Metal Testing Equipment

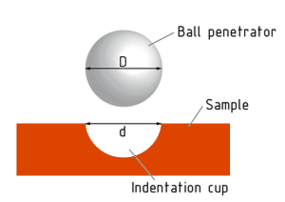

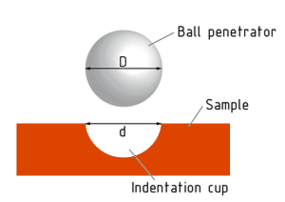

The Brinell hardness tester is used for testing permanent change of metal specimens using a tungsten carbide ball indenter of various sizes. It measures the resistance of the material to permanent deformation. The diameter of the indentation having deformed the material is then used to calculate the Brinell hardness value. The Brinell indentation is commonly measured using a manual 20x/40x magnification microscope or through the use of CCD optics for removing all aspects of human error. The Brinell Hardness Tester is a destructive unit of hardness calculations and is conducted according to the ASTM E10 and the ISO 6506 industry standard. The full Brinell Hardness Testing System Review is available for your reference. Read More...

Products

BrinGen - 3000 Series - Digital Brinell and Automatic Brinell Hardness Tester - Closed Loop System

BringGen 3000 is a digital and automatic Brinell testing system equipped with closed loop technology. The forces range from 62.5kgf to 3000kgf and are electronically controlled according to ASTM E10 for precise and repeatable measurements.

BrinGen Scope - Optically Advanced CCD Brinell Measuring Scope for Manual or Digital Brinell Hardness Testing System

BrinGen Scope - is a Optically Advanced CCD Brinell Measuring Scope for Manual or Digital designed as Brinell Hardness Testing automatic scanning system. It is engineered to work with a computer or a laptop to make your testing program faster and more accurate. The Optical Brinell Scope is equipped with real-time result support.

Hardness Test Blocks, Indenters and Hardness Testing Accessories

Certified Test Blocks are a requirement as a reference material for any type of hardness testing. At NextGen, we understand the importance of a Test Block to ensure the accuracy of your hardness testing procedures.

Metallography Consumables

Learn about the full scope of NextGen's cutting, polishing & grinding, mounting and etching metallography consumables. Our consumables are compatible with virtually all global brands, offering a rare combination of exceptional quality, longevity and affordability.