Metal Testing Equipment

Standards

ISO 2507, ISO 75, ISO 306, ASTM D648, ASTM D1525, GB/T 8802, GB/T 1633, GB/T 1634

Description

The HDT/VICAT testing machine offers high precision, reliability, and efficiency for the thermal analysis of thermoplastics and polymers. Engineered with advanced sensors and high-temperature-resistant components, it ensures minimal deformation, fast response, and precise data transmission, delivering consistent and accurate test results. When integrated with a chiller system, testing capacity doubles, significantly enhancing productivity.

The test station, made from a low-expansion coefficient alloy, maintains measurement accuracy up to 200°C without recalibration, complying with international standards. Widely used for HDT and Vicat softening temperature testing, this HDT/VICAT machine is essential for plastic and pipe manufacturers, quality control laboratories, construction engineering, and research institutions. Designed for product development, material testing, and regulatory compliance, it is a crucial tool for manufacturers, quality assurance teams, and research professionals seeking precise and efficient thermal analysis solutions.

HDT/Vicat Testing Machine Features

-

Simultaneous HDT and VICAT Testing – Conduct both tests at the same time, improving efficiency and throughput.

-

High-Stability Test Station – Minimal deformation under heat, with deflection temperature accuracy up to 200°C without recalibration.

-

Automatic Loading & Lifting – Eliminates manual weight handling for easier and more efficient operation.

-

Compact & Cost-Effective Design – Tank volume is reduced by over 50%, significantly lowering operational costs compared to traditional designs.

-

Precision Displacement Measurement – Swiss-made high-precision micrometer ensures exceptional accuracy and stability.

-

Multi-Station Capability – Supports up to six test stations, with up to six deformation transducers and one temperature transducer for precise monitoring.

-

Motor-Driven Test Stations – Easily raise stations from the bath at the touch of a button, simplifying specimen placement.

-

Fully Automated Testing Process – Once the software is started, the test runs automatically according to user-defined parameters.

-

Automatic Bath Cooling – After test completion, the system cools the bath to 280°C, improving equipment utilization for continuous testing.

-

User-Friendly Software – Professional testing software with an intuitive interface for easy operation and data management.

Optimized Cooling System for Maximum Efficiency

Equipping the HDT/VICAT testing machine with a chiller system significantly enhances cooling performance, reducing downtime and increasing operational efficiency. Compared to traditional cooling methods, this advanced system offers several key advantages:

-

High Initial Cooling Temperature – The system supports an initial cooling temperature of up to 280°C, ensuring rapid heat dissipation.

-

Fast Cooling Speed – When used with a chiller, cooling time is reduced to just 45 minutes, dramatically improving equipment utilization and workflow efficiency.

-

Optimized Temperature Control – The chiller lowers the oil temperature to below 25°C, minimizing test errors and ensuring compliance with ISO and ASTM standards for initial heating temperatures.

-

Water-Saving Design – The water chiller recycles water, significantly reducing water consumption while maintaining effective cooling.

Test Station

-

Flexible Test Configurations – Available with 3, 4, or 6 test stations to accommodate different testing needs.

-

Precision Loading System – Includes 10N and 50N dead weights for accurate load application.

-

Ultra-Accurate Deformation Measurement – Swiss-made high-precision micrometer with 0.001mm resolution and ±0.005mm accuracy ensures precise specimen deformation analysis.

-

High-Accuracy Temperature Control – Japan-made RKC temperature controller with ±0.5°C accuracy guarantees consistent thermal conditions.

-

Invar Steel Test Station Assembly – Constructed from low-expansion Invar Steel, minimizing deformation at high temperatures for exceptional test stability and accuracy.

Technical Specifications

| Model | NG-HDT300 | NG-HDT400 | NG-HDT600 |

| Type | A | B | C |

| Test station | 3 | 4 | 6 |

| Immersion bath | 1 | 1 | 1 |

| Heat transfer medium |

Methyl Silicon oil,22 liter Viscosity: 300 cSt, or 300 mm2/s Silicon oil brand: DON CORNING PMX-200 350 cSt, KF96-300 Or transformer oil, 10#, 22 liter |

||

| Temperature sensor | 3 | 4 | 6 |

| Temperature range |

Ambient (20℃)-300℃ |

||

| Temperature accuracy |

±0.5℃ |

||

| Heating Speed | Speed A:

5±0.5℃/6min Speed B: 12±1℃/6min |

||

| Micrometer | 3 | 4 | 6 |

| Deformation measurement range | 0-10mm | ||

| Deformation resolution | 0.001mm | ||

| Deformation measurement accuracy | 0.003mm | ||

| Vicat loading capacity |

GA=10N±0.2N, GB=50N±1N |

||

| Deformation measurement range | 0-10mm | ||

| HDT Test |

Method A: USE FIBRE STRESS 1.80Mpa Method B: USE FIBRE STRESS 0.45Mpa Method C: USE FIBRE STRESS 8.00Mpa |

||

| HDT Test Span |

Outer span: 100mm, ASTM D648 Inner span: 64mm, ISO 75 |

||

| Maximum heating power | 5000W | ||

| Power requirements |

220V 50/60Hz 3 Phase |

||

| Dimensions | 32" x 24.5" x 28.5" | ||

| Weight | 253 lbs | 253 lbs | 617 lbs |

| Cooling |

Nature cooling or water cooling (less than 150℃) |

||

Standard Accessories

| Model | NG-HDT300 | NG-HDT400 | NG-HDT600 |

| Type | A | B | C |

| Main Frame | 1 set | 1 set | 1 set |

| Test Stations | 3 | 4 | 6 |

| Swiss-made Micrometers | 3 sets | 4 sets | 6 sets |

| Platinum resistance temperature sensors | 3 sets | 4 sets | 6 sets |

| Temperature controllers | 3 sets | 4 sets | 6 sets |

| Loading nose for HDT | 3 sets | 4 sets | 6 sets |

| Needle for VICAT | 3 sets | 4 sets | 6 sets |

| Weight set (10N, 50N) | 3 sets | 4 sets | 6 sets |

| Test software | 1 set | 1 set | 1 set |

Related Products

Wedge Tensile Grips for High-Load Metal and Composite Testing

Precision Wedge Grips for High-Strength Tensile Testing NextGen’s wedge tensile grips are engineered to deliver superior performance in tensile strength testing using Universal Testing Machines (UTMs). These grips use a mechanical wedge action that enhances gripping pressure proportionally with the […]

Pneumatic Grips for Fast and Repeatable Clamping

Precision Clamping Solutions with Compressed-Air Actuation from NextGen NextGen’s pneumatic grips are engineered for precise, high-throughput testing applications using universal testing machines (UTMs). These air-actuated systems ensure uniform clamping pressure, reduced operator fatigue, and faster sample mounting, ideal for quality […]

Shoulder Fixtures for Pull-Off and Component Testing

Precision Shoulder Grips for Tensile Testing on NG-EML and SHM Series UTMs NextGen’s shoulder fixtures are specialized tensile grips designed to accommodate specimens with shoulder geometries. These fixtures are critical for standardized testing in accordance with ISO and ASTM protocols […]

Compression Fixtures for Axial Load Testing of Rigid Samples

Precision Compression Test Fixtures for NG-EML and SHM Series UTMs NextGen’s compression fixtures are designed for high-accuracy compression testing of a range of materials including metals, polymers, elastomers, foams, composites, and construction materials. These fixtures are engineered for seamless integration […]

Bending Fixtures for Standard 3-Point Flexural Testing

3-Point and Marker Bending Fixtures for Flexural Testing NextGen’s bending fixtures are engineered for precision flexural testing of various materials, including thermoplastics, composites, metals, and laminated structures. Designed to operate with NG-EML and SHM Universal Testing Machines, these fixtures offer […]

Eccentric Roller Grips for Thin and Flexible Specimens

Optimized Clamping System for Tensile Testing of Sheet Materials and Soft Specimens Eccentric roller grips from NextGen Test are designed to meet the demanding needs of tensile testing applications involving thin, flexible, or soft materials. Utilizing a friction-based clamping mechanism […]

Self-Tightening Grips for Deformable and Elastic Materials

Self-Tightening Grips for Tensile Testing NextGen’s self-tightening grips are engineered for precise tensile testing of deformable and elastic materials such as elastomers, foams, thin plastics, textiles, and biomedical specimens. These grips automatically increase clamping pressure as tensile force is applied, […]

Snubbing Grips for Wire and Cable Tensile Testing

Overview of Snubbing Grips for Tensile Testing of Wires, Cables, Ropes, and Geogrids Snubbing grips (also known as capstan grips) are designed to secure challenging specimens like steel wires, wire ropes, fiber ropes, textile strips, and geogrids during tensile testing. […]

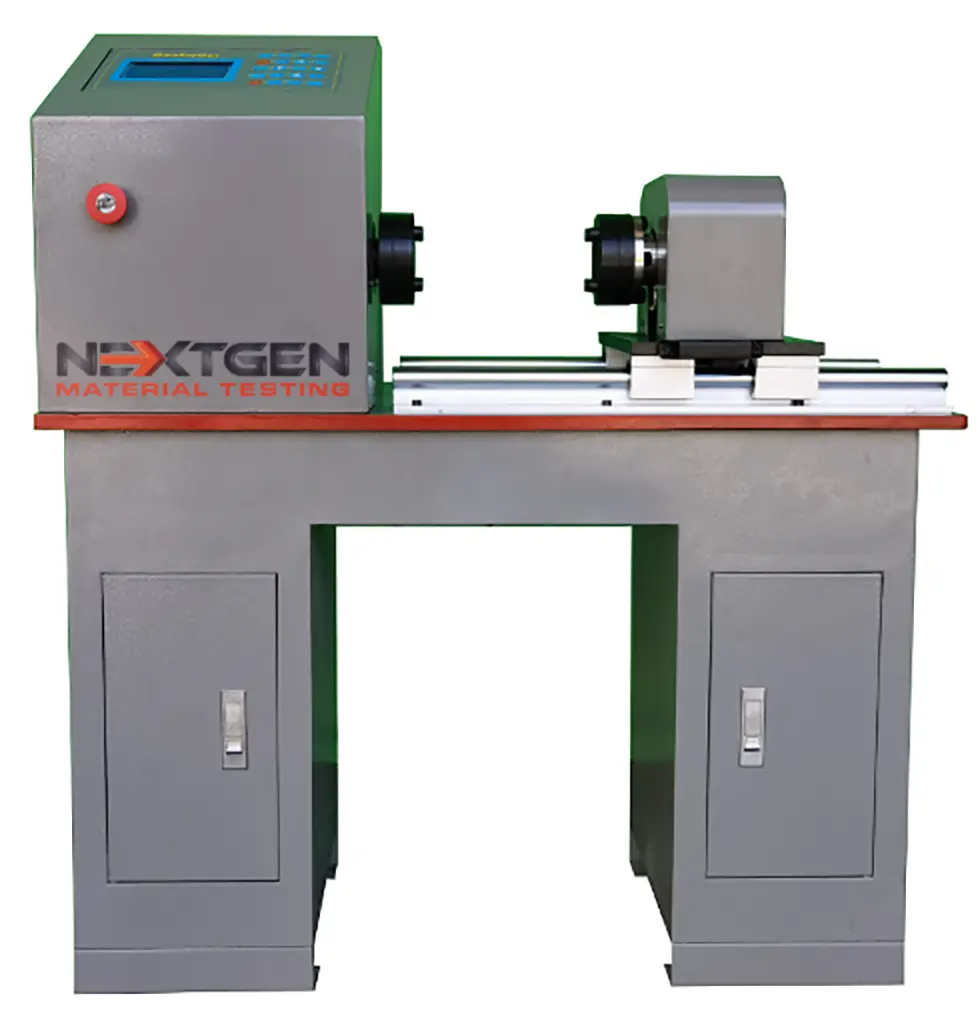

NextGen GenTor Horizontal Torsion Tester

NextGen GenTor Torsion Tester boasts a horizontal type load frame with high stiffness, ensuring accurate and reliable test results.

DWT-1800 Computer Controlled Drop Weight Impact Testing Machine

DWT-1800 Impact Testing Machine is specifically designed for determining the non-plastic transformation temperature of ferritic steel.