Rubber Testing Equipment

Standards

Certified

Description

The RPA Ultra is a closed cavity moving die rheometer that offers unconstrained oscillation strain and a frequency breakthrough of up to 100 Hz thanks to a rotating lower die. The advanced RPA device measures the dynamic and static characteristics of raw rubber compounds and elastomers throughout the curing process. Another technological advance is the increased shear rate range, which now spans 0.001 to 500 1/s. A high shear rate might be used to imitate the extrusion process in a genuine production setting. Learn more about rubber testing equipment here.

Due to the innovative engineering of the advanced rubber process analyzer, the sealed biconical dies and their capacity to significantly reduce slippage during a testing process. the RPA Ultra advanced rheometer can excel in measurement repeatability and reproducibility. As a terrific addition to the RPA Ultra, the new BareissOne software makes your testing process much simpler to manage and the findings much clearer. Click here if you want to check more Rubber Testing equipment from NextGen Material Testing.

Advanced Rubber Process Analyzer Features:

- High grade sheet material solid construction

- Film cartridge for test cavity continuous feeding

- No more strain cap with a rotatable lower die

- Easy mobility using retractable casters

- Rubber process analyzer is equipped with 12“ touch display for easy user interface with a clear set of menus to provide navigation through all the available function

- A tray that can load multiple samples automatically

|

|

|

| RPA Ultra Rotational Lower Die | RPA Automatic Sample Loading System | RPA Ultra Film Catridge |

RPA Ultra Additional Options

- Moving die rheometer. A fixed upper die and a fully rotating lower die offering unbounded oscillation strain

- Automatic sample loading mechanism available as an option to increase testing capacity of the RPA

- Film catridge for quick and simple roll reloading

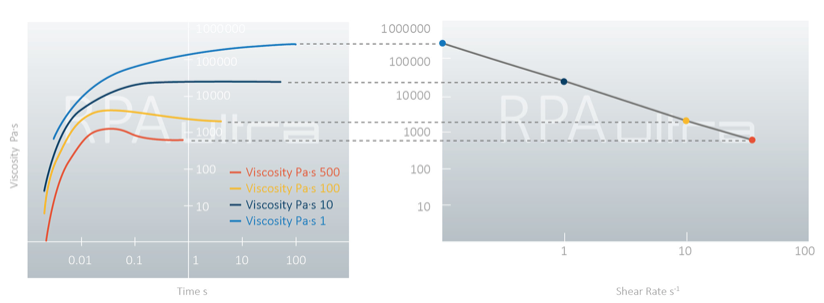

RPA Ultra Steady Share Viscosity

RPA Steady Share Viscosity Graph

One of the most crucial features for defining the process parameters for extrusion and injection molding is the constant shear viscosity. It is essential for understanding the manufacturing process of an unvulcanized rubber compound. The RPA Ultra offers the operator two test modes: dynamic and sustained shear, thanks to its rotating bottom die with limitless strain.

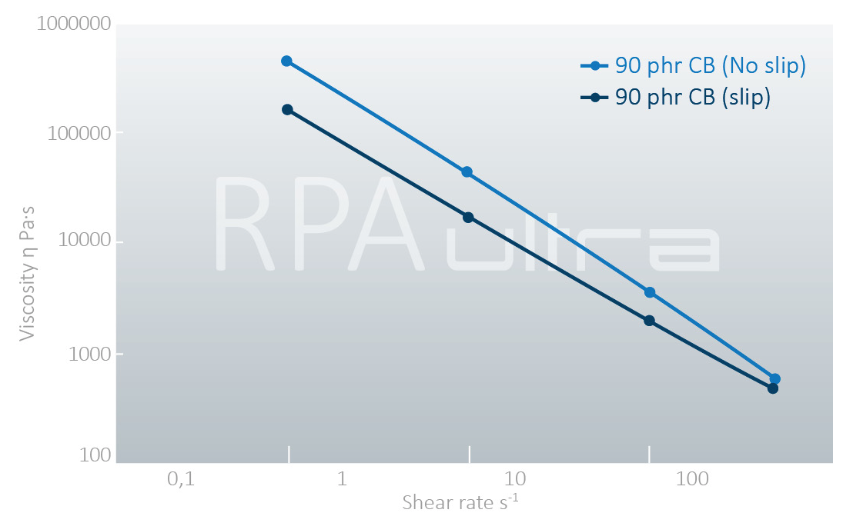

Wall Slip

Rubber Process Analyzer Wall Slip Graph

The problem of Wall Slip is a severe obstacle in producing rubber compounds. Slippage can happen, for instance, between the extruder wall and the flowing material and is a rheological event. As an alternative, we provide a defined polished die set in place of the upper die. Thus, this enables the execution of Wall Slip tests in conjunction with internal controlled pressure.

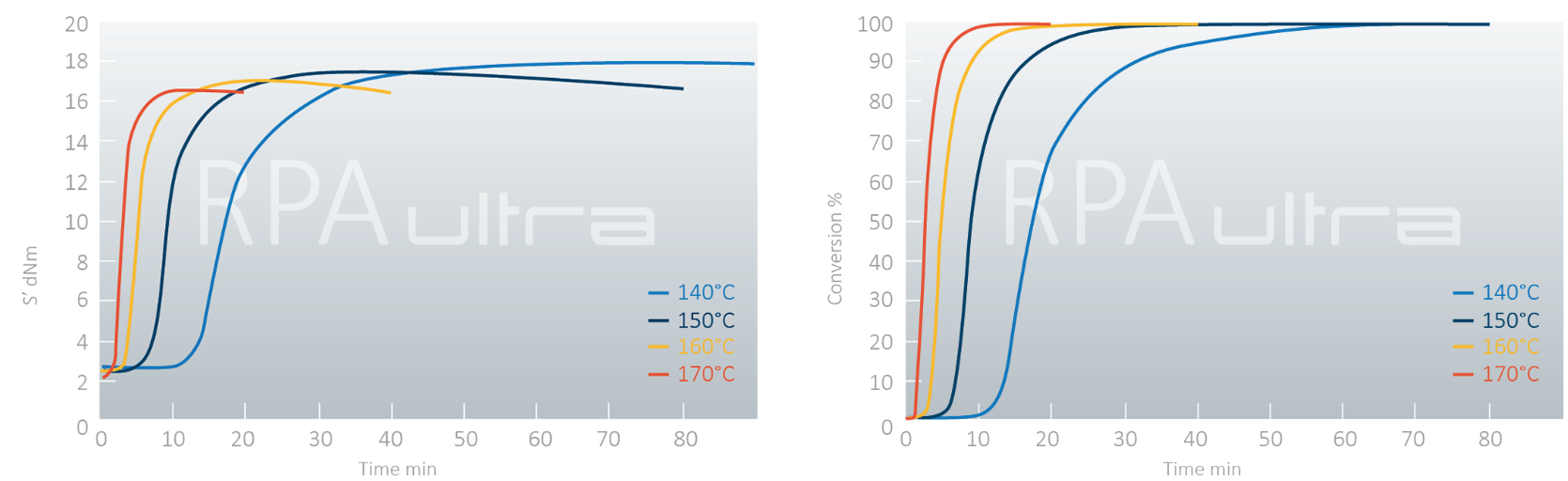

Rubber Process Analyzer Isothermal Test

RPA Isothermal Test Graph

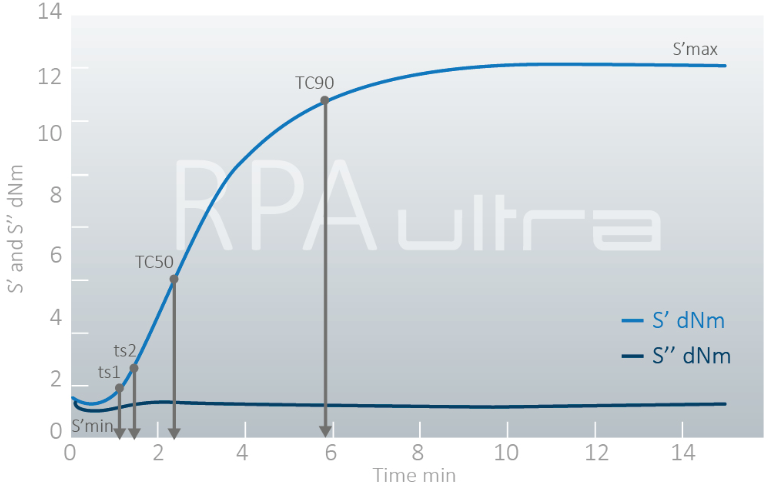

The isothermal cure tests on rubber compounds are among the most common and essential studies done. The BareissOne software determines all significant test parameters, including maximum and lowest torque, TC values, reaction time and rate, etc., and makes them available to the user in tabular or/and graphical form for additional analysis.

RPA Ultra Non-Isothermal Test

RPA Ultra Non-Isothermal Test Graph

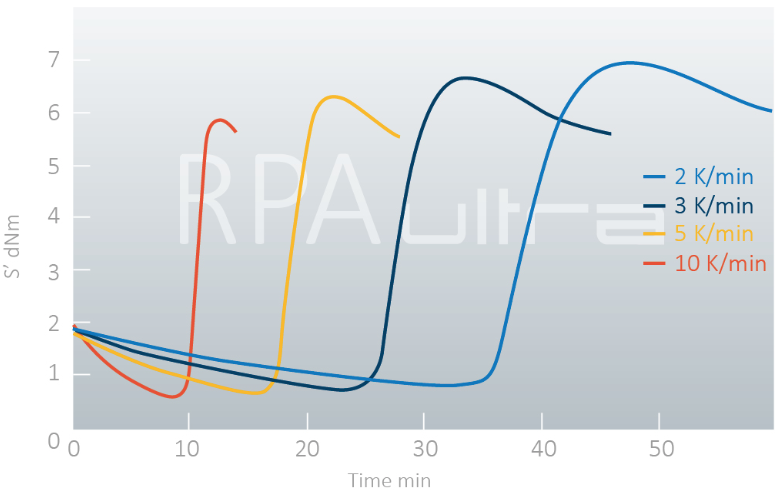

Non-isothermal measurements (temperature sweep) are frequently performed at various heating rates to assess a sample's behaviour over a wide temperature range. The BareissOne program includes a module for kinetic calculations made possible by this measurement at various heating rates.

Moving Die Rheometer Kinetics

RPA Moving Die Rheometer Kinetics Graph

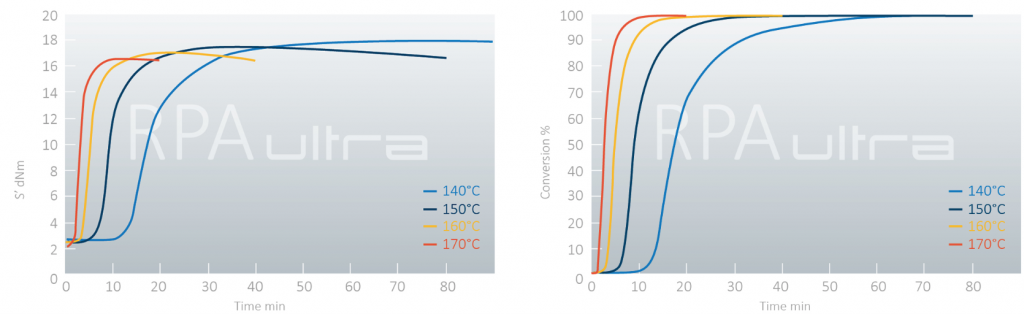

An isothermal test provides data for each temperature, including incubation duration, reaction sequence, and conversion rate constant. The computation complies with the DIN 53529 specification. Next, the activation energies of the incubation and the conversion can also be determined using the incubation period and the conversion rate constant at least three different temperatures. These are crucial variables for calculating the test specimen's heating time and are also used in the production process.

Frequency Sweep

RPA Ultra Frequency Sweep Graph

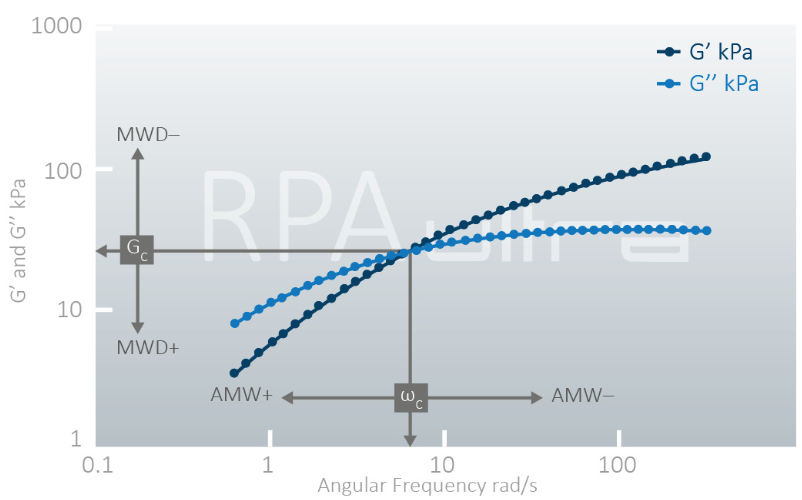

The user thoroughly follows the viscoelastic behaviour and molecular structure by analyzing a sample over a broad range of frequencies (molecular weight and molecular weight distribution). Moreover, due to the sample's frequency-dependent behavior, several viscoelastic parameters, including complex modulus, elastic modulus, loss modulus, complex viscosity, phase angle, etc., are calculated at each frequency.

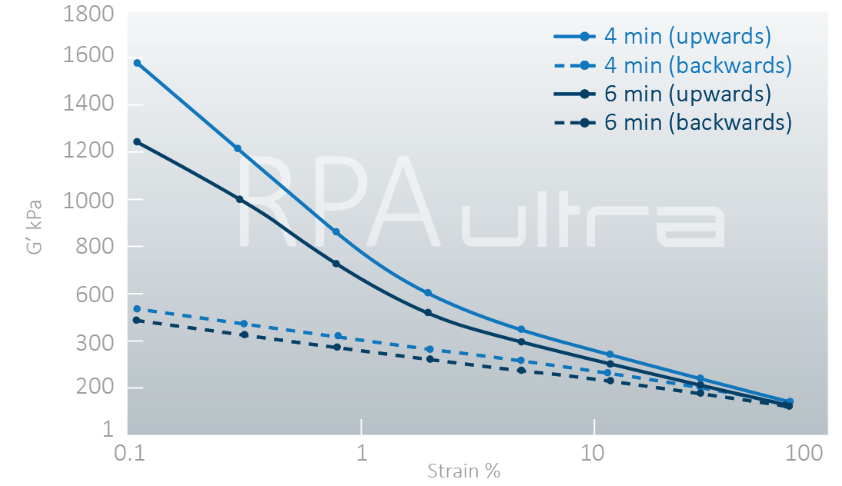

RPA Ultra Strain Sweep

RPA Ultra Strain Sweep Graph

A specimen's behaviour can be seen when it is measured over a broad strain range, such as the linear viscoelastic range (LVE) up to large amplitude oscillatory shear (LAOS). The Payne test, used to analyze the (filler/polymer) filler networks at low strain amplitudes, provides the details on the filler content and filler dispersion levels.

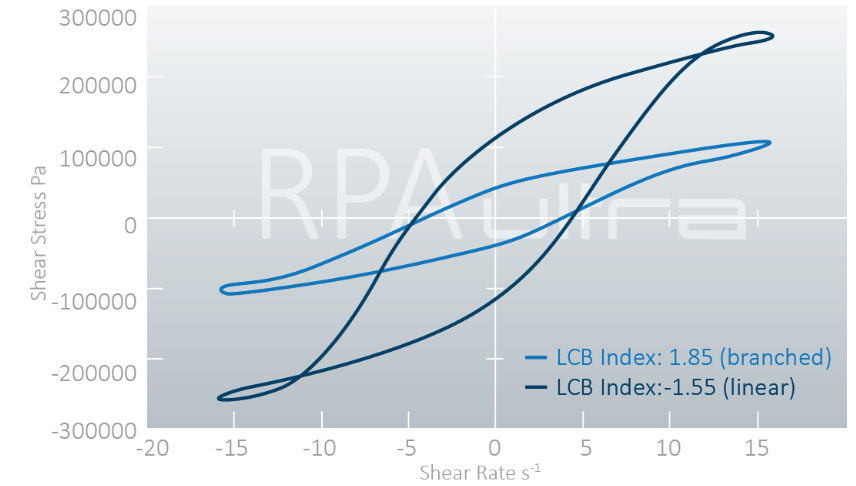

Large Amplitude Oscillatory Shear (LAOS)

RPA Ultra Large Amplitude Oscillatory Shear (LAOS) Graph

LAOS is a strain sweep used to examine and assess a sample's nonlinear viscoelastic behaviour at relatively large amplitudes.

The polymer architecture of a substance—linear or branched polymer—determines its nonlinear behaviour. For FT- Rheology, the LAOS data are also utilized. Using the harmonic spectrum from Fourier analysis, the LCB index (Long Chain Branching) or the Q parameter is calculated (FFT).

Advanced Rheometer Matrix-Test

One parameter (frequency or strain) is held constant while the other parameter (frequency or strain) is adjusted over a range in the frequency and strain sweeps previously mentioned. On top of that, due to the flexibility of matrix testing, which enables the user to alter both the frequency and strain during a sweep, more data can be obtained from a single measurement.

RPA Ultra Technical Specifications

| RPA Ultra - Advanced Rubber Process Analyzer Rheometer | |

| Max. shear rate in rotation | 500 1/s |

| Max. shear rate in oscillation | 100 1/s |

| Max. ramp rat | 1.33°C/s-> 80°C/m |

| Max. cool rat | 0.5°C/ |

| Die config | Sealed die, biconical and plate-plate |

| Drive system | High dynamic torque motor, High resolution controller |

| Oscillation frequency | 0.001 to 100 Hz |

| Oscillation strain | +/- 0.001° to unlimited, ‚+/- 0.014% to unlimited -> rotational |

| Temperature range | Ambient to 235°C |

| Measured data |

Torque, temperature, frequency, strain; Optional: Normal force, die pressure |

| Caculated data |

S ́, S ̋, S*, G ́, G ̋, G*, tan |

| Die gap |

0.45 mm nominal |

| Sample volume |

4.5 cm^2 |

| Electrical |

400V/16A |

| Closing system |

Soft closing to prevent foil rips and damage of test samples, optionally variable closing force |

| Torque range |

0.0001 to 250 dNm |

| Normal force / Pressure (opt) |

up to 10 kN |

| Subroutines |

Isothermal, Non-Isothermal, Timed, Temperature Sweep, Strain Sweep, Frequency Sweep, Steady Shear, Relaxation, Hysteresis, Tension Test, LAOS,Matrix Test |

| Interface |

Ethernet |

| Data points |

Over 3500 data points available for each static subtest Including S‘ Min, |

| Pneumatics |

min. 4.5 Bar (11.5 kN) / 60 psi |

FAQs

The rubber items will first undergo internal and external cleaning. Prior to submitting the rubber products to lab testing and inspections, this phase makes sure that any unwelcome or unclean components have already been removed. The rubber goods are first cleaned, and after that, they are visually examined. The condition of the products can be determined visually. As they already provide certain threats to the users, those that already have cracks, punctures, and scratches are excluded from further testing.

Electrical testing comes after rubber testing. The maximum electrical voltage that the rubber products can withstand is checked in this step. Testing is not conducted on rubber items that cannot operate at the appropriate electrical voltage because they would quickly catch fire from the heat. To determine whether the rubber materials can withstand the strain, fracture propagation, and crack nucleation, they are tested in various operating settings and severe fatigue scenarios.

The rubber products are then certified and date-stamped to show that numerous testing procedures have been completed successfully. Finally, the certified rubber products are packaged and delivered.

Click here to request information on lead PO time for NextGen’s RPA Ultra - Advanced Rubber Process Analyzer Rheometer.

Today, a variety of industries have the choice to make the most of a wide range of materials when making their components and products. Rubber is one of the materials they frequently use.

Due to its many benefits, rubber is one of the most frequently used materials. For starters, rubber products have extraordinarily high tensile and tear strengths, making them appropriate for the majority of industrial and even household uses. Rubber components and goods are renowned for their resistance to friction and abrasion. Even harsh temperatures are no match for them.

Testing rubber products ensures that they can be used safely and determines whether or not they are compatible with particular uses. Project locations and manufacturing facilities that prioritize defective or incompatible rubber materials risk catastrophic failures. Testing them can prevent injuries and damage to adjacent individuals as well as to nearby items and equipment. By doing this, users can also gain extensive knowledge about the rubber materials that are ideal for their processes.

Click here to obtain a personalized quote for NextGen’s RPA Ultra - Advanced Rubber Process Analyzer Rheometer.

ODR (oscillating disc rheometer) and MDR (moving die rheometer) are the two types of rheometers used in the rubber business. However, they serve similar functions.

We close the rheometer after placing a piece of raw, unvulcanized rubber within its cavity. The type of compound and the crosslinking technique determine the temperature at which the rubber compound is exposed to pressure (vulcanization). Inside the cavity of the ODR rheometer is a biconical rotor that oscillates left and right by an average of 3 degrees. The sensor measures the resistance that the rubber exerts against the rotating rotor during the vulcanization process.

The stiffness or viscoelastic qualities of the compound determine the torque needed to cause oscillation. Thus, a degree of vulcanization as a function of time and temperature is measured by the rheometer. A vulcanization curve or rheometric curve is represented by the graph of the torque curve on the rotor as a function of time.

Click here to obtain a personalized quote for NextGen’s RPA Ultra - Advanced Rubber Process Analyzer Rheometer.

Testing of polymers, like rubber, is done to determine the type of polymer, physical characteristics, mechanical properties, and crucial tests like low temperature testing down to -60°, ozone crack test, abrasion test, tensile test, compression test, etc.

Raw rubber compounds do not show any elastomeric characteristics. The rubber compounds must go through the vulcanization process in order to achieve this, which requires the molecular chains to be crosslinked together. When rubber compounds are being vulcanized, a rheometer is a laboratory tool used to measure their viscoelastic qualities.

ODR (oscillating disc rheometer) and MDR (moving die rheometer) are the two types of rheometers used in the rubber business. However, they serve similar functions.

The compound becomes harder throughout the vulcanization process, which takes place in the cavity. Increase both the force and the torque on the rotor at the same time. Because the rubber has non-Newtonian characteristics, it also has an elastic and viscous component. The degree of vulcanization directly correlates with the shear forces.

Click here to obtain a personalized quote for NextGen’s RPA Ultra - Advanced Rubber Process Analyzer Rheometer.

What makes NextGen’s RPA Ultra - Advanced Rubber Process Analyzer Rheometer stand out on the market?

Many manufacturing businesses use rubber property testing as a critical component of their delivery of our daily consumables, including apparel, a variety of seals (leak protectors), production conveyor belts, and even stationary utensils. The characteristics of rubber elastomers are both special and advantageous. These compounds are virtually often used, making quality testing of them important because they are fundamental to both our daily lives and the production processes.

There are numerous categories for rubbers, including Natural Rubbers, Silicones, and many in between, including Nitrile, Hypalon, and Styrene Butadiene. These are categorized according to their physical characteristics, which include things like resistance to things like oil, heat, sunlight, ozone, and flames, as well as things like tensile, elongation, water, oxygen, and abrasion. Rubbers are utilized as seals in many different manufacturing processes to create a leak-proof environment for materials like chemicals, oils, fuels, and other high-temperature elements.

NextGen’s RPA Ultra - Advanced Rubber Process Analyzer Rheometer is :

- German manufactured

- Highest Accuracy and Repeatability

- Industry Certified

- Complete Calibration Solution

- Free Proof of Concept

- Custom Turnkey Solution Availability

Click here to obtain a personalized quote.

The incredibly dependable rubber automation system is compatible with BrassOne rotorless curemeters and rheometers. Rubber samples may be tested automatically using this carousel-based autosampler. The automated rheometer transforms into a highly integrated component of the factory control process when combined with the Scarabaeus Software's automated analysis, statistics, and control chart generation. In a research or product development context, this increased data flow is especially crucial for screening several formulations.

A suction transfer system is used to convey samples from the autosampler tray to the test position. Uncured rubber from a variety of sources can be used because this technology is very forgiving of non-ideal sample geometries. In order to maintain production, samples are loaded into a carousel, where additional specimens may be added even as another test is running. A suction transfer system is used to convey samples from the autosampler tray to the test position. Uncured rubber from a variety of sources can be used because this technology is very forgiving of non-ideal sample geometries. In order to maintain production, samples are loaded into a carousel, where additional specimens may be added even as another test is running.

NextGen’s RPA Ultra - Advanced Rubber Process Analyzer Rheometer has Soft closing to prevent foil rips and damage of test samples, optionally variable closing force.

Click here to obtain a personalized quote.

To seal the sample effectively and consistently, all NextGen rotorless rheometers and curemeters use a high-pressure pneumatic system. During gap closure, the high-capacity pneumatic system provides up to 8 bar of nominal pressure on the sample. Mechanical bearings are used to guarantee efficient load transfer from the system to the sample without incurring load frame losses. Direct measurements and records are made of the actual sealing pressure. The test specimen is tightly contained by this high-pressure automated sample containment, which also eliminates operator dependence. For materials that experience positive or negative volumetric changes during curing as well as extremely stiff materials like carbon-filled fluoroelastomers, this sealing process is crucial.

The test specimen is tightly contained by this high pressure automated sample containment, which also eliminates operator dependence. For materials that experience positive or negative volumetric changes during curing as well as extremely stiff materials like carbon-filled fluoroelastomers, this sealing process is crucial.

NextGen’s RPA Ultra – Advanced Rubber Process Analyzer Rheometer is manufactured in Germany.

Click here to obtain a personalized quote.

The RPA Ultra is the ideal solution for labs that require extra testing capacity since it offers the best quality rubber rheometer data on a user-configurable platform. All of the same premium features are present in the RPA Ultra, including the ultra-rigid test frame, variable direct drive motor, exclusive ultrahigh-stiffness torque transducer, precise temperature control with optional cooling, an available autosampler, potent control and analysis software. The fundamental model enables all MDR standard cure testing (ASTM/DIN/ISO) by providing a broad continuous strain range and user-defined frequency. Additionally, any or all of the RPA Ultra's functions, such as variable strain, frequency, stress relaxation, advanced oscillation, LAOS testing, and sample pressure monitoring, can be configured into the RPA Ultra or upgraded to accommodate them.

- Exclusive ultra-high-stiffness, wide torque range, high sensitivity, variable direct drive motor with high resolution for exact strain control;

- Stiff test frame for precise data that is devoid of conformity

NextGen’s RPA Ultra – Advanced Rubber Process Analyzer has a film cartridge.

Click here to obtain a personalized quote.

Does NextGen’s RPA Ultra – Advanced Rubber Process Analyzer have an Automatic Sample Loading System?

The processing and ultimate characteristics of rubber, polymer, and elastomer materials are assessed by rubber testing. Rubber is utilised in goods that must endure deformation and preserve their original shape in automotive, industrial, consumer, and construction applications. Rubber is used in various products that profit from its special material features, from tough tyres to rebounding kickballs.

Rheometers, curemeters, and viscometers are used during rubber testing to enhance production and end-use qualities. Important properties of rubber, such as minimum and maximum viscosity, scorch time, and conversion time, are measured by rubber rheometers. Under isothermal and non-isothermal test circumstances, rubber compounds' curing profiles are measured by curemeters at constant, user-defined strain and frequency. Rubber polymers and compounds are tested for standard viscosity, scorch resistance, and stress relaxation under isothermal test conditions using viscometers.

NextGen’s RPA Ultra – Advanced Rubber Process Analyzer has an Automatic Sample Loading System.

Click here to obtain a personalized quote.

The MDR one Moving Die Rheometer (MDR) is a rotorless curemeter that is dependable, accurate, and simple to use, making it ideal for routine and standards-based testing of rubber curing. The MDR one is set up to measure rubber compound curing profiles in both isothermal and non-isothermal test environments while maintaining constant user-defined strain and frequency. Seal biconical dies that adhere to all pertinent ASTM, ISO, and DIN standards are used in the MDR one. The innovative design makes it the perfect platform for QC or R&D settings thanks to its direct drive motor, precision temperature control with optional cooling, and user-friendly Scarabaeus Software for control and analysis. A multi-functional transducer for sample pressure measurement, such as gas production in cellular rubber composites, is an optional configuration for the MDR one.

NextGen’s RPA Ultra – Advanced Rubber Process Analyzer is equipped with rotational lower die.

Click here to obtain a personalized quote.

The RPA Ultra is a closed cavity moving die rheometer that, as a result of a revolving bottom die, provides unrestricted oscillation strain and a frequency breakthrough of up to 100 Hz. Throughout the curing process, the sophisticated RPA gadget measures the dynamic and static properties of raw rubber compounds and elastomers. A further development in technology is the expanded shear rate range, which currently covers 0.001 to 500 1/s.

Owing to the sophisticated rubber process analyzer's creative engineering, sealed biconical dies, and ability to reduce slippage during a testing procedure considerably. When it comes to measurement reliability and reproducibility, the RPA Ultra advanced rheometer can shine. The new BareissOne software is a fantastic addition to the RPA Ultra since it makes managing your testing process much easier and the results much clearer.

Click here to obtain a personal quote.

Using blowing agents to generate a cellular design frequently improves the density and mechanical performance of the final product. During their breakdown and the curing reaction, these blowing agents produce gas. It is possible to characterize both curing and blowing in a single experiment by measuring sample pressure during the curing reaction and quantifying the blowing reaction. In order for the final result to have the proper cell architecture, these two processes must be balanced.

Processing greatly affects the van der Waals interactions, which enhance modulus in rubber packed with carbon black. In this illustration, identical samples are taken out of the mixer and milled for various amounts of time. Up to 8 minutes of milling, the carbon network structure was reduced with each additional minute of milling, after which the modulus did not vary with milling time. This gives important details on how much milling is required to get a consistent working material.

NextGen’s RPA Ultra – Advanced Rubber Process Analyzer pneumatic parameters are min. 4.5 Bar (11.5 kN) / 60 psi.

Click here to obtain a personal quote.

One of the most common and important tests performed on rubber compounds are the isothermal cure tests.

Experiments with isothermal curing are essential for manufacturing rubber and elastomers. BrassOne rubber rheometers offer highly accurate data that is easy to interpret. It is simple and automatic to determine every significant feature, including minimum and maximum viscosity, scorch time, and conversion time. For comparison or alternative studies, the data can alternatively be handled completely pictorial.

The RPA may conduct non-isothermal cure tests in addition to the widely used isothermal cure techniques. These experiments are especially useful for imitating non-isothermal industrial processes because they may be designed to follow almost any temperature profile. To provide a more comprehensive set of material data, non-isothermal curing investigations can be combined with isothermal testing like strain and frequency sweeps before or after cure.

Here are NextGen’s RPA Ultra – Advanced Rubber Process Analyzer data points:

Over 3500 data points available for each static subtest Including S‘ Min,

S‘ Max, TS 1, TS 2, TC 10,

TC 30, TC 50, TC 90

Integrated, automatic reporting features for dynamic tests

Click here to obtain a personal quote.

One of the most effective ways to comprehend the molecular structure of a material is to measure its frequency-dependent viscoelastic characteristics. A frequency sweep can reveal details about the molecular weight distribution and average molecular weight (crossover frequency) (crossover modulus).

Standard test procedures frequently specify that a single strain and frequency value (0.5°, 1.67 Hz) be used for all materials, yet these are not necessarily the best circumstances for all materials. In the current example, the test material is isothermally cured five times each at each of three deformation amplitudes. The experimental variability is rather wide at the standards of 0.5° and 0.4°. This is because the strains used in these studies are greater than the material's linear viscoelastic limit. Testing at a lower amplitude (0.3°) yields reliable results with much-increased reproducibility.

NextGen’s RPA Ultra – Advanced Rubber Process Analyzer subroutines are Isothermal, Non-Isothermal, Timed, Temperature Sweep, Strain Sweep, Frequency Sweep, Steady Shear, Relaxation, Hysteresis, Tension Test, LAOS,Matrix Test.

Click here to obtain a personal quote.

What is the Normal force / Pressure (opt) of NextGen’s RPA Ultra – Advanced Rubber Process Analyzer?

A certified torque calibration instrument simplifies torque calibration. This feature enables the user to calibrate the instrument themselves, improving data accuracy and efficiency while decreasing the need for service engineers to do the calibration.

A patented broad-range stiff torque transducer is advantageous for the RPA Ultra. This durable, non-compliant tool accurately and precisely measures the greatest variety of torques. The observed torque, modulus, and viscosity values are now much more accurate and precise.

A high-pressure pneumatic system is used by the RPA Ultra to reliably and properly seal the sample. During gap closure, the high-capacity pneumatic system applies up to 8 bars of nominal pressure. Mechanical bearings are used to guarantee efficient load transfer from the system to the sample without incurring load frame losses. Direct measurements and records are made of the actual sealing pressure. This high-pressure automated sample containment tightly contains the test specimen, which eliminates operator dependence. This sealing process is crucial for materials that experience positive or negative volumetric changes during curing, as well as extremely stiff materials like carbon-filled fluoroelastomers.

NextGen’s RPA Ultra – Advanced Rubber Process Analyzer Torque Range is 0.0001 to 250 dNm

Click here to obtain a personal quote.

A certified torque calibration instrument simplifies torque calibration. This feature enables the user to calibrate the instrument themselves, improving data accuracy and efficiency while decreasing the need for service engineers to do the calibration.

A patented broad-range stiff torque transducer is advantageous for the RPA Ultra. This durable, non-compliant tool accurately and precisely measures the greatest variety of torques. The observed torque, modulus, and viscosity values are now much more accurate and precise.

A high-pressure pneumatic system is used by the RPA Ultra to reliably and properly seal the sample. During gap closure, the high-capacity pneumatic system applies up to 8 bars of nominal pressure. Mechanical bearings are used to guarantee efficient load transfer from the system to the sample without incurring load frame losses. Direct measurements and records are made of the actual sealing pressure. This high-pressure automated sample containment tightly contains the test specimen, which eliminates operator dependence. This sealing process is crucial for materials that experience positive or negative volumetric changes during curing, as well as extremely stiff materials like carbon-filled fluoroelastomers.

NextGen’s RPA Ultra – Advanced Rubber Process Analyzer Torque Range is 0.0001 to 250 dNm

Click here to obtain a personal quote.

In the RPA Ultra, a strong direct drive motor applies precise deformation. The accurate application of a constant rate, step, or periodic deformation is essential for a high-quality rheological or dynamic measurement. Start-up lags, compliance issues, and translational losses present in clutch- or belt-driven designs are not present in direct drive systems. The RPA elite's improved motor design makes sure that the sample is always subjected to the most precise and repeatable deformations.

In any rubber rheometer, the RPA Ultra uses the highest ratio of continuously changeable frequency and amplitude. This gives crucial, pertinent information like:

- High-filled rubbers' linear viscoelastic response to low strain

- High-strain behaviour under harsh processing and use circumstances

- Behaviour of terminal materials at low frequencies

- Response to high-frequency measurements of high-speed deformations

The RPA Ultra die surfaces have radial serrations that are strategically placed to ensure constant sample contact even at the highest strain levels. To improve sample release and eliminate the need to clean dies between experiments, polyester or polyamide films may be utilized.

NextGen’s RPA Ultra – Advanced Rubber Process Analyzer sample volume is 4.5 cm^2.

Click here to obtain a personal quote.

The sealed cavity biconical die design, which is the industry standard, is used in the RPA Ultra rotorless shear rheometer. The dies are made of sturdy, highly rigid, low thermal expansion stainless steel to reduce system compliance and stop temperature-related gap variations. The motor below and the torque transducer above are directly connected to the test fixtures for accurate measurement and deformation control.

Under isothermal, step, and temperature ramp circumstances, direct-contact electric heaters positioned inside the dies offer exceptional temperature control and stability. When a cold sample is added, this extremely responsive device quickly returns to the programmed test temperature, giving the most accurate readings for scorch time and other cure properties. Absolute sample containment is provided by extremely robust user-replaceable seals in all temperatures and environmental factors.

NextGen’s RPA Ultra – Advanced Rubber Process Analyzer Die Gap is 0.45 mm nominal.

Click here to obtain a personal quote.

The brand-new rubber testing equipment is specially created to provide the greatest level of torque, amplitude, frequency, temperature, and pressure measurement and control, establishing a NEW STANDARD for testing rubber goods at all phases of production.

The most sophisticated data processing techniques are required for rubber testing due to the complicated deformations and stress-strain response. The RPA Ultra from BrassOne performs computations based on an analysis of 90 data points for each cycle of oscillation, using a cutting-edge 20-bit encoder and innovative data sampling methodology.

Torque and displacement non-linearities are measured and reported by the RPA Ultra. If the test conditions are not optimal, higher harmonics that indicate non-linearity in the applied displacement or estimated torque are displayed for each data point, alerting the operator with a straightforward indicator and saving this information for further data validation.

NextGen’s RPA Ultra – Advanced Rubber Process Analyze can calculate the following data:

S ́, S ̋, S*, G ́, G ̋, G*, tan

δ, phase angle, cure

speed, η ́, η ̋, η*

Click here to obtain a personal quote.

The RPA Ultra's crosshead and testing frame are incredibly rigid, eliminating instrument compliance's impact on test results. Erroneously low values of measured characteristics like modulus and torque, irregular strain and torque waveform signals, and other mistakes are caused by instrument compliance, also known as instrument deformation.

The H-shaped load frame of the RPA Ultra has a robust crosshead brace and large-diameter steel rods that provide unequalled strength to withstand instrument deflection as the motor deforms the sample. Even for completely loaded, fully cured rubbers, its unique design guarantees that the desired strain is achieved with each cycle of deformation. Additionally, under all circumstances, a non-compliant system permits genuinely sinusoidal strain profiles. The improved design also ensures accurate vertical load application, accurate alignment, and smooth motion.

NextGen’s RPA Ultra – Advanced Rubber Process Analyzer measures the following data: Torque, temperature, frequency, strain; Optional: Normal force, die pressure.

Click here to obtain a personal quote.

This mathematical relationship is no longer applicable for polymers with unknown LCB (Long Chain Branching) levels. In the case of polymer discrimination or quality control, however, computing and reporting the crossover point coordinates for these materials is exceedingly efficient and sensitive—at least much more so than Mooney. In this situation, it's feasible that no crossover point can be seen for either extremely high LCB levels or extremely low viscosities. In this situation, the test temperature must be modified. According to the Time-Temperature Superposition principle, the test temperature should be increased if the crossover point appears to be toward higher frequency and dropped if it appears to be toward lower frequency.

Beyond the capabilities of any other rubber rheometer, the RPA Ultra's fully flexible architecture enables advanced testing capabilities, such as complete post-cure viscoelastic characterization, fully programmable sealing pressure, large amplitude oscillatory shear (LAOS), and arbitrary waveform deformations.

NextGen’s RPA Ultra – Advanced Rubber Process Analyzer Oscillation Strain is

+/- 0.001° to unlimited,

‚+/- 0.014% to unlimited

-> rotational

Click here to obtain a personal quote.

The well-known Mooney viscometer is typically used to test and certify the rheological properties of pure gum rubber in accordance with ISO 289. This test is often performed to determine which polymer to employ for a particular recipe. Most rubber technologists know that this method falls short in providing information on compound flow behaviour, particularly when comparing polymers with equal ML(1+4) from different suppliers. Despite the fact that more polymer suppliers are now offering this attribute, Money Stress Relaxation has enhanced polymer source discrimination but is not yet commonly used by polymer users.

Descriptive testing of gum rubber is now simple and reproducible thanks to the development of closed cavity oscillatory rheometers, also known as Moving Die Rheometers, Dynamic Mechanical Analyzers, and Rubber Process Analyzers. These devices allow for the testing of the mechanical characteristics of polymeric materials as a function of frequency at various controlled temperatures.

NextGen’s RPA Ultra – Advanced Rubber Process Analyzer Oscillation frequency is 0.001 to 100 Hz.

Click here to obtain a personal quote.

For rubber producers and formulators, rheometric curves are crucial because they display the processability and property values of the finished product. For the rubber processor, understanding the rheometric curve and its characteristics must be a vital component of the compounds in their daily job, not only to approve their admission into the process but also to determine the ideal times and temperatures to process it. The statistical collection of rheometric data provides the window of properties to which processing rubber is safe under the parameters specified in its procedure.

The temperature at which the rheology test is conducted directly impacts the recorded values of times on the rheometric curve.

These values get shorter as the temperature rises, although not directly proportionally.

NextGen’s RPA Ultra – Advanced Rubber Process Analyzer Drive System consists of High dynamic torque motorand high resolution controller.

Click here to obtain a personal quote.

The ratio of the cure rate to the cure speed: CR = 100 / (tc90-ts2)

In essence, the cure rate measures the ascending curve's linear slope.

Curing speed is the rate of crosslinking and the development of the compound's stiffness (modulus) after the point burnt (ts5). Beyond this temperature, the compound begins to transition from a soft plastic to an elastic, resilient substance.

The bonds that bind the lengthy polymer chains to one another are created during the curing step. The polymer chains join more tightly as more bonds are formed, and the compound becomes stiffer (modulus) as a result.

Curing speed is a crucial vulcanization characteristic since it controls the amount of time needed to produce the crosslink or cure time.

NextGen’s RPA Ultra – Advanced Rubber Process Analyzer Die Config is Sealed die, biconical and plate-plate.

Click here to obtain a personal quote.

In the rheometric curve, the following values are obtained automatically by the same device:

- MI, ML, MH/MHR torque values (strength)

Time values include ts1, ts2, tc10, tc50, and tc90.

Thermoplasticity, cure speed, and reversion time are derived values.

The viscosity of the unvulcanized substance provides minimal torque.

The safety procedure is measured by the curing time.

The shear modulus or stiffness of the rubber compound is measured by the total curve.

MI (Initial Torque) (Initial Torque). It is the torque that was measured at test-start time zero.

The viscosity and torque of the compound decrease as it heats under pressure, according to the ML (minimum torque) formula. The term "ML" refers to the lowest registered torque measurement. It essentially serves as a gauge for the non-vulcanized compound's stiffness and viscosity.

MH (Maximum Torque): The torque rises proportionately as curing starts.

The slope of the rising torsion varies depending on the type of compound. The pair typically reaches its maximum value after some time. Curing reversal takes place, and the torque tends to drop if the test is run long enough. The "reversion curve" is the name given to this particular reversal curve.

NextGen’s RPA Ultra – Advanced Rubber Process Analyzer Rheometer Max. cool rat is 0.5°C/.

Click here to obtain a personal quote.

Knowing how rubber is crosslinked in order to determine its processability, curing time, and ultimate properties is fundamentally important in the rubber industry.

In a tool known as the Oscillating Disk Rheometer, analyses are performed for this purpose on rubber even without vulcanizing ("green rubber").

This apparatus displays the final physical qualities in addition to the crosslinking characteristics. A "fingerprint" of the vulcanizing process and its processability features can be seen in the rheometric curve that was obtained.

All of the vulcanization parameters of the rubber compound can be readily obtained from the torque vs. curing time curve.

The "rheometric curve" represents torque (force) versus real cure time. Three phases make up this curve:

Phase 1 (A): The first phase provides information about the rubber compound's processing behaviour.

Phase 2 (B): Describe the rubber compound's curing properties.

Phase 3 (C): Provides a good indication of the rubber compound's physical characteristics.

NextGen’s RPA Ultra – Advanced Rubber Process Analyzer Rheometer Max. ramp rat is 1.33°C/s-> 80°C/m.

Click here to obtain a personal quote.

The primary characteristic of these polymers is elasticity. The following characteristics, taken collectively, can be used to describe the usual elasticity of rubber (vulcanized):

- Modul with a low starting stiffness

- High tensile strength, high elongation, and fracture under traction or shear

- Large deformations recover quickly and completely, even if they persist for a long time.

- A broad temperature range across which these qualities persist

While there are additional techniques, such as amines, silanes, anilines, and others, sulphur and peroxides currently perform the two types of crosslinking reactions that are most frequently used (by volume) in the industry.

Crosslinking of sulphur

It consists of the chemical union of sulphur atoms through bonds, which takes place in the presence of heat and pressure.

Crosslinking with peroxide

It entails employing organic peroxides to bind the polymer chains along the carbon atom chemically.

These materials exhibit higher ageing resistance at high temperatures and suffer from less compression deformation.

NextGen’s RPA Ultra – Advanced Rubber Process Analyzer Rheometer Max. shear rate in oscillation is 100 1/s.

Click here to obtain a personal quote.

The rubber industry provides a wide range of goods that are used in many different industries as inputs and finished goods.

The most significant users are found in the tyre, automotive assembly, plastics, storage, footwear, furniture, pharmaceutical, and generally all equipment and machinery industries (bands, cameras, packaging, etc.)

As a final rubber product, there are companies devoted to making goods with certain final attributes, such as electrical properties, resistance to permanent deformation, resistance to lubricants and gasoline, atoxicity, antimicrobials, and antifungals, among others.

A polymer, whether natural or artificial, with elastic qualities is called an elastomer or rubber. To put it another way, this polymer can deform when a force is applied, and it will roughly regain its original dimensions when the force is removed. Elastomers can be categorized chemically into between 25 and 30 groups; six of these groups account for 90% of all elastomers used today.

NextGen’s RPA Ultra – Advanced Rubber Process Analyzer Rheometer Max. shear rate in rotation is 500 1/s.

Click here to obtain a personal quote.

Answer:

- Rheometer for moving dies. a bottom die that is fully revolving and has an above die that is fixed.

- The RPA has an optional automatic sample loading system that can boost testing capacity.

- Using a film catridge makes roll reloading quick and easy.

Click here to obtain a personal quote.

Constant shear viscosity is one of the most important characteristics for setting the process parameters for extrusion and injection moulding. It is crucial to comprehend how a rubber compound made without vulcanization is made. The revolving bottom die with infinite strain of the RPA Ultra gives the operator two test modes: dynamic and sustained shear.

In the investigation of the kinetics of rubber cross-linking, the ODR has proven to be a helpful instrument. It is simple to use to calculate cure times. Additionally, it can be used to develop vulcanizates by contrasting various cure package systems. The ODR should be configured to oscillate between 3 and 100 times per minute with a 3-degree arc.

The sample will become hotter if the arc is larger or the oscillation rate is higher. When this occurs, the curing profile is measured by the device at a temperature greater than that set, and the data are useless. According to some reports, 900 CPM can result in a temperature difference of up to 80 °C.

Click here to obtain a personal quote.

An isothermal test offers information at each temperature, such as the length of the incubation, the order of the reactions, and the constant conversion rate. The calculation meets DIN 53529's requirements. Then, using the incubation time and the conversion rate constant at least three distinct temperatures, it is possible to determine the activation energies of the incubation and the conversion. Both in the production process and for estimating the heating time for the test specimen, these factors are essential.

An aluminosilicate source must be activated by an alkaline solution as part of the geopolymerization process. Rheology follows its kinetics. From the initial stage, geopolymer paste, until the gel point with the construction of a geopolymer network, oscillatory rheological measurements are used to track the storage modulus (G′) and loss modulus (G′′). The findings indicate that a rise in temperature reduces reaction time. The Reaction Time-Temperature Superposition (RTTS) principle is introduced to forecast this phenomenon. Additionally, it is noted that altering and adjusting the reaction time is possible when utilizing metakaolin mixes with various reactivities. The creation of the geopolymer network is determined to require a certain weight percentage of reactive metakaolin.

Click here to obtain a personal quote.

In the non-destructive deformation range, frequency sweeps are typically used to describe the time-dependent behaviour of a sample. Low frequencies are used to imitate sluggish motion on long timescales or at rest, while high frequencies are used to represent fast motion on short durations. Frequency sweeps have been successfully used in practice to obtain data on the behaviour and internal structure of polymers as well as the long-term stability of dispersions.

Many users use the maximum to minimum frequency measurement method because it frequently yields a shorter testing period because the controller may be adjusted more quickly. If, on the one hand, the measurement occurs inside the LVE region and, on the other hand, the sample exhibits no change throughout the test time, the same result is achieved for either approach.

By examining a sample across a wide range of frequencies, the user closely monitors the viscoelastic behaviour and molecular structure (molecular weight and molecular weight distribution). Additionally, a number of viscoelastic characteristics, such as complex modulus, elastic modulus, loss modulus, complex viscosity, phase angle, etc., are determined at each frequency due to the frequency-dependent behaviour of the sample.

Click here to obtain a personal quote.

The most precise and reproducible dynamic rubber testing tool is BrassOne RPA, which was created using the best rheological technologies. The BrassOne rubber process analyzer provides useful information on the molecular features of the raw material or compound, processing traits, process modelling, and problem-solving. Additionally possible are post-cure dynamic testing and product environment simulations.

Traditional measurements of extrudates have been made with a micrometre or by weight per unit length, according to the reports of various investigators.

Penetration, softening point, and ductility experiments were empirical rheological tests performed on unmodified and modified bitumen with varying nanoclay contents. The thermodynamic driving force was used to modify bitumen with nanoclay at the nanoscale level. The empirical tests were carried out in accordance with accepted testing practices.

When a specimen is measured throughout a wide range of strains, such as the linear viscoelastic range (LVE) up to large amplitude oscillatory shear, the behaviour of the specimen can be examined (LAOS). The filler content and filler dispersion levels are revealed by the Payne test, which is used to assess the (filler/polymer) filler networks at low strain amplitudes.

Click here to obtain a personal quote.

The elastic recovery in polymer melts and their compounds is measured by rheological tests, which are more frequently employed for product quality control. This is often done by taking measurements of the expansion (or contraction) of materials that are being extruded. Die swell refers to a polymer's propensity to expand when it emerges from an extruder die, whether it be thermoplastic or rubber.

Die swell is typically used to describe the extruded size to die size ratio. The relative elasticity of the moving polymer stream is determined by this characteristic. When the sample emerges from the die, residual stresses are released, which results in die swell. In the rubber and plastics sectors, measuring this behaviour has gained widespread acceptance as a crucial sign of polymer processability.

In the frequency and strain sweeps stated earlier, one parameter (frequency or strain) is held constant while the other parameter (frequency or strain) is varied over a range. Additionally, more data can be gathered from a single measurement thanks to the adaptability of matrix testing, which enables the user to change both the frequency and strain during a sweep.

Click here to obtain a personal quote.

The most efficient rotorless oscillating shear rheometer for the comprehensive characterization of polymers, rubber, and rubber compounds at all stages of manufacturing is the BrassOne RPA Ultra rubber process analyzer (RPA). The RPA Ultra offers priceless viscoelastic information on raw materials, materials that have undergone curing, and materials that have been cured in place. The most precise and accurate torque, viscosity, and viscoelastic properties of elastomers are delivered by the ultra-rigid test frame, high-resolution variable direct drive motor, ultra-stiff wide-range torque transducer, and precision temperature control over the broadest ranges of testing conditions.

The nonlinear viscoelastic behaviour of a sample is investigated and evaluated using the LAOS strain sweep at reasonably large amplitudes. A substance's nonlinear behaviour depends on whether it has a linear or branched polymer structure. The LAOS data are also used for FT- Rheology. The Q parameter, also known as the LCB index (Long Chain Branching), is derived using the harmonic spectrum from Fourier analysis (FFT).

Click here to obtain a personal quote.

Quick operator input makes it simple to qualify many comparable materials. For a specific material, predefined test parameters with tolerances can be assigned. After a test, a straightforward pass/fail signal reveals if the specimen is within the permitted ranges for the chosen material, enabling rapid and straightforward decision-making.

Test results are easily transformed into information that may be used for process control and manufacturing. Standard performance metrics, including minimum and maximum torque, scorch times, conversion times, and more, can be programmed into automated data analysis. Histograms, control charts, and summary reports are used to track processes as these data are evaluated against user-defined limitations.

Non-isothermal measurements (temperature sweep) are frequently carried out at various heating rates to assess a sample's behaviour over a wide temperature range. The BareissOne programme includes a module for kinetic calculations, which are made possible by this measurement at various heating rates.

Click here to obtain a personal quote.

Thermoplastic elastomer properties can be specified using a set of parameters obtained via non-isothermal stress relaxation, sometimes referred to as temperature scanning stress relaxation, when it is carried out at a particular heating rate. It can also describe how the cross-linked rubber network degrades over the course of a few realistic testing hours.

At constant temperature and strain, stress relaxation studies are commonly conducted as time-dependent experiments. It is well known that temperature significantly affects how quickly rubber relaxes. A credible test employing isothermal stress relaxation requires exceptionally extended testing intervals, such as days or weeks, depending on the application, for examining ageing behaviour such as network degradation.

The isothermal cure tests on rubber compounds are among the most popular and significant studies done. The BareissOne software determines all significant test parameters, including maximum and lowest torque, TC values, reaction time and rate, etc., and makes them available to the user in tabular or/and graphical form for additional analysis.

Click here to obtain a personal quote.

With the help of this brand-new kind of advanced RPA testing, it is possible to retrieve important data that is present in higher harmonics, stable shear viscosity, or non-elliptical Lissajous figures. For the first time in areas that are extremely relevant to production, the spinning lower chamber enables the determination of the stable shear viscosity of materials. As a result, testing now has unparalleled quality.

RPA Ultra Features:

- High grade sheet material solid construction

- Film cartridge for test cavity continuous feeding

- No more strain cap with a rotatable lower die

- Easy mobility using retractable casters

- Rubber process analyzer is equipped with 12“ touch display for easy user interface with a clear set of menus to provide navigation through all the available function

- A tray that can load multiple samples automatically

Click here to obtain a personal quote.

The oscillation or reciprocation frequency should range from 0.05 Hz to 2 Hz, and testing may be conducted at two or more frequencies. If only one frequency is used, 1,7 Hz 0,1 Hz is advised. Larger amplitudes often result in greater sensitivity, but the practical range of amplitudes is constrained by the potential of slippage between the test pieces and the die surface or rotor. An amplitude of 1° is recommended for oscillating-disc curemeters. However, 3° may be feasible and valuable in some cases. For reciprocating curemeters, the range may be between 0,01 mm and 0,1 mm or between 0,1° and 2° for rotorless curemeters.

The vulcanization temperature is chosen as that appropriate for the rubber compound being tested and intended processing. The range of 100 °C to 200 °C is recommended.

NextGen’s RPA Ultra – Advanced Rubber Process Analyzer Rheometer complies with ISO 6502 standard.

Click here to obtain a personal quote.

As vulcanization advances, the rubber test piece becomes more firm. The test is over when the recorded force or torque reaches its maximum or equilibrium value or when the allotted amount of time has passed. The parameters of the rubber compound and the test temperature affect how long it takes to generate a vulcanization curve.

In a die cavity that may be closed or nearly closed and is kept at a high temperature, a rubber test piece is present. Two dies, one of which oscillated over a modest linear or rotational amplitude, formed the cavity. Depending on the stiffness (shear modulus) of the rubber compound, this action causes a sinusoidal alternating linear or torsional strain in the test piece as well as a sinusoidal shear force or torque. The oscillating force or torque's amplitude, represented by the envelope curve, is continually recorded as a function of time.

NextGen’s RPA Ultra – Advanced Rubber Process Analyzer Rheometer complies with ASTM D5289 standard.

Click here to obtain a personal quote.

Related Products

Aging Oven

Our aging oven is well-suited for performing drying, baking, wax melting, and sterilization experiments in industrial and mining enterprises, as well as in laboratories, colleges, and research institutions.

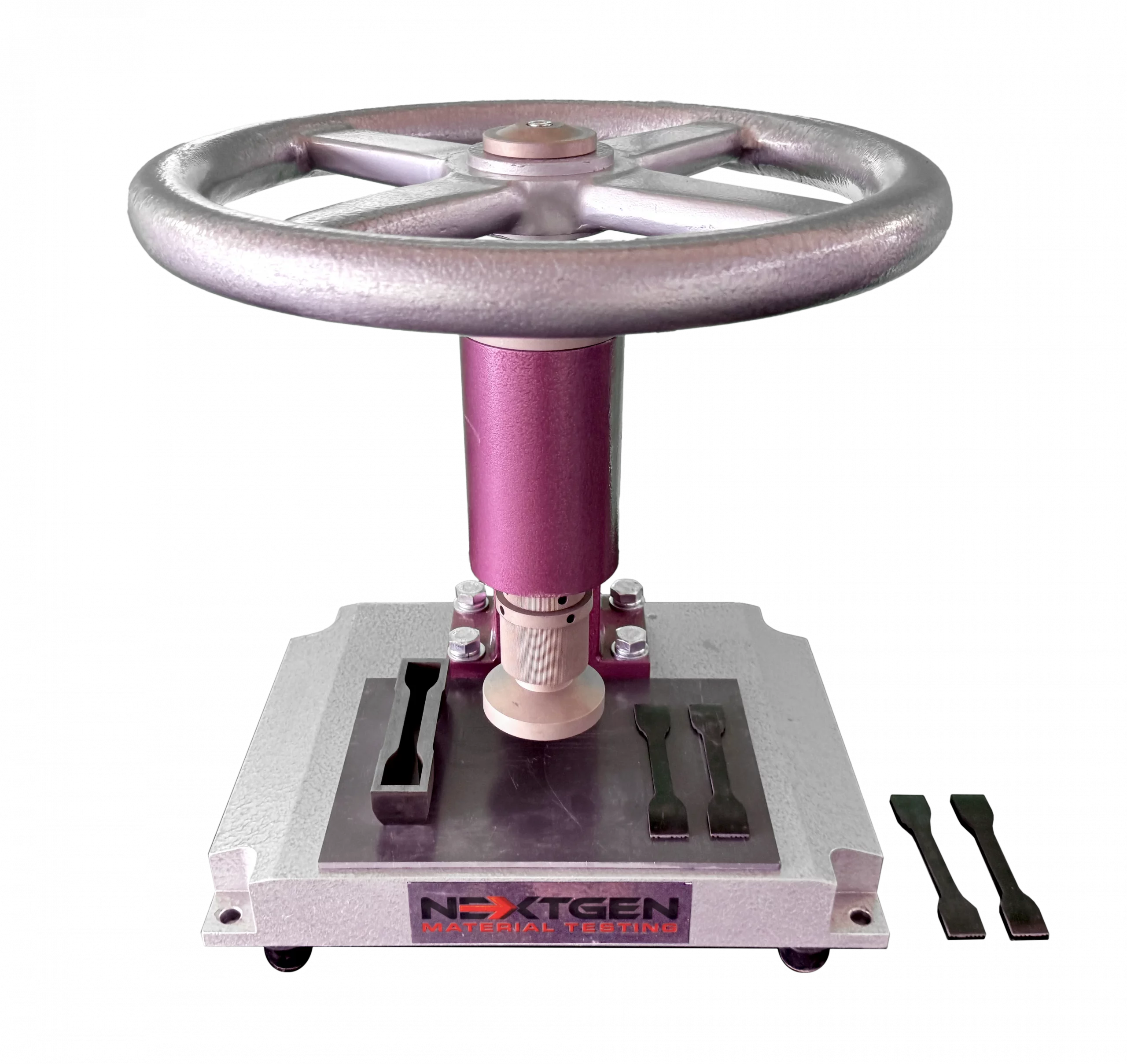

NG-T-Press M Series - Manual Cutting Press System for Rubber Tensile Specimens

Our newest manual cutting press system is suitable for laboratories to create specimens from rubber, tape, and special materials.

Rotary Abrasion Tester Single & Dual Wheel

GenRotary used evaluate abrasion resistance. It can conduct tests on a wide range of materials such as: cloth, paper, paint, plywood, leather, tile, glass, rubber etc. It tests the specimen by rotating it while in contact with the grinding wheel and applying the required pressure. The Joss of weight reflects on the change in weight of the specimen. The unit also has an intelligent power failure recovery function.

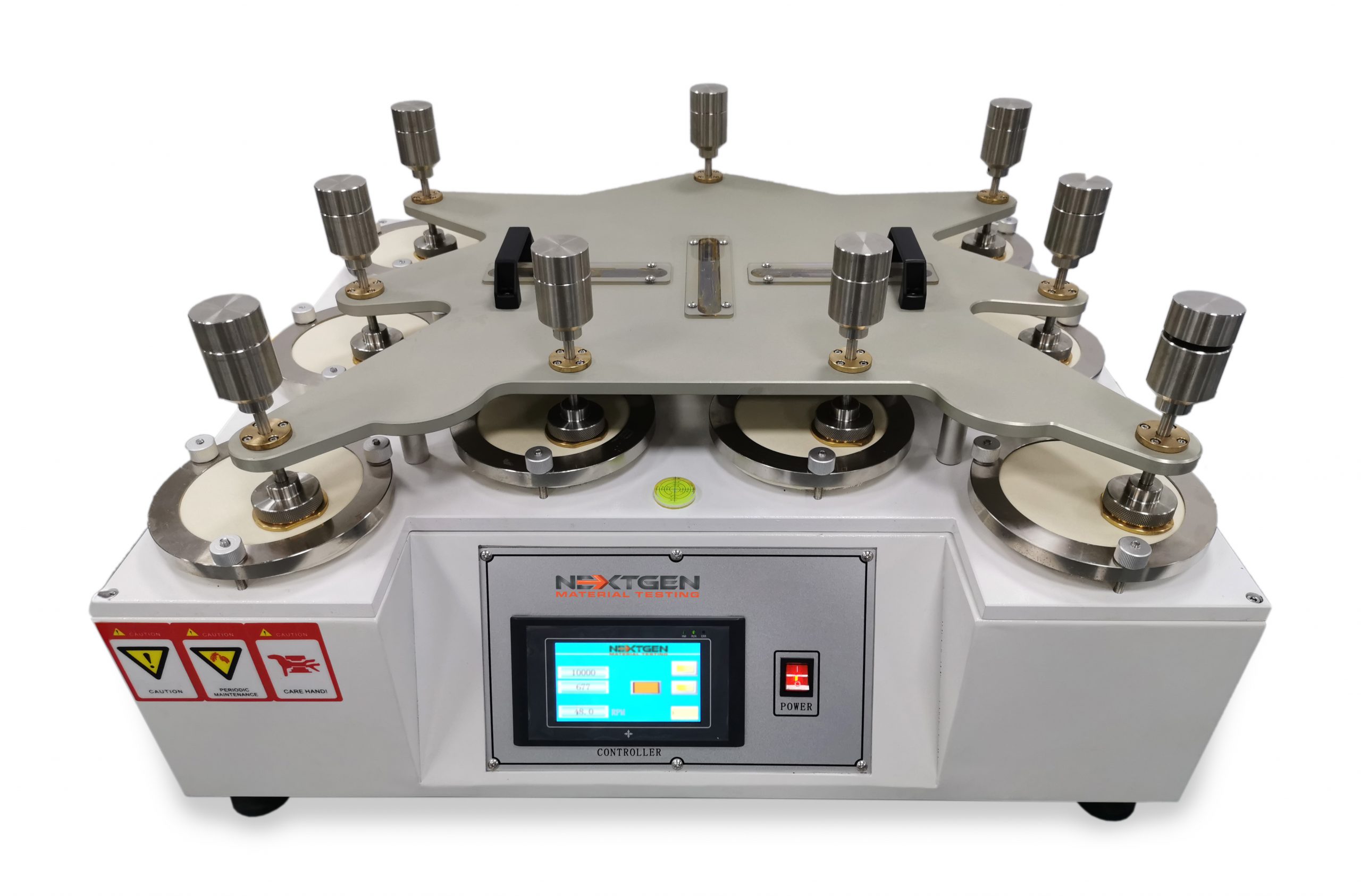

9-Station Martindale Abrasion Tester

The GenDale - Martindale Abrasion Tester is mainly used to test shoe fabric, shoe lining, and many other types of shoe related materials.

GenRoss-CH - Ross Flex Tester with Low Temperature Chamber

GenRoss-CH is an advanced Ross Flex Tester designed for assessing the cold resistance of materials in low temperature environments.

Linear Taber Abrasion Tester

NextGen's linear abrasion meters evaluate the abrasion and scratch resistance of products, along with color transmission.

NextGen Environmental Chambers NG-EC 100,150,225,408,1000

The temperature and humidity NextGen Environmental Chambers features a sturdy cabinet made of cold-rolled steel and stainless steel.

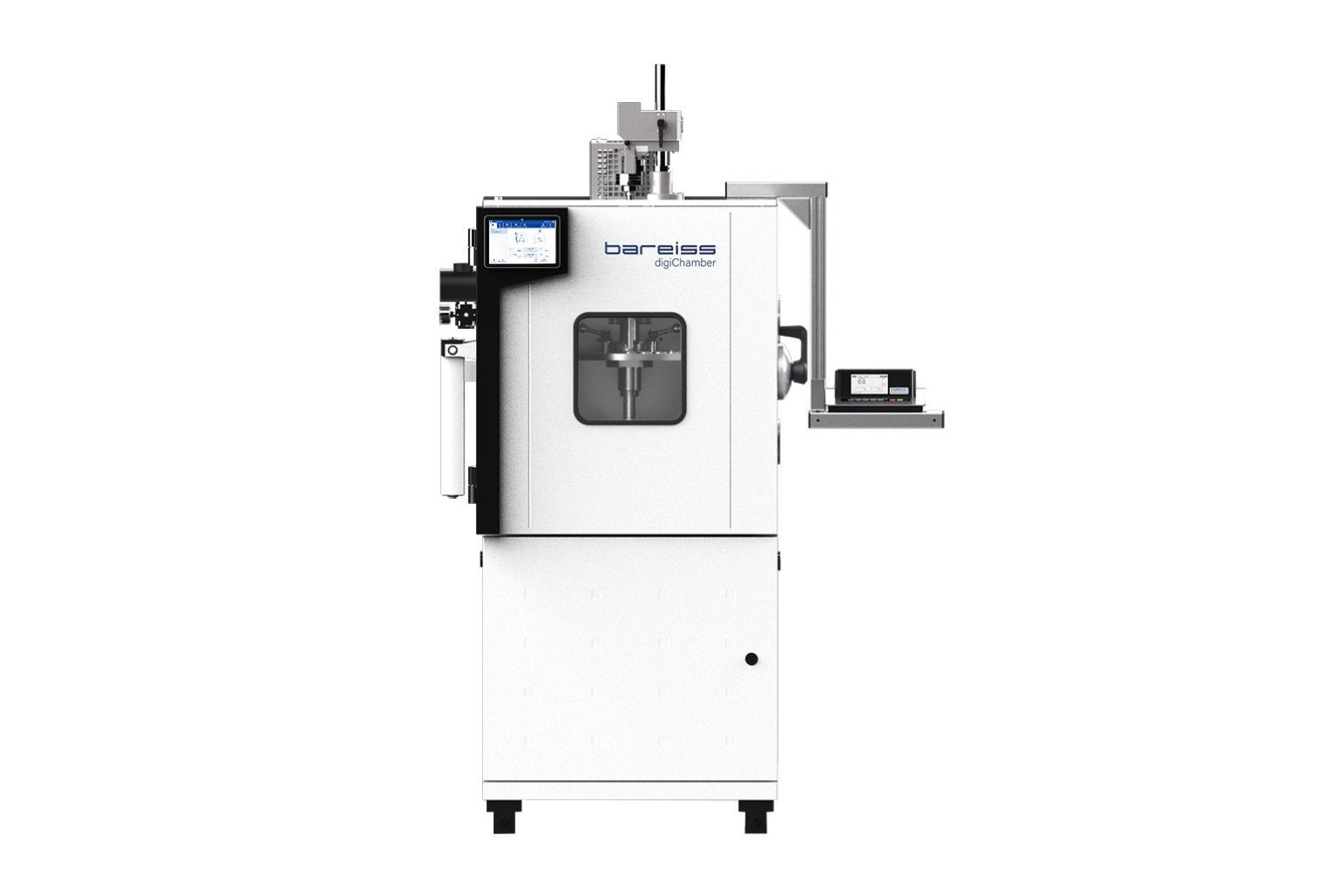

digiChamber - Temperature Controlled Hardness Testing

Discover digiChamber from NextGen Material Testing, the advanced temperature-controlled hardness tester developed by Bareiss.

HDA 120 - Hardness and Density Automation Test System

The HDA 120 test system is a versatile solution for semi-automatic detection of sample hardness and density.

Automatic Shore, IRHD and VLRH Hardness Testing System

NextGen is proud to present our German line of fully-automatic Shore, IRHD and VLRH hardness testing system for plastic materials, plastic and foam compounds for the ultimate precision, accuracy and repeatability, exceptional ease-of-use and maintenance. Experience the industry leader for specimen testing including rubbers, plastics, foams, composites, o-rings, and more.

Advanced Portable Shore Durometer System with Test Stand Options

HPEIII is NextGen's advanced German line of equipment that is the new generation of HPE systems ideal for various plastic and plastic compound testing. The new system enhancements offer advantages including temperature sensor, reading values of ambient temperature and humidity, historical hardness value display, larger LCD display, standard USB connection and much more. These advanced portable systems can be paired up with either manual or automatic motorized test stands to help eliminate the human error factor and maximize accuracy and repeatability between test when switching from one operator to the next.

Classic Analogue Shore Durometer with Test Stand Options

This German-manufactured system has been the global benchmark of Shore hardness testing systems since 1954. With ever enhanced ergonomic design, the HP Shore Hardness Tester is both visually appealing and precise rubber and plastic testing system as it has been for nearly 50 years.

Akron Abrasion Tester

GenKron is used together with a special balance for testing the abrasive consumption of materials. The measurements are done through volumetric loss of a rotating specimen exposed to the action of a standard grinding wheel. It is especially suited for testing harder materials such as shoe soles, tires and other rubber materials.

Burst Strength Tester for Fabric

GenBurst is designed to test anti-rupture strength of variety of materials such as leather, paper and fabric. The unit tests the resistance of specimens to bursting using a hydraulic diaphragm bursting tester.

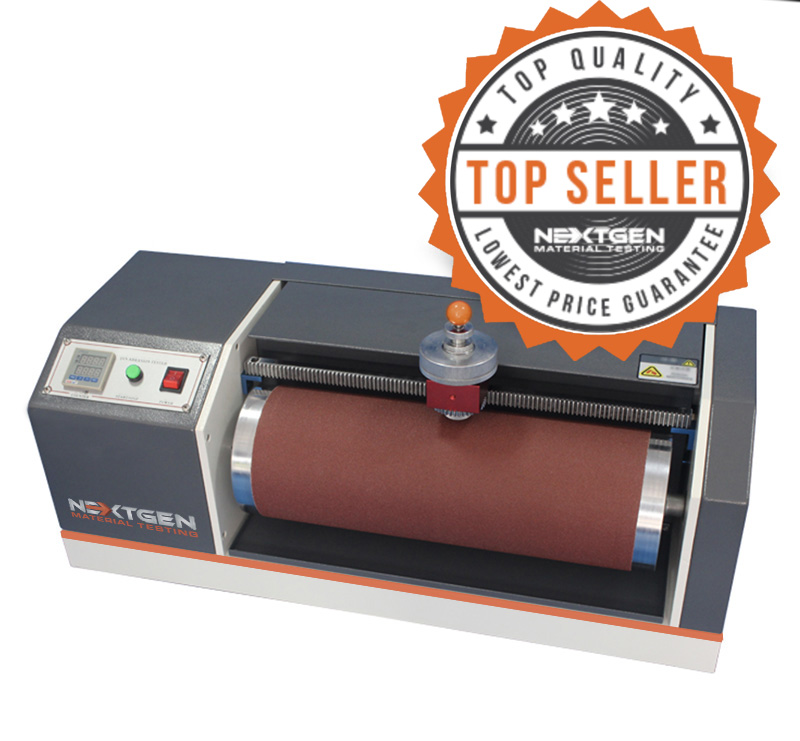

DIN Abrasion Tester

GenDin, is designed to conform to the ASTM D5963 and IS0 4649 standards. This top quality and highly popular abrasion tester will allow you to measure the abrasion resistance of rubbers (vulcanized thermo set rubbers and thermoplastic elastomers) that are subject to abrasive/frictional wear on their actual service. Since wear is always a result of abrasion, different test methods have been developed for the simulation of long term wear.

Demattia Flex Cracking Tester

GenFlex tests the ability of rubber products to withstand repeated flexing without developing cracks is of prime importance where such products are used in conditions undergoing repeated flexing. Flexing endurance of rubber products is determined by simulating in laboratory the action of flexing repeatedly under standard conditions of speed, mode, and degree of flexing.

Discoloration Meter

The machine is used to simulate an environment of sunlight radiation on a specimen to identify the resistance of fabric to discoloration.

Electric Crocking Tester - GenCrock

The machine is used to test the dyeing of the fabric, and the fade degree of the leather after dry or wet rubbing. The test method involves the specimen to be fastened to the base of the crocking meter and rubbed with an abrasive hammer attached to a wet or a dry cloth under controlled conditions. The transfer of colour is then measured using a scale to evaluate the rating of the specimen's dyeing grade.

Freezing Tester - GenFreeze

GenFreeze is specially designed to test the characteristics of various materials in a cold environment to ensure suitability for use in a cold climate. Based on the testing demand, adjust the beater and flexing grip, then load to the desired position. It can be used to test rubbers, leather, and plastics, PU leather etc. The unit can be adjusted to meet different requirements.

Martindale Abrasion Tester - GenDale

GenDale is mainly used to test shoe fabric, shoe lining, and many other types of shoe related materials. The unit can test up to four specimens at the same time for abrasion. The fabric specimen is measured by having rubbing applied on it via a complex direction of back and forth motion. The accuracy of abrasion strength is determined by the specific number of cycles conducted until a hole appears in the test area of the fabric specimen.

Mooney Viscosity Testing Machine - GenMooney

GenMooney is a viscosity testing machine is applied to measure the viscosity of the unmixed or mixed unvulcanized natural rubber, synthetic rubber and regenerated rubber .This tester has many functions such as fast warming, maintaining temperature, data stability, etc. It is equipped with an automated calibration feature for a simple data calibration of each experiment.

NBS Rubber Abrasion Tester - GenNBS

GenNBS is used to test the abrasion resistance of vulcanized rubber or other rubber compounds. It is commonly used for the soles and heels of footwear. It has an intelligent power failure recovery system. The unit conducts measurements through volumetric loss of specimens exposed to the action of a normalized abrasive medium secured to a rotations cylinder.

Oscillating / Automatic Disc Rheometer (ODR)

This machine is designed to get the characteristic curve and characteristic parameters of rubber vulcanization by measuring the applied moment of rubber to the oscillating dye body. NG-ODR rotor-free vulcameter has an excellent stability of results. The data and diagrams can be used as a reference for development, research and production quality.

Salt Spray Tester - GenSalt

GenSalt is designed to test the surface of different materials for resistance to corrosion. The unit is commonly used to test coated materials of a metallic nature in a controlled corrosive environment. The test can be used on rust-proof painting, anodizing, electroplating and rust-proof of grease. The machine imitates expedited corrosion process via salt spraying on a given test sample to identify the corrosion (oxides) resistance. Test results are based on the longevity of time a material can resist visible corrosion on the test sample.

Wyzenbeek Abrasion Tester - GenWyze

The machine is designed to test the abrasion resistance of fabrics and metals. The abrasion of fabrics is tested when the specimen is pulled over the frame and rubbed against an abradant over a curved surface. The number of cycles, also known as double rubs, conducted on the specimen before the fabric shows visible wear is used to determine the rating of abrasion.

Vertical Rebound Resilience Tester - GenRebound

GenRebound tests the resilience of rubber compounds. The machine must be adjusted in a horizontal position and the plunger raised at a specific height. The plunger is then released onto the specimen for a given number of impacts. The measurements are based on the 4th, 5th, and 6th impacts. The average of the three (3) measurements is then calculated for the test result. The machine is highly useful in production of compounds designed to absorb vibration or shock according to the ASTM standards.

Digital Densimeter Systems

Description The NG-DM-A Series offers high-accuracy digital Densimeters designed for a wide variety of material testing needs. These elegant and compact densimeter systems offer capacity ranges from 150g to 3000g with accuracy of 0.001g/cm3 down to 0.0002g/cm3. Advanced Densimeter System […]

Ross Flex Tester

Ross Flex Tester is designed to determine the resistance of vulcanized or synthetic elastomers to cut growth. The system does so under continuously bend flexing in 90°.