Metal Testing Equipment

Standards

ISO 148, EN10045, ASTM E23, DIN 50115, ASTM E74 (Class AA)

Description

The GenNotch 4000UPG Series is a triple specimen chamber motorized Charpy Notch Making Machine designed specifically for creating Charpy Test notch specimens. This floor placed stand-alone machine, comes with an easy-to-use interface for simple operation. The GenNotch 4000UPG is built to cut Charpy and Izod notches in both V-type and U-type shapes. It produces industry standards complied top-quality notched samples comparable to those made with a milling machine.

GenNotch 4000UPG Series -Triple Charpy Notch Making Machine Technical Specification

|

GenNotch 4000UPG |

|

|

Broacher Travel |

340±10mm |

|

# of Samples at one cycle time |

3 |

|

Speed |

2-3m/min |

|

Lubrication System |

Lubricating oil circulation, the oil is interchangeable |

|

Hydraulic Oil |

L-HM46 (Anti-wear) |

|

Oil Volume |

20L |

|

Power Consumption |

450W |

|

PowerRequirements |

3-phase, 5-line, AC 220V±10%, 50/60Hz |

|

Machine Dimension (LxWxH) |

27.16 x 25.6 x 61.0-inches / 69 x 65 x 155 cm |

|

Weight |

562lbs / 255kg |

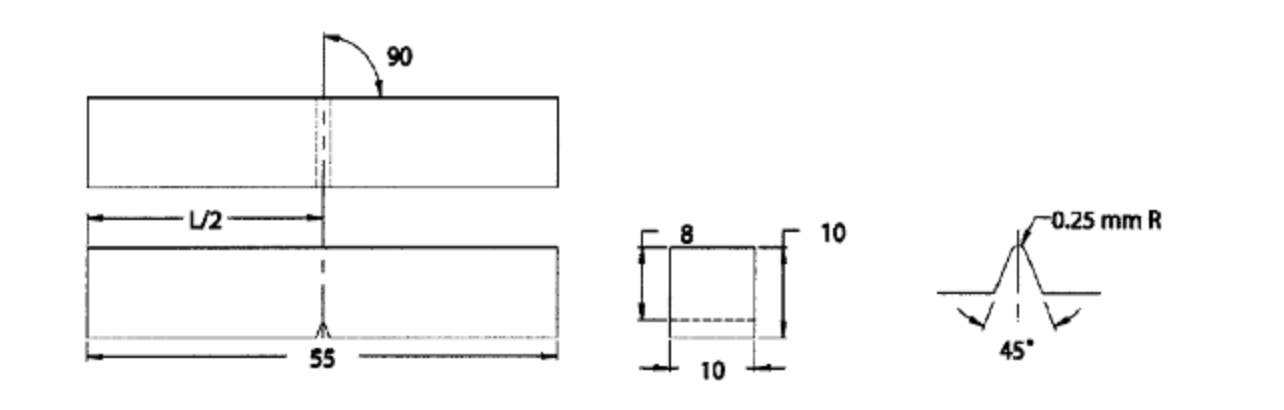

Test Specimens

-

Specimen size: 10x10(7.5, 5, 2.5) x55mm

-

Specimen hardness≤HRC34 Specimen tensile strength: <600MPa

-

If hardness ≤42HRC, M42 material for broacher knife will be used. For higher strength than 600MPa, the broacher knife will be customized and customer need provide specimen.

Notch Type

-

V2 type (ISO148) and Type A (ASTM E23)

-

U5 type (ISO148, GB/T229, Gost 9454) and Type C (ASTM E23), non-standard type, short using life, no warranty

Notching Options

-

U2: depth 2mm, width 2mm, r=1mm±0.05mm, comply with GB/T229, Gost 9454

-

U3: depth 3mm, width 2mm, r=1mm±0.05mm, comply with Gost 9454

Related Products

Class J - Charpy and Izod Automatic Impact Testing System - 1J - 50J

Class J is widely used for lzod and Charpy impact test on softer metals, plastics and rubber specimens. Equipped with tensile impact pendulum and fixtures, it can carry on tests on plastic film and sheet. The newly enhanced design offers the most cost-effective configuration to address Charpy test from 1J to 50J (0.7 - 37 ft/lbs), and lzod test from 1J to 22J (0.7 - 16 ft/lbs).

Class D Single-Column Charpy Impact Tester – High-Precision Pendulum Testing Machine

NextGen’s Class D Single-Column Charpy Impact Testing System is built for high rigidity and dependable specimen testing across a wide energy range. It supports impact energies from around 150 J (111 ft-lbs) up to around 750 J (553 ft-lbs), covering most standard metal testing needs. The unit includes a digital display and offers a software upgrade option for data plotting. Additional features, such as automated specimen feeding and integrated cooling or heating systems, are available as optional enhancements.

Class G Single-Column Charpy & Izod Impact Tester – High-Precision Pendulum Testing Machine

NextGen's Class G – Single Column Charpy and Izod Impact Testing system provides a high level of rigidity and specimen testing capacity. This Charpy and Izod Impact tester has a minimum capacity of 150 J (111 ft/lbs) and a maximum capacity of 750 J (553 ft/lbs). The system comes standard with a digital display with software upgrade function for data plotting. The Class G impact system can also include automatic specimen feeding, cooling and heating systems as optional upgrades.

Class H - Servo-Motor Dual Column Charpy Impact Tester - 300J, 450J, 600J or 750J

NextGen's Class H – Servo-Motor Dual Column Charpy Impact Testing system offers of an exceptional combination of versatility and robust build. This impact system provides our most durable options designed with a dual column configuration. The system offers the ultimate versatility of testing 300J (212 ft/lbs), 450J (332 ft/lbs), 600J (442 ft/lbs) and a maximum of 750J (553 ft/lbs) capacities based on both Charpy and Izod test methods. The unit comes standard equipped with a servo motor and is designed to test at any preset angle. The unit comes standard with all the functions of our Class G tester as well as enhanced functionality upgrade of a force transducer inside the strikerwhich enables the determination of characteristic force, energy and displacement parameters such as pre-maximum force energy (Wm), the post maximum force energy, the general yield force (Fgy), the force at brittle fracture initiation (Fbf) and the arrest force (Fa).

Specimen Notching/Broaching Machine

NextGen offers an economical solution for Specimen notching and broaching for Charpy and Izod specimens. This certified system complies with ASTM ISO148, EN10045, ASTM E23, DIN 50115 standards. This automated, motorized solution is capable of preparing two specimens at any one given time up to 46 HRC. A variety of broaches are available for different geometries of notches.

Impact Specimen Cooling and Heating Temperature Chamber – GenChamber

NextGen offers a full range of impact specimen cooling and heating chamber designed to meet virtually all Charpy, Izod and Tensile Impact Testing requirements. NextGen's temperature chambers are a combination of user-friendliness, compact and robust build, offering the ultimate versatility of cooling and heating requirements.

Charpy/Izod Notch Verification Projector System NG-NPS-CIS

Enhance your material testing accuracy with our advanced Charpy/Izod Notch Verification Projector System NG-NPS-CIS.

DWT-1800 Computer Controlled Drop Weight Impact Testing Machine

DWT-1800 Impact Testing Machine is specifically designed for determining the non-plastic transformation temperature of ferritic steel.

Low-capacity Vertical Drop Weight Testers Up To 2000J NG-FWT1 & NG-FWT2

Discover NextGen's NG-FWT1 & NG-FWT2 low-capacity drop weight testers up to 2000J (1475 ft/lbs), designed for precise impact resistance testing of metals & non-metals.