Metal Testing Equipment

Description

Introducing the GenGrind FA-IC, a state-of-the-art single-chip microcomputer controlled grinding and polishing machine. The GenGrind FA-IC features a durable ABS material shell, providing a beautiful appearance and excellent resistance to corrosion. With its stepless speed control and reversible rotational direction, this machine offers versatile functionality. The grinding head offers two methods: individual pressure and central pressure. By effectively replacing manual grinding and polishing processes, the GenGrind FA-IC significantly reduces labor requirements while enhancing the quality and efficiency of sample preparation. It is the perfect equipment for metallographic sample preparation. More information available in our MEGA blog!

GenGrind FA-IC Dual Standard Configuration

-

Dual Wheel GenGrind FA-IC (Individual and Central Force Control)

-

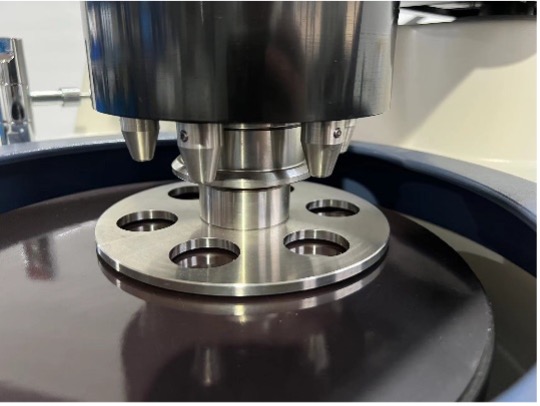

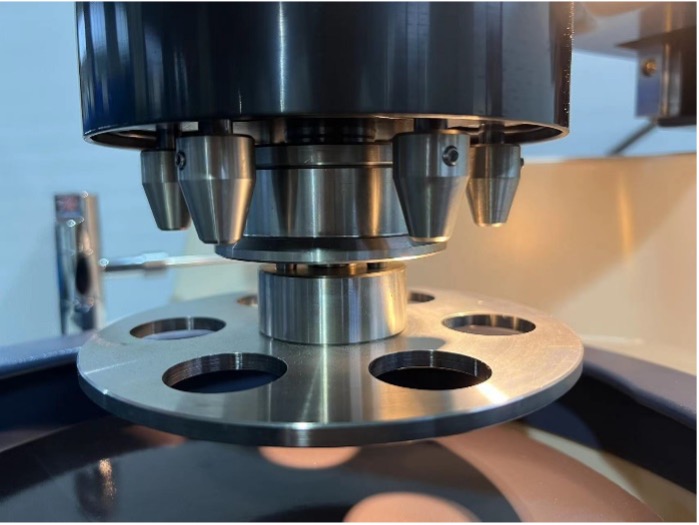

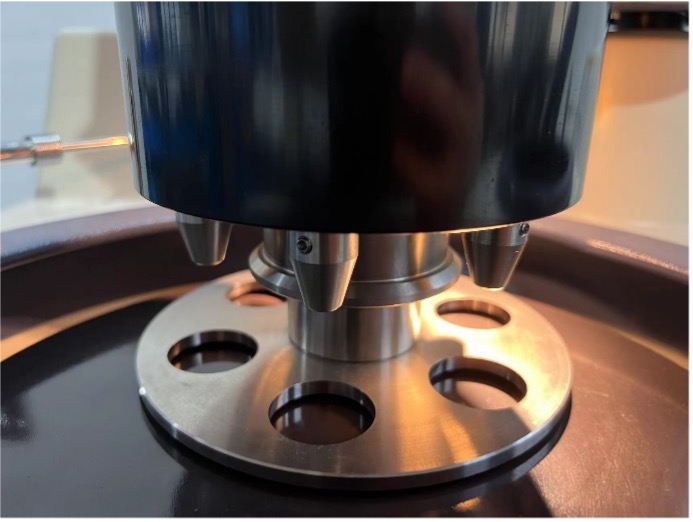

Automatic Power Head

-

Water Pipe

-

Splash Cover

-

Aluminum Grinding Platen

-

O-Ring

-

Aluminum Polishing Platen

-

Quick Release Sample Holder Adapter

-

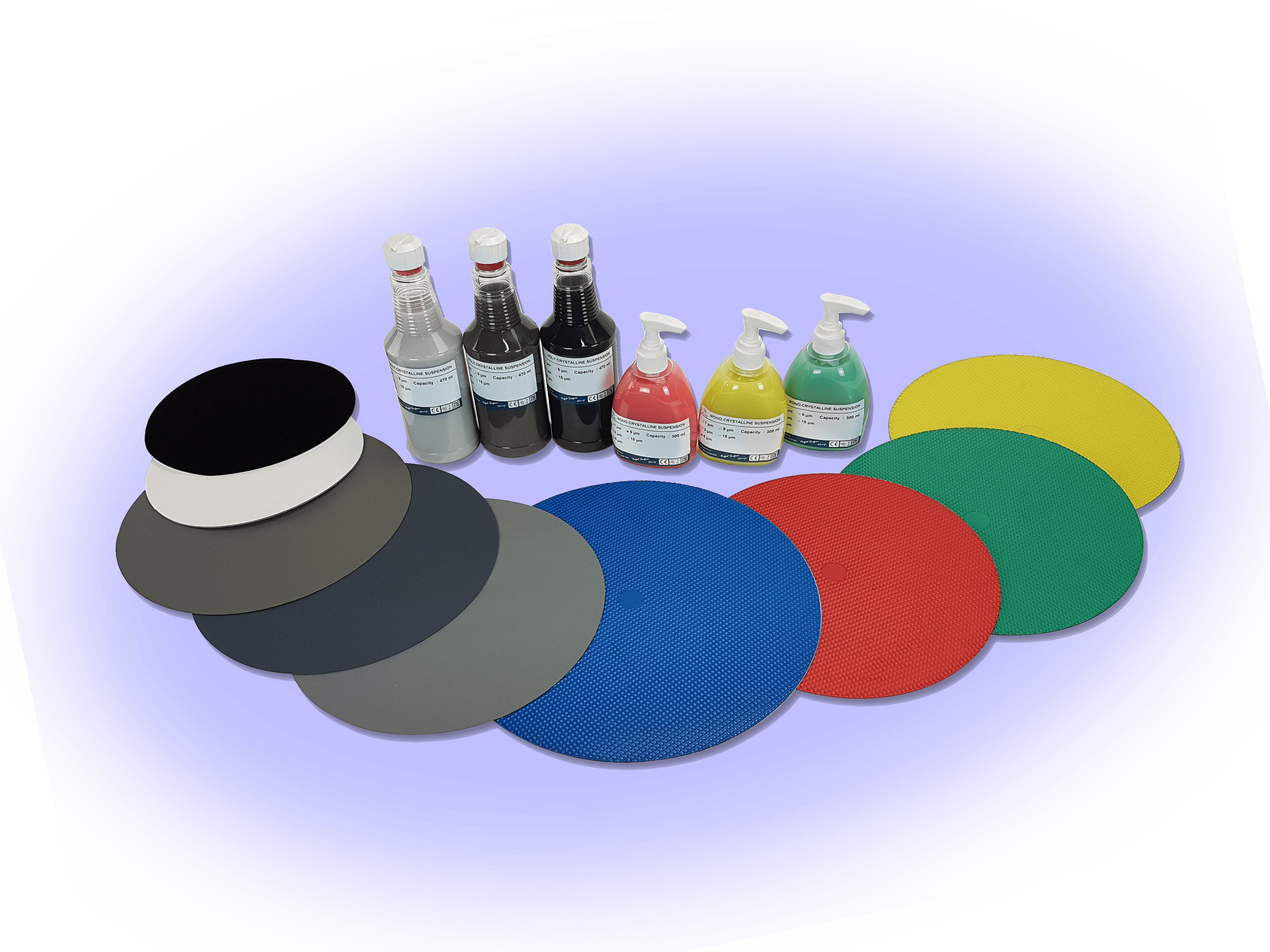

4x Silicon Carbide Papers

-

2x Abrasive Polishing Cloths

-

Operational Manual

GenGrind FA-IC Features

-

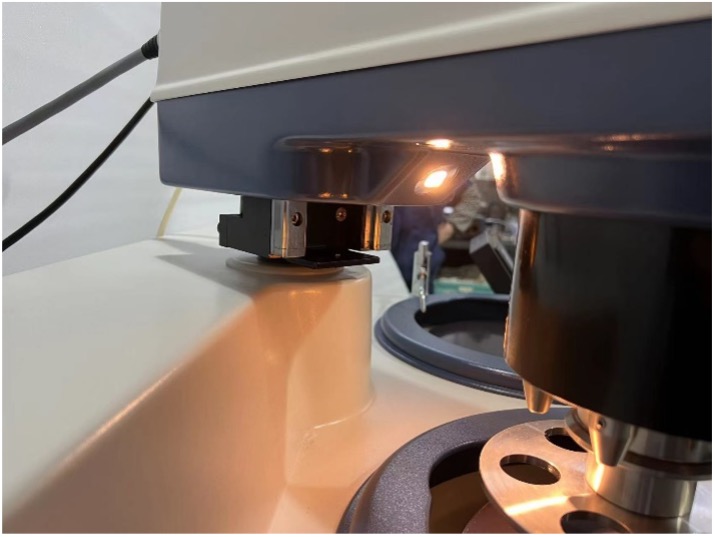

High-definition LCD touch screen for easy operation with clear and intuitive display.

-

Automatic grinding and polishing system with customizable time, speed, and automatic water control, eliminating the need for manual intervention.

-

Special self-adaptive design of the grinding disc ensures a perfect fit with the sample, resolving multi-faceted issues and ensuring consistent grinding surfaces.

-

Automatic locking function of the grinding head ensures safe and convenient operation.

-

Magnetic grinding disc design enables quick disc replacement, and the Teflon-coated disc surface prevents residue from building up on your abrasive paper and polishing cloths.

-

Dual Wheel design allows independent grinding and polishing processes without the need to constantly change your papers/pads.

-

DC brushless motor offers a long lasting service life, reduced noise, and powerful performance for efficient grinding and polishing.

-

Strong and spacious support design ensures precision rotary balance, while the leak proof spindle design protects the bearings from damage.

-

Built in memory capabilities allowing you to store up to ten different grinding and polishing procedures - allowing for different parameter settings for various samples.

GenGrind FA-IC 250 / 300 Dual Technical Specification

| Model |

GenGrind FA-IC 250 Dual

|

GenGrind FA-IC 300 Dual

|

||||

|---|---|---|---|---|---|---|

| Disc Diameter | 250mm (10") | 300mm (12") | ||||

| Grinding Papers and Polishing Cloth Diameters | 250mm (10") | 300mm (12") | ||||

| Disc Speed | Stepless Speed 50-100rpm | |||||

| Disc Rotational Direction | Clockwise or Counterclockwise | |||||

| Disc Electromotor |

DC Brushless Motor, 110V, 1.2kW

|

|||||

|

Power Head Motor

|

DC Brushless Motor, 110V, 750W

|

|||||

| Head Speed |

Stepless Speed 20-120rpm

|

|||||

| Sample Holding Qty |

Standard is 6pcs @ 30mm Dia. (other sizes available upon request - Φ25mm, Φ30mm, Φ40mm or 1”, 1.25”, 1.5” or custom)

|

|||||

| Pressure Method | Individual or Central Control | |||||

| Individual Pressure Force | 0-50N | |||||

| Central Pressure Force | 0-160N | |||||

| Control and Display |

7-inch LCD Touch Screen

|

|||||

| Power Supply |

110V / 60Hz / 1Ph or 220V / 50Hz / 1Ph 12A |

|||||

| Safety | Emergency Stop Button | |||||

| Dimensions and Weight |

47” x 31.5” x 30”; 295lbs / 1200 x 800 x 760mm; 134kg |

|||||

FAQs

In terms of dimensions, the GenGrind FA-IC Dual Models are specified as following: 1200 x 800 x 760mm or 47" x 31.5" x 30", and a weight of 134kg.

A clear understanding of these dimensions can guide the installation of these models in a laboratory or industrial environment, ensuring a proper fit within the designated area based on the space requirements.

In addition to this, the weight of 134kg indicates a very solid and durable construction, essential for stable operation during grinding, polishing, and deburring processes, yet manageable if there is a need for relocating or repositioning within the workspace.

This compact yet robust design is reflected in the dimensions and weight of the models, which shows how well they are suited to all kinds of metallographic sample preparation needs, aligned with the spatial and operational constraints of any given situation.

Click here to learn more about the product or here to receive a personalized quote.

There is an Emergency Stop Button designed into the GenGrind FA-IC Dual Models, which is a crucial component of the safety of the machine.

By using this button, you are able to stop the operation of the machine immediately during unexpected situations, which improves the safety of the user and prevents potential damage to the machine or to the samples as a result of this.

In addition, the inclusion of the Emergency Stop Button is an indication of the model's adherence to safety standards, ensuring a safer working environment during the preparation of metallographic samples.

This safety feature is a testament to the user-friendly design of the GenGrind FA-IC Dual Models, which aligns with the requisite safety protocols in industrial and laboratory environments. It is also a testament to the high quality of the product.

Click here to learn more about the product or here to receive a personalized quote.

In terms of the power supply specifications for the GenGrind FA-IC Dual Models, which are outlined as 110V/60Hz/1Ph or 220V/50Hz/1Ph 12A, it is clear that these models require specific electrical requirements in order to function properly.

A key feature of this specification is the machine's ability to adapt to a wide range of electrical standards, so it can be used across a wide range of regions requiring a variety of electrical infrastructures.

Understanding the power supply requirements is crucial for the correct installation and safe operation of machines. It ensures that the equipment is compatible with the electrical setup of the facility, thereby preventing any potential electrical issues that might arise.

Moreover, this feature emphasizes the global usability of the GenGrind FA-IC Dual Models, catering to a wide range of industrial and laboratory environments, making them a reliable choice for diverse metallographic sample preparation needs.

Click here to learn more about the product or here to receive a personalized quote.

It is a feature of the GenGrind FA-IC Dual Models that there is a 7-inch LCD Touch Screen for ease of operation and to display all settings and parameters in a clear, concise manner. This is a feature that facilitates easy operation and provides a user-friendly interface for the user.

With intuitive navigation and instant feedback, this solution simplifies the setup and control of the grinding and polishing process, allowing for easy setup and control.

In addition, the touch screen enhances the user experience by offering a straightforward approach to modifying settings. It monitors the progress of sample preparation as well, and ensures that the sample preparation tasks are completed accurately.

GenGrind FA-IC Dual Models are equipped with a 7-inch LCD Touch Screen, which is a reflection of the modern and user-centric design of the GenGrind FA-IC Dual Models, making them an efficient way to prepare metallographic samples for a wide range of applications.

Click here to learn more about the product or here to receive a personalized quote.

In the GenGrind FA-IC Dual Models, the Central Pressure Force feature, which has a range of 0-160N, plays an integral role in achieving uniform pressure application across all samples during the grinding and polishing processes.

The purpose of this feature is initially to ensure consistency and efficiency in batch processing, catering to a range of materials with different hardness and properties, which are subject to different processing conditions.

Moreover, the ability to fine-tune the pressure within this range allows for optimal sample preparation, resulting in a high-quality surface finish, which is crucial for an accurate metallographic analysis to be conducted.

A broad pressure range demonstrates the flexibility and adaptability of the GenGrind FA-IC Dual Models, making them a reliable choice for diverse metallographic sample preparation tasks, ensuring accuracy and reproducibility of results across a wide range of projects and laboratory settings.

Click here to learn more about the product or here to receive a personalized quote.

A GenGrind FA-IC Dual Model is equipped with an Individual Pressure Force feature, which indicates a range of pressure of 0 to 50 N. During grinding and polishing, this range of pressure is very important since it provides precise control over the force applied to each sample.

Initially, this feature ensures that the pressure can be adjusted according to the material characteristics and specific requirements of the sample preparation protocol. It caters to diverse materials' hardness and consistency, ensuring optimal preparation outcomes.

Furthermore, having a defined yet adaptable pressure range enhances sample preparation precision and quality. It minimizes the risk of material damage or loss of sample integrity, which is crucial for accurate metallographic analysis.

The provision for adjusting individual pressure showcases the user-centric design of the GenGrind FA-IC Dual Models, making them a flexible and reliable choice for varied metallographic sample preparation needs across different projects and laboratory settings.

Click here to learn more about the product or here to receive a personalized quote.

The Pressure Method feature in the GenGrind FA-IC Dual Models offers two distinct options: Individual or Central Control, each catering to different operational needs.

Individual Control allows for customized pressure application to each sample, ensuring precise grinding and polishing based on each sample's unique requirements. This method is particularly beneficial when dealing with samples of varying material properties.

On the other hand, Central Control facilitates a uniform pressure application across all samples simultaneously, ideal for batch processing especially when dealing with similar materials. This method enhances efficiency and consistency during grinding and polishing.

The choice between Individual or Central Control significantly expands machine versatility and adaptability. It allows operators to optimize the pressure control method based on project requirements, ensuring both efficiency and precision in metallographic sample preparation. This feature embodies the user-centric design of the GenGrind FA-IC Dual Models, making them a reliable and flexible choice for a myriad of metallographic sample preparation tasks.

Click here to learn more about the product or here to receive a personalized quote.

The Sample Holding Quantity feature, which is available in the GenGrind FA-IC Dual Models, is an important aspect that identifies the machine's capability and flexibility to meet a variety of customer needs.

Initial indications suggest that the system can hold up to six samples with a diameter of 30mm at a time. Laboratories need this capacity to plan and execute sample preparation tasks efficiently.

Furthermore, the feature offers flexibility by accommodating other sample sizes upon request, such as Φ25mm, Φ30mm, Φ40mm or 1”, 1.25”, 1.5”, or custom sizes. This versatility caters to a broad spectrum of metallographic sample preparation needs across different projects.

Finally, this versatility and adaptability make the GenGrind FA-IC Dual Models an excellent choice for metallographic sample preparation because of the user-centric design and versatility of these instruments, making them an ideal choice for applications involving a wide range of sample sizes.

Click here to learn more about the product or here to receive a personalized quote.

What is the Significance of the Stepless Speed Feature for Head Speed in GenGrind FA-IC Dual Models?

In GenGrind FA-IC Dual Models, there is a Stepless Speed feature for controlling the Head Speed in the range of 20-120rpm, which is fundamental to precise grinding and polishing control.

The first benefit of this feature is that it allows operators to fine-tune the pace of the head based on the material properties and the preparation protocol, which ensures that the samples will have an optimal surface finish and integrity.

Furthermore, the flexibility of speed adjustment facilitates the handling of a diverse range of materials and preparation requirements due to the ability to adjust the speed. It is for this reason that the GenGrind FA-IC Dual Models are versatile enough to handle a variety of metallographic sample preparation applications.

As a final point, this feature is indicative of the user-centric design of the GenGrind FA-IC Dual Models, designed to provide a customizable and efficient solution for metallographic sample preparation, increasing the overall efficiency and effectiveness of the process.

Click here to learn more about the product or here to receive a personalized quote.

As part of the GenGrind FA-IC Dual models, the Power Head Motor is a DC Brushless Motor that is operated at 110V, 750W and is designed to drive the grinding and polishing head. This component is an integral part of the system.

The motor is initially responsible for providing the requisite torque as well as speed, which in turn ensures that the head operates smoothly and efficiently, which is vital for precise metallographic sample preparation.

Furthermore, DC Brushless Motor technology is known for its longevity, low maintenance requirements, and consistent performance, attributes that are vital for ensuring the reliability and effectiveness of the GenGrind FA-IC Dual models over time.

Lastly, the specified power rating of 750W demonstrates a balance between providing ample power for demanding tasks while maintaining energy efficiency, which is critical in today's laboratory environments where operational cost management is essential.

Click here to learn more about the product or here to receive a personalized quote.

The Disc Electromotor, equipped with a DC Brushless Motor operating at 110V, 1.2kW, in GenGrind FA-IC Dual models, is a crucial component ensuring the effective functioning of the grinding and polishing processes.

Initially, this electromotor serves as the powerhouse that drives the grinding and polishing discs. It ensures that the discs rotate at the desired speed, enabling precise grinding and polishing of metallographic samples.

Furthermore, DC Brushless Motor technology represents a step towards enhanced efficiency and reduced maintenance. This type of motor is known for its longevity, reliable performance, and lower maintenance requirements than traditional motor types, ensuring that the GenGrind FA-IC Dual models remain operational with minimal downtime.

Moreover, the motor's power rating of 1.2kW testifies to its capability to handle demanding grinding and polishing tasks while maintaining energy efficiency. This balance between power and efficiency is critical in modern laboratory environments where operational costs are concerned.

Lastly, the electromotor's performance has a direct impact on sample preparation quality. A reliable and powerful motor ensures that samples are prepared accurately and within a reasonable time frame, thus enhancing the overall productivity and effectiveness of the metallographic sample preparation process.

Click here to learn more about the product or here to receive a personalized quote.

The Disc Rotational Direction feature in the GenGrind FA-IC Dual models, which allows for both clockwise and counterclockwise rotation, significantly enhances grinding and polishing operations flexibility and efficacy.

Initially, this feature enables customization of the rotational direction based on material properties and desired surface finish. Different materials may respond better to a particular rotational direction, making this feature instrumental in optimal results.

Furthermore, the ability to alter rotational direction can lead to better surface finishes and faster material removal rates. It provides an added level of control to operators, allowing them to adjust the process as per the requirements of the task at hand.

The inclusion of the Disc Rotational Direction feature underscores the design focus of GenGrind FA-IC Dual models on providing a user-centric, adaptable, and efficient solution for metallographic sample preparation. By catering to various operational needs and preferences, it significantly enhances the overall efficiency and effectiveness of grinding and polishing processes.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC Dual models, namely the GenGrind FA-IC 250 Dual and GenGrind FA-IC 300 Dual, boast a Stepless Speed feature ranging from 50-100rpm, which ensures precise and effective grinding and polishing processes.

Initially, the Stepless Speed feature allows for fine-tuning of the disc speed, catering to the specific requirements of different materials and sample preparation protocols. This flexibility is pivotal to achieving the desired surface finish and ensuring the integrity of the samples.

Furthermore, this range of speeds facilitates the optimization of grinding and polishing processes based on the nature of the task at hand. It helps achieve a balance between efficiency and quality, thus ensuring metallographic sample preparation is both accurate and time-efficient.

Lastly, the Stepless Speed feature significantly enhances the versatility of the GenGrind FA-IC Dual models. It accommodates a wide array of metallographic sample preparation tasks, making these models a reliable and adaptable choice for laboratories with diverse needs.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC Dual models, specifically the GenGrind FA-IC 250 Dual and the GenGrind FA-IC 300 Dual, are designed to ensure consistency and precision in metallographic sample preparation.

Firstly, the specified diameters for grinding papers and polishing cloths are meticulously matched with the disc diameters of the respective models. In the GenGrind FA-IC 250 Dual, a diameter of 250mm (10") is maintained, while the GenGrind FA-IC 300 Dual accommodates a diameter of 300mm (12"). This correspondence ensures a seamless fit, which is fundamental for precise grinding and polishing outcomes.

Secondly, maintaining this congruence between the disc and consumable diameters helps minimize any potential slippage or misalignment during grinding and polishing operations. This aspect is crucial as any misalignment can adversely affect sample preparation quality, leading to inaccurate results.

Lastly, these specified diameters underscore the importance of precision and consistency in metallographic sample preparation. By ensuring that the grinding papers and polishing cloths perfectly fit the discs, the GenGrind FA-IC Dual models exhibit a well-thought-out design aimed at optimizing the efficiency and accuracy of the metallographic sample preparation process.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC Dual Wheel Fully Automatic Series caters to diverse laboratory requirements by offering two distinct models: the GenGrind FA-IC 250 Dual and the GenGrind FA-IC 300 Dual. The core difference lies in their disc diameter.

The GenGrind FA-IC 250 Dual accommodates a disc diameter of 250mm (10"), making it a compact choice for laboratories with standard or small-scale grinding and polishing needs.

Conversely, the GenGrind FA-IC 300 Dual, with a disc diameter of 300mm (12"), provides a more expansive working surface. This model is apt for larger or multiple sample preparations, providing a large grinding and polishing area that handles a higher volume of samples or larger sample sizes.

These model variations are meticulously designed to provide laboratories with the flexibility to choose a model that aligns with their specific operational needs. By offering different disc diameters, the GenGrind FA-IC series ensures that laboratories can select a model that fits their sample size and throughput requirements, thereby optimizing the efficiency and effectiveness of their metallographic sample preparation process.

Click here to learn more about the product or here to receive a personalized quote.

GenGrind FA-IC Dual Wheel Fully Automatic is incorporated with an integrated memory module that embodies a vital function for the efficient and personalized preparation of samples.

Initially, this feature allows storage of up to ten different grinding and polishing procedures. This is immensely beneficial for laboratories dealing with varied materials requiring distinct preparation protocols, enabling a swift switch between different procedures without reconfiguration.

Moreover, the fact that it allows for variable parameter settings for different samples allows for a level of customization that is crucial for obtaining precise and accurate results in metallographic analyses because it can adjust parameters for different samples.

Lastly, these memory capabilities streamline the workflow, reducing setup time, and minimizing error chances during setup. It not only enhances the efficiency but also the consistency of the sample preparation process, which is crucial for reliable metallographic analysis.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC Dual Wheel Fully Automatic encapsulates a robust engineering approach with its strong and spacious support design alongside a leak-proof spindle design, each serving critical roles in the machine's operation.

Initially, the strong and spacious support design is crucial for ensuring precision rotary balance during grinding and polishing processes. This design provides a stable foundation, allowing for accurate and controlled movements of the grinding and polishing heads, which is imperative for achieving the desired surface finish on metallographic samples.

Furthermore, the leak-proof spindle design is a significant feature aimed at protecting the bearings from potential damage. By preventing the ingress of contaminants such as grinding residues or liquids, this design ensures the longevity and continuous smooth operation of the spindle, which in turn, contributes to the overall durability of the GenGrind FA-IC.

Together, the strong support and leak-proof spindle design combine precision and durability. By ensuring a precise rotary balance and safeguarding critical internal components from potential damage, these design elements significantly enhance the operational reliability and longevity of the GenGrind FA-IC Dual Wheel Fully Automatic, making it a dependable choice for rigorous metallographic sample preparation tasks.

Click here to learn more about the product or here to receive a personalized quote.

This DC Brushless Motor is a key feature of the GenGrind FA-IC Dual Wheel Fully Automatic that greatly enhances the performance of the machine and enhances the user's experience with the machine.

In the first place, the motor is well known for its long lifespan and reliability. As a result of this longevity, fewer maintenance requirements need to be undertaken, and less downtime has to be experienced, which is crucial for maintaining high productivity in busy laboratories.

Secondly, the reduced noise operation of the DC Brushless Motor contributes to a more comfortable and less distracting work environment. This is particularly beneficial in settings where multiple pieces of equipment operate simultaneously, helping to maintain a conducive work atmosphere.

Lastly, the powerful performance of the DC Brushless Motor ensures that grinding and polishing processes are carried out efficiently. The motor's power facilitates quicker completion of tasks without compromising the quality of the sample preparation.

Click here to learn more about the product or here to receive a personalized quote.

The Dual Wheel Design of the GenGrind FA-IC Dual Wheel Fully Automatic is a sophisticated feature engineered to enhance metallographic sample preparation efficiency and flexibility.

Firstly, this innovative design enables independent grinding and polishing processes. Segregating these crucial steps, it eliminates the cumbersome need for constant paper or pad changes, thus significantly saving time and reducing the chance of errors during the transition between processes.

Secondly, by allowing simultaneous operations, the Dual Wheel Design drastically accelerates sample preparation. This is a boon for busy laboratories where time efficiency is critical to managing high sample throughput.

Furthermore, the Dual Wheel Design facilitates a more organized and straightforward workflow. Operators can effortlessly switch between grinding and polishing tasks without the hassle of changing papers or pads, allowing them to focus more on preparation quality than operational logistics.

Lastly, this design enhances operational efficiency and contributes to sample preparation consistency and quality. Providing dedicated wheels for grinding and polishing ensures that each stage of preparation is executed to the highest standards, contributing to the overall accuracy and reliability of the metallographic analysis.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC Dual Wheel Fully Automatic incorporates a magnetic grinding disc design and a Teflon-coated disc surface, each serving distinctive purposes to enhance the efficiency and quality of the metallographic sample preparation process.

Firstly, the magnetic grinding disc design simplifies disc replacement. The magnetic feature allows for quick and effortless disc changes, significantly reducing downtime and enhancing operational efficiency. This is especially beneficial in busy laboratories where time is of the essence.

Secondly, the Teflon-coated disc surface prevents residue buildup on abrasive paper and polishing cloths. This coating ensures cleaner operation, reducing cross-contamination chances, which is crucial for maintaining sample integrity. Additionally, it minimizes the maintenance required to keep the machine in optimal working condition, further contributing to operational efficiency.

Lastly, the combination of these two features showcases the thoughtful engineering in the GenGrind FA-IC, aimed at making the metallographic sample preparation process more efficient, user-friendly, and reliable. Together, they significantly contribute to a smoother and more efficient workflow, making the GenGrind FA-IC a valuable asset for metallographic laboratories.

Click here to learn more about the product or here to receive a personalized quote.

A thoughtful feature of the GenGrind FA-IC Dual Wheel Fully Automatic is the automatic locking function of the grinding head, which promotes both safety and convenience during the preparation of metallographic samples.

Firstly, the automatic locking function ensures the grinding head is securely fastened during operation. This safety measure prevents any unwanted movements or dislodging, thereby mitigating potential hazards during high-speed grinding and polishing tasks.

Secondly, the ease of locking and unlocking the grinding head contributes to operation convenience. It simplifies the process, allowing operators to swiftly transition between different stages of sample preparation without having to manually adjust the grinding head, saving valuable time and effort.

Lastly, by amalgamating safety measures with operational convenience, the automatic locking function accentuates the user-friendly design of the GenGrind FA-IC Dual Wheel Fully Automatic. It illustrates the machine's commitment to providing a safe, convenient, and efficient environment for operators, ensuring that metallographic sample preparation is both precise and efficient.

Click here to learn more about the product or here to receive a personalized quote.

In the GenGrind FA-IC Dual Wheel Fully Automatic, the self-adaptive design of the grinding disc is one of the key features that ensure consistent and precise metallographic sample preparation thanks to its self-adaptive design.

First of all, this innovative design ensures a perfect fit with the sample, regardless of its geometry. When dealing with samples that are of different shapes and sizes, the ability to achieve a uniform grinding surface is absolutely crucial.

Furthermore, this self-adaptive design significantly improves the reliability of the preparation process by addressing several multi-faceted issues commonly encountered during the grinding process, such as uneven surfaces or inconsistent outcomes.

Lastly, this self-adaptive design ensures accurate metallographic analysis thanks to the consistent grinding surfaces that are achieved. The purpose of this method is to minimize potential errors during the grinding phase in order to lay a strong foundation for the subsequent stages of preparation of metallographic samples.

Click here to learn more about the product or here to receive a personalized quote.

The Automatic Grinding and Polishing System of the GenGrind FA-IC Dual Wheel Fully Automatic is fully engineered to significantly streamline metallographic sample preparation.

Firstly, the system allows customizable time and speed settings. This feature provides operators with the flexibility to customize grinding and polishing processes according to the specific requirements of different materials, ensuring optimal preparation quality.

Secondly, the inclusion of automatic water control is a notable feature that maintains the necessary cooling and cleaning during operation, eliminating the need for manual intervention. This automatic control ensures a consistent operational environment, which is crucial for reliable and reproducible results.

Lastly, by automating grinding and polishing processes, the GenGrind FA-IC substantially reduces manual labor, freeing up operators for other crucial tasks. This automation not only enhances operational efficiency but also contributes to higher throughput, making it a highly efficient and user-friendly solution for metallographic sample preparation.

Click here to learn more about the product or here to receive a personalized quote.

The high-definition LCD touchscreen featured in the GenGrind FA-IC Dual Wheel Fully Automatic significantly elevates the user experience by offering an intuitive and user-friendly operation interface.

Firstly, the clear and bright touchscreen display ensures easy readability. This allows operators to effortlessly navigate through different settings and monitor ongoing processes in real-time. This is crucial for maintaining quality and precision in metallographic sample preparation.

Secondly, touch screen functionality simplifies the input of commands and customization of settings according to the specific requirements of the task at hand. This ease of operation reduces the learning curve for beginner users and enhances experienced operators' efficiency.

Lastly, the intuitive design of the interface helps reduce the time and effort required to set up and operate the machine, making the overall process of metallographic sample preparation more efficient and less time-consuming.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC Dual Standard Configuration is meticulously curated to facilitate precise and efficient metallographic sample preparation. It encompasses a range of components each playing a vital role in the process.

The core of the configuration is the Dual Wheel GenGrind FA-IC which offers Individual and Central Force Control, enabling tailored pressure application during grinding and polishing. Accompanying this is the Automatic Power Head which further simplifies the operation, making the process more user-friendly.

For handling cooling and cleaning requirements during operation, a water pipe and a splash cover are included. These components are essential for maintaining the machine's operational integrity and ensuring the longevity of the grinding and polishing plates.

The Aluminum Grinding Platen and Aluminum Polishing Platen provide durable and effective surfaces for the respective processes, ensuring optimal results. The inclusion of a Quick Release Sample Holder Adapter facilitates easy sample handling, enhancing workflow efficiency.

The provision of 4 Silicon Carbide Papers and 2 Abrasive Polishing Cloths ensures that operators have the necessary consumables to complete the metallographic preparation process. Lastly, an Operational Manual is included to provide clear instructions and guidance, ensuring users can effectively utilize the GenGrind FA-IC to its full potential.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC Dual Wheel Fully Automatic significantly streamlines metallographic sample preparation by replacing manual grinding and polishing procedures. This automation substantially reduces labor requirements, allowing technicians to focus on other crucial aspects of laboratory workflow.

Furthermore, the GenGrind FA-IC enhances sample preparation quality and efficiency. The machine's precision and consistency in grinding and polishing ensure superior sample quality, which is paramount for accurate metallographic analysis. By automating these processes, the GenGrind FA-IC eliminates human errors, which often occur in manual operations, leading to more reliable and reproducible results.

Moreover, the machine's design, featuring step-less speed control and dual pressure methods, ensures versatile and adaptable operation. This accommodates a wide range of materials and preparation needs. This flexibility, coupled with reduced labor needs and improved sample quality, makes the GenGrind FA-IC the ideal equipment choice for metallographic sample preparation, offering a blend of efficiency, precision, and ease of use.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC Dual Wheel Fully Automatic is equipped with a grinding head that offers two distinct pressure methods: individual pressure and central pressure. This significantly broadens its operational scope and precision in metallographic sample preparation.

Firstly, the individual pressure method provides personalized pressure application to each sample. This is invaluable for handling materials of varying hardness and characteristics, ensuring each sample receives the precise pressure needed for optimal grinding and polishing.

Secondly, the central pressure method applies uniform pressure across multiple samples simultaneously. This is particularly beneficial for batch processing, ensuring a consistent level of preparation across all samples, which is crucial for reliable and accurate metallographic analyses.

Moreover, the ability to switch between these two pressure methods provides operators with the flexibility to choose the most suitable method based on the specific requirements of the task at hand. This adaptability is especially crucial in environments where a wide range of materials are being analyzed, ensuring that the GenGrind FA-IC can cater to a broad spectrum of metallographic sample preparation needs.

Click here to learn more about the product or here to receive a personalized quote.

Featuring step-less speed control, and reversible rotational direction, the GenGrind FA-IC Dual Wheel Fully Automatic offers enhanced functionality thanks to its stepless speed control.

In the first place, step-less speed control allows for precise control over grinding and polishing speeds, which is crucial because there are so many different materials and preparation standards. This flexibility ensures optimal preparation quality, meeting metallographic analysis requirements.

Additionally, the reversible rotational direction of the grinding and polishing machine allows the user to adapt the grinding and polishing process to accommodate the different sample geometries and preparation requirements of the customer. The ability to achieve desired surface finishes and accurate analytical results can only be achieved with this level of adaptability.

Together, these features serve to demonstrate how the GenGrind FA-IC is capable of handling a wide range of tasks related to the preparation of metallographic samples, highlighting its utility as a versatile, user-centric machine.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC Dual Wheel Fully Automatic is encased in a durable ABS material shell, providing both aesthetic and functional advantages crucial for metallographic sample preparation environments.

Firstly, the ABS material shell showcases a stylish appearance, aligning with modern laboratories' professional aesthetics. This polished look reflects the state-of-the-art technology employed in the GenGrind FA-IC, portraying a reliable and modern image to operators and visitors alike.

Secondly, the ABS material's durability provides excellent resistance to corrosion. In metallographic sample preparation, equipment often comes into contact with various materials that could corrode over time. The ABS shell ensures that the GenGrind FA-IC remains protected against such corrosive elements, extending the machine's lifespan.

Lastly, the ABS shell safeguards the GenGrind FA-IC's sophisticated internal components. This protection is essential for maintaining the high performance and reliability of the machine during grinding and polishing processes, ensuring that metallographic sample preparation is not compromised.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC Dual Wheel Fully Automatic heralds an era in metallographic sample preparation, driven by its state-of-the-art single-chip microcomputer control. This control mechanism orchestrates grinding and polishing processes, vital for accurate metallographic sample preparation.

Machine automation significantly minimizes manual intervention, promoting higher accuracy and consistency in sample preparation. By automating these critical steps, the GenGrind FA-IC propels efficiency, ensuring a streamlined workflow from grinding to polishing.

The dual-wheel design of the GenGrind FA-IC is another notable feature, permitting independent grinding and polishing processes. This design facilitates a seamless transition between these stages, crucial for maintaining high throughput in demanding laboratory or industrial settings.

Moreover, the user-friendly interface, encompassing a high-definition LCD touchscreen, simplifies operation and allows for customizable settings to accommodate varying sample preparation requirements. This user-centric design ensures intuitive operation, making it accessible to both experienced and novice operators.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC Dual Wheel Fully Automatic is a sophisticated machine engineered for metallographic sample preparation. Its primary objective is to automate the grinding and polishing phases, ensuring high-quality preparation of metallographic samples.

With its state-of-the-art single-chip microcomputer control, the machine offers precise grinding and polishing, which is crucial for accurate microscopic analysis. The automation significantly cuts down the manual labor, making the process more efficient and consistent.

Furthermore, the GenGrind FA-IC is designed with a dual-wheel feature, allowing for independent grinding and polishing processes, reducing the time and effort typically required in manual operations. This feature is particularly beneficial in labs and industries where high throughput and reliability are paramount.

The machine embodies a blend of robust construction and user-friendly operation, making it a vital piece of equipment for achieving refined metallographic sample preparation, which is foundational for subsequent analytical processes in metallurgical studies.

Click here to learn more about the product or here to receive a personalized quote.

GenGrind FA Series is a pneumatic polisher and grinder unit. The value of a pneumatic system over a spring force system is that the force load offered by the pneumatic system is more stable, thereby offering a much better surface grind / polish. Learn more by requesting a quotation today.

Related Products

GenGrind N Series 8” 200S / 10" 250S / 12" 300 S - Advanced Metallographic Grinder & Polisher - Variable Speed 50-1000rpm –Touch Screen Controlled

Introducing the GenGrind N Series metallographic grinders and polishers, offered in sizes 8", 10", or 12" diameter.

GenGrind SA-I 250S 10" Single Wheel Semi Automatic Grinder & Polisher - Variable Speed 100-1000rpm – Individual Force Control - Touch Screen Controlled with Automatic Specimen Mover Power Head – (various wheel sizes available)

Discover the single wheel semi automatic GenGrind 10" SA-I 250S, your ultimate answer to grinding and polishing needs.

GenGrind SA-C 250S 10" Single Wheel Semi Automatic Grinder & Polisher - Variable Speed 100-1000rpm – Central Force Control - Touch Screen Controlled with Automatic Specimen Mover Power Head – (various wheel sizes available)

Introducing the GenGrind SA-C 250S – your ultimate single wheel semi automatic grinding and polishing solution.

GenGrind FA-IC 250D 10" Dual Wheel Fully Automatic Grinder & Polisher - Variable Speed 100-1400rpm – Both Individual and Central Force Control - Touch Screen Controlled with Automatic Specimen Mover Power Head – (various wheel sizes available)

Introducing the GenGrind FA-IC 250D Dual Wheel Polisher and Grinder, a fully automatic metallographic grinding and polishing machine

GenGrind FA-IC 250S 10" Single Wheel Fully Automatic Grinder & Polisher - Variable Speed 100-1400rpm – Both Individual and Central Force Control - Touch Screen Controlled with Automatic Specimen Mover Power Head – (various wheel sizes available)

GenGrind FA-IC 250S Single Wheel Polisher and Grinder, an advanced and fully automatic metallographic grinding and polishing machine

GenGrind Belt BF - Floor Standing Heavy Duty Dual Stage Belt Grinder for Metallographic Sample Preparation

The GenGrind Belt BF Series is a heavy duty dual stage, wet or dry belt grinder offering a robust, floor standing solution for high volume manual belt grinding applications. GenGrind Belt BF - Heavy Duty Dual Stage Belt Grinder for metallographic sample preparation is designed for high material removal of various sample shapes and configurations.

GenGrind Belt BT - Dual Stage Tabletop Belt Grinder for Metallographic Sample Preparation

The GenGrindBelt BT series is a dual stage, wet or dry table top belt grinder offering the most economical solution for manual grinding applications. The GenGrind BT - Dual Stage Belt Grinder for Metallographic Sample Preparation is designed for high material removal of various sample shapes and configurations. The BT - Belt Grinder system is a table top belt grinder suitable for laboratories designed for high material removal.

Metallography Consumables

Learn about the full scope of NextGen's cutting, polishing & grinding, mounting and etching metallography consumables. Our consumables are compatible with virtually all global brands, offering a rare combination of exceptional quality, longevity and affordability.