Metal Testing Equipment

Description

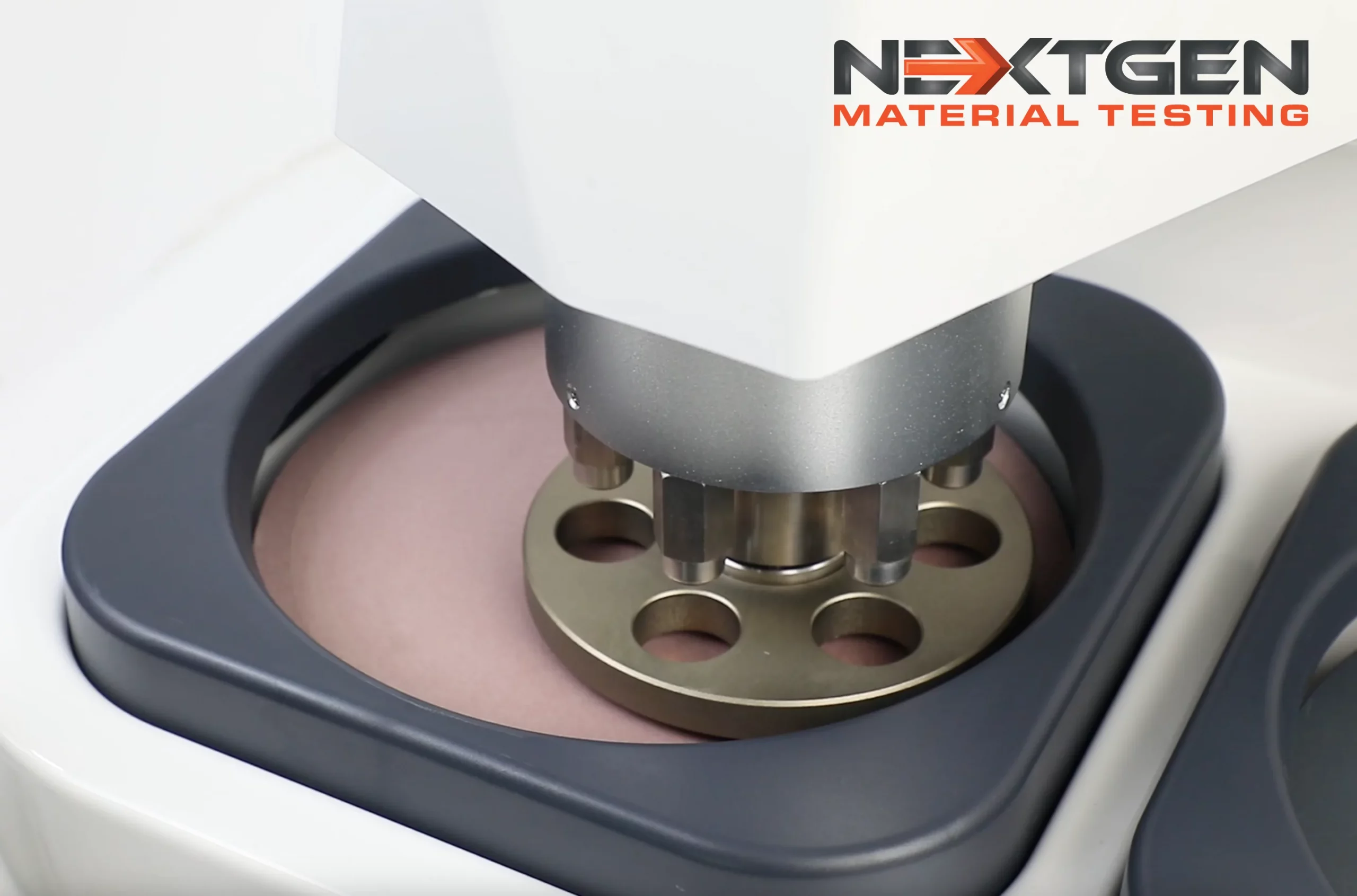

Introducing the GenGrind FA-IC 250D Dual Wheel Polisher and Grinder, an advanced and fully automatic metallographic grinding and polishing machine. This state-of-the-art equipment seamlessly integrates pre-grinding, grinding, and polishing processes to deliver exceptional results.

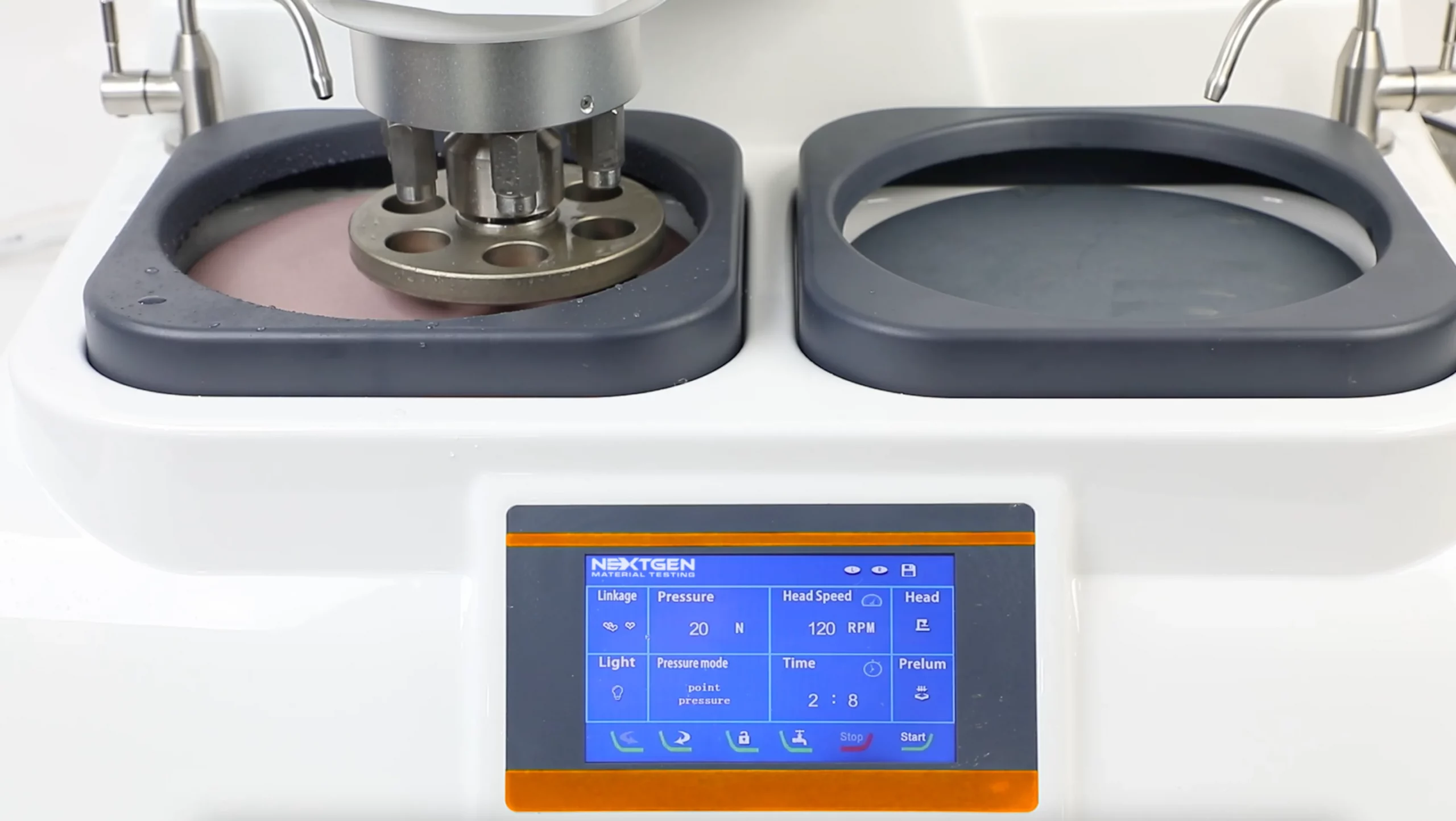

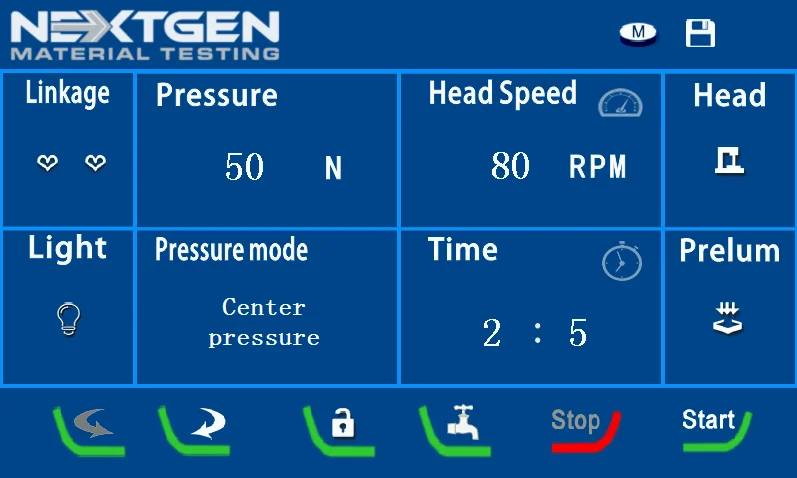

Controlled through a user-friendly touch screen interface, the GenGrind FA-IC features a DC brushless motor driving the grinding and polishing plate, while the grinding head is efficiently powered by a stepper motor. This design ensures stable rotation, low noise levels, and utmost safety and reliability during operation.

The machine allows users to customize various settings such as rotational speed, pressure, and sample preparation time according to their specific requirements. These adjustments are effortlessly made through the intuitive touch screen, enabling users to cater to different needs with ease.

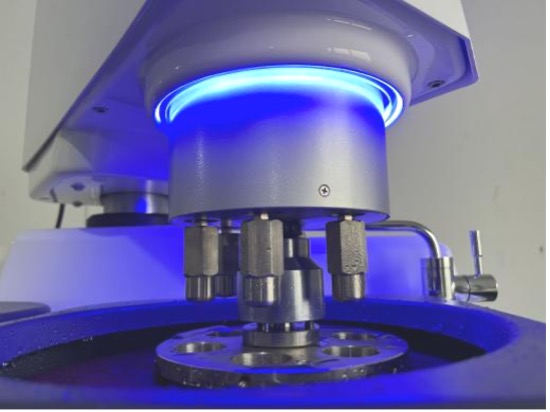

Incorporating its own lighting system, the GenGrind FA-IC provides convenient sample handling and placement. Additionally, its cooling device effectively prevents overheating during grinding, safeguarding the integrity of the metallographic structure. This feature is particularly beneficial in preserving the quality of metallographic samples.

Whether in metallographic laboratories within factories, colleges, or research institutes, the GenGrind FA-IC Single Wheel Polisher and Grinder stands as the ultimate choice for precision grinding and polishing applications. Its cutting-edge capabilities and reliable performance make it the preferred solution for achieving impeccable metallographic results.

GenGrind FA-IC 250D Features

-

Super cost-effective, offering outstanding value for money.

-

Dual working plates with standard dimensions of 254mm, providing 50% more working area compared to regular grinding and polishing machines.

-

Capable of polishing 6 pieces of 30mm diameter samples in a single operation, maximizing productivity.

-

High-end ABS shell, giving it a sophisticated and modern appearance.

-

User-friendly touch screen display for clear and intuitive interface, ensuring simple operation.

-

Adjustable testing time, rotating speed, and pressure to suit specific needs.

-

The grinding head is equipped with an electromagnetic clutch for convenient and quick operation, automatically locking when needed.

-

Offers stepless speed regulation from 100 to 1400rpm or four constant speed options, with the ability to define three common speeds for pre-grinding, grinding, and polishing.

-

Allows storage of up to 100 groups of grinding and polishing programs for quick recall and efficient workflow.

-

Features a magnetic disc design for swift disc changes, enhancing the replacement of sandpaper and polishing cloth.

-

Boasts a sample chuck with free-rotating design, complemented by an internal lighting system, ensuring ease in sample handling.

-

Equipped with a built-in nozzle, sewage collection tank, and automatic cleaning, streamlining maintenance tasks.

-

Utilizes DC brushless and stepper motors for stable rotation, low noise levels, and prolonged machine life.

-

The base is made of a single-piece aluminum alloy material, offering lightweight construction, excellent shock absorption, and corrosion resistance.

7" Touch Screen User Friendly Control Display

GenGrind FA-IC 250D Technical Specification

| Model | GenGrind FA-IC 250D |

| Working Plate | Standard Ø254mm with magnetic disc; 2.2KW |

| Speed of working plate |

100-1400 r/min stepless speed Support clockwise / anticlockwise direction rotating |

| Four level constant speeds (stepless speed) | V1=300r/min, V2=500r/min, V3=800r/min, V4=1000r/min (each speed can be set between 100-1400r/min) |

| Grinding head speed | 0-200r/min |

| Grinding head power | 0.2kw (clockwise rotating) |

| Grinding head lock mode | Automatic electronic lock |

| Sample holder | Standard Ø30mm 6 pieces of samples |

| Automatic mode | Can be programmed. Speed, running time and grinding wheel steering switch, with timing function |

| Samples pressure range |

Center load: 0-150N (Commonly used 40-120N) Single point load: 0-90N |

| Pressure loading type |

Single point pneumatic pressurization + Central pressure |

| Pressure adjustment |

Digital voltage regulation |

| Timing function |

0-99 minutes |

| Power supply |

AC220V, 50/60Hz, 2.8kW |

| Dimensions |

30.31" x 28.74" x 27.56" / 770 x 730 x 700 mm |

| Weight |

220 lbs / 100 kg |

GenGrind FA-IC 250D Standard Configuration

-

GenGrind FA-IC 250S Single Wheel Fully Automatic Grinder and Polisher with Individual and Central Pneumatic Force Control

-

Grinding Plate 254mm

-

Polishing Cloth with PSA (250mm) (4)

-

Grinding Papers 400# (4)

-

Grinding Papers 800# (4)

-

Grinding Paper 1200# (4)

-

Waterproofing Ring (On Machine)

-

Paper Disc

-

Magnetic Disc

-

Water Inlet Hose 0.75”

-

Water Outlet Hose 32mm

-

Power Line and Operational Manual

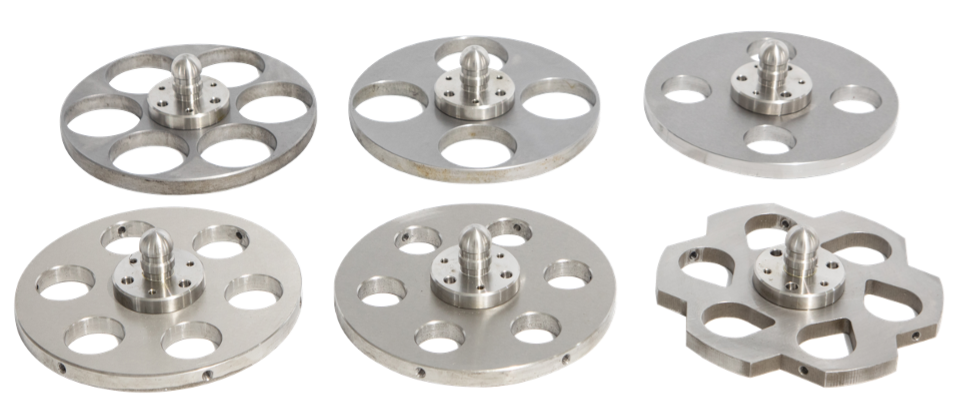

Specimen Sample Examples

Important Note: Sample Specimen Size to be indicated at time of order!

FAQs

The primary purpose of the GenGrind FA-IC 250D is to automate and enhance the precision of metallographic sample preparation through grinding and polishing. This machine is engineered to simplify and standardize the preparation process for material analysis by integrating multiple functions into a single, efficient system. It combines pre-grinding, grinding, and polishing operations, resulting in consistent results with minimal manual intervention.

This equipment is especially useful in laboratories, research institutions, and academic settings where high-quality sample preparation is a necessity. Its dual-wheel configuration and programmable features help prepare multiple samples at once, increasing productivity and saving time. By providing control over speed, pressure, and timing, it guarantees that each sample is treated according to its specific requirements.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC 250D stands out by its advanced memory features, full automation, and dual pressure modes (central and individual pneumatic force), which are uncommon in this price range. This model was designed to optimize the entire metallographic preparation process, from pre-grinding to final polishing, with minimal operator effort, in contrast to many systems that concentrate just on basic grinding.

A dual-plate system with 254mm discs is one of its main advantages, as it allows for the preparation of 6 samples at the same time, resulting in a 50% larger working area than typical machines. In addition, it enables users to save up to 100 preparation programs, which results in faster setups and improved consistency throughout batches.

The daily operation is made faster, cleaner, and easier than most alternatives by the 7" touchscreen, magnetic disc system, automatic sample locking, built-in lighting, and internal cleaning system. When precision and productivity are required in a single machine, the GenGrind FA-IC 250D is the clear choice due to these minor yet critical details.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC 250D is recognized for being super cost-effective, delivering excellent value for money in professional grinding and polishing applications. It is built to offer high-level features and automation typically found in more expensive equipment, making it a practical choice for institutions and laboratories seeking both performance and affordability. This balance of price and functionality makes it accessible without compromising any quality or capability.

Its ability to process multiple samples at once, combined with programmable functions and dual-wheel operation, significantly reduces time and labor costs over time. These productivity benefits, along with the machine’s durable build and low maintenance needs, contribute to its long-term economic advantage. As such, it presents a strong return on investment for users needing reliable metallographic preparation.

Click here to learn more about the product or here to receive a personalized quote.

What are the advantages of the dual working plates with 254mm dimensions in the GenGrind FA-IC 250D?

The GenGrind FA-IC 250D features dual working plates, each with a standard diameter of 254mm, which provide 50% more working surface than conventional single-wheel grinding and polishing machines. This expanded area is particularly beneficial for high-volume sample processing, allowing more samples to be handled at once without compromising accuracy or quality.

This increased working space supports improved workflow efficiency, especially in laboratories or institutions where time and precision are essential. It allows users to perform different grinding or polishing steps in parallel, reducing the need to frequently switch discs or reconfigure the setup. The dual-plate design also leads to smoother operations by minimizing bottlenecks in sample preparation, which makes it suitable for both small-scale and industrial applications.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC 250D polishes up to 6 samples, each 30mm, in a single operation. This multi-sample capacity significantly increases productivity, especially in busy laboratory environments where efficiency is critical. By processing multiple specimens at once, users save time and effort compared to manual or single-sample machines.

This feature is particularly useful for routine sample preparation in research, quality control, or academic settings. It reduces the number of operational cycles needed to prepare a batch of samples, thereby simplifying the workflow. Additionally, uniform polishing across multiple samples provides consistency in results, which is crucial when comparing materials or analyzing surface characteristics. The ability to work with several samples at the same time makes this machine a valuable asset for high-throughput operations.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC 250D features a high-end ABS shell that not only contributes to its modern and refined appearance but also enhances its durability and practicality. ABS plastic is known for being lightweight yet impact-resistant, which makes it a reliable choice for equipment housing in demanding laboratory environments. Its smooth surface is also easy to clean, supporting hygienic operation and long-term maintenance.

Beyond functionality, the sophisticated design of the ABS shell helps the machine fit well into professional and educational settings, projecting a clean and advanced aesthetic. The material also resists corrosion and wear, extending equipment's lifespan. Together, these factors make the ABS shell a thoughtful design element that balances visual appeal with practical performance.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC 250D has a user-friendly touchscreen display that provides a clear and intuitive interface, simplifying the entire operation process. This control panel allows users to easily adjust settings such as speed, pressure, and timing with just a few taps, even by users with limited technical knowledge.

The touch screen offers real-time visual feedback, helping operators monitor and fine-tune grinding and polishing parameters with precision. Its straightforward layout minimizes the learning curve, making sure that users can quickly become comfortable with the machine’s features. This enhances workflow efficiency and reduces errors, especially in fast-paced laboratory environments where reliable performance and ease of use are critical.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC 250D allows users to adjust testing time, rotating speed, and pressure directly through its touchscreen interface. This means users can quickly set specific parameters for each stage of the preparation process based on the material or desired finish, helping to improve accuracy and efficiency during grinding and polishing.

These adjustable features are especially useful when preparing different types of samples, as each material may require unique settings. By giving users control over these variables, the machine supports consistent results and reduces the risk of overprocessing or damaging samples. In laboratories or facilities that handle a variety of metallographic materials, this flexibility is ideal.

Click here to learn more about the product or here to receive a personalized quote.

The grinding head of the GenGrind FA-IC 250D includes an electromagnetic clutch, which improves operation ease and speed. This component allows quick engagement and disengagement of the grinding heads without manual adjustments. It helps operators switch between steps efficiently, which is especially useful in high-throughput environments.

When needed, the electromagnetic clutch automatically locks the grinding head in place, ensuring stability during use. This feature supports precise processing and enhances safety by preventing unwanted movement. Its automatic locking mechanism removes the need for manual locking tools, saving time and reducing handling errors. This makes the machine more practical and efficient for everyday sample preparation tasks.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC 250D provides flexible speed control through stepless speed regulation ranging from 100 to 1400 RPM. This allows users to set the exact speed needed for each stage of sample preparation, whether they are working with delicate materials or require faster processing. It supports precision by letting operators fine-tune speed based on sample type and process goals.

In addition to manual speed adjustment, the machine also includes four preset constant speed options. Users can define and store three frequently used speeds for pre-grinding, grinding, and polishing. This feature simplifies workflow and provides consistency across repeated tasks. It is especially helpful for users that process similar types of samples and want reliable, repeatable results.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenGrind FA-IC 250D can store up to 100 different grinding and polishing programs, allowing users to quickly recall and apply specific settings for different tasks. This is very useful in labs where multiple sample types are prepared regularly and consistency across processes is important. It removes the need to manually re-enter parameters each time a process is repeated.

With this feature, users can save settings like speed, time, pressure, and rotation direction for different sample types. It supports a more organized workflow, reduces setup time, and guarantees uniform results across batches. This capability is ideal for research and production environments that demand accuracy and repeatability in metallographic sample preparation.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC 250D features a magnetic disc system that makes changing sandpaper and polishing cloth fast and simple. This construction removes the need for adhesives or mechanical fastening, allowing users to remove and replace discs in just a few seconds. It reduces downtime between steps, especially when switching between grinding and polishing tasks.

This quick-change system improves workflow efficiency and minimizes handling errors. It guarantees that the polishing surfaces are properly aligned and secure during use. Magnetic design is especially helpful in laboratories where multiple materials are processed daily, supporting smoother and more organized operation. It adds to the machine’s overall convenience and user-friendliness.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC 250D includes a sample chuck with a free-rotating mechanism, allowing for easier positioning and removal of samples. This feature helps users align samples quickly and accurately without resistance, reducing the risk of damaging delicate materials during setup. It improves the handling experience, especially when dealing with multiple or irregularly shaped specimens.

Complementing this is the built-in internal lighting system, which enhances visibility inside the working area. Clear lighting allows users to monitor sample placement and condition throughout the process. This is particularly valuable for detailed preparation work, where precision matters. Together, the rotating chuck and lighting make daily use more efficient and reduce operator error.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC 250D is equipped with a built-in nozzle, a sewage collection tank, and an automatic cleaning system, all designed to reduce routine maintenance effort. The built-in nozzle helps rinse the working area, removing debris and residue from grinding and polishing quickly and effectively. This makes certain that the machine stays clean during extended use without frequent manual intervention.

The sewage collection tank safely collects used water and particles, keeping the workspace tidy and preventing clogs in drainage systems. Additionally, the automatic cleaning function minimizes manual washing between tasks. These features make daily upkeep faster and more efficient, which is especially useful in busy labs that require consistent cleanliness and performance.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC 250D is powered by DC brushless and stepper motors, which offer stable and precise rotation throughout grinding and polishing operations. These motors are known for their consistent performance, which is a necessity for producing uniform sample surfaces. They help maintain a controlled speed under varying loads, ensuring accurate and repeatable results during each use.

In addition to stability, these motors operate quietly, making the working environment more comfortable, especially in shared laboratory spaces. They also have fewer moving parts compared to traditional motors, which reduces wear and tear over time. This design leads to longer machine life and lowers maintenance or part replacement frequency, supporting reliable operation in demanding applications.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC 250D base is constructed from single-piece aluminum alloy, which provides strong structural support while keeping the machine lightweight. This type of construction minimizes vibration during operation, allowing for more stable grinding and polishing. The reduced movement helps maintain consistent results, which is important for accurate sample preparation.

In addition, the aluminum alloy offers natural corrosion resistance, making it well-suited to wet environments often encountered during metallographic processes. Its shock-absorbing properties also contribute to a quieter and smoother working experience. By combining strength, light weight, and durability, the single-piece base design adds to the machine’s overall reliability and ease of use in daily lab work.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC 250D is equipped with a standard working plate that has a diameter of 254 mm and features a magnetic disc system. This size provides a generous surface area for grinding and polishing multiple samples at once, helping to improve efficiency in labs where high-volume or repetitive sample preparation is required. The magnetic disc construction also allows for quick and easy attachment and removal of abrasive materials.

The working plate is driven by a powerful 2.2 kW motor, which guarantees consistent rotation and reliable performance across different materials and process conditions. This level of power supports stable speed even under load, allowing precise and uniform sample preparation. Together, the size and motor strength of the working plate contribute to versatility and efficiency.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC 250D working plate supports a range of speeds from 100 to 1400 revolutions per minute (r/min) with stepless speed adjustment. This means users can precisely control the rotation speed based on the specific requirements of each sample, whether performing delicate polishing or more aggressive grinding. The ability to set exact speeds helps to achieve consistent and repeatable results across different materials.

In addition to adjustable speed, the working plate can rotate in both clockwise and anticlockwise directions. This bidirectional function adds flexibility to the process, allowing users to better manage material flow and surface contact during sample preparation. It is particularly useful for adjusting techniques based on material behavior, making the machine adaptable to various types of laboratory needs.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC 250D features four constant speed levels labeled V1 to V4, which are preset at 300, 500, 800, and 1000 revolutions per minute (r/min). These options provide users with quick access to commonly used speeds for various stages of grinding and polishing, thus improving daily operation more efficiently and consistently across different samples.

While these presets offer convenience, each can also be adjusted within the full range of 100 to 1400 r/min. This allows users to customize the speed settings to suit specific materials or preparation steps. The ability to fine-tune even the preset speeds adds flexibility and control so that the machine can handle a wide variety of metallographic tasks with precision.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC 250D grinding head operates in a speed range of 0 to 200 revolutions per minute (r/min). This adjustable speed allows users to control how samples are pressed against the working plate during grinding and polishing, which is necessary for handling different materials and achieving specific surface finishes.

Having control over the grinding head's speed allows the pressure and motion to be matched to the sample's hardness and sensitivity. Lower speeds can be used for delicate specimens, while higher speeds may be better suited to more robust materials. This flexibility contributes to sample preparation accuracy and consistency in laboratory environments.

Click here to learn more about the product or here to receive a personalized quote.

The grinding head of the GenGrind FA-IC 250D operates with a power rating of 0.2 kW and rotates clockwise. This power level is well-suited to controlling sample movement during grinding and polishing, helping to guarantee even contact between the sample and the working plate without excessive force or surface damage.

The clockwise rotation supports consistent processing, particularly when used alongside adjustable head speed and pressure settings. This combination allows fine-tuned operation across different materials and preparation techniques. The balance of power and directional control contributes to both precision and safety, which makes the grinding head a key component in achieving high-quality metallographic results.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenGrind FA-IC 250D is equipped with an automatic electronic lock for the grinding head. This feature allows the machine to hold the head securely during operation, eliminating manual locking. It enhances user convenience and guarantees grinding head stability throughout the grinding and polishing process.

The automatic lock prevents movement that could affect sample quality or operator safety. It also speeds up setup and transitions between tasks, as the system engages and disengages without tools or manual adjustment. In a laboratory environment, this simplifies the process of preparing samples and reduces the risk of error.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC 250D comes with a standard sample holder designed to handle 6 samples, each 30mm. This setup allows multiple specimens to be processed at the same time, significantly improving workflow efficiency in laboratories where high throughput is important.

A uniform sample size facilitates consistent preparation across all specimens, which is essential for accurate metallographic analyses. Holding 6 samples at once reduces the number of operational cycles needed, saving time and increasing productivity. This makes the machine especially suitable for quality control, research, and academic settings where multiple samples often need to be prepared under the same conditions.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC 250D features an automatic mode that allows users to program key functions such as speed, running time, and grinding wheel rotation direction. This programmable control standardizes the sample preparation process, guaranteeing consistency and accuracy for repeated tasks. The system also includes a timing function, allowing users to set exact durations for each phase of grinding or polishing.

This automation reduces the need for manual adjustments during operation, freeing up time for other tasks and minimizing user error. By storing specific process settings, users can achieve repeatable results in different batches of samples.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC 250D offers adjustable sample pressure settings to suit different preparation needs. For center loading, the pressure range is from 0 to 150 newtons (N), with a commonly used range between 40 and 120 N. This allows for an even distribution of force over multiple samples, which is ideal for batch processing and maintaining uniformity during grinding and polishing.

For single-point loading, the pressure can be set between 0 and 90 N. This setting is useful for individual samples or when specific pressure control is needed based on sample size or material type. Having these adjustable pressure options gives users the flexibility to handle an array of metallographic materials with accuracy and care.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC 250D uses single-point pneumatic pressurization and central pressure loading. This dual approach gives users the flexibility to apply force either to individual samples or evenly across a group of samples, depending on their specific preparation needs. Pneumatic pressurization is necessary for smooth and controlled force application, which is especially important for delicate or complex materials.

The central pressure method is ideal for processing multiple samples at once, providing uniform contact with the grinding surface. Meanwhile, the single-point setting allows focused control of individual specimens.

Click here to learn more about the product or here to receive a personalized quote.

Pressure on the GenGrind FA-IC 250D is adjusted using digital voltage regulation, allowing users to make precise and consistent changes to the applied force during grinding and polishing. This method provides clear, accurate control over pressure settings, which is necessary for handling different types of material and achieving specific surface finishes.

Digital adjustment also improves repeatability by letting users return to the same pressure values for future tasks. It removes the guesswork associated with manual settings and guarantees uniform results for all batches. For successful metallographic analysis, accuracy, reliability, and consistency are especially important.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC 250D includes a built-in timing function that allows users to set processing durations from 0 to 99 minutes. This feature automates the grinding and polishing process by letting the machine run for a defined time without constant monitoring. It guarantees that each preparation stage is completed accurately and according to the set duration.

Using the timing function also helps prevent overprocessing, which can damage samples or affect results quality. By having control over how long each step runs, users can create consistent procedures for different materials and applications. This adds to machine reliability and supports efficient workflow in research and industrial laboratories.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC 250D operates on a power supply of AC220V with a frequency of 50 or 60Hz and a total power consumption of 2.8kW. This specification ensures the machine has sufficient power to drive both the grinding and polishing plates, as well as the motorized components like the grinding head and control systems.

This standard power requirement makes the machine compatible with most laboratory electrical setups worldwide. The 2.8kW rating also reflects the machine's strength, supporting its performance during continuous or heavy-duty operation. A reliable power supply is necessary for stable speed, precise pressure control, and consistent results during metallographic sample preparation.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC 250D has physical dimensions of 30.31 inches in length, 28.74 inches in width, and 27.56 inches in height, which corresponds to 770 x 730 x 700 millimeters. These compact yet sturdy dimensions make the machine suitable for many laboratory setups, allowing it to fit comfortably on workbenches or within dedicated prep areas without occupying excessive space.

Despite its compact size, the unit offers a spacious working area due to its dual-plate design. The balanced proportions support user accessibility and ease of maintenance while keeping the equipment stable during operation. Moreover, this size contributes to the overall practicality of the device, especially in environments with limited workspace or multiple instruments.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC 250D weighs approximately 220 pounds or 100 kilograms. This weight provides the machine with a stable and secure base during grinding and polishing operations, helping to minimize vibration and improve precision in sample preparation. The solid build supports consistent performance, especially when handling multiple or heavier samples.

At the same time, the 100 kg weight makes the machine manageable for placement and relocation in a lab environment. It strikes the right balance between sturdiness and practical mobility. Because of this, it is well suited for laboratories where the layout of equipment and the space may need to be adjusted over time.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC 250D standard configuration includes all key components required for immediate operation and efficient sample preparation. It comes with the GenGrind FA-IC 250S Single Wheel Fully Automatic Grinder and Polisher, which features both individual and central pneumatic force control systems to handle various sample types with precision.

Also included are one 254mm grinding plate, four PSA-backed polishing cloths (250mm), and a set of grinding papers: four each of 400#, 800#, and 1200# grits. Additional accessories such as a waterproofing ring (pre-installed), paper disc, magnetic disc, and both water inlet and outlet hoses (0.75” and 32mm respectively) are provided. The power line and operational manual complete the package, providing assurance that the machine is ready for setup and use.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind FA-IC 250D is ideal for metallographic sample preparation professionals and organizations. This includes research laboratories, quality control departments in manufacturing, academic institutions, and material testing facilities. Its automated features and precision controls make it valuable for users who require consistent, high-quality surface preparation for microscopic analysis or material evaluation.

Researchers and technicians handling a wide range of metals and alloys benefit from its programmability, dual-force control, and multi-sample capability. Educators and students in materials science or engineering also find them useful for training and demonstrations. Its ability to process multiple samples efficiently while maintaining accurate settings makes it suitable for both routine testing and advanced study in technical environments.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

GenGrind N Series 8” 200S / 10" 250S / 12" 300 S - Advanced Metallographic Grinder & Polisher - Variable Speed 50-1000rpm –Touch Screen Controlled

Introducing the GenGrind N Series metallographic grinders and polishers, offered in sizes 8", 10", or 12" diameter.

GenGrind SA-I 250S 10" Single Wheel Semi Automatic Grinder & Polisher - Variable Speed 100-1000rpm – Individual Force Control - Touch Screen Controlled with Automatic Specimen Mover Power Head – (various wheel sizes available)

Discover the single wheel semi automatic GenGrind 10" SA-I 250S, your ultimate answer to grinding and polishing needs.

GenGrind SA-C 250S 10" Single Wheel Semi Automatic Grinder & Polisher - Variable Speed 100-1000rpm – Central Force Control - Touch Screen Controlled with Automatic Specimen Mover Power Head – (various wheel sizes available)

Introducing the GenGrind SA-C 250S – your ultimate single wheel semi automatic grinding and polishing solution.

GenGrind FA-IC 250S 10" Single Wheel Fully Automatic Grinder & Polisher - Variable Speed 100-1400rpm – Both Individual and Central Force Control - Touch Screen Controlled with Automatic Specimen Mover Power Head – (various wheel sizes available)

GenGrind FA-IC 250S Single Wheel Polisher and Grinder, an advanced and fully automatic metallographic grinding and polishing machine

GenGrind Belt BF - Floor Standing Heavy Duty Dual Stage Belt Grinder for Metallographic Sample Preparation

The GenGrind Belt BF Series is a heavy duty dual stage, wet or dry belt grinder offering a robust, floor standing solution for high volume manual belt grinding applications. GenGrind Belt BF - Heavy Duty Dual Stage Belt Grinder for metallographic sample preparation is designed for high material removal of various sample shapes and configurations.

GenGrind Belt BT - Dual Stage Tabletop Belt Grinder for Metallographic Sample Preparation

The GenGrindBelt BT series is a dual stage, wet or dry table top belt grinder offering the most economical solution for manual grinding applications. The GenGrind BT - Dual Stage Belt Grinder for Metallographic Sample Preparation is designed for high material removal of various sample shapes and configurations. The BT - Belt Grinder system is a table top belt grinder suitable for laboratories designed for high material removal.

GenGrind FA-IC Dual Wheel Fully Automatic

Introducing the GenGrind FA-IC, a state-of-the-art single-chip microcomputer controlled grinding and polishing machine.

Metallography Consumables

Learn about the full scope of NextGen's cutting, polishing & grinding, mounting and etching metallography consumables. Our consumables are compatible with virtually all global brands, offering a rare combination of exceptional quality, longevity and affordability.