Metal Testing Equipment

Standards

ASTM-A1038-05, DIN 50159-1, JB/T 9377-2010

Description

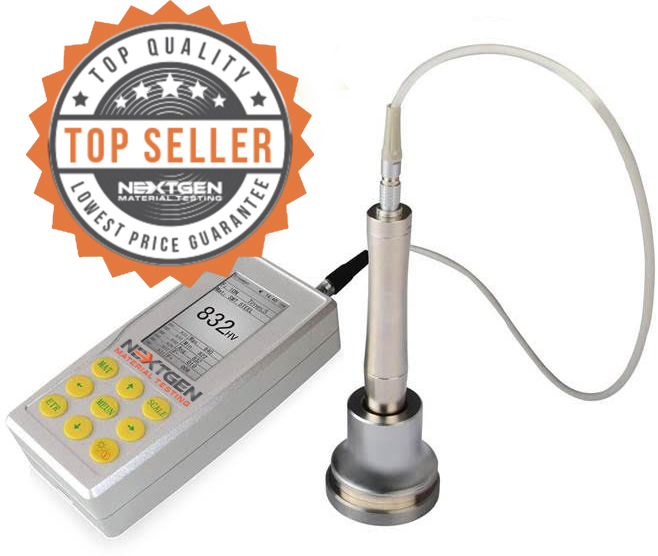

The UH200 non-destructive ultrasonic hardness tester, relying on the principle of ultrasonic vibration sensor rod, can easily and swiftly detect the material hardness of several metals without any damage.

This method produces no indentation and it has both high precision and speed. It makes use of a single chip technology and advanced sensing system which makes it better than the usual ultrasonic hardness testers in both function and structure. UH200 support value conversion among HV, HB, HRC, and others and the average of the multi-point measurement can be derived. Accurate display and printing of the results is also possible. It is popularly used in testing hardness of metal foil, finished workpiece, metal thin layer (electroplating layer, carburizing layer, nitriding layer, etc.), the special shape parts are easy to dismantle but the hard parts are difficult to move. It is a good equipment for testing precision to save cost and improve production pass rate. Read more about the potential application for the UH200 in our newest Mega Blog.

Working Principle

The ultrasonic hardness tester has a hand-held host and probe connected with the cable. The probe contains a vibration bar to connect the Vickers pressure head. The vibrating bar produces ultrasonic vibration, after the boot, the frequency of the vibration is fixed to the sensor on the vibrating bar to sensate, the probe head lower end is pressed into the material surface tightly, the micro-vibration rod to the shock to the material Microcrystal, to enable the grain vibrate at different frequencies, it will result in resonance once there is a synchronization of the two vibration frequency, this makes it possible for the sensor to detect the resonance frequency before and after. The value of the material hardness can be calculated based on the number of frequency change and the elastic modulus of the material.

Features:

The Ultrasonic Contact Impedance (UCI) tester is used for measuring the hardness value of small items, objects with a thin wall, complex forms, and to measure the hardness of surface hardened layers.

The built-in camera allows user to picture of testing object and mark tested area with corresponding hardness value.

UCI Hardness Tester has the sealed housing with rubber protective strips. It is ideal for use in workshop, and in-field conditions with high humidity, dust, etc. The hardness tester has frost-resistant display, which allows user to use the device at any season and in any virtually any climate zone. The device has PC software with a comfortable and intuitive interface.

- Highest Accuracy - ±3% HV, ±1.5HR, ±3%HB

- Microscopic Indentation - Indentation can be observed by high-power microscope only

- Quick Measurement - Result in 2 seconds

- Large LCD Display - Direct display of measurement results, time count, maximum, minimal, average and deviation.

- User-Friendly Interface - The system is easy to learn and operate even after short training

- 2-Year Extended Warranty for the Main Unit (Excludes Probe)

- Large Storage Capacity - Saves up to 2000 groups of measurement data

- Simple Calibration - Saves up to 20 groups calibration data for invoking and improve calibration efficiency.

- Hardness measurement of any mass products with a thickness of over 1 mm - inaccessible to the dynamic (Leeb) hardness testers (small parts, thin-walled structures, pipes, tanks, steel sheets, articles of complex shape, hardness control of metal coatings, etc.)

- Measuring the hardness of the surface hardened layer

- Small imprint after measuring (mirror surfaces of shafts necks, blades, gear teeth, etc.)

- Wide range of hardness testing

- Various measurement modes

- Calibration of any scale in any range

- Convenience and ease for measurement

- Optimized number of buttons

- Large full color graphic display with bright back-lighting

- Calibrations stored in memory of probe

- Internal memory and communication with PC

- New, intuitive menu with tips on the buttons

- Optional wireless mini printer

- Water resistant case

- Rubber protected bumper

- Graph - the mode of building of graph

- Histogram - the mode of building of histogram

- Statistics - the mode of statistic

- Smart - the mode of filtering of incorrect measurements

UCI method for the hardness testing:

The UCI hardness measuring method complies to ASTM A1038. The ultrasonic contact impedance (UCI) probe is purposed to be used for hardness measuring testing areas with minimal thickness (starting from 1 mm). It is specifically designed for objects of complex surface shape, and for measuring surface hardened layers hardnesses.

This method is very fast and easy: place the probe on the tested object surface, press the probe with the required effort to the surface and save the hardness value, shown on the display of the device. Small size diamond indenter allows measuring hardness value of all items thicker than 1 mm. The UCI method of hardness testing is the least destructive because the hardness tester with UCI probe leaves much smaller prints (imprints) than the majority of bench hardness tester would. That's why a portable hardness tester with UCI probe is the best choice. The unit comes with CE certificate of conformity for Portable UCI Hardness Tester.

Technical Specification:

Product NameUH200 – Ultrasonic Hardness Tester

| Model | UH200 |

| Loading Force | 5kgf manual probe (optional 1/2/10kgf manual probe) (optional motorized probe: 0.3/0.5/0.8/1kgf) |

| Measuring Range | Main Line: HB: 85-650; HV 10-2980 HV; HRC 20-70; HRB: 41-100; HRA: 61-85.6 HS: 34.2-97.3; Mpa: 255-2180N/mm Economical Line: HRC(10-80) HB (200-550) HV (200-999) |

| Hardness Scale | HV, HB, HRC, etc. |

| Measuring Accuracy | HV: ±3%HV; HRC: ±1.5HRC; HB: ±3%HB |

| Indenter | 136° Vickers Diamond Indenter |

| Measuring Direction | Support 360° |

| Hardness Indication | LCD display |

| Data display | Loading force, Testing-times, Testing result, Average, Maximum, Minimum, Deviation and Conversion scale. |

| Data Storage | Saves 2000 groups of measuring data and 20groups of calibration data |

| Operating Environment | Temperature: -10℃~50℃; Humidity: 30%~80%R.H |

| Operating Voltage | DC 6V |

| Dimensions | Machine: 160x80x31mm; Packing: 35x35x15cm |

| Net Weight | Approximate 500g (Without probe) |

| Gross weight | 5kg (After packing with standard accessories) |

Standard Package:

Product NameQ'ty

| Main Instrument | 1 |

| 5kgf Manual Probe | 1 |

| USB Cable | 1 |

| Probe Cable | 1 |

| Probe Silicone Cap | 1 |

| Instrument Manual | 1 |

| Accessories Box | 1 |

| Certificate | 1 |

Instrument Maintenance

Be cautious when using it to avoid any damage

In a strong magnetic field the accuracy of the precision sensor measurement will be reduced. While in use or after use, it is very essential to keep the instrument away from strong magnetic materials or fields.

FAQs

With the help of an ultrasonic vibration sensor rod and the UH200 non-destructive ultrasonic hardness tester, it is possible to quickly determine the hardness of various metals without causing any damage.

A hand-held host and probe connected by a cable make up the ultrasonic hardness tester. To connect the Vickers pressure head, the probe has a vibration bar. The vibrating bar generates ultrasonic vibration. After the boot, the vibration frequency is fixed to the sensor on the vibrating bar to sense, the probe head lower end is pressed firmly into the material surface, and the micro-vibration rod to the shock to the material Microcrystal to enable the grain to vibrate at different frequencies. Once the two vibration frequencies are synchronized, it will result in resonance, making it possible for the sensor to sense.

NextGen’s Ultrasonic Contact Impedance Hardness Tester – UH200 can display the following data: Loading force, Testing-times, Testing result, Average, Maximum, Minimum, Deviation and Conversion scale.

Click here to obtain a personalized quote!

The simplest response is that Rockwell hardness describes a metal object's resistance to penetration and permanent deformation by another material, such as a knife blade. It is a system of non-destructive metallurgical testing that assesses the true hardness and strength of steel, such as that used in the manufacture of knives. Engineers employ a common procedure called Rockwell testing to precisely express the hardness of metals.

The Rockwell hardness scale is used by all companies that produce steel products in America. No matter if the product is a ball bearing or a knife blade, the RC scale is the industry standard. Two experts in the field recommend Rockwell testing and how to carry them out.

The apparatus used to measure Rockwell hardness is relatively simple. It entails a mechanical process in which the depth of the indentation is measured as an indenting tool is pressed against the metal subject surface at various rates. The pressure application is precisely controlled by testing professionals based on the type of metal they are working with.

NextGen’s Ultrasonic Contact Impedance Hardness Tester – UH200 operating voltage is 6V.

Click here to obtain a personalized quote!

The Rockwell scale gauges a material's hardness by how resistant it is to being indented. The Rockwell test measures the difference between the depths of an indenter's penetration of a material under a large load and a preload (minor load). A single letter is used to designate various scales that use various loads or indenters. A result is a dimensionless number represented by the letters HRA, HRB, HRC, etc., where the final letter denotes the relevant Rockwell scale.

When evaluating metals, the linear correlation between indentation hardness and tensile strength exists.

A minor load and a significant load must be applied to ascertain a material's Rockwell hardness. The minor load establishes the zero position. While the heavy weight is applied and removed, the light load is kept constant. A dial with a harder material has a lower reading when measuring the depth of penetration in relation to the zero datum. In other words, there is an inverse relationship between hardness and penetration depth. By only displaying hardness values, Rockwell hardness avoids the time-consuming calculations required by other hardness evaluation systems.

NextGen’s Ultrasonic Contact Impedance Hardness Tester – UH200 economical line measuring range is HRC(10-80) HB (200-550) HV (200-999).

Click here to obtain a personalized quote!

A common rule of thumb for choosing a Rockwell scale is to choose the scale that specifies the biggest load and the largest indenter possible without going beyond permitted operation limits and taking into account circumstances that could affect the test outcome. These circumstances include testing on cylindrical specimens, test impressions that are too close to the specimen's edge or another impression, and test specimens that are thinner than the required minimum thickness for the depth of indentation.

To achieve accurate loading, the test axis should also be within two degrees of perpendicular. Furthermore, neither the test sample nor the tester should be deflected during the loading application by factors such as dirt under the test specimen or on the elevating screw. The surface finish must be kept spotless, and any decarburization after heat treatment must be eliminated.

For testing on a specific Rockwell scale, sheet metal can be too thin and too brittle to pass without going over the minimum thickness criteria and possibly denting the test anvil. In this situation, a diamond anvil can be utilized to consistently impact the outcome.

NextGen’s Ultrasonic Contact Impedance Hardness Tester – UH200 main line measuring range is HB: 85-650; HV 10-2980 HV; HRC 20-70; HRB: 41-100; HRA: 61-85.6 HS: 34.2-97.3; Mpa: 255-2180N/mm.

Click here to obtain a personalized quote!

Compared to other methods of hardness testing, the Rockwell test is typically quicker and more precise. All metals can be tested using the Rockwell method, with the exception of those where excessive variation would be introduced by the test metal's structure or surface conditions, where the indentations would be too large for the application, or where the sample size or sample shape would prevent its use.

The permanent depth of an indentation caused by a force or load on an indenter is measured using the Rockwell method. A sample is first subjected to a preliminary test force using a diamond or ball indenter, often known as a preload or mild load. In order to lessen the impacts of surface polish, this preload penetrates the surface. The baseline depth of indentation is measured following the holding of the preliminary test force for a predetermined dwell time.

From 3 kgf (used in the "Superficial" Rockwell scale) to 10 kgf (used in the "Regular" Rockwell scale), preliminary test loads (preloads) are available. Test forces totalling 15 kgf to 150 kgf (superficial and regular), as well as 500 to 3000 kgf, are used (macrohardness).

NextGen’s Ultrasonic Contact Impedance Hardness Tester – UH200 loading force is 5kgf manual probe (optional 1/2/10kgf manual probe)

(optional motorized probe: 0.3/0.5/0.8/1kgf).

Click here to obtain a personalized quote!

The UH200 non-destructive ultrasonic hardness tester can quickly and easily determine the material hardness of various metals without causing any damage by operating on the principle of an ultrasonic vibration sensor rod.

The Ultrasonic Contact Impedance (UCI) tester is used to gauge the hardness of small objects, those with thin walls, those with complicated geometries, and layers that have undergone surface hardening.

The user can take a picture of the object being tested and mark the tested region with the appropriate hardness rating using the built-in camera.

The sealed enclosure of the UCI Hardness Tester contains rubber protecting strips. It works best in environments like workshops and outdoor settings where there is a lot of dust and humidity. The hardness tester's frost-resistant display enables users to use the tool in almost any temperature zone and during any season. The gadget contains PC software with a welcoming and simple user interface.

NextGen’s Ultrasonic Contact Impedance Hardness Tester – UH200 Standard Package:

|

Product Name |

Q'ty |

|

Main Instrument |

1 |

|

5kgf Manual Probe |

1 |

|

USB Cable |

1 |

|

Probe Cable |

1 |

|

Probe Silicone Cap |

1 |

|

Instrument Manual |

1 |

|

Accessories Box |

1 |

|

Certificate |

1 |

Click here to obtain a personalized quote!

The method used by UCI to measure hardness complies with ASTM A1038. The ultrasonic contact impedance (UCI) probe's intended use is for hardness testing in areas with a thin thickness (starting from 1 mm). It is explicitly made for assessing the hardness of surface-hardened layers and objects with complex surface shapes.

This technique is quick and straightforward: place the probe on the surface of the object being tested, apply the necessary pressure, and save the hardness value that appears on the device's display. All objects thicker than 1 mm can have their hardness value measured using a small diamond indenter. The hardness tester with the UCI probe leaves far smaller prints (imprints) than the majority of bench hardness testers would, making the UCI method of hardness testing the least harmful. The ideal option is a portable hardness tester with a UCI probe. Portable UCI Hardness Tester comes with a CE certificate of compliance.

Ultrasonic Contact Impedance Hardness Tester – UH200 has 136° Vickers Diamond Indenter.

Click here to obtain a personalized quote!

The Rockwell hardness test is one of the most widely used indentation hardness tests today. The Brinell and Vickers hardness tests are also used, albeit less frequently. Most indentation hardness tests quantify the deformation that takes place when an indenter penetrates the material being tested. When conducting a Rockwell hardness test, the indenter is subjected to two levels of force at predetermined rates and dwell periods. In contrast to the Brinell and Vickers tests, where the indentation's size is assessed after it has been made, this is different. The difference in the depth of the indenter at two precise points during the testing cycle determines the material's Rockwell hardness.

A formula was developed to provide a number lying within an arbitrary range of values known as a Rockwell hardness scale, which is used to determine the value of hardness.

The measuring accuracy of NextGen’s Ultrasonic Contact Impedance Hardness Tester – UH200 is HV: ±3%HV; HRC: ±1.5HRC; HB: ±3%HB.

Click here to obtain a personalized quote!

The Ultrasonic Contact Impedance Procedure (UCI Method) is used in the ASTM A1038 test method to evaluate comparative hardness values on metallic samples. Measurements of hardness can be made using the UCI hardness test in places that are challenging to reach, including the sides of teeth or the roots of gears. The ASTM A1038 hardness test is a cursory assessment that is merely performed to gauge how hard the surface being tested is.

The probe is connected to the indicating unit, and the instrument is turned on to carry out the ASTM A1038 hardness test. The probe is securely grasped, with its axis perpendicular to the surface of the test piece. In the loading stage, constant pressure is applied to the test item. For as long as the load is active, the vertical probe position must be maintained. The equipment then displays the hardness result and emits an auditory signal to notify the completion of the measurement.

To sum up, NextGen’s Ultrasonic Contact Impedance Hardness Tester – UH200 complies with ASTM-A1038-05 Standard.

Click here to obtain a personalized quote!

In accordance with DIN 50159-1, the specimen should typically have a minimum thickness of 5 mm to prevent interference from the original ultrasonic signal from the vibrating rod that was partially transferred into the piece. This fact might lead to an incorrect interpretation of the findings.

However, the superposition of the ultrasonic waves can be prevented by coupling, which involves putting a thin oil coating over the interface between the sample and an additional large substance. In this manner, the wave propagates into the neighbouring body rather than being reflected, and interference is avoided. For such, you might use the precision measurement stand's base plate.

Another approach involves embedding the sample, which works well for surface measurements made with the UT200 scanner. Both approaches make it possible to do tests on smaller samples.

NextGen’s Ultrasonic Contact Impedance Hardness Tester – UH200 complies with DIN 50159-1.

Click here to obtain a personalized quote!

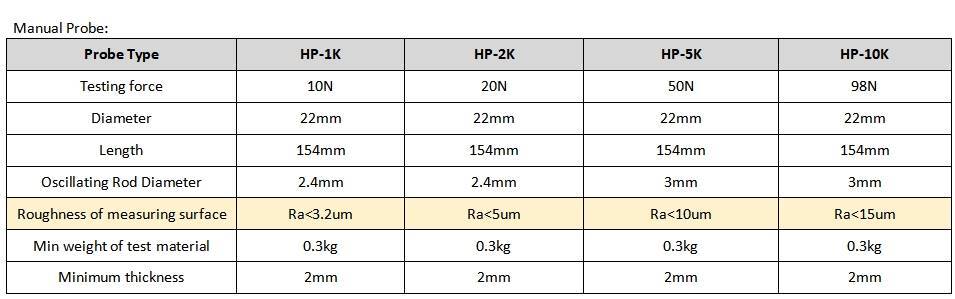

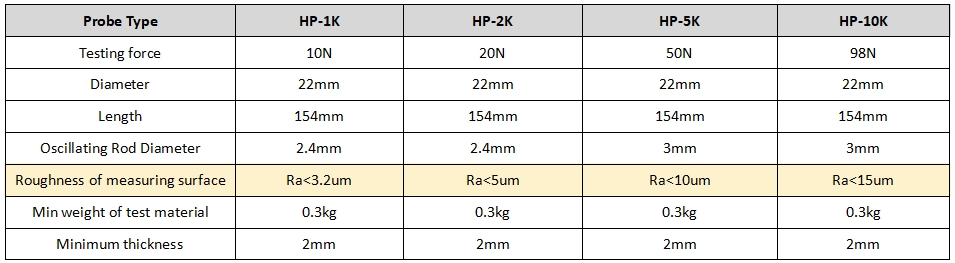

The surface roughness of your material depends on the type of probe you are hoping to test with. The below chart does an excellent job guiding you in the right direction based on your desired probe type. NOTE: HP-1K = 1kg probe, HP-2K = 2kg probe, etc.

Please refer to the below calibration steps for your Ultrasonic Hardness Testing System:

Step 1:

There are two HRC Blocks, one is 26.5, the other is 61.9. (Please check your block which may have a different value).

Step 2:

Measure the higher value hardness block first a few times. This will offer you a calculation of the average value. Note it down.

Step 3:

Press the "Set" button, the display shows "E". That is the set state. In this case, if you press the SET button, there will be 4 group values. First: the high block value 61.9; second: the high profile value (which may be around 45 - this is set by factory to guarantee accuracy; third: the Low block value, 26.5; forth: is the low profile value, (which may be around 14 - this is also set by the factory to guarantee accuracy).

When you calibrate the system, you need to only adjust the High profile value and the low profile value to correctly adjust the systems calibration. If on the first step when running your tests, you get a high average value of for example, 65; you need to adjust the high profile value to a higher value. It won't be (65-61.9=3.1), however, it may be 1,2,1.5,2.5. You will need to try it a few times to find the accurate value until you get your hardness block value of 61.9.

When calibrating the low value, the same process applies. Adjust the profile value to a higher value, when the test value is lower than the block value.

There are a few factors that may affect the reading accuracy. They include thickness, hardness, weight and also surface roughness. Please refer to the below roughness table for reference.

Here are the two most important questions we ask our clients to answer to help offer the optimal solution for their UCI needs.

#1 What are the hardness ranges of your materials?

#2 Would you happen to know the surface roughness of your materials?

Contact us today and one of our qualified representatives today to get the help that you need with the right solution for your Ultrasonic hardness testing requirements.

When performing UCI testing on harder and thinner materials of around 3mm because knives typically have a very high hardness, a 2mm or 3mm (1/8") thickness can be accurately tested directly. For example, gears and knives are typically hardened materials with hardness values in the carbide ranges. Provided the specimens are over 2mm thick, the operator is not required to stack the materials in order to gain accurate reading results.

Please refer to the below picture example of an abrasive cutting wheel with a 2 mm thickness tested on our UH200 model.

When performing the Ultrasonic Hardness Test while testing thinner materials, in the 2-5mm range, an excellent solution is to stack the specimens to increase thickness. The goal is to bring the thickness over 5mm (0.2"). This will drastically improve your accuracy.

The same concept applies to the specimen's weight. In order to optimize accuracy, the weight of the specimen should be over 300g. Should your specimens be lighten than 300g, a stacking option may be highly beneficial to meet this weight requirement. This too will improve your testing result accuracy.

The UH200 model offers operating temperature between -10*C - +50*C. Additionally, the unit can be stored within temperature ranges of -30*C - +60*C.

The Ultrasonic tester can get the HV scale directly, and support conversions for the following scales and ranges:

HBW (85-650) / HRA (61-85.6) /HRB (41-100) /HRC (20-70)/HS (34.2-97.3), etc.

NextGen's Ultrasonic hardness tester offers HV scale range of 8-1500 HV for the Main Line model and 200-999 for the Economical Line model.

The UH200 ultrasonic tester comes standard with a Brinell scale which it automatically converts and displays hardness readings on the unit. Simply set the scale to HBW and the unit will take care of the rest.

Krautkramer Mic 10 tester is a German engineered unit. They have an overall good market presence for over 10 years. Based on our most recent competitive research, the technology is somewhat out of date with the primary design being virtually identical to what it was when first manufactured.

UH200 offers a unit that provides your facility with a machine offering the same functions. The difference is our improved ease of use and accuracy. The major difference, however is the price. Request quote today to learn more.

The main accessories available for the UH200 ultrasonic hardness testing instrument include a variety of probes. There are manual as well as automatic motorized probes. Probes for hard to reach areas with long needle point indenters and shorter probes for getting into tight spaces. We also have a variety of forces available for our probes which require different loading forces before a measurement is ready. This is especially useful when you are looking to UCI test more fragile specimens.

With a variety of hardness probes requiring different forces, the ultrasonic contact impedance hardness testing system is prepared to test on applications as delicate as metal foil and reach as far as finished work pieces, electroplating layers, carburizing layers, nitriding layers and other heat treat hardness testing requirements.

While the UCI tester does use a Vickers indenter, the instrument will provide values in Vickers, Brinell and Rockwell (HRC and HRB). With the UH200 UCI portable hardness tester, you can set and forget about constantly requiring to change your favorite scale.

Using a Vickers indenter and ultrasonic technology, the hardness tester is first calibrated using a sample of known hardness. The working principle, in short, is the use of an oscillating rod inside your hardness probe. When you apply force to the indenter on your sample, you change the frequency of the oscillating rod. By doing this, and having calibrated using the sample of known hardness, the ultrasonic hardness tester can compare and determine your material hardness.

Related Products

NG - LeebGen 3000 - Leeb Rebound Portable Hardness Tester

LeebGen3000 is a non-destructive precision metal hardness tester developed according to the latest industry standards. LeebGen 3000 is equipped with features which provide the instrument with a combination of a user-friendly interface and exceptional test result accuracy. This in turn allows for ease of operation and an accurate conversion display of virtually any metal hardness testing value.

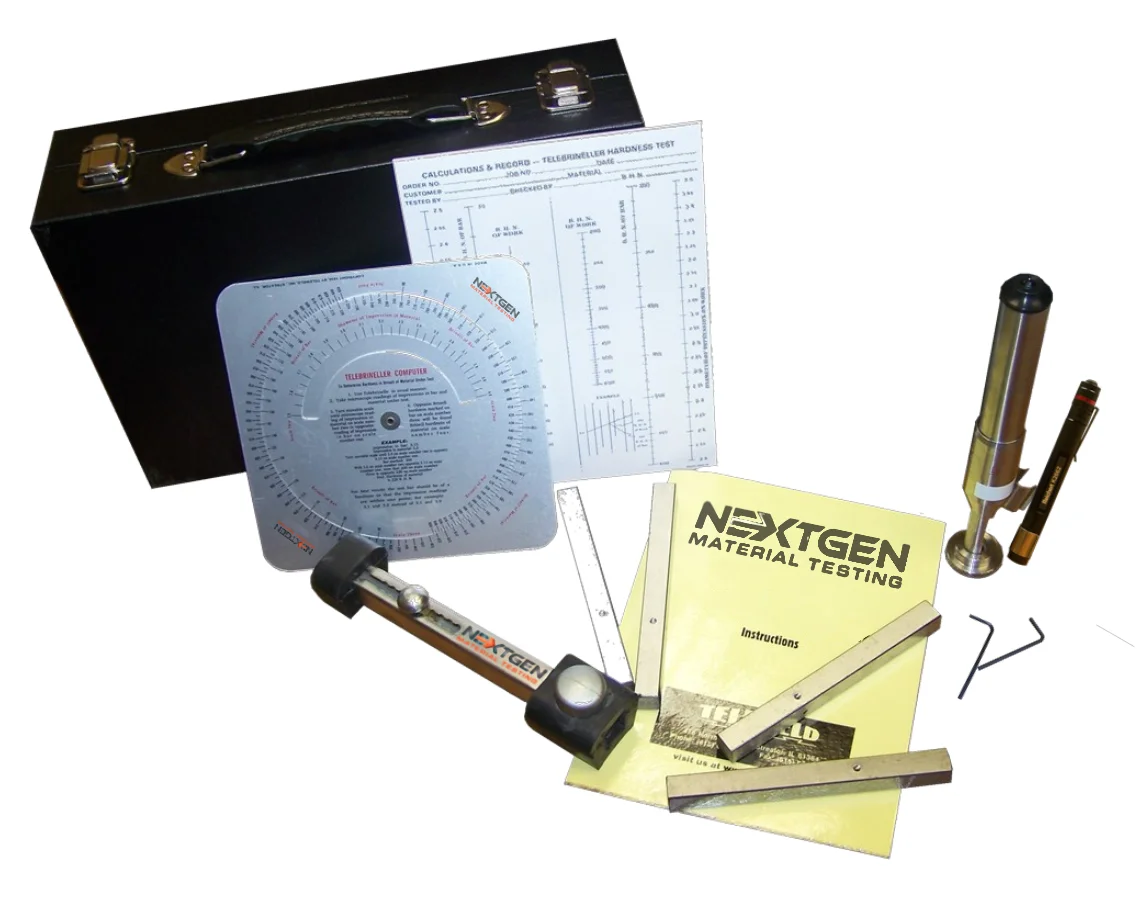

NextGen Telebrineller Brinell Hardness Testing System

The Telebrineller Brinell Hardness Testing System stands out as the best QA solution for ensuring top-notch quality. Developed specifically for welding crews, Telebrineller draws on over fifty years of field experience and solid metallurgical knowledge. Portable and practical, the entire Telebrineller system, housed in a case, weighs less than ten pounds. It's an ideal choice for Brinell hardness testing in any situation.

Surface Roughness Testers

High accuracy surface roughness testing systems for material surface analysis and statistical processing of data. Multiple model variations to help fit your technical and budgetary expectations.

Hardness Test Blocks, Indenters and Hardness Testing Accessories

Certified Test Blocks are a requirement as a reference material for any type of hardness testing. At NextGen, we understand the importance of a Test Block to ensure the accuracy of your hardness testing procedures.

Metallography Consumables

Learn about the full scope of NextGen's cutting, polishing & grinding, mounting and etching metallography consumables. Our consumables are compatible with virtually all global brands, offering a rare combination of exceptional quality, longevity and affordability.