Plastic Testing Equipment

Standards

DIN 53512, ASTM D 1054, ISO 4662

Certified

Description

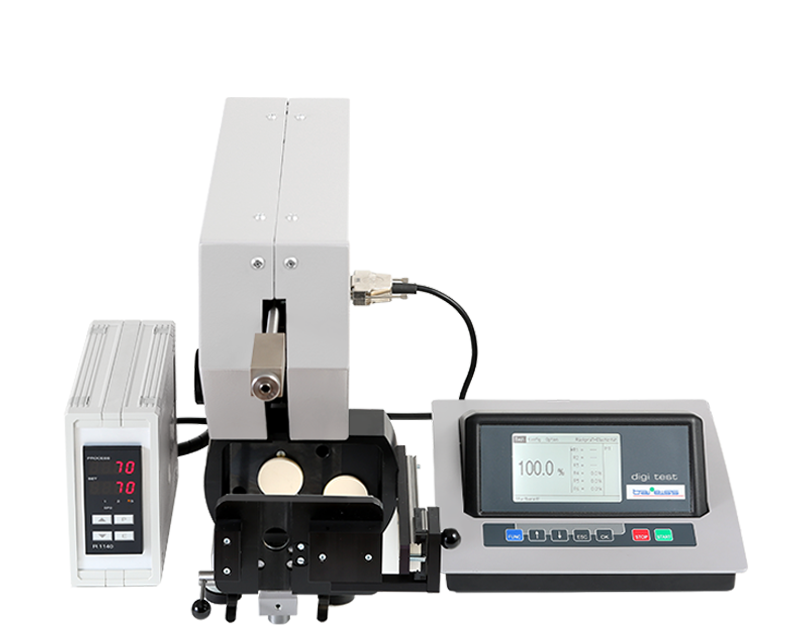

NextGen's Pendulum Rebound Resilience Tester series offer both manual and fully-automatic options with digital display terminal. These rebound testers will determine the dynamic behavior of various materials and supply the differentiation of these materials' qualities. It will also identify material changes after aging and fatigue. The Pendulum Rebound Tester is out there with an adjustable heater for sample temperatures up to 100 ℃. It can simulate the effect of heat on the elasticity of samples with different formulations.

The objective of tests on elastomers and foams is the straightforward and fast measurement of material elasticity. One material that is up to 100% elastic stores supplied energy and releases it at the moment the force is no longer applied. In contrast, material that is up to 100% plastic absorbs supplied energy completely. These characteristics are used to measure rebound resilience.

These systems are developed for the determination of the resilience elasticity of elastomers, soft elastic foams and similar materials during shock loading calculation of the median value in accordance with DIN 53512, ASTM D 1054, and ISO 4662 standards. Read more in our newest mega blog!

Features

- Determination of the dynamic behaviour of different materials

- Differentiation of different material qualities

- Extremely low-maintenance - Fully automatic sequence with geared motor as sole actuator.

- Identification of material changes after dynamic fatigue tests and after aging

- Quality assurance during the production process and at the finished product

- Wear-free mechanism - ideal for continuous operation.

- Frictionless pendulum encoder

- Independent Electronic Unit with LCD Display

- Selectable temperature ranges from 10 ℃ to max. 100 ℃ on the contact surface of the specimen. a second specimen can be preconditioned at the same time.

- Diameter of specimens 29 - 53 mm, thickness of specimens 12 mm

- Integrated routine enables rapid error analysis.

- PC connection via the integrated RS232 C interface for output and processing of test results.

Technical Specifications

| Model # | Pendulum Rebound Resilience Tester |

|---|---|

| Power Supply: Input: | 100 – 240 VAC ; 50 / 60 hz 1P |

| Resolution: | 0.1 % |

| Measuring Ranges: | Rubber resilience |

| Data Output: | V24 RS 232 - 9600 baud, 1 start bit, 8 data bits, 1 stop bit |

| Length of Pendulum: | 200 mm |

| Angle of Incidence: | 90° |

| Impact Velocity: | 2 m/s |

| Adjustment For Specimen Thickness: | 0 ... 60 mm |

| Scale Value: | 1 mm |

| Dimensions (LXWXH) | Main instrument: 7.87x 9.84 x 22.44" 200 x 250 x 570 mm |

| Electronic Unit: 7.87 x 6.73 x 3.54" 200 x 171 x 90 mm |

|

| Weight | Main Instrument: 73 lbs / 33 kg |

| Electronic Unit: 4.4 lbs / 2 kg | |

| Heating Module: 6.6 lbs / 3 kg |

Accessories

- Dakks Calibration Certification from the Manufacturer

- Anvil plate

- Heating module

- 200N Clamping Device

- HardTest - Intuitive Software

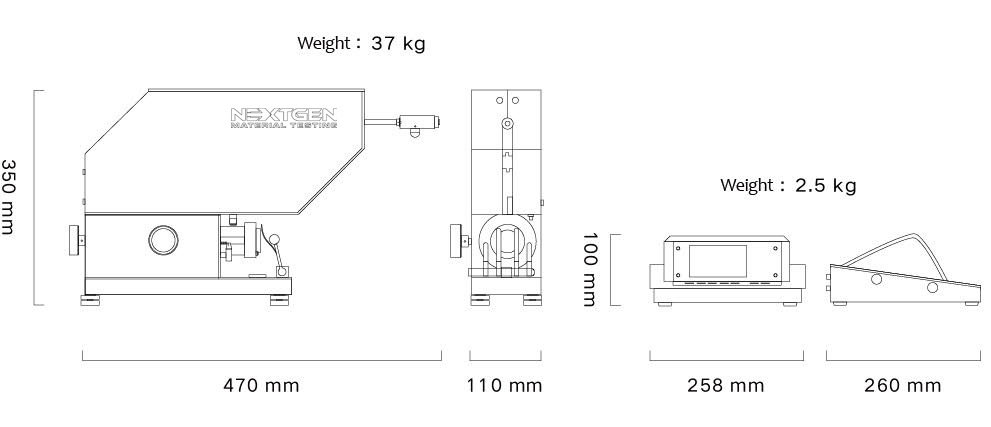

System Dimensions

FAQs

Yes, the Pendulum Rebound Resilience Tester by NextGen is designed by the DIN 53512 standard. This standard is crucial in material testing, especially for determining the resilience and elasticity of elastomers and soft elastic foams under shock loading. The tester’s capability to accurately measure the dynamic behavior of materials aligns with DIN 53512 specifications, ensuring precise and reliable results.

This tester's compliance with DIN 53512 is significant for industries and research institutions focusing on material quality and performance. It provides a dependable method for assessing the elasticity and durability of materials. This is essential in applications where material resilience under shock and stress is a critical factor. The tester's alignment with such an established standard highlights its suitability for rigorous testing environments. It assures users of its efficacy and reliability in material testing and analysis.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Pendulum Rebound Resilience Tester aligns with the ASTM D1054 Standard. This standard is specifically designed for testing elastomeric materials' resilience, focusing on their ability to withstand impact and rebound. The tester’s design and functionality are tailored to meet ASTM D1054 criteria, providing an accurate and consistent assessment of material resilience. This compliance is particularly crucial for industries dealing with rubber and other elastomeric materials, as it assures that the testing equipment adheres to recognized industry standards.

Compliance with ASTM D1054 signifies the tester's capacity to provide dependable resilience data essential to quality control and product development. Its precision in measuring the rebound elasticity of materials under specific conditions makes it a valuable tool in sectors such as automotive, aerospace, and consumer goods where elastomer quality is pivotal. By meeting ASTM D1054 standards, the Pendulum Rebound Resilience Tester becomes a key instrument for manufacturers and researchers focused on developing and testing materials that require high resilience and durability.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Pendulum Rebound Resilience Tester is designed to comply with ISO 4662, a standard that specifies methods for determining rubber rebound resilience. This standard applies to rubber materials with a hardness between 30 IRHD and 85 IRHD. This includes the pendulum method, which plays a direct role in the Pendulum Rebound Resilience Tester's functionality since it is directly related to the pendulum method.

The tester’s capability to accurately measure rubber materials' rebound resilience makes it an ideal tool for adhering to ISO 4662's requirements. This compliance is crucial in industries where rubber products perform and last, such as automotive, aerospace, and manufacturing. Utilizing a tester that aligns with ISO 4662 guarantees that rubber materials maintain their quality and performance over time. This provides confidence in product reliability and adherence to international standards.

Click here to learn more about the product or here to receive a personalized quote.

NextGen's Pendulum Rebound Resilience Tester series offers both manual and fully automatic options, catering to diverse testing requirements. These options provide flexibility, allowing users to select the model that perfectly fits their operational needs. The manual version is ideal for users who prefer hands-on control during testing, offering a more interactive approach. In contrast, the fully automatic option streamlines the testing process, enhancing efficiency and reducing human intervention.

Both versions are equipped with a digital display terminal, which adds a significant advantage in user interface and readability. This terminal displays testing parameters and results clearly, enabling precise monitoring and control of the testing process. The digital display also facilitates easy adjustments to testing conditions, ensuring optimal settings.

These features make the Pendulum Rebound Resilience Tester series a versatile and essential tool for material testing. This is particularly true for industries that require accurate and reliable material resilience measurements, such as in automotive and aerospace component manufacturing, and in the material research and development sectors.

Click here to learn more about the product or here to receive a personalized quote.

It is possible to assess the dynamic behavior of various materials using the Pendulum Rebound Resilience Testers, which provide insight into their properties in terms of their dynamic behavior. Using these tests, you can determine how different materials will react to impact and stress, specifically how well they will rebound after impact. This capability is essential for understanding materials' elasticity and energy absorption properties, which are critical factors in many industrial applications.

By assessing materials' dynamic behavior, testers can identify key characteristics such as stiffness, flexibility, and durability. This information is invaluable in applications where material performance under dynamic conditions is a primary concern, such as automotive, aerospace, and sports equipment manufacturing. Differentiating material qualities allows for a more informed selection of materials for specific purposes. This guarantees that the chosen materials will perform as expected in their intended applications.

Click here to learn more about the product or here to receive a personalized quote.

The Pendulum Rebound Resilience Tester detects and analyzes changes in materials caused by aging and fatigue. This functionality is crucial for assessing the long-term durability and stability of various materials. The tester measures materials' resilience, which is a key indicator of their condition and quality. Over time and with repeated use, materials can change their physical properties, leading to reduced resilience.

By evaluating the resilience of materials before and after aging and fatigue, the tester provides valuable insights into how they deteriorate or change. This information is essential in fields such as automotive, aerospace, and construction, where material longevity and consistency are vital for safety and performance.

The ability to track material changes over time makes the Pendulum Rebound Resilience Tester a powerful tool for quality assurance, research, and development. It helps predict material lifespan, enhancing product reliability, and informing more resilient materials.

Click here to learn more about the product or here to receive a personalized quote.

The Pendulum Rebound Tester is equipped with an adjustable heater, a feature that significantly enhances its testing capabilities. This heater allows sample temperatures up to 100 degrees Celsius (°C), providing testing environments. The ability to alter temperature is crucial for evaluating how materials respond to different thermal conditions.

In many applications, materials' properties can vary significantly with temperature changes. For instance, materials may become more flexible or more rigid depending on temperature. By testing materials at various temperatures, the Pendulum Rebound Tester can assess their resilience and other properties under conditions that mimic real-world scenarios.

It was designed to allow manufacturers and researchers to understand the effects of temperature fluctuations on the performance of materials. This work aims to contribute to the development of products that maintain integrity and functionality even under extreme conditions of temperature.

Click here to learn more about the product or here to receive a personalized quote.

The Pendulum Rebound Tester simulates the effect of heat on different types of material samples. This is achieved through its adjustable heater, which can alter samples' temperature up to 100 degrees Celsius (℃). By doing so, the tester can mimic the conditions under which materials are exposed to heat in real-world applications, allowing for an accurate assessment of how heat impacts their elasticity.

This capability is particularly relevant for materials with different formulations, as heat affects each composition differently. For instance, some materials might become more elastic and pliable with increased temperatures, while others could become stiffer or more brittle. By testing these materials at different temperatures, the Pendulum Rebound Tester provides crucial insights into their thermal behavior.

This feature is invaluable in industries like electronics, where materials are often subjected to different thermal environments. Understanding how heat affects material elasticity enables manufacturers and researchers to predict material behavior under operational conditions, aiding in the selection of appropriate materials for specific applications and improving the reliability and safety of the final products.

Click here to learn more about the product or here to receive a personalized quote.

The primary objective of using the Pendulum Rebound Tester for testing elastomers and foams is to efficiently and straightforwardly measure the elasticity of these materials. Elastomers and foams are widely used in many applications due to their unique elastic properties. Accurately assessing their elasticity is crucial for their performance in end-use environments.

The Pendulum Rebound Tester provides a rapid and direct method of evaluating these materials' elasticity. It does so by measuring how the material responds to impact and stress, which is indicative of its ability to return to its original shape after being deformed. This property is especially important in applications where materials are subjected to frequent or intense stress.

High-throughput environments where time efficiency is critical require fast and straightforward testing. Additionally, the direct measurement of elasticity helps maintain consistent quality control, ensuring that every batch of material meets the required standards. By providing quick and accurate measurements, the Pendulum Rebound Tester assists manufacturers in making informed decisions about material selection and product design. This contributes to safer and more reliable products.

Click here to learn more about the product or here to receive a personalized quote.

The Pendulum Rebound Tester measures the rebound resilience of materials with varying degrees of elasticity and plasticity. This testing is crucial because materials behave differently under stress based on their composition. A material that is up to 100% elastic, like certain elastomers, will store energy during testing. It will release it when the force is removed. This will demonstrate a high level of resilience. This behavior is indicative of materials that can withstand repetitive stress without permanent deformation.

In contrast, materials with a higher degree of plasticity, up to 100% plastic, absorb energy during testing without rebounding. This indicates a lack of elasticity. Such materials are more likely to undergo permanent deformation when subjected to stress.

By measuring these characteristics, the Pendulum Rebound Tester helps determine materials' suitability for different applications. For instance, highly elastic materials are ideal for products requiring flexibility and durability under stress, such as automotive tires or seals. On the other hand, materials with higher plasticity might be better suited to applications where deformation under load is desirable. This precise measurement of rebound resilience is essential for industries that require materials to maintain their integrity and performance over time under various stress conditions.

Click here to learn more about the product or here to receive a personalized quote.

The Pendulum Rebound Tester aligns with international standards by being specifically designed to meet DIN 53512, ASTM D1054, and ISO 4662. These standards are recognized globally for their methodologies for assessing the resilience and durability of elastomeric materials and similar substances. The tester's systems determine the resilience and elasticity of elastomers, soft elastic foams, and comparable materials, especially under shock-loading conditions.

By complying with these standards, the tester delivers consistent, reliable, and universally acceptable results. This compliance is vital for industries that depend on precise material characteristics, such as the automotive, aerospace, and consumer goods sectors. The ability to conduct tests in line with these respected standards guarantees that materials meet the necessary quality and performance criteria. This is a crucial factor in maintaining product safety and efficacy. The Pendulum Rebound Tester's alignment with these international standards underscores its importance as a comprehensive tool for material testing and quality assurance.

Click here to learn more about the product or here to receive a personalized quote.

The Pendulum Rebound Tester is specifically designed to determine the dynamic behavior of various materials. This process involves assessing how materials respond to stress and impact, a key aspect of their performance in real-world applications. The tester measures materials' resilience and rebound when subjected to controlled shock loading, providing insights into their elasticity and energy absorption capabilities.

During testing, materials are impacted with a pendulum, and the tester measures how much energy is absorbed and released upon rebound. Materials with high resilience will exhibit greater rebound, indicating their ability to return to their original shape after deformation. This measurement is crucial for understanding material properties such as stiffness, flexibility, and durability.

Dynamic behavior assessment is essential in industries where material performance under stress is critical, like automotive, aerospace, and consumer goods manufacturing. By understanding how materials behave over time, manufacturers and researchers can predict their performance under operational conditions. They can also select appropriate materials for specific applications, and enhance product design for reliability and safety. The Pendulum Rebound Tester’s ability to precisely measure dynamic behavior makes it an invaluable tool in material testing and development.

Click here to learn more about the product or here to receive a personalized quote.

The Pendulum Rebound Tester differentiates between various materials' qualities by assessing their response to stress and impact. This differentiation is based on measuring the resilience and elasticity of materials when subjected to controlled dynamic testing. Each material, depending on its composition and properties, reacts differently to the impact and stress applied during the test.

Materials with higher elasticity will demonstrate an increased ability to absorb and release energy, indicated by higher rebound resilience. This characteristic is typical of materials that can withstand repetitive stress without permanent deformation. Conversely, materials with lower elasticity or greater plasticity will absorb more energy and exhibit less rebound, indicating a different set of qualities.

This ability to distinguish between different material qualities is essential for a wide range of applications. For example, in the automotive industry, materials with high resilience might be preferred for parts that undergo frequent stress. In contrast, materials with different qualities might be chosen for other applications. The Pendulum Rebound Tester's precise measurements allow for an accurate assessment of material qualities, aiding material selection, quality control, and product development across various industries.

Click here to learn more about the product or here to receive a personalized quote.

The Pendulum Rebound Tester boasts an extremely low-maintenance design, a notable feature that significantly enhances its usability and longevity in various testing environments. This low maintenance requirement is largely due to its fully automatic sequence, which minimizes the need for manual intervention and reduces the wear and tear commonly associated with repeated manual operations.

Central to the tester's automated functionality is its geared motor, which serves as the sole actuator. The use of a single geared motor simplifies the mechanical complexity of the device, leading to fewer parts that can wear out or require replacement. This design choice ensures consistent and reliable operation and reduces maintenance needs.

The tester's automatic sequence offers a streamlined and efficient testing process. It allows continuous operation without constant supervision or manual adjustments, making it ideal for high-throughput testing scenarios. This feature is particularly advantageous in industrial settings where time efficiency and accuracy are vital.

Click here to learn more about the product or here to receive a personalized quote.

The Pendulum Rebound Tester plays a crucial role in quality assurance both during the production process and in the evaluation of finished products. During production, this tester can be used to continuously monitor materials' resilience and elasticity as they are processed. This ongoing assessment helps make sure that the materials maintain consistent quality throughout the manufacturing phase, meeting the desired standards and specifications.

By identifying any deviations in material properties early in the production process, the tester allows for timely adjustments, preventing the progression of substandard materials through the production line. This proactive approach to quality control helps minimize the costs associated with defective products.

In the assessment of finished products, the Pendulum Rebound Tester verifies that the final products have retained their intended properties and are fit for their specific applications. This is especially true for products where material resilience and elasticity are critical to performance and safety.

Click here to learn more about the product or here to receive a personalized quote.

The Pendulum Rebound Tester is equipped with a wear-free mechanism, an essential feature that makes it ideally suited to continuous operation. This wear-free design means that the tester has fewer moving parts susceptible to wear and tear, which is a common issue with mechanical devices with repetitive motion. As a result, the tester can maintain its accuracy and functionality over long periods of use without frequent maintenance or part replacements.

The benefit of this design is particularly significant in high-throughput testing environments, where equipment is expected to perform consistently over extended periods. The wear-free mechanism ensures that the tester can handle a continuous stream of tests without downtime or performance degradation. This reliability is crucial for industries that require ongoing quality control and material testing.

Additionally, a wear-free mechanism contributes to the tester's overall longevity, making it a cost-effective investment in the long run. It reduces maintenance operational costs and minimizes the potential for testing interruptions due to equipment failure. This feature, combined with its continuous operation capability, makes the Pendulum Rebound Tester a valuable asset in any setting that demands reliable and efficient material testing.

Click here to learn more about the product or here to receive a personalized quote.

The Pendulum Rebound Tester is equipped with a frictionless pendulum encoder, a critical component that significantly improves performance and accuracy. The frictionless encoder means minimal resistance or interference during pendulum movement. This results in more precise and consistent measurements, as the pendulum can swing freely without drag which might affect the test results.

The frictionless pendulum encoder is particularly beneficial for accurately measuring materials' rebound resilience. Since pendulum movement is a key factor in determining how a material responds to stress and impact, friction could skew the results. By eliminating this variable, the frictionless encoder ensures that the data gathered is a true representation of the material's properties.

This type of encoder also benefits the tester's longevity. Frictionless operation means less wear on moving parts, contributing to the device's durability and maintenance-free aspect. For industries frictionless pendulum encoder in the Pendulum Rebound Tester is an invaluable feature for maintaining consistent quality and performance standards for their products.

Click here to learn more about the product or here to receive a personalized quote.

The Pendulum Rebound Tester features an Independent Electronic Unit equipped with an LCD, a key component in the operation and usability of the device. This unit serves as the control center for the tester, managing testing parameters and processes. The LCD provides a user-friendly interface, presenting clear and easily readable data and controls. This enhances the user's ability to monitor testing procedures, adjust settings, and interpret results accurately and efficiently.

The electronic unit's independence adds a layer of reliability to the tester. It operates separately from the mechanical components, reducing the risk of interference or errors caused by mechanical malfunctions. This separation ensures that electronic processing and display of results remain consistent and accurate, even in the event of physical wear or issues.

The inclusion of an LCD allows for real-time monitoring of tests, giving immediate feedback on the material's resilience and other measured properties. It also facilitates easy navigation through different testing modes and settings, making the testing process more streamlined and less prone to user error.

Click here to learn more about the product or here to receive a personalized quote.

The Pendulum Rebound Tester offers advanced temperature control capabilities. This allows users to select temperature ranges from 10 degrees Celsius (℃) to a maximum of 100 ℃ on the contact surface of the specimen. This feature is essential for testing how materials respond to different thermal conditions, providing insights into their behavior and properties at various temperatures.

The ability to adjust the contact surface temperature enables users to simulate a wide range of environmental conditions. This is crucial for materials that exhibit different properties at different temperatures, such as becoming more brittle or more elastic. Testing across a range of temperatures ensures a comprehensive understanding of material performance.

Additionally, the tester preconditions a second specimen simultaneously. This means that while one specimen is being tested, another can be prepared and brought to the required temperature, ready for immediate testing. This dual-specimen handling capability significantly improves testing efficiency, making it ideal for high-throughput environments. It allows for continuous testing with minimal downtime, increasing productivity and ensuring a more streamlined workflow in material testing procedures.

Click here to learn more about the product or here to receive a personalized quote.

The Pendulum Rebound Tester accommodates specimens with specific dimensions. It can handle specimens with a diameter ranging from 29 to 53 millimeters (mm) and a thickness of 12 mm. These dimensions are crucial as they define the range of specimen sizes that can be tested with the device.

The ability to test specimens with diameters between 29 and 53 mm provides versatility, allowing for the analysis of a wide variety of materials and products. This range is suitable for many applications, ensuring that the tester can be used for diverse testing requirements across different industries. The specified 12 mm thickness results in uniform and manageable specimens.

These size specifications guarantee that the materials are appropriately sized for the testing mechanism, allowing for accurate measurement of resilience and other properties. The specimen size makes the Pendulum Rebound Tester a flexible tool. It is capable of accommodating different types of materials and providing reliable data for material analysis and quality control.

Click here to learn more about the product or here to receive a personalized quote.

The Pendulum Rebound Tester features an integrated routine specifically designed for rapid error analysis. This function is a critical aspect of the tester's design, enhancing its reliability and efficiency. The integrated routine automatically detects and diagnoses errors during testing. This rapid error analysis capability ensures that any issues are promptly identified and addressed, minimizing downtime and potential inaccuracies in test results.

The benefit of having an integrated routine for error analysis is significant, especially in environments where continuous operation and accuracy are crucial. It allows immediate troubleshooting, reducing manual diagnostic time. This feature is particularly valuable in high-throughput testing scenarios, where delays or errors could significantly impact productivity and workflow.

Additionally, the ability to quickly analyze and rectify errors contributes to the overall integrity and reliability of the testing process. It ensures that the data collected is accurate and reflective of the material's true properties. This is essential for quality control and material research.

Click here to learn more about the product or here to receive a personalized quote.

The Pendulum Rebound Tester features an integrated RS232 C interface, which facilitates direct connection to a PC. This feature is crucial for efficient test results output and processing. The RS232 C interface allows for the seamless transfer of data from the tester to a computer system, where the results can be further analyzed, processed, and stored.

The ability to connect the tester to a PC offers several benefits. Firstly, it enables easy and efficient test data management. Users can quickly download results for analysis, create reports, and maintain records of tests conducted. This data management is vital for maintaining quality control logs, conducting research, and complying with documentation requirements in various industries.

Secondly, the PC connection allows for more advanced data analysis. Users can use software tools to perform in-depth analyses of test results, compare data sets, and draw meaningful conclusions about the material's properties and performance. This level of analysis is essential for developing new materials, improving existing products, and ensuring that materials meet the necessary standards and specifications.

Click here to learn more about the product or here to receive a personalized quote.

The Pendulum Rebound Tester is designed with a versatile power supply input, accommodating a range of 100 to 240 Volts Alternating Current (VAC) and compatible with both 50 and 60 Hertz (Hz) frequencies. This feature makes the tester adaptable to various electrical power standards worldwide, enhancing its usability across different regions and settings.

The ability to operate on a broad voltage range (100 – 240 VAC) ensures that the tester can be used in countries with different voltage standards without additional voltage converters or adapters. Global compatibility is particularly beneficial for multinational companies and research institutions that operate in multiple countries or export internationally.

Furthermore, the tester's compatibility with both 50 and 60 Hz frequencies adds to its flexibility, as electrical systems in different countries may operate on either of these frequencies. This dual frequency compatibility ensures tester performance remains stable and reliable, regardless of local power grid specifications.

Click here to learn more about the product or here to receive a personalized quote.

The Pendulum Rebound Tester boasts a resolution of 0.1%, a specification that significantly enhances its testing accuracy. This high resolution indicates the tester's ability to detect and display very small changes in the rebound resilience of the materials being tested. A resolution of 0.1% means that the tester can measure and report changes in material properties with fine detail and precision.

This high degree of resolution is particularly significant in applications where even minor variations in material performance can have significant implications. For example, in industries where material consistency and quality are critical the ability to precisely measure and analyze material properties ensures that only materials meeting strict standards are used.

The 0.1% resolution contributes to the reliability of the test results, providing confidence in the accuracy of the tester's data. This level of precision allows for a more detailed understanding of the material's behavior, aiding in quality control, research, and development processes. It ensures that any changes in material properties, whether due to manufacturing processes or environmental factors, are accurately captured and assessed.

Click here to learn more about the product or here to receive a personalized quote.

The Pendulum Rebound Tester is specifically designed to measure rubber resilience, indicating its capability to accurately assess rubber materials' elastic properties. The term "rubber resilience" refers to rubber's ability to absorb energy when deformed and return to its original shape. This property is crucial in applications where rubber is subjected to repetitive stress or impact, such as tires, seals, and vibration dampeners.

The tester’s measuring range for rubber resilience typically involves quantifying the extent to which the rubber material can return to its original form. This is after being deformed by an applied force. This is usually expressed as a percentage, representing the ratio of energy recovered to energy applied. A high resilience percentage indicates a material that is capable of returning to its original shape.

The specific range of measurements will depend on the rubber's formulation and hardness, as different types of rubber can exhibit varying degrees of resilience. The tester is equipped to handle this variability, providing accurate and reliable measurements across a spectrum of rubber types and formulations. This adaptability makes the Pendulum Rebound Tester an essential tool for industries that rely on rubber materials.

Click here to learn more about the product or here to receive a personalized quote.

The Pendulum Rebound Tester features a data output specification of V24 RS 232 - 9600 baud, including 1 start bit, 8 data bits, and 1 stop bit. This specification outlines the format and protocol for data transmission from the tester to external devices, such as computers, for further analysis and record-keeping.

The V24 RS 232 is a standard communication interface, commonly used for serial data exchange between devices. The 9600 baud rate indicates the speed of data transfer, with 9600 bits per second being a standard rate that balances speed with reliability in data transmission.

Serial communication uses 1 start bit, 8 data bits, and 1 stop bit. The start bit signals the beginning of data transmission, the 8 data bits carry the actual data, and the stop bit signifies the end of the data packet. This format ensures clear and structured data flow, reducing error risk during transmission.

Click here to learn more about the product or here to receive a personalized quote.

The Pendulum Rebound Tester utilizes a pendulum specifically designed to measure materials' rebound resilience. The pendulum's length is a vital specification that directly influences test results. It is meticulously calibrated to ensure consistent and reliable performance during testing.

This pendulum's construction and dimensions are integral to its function. The length is chosen to provide an optimal balance between sensitivity to material responses and stability during swings. Such precision in design allows for accurate impact force application on test specimens. This is a crucial aspect in determining the resilience and elasticity of materials like elastomers and foams.

Moreover, the pendulum's specifications are in line with material testing standards in various industries. Its design ensures that the swing and impact are consistent for each test, contributing to test repeatability and reliability. This consistency is essential for quality control and research purposes, where accurate material characterization is critical.

Click here to learn more about the product or here to receive a personalized quote.

The Pendulum Rebound Tester's design incorporates a 90° incidence angle. This particular angle is instrumental in ensuring resilience testing accuracy. A 90° angle of incidence means that the pendulum strikes the test material perpendicularly, which is essential for uniform and consistent force application during each test. This perpendicular impact is critical for accurately assessing rebound resilience.

The consistent 90° angle of incidence ensures that the impact force is directly and evenly applied to the material. This provides a reliable basis for measuring how much energy is absorbed and released by the material. This level of precision in the testing setup is crucial, especially when evaluating materials where resilience and elasticity are vital properties.

In quality control and material research, the ability to deliver a consistent and controlled impact at a 90° angle is invaluable. It allows for the accurate comparison of different materials under the same testing conditions, enhancing comparative analysis reliability.

Click here to learn more about the product or here to receive a personalized quote.

The Pendulum Rebound Tester is designed to deliver an impact velocity of 2 meters per second (m/s) during testing. This specific velocity is crucial for accurately assessing materials' resilience and elasticity. An impact velocity of 2 m/s ensures that the pendulum strikes the test material with sufficient force to effectively measure its rebound properties.

This velocity is carefully calibrated to provide a balance between delivering a significant impact on the material. It ensures that the material is not damaged or altered in a way that affects the test integrity. The chosen speed of 2 m/s is optimal for simulating real-world conditions under which many materials, especially elastomers and foams, are expected to perform.

The impact velocity directly influences the kinetic energy transferred to the material during testing. This energy transfer is a key component in evaluating a material's ability to absorb and release energy – a fundamental aspect of resilience. The precise control of the impact velocity at 2 m/s is, therefore, essential for ensuring the accuracy and reliability of the test results.

Click here to learn more about the product or here to receive a personalized quote.

The Pendulum Rebound Tester offers specimen thickness adjustment from 0 to 60 millimeters (mm). This feature is crucial for accommodating a wide variety of material samples of different thicknesses.

The ability to adjust for varying specimen thicknesses allows the tester to be used for a diverse array of materials. These materials range from very thin films to thicker elastomeric and foam samples. This adaptability is essential for accurately assessing each material's rebound resilience regardless of its thickness.

The broad range of up to 60 mm in thickness adjustment ensures that the tester can cater to the specific testing requirements and standards of different industries. It enables precise testing of materials under conditions that closely replicate their actual use, contributing to the reliability and relevance of the test results. This adjustability feature enhances the tester's utility in research, development, and quality control processes where materials of varying thicknesses need to be evaluated.

Click here to learn more about the product or here to receive a personalized quote.

The Pendulum Rebound Tester scale is set at 1 millimeter (mm). This scale value refers to the precision with which measurements can be detected and recorded by the tester. A scale value of 1 mm indicates that the tester can measure and display changes in the specimen's properties with a minimum resolution of 1 millimeter.

This level of precision is essential in accurately assessing materials' rebound resilience. It ensures that even slight variations in the material's response to impact can be captured. This is particularly true for materials where small differences in properties can have a significant impact on their performance.

The 1 mm scale value is especially crucial in research and development settings where detailed material behavior analysis is necessary. It allows for a nuanced understanding of how different materials react under stress, aiding in the development of products that require specific material characteristics. In quality control processes, this precision helps guarantee that materials meet the required standards and specifications, maintaining product quality consistency.

Click here to learn more about the product or here to receive a personalized quote.

The main instrument of the Pendulum Rebound Tester has dimensions of 7.87 inches in length, 9.84 inches in width, and 22.44 inches in height. This is equivalent to 200 x 250 x 570 millimeters (mm). These dimensions define the physical size of the tester, which is a crucial consideration for space planning and installation.

The compact design, as indicated by these dimensions, allows the tester to be accommodated in various laboratory and industrial settings without excessive space. Despite its relatively modest size, the tester is designed to perform complex material testing tasks effectively.

The height of 22.44 inches (570 mm) ensures that the pendulum has enough room to swing freely without obstruction, which is crucial for accurate testing. The length and width of 7.87 inches (200 mm) and 9.84 inches (250 mm) respectively, provide a stable base for the instrument, ensuring its steady operation during testing operations.

Click here to learn more about the product or here to receive a personalized quote.

The electronic unit of the Pendulum Rebound Tester has dimensions of 7.87 inches in length, 6.73 inches in width, and 3.54 inches in height, translating to 200 x 171 x 90 millimeters (mm). These dimensions indicate the size of the electronic unit, which is a separate component from the main instrument of the tester.

The electronic unit's compact size, as specified, is designed for convenience and ease of use. This allows it to be placed within a testing setup without occupying excessive space. This is particularly beneficial in laboratory or industrial environments where space conservation is critical.

Despite its relatively small size, this electronic unit is a critical part of the tester, housing the controls and data processing components. Its dimensions ensure that it can be easily integrated with the main instrument while still providing an accessible and user-friendly interface for operating the tester.

Click here to learn more about the product or here to receive a personalized quote.

The main instrument of the Pendulum Rebound Tester weighs 73 pounds (lbs), equivalent to approximately 33 kilograms (kg). This weight reflects the tester's robust construction, designed to ensure stability and durability during testing.

The weight of 73 lbs (33 kg) is significant as it contributes to the tester's overall stability. A stable testing platform is essential for accurate and reliable measurements, especially in tests involving dynamic forces, such as measuring rebound resilience. The substantial weight minimizes vibrations and movement that could otherwise affect the test results' precision.

Despite its weight, the tester is designed for practicality in a laboratory or industrial setting. Weight is a consideration for installation and placement, ensuring the tester is located in a suitable area where it can be operated safely and effectively. This weight specification is a key aspect of the tester's design. It balances the need for a sturdy and reliable testing apparatus with practical considerations for everyday use.

Click here to learn more about the product or here to receive a personalized quote.

The Pendulum Rebound Tester electronic unit weighs 4.4 pounds (lbs), equivalent to approximately 2 kilograms (kg). This relatively lightweight design enhances unit portability and handling. The lighter weight of the electronic unit, compared to the main instrument, allows for greater flexibility in its placement and setup within a testing environment.

This difference in weight between the main instrument and the electronic unit is practical for operational purposes. While the main instrument's heavier weight ensures stability during testing, the electronic unit's lighter weight allows it to be easily adjusted or relocated as needed. This can be particularly beneficial in laboratories or industrial settings where space optimization and reconfiguration are particularly crucial.

The 4.4 lbs (2 kg) weight of the electronic unit reflects a design that considers both functionality and user convenience. This ensures that the unit is robust enough to house the necessary electronic components while remaining user-friendly and adaptable to various testing scenarios.

Click here to learn more about the product or here to receive a personalized quote.

The Pendulum Rebound Tester heating module weighs 6.6 pounds (lbs), equivalent to about 3 kilograms (kg). This weight reflects the module's design, which incorporates the necessary components to effectively heat test specimens to the desired temperature.

The 6.6 lbs (3 kg) weight suggests that the heating module is sufficiently robust to maintain consistent temperatures, yet not so heavy as to impede its integration with the main instrument. This balance is crucial in ensuring that the heating module can be managed easily while still providing reliable and effective heating for a variety of material tests.

In material testing, the heating module's role is significant, as temperature can greatly affect materials' properties, particularly their elasticity and resilience. The weight and design of the heating module in the Pendulum Rebound Tester are crucial key factors in its ability to provide precise temperature control.

Click here to learn more about the product or here to receive a personalized quote.

The Pendulum Rebound Tester comes with a range of accessories that enhance its functionality and accuracy in material testing. These accessories include:

- DAkkS Calibration Certification from the Manufacturer: This certification guarantees that the tester meets specific accuracy and quality standards. It verifies that the device has been calibrated and tested according to DAkkS (Deutsche Akkreditierungsstelle) standards, providing users with assurance of its precision and reliability.

- Anvil Plate: The anvil plate serves as a stable and robust surface against which materials are tested in the Pendulum Rebound Tester. It is designed to withstand impacts during testing while providing a consistent and uniform surface for accurate measurement.

- Heating Module: This module adjusts the temperature of test specimens. It allows testing under various thermal conditions, assessing how temperature changes affect material properties, such as elasticity and resilience.

- 200N Clamping Device: This device securely holds test specimens in place during testing. The clamping force of 200 Newtons ensures that the specimens are firmly gripped. This prevents movement or slippage that could impact test results' accuracy.

- HardTest - Intuitive Software: This software interfaces with the Pendulum Rebound Tester, providing an intuitive platform for controlling test parameters, collecting data, and analyzing results. Software enhances the user experience, making it easier to conduct tests, process data, and interpret results.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

Melt Flow Indexer

Our melt flow indexer is a highly precise instrument designed for the measurement of melt flow rate (MFR)/(MI) or melt volume rate (MVR) in quality control and research applications.

NG-ImpactFall – Falling Weight Impact Tester

Our falling weight impact tester finds extensive application in conducting external impact strength tests on plastic and non-metal materials.

High Energy Elemendorf

Measure the tearing strength of plastic materials with the NG-HE Elemendorf, a versatile tester with advanced potential energy calculation.

NextGen Environmental Chambers NG-EC 100,150,225,408,1000

The temperature and humidity NextGen Environmental Chambers features a sturdy cabinet made of cold-rolled steel and stainless steel.

HDA 120 - Hardness and Density Automation Test System

The HDA 120 test system is a versatile solution for semi-automatic detection of sample hardness and density.

Automatic Shore, IRHD and VLRH Hardness Testing System

NextGen is proud to present our German line of fully-automatic Shore, IRHD and VLRH hardness testing system for plastic materials, plastic and foam compounds for the ultimate precision, accuracy and repeatability, exceptional ease-of-use and maintenance. Experience the industry leader for specimen testing including rubbers, plastics, foams, composites, o-rings, and more.

Advanced Portable Shore Durometer System with Test Stand Options

HPEIII is NextGen's advanced German line of equipment that is the new generation of HPE systems ideal for various plastic and plastic compound testing. The new system enhancements offer advantages including temperature sensor, reading values of ambient temperature and humidity, historical hardness value display, larger LCD display, standard USB connection and much more. These advanced portable systems can be paired up with either manual or automatic motorized test stands to help eliminate the human error factor and maximize accuracy and repeatability between test when switching from one operator to the next.

Classic Analogue Shore Durometer with Test Stand Options

This German-manufactured system has been the global benchmark of Shore hardness testing systems since 1954. With ever enhanced ergonomic design, the HP Shore Hardness Tester is both visually appealing and precise rubber and plastic testing system as it has been for nearly 50 years.

Automatic Capsule and Soft Gel Hardness Tester

Gelomat is an automatic capsule hardness tester designed for regular and soft gel capsule testing. This state of the art system is developed by the latest R&D technology to meet and exceed the highest quality standards for gelatin capsule testing. The system comes standard with your desired testing head and can be upgraded to optional accessories for maximum efficiency.

Fruit Firmness Tester

This German manufactured fruit firmness and fruit hardness testing device is designed specification for the determination of the pulp hardness of a given fruit. This state-of-the-art device is invaluable for trading companies serious about their quality control procedures. The unit helps identify the harvest date of the specific fruits relative to the time of transpirations and storage.

Ball Rebound Tester

Ball Rebound Tester is designed for measuring the rebound resilience of polymer foams.

Pusey & Jones Tester

Pusey & Jones is a rubber and rubber like material testing system. The unit is designed for testing rubber rollers in the paper industry. The system can test specimens with flat surfaces and thickness of 13 mm.