As a discipline that is fundamentally based on the microstructural analysis of metals and alloys, metallography provides access to the complex world of atomic interactions within materials. This field offers profound insight into the inherent characteristics and behaviors of a wide range of metals by studying their atomic structure. Also, metallography is known for its high degree of rigor due to its careful preparation of pristine samples, which directly influences the accuracy and reliability of subsequent microscopic evaluations. Within this detailed preparatory phase, the cut-off saw becomes more than just a mechanical device for sectioning, it becomes an instrument of precision as well. As a result, every dissected sample accurately reflects its original composition, free of any deformities or inadvertent modifications.

By using their abrasive wheels, cut-off saws are capable of handling a wide range of materials. These machines are ideally suited to the rigorous environment of metallography labs, which ensures that samples are prepared accurately and efficiently. It is in this context that the GenCut GL Series, a product of NextGen Material Testing Inc., stands out. In contrast to previous discussions focusing on the Automatic Precision Metallographic Cutters within the GenCut GL Series, this article highlights the recently introduced Metallographic Abrasive Cut Off Saws within the same series.

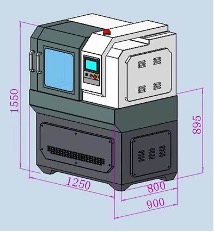

Models like the GenCut GL 120XY and GenCut GL 170XY are examples of the series’ innovation. Their user-friendly touchscreen interfaces simplify operations, and their distinct cutting capacities – 120mm for the GL 120XY and 170mm for the GL 170XY – demonstrate their adaptability. With the addition of automated XY tables, sample positioning has been improved to an extremely high level. As well as this, the integrated cooling system plays an important role in maintaining the sample’s condition during the cutting phase, thus ensuring that there is no deformation, and at the same time, optimizing the wheel’s lifespan.

For a full understanding of how these machines can impact and benefit business, it is necessary to gain a deeper insight into the field of cut-off saws. Let’s take a closer look at the broader applications of these saws and discover how the GenCut GL Series – Metallographic Abrasive Cut Off Saws can satisfy your specific requirements with their features, capabilities, and technical specifications.

What Are Cut-Off Saws?

Cut-off saws, also known as chop saws or abrasive saws, are used to cut through hard materials such as metals, ceramics, and concrete. Essentially, their operation consists of a thin grinding disc, similar to an abrasive disc, which grinds through the material to ensure a clean, precise cut without affecting its original properties. An analysis of the material’s structure and composition based on this feature is extremely important because it lays the foundation for accurate expectations in terms of how the material will behave under different conditions, which is vital for safety, quality assurance, and achieving desired performance outcomes in many applications. The Metallographic Abrasive Cut Off Saws of GenCut GL Series, which was specifically designed for metallographic applications, is an example of a tool that can handle this task.

Applications of Cut-Off Saws Across Industries

There are a variety of purposes for which cut-off saws are used in different industries, such as:

Aerospace and Automotive

Cutting and sectioning materials used in manufacturing and testing require cut-off saws in the aerospace and automotive industries. They facilitate quality control and industry standards compliance. As part of automotive quality assurance, they are often used to section parts for failure analysis.

Electronics

In the electronics industry, cut-off saws precisely cut circuit boards, silicon wafers, and other components. For electronic products to be reliable and perform well, accurate sectioning is essential for quality control and failure analysis.

Semiconductor Industry

Cut-off saws are also essential in semiconductor manufacturing for sectioning silicon wafers and other semiconductor materials. In order to achieve the required performance and specifications, precise cuts are necessary for quality control and process optimization.

Petrochemical Industry

It is common to use cut-off saws in the petrochemical industry in order to section materials for analysis, which can provide invaluable information regarding the material’s properties under various conditions.

Mining and Geological Exploration

Cut-off saws are used in mining and geological exploration to analyze rock samples. Mineral content, structural integrity, and other geological features can be determined by analyzing these samples.

Medical Device Manufacturing

Medical device manufacturers use cut-off saws to cut and section materials used in medical device production. As a result of the precise cutting process, medical devices can be analyzed and controlled with increased accuracy. This ensures their quality and safety, which is a top priority.

Key Features of Cut-Off Saws

As a matter of fact, the effectiveness of cut-off saws is directly dependent upon the features designed to improve their accuracy and operational efficiency. Let’s look at some of them:

Blade or Wheel Material

A cutting wheel or blade’s material plays an important role in ensuring saw effectiveness across a wide range of materials. It is common to use diamonds or abrasive grains embedded in a matrix, which are known for their hardness and cutting efficiency.

Adjustable Speed Control

Having the ability to control the cutting speed allows the user to get better precision and adaptability when cutting different materials, which results in a more accurate and efficient cutting process.

Lubrication System

By maintaining a proper lubrication level, the saw will not only run longer and perform more efficiently, but it will also reduce the amount of wear and tear on the cutting wheels and other components, and will last for a much longer period of time.

Safety Features

There are several safety features that can make cutting safer, such as blade guards, eye protection, and emergency stop mechanisms. These features contribute to reducing the risks associated with high-speed cutting.

Digital Display and Controls

It is particularly helpful in ensuring accurate cuts to have digital displays and controls that provide real-time feedback on the saw’s operation. This allows for precise adjustments and monitoring.

Vibration Damping

Vibration damping is a feature of the blade that reduces vibrations created during the cutting process, which in turn makes the precision of the cut and the overall quality of the cut to be higher.

Data and Insights

The meticulous process of sectioning materials using cut-off saws such as those in the GenCut GL Series facilitates a detailed microscopic examination that can reveal the composition, structure, and various other characteristics of the material examined. The precision inherent in this cutting phase is crucial not only for metallographic analyses but also for a number of applications that require precise sectioning and close study of the material. The high-precision cutting allows for an in-depth analysis of the material’s structure to be performed and valuable insight can be gained as a result of the analysis.

As we have gained a better understanding of what cut-off saws are used for, it is now time to review the products offered by NextGen Material Testing Inc.

Multi Function Abrasive Metallographic Cut-Off Saws of GenCut GL Series

Introducing the GenCut GL Series of Multi Function Abrasive Metallographic Cut-Off Saws, which are specifically designed to raise precision and efficiency in metallography laboratories to the highest level. The user interfaces of these machines ensure an intuitive user experience while navigating through the cutting process. Among the models highlighted in this series are the GenCut GL 120XY and the GenCut GL 170XY, which are designed to meet the demanding requirements of modern metallography labs.

GenCut GL 120XY and GenCut GL 170XY both feature a fully automated XY table for precise specimen manipulation and cutting. These cutters feature a double hood enclosed structure, which shows their commitment to the safety of the operator. They also feature quick clamping mechanisms that represent a critical component of optimizing the effectiveness of cutting processes.

There is a powerful cooling system, featuring two lines of coolant, which is a hallmark of these models. As a result, it effectively mitigates the heat generated during the cutting process, protecting the specimen from any deformity or burn residue that may result from the cutting process. This preserves the integrity of the specimen while also enhancing the cutting quality. Furthermore, it increases the efficiency of the cutting wheel and significantly prolongs the blade’s lifespan.

There will be more detailed information provided in the following section about the technical specifications, features, and standard configurations of each of the products.

GenCut GL 120XY – Abrasive Cut Off Saw with Touch Screen User Friendly Interface

The GenCut GL 120XY, a part of the esteemed GenCut GL Series of Cut Off Saws, stands as an example of cutting-edge engineering aimed at facilitating detailed metallographic analysis. In addition to providing metallography professionals with an unmatched user-friendly experience, this Multi Function Abrasive Cut Off Saw is also exceptionally reliable.

Safety and Efficiency

GL 120XY provides a large cutting capacity of 120mm in diameter, together with an automated XY table that enables precise positioning and cutting of specimens. In its design, the GL 120XY places a high priority on safety, as evidenced by its double hood and fully enclosed construction. In addition to safeguarding the operator, this enclosure also contains quick clamping mechanisms that enhance cutting efficiency.

Advanced Cooling System

As we already mentioned above, metallography requires the natural properties of the specimen to be preserved, and the GL 120XY meets this requirement with great success. Its sophisticated cooling system, with two coolant lines, diligently keeps the heat generated during cutting under control. By using this feature, one can ensure that the specimen will remain undistorted and free of any traces of burning, which will ensure the integrity of the sample for further analysis. In addition, the effective cooling system enables better-cutting quality as well as the extension of the lifespan of the cutting wheel and blades.

Technical Specifications

There are a number of features built into the GL 120XY that are designed to maximize performance. A few of its technical specifications are as follows:

- Model: GenCut GL120XY

- Cutting Wheel Dimensions: Φ350×2.5×Φ32mm

- Maximum Cutting Section: Φ120mm

Cutting Table Size: 400 x 300mm

Cutting Table Size: 400 x 300mm- Z-Axis (Cutting Blade Spindle Drop Distance): 150mm

- Y-Axis Movement Stroke: 300mm, with a Y-Directional Speed of the Table of 0-300mm/min

- X-Axis Travel: 100mm, Effective Tool Fed Distance of 300mm

- Rotation Speed: 2850rpm

- Control System: A 7” Colour Touch Screen Panel paired with a PLC Controller, enhances the user interface and control.

- Cutting Modes: Offer Flat Push Cutting and Intermittent Cutting.

- Cutting Speeds: 1-100mm/min

- Resetting Mode: Automatic

- Cooling System: Automatic Water Cooling with 2 Lines, ensuring specimen cooling during cutting.

- Machine Type: Vertical Cutting

- Input Power: 4kW

- Input Voltage: 380V 50/60Hz – 3Phase

Standard Configuration

A comprehensive set of components is included with the GenCut GL 120XY, which makes it ready to use right out of the box. Among the standard configurations are:

- GenCut GL120XY Cutting Saw

- Coolant Chamber

- Wrench 13#-15#

- Wrench 17#-19#

- Internal Hexagonal Wrench 6mm and 8mm

- Water Inlet Tube

- Drain Pipe

- Diamond Cutting Wheel (Φ350 x 2.5 x Φ32mm)

- Water Tank and Pump

- Operation Manual

GenCut GL 170XY – Multi Function Cut Off Saw with Large Cutting Capacity

Providing another excellent choice in metallography, the GenCut GL 170XY Multi Function Abrasive Cut Off Saw is an indispensable tool for the laboratories of today. Engineered for high precision and operational efficiency, this model amplifies sample preparation ease, while being compliant with the highest safety standards.

Enhanced Safety and Operational Efficiency

With a cutting capacity of 170mm in diameter and a fully automated XY table, the GL 170XY stands out from the competition. During the cutting process, the double hood fully enclosed structure emboldens the safety protocols by protecting the quick clamping mechanisms.

Robust Cooling System

One of the main characteristics of the GL 170XY, as with other models in this series, is its powerful cooling system, which consists of two lines of coolant. During the cutting process, this system is crucial for mitigating heat, thus preserving the specimen’s integrity from deformities or burn residues. In this way, cutting wheels and blades are able to generate superior cutting quality and last for a longer period.

Technical Specifications

Here are some key technical specifications of the GL 170XY:

- Model: GenCut GL 170XY

- Cutting Wheel Dimensions: Φ450×3.5mm×Φ32mm

- Maximum Cutting Section: Φ170mm

- Cutting Table Size: 600 x 800 mm

- Z-Axis (Cutting Blade Spindle Drop Distance): 290 mm

- Y-Axis Movement Stroke: 750 mm

- X-Axis Travel: 150 mm

- Cutting Feed Speed: 1-200mm/min

- Water Tank Capacity: 150L

- Power: 480V 60Hz 3 Phase

- Control System: 7” Colour Touch Screen Panel, PLC Controller

- Cutting Modes: Flat Push Cutting, Intermittent Cutting

- Cooling System: Automatic Water Cooling – 2 Lines

- Machine Type: Vertical Cutting

PLC-controlled automatic operation of the GL 170XY allows precise control in the X, Y, and Z directions, resulting in automated and accurate cutting. Furthermore, the intelligent cutting capabilities allow the feed amount to be adjusted according to the material hardness, while the cutting speed is regulated through frequency conversion.

Standard Configuration

In order to be prepared for operation, the GL 170XY is equipped with a comprehensive set of components:

-

- GenCut GL 120XY Cutting Saw

- Coolant Chamber

- Wrenches (62mm, 17-19mm, 46mm)

- Water Inlet Tube

- Drain Pipe

- Diamond Cutting Wheel (Φ500 x 4 x Φ32mm)

- Water Tank and Pump

- Operation Manual

Features and Ergonomic Design

A number of features are included in the GL 170XY that enhance operational flexibility and user experience. The system allows effortless switching between electronic hand-wheel control and automatic control. A touchscreen interface facilitates the display of a variety of cutting data. The machine has three cutting modes, intelligently adjusting the speed of the cutting based on the material’s hardness. With its vertical body design, the machine structure ensures safety, ease of maintenance, and accessibility for large workpieces. With an integrated cooling water tank, transparent protective cover, and ergonomic design, the GL 170XY provides the best performance.

Applications

There is a wide range of applications for the GenCut GL 170XY. It handles various types of materials, including ferrous and non-ferrous metals, heat-treated parts, forgings, semiconductors, crystals, ceramics, and rocks. Due to the design of the GL 170XY, it is designed to be easy to maintain and process large workpieces, proving to be a valuable asset for industries seeking efficient cutting and processing solutions. The machine is not only designed to meet the stringent requirements of modern metallography, but it also extends its functionality to an extensive range of industrial applications.

Comparing the GenCut GL 120XY and GenCut GL 170XY

Cutting Capacity and Table Sizes

It is important to note that, while both the GenCut GL 120XY and GL 170XY are impressive machines, both cater to different needs based on their cutting capacities. With a cutting diameter of 120mm, the GL 120XY is able to accommodate a broad range of applications, making it a versatile machine that can be used for a variety of applications. The GL 170XY, however, might be a better choice for labs or industries that often have to work with larger specimens, due to the fact that the disc diameter of this machine is 170mm. Furthermore, the GL 170XY provides a wider cutting area of 600 x 800 millimeters, as compared to the 400 x 300 millimeters of the GL 120XY, which gives you a greater degree of flexibility when working with materials.

Control Systems and Precision

Both models focus on producing a great user experience, with a 7″ touchscreen, an adjustable controller, and a PLC. By using these features, operators will be able to smoothly navigate throughout the cutting process. GL 170XY is, however, a bit more precise than its predecessor, with its precision being a notch higher. Due to its PLC-controlled automatic operation, the machine is able to be finely controlled in the X, Y, and Z directions. As a result, the machine is more adaptable, especially when it comes to cutting tasks that are particularly complex and require a lot of precision.

Cooling Systems

During the cutting process, it is crucial to protect the integrity of the specimen in order to prevent damage to it. While both models are equipped with a dual coolant line system to mitigate heat, the GL 170XY’s design suggests a more potent cooling mechanism. The reason for this is due to its capacity to handle larger specimens, which may generate more heat during the cutting process due to their size.

According to their design and functionality, both the GenCut GL 120XY and GL 170XY are outstanding examples of metallography in terms of their design and functionality. The choice between them is primarily determined by the specific requirements of the laboratory or industry. A wide range of metallographic requirements can be met by each model, regardless of its cutting capacity, table size, or control features.

Taking Precision to the Next Level with GenCut GL Series

Based on its characteristics and capabilities, the GenCut GL Series of Metallographic Abrasive Cut Off Saws from NextGen Material Testing Inc. is designed to meet the demanding needs of different industries related to material analysis and preparation. Metallographic Abrasive Cut Off Saws such as the GenCut GL 120XY and GL 170XY provide laboratories and manufacturing environments that require precision, reliability, and safety with an invaluable tool.

Infused with cutting-edge technology, the GenCut GL Series incorporates features that increase its operational capabilities, such as adaptive cooling systems and dynamic XY tables. Beyond simple cutting, the versatility of GenCut GL 120XY and GL 170XY extends to a wide range of materials, maintaining specimen integrity during each cut. Their design emphasizes both durability and ergonomics, facilitating ease of operation for end users. Furthermore, the GenCut GL Series’ integrated touch screens and automatic feed adjustments based on material hardness provide a unique combination of technology and user-centric design, which sets it apart from other precision cutting machines.

We have gained a deeper understanding of the overall capabilities of the GL120XY and GL170XY through our exploration. Despite this, these products have many other potential benefits for laboratories and manufacturers. These tools are crucial for preparing and analyzing materials precisely due to their user-centered designs and robust technical frameworks. The GenCut GL Series provides new opportunities in the material testing field, aligned with the pursuit of operational efficiency and precision.

Don’t miss this excellent opportunity! If you would like to find out if GenCut GL Series Metallographic Abrasive Cut Off Saws meet your testing requirements or if you would like to receive an online estimate, please feel free to contact us. Our team is available to assist you in understanding the details of our system so that it can be configured to meet your specific requirements.