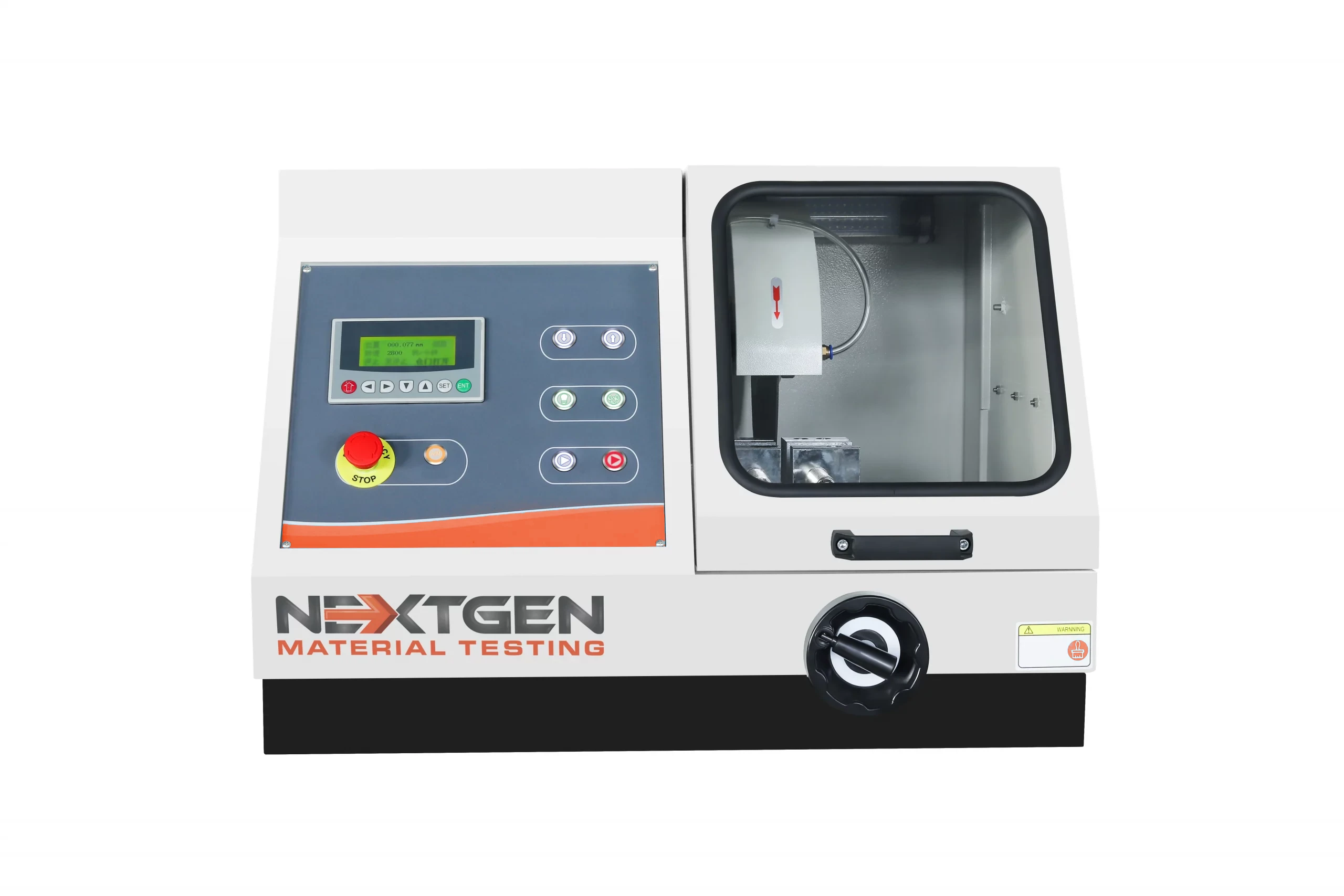

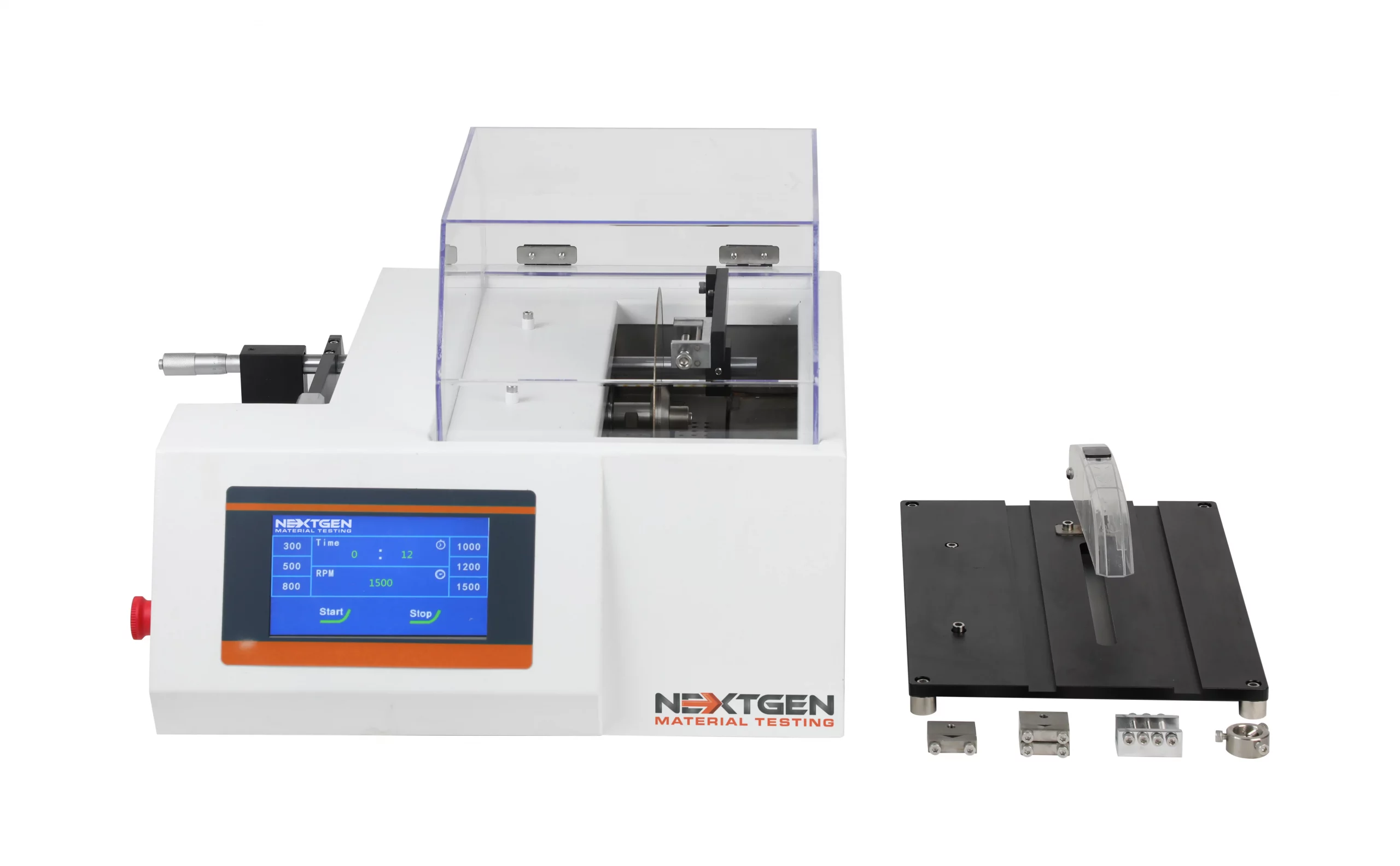

GenCut GL100M – Precision Manual Metallographic Sample Cutting Machine with Simple User-Friendly Operation and Large Cutting Capacity Φ100mm

Introducing the GenCut GL100M Manual Cutting Machine, expertly designed for precision metal sample cutting.

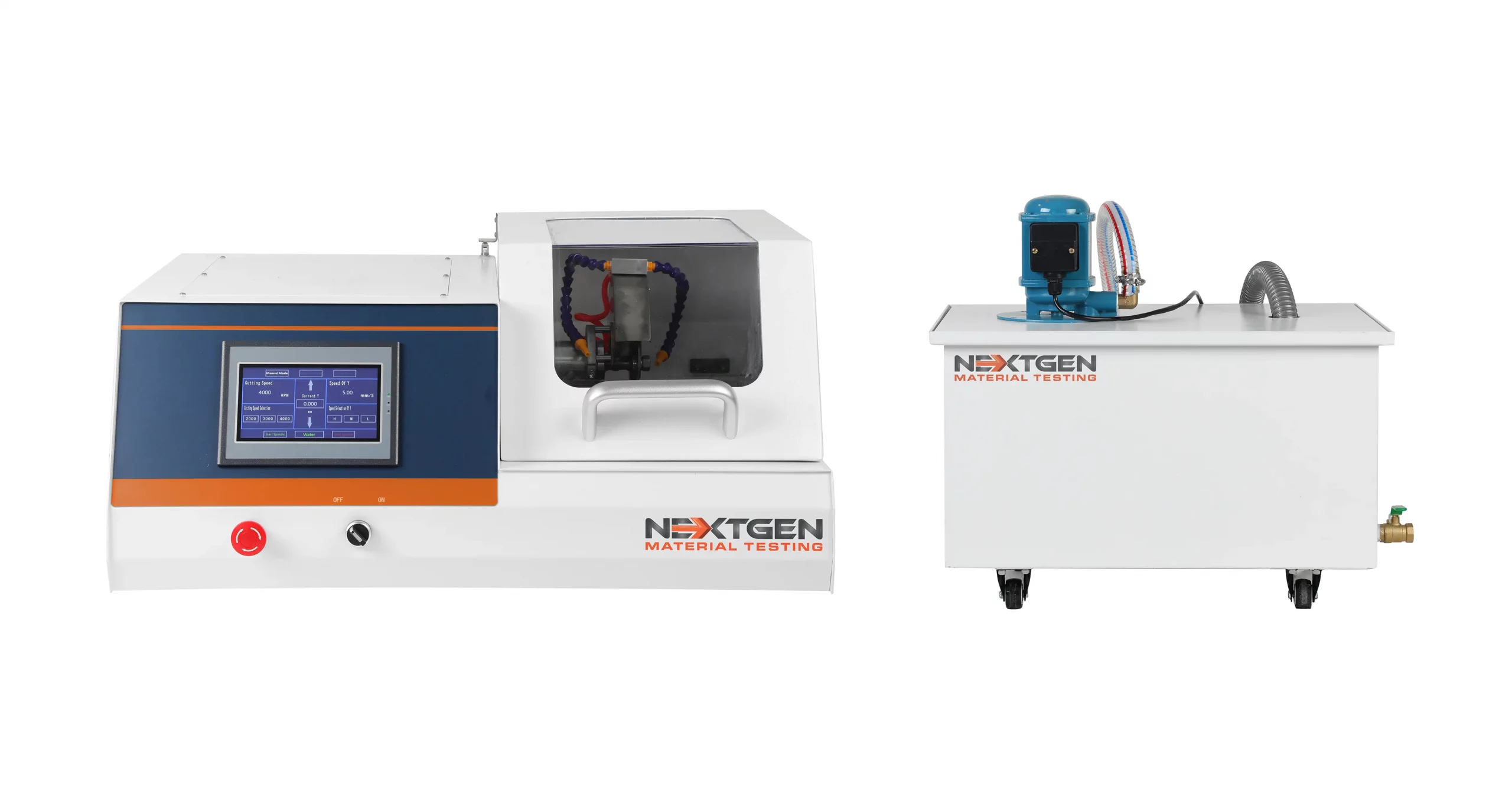

GenCut GL350 – Precision Metallographic Sample Cutting Machine with Simple User-Friendly Operation and Large Cutting Capacity Φ100mm

The GenCut GL350 is a cutting-edge high precision cutting machine equipped with advanced features and capabilities

GenCut GL80A – Precision Metallographic Sample Cutting Machine with Simple User-Friendly Operation and Large Cutting Capacity Φ80mm

Introducing the GenCut GL80A, a highly precise cutting machine offering both automatic and manual work modes.

GenCut GL 170XY – Multi Function Abrasive Cut Off Saw with Touch Screen User Friendly Interface and Large Cutting Capacity – Φ170mm

The GenCut GL 170XY has a large 170mm diameter maximum cutting capacity equipped with a fully automated XY table.

GenCut GL 120XY – Multi Function Abrasive Cut Off Saw with Touch Screen User Friendly Interface and Large Cutting Capacity Φ120mm

The GenCut GL 120XY has a large 120mm diameter maximum cutting capacity equipped with a fully automated XY table.

GenCut GL200E – High Speed Automatic Precision Metallographic Cutter with User-Friendly Touch Screen Interface with max. cutting diameter of 60mm

GenCut GL 200E precision cutting machine includes a touch screen and PLC control, with stable performance and real-time display parameters.

GenCut GL100E – Low Speed Precision Metallographic Automatic Cutter with User-Friendly Touch Screen Interface with max. cutting diameter of 25mm

GenCut GL100E low speed series metallographic precision cutter has variable speed control from 50-1000 rpm.

GenGrind N Series 8” 200S / 10" 250S / 12" 300 S - Advanced Metallographic Grinder & Polisher - Variable Speed 50-1000rpm –Touch Screen Controlled

Introducing the GenGrind N Series metallographic grinders and polishers, offered in sizes 8", 10", or 12" diameter.

GenGrind SA-I 250S 10" Single Wheel Semi Automatic Grinder & Polisher - Variable Speed 100-1000rpm – Individual Force Control - Touch Screen Controlled with Automatic Specimen Mover Power Head – (various wheel sizes available)

Discover the single wheel semi automatic GenGrind 10" SA-I 250S, your ultimate answer to grinding and polishing needs.

GenGrind SA-C 250S 10" Single Wheel Semi Automatic Grinder & Polisher - Variable Speed 100-1000rpm – Central Force Control - Touch Screen Controlled with Automatic Specimen Mover Power Head – (various wheel sizes available)

Introducing the GenGrind SA-C 250S – your ultimate single wheel semi automatic grinding and polishing solution.

GenGrind FA-IC 250D 10" Dual Wheel Fully Automatic Grinder & Polisher - Variable Speed 100-1400rpm – Both Individual and Central Force Control - Touch Screen Controlled with Automatic Specimen Mover Power Head – (various wheel sizes available)

Introducing the GenGrind FA-IC 250D Dual Wheel Polisher and Grinder, a fully automatic metallographic grinding and polishing machine

GenGrind FA-IC 250S 10" Single Wheel Fully Automatic Grinder & Polisher - Variable Speed 100-1400rpm – Both Individual and Central Force Control - Touch Screen Controlled with Automatic Specimen Mover Power Head – (various wheel sizes available)

GenGrind FA-IC 250S Single Wheel Polisher and Grinder, an advanced and fully automatic metallographic grinding and polishing machine

GenPress MFA Dual HYD Fully Automatic Dual Hydraulic Mounting Press – Hydraulic Controlled – 1-2” (25-50mm) Mold Assembly (other sizes available upon request)

GenPress MFA DUAL HYD Metallographic Sample Preparation is an advanced automatic mounting press for compression mounting of material samples

GenPress MFA MOT - Fully Automatic Motorized Mounting Press – Motor Controlled – 1-2” (25-50mm) Mold Assembly (other sizes available upon request)

GenPress MFA MOT mounting press system frees the operator to perform other tasks in the laboratory during the cycle allowing better efficiency

GenPress MFA HYD - Fully Automatic Hydraulic Mounting Press – Hydraulic Controlled – 1-2” (25-50mm) Mold Assembly

GenPress Mounting Press for Metallographic Sample Preparation is an advanced automatic mounting press for compression mounting of material sample

Class H - Servo-Motor Dual Column Charpy Impact Tester - 300J, 450J, 600J or 750J

NextGen's Class H – Servo-Motor Dual Column Charpy Impact Testing system offers of an exceptional combination of versatility and robust build. This impact system provides our most durable options designed with a dual column configuration. The system offers the ultimate versatility of testing 300J (212 ft/lbs), 450J (332 ft/lbs), 600J (442 ft/lbs) and a maximum of 750J (553 ft/lbs) capacities based on both Charpy and Izod test methods. The unit comes standard equipped with a servo motor and is designed to test at any preset angle. The unit comes standard with all the functions of our Class G tester as well as enhanced functionality upgrade of a force transducer inside the strikerwhich enables the determination of characteristic force, energy and displacement parameters such as pre-maximum force energy (Wm), the post maximum force energy, the general yield force (Fgy), the force at brittle fracture initiation (Fbf) and the arrest force (Fa).

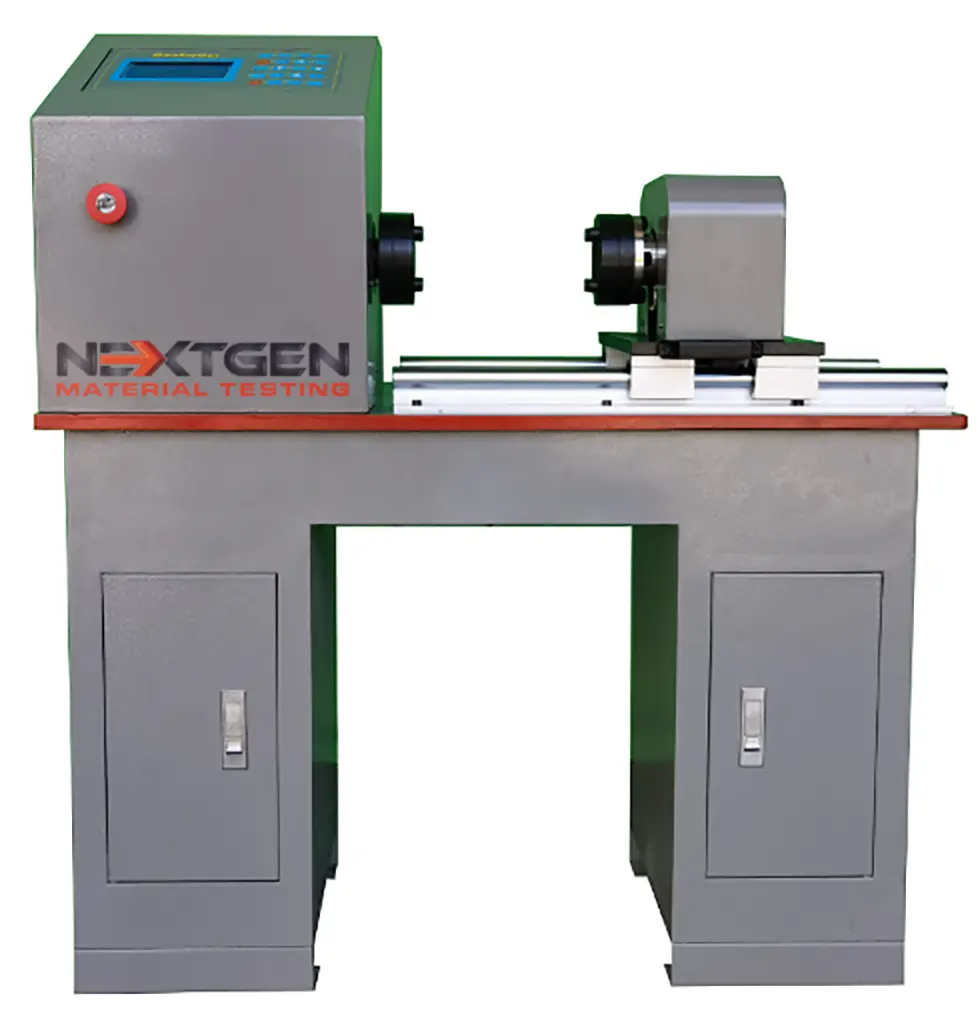

NextGen GenTor Horizontal Torsion Tester

NextGen GenTor Torsion Tester boasts a horizontal type load frame with high stiffness, ensuring accurate and reliable test results.

Triple Specimen Chamber Motorized Charpy Notch Making Machine

The GenNotch 4000UPG Series is a motorized Charpy & Izod Notch Making Machine with a triple specimen chamber.

NG-EML Series B – Dual Column Bench Top Universal Testing Machine (100 N – 10 kN)

The NG-EML Series B is a high-precision dual-column benchtop universal testing machine engineered for tensile, compression, and flexural testing in the 0.1 kN to 10 kN range. It features Class 0.5 accuracy, a rigid FEM-optimized frame, and a direct-drive servo system with advanced closed-loop control, making it ideal for testing rubber, plastics, metals, composites, and high-performance polymers in both R&D and quality assurance settings.

NG-EML Series C – Dual Column Bench Top and Floor Standing Universal Testing Machine (5 kN – 50 kN)

The NG-EML Series C is a precision-engineered dual-column universal testing machine for tension, compression, and flexural testing of metals, composites, rubbers, and polymers. Available in both bench-top and floor-standing formats, with force capacities from 5 kN to 50 kN and Class 0.5 accuracy.

NG-EML Series D – Floor Standing Universal Testing Machine (50 kN – 1000 kN)

The NG-EML Series D – Floor Standing Universal Testing Machine (50 kN–1000 kN) is a dual-column system for tensile, compression, flexural, shear, and cyclic testing of high-strength metals, composites, polymers, and advanced materials. Available in single-space and dual-space configurations, it meets ASTM E8, ISO 6892-1, ISO 527, and GB/T 228 standards. With closed-loop control, 1200 Hz sampling, ultra-low speeds (0.00005 mm/min), and waveform generation, it is ideal for aerospace, automotive, construction, and research labs.

Grips and Fixtures for NextGen Universal Testing Machines (UTMs)

NextGen's grips and fixtures are precision-engineered accessories that transform universal testing machines into versatile systems capable of tensile, compression, flexural, shear, and other mechanical tests. Designed to meet ASTM and ISO standards, these components ensure accurate, repeatable results across various materials and applications.

GenTest Data Acquisition Software - Advanced Universal Testing Machine Software

Upgrade to GenTest, the latest data acquisition software for universal testing machines. Ensure precise, repeatable material testing with an intuitive interface, powerful analysis tools, and full compliance with ASTM, ISO, DIN, and more.

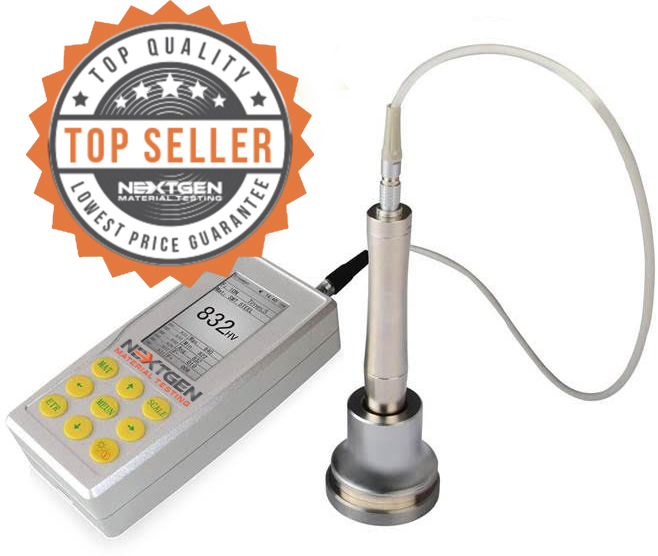

NG - LeebGen 3000 - Leeb Rebound Portable Hardness Tester

LeebGen3000 is a non-destructive precision metal hardness tester developed according to the latest industry standards. LeebGen 3000 is equipped with features which provide the instrument with a combination of a user-friendly interface and exceptional test result accuracy. This in turn allows for ease of operation and an accurate conversion display of virtually any metal hardness testing value.

GenVac MP3 Series - Epoxy Mounting Vacuum Impregnation System for Metallographic Sample Preparation

Experience our enhanced version of the GenVac MP Series. Our user-friendly touch screen interface along with automatic unit conversion and memory modes holds the title of one of the most advanced systems in the marketplace.

TensileTurn CNC XL - Heavy-Duty Round Specimen Preparation

TensileTurn CNC XL is the upgraded version of our TensileTurn CNC classic model. This powerful lathe is capable of turning round, square and irregular stock of tougher materials. The machine comes equipped with a robust tooling fixture, precision tailstock, and a high powered spindle. TensileTurn CNC XL is no doubt the ultimate round tensile test sample preparation machine capable of both tensile specimen preparation and advanced CNC machining. The unit is capable of meeting high capacity and high quantity output requirements for medium to large size laboratories and manufacturing facilities.

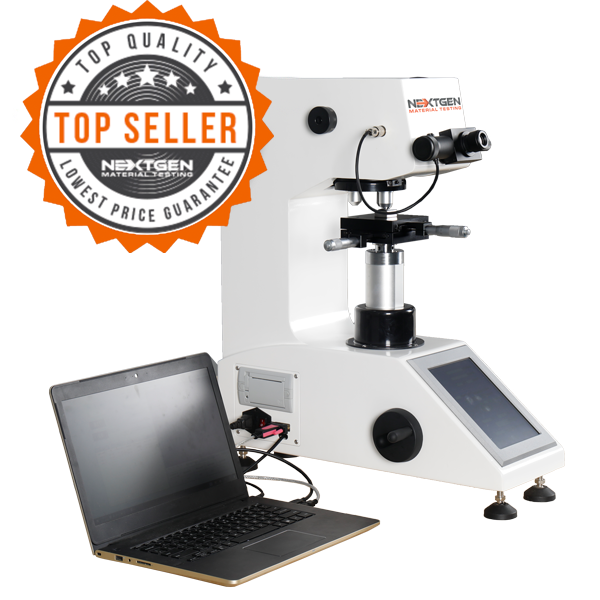

Ultrasonic Contact Impedance Hardness Tester - UH200

Welcome to our most advanced and cost-effective Ultrasonic Hardness Testing System. This portable machine is all you need and more!

TensileTurn CNC - Round Tensile Sample Preparation

Featuring a convenient size and high accuracy, the TensileTurn CNC can produce the highest accuracy in round tensile specimens. Able to prepare round tensile specimens, sub-size specimens, threaded tensile specimens, button-head tensile bars, fatigue specimens or any other round testing specimens, the TensileTurn CNC is easy to operate for both experienced and inexperienced operators.

TensileMill CNC XL - Flat Tensile Sample Preparation Equipment

This larger tensile sample preparation machines is the perfect fit for higher tensile sample preparation volumes. Equipped with our tensile software and Carbon Mach4 CNC software combo this machine is both simple to use and versatile for your long-term CNC machining requirements.

NG-SHM CLASS DP - Servo Hydraulic Testing Machine

600kN-2000kN - Servo-Hydraulic Universal Testing Machine - Side Action Wedge Grip 2/4 columns, servo-controlled hydraulic

NG-SHM Class D - Servo Hydraulic Universal Testing Machine

600kN-2000kN - Servo-Hydraulic Universal Testing Machine 2/4 columns, servo-controlled hydraulic

NG-SHM Class C - Servo Hydraulic Testing Machine

600kN-1000kN - Servo-Hydraulic Universal Testing Machine 6 column, servo-controlled hydraulic

NG-SHM Class B - Servo Hydraulic Testing Machine

300kN-3000kN - Servo-Hydraulic Universal Testing Machine 6 column, servo-controlled hydraulic

TensileMill CNC MINI - Compact Flat Tensile Sample Preparation

Despite its small size, the axis of the heavy cast iron frame on which the TensileMill CNC MINI slide on linear rails very smoothly. Its exceptional machining capability is provided by high powered servos and a 24,000 RPM ISO20 spindle.

Specimen Notching/Broaching Machine