Material testing is an integral part of the thermoplastic manufacturing process and is extensively used in the industry. There are three common measurement types: Melt Flow Index, Melt Flow Rate, and Melt Volume Rate.

The Melt Flow Index (MFI) is a parameter used in assessing thermoplastic polymers’ flow characteristics. It quantifies the mass of polymer, in grams, that flows through a capillary of specified dimensions under a set pressure within ten minutes. The measurement provides valuable insights into the best polymer grade for different processing applications for polymer processors.

Melt flow rate (MFR), often used interchangeably with MFI, indicates the material’s ability to flow under pressure, serving as an indirect measure of molecular weight. A higher MFR corresponds to a lower molecular weight, inversely proportional to melt viscosity under test conditions.

Melt Volume Rate (MVR) assesses polymer flow volume under specific conditions, offering insights into material flow behavior. Like MFI and MFR, MVR measurements are needed for selecting the appropriate polymer grade and optimizing processing conditions.

For all these measurements to be reliable and thermoplastics tested right, today’s testing equipment must be highly precise. Hence, we are going to review our innovative Melt Flow Indexer – designed to provide accurate and reliable measurements of MFI. This article discusses the features, technical specifications, and compliance standards of our Melt Flow Indexer. To fully understand the need for accurate and reliable measurements, we will also discuss measurements of MFI, MFR, and MVR.

The Basics of Measuring Parameters: MFI, MFR, and MVR

To gain a full understanding it is necessary to examine the primary measurements – MFI, MFR, and MVR.

Melt Flow Index (MFI)

The Melt Flow Index measures the mass of polymer, in grams, that flows through a standardized capillary under specific conditions of pressure and temperature within ten minutes. This measure is necessary for determining the appropriate polymer grade for specific processing applications, as specified in standards like ASTM D1238 and ISO 1133.

-

Purpose and Use: MFI evaluates polymers’ flow properties, helping manufacturers select materials that meet specific processing needs. A higher MFI indicates a polymer is easier to process but may have reduced mechanical strength.

-

Procedure: The polymer sample is heated to a set temperature and subjected to a defined load, forcing it through a die. The extruded polymer mass is then measured. Standard test conditions include 190°C for polyethylene and 230°C for polypropylene, with weights ranging from 2.16 kg to 5 kg.

-

Importance: A higher MFI indicates a lower molecular weight and viscosity, facilitating easier processing but potentially reducing mechanical strength. Conversely, a lower MFI suggests a higher molecular weight, which increases mechanical properties but may complicate processing.

Melt Flow Rate (MFR)

The Melt Flow Rate, or Melt Mass-Flow Rate, measures the mass of a polymer that flows through a die in a specified time under controlled temperature and pressure conditions. This measure is crucial for assessing polymer molecular weight and flow characteristics.

-

Purpose and Use: MFR evaluates thermoplastic polymers’ flow properties, indirectly indicating their molecular weight. It is important for determining the suitability of a polymer for different processing applications like injection molding and extrusion.

-

Procedure: A polymer sample is heated to a specific temperature and subjected to a defined load, forcing the material through a standardized die. The mass of the extruded polymer is measured over ten minutes, and the result is expressed in grams per ten minutes (g/10 min).

-

Importance: MFR is inversely proportional to the polymer’s molecular weight, meaning a higher MFR indicates a lower molecular weight and lower viscosity.

While MFR is closely related to MFI, it focuses on mass flow measurement. MFR is often used interchangeably with MFI but highlights mass flow under standardized conditions.

Melt Volume Rate (MVR)

The Melt Volume Rate measures the volume of polymer melt flowing through a die under defined conditions, expressed in cubic centimeters per ten minutes (cc/10 min).

-

Purpose and Use: MVR provides insights into polymers’ volumetric flow characteristics, required for understanding material behavior during processing. It is notably useful for comparing materials of different densities.

-

Procedure: The polymer is heated and extruded through a die under a specified load.The volume of the extruded polymer is measured to calculate the MVR. This helps in determining the ease with which the material can be processed into various shapes.

-

Importance: MVR is valuable for applications requiring precise volumetric control, such as injection molding and extrusion. It aids in optimizing processing conditions by providing a clear understanding of the material’s flow characteristics under specific conditions.

MVR focuses on volumetric flow rates, making it particularly useful for applications where material flow volume is more critical than mass flow. This distinguishes it from MFI and MFR, which are more focused on mass flow.

Introduction to the MFR450 Melt Flow Indexer

The MFR450 Melt Flow Indexer is a highly precise instrument designed to measure both melt flow rate (MFR) and melt volume rate (MVR), making it indispensable for quality control and research applications in thermoplastic material analysis. This device is excellent for assessing the viscous flow performance of various thermoplastic materials, making it suitable for factories, product quality testing stations, scientific research institutes, and related sectors.

The MFR450 Melt Flow Indexer is a highly precise instrument designed to measure both melt flow rate (MFR) and melt volume rate (MVR), making it indispensable for quality control and research applications in thermoplastic material analysis. This device is excellent for assessing the viscous flow performance of various thermoplastic materials, making it suitable for factories, product quality testing stations, scientific research institutes, and related sectors.

One of the standout features of the MFR450 is its wide measuring range, which spans from 0.1g/10min to 2000g/10min. This extensive range provides versatility, enabling the device to handle different testing requirements efficiently. Such a wide measurement capability ensures that the MFR450 can be applied to a broad array of industries and testing applications.

MFR450 design focuses on user convenience and operational efficiency. It features a compact structure complemented by a funnel-shaped mouth part, which simplifies polymer sample feeding. This design facilitates straightforward handling and minimizes the risk of errors during testing additionally promoting ease of use.

Furthermore, the MFR450 is equipped with a detachable die support plate, a critical feature that reduces sample accumulation and prevents jamming during operation. This significantly boosts device reliability and provides consistent, uninterrupted testing, improving overall operational efficiency.

Additionally, the MFR450 comes with a comprehensive range of accessories designed to meet all types of testing conditions. These accessories boost the device’s functionality and adaptability, allowing it to cater to different kinds of testing environments and requirements easily.

MFR450 Melt Flow Indexer Features

The MFR450 Melt Flow Indexer has a lot of features designed to maximize efficiency and accuracy in polymer testing. The main features of this product are:

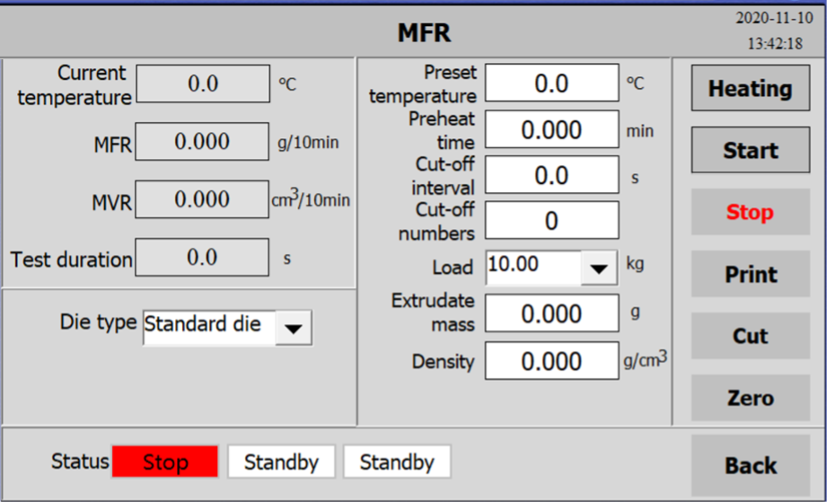

User-Friendly Interface

The operation interface is designed for user convenience. This functionality reduces testing complexity and enhances the user experience.

Method Flexibility

The MFR450 provides the flexibility to switch freely between the mass and the volume method. This intuitive test interface minimizes operational challenges, making testing easier.

High-Quality Construction

Key components, such as the cylinder and piston, are made from high-temperature-resistant, low-expansion-coefficient alloy materials. These parts are treated with a special surface heat treatment, offering resistance to high-temperature deformation, high hardness, and prolonged durability.

Precision Temperature Control

The device uses an Omron temperature control meter, providing accurate temperature control. This system ensures maximum temperature precision while maintaining temperature fluctuations within a minimal range.

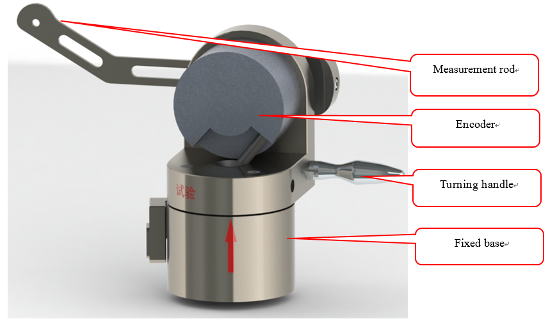

Optical Displacement Measuring Device

Incorporating an optical high-precision displacement measuring device, the MFR450 ensures precise and reliable data.

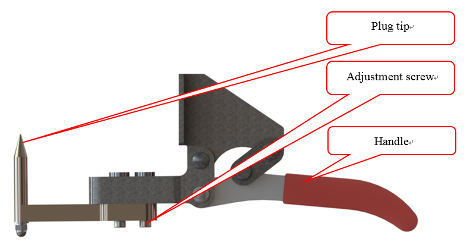

Melt Flow Indexer Automatic Cutting Device

The tester features an automatic cutting device driven by a miniature motor. Operators can set the cutting time, allowing the machine to cut at specified intervals accurately. This feature offers precise time control and minimal errors. Additionally, the cutting device can also be operated manually for increased simplicity and convenience.

Microcomputer Controller

Equipped with a microcomputer controller, the MFR450 can manage the entire testing process, including data processing and printing. The built-in microprinter allows for easy test results output, speeding up the data collection process.

Preheating Alarm

After reaching the pre-set preheating time, the device automatically sounds an alarm, prompting the user to place the weights, providing timely and accurate testing procedures.

Special Weight Box

The MFR450 includes a dedicated weight box with individual grooves to prevent accessory loss, resulting in efficient and organized testing procedures.

Structure of the MFR450 Melt Flow Indexer

Amongst its many outstanding features, the MFR450 Melt Flow Indexer is thoughtfully designed to offer precise and reliable testing of polymers. The following are some of its most important structural components:

Melt Flow Indexer Main Body

The MFR450 main body is constructed from high-quality alloy with a 1.5mm thickness. The equipment features a wide base structure, which provides stability during operation. This design aspect contributes significantly to the overall reliability and accuracy of the equipment.

Oven

The oven is cast as a single body from red copper, which provides excellent temperature uniformity and stability within the test area.

Encoder

At the core of the measurement component is an imported Baumer encoder, known for its high measurement accuracy and consistent data reliability.

Piston

The piston rod, weighing 325g, is nitrided to achieve exceptionally high hardness. This treatment improves piston durability and self-guided performance.

Specialized Die Plug

The MFR450 is equipped with a specialized die plug designed for materials with high melt flow rates. This feature ensures that the equipment can handle a broad spectrum of polymer viscosities effectively.

Micro Printer

The built-in micro printer allows direct printing of test parameters or results immediately after the test is completed.

Cutting Motor Reliability

The MFR450 Melt Flow Indexer cutting motor exhibits high repeatability, ensuring consistent performance across multiple tests. Additionally, a self-locking function is integrated into the program to prevent external interference from affecting test results.

Die Plug

The die plug is a component designed to facilitate the testing of samples with high melt flow rates. Positioned on the side of the oven, it features a red handle that allows the die outlet to be efficiently obstructed, preventing rapid sample loss. This functionality enables swift movement of the die plug before the test commencement, providing precise control over sample and testing conditions.

Technical Specifications of the MFR450 Melt Flow Indexer

Having familiarized ourselves with the features of the MFR450, it is now time to review the technical specifications. This will enable us to understand the full capabilities of this advanced tool in precise numerical terms.

-

Model: MFI452

-

Type: B

-

Temperature Range: 50~450°C

-

Temperature Variation in 4 Hours: ≤±0.5°C

-

Maximum Permitted Deviation from Required Test Temperature (75mm above the top surface of the standard die): ≤0.25°C

-

Temperature Resolution: 0.1°C

-

Measurement Range:

-

Method A: 0.1~50 g/10min

-

Method B: 0.1~2000 g/10min

-

-

Displacement Error: ≤±0.02 mm

-

Displacement Resolution: 0.003 mm

-

Displacement Measurement Range: 25.5 mm

-

Interval for Temperature Recovery After Changing Testing Samples: ≤3 minutes

-

Resolution of Timing: 0.01 second

-

Inner Diameter of Die: Φ2.095±0.005 mm

-

Inner Diameter of Cylinder: Φ9.550±0.007 mm

-

Weights Accuracy: ≤±0.5%

-

Possible Combinations of Standard Weights: 325 g, 1200 g, 2160 g, 3800 g, 5000 g, 10000 g, 21600 g

-

Dimensions: 13.80″ x 17.15″ x 26.0″ / 350 x 435 x 660 mm

-

Weight: 71 lbs / 35 kg

-

Power Supply: 220V±10%, AC, 50Hz, 1.5kW

Standard Configurations of the MFR450 Melt Flow Indexer

The MFR450 Melt Flow Indexer is equipped with a comprehensive set of standard configurations for a wide selection of polymer testing applications. A list of the standard equipment and accessories that come with each unit can be found below:

-

Main Machine: Includes a built-in 7” touch screen, micro-printer, cylinder, temperature controller, heater, and cutting blade, all integrated into one set. This assembly makes sure that all the necessary components are readily accessible and designed to work smoothly together.

-

Piston Head: Treated with nitriding to achieve a Vickers hardness of at least 600HV, ensuring durability and resistance to wear under operational conditions.

-

Standard Die: Precision-engineered with a diameter of Φ2.095±0.005mm and a length of 8±0.025mm, also treated with nitriding to reach a Vickers hardness of at least 700HV. This high level of hardness guarantees die integrity even under repeated use and high-pressure conditions.

-

Combined Weights: A set of weights including 325g, 1200g, 2160g, 3800g, and 5000g. These are used to apply different levels of pressure during testing, allowing flexibility in simulating different industrial conditions.

-

Comprehensive Cleaning and Handling Tools: Includes a compressing rod, barrel cleaning brush, barrel cleaning rod, die cleaning tool, sample feeder, funnel, bubble level, scraper, tweezers, cutting blade, fuse, and a Go-No-Go gauge.

Optional Accessories for the MFR450 Melt Flow Indexer

In addition to its standard configuration, the MFR450 Melt Flow Indexer can be further customized with a selection of optional accessories, designed to expand its functionality and adaptability to specific testing requirements. These include:

Encoder for MVR Test

The optional encoder is an accessory for MVR tests. Positioned at the top of the measuring rod, it directly contacts the piston rod, transmitting real-time displacement data. The encoder measures the vertical displacement of the piston rod, converting this movement into signal pulses. These pulses are processed by the Programmable Logic Controller (PLC), which outputs the instantaneous displacement of the piston rod. The encoder can be adjusted to different positions according to the test methods, providing flexibility to meet different testing requirements.

Additional Weights for Different Testing Cases

-

10kg Load: Includes an additional 5000g dead weight, allowing for increased pressure application during testing. Suitable for polymers requiring more force.

-

21.6kg Load: Comprises three more 5000g weights and one additional 1600g dead weight, offering an extended range of load configurations for testing under different conditions and standards.

Specialized Dies for Specific Requirements

-

Φ1.05 Die: Designed for finer, more precise extrusions, this die is ideal for testing polymers with lower viscosity or those requiring higher detail in flow rate analysis.

-

Φ1.18 Die: Slightly larger than the standard, this die is suitable for a greater variety of polymer types and is particularly useful for materials with higher melt flow rates.

Standards Compliance of the MFR450 Melt Flow Indexer

In conclusion, our product complies with all required thermoplastic testing standards. The MFR450 Melt Flow Indexer meets a number of international standards, guaranteeing its capability to address high-quality and performance needs. Listed below is an overview of each standard it complies with:

ISO 1133

ISO 1133 defines methods for determining thermoplastic melt mass- and volume-flow rates. This standard includes procedures for measuring flow rates under controlled conditions so that MFR450 measurements are consistent with global testing practices. The standard also details different methods, such as for materials sensitive to a time- or temperature-dependent history.

ASTM D1238

This American standard specifies test methods for measuring thermoplastic flow rates, similar to ISO 1133. It is integral to assessing material quality through melt flow behavior, offering a detailed procedure for conducting MFR and MVR tests.

ASTM D3364

The ASTM D3364 standard focuses on testing the flow rates of poly(vinyl chloride) (PVC) compounds. It offers a specialized approach to assessing melt viscosities under conditions that closely resemble operational shear rates. This method increases the ability to evaluate PVC’s processing characteristics by analyzing its response to thermal, shear, and rheological stresses.

BS 2782

The BS 2782 standard offers a comprehensive suite of test methods for plastics, applicable to a broad range of products from molding and extrusion compounds to semi-fabricated products like sheets and rods. It focuses on ensuring that the testing methods provided cater to different manufacturing conditions while being adapted to specific conditions.

DIN 53735

The German standard DIN 53735 covers plastic testing procedures, similar to ISO and ASTM standards. It focuses on the accurate and repeatable measurement of material properties under specified conditions.

JIS K7210

This Japanese standard outlines procedures for testing plastic physical properties, making sure products meet the high-quality standards necessary for consumer safety and manufacturing consistency.

Excellence in Thermoplastic Testing with the MFR450 Melt Flow Indexer

Throughout this comprehensive review, we have explored the multifaceted capabilities of the MFR450 Melt Flow Indexer, a leading tool designed for precision thermoplastic testing. This instrument stands out for its ability to accurately measure Melt Flow Index, Melt Flow Rate, and Melt Volume Rate. These measurements provide valuable data that helps manufacturers choose the correct polymer grades for various applications.

The MFR450 is engineered with user-focused features such as a user-friendly interface, method flexibility, and high-quality construction, which includes components made from specialized alloys for high-temperature resistance and durability. Its precision temperature control and innovative optical displacement measuring device further optimize its performance, providing reliable and repeatable results. Additionally, the indexer is equipped with a range of optional accessories that extend its functionality, making it adaptable to a wide array of testing requirements.

Complying with international standards such as ISO 1133, ASTM D1238, and ASTM D3364, the MFR450 guarantees that all testing is up to global benchmarks. This makes it a key asset for industries requiring rigorous material testing protocols. Its extended measurement range and the inclusion of advanced testing features like the automatic cutting device and microcomputer controller demonstrate its readiness to meet modern material testing challenges.

NextGen Material Testing Inc. is dedicated to helping you make the right choice, whether you need material testing services or testing equipment. Our team is ready to help you select the right tools to meet your specific requirements. For more information, you can request a quote online or contact us directly. We are here to help make sure that your testing processes are efficient, accurate, and aligned with industry-leading standards.