Metal Testing Equipment

Description

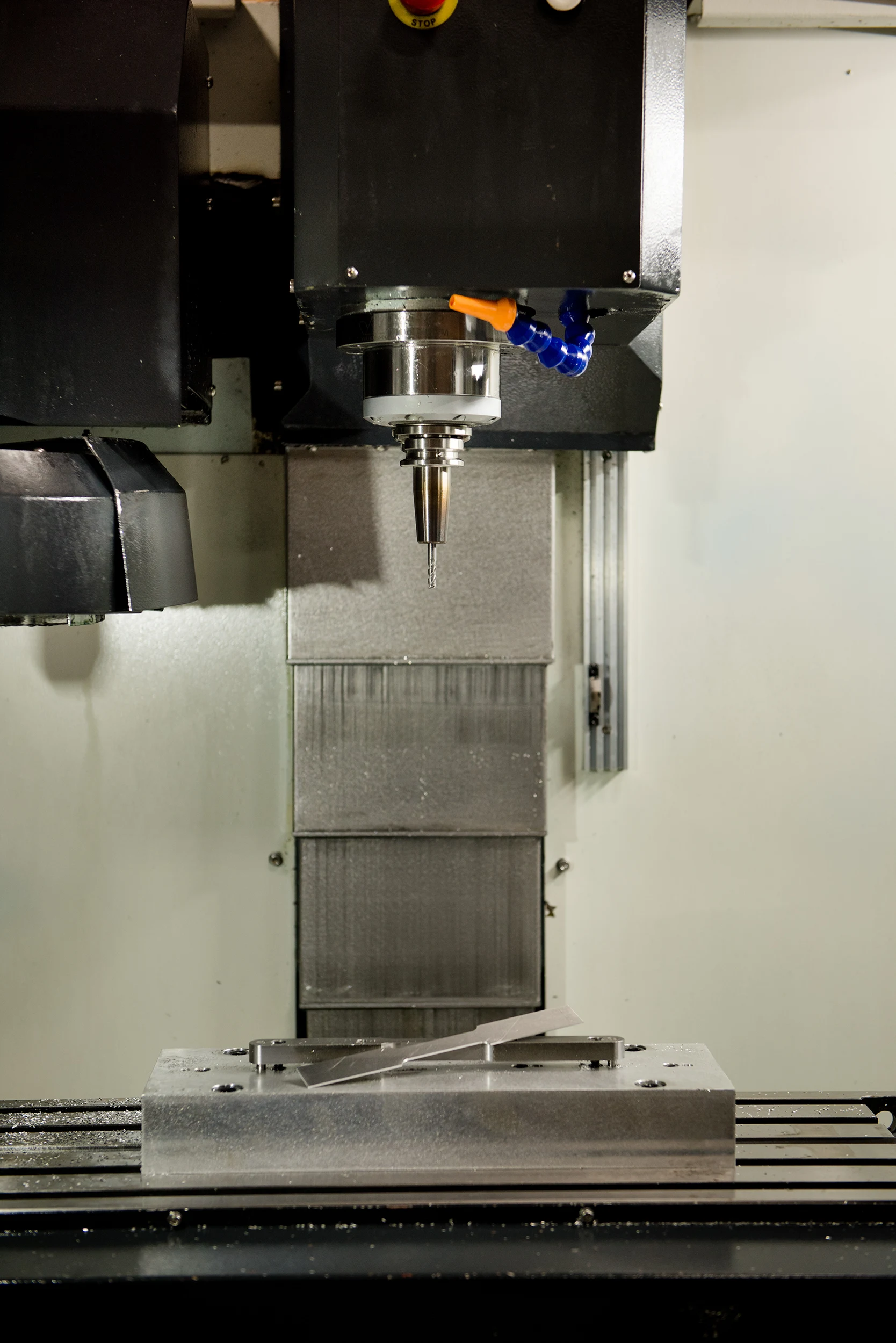

Every manufacturing floor would benefit from the dynamic and powerful addition offered by TensileMill CNC XL - Large Flat Tensile Sample Preparation machine. Removal rates for materials are increased by servos and the high powered spindle. CNC control based on Mach4 when combined with substantial memory simplifies the loading and execution of large and complex programs. Machine programming for smaller jobs is made fast and easy by wizards as they facilitate the fast creation of pockets, text engraving, hole patterns etc.

Controller

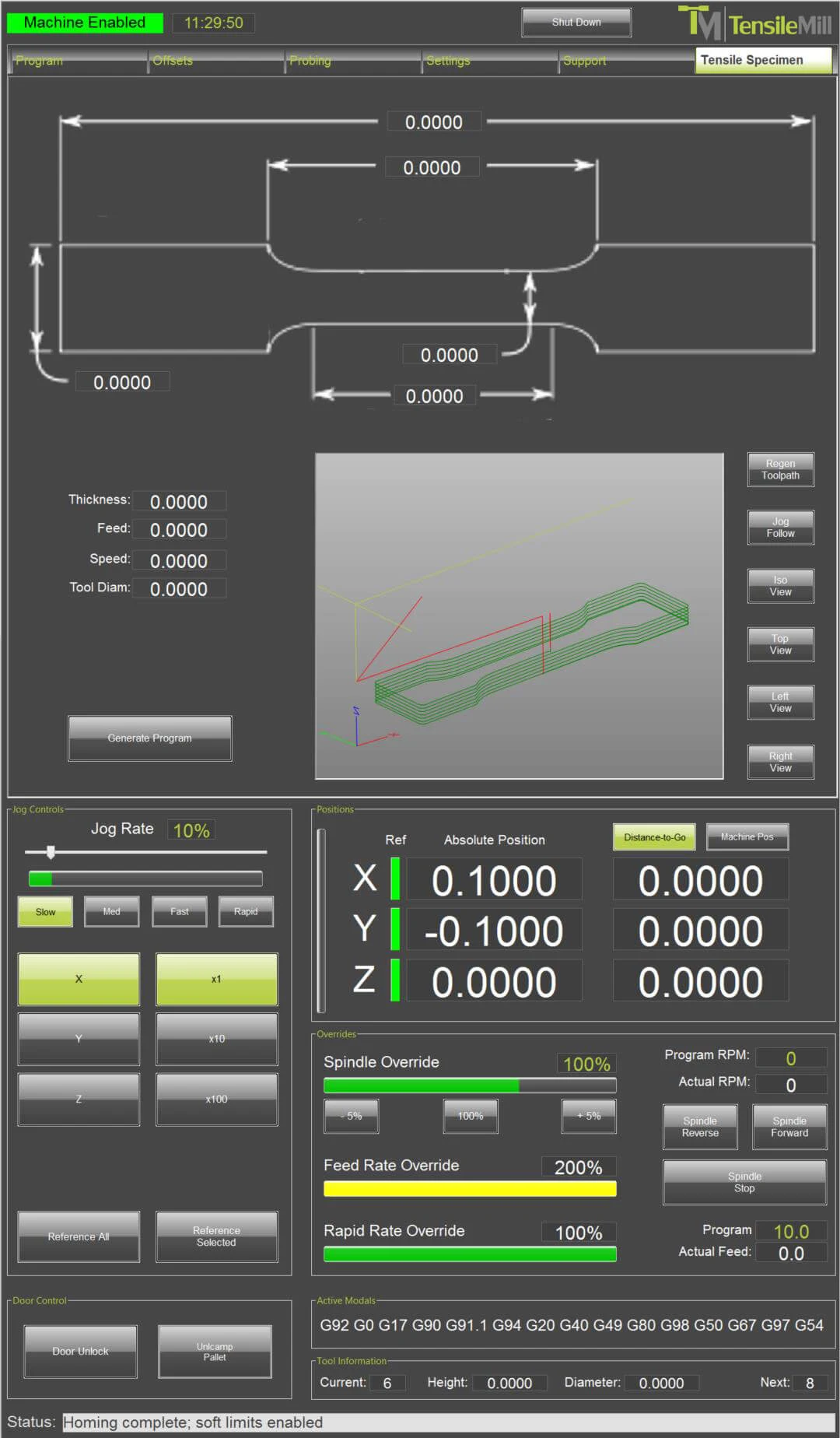

Our touch screen controller which is easy to manipulate carries our complete Carbon software. The features of our control systems; 64 Gb of storage, WiFi, Ethernet, 4 Gb of RAM, USB ports, 254 tool offsets, macro B programming, 126 work offsets, scaling and mirroring, drilling canned cycles, helical interpolation, cutting edge dual mode cutter compensation, advanced trajectory planning etc. In addition to the software interface for tensile milling, the operator is allowed by Carbon to get access to the Industrial CNC Software (MACH4), which is used to control professional CNC functions. New features are being developed constantly for our Carbon software and at no extra cost, updates are included into every TensileMill CNC XL system.

The TensileMill CNC XL - Large Flat Specimen Preparation design is the enhanced model of our classic TensileMill CNC. The upgraded design presents larger table dimensions, tooling options, travel distance and servo power to support your needs of tougher material, and higher quantity tensile sample preparation.

Technical Specifications

| TensileMill CNC XL | |

|---|---|

| Dimensions | |

| Dimensions (D x W x H) | 66.1 x 75.79 x 86.54 in |

| Table Size | 31.5 x 10.24 in |

| Load Capacity | 330 lb |

| T-Slot Size | .63 in |

| Weight | 2976 lb |

| Working Travel X | 15.75 in |

| Y | 9.1 in |

| Z | 15.75 in |

| Spindle | |

| Speed | 10,000 RPM |

| Power | 5 hp |

| Torque | 10.8 lb-ft |

| Lubrication | High speed grease |

| Bearings | Angular contact ball |

| Auto Tool Changer | |

| Taper | BT30 |

| Pull Stud | MAS P30T-1 |

| Max Tool Diameter | 3.14 in |

| Max Tool Weight | 13.2 lb |

| Tool Change Type | Umbrella |

| Tool Numbering | Random pot assignments |

| Tool Change Time | 6sec |

| Servos | |

| Servo Power | 1.75 hp |

| Servo Torque | 1175.4/3299.6 oz-in |

| Max Feedrate | 1000 ipm |

| Ball Screws | PMI double nut, 20 mm on X and Y, 25 mm on Z |

| Power | |

| Input Voltage | 220 3 phase |

| Control | |

| Type | PC based Mach4 control |

| Processor | 64 bit 5th generation Intel Broadwell |

| Program storage | 64 GB SSD, unlimited number of programs |

| Memory | 4 GB standard (upgradable) |

| Display | Full color multi-touch (glove compatible) |

| Modes | Auto/MDI/Jog, auto switching |

| Wizards | On machine programming with graphic wizards. |

| Units | Inch/Metric |

| Overrides | Feed (0%-150%), Spindle(50%-150%), Rapid(0%, 25%, 50%, 100%), all user configurable |

| G code | Fanuc compatible, Mach3 compatible |

| Custom Macro | Fanuc Macro B compatible |

| External Communication | TCP Modbus |

| M-Codes | Unlimited user defined M codes, 5 inputs and 5 outputs available (upgradeable) |

Features

- The linear guide ways and strong cast iron frame offers a strong foundation for machines with high speed.

- Large 20 mm ball screws on X and Y, 25 mm on Z.

- The higher material removal rate is powered by a belt driven 5 horsepower 10,000 RPM servo spindle with BT30 taper.

- Servo spindle with complete synchronous position control. Disc spring tool clamping with gripper having collet shaped gripper. It also features air over hydraulic tool release.

- It also has 10 automatic tool changer with shapes like station umbrellas. It makes it possible to assign any tool to any desired position.

- Clean and simple control panel with large format touch screen, MPG and integrated status light.

- Mach4 control software is flexible and powerful. Integrated wizards for on machine programming.

- Wireless and Bluetooth standard

- Fanuc G code compatible, Fanuc Macro B included

- 5th generation 64 bit Broadwell processor

- Industrial PC loaded with a 64 GB solid state hard drive and 4 GB of RAM.

- 30 Taper CNC Machining Center

FAQs

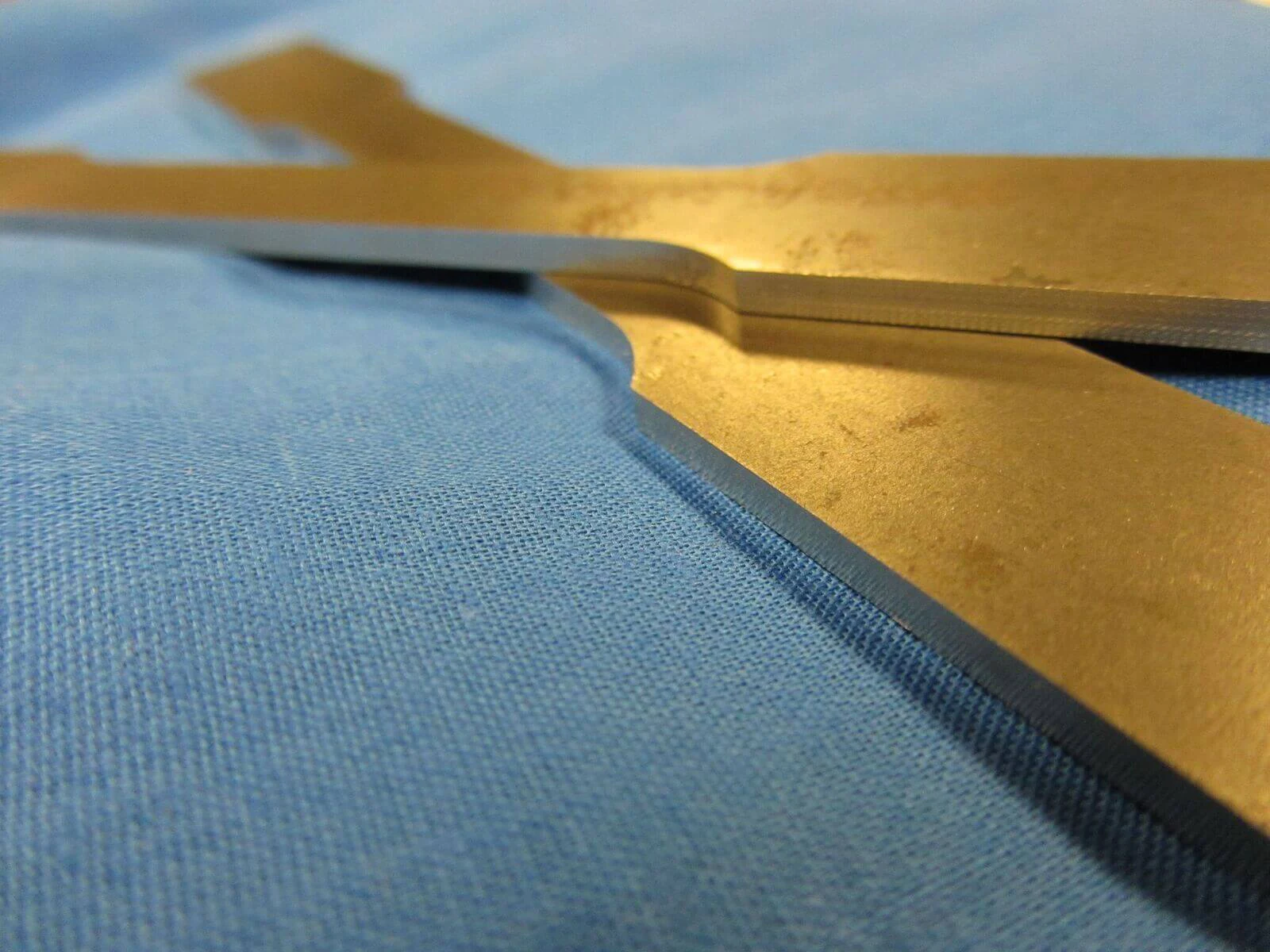

If you want to pinpoint the exact quantity of specimens that can be prepared in one cycle, we advise that you speak with one of our Product Consultants to further discuss your application. Flat tensile mill quantity samples and the time it takes to complete the machining process will usually depend largely on the material type, the hardness, and the thickness of your material. Submit your request or call us today for any additional details!

The TensileMill CNC XL will be supplied with all of your necessary end-mills and tooling fixtures for any long term operations. Additional fixtures can be very easily acquired from TensileMill CNC. Request a quote today.

Even though the tooling fixtures are designed to last a lifetime with the proper maintenance, if you wish too, additional fixtures can also be purchased along the road.

The capacity offered by TensileMill CNC XL is better and more superior than both the Classic and the MINI. The machine offers a much bigger and better frame which is capable of handling tougher and larger samples. The standard tool charger allows for automation of tensile sample preparation needs. The unit is able to be programmed for tensile sample preparation and for advanced CNC machining requirements with the on-of-a-kind software that comes standard with the unit.

The longest Tensile specimen that can be prepared using the TensileMill XL will depend with the working travel distance of (X by Y by Z) 15.75 by 15.75 by 9.1. This machine is ideal for dynamic and skillful tensile sample preparation. The unit can handle large stacking volumes of various material hardness with ease. If you have a laboratory which requires a high volume of tensile preparation, the XL will be the perfect fit for you. Request quote today to learn more.

The XL model is a versatile machine which offers the best of both worlds when it comes to tensile specimen preparation and general purpose CNC machining. The unit can be equipped with a few options for tensile clamping fixtures:

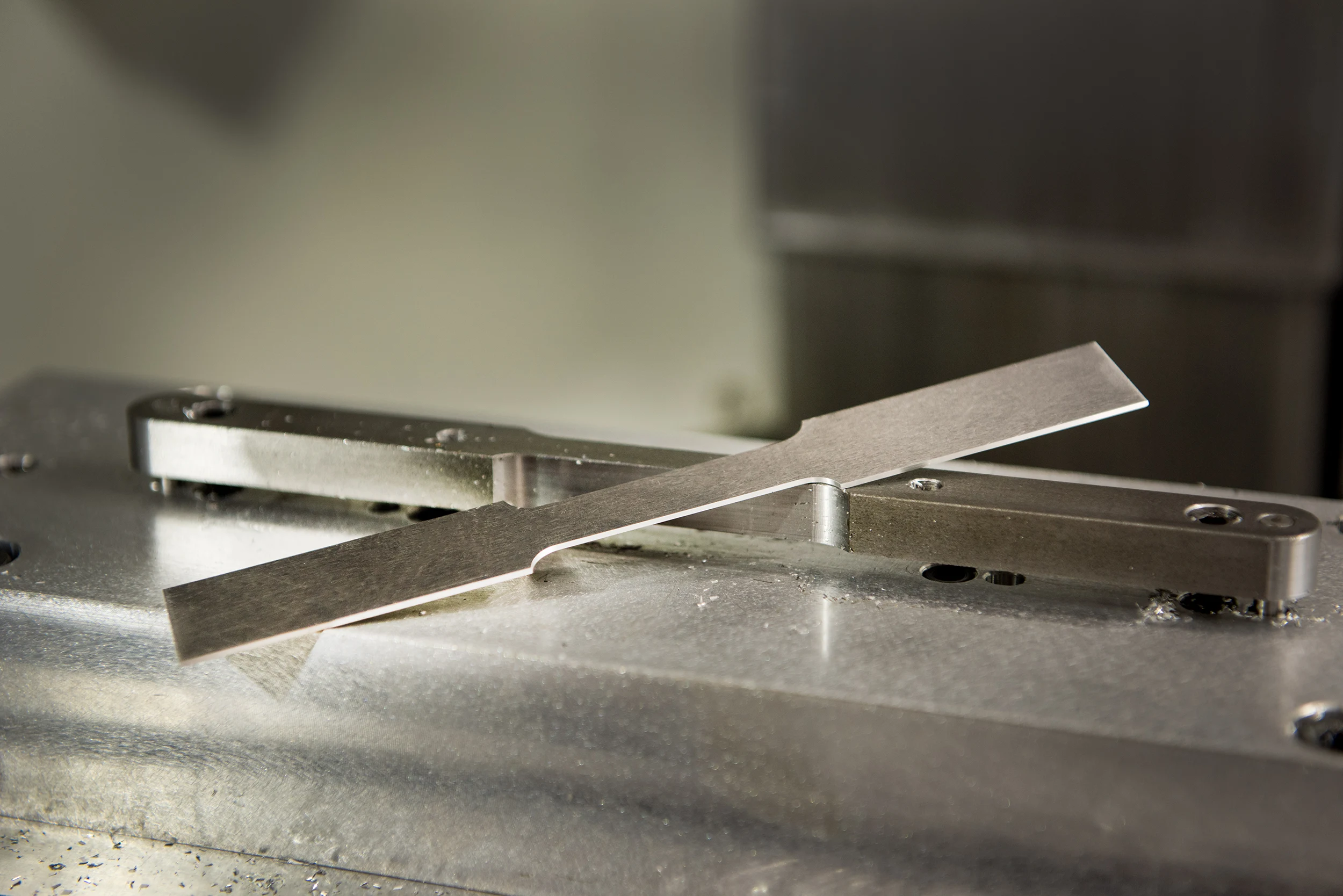

Double Clamping Fixture (Standard) TensileMill CNC XL comes with a standard double clamping fixture.

Technical Details:

This option offers you the ability to prepare 2 stacks of up to 12" long, 2" wide, and up to 1" thick (note that this depends on the material).

Triple Clamping Fixture (Upgrade):

The triple fixture is an upgrade option that is commonly used for specimen preparations for higher volume, regular, and/or sub-size specimen preparations.

Technical Details:

This option offers you the ability to prepare 3 stacks of specimens that go up to 12" long, 1" wide, and up to 1" thick (again this depends on the material). The side fixtures can also be removed to prepare a thicker specimen in the middle fixture. These offers add versatility to the user.

Custom Clamping Fixture:

Sheet metal fixtures, tube fixtures, and others are available based on your specific technical requirements. TensileMill CNC Inc. is also very capable of designing a specialty fixture based on your needs.

TensileMill CNC XL will in fact be supplied with all of your necessary end-mills and tooling fixtures for long term operation. Additional end-mills and fixtures can be easily acquired from TensileMill CNC requesting a quote today.

The tooling fixtures are designed to last a lifetime including proper maintenance, additional fixtures can also be purchased down the road.

Following the basic preventative maintenance procedures is the general rule for all quality control equipment. Keeping your unit clean and keeping the lube tank full is a little bit of a special recommendation. Contact us if you have any other questions.

The XLis a specialty unit which can be customized to your specific needs. The base price of the XL includes the turnkey solutions based on your technical requirements. Base fixtures, clamping fixtures, ER collets, End Mills, ISO 20 Spindle Upgrade and more are also a part of this upgraded version of the Classic unit.

Related Products

TensileMill CNC MINI - Compact Flat Tensile Sample Preparation

Despite its small size, the axis of the heavy cast iron frame on which the TensileMill CNC MINI slide on linear rails very smoothly. Its exceptional machining capability is provided by high powered servos and a 24,000 RPM ISO20 spindle.