Metal Testing Equipment

Description

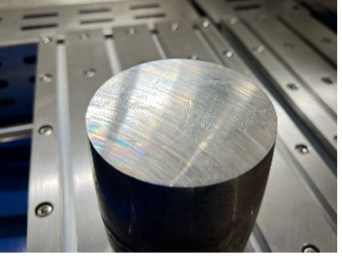

The GenCut GL 170XY has a large 170mm diameter maximum cutting capacity equipped with a fully automated XY table. Equipped with a double hood fully enclosed structure for the safest operation along with quick clamping mechanisms to achieve the most efficient cutting processes.

A powerful cooling system with two coolant lines reduce the ability for the specimen to get too hot during the cutting process. This ensures the specimen remains intact without any deformity or burn residue. It also allows the GenCut GL 170XY to achieve the best cutting quality while increasing the utilisation rate of the cutting wheel and maximizing the life of the blades. Read more in our MEGA BLOG!

Technical Specifications

|

Model |

GenCut GL 170XY |

|

Cutting Wheel |

Φ450×3.5mm×Φ32mm |

|

Maximum Cutting Section |

Φ170mm |

|

Cutting Table Size |

600 x 800 mm |

|

Z-Axis (Cutting Blade Spindle Drop Distance) |

290 mm |

|

Y-Axis Movement Stroke |

750 mm |

|

X-Axis Travel |

150 mm |

|

Cutting Feed Speed |

1-200mm/min |

|

Water Tank Capacity |

150L |

|

Power |

480V 60Hz 3Phase |

|

Control System |

7” Colour Touch Screen Panel, PLC Controller |

|

Cutting Modes |

Flat Push Cutting, Intermittent Cutting

|

|

Cooling System |

Automatic Water Cooling – 2 Lines

|

|

Machine Type |

Vertical Cutting

|

The GenCut GL170XY is a PLC-controlled automatic metallographic sample cutting machine. It offers precise control in the X, Y, and Z directions, allowing for automated and accurate cutting. GL170XY is equipped with intelligent cutting capabilities, enabling the adjustment of the feed amount based on the hardness of the material. The cutting speed is controlled through frequency conversion, providing exceptional reliability and precise control over the entire cutting process.

GenCut GL 170XY Standard Configuration

-

GenCut GL 120XY Cutting Saw

-

Coolant Chamber

-

Wrench 62mm

-

Wrench 17-19mm

-

Wrench 46mm

-

Water Inlet Tube

-

Drain Pipe

-

Diamond Cutting Wheel

-

Φ500 x 4 x Φ32mm

-

Water Tank and Pump and Operation Manual

GenCut GL 170XY Features

-

The GenCut GL170XY allows for seamless switching between electronic hand wheel control and automatic control, providing flexibility in operation.

-

The touch screen interface of the GenCut GL170XY conveniently displays various cutting data, enhancing user experience.

-

With precise positioning capabilities, the GenCut GL170XY ensures accurate and reliable cutting.

-

The GenCut GL170XY offers three cutting modes: chopping, intermittent cutting, and reciprocating cutting. It intelligently adjusts the cutting speed based on the material's hardness, enabling fast and efficient cutting.

-

To facilitate easy cleaning of the cutting room and ensure the safety of the spindle motor, the GenCut GL170XY incorporates a mechanical and electrical separation design.

-

The cutting room security cover of the GenCut GL170XY features a large observation window, allowing users to observe the entire sample cutting process with ease.

-

Integrated LED lights in the cutting room provide effective illumination, ensuring excellent visibility throughout the cutting area.

-

The GenCut GL170XY features an indoor ventilation fan that efficiently eliminates steam and smoke generated during cutting, improving indoor brightness and clarity.

-

Designed with user comfort in mind, the GenCut GL170XY adheres to ergonomic principles. It operates with low noise, boasts user-friendly controls, showcases a visually appealing appearance, and prioritizes safety. As a result, it is an ideal equipment choice for laboratory sample preparation.

Machine Structure

-

The GenCut GL170XY features a vertical body form, consisting of the upper safety cover, middle frame, right sliding door, side door, lower frame with electrical box and tool box, fixture, rinsing tap, and an independent cooling water tank.

-

With its concise design and robust structure, the GenCut GL170XY utilizes a frequency conversion motor and direct cutting disc, enabling stepless speed regulation. The direct driving mechanism ensures high efficiency, low noise, minimal maintenance, and extended service life.

-

The GenCut GL170XY incorporates a specialized cutting design for large workpieces, facilitating easier maintenance and processing of such workpieces. The sliding door and hinged door provide ample space and unrestricted access, making it convenient to position large workpieces. The cutting room allows entry from three directions (up, front, and left).

-

To ensure safety and provide observation during cutting, the work area of the GenCut GL170XY is completely enclosed and features a transparent protective cover.

-

Equipped with a dedicated cooling water tank, the GenCut GL170XY stores cooling liquid for optimal performance. It is recommended to avoid using tap water as a cooling liquid. After completing the cutting work, the left rinsing tap can be used to clean the cutting room, and then the safety door can be closed.

The GenCut GL170XY machine is designed to cater to a wide range of applications, including but not limited to ferrous metals, non-ferrous metals, heat-treated parts, forgings, semiconductors, crystals, ceramics, and rocks. Its versatility allows for efficient cutting and processing across diverse materials and industries.

FAQs

The design of the GenCut GL170XY abrasive cut-off saw is tailored to offer exceptional versatility, enabling it to efficiently cut and process a wide array of materials. This versatility is crucial for applications in various industries, including metallurgy, semiconductor manufacturing, geology, and ceramics.

A key feature contributing to this versatility is the saw's robust construction. It is built to withstand the rigors of cutting hard materials like ferrous metals, heat-treated parts, and forgings, ensuring durability and precision in these demanding applications.

The saw's cutting mechanism is adept at handling both ferrous and non-ferrous metals, making it a valuable tool in diverse metallurgical contexts. Its precision and stability are particularly beneficial for cutting delicate materials such as semiconductors, crystals, and ceramics, where a gentle yet accurate cut is essential to preserve the integrity of the sample.

Furthermore, the GenCut GL170XY is equipped with a cooling system that regulates temperature during cutting, a critical feature when working with materials like metals that generate substantial heat. This cooling system helps in preventing overheating and potential damage to the samples.

In addition, the saw's ability to accommodate large workpieces and provide easy access for sample placement and adjustment enhances its adaptability. This flexibility is vital in processing larger or irregularly shaped samples, such as rocks in geological studies.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL170XY's dedicated cooling water tank is an integral component designed to enhance the saw's cutting performance. The recommendation to avoid using tap water as a cooling liquid in this tank is based on several considerations related to the quality and effectiveness of the cooling process.

Tap water often contains minerals and impurities that can lead to scale buildup and corrosion within the cooling system. Over time, these deposits can clog the cooling channels, reduce the efficiency of heat transfer, and ultimately diminish the performance and lifespan of the saw. Instead, using a specially formulated cooling liquid can prevent these issues, ensuring optimal cooling and prolonging the equipment's durability.

After the completion of cutting work, the GenCut GL170XY's left rinsing tap plays a vital role in the maintenance of the cutting room. This rinsing tap enables easy and efficient cleaning of the cutting area. Providing a convenient water source allows for the quick removal of debris, dust, and cutting residues that accumulate during the cutting process. Regular cleaning not only maintains a clear and unobstructed view for the operator but also helps preserve the condition of the cutting room and the saw's components.

Click here to learn more about the product or here to receive a personalized quote.

The enclosed work area and transparent protective cover of the GenCut GL170XY are critical design elements that play a significant role in enhancing both safety and observation during the cutting process. These features are meticulously integrated to address the dual needs of protection and visibility, which are paramount in metallographic cutting operations.

Firstly, the complete enclosure of the work area is a fundamental safety measure. It acts as a physical barrier, preventing accidental contact with moving parts, particularly the cutting disc. This enclosure also serves to contain any flying debris, sparks, or splashes generated during cutting, thereby protecting the operator from potential injuries. Additionally, it helps in mitigating the spread of dust and particulate matter, contributing to a cleaner and healthier work environment.

The transparent protective cover is another vital feature. While ensuring safety by providing a barrier, its transparency allows for clear observation of the cutting process. This visibility is crucial for precision in cutting operations, enabling the operator to monitor the progress of the cut and make real-time adjustments as needed. A clear view of the work area also helps in identifying any issues promptly, thereby reducing the risk of sample damage or equipment malfunction.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL170XY is strategically designed to handle large workpieces, a feature that significantly enhances its utility in settings where sizable samples are frequently processed. This specialized design addresses several key aspects of handling and cutting large workpieces, making maintenance and processing both efficient and convenient.

One of the standout features is the incorporation of both a sliding door and a hinged door. This combination provides ample space and unrestricted access to the cutting area. The sliding door allows for easy lateral movement of large workpieces, reducing the physical effort required to position them. Meanwhile, the hinged door offers additional flexibility, especially useful for loading and unloading bulky or heavy samples.

Furthermore, the cutting room's design, which allows entry from three different directions (up, front, and left), is a critical aspect of its functionality. This multi-directional access facilitates the positioning of large workpieces from various angles, ensuring that even the most awkwardly shaped or sized samples can be accommodated. This feature is particularly beneficial for intricate cutting tasks where precise positioning is crucial.

The ability to access the cutting room from multiple directions not only simplifies the process of positioning large workpieces but also aids in their maintenance. Easy access is vital for regular cleaning, adjustments, and blade changes, particularly when dealing with larger samples that might otherwise obstruct these essential tasks.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL170XY incorporates a frequency conversion motor and a direct cutting disc, offering several advantages that enhance its performance in metallographic sample preparation. These features collectively contribute to its reputation as a high-efficiency, low-maintenance cutting tool.

Firstly, the frequency conversion motor enables step-less speed regulation. This capability allows users to precisely adjust the cutting speed to suit different materials and requirements. Such versatility is crucial for achieving optimal cutting results across a wide range of sample types, from softer metals to harder alloys.

Secondly, the direct driving mechanism of the cutting disc ensures high efficiency. Unlike belt-driven systems, the direct drive transfers power more effectively, reducing energy loss. This results in faster and more accurate cuts, improving overall productivity.

Additionally, the direct drive system contributes to lower noise levels. This is particularly beneficial in laboratory settings where a quiet work environment is essential for concentration and communication. Reduced noise also enhances user comfort, especially during prolonged use.

Moreover, the direct driving mechanism requires minimal maintenance. Without the need for regular belt replacements or adjustments, the saw demands less upkeep, reducing downtime and maintenance costs. This aspect is especially valuable in busy laboratory environments where time and resources are often limited.

Click here to learn more about the product or here to receive a personalized quote.

How does the vertical body form of the GenCut GL170XY enhance its functionality and user experience?

The GenCut GL170XY's vertical design is ingeniously crafted to maximize both efficiency and user convenience in abrasive cutting applications. This design integrates several key components, each contributing significantly to the saw's overall performance.

At the top, the upper safety cover is pivotal for operator safety, shielding users from direct exposure to cutting operations. This cover effectively contains any debris or splashes, maintaining a clean and safe working environment.

The middle frame, forming the core of the saw's structure, ensures stability and support. Its robust design minimizes vibrations, a crucial factor for achieving precise and accurate cuts. This stability is especially important when working with delicate or intricate samples.

On the sides, the right sliding door and the additional side door provide easy and practical access. This accessibility is essential for straightforward sample placement, adjustments, and routine maintenance, allowing for a smoother and more efficient workflow.

The lower frame, incorporating an electrical box and a tool box, centralizes the saw’s controls and maintenance tools. This strategic placement not only saves space but also enhances the operator's ease of access to essential controls and instruments.

In addition, features like the fixture for sample stability, a rinsing tap for immediate cleaning, and an independent cooling water tank for temperature regulation, collectively enhance the saw's functionality. The fixture ensures secure sample positioning, the rinsing tap aids in maintaining a clear view during operations, and the cooling tank helps in managing the blade and sample temperature, extending their longevity.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL 170XY abrasive cut-off saw is designed with a strong focus on ergonomics, enhancing user comfort and operational efficiency in laboratory sample preparation. This ergonomic design encompasses several key aspects, contributing to its overall effectiveness and appeal.

Firstly, the saw operates with low noise levels. This feature is crucial in a laboratory environment where concentration and precision are paramount. Low noise operation not only creates a more comfortable and less distracting work environment but also contributes to reducing operator fatigue, especially during extended periods of use.

In addition, the user-friendly controls of the GenCut GL 170XY facilitate ease of operation. Intuitive controls allow for quick and efficient adjustments, which is particularly beneficial for operators handling multiple samples or working under time constraints. This ease of operation is essential for maintaining consistency and accuracy in sample preparation.

The saw also features a visually appealing appearance. While aesthetics might seem secondary in a laboratory setting, a well-designed machine can enhance the overall work environment, contributing to a more organized and professional atmosphere.

Click here to learn more about the product or here to receive a personalized quote.

The inclusion of an indoor ventilation fan in the GenCut GL 170XY abrasive cut-off saw is a significant feature that enhances the overall cutting environment. This fan plays a pivotal role in efficiently eliminating steam and smoke generated during the cutting process, which has multiple benefits for both the operator and the machine.

Firstly, the removal of steam and smoke ensures a clearer and brighter working area. This is crucial for visibility, allowing operators to observe and precisely control the cutting process. Improved visibility directly correlates with enhanced accuracy and safety, as it helps in monitoring the progress of the cut and detecting any potential issues early.

Additionally, the ventilation fan contributes to a healthier working environment. By extracting harmful fumes and particles generated during cutting, it reduces the operator's exposure to potentially hazardous materials. This aspect is particularly important in maintaining indoor air quality and ensuring compliance with health and safety regulations.

Also, the fan aids in protecting the machine itself. By removing steam and smoke, it prevents the buildup of residues on the saw's components, which can affect its functionality and lifespan. Regular removal of these byproducts helps in maintaining the machine's efficiency and reduces the frequency of maintenance and cleaning.

Click here to learn more about the product or here to receive a personalized quote.

The integrated LED lights in the cutting room of the GenCut GL170XY are a vital feature that enhances the machine's functionality by providing effective illumination. This lighting plays a crucial role in ensuring excellent visibility throughout the cutting area, which is essential for precise and safe operation.

Firstly, the bright and focused illumination from the LED lights allows operators to clearly see the sample, cutting wheel, and other critical components during the cutting process. This visibility is key to achieving accurate cuts, as it enables the operator to monitor the alignment and progress of the cut in real time. Better visibility leads to improved precision, which is especially important in metallographic sample preparation where every detail matters.

Moreover, the use of LED lighting ensures consistent illumination in the cutting area. LEDs are known for their long lifespan and consistent light output, which means they provide reliable lighting over time, reducing the need for frequent replacements or adjustments. This consistent lighting condition is important for maintaining the quality and consistency of cuts across different operations.

Click here to learn more about the product or here to receive a personalized quote.

The cutting room security cover, equipped with a large observation window on the GenCut GL170XY, plays a significant role in enhancing both safety and usability. This design feature adds a crucial layer of security while also allowing users to conveniently monitor the entire sample cutting process.

The primary function of the security cover is to ensure safety during operation. It acts as a barrier, protecting the user from potential hazards such as flying debris, sparks, and excessive noise. By containing these within the cutting room, the saw ensures a safer working environment. This is especially important in settings where operators are handling multiple tasks and need assurance of safe operation.

The large observation window integrated into the security cover is particularly beneficial. It allows users to have a clear view of the sample and the cutting wheel during the cutting process. This visibility is crucial for monitoring the progress of the cut and making real-time adjustments if necessary. It ensures that users can observe the cutting action closely without compromising on safety.

Click here to learn more about the product or here to receive a personalized quote.

The mechanical and electrical separation design of the GenCut GL170XY is a critical feature that significantly contributes to both the ease of maintenance and the safety of the equipment. By distinctly separating the mechanical components, such as the cutting room, from the electrical parts, including the spindle motor, the saw achieves several important benefits.

Firstly, this separation facilitates easier and more efficient cleaning of the cutting room. Since the cutting process often involves the production of metal filings, debris, and coolant splashes, the ability to clean the mechanical area without risking damage to the electrical components is crucial. This not only ensures the longevity and proper functioning of the saw but also maintains a safe and clean working environment.

Moreover, the separation enhances the safety of the spindle motor, a key component of the saw. By isolating it from the mechanical cutting area, the risk of contamination or damage from debris and fluids is greatly reduced. This protective measure ensures the motor's longevity and reliability, which is vital for consistent performance and reducing the likelihood of equipment failure.

Click here to learn more about the product or here to receive a personalized quote.

The touch screen interface of the GenCut GL170XY greatly impacts and enhances the user experience, primarily by providing convenient access to various cutting data. This modern interface elevates the ease of use of the machine, allowing operators to interact with the saw more intuitively and efficiently.

One significant advantage is the real-time display of cutting data. Users can monitor key parameters such as cutting speed, position, and progress directly from the screen, ensuring that they are always informed about the operation's status. This immediate access to data allows for quick adjustments and more precise control over the cutting process.

Moreover, the touch screen interface simplifies the operation of the machine. With its user-friendly design, operators can easily navigate through different functions, settings, and controls. This accessibility is particularly beneficial for users who may not have extensive technical knowledge, making the saw more approachable and easier to operate.

Additionally, the interface likely includes features such as saved cutting profiles, which streamline the process for repetitive or standardized tasks. By allowing users to save and quickly access preferred settings, the machine can increase productivity and reduce setup time.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL170XY's feature of allowing operators to switch between electronic hand-wheel control and automatic control significantly enhances its operational flexibility. This dual-mode capability caters to a wide range of cutting requirements and user preferences, making the saw adaptable to various sample preparation scenarios.

The electronic hand-wheel control mode offers the advantage of manual precision. It allows operators to make fine adjustments and direct control over the cutting process, which is particularly useful for delicate or intricate cuts. This mode is ideal for applications where the feel and intuition of the operator play a crucial role in achieving the desired outcome.

On the other hand, the automatic control mode is designed for efficiency and consistency in repetitive or standard cutting operations. In this mode, the saw operates based on pre-set parameters, ensuring uniformity and precision across multiple cuts. This is especially beneficial in high-throughput environments or when working with standardized samples.

The seamless transition between these two modes means that operators can choose the most appropriate method for their current task, combining the benefits of both manual dexterity and automated precision. This flexibility not only makes the GenCut GL170XY versatile but also ensures that it can meet a broad spectrum of metallographic cutting needs with ease.

Click here to learn more about the product or here to receive a personalized quote.

The standard configuration of the GenCut GL 170XY abrasive cut-off saw includes several key components, each playing an integral role in its operation:

- GenCut GL 120XY Cutting Saw: This is the primary cutting tool within the system, designed for precision and efficiency in slicing through various materials for metallographic analysis.

- Coolant Chamber: This chamber houses the cooling system, which is vital for managing the heat generated during cutting operations, thereby protecting the sample integrity and extending the life of the cutting wheel.

- Wrench Set (62mm, 17-19mm, 46mm): These tools are essential for routine maintenance and adjustments of the saw, ensuring that it remains in optimal working condition.

- Water Inlet Tube and Drain Pipe: These components are part of the cooling system, with the inlet tube supplying coolant to the cutting area and the drain pipe removing used coolant, thereby maintaining a clean and efficient cutting environment.

- Diamond Cutting Wheel (Φ500 x 4 x Φ32mm): This high-quality cutting wheel is designed for precision and durability, capable of handling a wide range of materials with minimal wear.

- Water Tank and Pump: These components supply and circulate the coolant throughout the cutting system, playing a critical role in temperature management and debris removal during the cutting process.

- Operation Manual: This provides comprehensive instructions on the usage, maintenance, and safety procedures for the GenCut GL 170XY, ensuring users can operate the equipment effectively and safely.

Click here to learn more about the product or here to receive a personalized quote.

The frequency conversion control of the cutting speed in the GenCut GL170XY is a key feature that significantly contributes to its overall performance and reliability. This advanced technology allows for precise and variable control over the speed of the cutting wheel, which is essential for adapting to different types of materials and cutting requirements. By being able to adjust the speed, operators can fine-tune the cutting process to match the specific characteristics of each sample, such as its hardness, size, and desired finish.

The use of frequency conversion for speed control also leads to greater consistency in cuts. This consistency is vital for ensuring that each sample is prepared accurately, maintaining the integrity and quality needed for detailed metallographic analysis. Moreover, precise speed control helps in extending the life of the cutting blades and wheels. By optimizing the speed for each cutting operation, the wear and tear on these components are reduced, leading to lower maintenance costs and longer intervals between replacements.

Click here to learn more about the product or here to receive a personalized quote.

The PLC-controlled automatic system of the GenCut GL170XY plays a pivotal role in enhancing its metallographic sample cutting capabilities. The integration of a Programmable Logic Controller (PLC) allows for precise and automated control over the cutting process, particularly in the X, Y, and Z directions. This level of control is crucial for ensuring accuracy in cuts, which is essential for metallographic analysis where the integrity of the sample is of utmost importance.

Furthermore, the PLC system enables automated adjustments based on the material being cut. This intelligent cutting feature adjusts the feed amount to match the hardness of the material, ensuring optimal cutting conditions for each sample. This not only improves the quality of the cuts but also reduces the potential for damage to the samples and wear on the cutting equipment.

The ability to automate these processes increases efficiency and repeatability, making the GenCut GL170XY suitable for high-volume or precision-demanding environments. This level of automation minimizes the need for constant operator intervention, allowing for more streamlined and consistent operations. Overall, the PLC-controlled automatic system of the GenCut GL170XY represents a significant advancement in metallographic sample preparation, offering enhanced precision, adaptability, and efficiency.

Click here to learn more about the product or here to receive a personalized quote.

The vertical cutting design of the GenCut GL 170XY abrasive cut-off saw offers several key advantages that make it highly effective for precision sample preparation. Firstly, this design allows for better control and stability during the cutting process. By cutting vertically, the force is applied uniformly across the sample, resulting in cleaner, more accurate cuts. This is particularly beneficial when working with delicate or irregularly shaped specimens, where precision is paramount.

Additionally, the vertical orientation minimizes the use of space, making the saw suitable for laboratories or facilities with limited workspace. It also enhances safety, as the cutting action is more contained compared to horizontal systems. This vertical approach reduces the risk of debris scattering, which is crucial for maintaining a clean and safe working environment.

Moreover, the vertical cutting mechanism allows for easier alignment and positioning of the sample. This is especially useful when dealing with multiple samples or complex cutting requirements, as it simplifies the process and ensures consistency across different cuts. The GenCut GL 170XY's vertical cutting design, therefore, combines precision, safety, and efficiency, making it an ideal choice for various metallographic sample preparation needs.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL 170XY abrasive cut-off saw incorporates an automatic water cooling system with dual coolant lines, playing a crucial role in the cutting process. This system is designed to effectively manage heat generation during cutting operations. By doing so, it prevents overheating of the specimen, a critical aspect in maintaining its structural integrity. Overheating can lead to deformation or the formation of burn residues, which can compromise the quality of the sample and the accuracy of the cut.

Moreover, the cooling system extends the lifespan and efficiency of both the cutting wheel and blades. By keeping these components cool, it reduces wear and tear, thereby enhancing their durability and performance. This results in more consistent and precise cuts over time, ensuring the reliability of the cutting process. Additionally, the cooling system contributes to the overall efficiency of the cutting operation, enabling the saw to handle a variety of materials without compromising on quality. Its integration into the GenCut GL 170XY demonstrates a commitment to precision, durability, and efficient operation in sample preparation tasks.

Click here to learn more about the product or here to receive a personalized quote.

In order to meet the cutting needs of various types of materials and a variety of cutting requirements, the GenCut GL 170XY - Abrasive Cut Off Saw offers three distinct cutting modes. Among these modes are Flat Push Cutting, Intermittent Cutting, and Reciprocating Cutting.

Flat Push Cutting is suitable for straightforward, continuous cuts, providing efficiency and precision. Intermittent Cutting, on the other hand, involves periodic cutting actions, which helps in managing heat buildup and is particularly useful for materials that are sensitive to heat or prone to deformation. This mode ensures the integrity of the specimen is maintained throughout the cutting process.

Depending on the material’s properties and the specific requirements of the task, each mode is designed to optimize the cutting performance in accordance with the material’s properties to demonstrate the versatility and adaptability of the saw to different cutting scenarios.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL 170XY – Abrasive Cut Off Saw is equipped with an advanced control system comprising a 7-inch color touchscreen panel and a Programmable Logic Controller (PLC). This dual-component system enhances the saw's usability and precision.

The touchscreen panel serves as an interactive interface, displaying vital cutting data in real time. It simplifies the operation by allowing users to easily access and modify settings, facilitating a more efficient and user-friendly experience.

On the other hand, the PLC controller is the core of the machine's automation. It reliably manages the saw's functions, orchestrating the cutting processes with high accuracy. This controller is instrumental in ensuring consistent performance, especially in complex cutting operations. Its programmability means it can be tailored to suit various cutting requirements, enhancing the saw's versatility across different applications.

Together, these elements form a control system that is both sophisticated and intuitive, making the GenCut GL 170XY – Abrasive Cut Off Saw a highly capable tool for precision cutting in metallography and other relevant fields.

Click here to learn more about the product or here to receive a personalized quote.

The power specification for the GenCut GL 170XY – Abrasive Cut Off Saw is 480V, 60Hz, 3Phase. This specification is crucial for understanding the saw's operational requirements and capabilities. The 480V indicates a high voltage requirement, signifying the saw's powerful performance capacity, suitable for demanding cutting tasks. The 60Hz frequency aligns with the standard electrical systems in many countries, ensuring compatibility and ease of integration into existing industrial setups.

Furthermore, the three-phase electrical supply is a key aspect of its design. Three-phase power is known for its efficiency and stability, especially important for heavy-duty equipment like the GenCut GL 170XY. It provides a consistent power supply, which is essential for maintaining uninterrupted and smooth operation. This type of power supply is less likely to experience fluctuations, thus safeguarding the saw against potential electrical issues that could affect its performance or longevity.

The 480V, 60Hz, 3Phase power specification of the GenCut GL 170XY not only ensures that it can handle intensive metallographic cutting tasks but also underlines the saw's compatibility with industrial power systems, contributing to its reliability and effectiveness in professional settings.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL 170XY – Abrasive Cut Off Saw is designed with a water tank that can hold up to 150 liters. This substantial capacity plays a crucial role in the saw's operation. Firstly, the large volume of coolant available significantly reduces the risk of overheating during extended cutting sessions. Overheating can be detrimental to both the specimen's integrity and the saw's blade life. Thus, the 150-liter tank is essential for maintaining optimal operating temperatures.

Additionally, this capacity is beneficial in high-demand environments. The larger the tank, the less frequently it needs to be refilled, which translates to fewer interruptions and more continuous operation. This is particularly advantageous in laboratory or industrial settings where the saw is in constant use, as it enhances overall productivity and efficiency.

Furthermore, consistent cooling provided by this tank capacity ensures the quality of cuts remains high. Accurate and precise cuts are vital in metallographic analyses, and proper cooling is key to achieving this. In conclusion, the 150-liter water tank is a vital component of the GenCut GL 170XY, contributing significantly to its efficiency, reliability, and the quality of its output in various sample preparation tasks.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL 170XY – Abrasive Cut Off Saw offers a cutting feed speed range from 1 to 200 mm/min. This broad range enables considerable flexibility and precision in the cutting process. At the lower end of the spectrum, the slow speed of 1 mm/min is ideal for delicate or highly precise cuts, where maintaining the integrity of the sample is crucial. On the other hand, the upper limit of 200 mm/min allows for faster cuts, which is beneficial when dealing with less sensitive materials or when time efficiency is a key consideration.

This variability in feed speed is essential for tailoring the cutting process to different types of materials and requirements. It ensures that each sample is cut under optimal conditions, thereby enhancing the quality of the cuts and, consequently, the accuracy of subsequent analyses. Such flexibility makes the GenCut GL 170XY a versatile tool in various metallographic sample preparation scenarios, capable of adapting to a wide range of cutting needs.

Click here to learn more about the product or here to receive a personalized quote.

The X-axis travel in the GenCut GL 170XY – Abrasive Cut Off Saw measures 150 mm. This specific measurement of the X-axis travel is crucial for the saw's functionality. It dictates the horizontal movement capability of the cutting blade, which is essential for precise positioning and alignment of the specimen during the cutting process. The 150 mm travel size, while compact, provides enough range to accommodate a variety of sample sizes and shapes, ensuring versatility in sample preparation.

Additionally, this travel size on the X-axis is instrumental in achieving precise and accurate cuts, a necessity for detailed and accurate metallographic analyses. The ability to make fine adjustments in the horizontal plane allows for greater control over the cutting process, ensuring high-quality results. Thus, the 150 mm X-axis travel is a key feature that enhances the precision, versatility, and overall performance of the GenCut GL 170XY.

Click here to learn more about the product or here to receive a personalized quote.

The 750 mm Y-axis movement stroke in the GenCut GL 170XY – Abrasive Cut Off Saw plays a significant role in its operational capabilities. This feature, defining the extent to which the cutting blade can move laterally, allows for greater flexibility in handling a variety of sample sizes and shapes. This large range of motion is particularly beneficial for cutting larger or irregularly shaped specimens, providing the versatility needed in diverse metallographic applications.

Additionally, the extensive Y-axis stroke enables precise adjustments in positioning the sample for cutting. This precision is crucial for achieving accurate cuts, a key requirement in metallographic analysis where the quality of the cut can impact the integrity of the sample's analysis.

The 750 mm stroke thus not only broadens the range of samples that the GenCut GL 170XY can accommodate but also ensures that these samples are cut with the utmost accuracy and efficiency. This feature makes the saw a valuable tool in settings where versatility and precision are paramount in sample preparation.

Click here to learn more about the product or here to receive a personalized quote.

The 290 mm Z-axis, or cutting blade spindle drop distance, in the GenCut GL 170XY is a key feature that greatly influences its performance. This measurement indicates the maximum distance the cutting blade can move downwards, impacting the saw in several ways:

- Versatility in Cutting Depth: The 290 mm drop distance allows for a wide range of cutting depths, accommodating different thicknesses of samples. This adaptability is essential for precision in metallographic sample preparation, where varying sample sizes are common.

- Enhanced Precision and Control: Such a significant drop distance offers greater control over the cutting process. Operators can adjust the blade's position with precision, ensuring accurate and clean cuts, which are vital for detailed analysis of the sample's composition and structure.

- Improved Safety: The ability to control the blade's movement to this extent also enhances safety. Operators can precisely manage the blade's interaction with the sample, reducing the risk of accidents.

- Operational Efficiency: The 290 mm Z-axis contributes to operational efficiency. It allows for quick adjustments for different sample sizes, streamlining the cutting process and saving time, especially when dealing with a variety of sample types.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL 170XY – Abrasive Cut Off Saw is equipped with a cutting table sized 600 x 800 mm, a feature that significantly enhances its functionality. This large table size is crucial for multiple reasons:

- Accommodation of Various Sample Sizes: The ample space provided by the 600 x 800 mm table allows for the handling of a wide range of sample sizes. This versatility is essential in metallographic analysis, where samples may vary greatly in size and shape.

- Efficiency in Sample Processing: The spacious table enables users to work with multiple samples concurrently or manage larger specimens more effectively. This capability increases throughput, especially in high-volume settings, saving time and improving workflow.

- Precision and Control: The generous table size affords better control and precision in positioning and cutting samples. This precision is vital for ensuring accurate cuts, which directly impacts the quality of metallographic analysis.

- User Convenience: A larger table size provides users with more room to maneuver, enhancing comfort and reducing the likelihood of errors during the sample preparation process.

The dimensions of the cutting table in the GenCut GL 170XY play a pivotal role in its efficiency, versatility, and precision, making it an invaluable tool in various metallographic applications.

Click here to learn more about the product or here to receive a personalized quote.

The maximum cutting section capacity of Φ170mm in the GenCut GL 170XY – Abrasive Cut Off Saw is a defining feature that significantly enhances its functionality and versatility. This large diameter capacity allows the saw to accommodate a wide range of specimen sizes, making it a versatile tool for various metallographic analyses. It caters to the needs of laboratories and industrial settings where samples of varying sizes and materials need precise cutting.

This 170mm capacity is particularly important for handling larger or more complex specimens that require detailed examination. The ability to cut larger sections means that the saw can be used for a broader spectrum of materials, from standard metal samples to larger industrial components. This adaptability is crucial in environments where time and precision are critical, as it allows for efficient processing of multiple samples without the need for changing tools.

Furthermore, this capacity ensures that the cuts are not only large but also precise. The design of the GenCut GL 170XY, in conjunction with its cutting capacity, guarantees that each cut is clean and accurate, which is essential for the subsequent analysis of the material's microstructure. The precision of these cuts contributes to the reliability of the analyses and the quality of the results.

Click here to learn more about the product or here to receive a personalized quote.

The cutting wheel of the GenCut GL 170XY – Abrasive Cut Off Saw is meticulously designed to ensure optimal performance. It measures Φ450×3.5mm×Φ32mm. The 450mm diameter provides a broad cutting area, enabling the saw to handle a variety of sample sizes and types effectively. This size is particularly beneficial for processing larger or irregularly shaped samples, offering versatility in cutting applications.

The thickness of the wheel, at 3.5mm, is chosen to balance cutting efficiency and durability. It allows for precise, clean cuts while maintaining the structural integrity of the wheel through extended use.

Additionally, the 32mm center hole is standardized to fit the saw perfectly. This ensures a stable and secure attachment, which is critical for accurate and consistent cutting performance.

These dimensions and characteristics of the cutting wheel are integral to the GenCut GL 170XY’s ability to deliver precise, efficient, and reliable cuts, making it a valuable tool in metallographic sample preparation.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL 170XY – Abrasive Cut Off Saw features a robust cooling system, equipped with two coolant lines, designed to prevent overheating of the specimen during the cutting process. This powerful cooling system plays a critical role in maintaining the integrity of the specimen. By keeping the temperature controlled, it prevents the specimen from getting too hot, thus avoiding deformities or burn residues.

Additionally, this cooling mechanism contributes significantly to the overall cutting quality. It ensures that cuts are clean and precise, which is essential for accurate metallographic analysis. Moreover, the efficient cooling also positively impacts the longevity of the cutting equipment. It increases the utilization rate of the cutting wheel and extends the life of the blades, making the GenCut GL 170XY more cost-effective and reliable for prolonged use. This combination of specimen quality preservation and enhanced equipment durability underscores the saw's value in providing high-quality, efficient cutting solutions.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL 170XY – Abrasive Cut Off Saw is designed with advanced safety and efficiency features. A notable aspect is its double hood, fully enclosed structure, which significantly enhances operational safety. This enclosure safeguards the user from potential hazards like debris and sparks during cutting, while also mitigating noise and dust.

Efficiency is boosted by the saw's quick clamping mechanisms. These mechanisms allow for rapid and secure mounting of samples, streamlining the setup process. The quick clamping ensures that samples are firmly held, a critical factor for achieving precise and accurate cuts.

These features, the protective double hood and efficient clamping system, collectively establish the GenCut GL 170XY as a leading tool in its class. They are crucial for maintaining a safe work environment and ensuring high-quality, efficient sample preparation in metallography labs and similar settings.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL 170XY – Abrasive Cut Off Saw stands out with its substantial cutting capacity, capable of handling samples up to 170mm in diameter. This large cutting diameter is crucial for accommodating a wide range of metallographic samples, making it versatile for various applications.

In addition to its impressive cutting capacity, the saw is equipped with a fully automated XY table. This feature significantly enhances the precision of the cutting process. The automation allows for meticulous positioning and movement of the sample, ensuring consistent and accurate cuts. This level of control is essential for preparing samples where precise dimensions and smooth cuts are necessary.

Furthermore, the integration of the automated XY table not only improves the accuracy but also the efficiency of the cutting process. It streamlines the sample preparation workflow, making it easier and quicker to prepare multiple samples with consistent quality. This efficiency is particularly beneficial in busy laboratories where time and accuracy are of the essence.

Overall, the combination of a large cutting capacity and an advanced automated table makes the GenCut GL 170XY a highly capable and reliable tool in the field of metallography. Its design caters to the needs of professionals who require both precision and versatility in sample preparation.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL 170XY is classified as Metallography Sample Preparation Equipment, specifically within the category of Abrasive Metallographic Cutting Equipment. This tool plays a crucial role in preparing metal samples for detailed analysis.

It's designed to handle a variety of materials, especially metals, facilitating precise and controlled cuts. This precision is vital in metallography, the study of metal structures and components, where clean and accurate sections of samples are essential.

The abrasive cutting method employed by the GenCut GL 170XY ensures the integrity of the samples is maintained during the preparation process. It allows for the examination of the microstructure of metals, which is key in understanding their properties and behaviors.

The GenCut GL 170XY is a vital tool in laboratories and research facilities. It supports a range of studies and applications, from basic material characterization to advanced research in material science, metallurgy, and engineering. Its design and features, including the automated XY table and the advanced cooling system, make it a reliable and efficient choice for sample preparation.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

GenCut GL 120XY – Multi Function Abrasive Cut Off Saw with Touch Screen User Friendly Interface and Large Cutting Capacity Φ120mm

The GenCut GL 120XY has a large 120mm diameter maximum cutting capacity equipped with a fully automated XY table.

Metallography Consumables

Learn about the full scope of NextGen's cutting, polishing & grinding, mounting and etching metallography consumables. Our consumables are compatible with virtually all global brands, offering a rare combination of exceptional quality, longevity and affordability.