Plastic Testing Equipment

Certified

Description

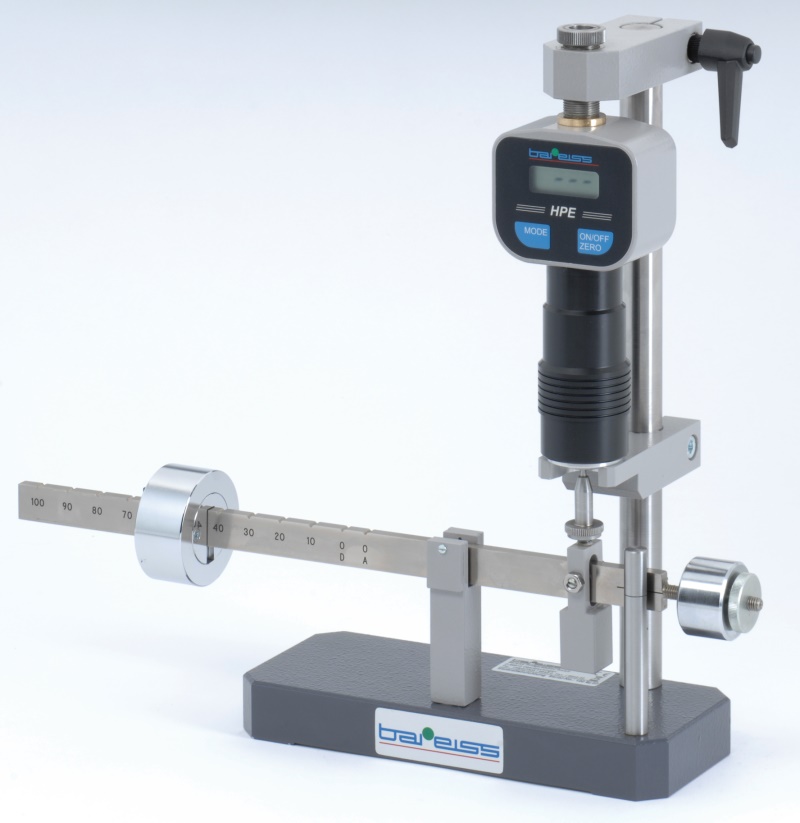

This German manufactured fruit firmness penetrometer and fruit hardness testing device is designed specification for the determination of the pulp hardness of a given fruit. Additionally, the system is fully capable of testing the firmness of vegetables, meat and even fish thanks to the interchangeable indenters. This state-of-the-art device is invaluable for trading companies serious about their quality control procedures. This fruit texture analyzer helps identify the harvest date of the specific fruits relative to the time of transpirations and storage. One of the most valuable features of the ideal replacement for fruit penetrometer system is that it offers a rare non-destructive testing solution for your fruits and vegetables which can save thousands of dollars in inventory. Please visit our blog page to learn more about the importance of a reliable Fruit Firmness Tester in the Food Industry.

A unique value of the tester is that it is a non-destructive test method to determine the ripeness of fruit, vegetables and other food products. The fruit hardness tester can be used on the following:

The tester provides important quality control information designed for quality control and price setting benefiting both the seller and the end-user. The system is famous for its ability of using the portable fruit hardness tester for both indoor and outdoor workplace conditions. Out fruit firmness tester is also the optimal solution to replace a vegetable penetrometer.

System Benefits

- Non destructive testing to preserve inventory

- Highly reproducible and accurate

- Interchangeable test anvils for virtually all types of fruits, vegetables, fish and other products

- Available calibration certification

- Leading instrument for the food industry

- The ideal replacement for fruit penetrometer

Testing Method

When performing a fruit firmness test, the operator measures the opposite sides of each fruit, vegetable or other food products for the purpose of identifying the firmness value on both the sun-side and the shadow-side. By applying a constant pressure on the fruit over a defined measuring time, the system indicates the hardness value of the specific product. The major benefit of this non-destructive test is that the fruit firmness tester does not penetrate the peel of the tested food product.

Standard Configurations

- Fruit firmness tester – main unit

- Designated test anvil

- Charger

- Foam-fitted Case.

NOTE: Additional anvils are sold separately.

Features

- German manufactured

- Ergonomic and portable design

- Interchangeable anvils designed to test fruits, vegetables, meat, and fish

- The optimal solution to replace a vegetable penetrometer

- The system comes standard with 1 anvil with additionally anvils which can be purchased at a later time.

Anvil Specifications

| Indenter Size | Fruit or Vegetable |

|---|---|

| zyl 0,1 cm2 (Ø 3,65 mm) |

for peaches, apricots and plums |

| zyl 0,25 cm2 (Ø 5,63 mm) |

for cherries, melons, tomatoes, blueberries, grapes, eggplant |

| zyl 0,50 cm2 (Ø 7,98 mm) |

or strawberries, water melons, broccoli, meat, tofu |

| Ø 5,0 mm | ball for avocados, papayas, apples, mangoes, cucumber, pepper,pears, oranges and citrus fruits, onions (soft) |

| Ø 2,5 mm | ball for kohlrabi, carrots, cucumber, radish, courgette, onion (firm) |

| radius 6,35 mm | for boiled potatoes, bananas, smoked fish, boiled beetroot |

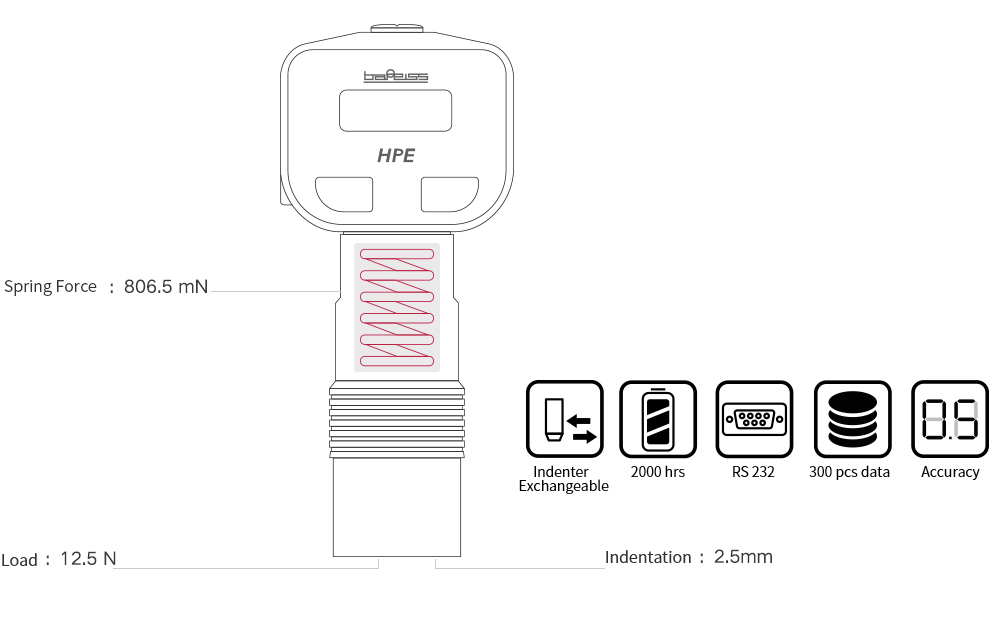

Technical Specifications

| Model | Fruit Firmness Tester |

|---|---|

| Measuring Range | 0-100 Empirical Units for Comparison |

| Battery Life | 200 Hours |

| Memory | 300 Readings |

| Output | RS232 |

| Dimensions (L x W x H) |

7.5 x 2.75 x 1.58" 190 x 70 x 40 mm |

| Weight | 1.3 lbs / 0. 6kg |

Accessories

Calibration Device Check for the HPE (Fruit Firmness Tester Units)

The calibration device is supplies in accordance with ISO 9000 standard. The system is checked for accuracy of Shore hardness testers via spring force control by intervals of ten for the measuring ranges Shore A/B/0/C/D/DO and L, L/c. DIN 53 505, EN ISO 868, NF EN ISO 868, ASTM D2240, JIS K 6253.

Full Scope of Test Anvil sfor the Fruit Firmness Tester

The unit can be equipped with any one of the following test anvils for your fruit, vegetables, meat and fish firmness testing including:

- 0.1 cm2 for peaches, apricots and plums

- 0.25 cm2 for cherries and tomatoes test anvil

- 0.50 cm2 for strawberries Taster Kugel

- Ø 5 mm for apples and avocados Taster Kugel

- Ø 2.5 mm for carrots, cucumbers, radish, kohlrabi and melons

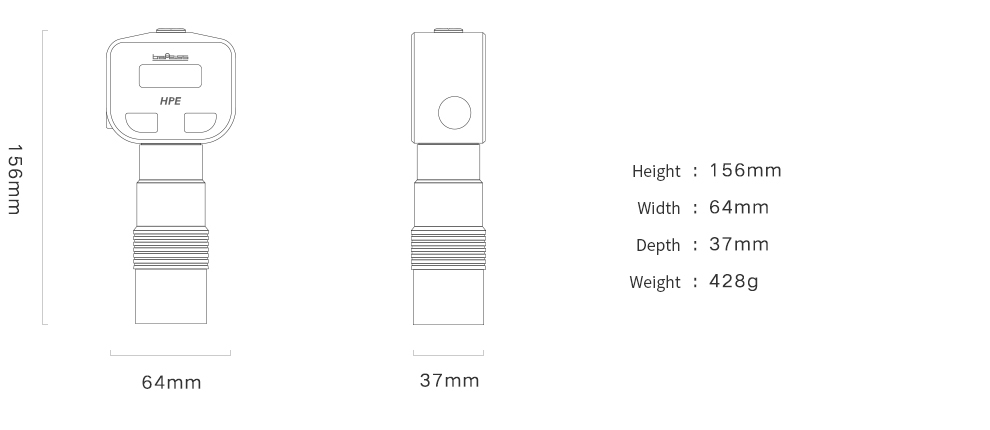

System Dimensions

FAQs

The Fruit Firmness Tester by NextGen is a versatile tool that can be used to test a variety of fruits. The system can measure the firmness of hard and soft fruits, including but not limited to apples, pears, peaches, kiwifruit, mangoes, avocados, strawberries, grapes, and cherries.

For hard fruits such as apples and pears, the tester is equipped with an 11 mm plunger designed to penetrate the fruit's skin and measure its firmness. For softer fruits like peaches and strawberries, a 3 mm plunger is used to ensure accurate readings without damaging the fruit.

The Fruit Firmness Tester from NextGen Material Testing can also be used to test other types of fruits, such as avocados, which require a different testing method due to their unique texture. The device is equipped with a specialized adaptor to hold the avocado in place while the firmness is measured.

Click here to request a personalized quote today!

Measuring fruit firmness plays a crucial role in ensuring the quality and longevity of fruits. This importance is highlighted by the fact that fruit growers and producers frequently use firmness testing to make important decisions, such as when to harvest fruits, when to transport them, and when to sell them.

Fruit firmness is a vital indicator of the fruit's maturity, freshness, and ripeness, as well as its ability to withstand handling and transportation. Fruits that are too firm may not be fully ripe or may lack flavour, while fruits that are too soft may be overripe and vulnerable to damage. By measuring fruit firmness, you can ensure that fruits are at the optimal stage of ripeness and quality, which translates into better flavour and longer shelf life.

The Fruit Firmness Tester from NextGen provides a reliable and accurate method for measuring fruit firmness, making it an invaluable tool for fruit growers, distributors, and researchers.

Click here to request a personalized quote today!

The NextGen fruit firmness tester is a handheld device that measures the firmness of fruit by applying a small amount of pressure to the fruit's surface. The device uses a small plunger attached to a spring-loaded mechanism inside the tester. When the plunger is pressed against the fruit's surface, the spring is compressed, and the device records the force required to compress the spring.

To use the NextGen fruit firmness tester, the user simply places the plunger on the surface of the fruit and presses down gently until the plunger reaches the fruit's flesh. The device will display a reading of the firmness of the fruit in units of pressure, typically in Newtons or pounds-force.

The tester can be calibrated for different types of fruit and can be adjusted to accommodate variations in fruit size and shape. Moreover, proper calibration before use to ensure accurate readings is a must!

Click here to request a personalized quote today!

The NextGen fruit firmness tester can test a wide range of fruits, such as apples, pears, peaches, tomatoes, etc. These fruits are often subject to strict quality control measures, and measuring their firmness is an essential part of this process to minimize business mistakes.

The tester works by applying a specified amount of pressure to the fruit and then measuring the resistance that the fruit offers using a small probe that is attached to the device externally. The probe is inserted into the fruit, and the device then provides a digital readout of the firmness of the fruit.

The NextGen fruit firmness tester can be used to test fruits that are difficult to test using other methods. This includes fruits with irregular shapes or textures, as well as fruits that are particularly soft or delicate.

Click here to request a personalized quote today!

NextGen's Fruit Firmness can measure the firmness values Tester range from 0.5 to 45 kg/cm², depending on the type of fruit being tested. You can measure both soft and hard fruits, providing valuable information for growers and suppliers.

For softer fruits such as berries, the NextGen's fruit firmness tester can measure values from 0.5 to 10 kg/cm². In contrast, for harder fruits such as apples, pears, and peaches, the device can measure values in the higher range, up to 45 kg/cm².

The ability to measure such a wide range of firmness values makes the NextGen's fruit firmness tester a versatile tool for farmers, suppliers, and researchers alike. With our tester, you can obtain accurate and reliable measurements that can be used to determine the ripeness and quality of their fruit, as well as to optimize harvesting and post-harvesting practices.

Click here to request a personalized quote today!

Yes, NextGen's fruit firmness tester can be connected to a computer or mobile device for data analysis. The tester comes with a USB cable which you can use to connect to a computer or laptop. Once connected, you can transfer data to the computer automatically or manually, depending on the mode you chose. Excel compatibility is available, and can be used to generate reports, graphs, and other data visualization tools.

In addition, NextGen has also developed a mobile app that can be downloaded and installed on smartphones and tablets. The app allows users to connect their fruit firmness tester to their mobile device via Bluetooth and transfer data wirelessly. It is user-friendly and offers features such as real-time data analysis, data management, and sharing capabilities. The app also enables operators to configure the device settings, including the test parameters and unit of measurement.

Connecting your NextGen Fruit Firmness tester to a computer allows you to track changes in fruit firmness over time, analyze trends, and make informed decisions on harvesting, processing, and storage.

Click here to request a personalized quote today!

Proper cleaning and maintenance of your NextGen fruit firmness tester are crucial for accurate and consistent readings and for prolonging the device's lifespan. After each use, cleaning the tester with a damp cloth and mild detergent is recommended. Avoid using abrasive or harsh chemicals, as this may damage the device. Be sure to dry the tester thoroughly before storing it in a clean and dry place.

It is also important to regularly calibrate the tester to ensure its accuracy. Calibration involves comparing the readings of the tester to a known standard and adjusting as necessary. NextGen Material Testing provides instructions on how to perform calibration using their provided calibration weights.

In addition to regular cleaning and calibration, it is recommended to periodically inspect the tester for any signs of wear or damage. If any parts appear damaged or worn, consider having them replaced or repaired by a qualified technician to ensure the device continues to function properly.

Click here to request a personalized quote today!

Vibration measurements are widely used to assess the firmness of fruits. The test is performed the following way. When a fruit is vibrated, the force generated by the vibration can penetrate the fruit's surface and generate an oscillation that travels through the flesh. The amplitude and frequency of the oscillation depend on the fruit's firmness, which can be quantified using various methods.

One commonly used method for measuring fruit firmness is the non-destructive acoustic method. This method involves using a small accelerometer to measure the frequency and amplitude of the vibration generated by tapping the fruit with a small metal rod. The fruit's firmness is then calculated based on the relationship between its oscillation frequency and stiffness.

Another method is the destructive penetrometer test, which involves pushing a probe into the fruit's flesh and measuring the force required to penetrate it. This method is more invasive and can damage the fruit but provides a more accurate firmness measurement. Using NextGen's Fruit Firmness Tester allows growers and distributors to ensure that they deliver products at peak ripeness, enhancing their flavour, texture, and shelf life.

Click here to request a personalized quote today!

Firstly, a fruit firmness tester provides more objective and accurate results than human sensory evaluation. Human sensory evaluation can be influenced by factors such as individual variation in perception, fatigue, and subjective interpretation of fruit texture. In contrast, a fruit firmness tester measures the force required to penetrate the fruit, providing a quantitative measure of fruit firmness. This eliminates subjectivity and ensures consistency in the measurement.

Secondly, using a fruit firmness tester is faster and more efficient than human sensory evaluation. The process of manually squeezing fruit to determine firmness can be time-consuming and may not be feasible for large-scale fruit testing. In contrast, a fruit firmness tester can provide results in a matter of seconds, making it a more efficient tool for fruit testing.

Finally, using a fruit firmness tester reduces the risk of damage to the fruit during testing. Squeezing fruit manually can cause bruising or other damage to the fruit, affecting its quality and shelf life. The non-destructive nature of a fruit firmness tester allows for repeated measurements without damaging the fruit.

Click here to request a personalized quote today!

Ultrasonic waves can propagate through materials, and the texture and structural properties of the materials influence their propagation characteristics.

When an ultrasonic wave is transmitted into a fruit, it travels through the material until it reaches the opposite surface, where it is reflected to the transmitter. The time it takes for the wave to travel through the fruit and back to the transmitter is recorded. This time is used to calculate the velocity of the wave. The velocity of the wave is related to the density and elasticity of the fruit tissue, which are indicators of fruit quality.

There are different types of ultrasonic sensors that you can use. They are contact and non-contact sensors. Contact sensors are placed on the surface of the fruit, while non-contact sensors emit waves from a distance. The advantage of non-contact sensors is that they do not deform the fruit and can be used to measure the texture of delicate fruits without causing damage.

Click here to request a personalized quote today!

A penetrometer consists of a probe that penetrates the fruit and measures the force required to do so. The best way to use a penetrometer to test fruit firmness is to follow a standardized protocol. Here are the steps to follow:

- Choose the right probe size: Select the appropriate probe size for the fruit you are testing. A larger probe may cause the fruit to rupture, while a smaller probe may not penetrate the fruit deeply enough.

- Position the fruit correctly: Place it on a stable surface and ensure it is positioned vertically, with the stem-end facing up. This will allow the probe to penetrate the fruit at the correct angle.

- Apply pressure gradually: Apply pressure to the probe gradually and steadily until it penetrates the fruit to a depth of 8-10 mm. Avoid jerky movements, as they can lead to inaccurate readings.

- Record the reading: Once the probe has penetrated the fruit, record the maximum force required to do so. This value represents the firmness of the fruit.

- Repeat the test: To ensure accuracy, repeat the test on multiple fruits and take the average of the readings.

By following this protocol, you can ensure that your penetrometer readings are accurate and reliable.

Click here to request a personalized quote today!

By accurately measuring the firmness of fruits, it becomes easier to determine the optimal time for harvesting and storage. This is because fruit firmness is an essential indicator of ripeness, and determining it accurately can prevent premature harvesting or storage beyond the optimum time. Harvesting at the right time ensures that fruits will reach the market in perfect condition and remain fresh for longer, reducing the likelihood of spoilage and waste.

Additionally, fruit firmness testers can help identify variations in fruit quality and firmness, enabling producers to grade and sort fruits accordingly. This ensures that only the best quality fruits are sent to market, while lower-grade fruits can be used for other purposes such as processing or animal feed.

Overall, the use of fruit firmness testers in the fruit industry can lead to better quality fruits, reduce spoilage, and increase marketability, all of which contribute to reducing food waste.

Click here to request a personalized quote today!

Generally, fruit that is stored for longer periods of time tends to soften as it continues to ripen. Therefore, the ideal firmness level for long-term storage fruit is typically higher than that of fresh fruit.

For example, apples that are intended for long-term storage are typically picked at a firmer stage of ripeness and stored at a temperature of around 32-35°F with controlled humidity levels. The ideal firmness level for these apples would be around 16-18 lbs of force when measured using a fruit firmness tester such as a penetrometer.

Similarly, pears that are intended for long-term storage are also typically picked at a firmer stage of ripeness and stored at a temperature of around 30-31°F with controlled humidity levels. The ideal firmness level for these pears would be around 11-13 lbs of force when measured using NextGen's fruit firmness tester.

Click here to request a personalized quote today!

The Streif index is a mathematical formula that uses fruit firmness measurements to predict the optimal harvest time for fruits. It is used for fruits that are harvested before ripening, such as apples, pears, and cherries. The index is calculated using the fruit's maximum force of rupture, which is the force required to break the skin or flesh of the fruit.

To calculate the Streif index, the maximum force of rupture is divided by the fruit's diameter. This results in a ratio that represents the fruit's firmness-to-size relationship. This ratio is then used to predict the optimal harvest time for the fruit. The ideal Streif index value varies depending on the type of fruit and the intended use. A higher Streif index value indicates a firmer fruit, which is desirable for storage and transportation purposes.

Using the Streif index allows growers can harvest their fruits at the optimal time, reducing the risk of premature harvesting or over-ripening, resulting in better fruit quality and increased profits. Furthermore, it can also help minimize food waste by ensuring that the fruits are not harvested too early, preventing them from being spoiled before reaching the market.

Click here to request a personalized quote today!

Non-destructive acoustic impact response involves generating a small impact on the surface of the fruit using a device, such as an accelerometer, and then measuring the resulting sound waves. These sound waves are analyzed to determine various properties of the fruit, such as its firmness, maturity, and quality.

During the test, the accelerometer is attached to the fruit surface, and then a tiny impact is applied using a spring-loaded striker. The accelerometer records the resulting vibrations, which are then analyzed to determine the fruit's texture properties.

Non-destructive acoustic impact response provides a quick and non-invasive method to assess fruit texture. Non-destructive acoustic impact response has also been found to be a reliable method for assessing the quality of fruits, which can help reduce waste by identifying fruits that are too ripe or damaged and not suitable for sale.

Click here to request a personalized quote today!

The Fruit Firmness Tester's calibration device is supplied per the ISO 9000 standard. This international standard outlines the requirements for a quality management system in organizations. It provides a systematic approach to managing the processes and activities of a company to ensure customer satisfaction and continuous improvement. The Fruit Firmness Tester is a critical tool used in the food industry for measuring the firmness and ripeness of fruits, vegetables, and other food products. The instrument must be calibrated correctly to ensure accurate and consistent results.

The calibration device supplied with the Fruit Firmness Tester checks for the accuracy of Shore hardness testers via spring force control by intervals of ten for the measuring ranges Shore A/B/0/C/D/DO and L, L/c. This ensures that the Fruit Firmness Tester is accurate and reliable in its readings, allowing for effective quality control measures to be taken in the food industry. The calibration device meets the standards set forth by DIN 53 505, EN ISO 868, NF EN ISO 868, ASTM D2240, and JIS K 6253, which are recognized international standards for calibration and testing equipment.

Click here to request a personalized quote today!

The standard configuration of NextGen's fruit firmness tester includes the main unit of the tester, a designated test anvil, a charger, and a foam-fitted case. You can use the fruit firmness tester right out of the box without any additional purchases required.

The main unit of NextGen's fruit firmness tester is ergonomic and portable, making it easy to use indoors and outdoors. The tester also comes with a designated test anvil, specifically designed for testing fruit and vegetable firmness. The charger included in the standard configuration ensures that the tester is always ready for use, while the foam-fitted case protects the device during transport and storage.

Please note that the standard configuration of the fruit firmness tester only includes one anvil. However, the tester is designed to accommodate interchangeable test anvils, which can be purchased separately. These additional anvils allow the tester to be used for a wide range of applications, including testing the firmness of meat and fish.

Click here to request a personalized quote today!

NextGen's Fruit Firmness Tester comes with a few accessories that can be purchased separately. One of the available accessories is the calibration device, which complies with ISO 9000 standard. The calibration device is used to check the accuracy of the Shore hardness testers via spring force control by intervals of ten for the measuring ranges Shore A/B/0/C/D/DO and L, L/c. This ensures that the device remains calibrated and accurate over time.

Another accessory available for the Fruit Firmness Tester is the additional anvils. While the device comes standard with one anvil, additional anvils can be purchased later to expand the range of fruits, vegetables, meat, and fish that can be tested. The available anvil sizes include 0.1 cm2 for peaches, apricots, and plums, 0.25 cm2 for cherries, melons, tomatoes, blueberries, grapes, and eggplant, 0.50 cm2 for strawberries, watermelons, broccoli, meat, and tofu, Ø 5.0 mm ball for avocados, papayas, apples, mangoes, cucumber, pepper, pears, oranges, and citrus fruits, Ø 2.5 mm ball for kohlrabi, carrots, cucumber, radish, courgette, and onion, and radius 6.35 mm for boiled potatoes, bananas, smoked fish, and boiled beetroot.

Other available accessories for the Fruit Firmness Tester include a foam-fitted case to protect the device during transportation and storage and a charger to ensure that the device is always ready for use

Click here to request a personalized quote today!

The accuracy of NextGen’s Fruit Firmness Tester is checked by using certified test blocks or samples. These blocks are made to a specific hardness and are traceable to a national or international standard. The firmness tester is then used to measure the hardness of the test blocks, and the results are compared to the known hardness values of the blocks. Any deviation from the expected values indicates a need for calibration or adjustment of the tester.

Another method for checking the accuracy of Fruit Firmness Tester by using multiple testers to measure the hardness of the same sample. If the results are consistent across all testers, it is an indication that they are accurately calibrated. Any differences in the results may indicate that one or more of the testers need calibration.

Regular calibration and maintenance of NextGen’s Fruit Firmness Tester are crucial to ensure their accuracy. Calibration intervals and procedures may vary depending on the manufacturer's recommendations, frequency of use, and the quality management system in place.

Click here to request a personalized quote today!

The NextGen Fruit Firmness Tester is a portable device designed to accurately measure the firmness of fruits. It is lightweight and compact, making it easy to use and transport.

NextGen's Fruit Firmness Tester weighs approximately 800 grams (28.2 ounces), making it easy to hold with one hand. Its dimensions are 180mm x 76mm x 48mm (7.1in x 3in x 1.9in).

The compact size and lightweight nature of the NextGen Fruit Firmness Tester make it a convenient tool for use in the field or laboratory. It can be used to measure the firmness of fruits such as apples, pears, kiwifruit, cherries, and peaches. It is also ideal for use in the processing and packaging of fruits to ensure quality control.

Related Products

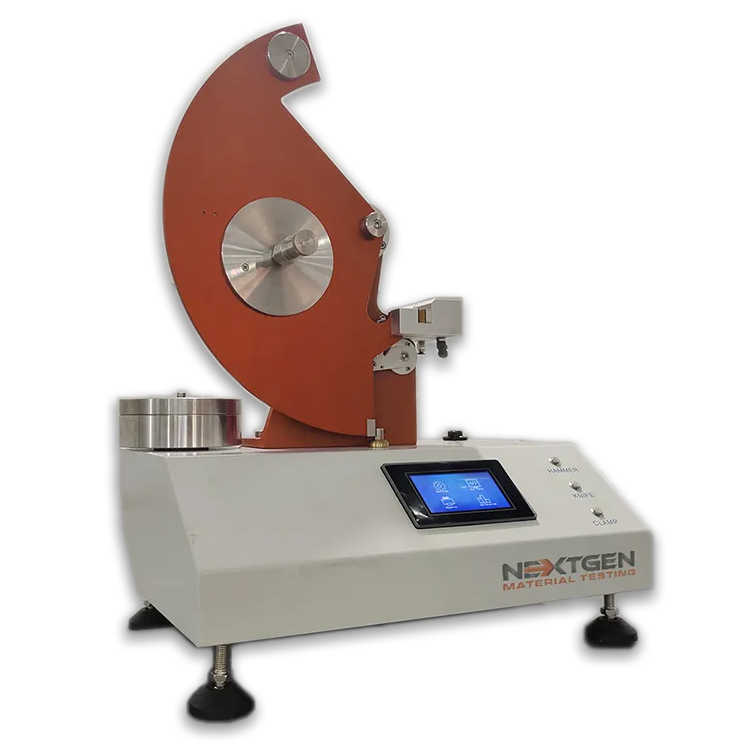

GenElm Series Elmendorf Tearing Tester – 64N and 128N Models

The GenElm Series Elmendorf Tearing Tester is designed for precise measurement of tear strength in fabrics, plastic films, paper, nonwovens, and technical textiles. Available in 64 N and 128 N models, it complies with ASTM, ISO, and DIN standards to provide accurate and comparable results across laboratories. The system features a touch-screen interface, pneumatic clamping, automatic specimen cutting, and data export via RS232, combining usability with consistent performance.

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

HDT/VICAT Testing Machine – Thermal Analysis for Plastics NG-HDT

The NG-HDT HDT/Vicat testing machine measures HDT and Vicat softening temperature (VST) for thermoplastics, including pipes and fittings. It supports common ISO, ASTM, and GB/T methods run under constant load with controlled heating. The system is available in 3-station and 6-station configurations with touchscreen control for the full test sequence. Measurement uses Class A PT100 temperature sensing and LVDT displacement monitoring, with an immersion oil bath rated up to 300°C (572°F). Results can be saved and exported over Ethernet, with options such as a chiller and external oil-vapor extraction/filtration.

Class J - Charpy and Izod Automatic Impact Testing System - 1J - 50J

Class J is widely used for lzod and Charpy impact test on softer metals, plastics and rubber specimens. Equipped with tensile impact pendulum and fixtures, it can carry on tests on plastic film and sheet. The newly enhanced design offers the most cost-effective configuration to address Charpy test from 1J to 50J (0.7 - 37 ft/lbs), and lzod test from 1J to 22J (0.7 - 16 ft/lbs).

Melt Flow Indexer

Our melt flow indexer is a highly precise instrument designed for the measurement of melt flow rate (MFR)/(MI) or melt volume rate (MVR) in quality control and research applications.

NG-ImpactFall – Falling Weight Impact Tester

Our falling weight impact tester finds extensive application in conducting external impact strength tests on plastic and non-metal materials.

High Energy Elemendorf

Measure the tearing strength of plastic materials with the NG-HE Elemendorf, a versatile tester with advanced potential energy calculation.

NextGen Environmental Chambers NG-EC 100,150,225,408,1000

The temperature and humidity NextGen Environmental Chambers features a sturdy cabinet made of cold-rolled steel and stainless steel.

HDA 120 - Hardness and Density Automation Test System

The HDA 120 test system is a versatile solution for semi-automatic detection of sample hardness and density.

NG-EML Series B – Dual Column Bench Top Universal Testing Machine (100 N – 10 kN)

The NG-EML Series B is a high-precision dual-column benchtop universal testing machine engineered for tensile, compression, and flexural testing in the 0.1 kN to 10 kN range. It features Class 0.5 accuracy, a rigid FEM-optimized frame, and a direct-drive servo system with advanced closed-loop control, making it ideal for testing rubber, plastics, metals, composites, and high-performance polymers in both R&D and quality assurance settings.

NG-EML Series C – Dual Column Bench Top and Floor Standing Universal Testing Machine (5 kN – 50 kN)

The NG-EML Series C is a precision-engineered dual-column universal testing machine for tension, compression, and flexural testing of metals, composites, rubbers, and polymers. Available in both bench-top and floor-standing formats, with force capacities from 5 kN to 50 kN and Class 0.5 accuracy.

NG-EML Series D – Floor Standing Universal Testing Machine (50 kN – 1000 kN)

The NG-EML Series D – Floor Standing Universal Testing Machine (50 kN–1000 kN) is a dual-column system for tensile, compression, flexural, shear, and cyclic testing of high-strength metals, composites, polymers, and advanced materials. Available in single-space and dual-space configurations, it meets ASTM E8, ISO 6892-1, ISO 527, and GB/T 228 standards. With closed-loop control, 1200 Hz sampling, ultra-low speeds (0.00005 mm/min), and waveform generation, it is ideal for aerospace, automotive, construction, and research labs.

GenTest – Advanced UTM Testing Software

GenTest Software provides test control and data acquisition for universal testing machine workflows used in quality control and materials testing. It combines method templates, step-based sequencing, live curve monitoring, and built-in calculations in one environment. The software supports standards-based testing programs aligned with ASTM, ISO, DIN, EN, and BS. Results and reports remain linked to the method and specimen inputs for consistent review, auditing, and customer documentation.

Automatic Shore, IRHD and VLRH Hardness Testing System

NextGen is proud to present our German line of fully-automatic Shore, IRHD and VLRH hardness testing system for plastic materials, plastic and foam compounds for the ultimate precision, accuracy and repeatability, exceptional ease-of-use and maintenance. Experience the industry leader for specimen testing including rubbers, plastics, foams, composites, o-rings, and more.

Advanced Portable Shore Durometer System with Test Stand Options

HPEIII is NextGen's advanced German line of equipment that is the new generation of HPE systems ideal for various plastic and plastic compound testing. The new system enhancements offer advantages including temperature sensor, reading values of ambient temperature and humidity, historical hardness value display, larger LCD display, standard USB connection and much more. These advanced portable systems can be paired up with either manual or automatic motorized test stands to help eliminate the human error factor and maximize accuracy and repeatability between test when switching from one operator to the next.

Classic Analogue Shore Durometer with Test Stand Options

This German-manufactured system has been the global benchmark of Shore hardness testing systems since 1954. With ever enhanced ergonomic design, the HP Shore Hardness Tester is both visually appealing and precise rubber and plastic testing system as it has been for nearly 50 years.

Automatic Capsule and Soft Gel Hardness Tester

Gelomat is an automatic capsule hardness tester designed for regular and soft gel capsule testing. This state of the art system is developed by the latest R&D technology to meet and exceed the highest quality standards for gelatin capsule testing. The system comes standard with your desired testing head and can be upgraded to optional accessories for maximum efficiency.

Ball Rebound Tester

Ball Rebound Tester is designed for measuring the rebound resilience of polymer foams.

Pendulum Rebound Resilience Tester

Manual and Fully-Automatic Pendulum Rebound Resilience Tester. These rebound testers will determine the dynamic behavior of various materials and supply the differentiation of these materials' qualities. It will also identify material changes after aging and fatigue. The Pendulum Rebound Tester is out there with an adjustable heater for sample temperatures up to 100 ℃. It can simulate the effect of heat on the elasticity of samples with different formulations.

Pusey & Jones Tester

Pusey & Jones is a rubber and rubber like material testing system. The unit is designed for testing rubber rollers in the paper industry. The system can test specimens with flat surfaces and thickness of 13 mm.