Rubber Testing Equipment

Standards

ASTM D1052, ISO 5423, SATRA TM60, SATRA TM92, HG/T 2411

Description

GenRoss-CH is primarily used to test the cold resistance and folding resistance of shoes and shoe materials. Its purpose is to assess the adaptability of materials or finished products to low-temperature climates or cold regions. The instrument can accommodate various folding devices.

GenRoss-CH Features

-

Body surface treatment: The body is coated with US manufacture DuPont powder using an electrostatic spray painting process. It is then cured at high temperatures of 200 ℃ to ensure long-lasting color fastness.

-

Inner liner: The inner liner is made of high-quality stainless steel material, and its semi-circular four-corner design facilitates convenient cleaning.

-

Air circulation and temperature uniformity: The instrument is equipped with reasonable air ducts and circulation systems to ensure good temperature uniformity within the testing chamber.

-

Air convection and breeze devices: High-performance motors and blades are installed, along with air convection and breeze devices. These facilitate the updating and circulation of air within the chamber.

-

Enhanced performance: The use of nanostructured material for door seals and insulation materials enhances the overall performance of the machine.

-

Shell construction: The shell is made of cold-rolled steel plate and coated with plastic using an electrostatic spraying process.

-

Compressor: The instrument utilizes the original Taikang compressor, known for its strength and reliability.

-

Insulation material: The box is insulated with 100mm high-temperature resistant rigid polyurethane foam.

-

Heater: The instrument employs a finned heat dissipation tube-shaped stainless steel electric heater.

-

Cold and heat exchange device: The instrument adopts an ultra-high efficiency SWEP cold and heat exchange design for effective cold and heat exchange.

-

Temperature controller: The instrument is equipped with a Taiwan Weilun TH7010 Touchable Intelligent Programmable Temperature Controller, which offers precise control and ease of use.

Standard Configuration

-

Test piece size: 152 × 25mm

-

Bending angle: 90 °

-

Number of test pieces: 6 sets

-

Twist speed: 0-100 ± 5cpm adjustable

-

Diameter of winding shaft: 10mm

-

Cutting edge: 2.5mm

-

Counter: LCD, 0-9999999

GenRoss-CH Technical Specifications

|

System |

Balanced temperature regulator wet control system |

|

Temperature range |

-20 ℃~+150 ℃ |

|

Temperature fluctuation |

≤ ± 0.5 ℃ |

|

Temperature uniformity |

≤ 2 ℃ |

|

Temperature accuracy |

± 0.2 ℃ |

|

Heating time |

+25 ℃ →+85 ℃ Normal temperature to 85 ℃ takes about 30 minutes without load |

|

Cooling time |

+25 ℃ → -40 ℃ Normal temperature to -40 ℃ It takes about 50 minutes without load |

|

Window |

12.60 x 16.53 x 1.57-inches / 320 x 420 x 40mm 3-layer vacuum tempered glass |

|

Door hinge |

SUS # 304 imported hinge |

|

Energy saving light inside the box |

LED light emitting method |

|

Lead hole |

φ 1 50mm (with 1 rubber plug) |

|

Heating rate |

3-5 ℃/min (average) |

|

Cooling rate |

0.7~1 ℃/min (average) |

|

Inner box dimensions |

15.75 x 19.68 x 15.75-inches / 400 x 500 x 400mm |

|

Outer box dimensions |

41.34 x 78.74 x 45.28-inches / 1050 x 2000 x 1150mm |

|

Power supply |

AC220V 1ph 50/60 Hz |

FAQs

What type of lighting is used inside the GenRoss-CH – Ross Flex Tester with Low Temperature Chamber?

A high-quality energy-saving lighting solution is integrated into the interior of the GenRoss-CH - Ross Flex Tester with Low Temperature Chamber, making it a very efficient unit. As a result, this feature becomes particularly important for users who need to monitor or inspect their samples without being distracted by external light sources. The device employs an LED light-emitting method, renowned for its efficiency, longevity, and brightness.

LEDs, or Light Emitting Diodes, consume significantly less power than traditional incandescent or fluorescent bulbs. This ensures a reduction in energy consumption, aligning with modern sustainability goals. It also ensures the apparatus stays cooler, minimizing any potential influence on the chamber's internal temperatures. Additionally, LEDs offer a clear and bright light source, improving visibility inside the chamber.

Incorporating such a lighting system into the GenRoss-CH tester underscores the device's emphasis on modern, efficient, and user-friendly design components, ensuring the testing process is as streamlined and effective as possible.

Click here to learn more about the product or here to receive a personalized quote.

The GenRoss-CH – Ross Flex Tester with Low Temperature Chamber is designed to house its essential components and provide optimal testing conditions. The inner chamber, a pivotal component of the device, is spacious, allowing for a broad range of sample sizes and types. Specifically, the internal box dimensions span a width of 15.75 inches (or 400 mm), a depth of 19.68 inches (or 500 mm), and a height of 15.75 inches (or 400 mm).

These precise dimensions ensure that the device's core components have adequate space to function effectively. In addition, they provide ample room for the items being tested. The deliberate dimensions ensure that temperature uniformity, which is pivotal to the accuracy and reliability of results, is maintained throughout the chamber.

Given these considerations, the inner dimensions underscore the product's commitment to performance, accuracy, and versatility. Whether assessing cold resistance or folding resistance, users can be confident that GenRoss-CH provides an internally optimized environment to achieve consistent and reliable results.

Click here to learn more about the product or here to receive a personalized quote.

The GenRoss-CH – Ross Flex Tester with Low Temperature Chamber has been crafted with specific spatial considerations in mind. This ensures it fits seamlessly into a variety of settings, from specialized labs to industry-standard workspaces. When discussing its external dimensions, the unit extends to a breadth of 41.34 inches (or 1050 mm), a height of 78.74 inches (or 2000 mm), and a depth of 45.28 inches (or 1150 mm).

These measurements indicate a relatively compact design, especially when considering the machine's multifaceted capabilities. The specific dimensions have been optimized to ensure that while the equipment is robust and feature-packed, it doesn't impose demanding spatial requirements on its environment.

Furthermore, the consideration given to external dimensions reflects the broader design philosophy that prioritizes both functionality and user-friendliness. By maintaining such a streamlined size, the GenRoss-CH can be incorporated into diverse settings without major infrastructure modifications or demanding an inordinate amount of space.

Click here to learn more about the product or here to receive a personalized quote.

The GenRoss-CH – Ross Flex Tester with Low Temperature Chamber is engineered to function on a distinctive power input setting. It requires an AC220V electrical input, functioning in a single-phase (1ph) configuration. A further dimension of its versatility can be seen in its ability to adapt to different frequencies. Designed to work with both predominant electrical grid frequencies of 50Hz and 60Hz.

It is important to keep in mind that the frequency parameters mentioned above have a global significance. The 50Hz and 60Hz frequencies correspond to the standard electrical grid frequencies predominantly utilized in different regions around the world. Therefore, this aspect of the GenRoss-CH speaks volumes about its global applicability and user-friendly design.

The power supply specifications underscore the device's readiness for hassle-free setup in diverse electrical environments. This eliminates potential challenges tied to regional power standards, offering users a smoother and more reliable experience during both the installation and operational phases.

Click here to learn more about the product or here to receive a personalized quote.

The GenRoss-CH – Ross Flex Tester with Low Temperature Chamber boasts a meticulously designed viewing window with dimensions of 12.60 x 16.53 x 1.57 inches or equivalently, 320 x 420 x 40mm. This generous size ensures clear visibility into the chamber, allowing users to monitor tests without compromising internal conditions.

More than just its size, the window is constructed with 3-layer vacuum tempered glass. Multiple advantages can be derived from such a construction. Firstly, tempered glass ensures durability and resilience against potential impacts or abrupt temperature changes. Secondly, the vacuum layers provide insulation, maintaining the chamber's internal temperature while preventing heat transfer or loss. Lastly, the triple-layer construction offers enhanced safety, ensuring the chamber remains sealed and secure throughout the testing phase.

The viewing window on the GenRoss-CH is not only an access point for visual monitoring but also a testament to the chamber's advanced design, prioritizing safety, durability, and efficiency.

Click here to learn more about the product or here to receive a personalized quote.

As a result of its exceptional cooling capabilities, the Ross Flex Tester with Low Temperature Chamber GenRoss-CH - Ross Flex Tester with Low Temperature Chamber is an ideal choice for many applications. At a conventional or ambient temperature of +25°C, the device can be effectively cooled down to a temperature of -40°C in roughly 50 minutes when the device starts at a conventional or ambient temperature of +25°C. Please note that this is done under conditions where no load is present in the building.

This dependable cooling ability is instrumental in tests requiring swift temperature drops. Rapid cooling ensures minimized downtime and enhances laboratory or testing productivity. Such swift cooling, combined with its reliable performance, positions the GenRoss-CH as a prime selection for professionals requiring a consistent and efficient cooling solution for their testing needs. The precise control over temperature changes also guarantees accurate and reliable results, underscoring the device's worth in specialized applications.

Click here to learn more about the product or here to receive a personalized quote.

The GenRoss-CH - Ross Flex Tester with Low Temperature Chamber is designed to provide efficiency in the process of adjusting temperatures within the device when using the device. A temperature chamber can reach 85°C within approximately 30 minutes if it is started at an ambient or normal temperature of 25°C, and if it starts at a temperature of 25°C. It is important to note that this is only valid if there are no loads inside.

Having this relatively rapid heating capability ensures that users are able to conduct their tests promptly without having to wait for long periods of time. It is especially useful in industries and research areas where time efficiency is crucial to the success of the project that the instrument is responsive to temperature adjustments in a quick and efficient manner. This feature also emphasizes the high performance and reliability of the GenRoss-CH, making it a preferred choice for professionals looking for both speed and accuracy in their temperature-controlled tests.

Click here to learn more about the product or here to receive a personalized quote.

It is estimated that the temperature fluctuation of this device is less than or equal to the 0.5°C. It is important to note that this minimal fluctuation in temperature is indicative of the fact that when a certain temperature is set, the actual temperature within the chamber will remain extremely close to the desired value, veering by no more than half a degree Celsius from the set temperature.

This level of accuracy is crucial for tests that are subject to stringent environmental conditions. This ensures that samples are subjected to consistent and predictable temperatures throughout the experiment. Such precision, in turn, guarantees reliable results and reduces the margin of error, which is of paramount importance in industries that rely on exact measurements and conditions. This feature underscores the reliability of the GenRoss-CH as a top-tier instrument in its field, offering both researchers and industry professionals a tool that delivers consistent performance in temperature-sensitive experiments.

Click here to learn more about the product or here to receive a personalized quote.

The GenRoss-CH – Ross Flex Tester with Low Temperature Chamber showcases extensive operational temperature threshold capability. Specifically engineered to cater to diverse testing needs, it possesses a temperature range that starts from a chilly -20℃ and stretches up to a heated +150℃. This vast temperature spectrum underscores the machine's adaptability, enabling it to emulate a multitude of environmental conditions. This allows it to gauge how materials react under extreme conditions.

Temperature simulation flexibility is essential for industries that require rigorous testing of their materials or products. This ensures that they can withstand or function optimally in both freezing and extremely hot conditions.

The broad range also offers a glimpse into the tester's advanced technical design and commitment to delivering precise results, making it an invaluable tool for research and quality assurance professionals. With such capabilities, industries can anticipate material behaviors, strategize product designs, and make informed decisions that cater to specific environmental needs, thus ensuring product longevity and user satisfaction.

Click here to learn more about the product or here to receive a personalized quote.

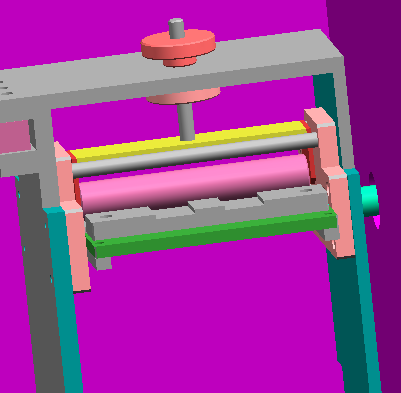

To begin with, the tester comes with a chamber specifically designed for the Ross Flex test. The instrument can accommodate test pieces of 152 × 25mm. This ensures that standard-sized samples can be tested consistently.

The bending angle, an essential parameter for testing, is set at 90°, offering a standardized benchmark for evaluating materials. Furthermore, during a single testing cycle, the instrument can process up to 6 sets of test pieces. This is advantageous for batch testing and increases throughput.

Regarding the twisting mechanism, the speed can be adjusted within a range of 0-100 cycles per minute, with a permissible variance of ± 5cpm. The tester's winding shaft diameter is 10mm, while the cutting edge is 2.5mm, ensuring precise and uniform stress application.

Lastly, the counter, equipped with an LCD display, provides a wide range, counting from 0 to 9,999,999. This extended range ensures that tests can run for a long time without interruptions.

Click here to learn more about the product or here to receive a personalized quote.

The GenRoss-CH – Ross Flex Tester with Low Temperature Chamber is fitted with a Taiwan Weilun TH7010 Touchable Intelligent Programmable Temperature Controller. This particular controller is a product of advanced technological design and offers a suite of advantages for users.

First and foremost, the "touchable" feature indicates a user-friendly interface, allowing straightforward interactions. Users can easily set, adjust, and monitor temperature parameters without a steep learning curve. This digital interface promotes ease of operation and precision in temperature settings.

Moreover, the term "intelligent programmable" signifies that the controller can be programmed to adhere to specific temperature profiles, potentially allowing for automated testing cycles. This is particularly useful in testing scenarios where temperature variations need to be carried out in a pre-defined manner.

The combination of precise control and user-friendliness ensures GenRoss-CH consistently provides reliable results. By incorporating the Taiwan Weilun TH7010, the instrument empowers users to have increased control over their testing conditions. This makes the entire testing process more efficient and dependable.

Click here to learn more about the product or here to receive a personalized quote.

The GenRoss-CH – Ross Flex Tester with Low Temperature Chamber integrates a state-of-the-art cold and heat exchange device into its design. Specifically, it uses an ultra-high-efficiency SWEP cold and heat exchange system.

SWEP is renowned for its advanced and efficient heat exchanger designs. This choice in design for the GenRoss-CH signifies a commitment to excellence and performance. The SWEP design ensures rapid and effective cold and heat exchange. This optimizes the chamber's ability to reach desired temperatures swiftly and maintain them consistently. This is crucial to ensuring accurate and reliable test outcomes.

Furthermore, the "ultra-high efficiency" characteristic of the SWEP design means that the system operates at optimal energy levels, ensuring minimal energy waste. This reduces operational costs for users and contributes to a more sustainable and environmentally-friendly operation.

By adopting the SWEP cold and heat exchange design, the GenRoss-CH ensures rapid temperature transitions, consistent temperature maintenance, energy efficiency, and overall improved performance in its testing procedures.

Click here to learn more about the product or here to receive a personalized quote.

The GenRoss-CH – Ross Flex Tester with Low Temperature Chamber utilizes a specific insulation material to optimize its performance. The chamber's box is insulated using 100mm high-temperature resistant rigid polyurethane foam.

Polyurethane foam is recognized in various industries for its excellent insulation properties. Its structure comprises millions of tiny cells filled with low-conductivity gas, which restricts heat passage. Therefore, it offers superior thermal resistance. This means the chamber's internal temperatures can be maintained more consistently and efficiently, ensuring accurate and reliable test outcomes.

In addition, the high-temperature resistance of this particular type of polyurethane foam means that the insulation will remain effective even when subjected to elevated temperatures. This ensures that the chamber's structure will not degrade or deteriorate rapidly over time, promoting the instrument's durability and longevity.

The choice of 100mm thickness further reinforces insulation capability, providing a substantial barrier against thermal transfer. In essence, the employment of high-temperature resistant rigid polyurethane foam in the GenRoss-CH machine ensures optimal insulation, energy efficiency, and the overall performance and reliability of the tester in various temperature scenarios.

Click here to learn more about the product or here to receive a personalized quote.

The GenRoss-CH – Ross Flex Tester with Low Temperature Chamber employs innovative technology by utilizing nanostructured materials, particularly for door seals and insulation. These materials have properties distinct from traditional bulk materials, often providing superior performance in certain applications.

In the context of the GenRoss-CH machine, the nanostructured materials used in door seals offer an outstanding barrier, ensuring a tight seal that minimizes air or temperature leaks. This is essential for maintaining consistent testing conditions within the chamber and ensuring test results accuracy and reliability. A robust seal also aids in energy conservation, as the machine does not have to work as hard to maintain a set temperature if there are minimal losses.

Furthermore, nanostructured insulation materials contribute to machine efficiency. Given the intricate nanoscale structures, these materials exhibit exceptional thermal resistance, minimizing heat transfer. This means that the chamber can maintain its internal temperature more effectively, with reduced energy consumption.

Click here to learn more about the product or here to receive a personalized quote.

The GenRoss-CH – Ross Flex Tester with Low Temperature Chamber has innovatively incorporated air convection and breeze devices to optimize airflow and enhance circulation within the testing chamber. At the core of this system are high-performance motors and blades which provide robust force for circulating air efficiently throughout the chamber.

These motors drive the blades to generate a consistent and controlled flow of air. This ensures that every corner of the chamber experiences equal circulation. This is crucial for ensuring uniform testing conditions and preventing any discrepancies due to unbalanced air distribution.

In addition to the convection mechanisms, the breeze devices refresh the air within the chamber. They help circulate the air but also update it, which is essential for tests where air quality might impact the results.

The combination of high-performance motors, blades, and air convection and breeze devices works collaboratively to maintain consistent and updated air flow. This ensures that the chamber provides the most conducive and uniform environment for the tests it is designed to conduct.

Click here to learn more about the product or here to receive a personalized quote.

The GenRoss-CH – Ross Flex Tester with Low Temperature Chamber demonstrates an advanced approach to precise air circulation and temperature uniformity within its testing chamber. The system is strategically equipped with well-designed air ducts that play a vital role in regulating and directing airflow. These ducts are calibrated to allow air to flow in a manner that promotes even temperature distribution across all regions of the chamber.

Furthermore, the circulation systems integrated into the tester play a very important role in maintaining this equilibrium. These systems ensure that the air within the chamber is constantly in motion, mitigating the risk of temperature variance or the formation of 'hot' or 'cold' spots. Such a dynamic circulation setup is a vital element, especially in testing scenarios where even minor temperature inconsistencies can affect the outcome.

The combination of the air ducts and the circulation systems works in tandem to guarantee that the temperature within the testing chamber remains uniform. This provides accurate and reliable results for every test conducted.

Click here to learn more about the product or here to receive a personalized quote.

The inner liner of the GenRoss-CH – Ross Flex Tester with Low Temperature Chamber showcases engineering and thoughtful design. A high-quality stainless steel liner is used to ensure the tester's durability and resistance to corrosion, both of which are vital due to changing environmental conditions and the variety of materials it has to deal with.

The quality of the material of the inner liner is worthy of special mention, as well as its design. On each of its four corners, the product features a semi-circular design. A design choice such as this, rather than the conventional sharp corners or right-angle corners, greatly simplifies the cleaning process. Such a shape eliminates hard-to-reach areas, allowing users to clean the liner more efficiently and ensuring residues or contaminants don't accumulate over time. This design, combined with the choice of stainless steel, ensures the liner remains in optimal condition, facilitating accurate tests while reducing maintenance challenges.

Click here to learn more about the product or here to receive a personalized quote.

The Ross Flex Tester with Low Temperature Chamber GenRoss-CH has been built to be durable as well as aesthetic in appearance. As a result of this, the body of the device is treated in an extremely detailed and comprehensive manner in order to accomplish this goal.

To begin with, the body is coated with a high-quality DuPont powder, which is sourced from a well-established US manufacturer, in the initial stages of the process. This coating is applied using an electrostatic spray painting technique, which guarantees even coverage and optimal adherence to the equipment's surface.

After this application, the coated body is subjected to a curing process at an elevated 200 °C temperature. This step ensures color's long-lasting durability and resilience against wear and tear. The combined approach of using DuPont powder, electrostatic spray, and high-temperature curing is pivotal in ensuring that the instrument remains both robust and visually appealing throughout its operational lifespan.

Click here to learn more about the product or here to receive a personalized quote.

The GenRoss-CH – Ross Flex Tester with Low Temperature Chamber has been designed with adaptability in mind, particularly when accommodating a variety of folding devices. Such flexibility is crucial as it allows a wide variety of tests to be conducted. These tests simulate different real-world scenarios that a shoe or shoe material might encounter. This versatility ensures that different materials or finished products can be tested under multiple bending and folding conditions, offering a comprehensive view of their performance.

Due to its compatibility with a variety of folding devices, the folding device has become an indispensable tool for researchers and manufacturers alike. This enables them to assess and improve their products' resilience, durability, and adaptability. With such a feature, regardless of the specific folding test that is required, and regardless of the type of folding test that is being conducted, the GenRoss-CH can effectively cater to those needs, thus cementing its position as an essential instrument in material testing.

Click here to learn more about the product or here to receive a personalized quote.

The GenRoss-CH – Ross Flex Tester with Low Temperature Chamber is a specialized instrument designed to evaluate the cold resistance and folding resistance of shoes and shoe materials. Cold resistance testing is vital for understanding how shoe materials perform in cold climates, ensuring they don't become brittle or compromise functionality. This is especially crucial for products aimed at markets with colder seasons or located in colder regions. Meanwhile, folding resistance testing measures how a material reacts to repeated bends or bendings. This mirrors the stress shoes undergo during regular wear, indicating their durability and lifespan.

As a result of GenRoss-CH's ability to provide manufacturers with insight into these two essential parameters, the company can help them maintain high-quality standards for their products, ensuring end-user comfort, safety, and satisfaction. Utilizing GenRoss-CH ensures that both materials and finished shoes are robust, durable, and fit for purpose, upholding brand reputation and building consumer trust.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenRoss-CH – Ross Flex Tester with Low Temperature Chamber is designed in accordance with a variety of well-known industry standards, including the HG/T 2411 standard. HG/T 2411 is an established benchmark that sets forth specific requirements and testing methodologies for particular materials or products. Adherence to this standard indicates that the GenRoss-CH Tester has been manufactured and calibrated to meet the strict criteria outlined in HG/T 2411, ensuring its suitability for the intended tests.

Incorporating the HG/T 2411 standard into its design and functionality emphasizes the GenRoss-CH Tester's dedication to delivering precise, consistent, and industry-approved results. When equipment, such as the GenRoss-CH, complies with such standards, it instills trust and confidence in industries, manufacturers, and research institutions, assuring them of the validity and reliability of their test outcomes.

The GenRoss-CH Ross Flex Tester's conformity to the HG/T 2411 standard underscores its unwavering commitment to precision, quality, and industry-recognized performance, solidifying its position as a pivotal equipment piece for accurate and rigorous material testing.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenRoss-CH – Ross Flex Tester with Low Temperature Chamber has been specifically designed to adhere to various established industry standards, including the SATRA TM92 standard. SATRA TM92 is one of the globally recognized benchmarks concerning footwear testing methodologies. Adhering to this standard signifies that the equipment, in this case, the GenRoss-CH Tester, meets the rigorous criteria for testing footwear in relation to its resilience, flexibility, and overall performance under certain conditions.

Adherence to the SATRA TM92 standard further accentuates the GenRoss-CH Tester's capability to provide consistent, accurate, and industry-recognized results when evaluating footwear materials' cold resistance and flexing durability. This level of compliance is particularly crucial for industries, manufacturers, and research entities in the footwear domain as it ensures that the data and outcomes derived from their tests are both valid and reliable.

The GenRoss-CH Ross Flex Tester's alignment with the SATRA TM92 standard is a testament to its commitment to excellence, precision, and high-quality performance, making it an indispensable tool for rigorous footwear testing and material analysis.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenRoss-CH – Ross Flex Tester with Low Temperature Chamber is explicitly designed to comply with various industry standards, including the SATRA TM60 standard. The SATRA TM60 standard pertains to methods for testing footwear and related materials' flexibility and resilience under specific conditions, such as cold temperatures.

Compliance with SATRA TM60 ensures that the GenRoss-CH Tester is equipped to provide accurate and consistent results aligned with SATRA's rigorous benchmarks, an internationally recognized authority in footwear testing. By aligning with this standard, the GenRoss-CH Tester underscores its precision, reliability, and quality commitment.

For industries and research entities focusing on footwear and related materials, compliance holds significant importance. When assessing the cold resistance and folding durability of shoes and shoe materials, using equipment that adheres to recognized standards like SATRA TM60 ensures the validity and reliability of the results.

The GenRoss-CH Ross Flex Tester's conformity to the SATRA TM60 standard exemplifies its proficiency in delivering dependable testing outcomes in line with global industry benchmarks. This makes it a trusted tool in footwear testing and analysis.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenRoss-CH – Ross Flex Tester with Low Temperature Chamber has been designed to comply with a range of industry standards, including the ISO 5423 standard. The International Organization for Standardization's (ISO) 5423 standard outlines specifications and methods for assessing footwear materials' flexibility and resilience under cold conditions.

Adherence to the ISO 5423 standard signifies that the GenRoss-CH Tester possesses the requisite capabilities to provide accurate, reliable, and consistent results in line with globally recognized benchmarks. Such compliance underscores the manufacturer's commitment to ensuring the highest level of precision, quality, and functionality in their equipment.

In research and industrial environments, where detailed and dependable analysis is crucial, the GenRoss-CH Tester’s compliance with the ISO 5423 standard provides considerable assurance. Its alignment with this prestigious standard emphasizes its robust capability to evaluate cold resistance and folding durability of shoes and shoe materials. For organizations and professionals emphasizing rigorous testing procedures aligned with international criteria, the GenRoss-CH Tester emerges as an essential tool, given its strict adherence to this and other globally recognized standards.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenRoss-CH – Ross Flex Tester with Low Temperature Chamber is specifically engineered to adhere to several industry standards, including that of the ASTM D1052 standard. This standard, set by the American Society for Testing and Materials (ASTM), delineates the criteria for determining the resistance of materials to cracking or other forms of damage when subjected to bending conditions.

Compliance with ASTM D1052 is indicative of the instrument's rigorous design and precision, ensuring its proficiency in providing reliable and consistent results. Such adherence reaffirms the dedication of equipment manufacturers to meet globally acknowledged standards, ensuring the highest degree of quality and performance.

In a professional context, where precision and consistency are crucial, the GenRoss-CH Tester's alignment with this standard offers significant assurances. The inclusion of ASTM D1052 within the unit's compliance framework underlines its applicability in specialized fields. This is especially those focusing on the analysis of cold and folding resistances of footwear materials. Institutions and establishments prioritizing verifiable accuracy in their testing mechanisms would find the GenRoss-CH Tester particularly beneficial, given its adherence to this esteemed standard.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

ICI / Mace Snag Tester

Discover the Fabric Textile ICI / Mace Snag Tester, a reliable tool for assessing fabric snagging under normal wear conditions.

Moving Die Rheometer (MDR)

Introducing the NG-MDR Moving Die Rheometer, your solution for accurately assessing the curing and processing characteristics of vulcanized rubber compounds. Designed for precision, this state-of-the-art rheometer captures the characteristic curve and parameters of rubber vulcanization by measuring the torque applied to the oscillating die.

Aging Oven

Our aging oven is well-suited for performing drying, baking, wax melting, and sterilization experiments in industrial and mining enterprises, as well as in laboratories, colleges, and research institutions.

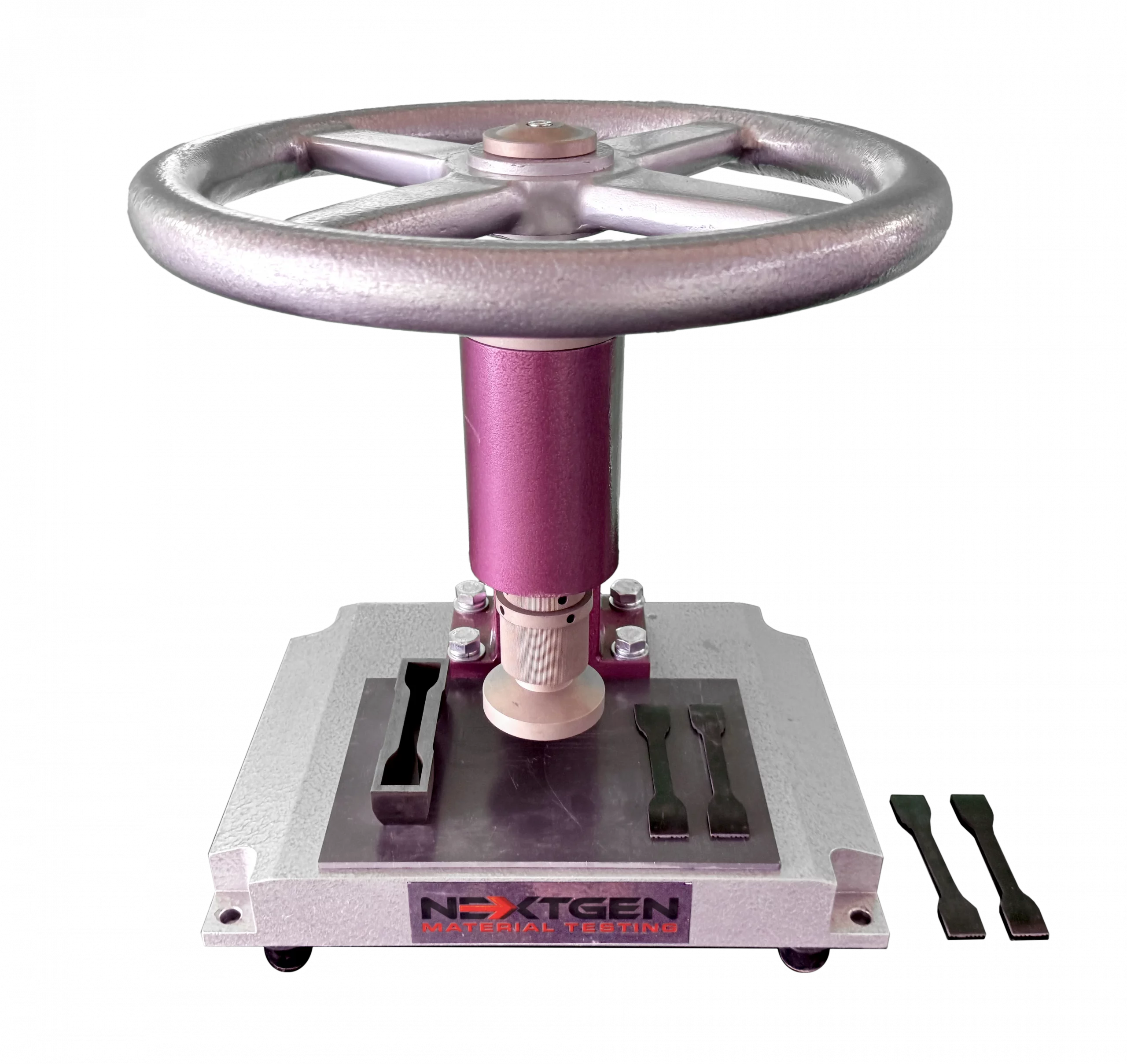

NG-T-Press M Series - Manual Cutting Press System for Rubber Tensile Specimens

Our newest manual cutting press system is suitable for laboratories to create specimens from rubber, tape, and special materials.

Rotary Abrasion Tester Single & Dual Wheel

GenRotary used evaluate abrasion resistance. It can conduct tests on a wide range of materials such as: cloth, paper, paint, plywood, leather, tile, glass, rubber etc. It tests the specimen by rotating it while in contact with the grinding wheel and applying the required pressure. The Joss of weight reflects on the change in weight of the specimen. The unit also has an intelligent power failure recovery function.

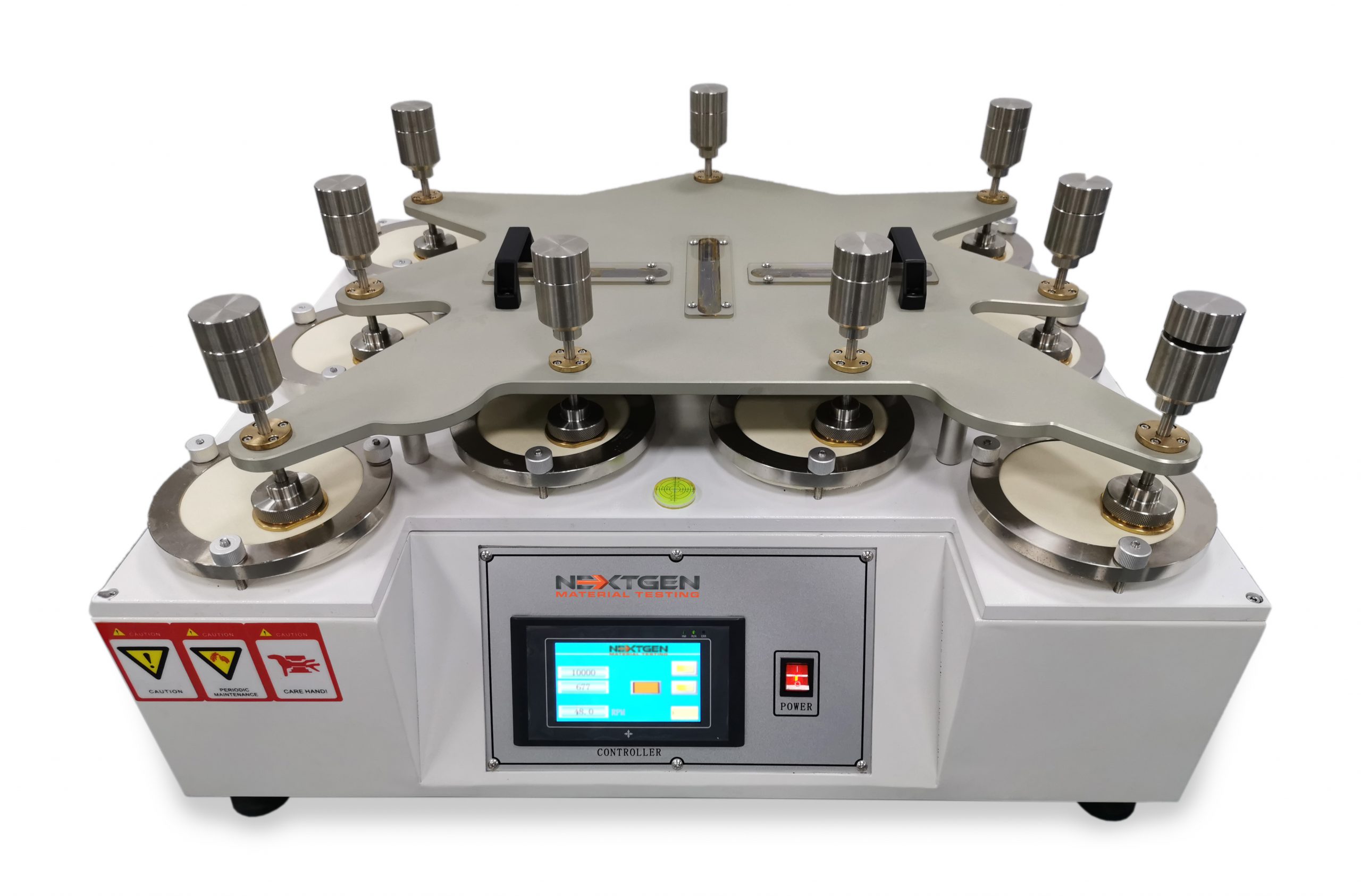

9-Station Martindale Abrasion Tester

The GenDale - Martindale Abrasion Tester is mainly used to test shoe fabric, shoe lining, and many other types of shoe related materials.

Linear Taber Abrasion Tester

NextGen's linear abrasion meters evaluate the abrasion and scratch resistance of products, along with color transmission.

NextGen Environmental Chambers NG-EC 100,150,225,408,1000

The temperature and humidity NextGen Environmental Chambers features a sturdy cabinet made of cold-rolled steel and stainless steel.

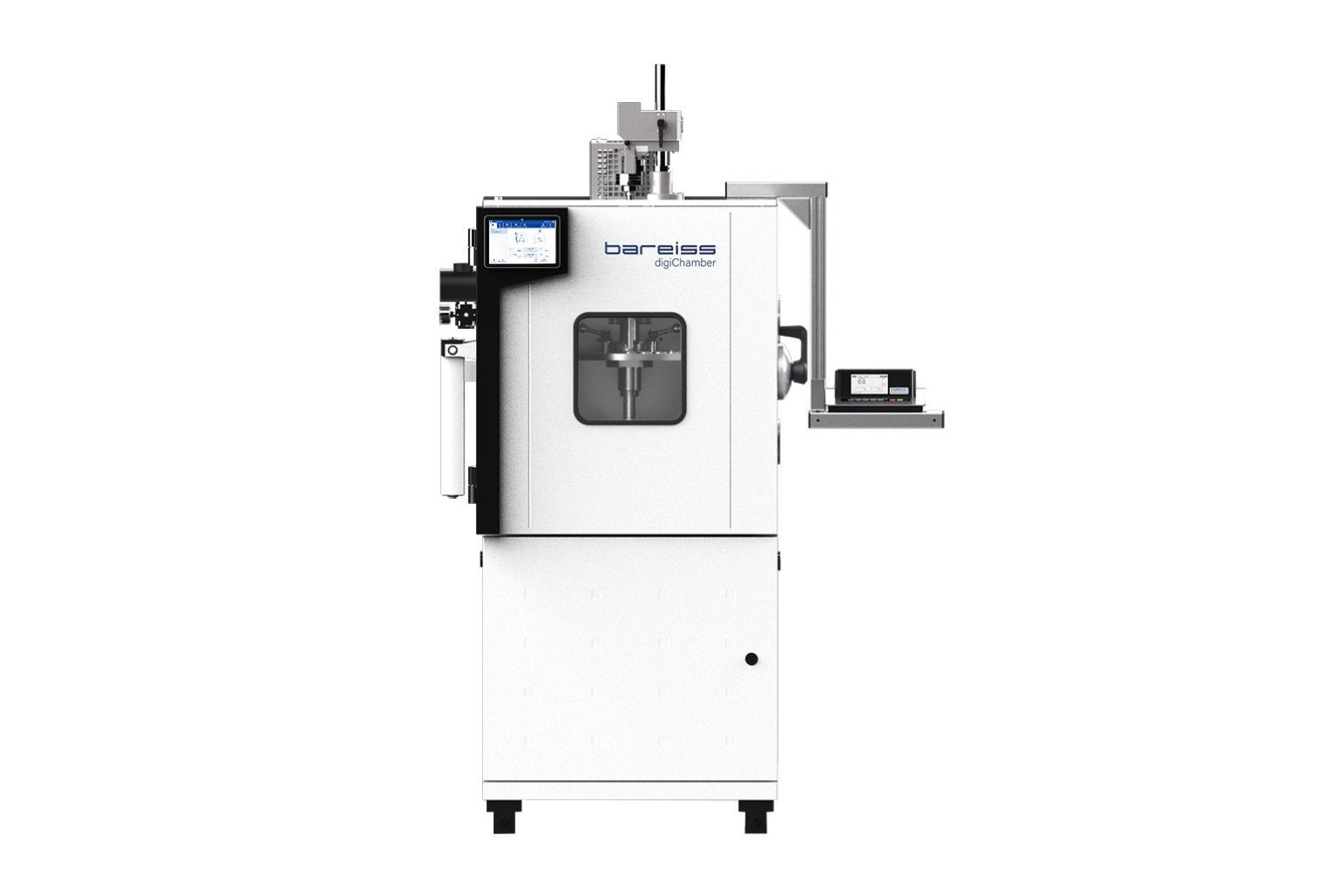

digiChamber - Temperature Controlled Hardness Testing

Discover digiChamber from NextGen Material Testing, the advanced temperature-controlled hardness tester developed by Bareiss.

HDA 120 - Hardness and Density Automation Test System

The HDA 120 test system is a versatile solution for semi-automatic detection of sample hardness and density.

RPA Ultra - Advanced Rubber Process Analyzer Rheometer

RPA Ultra is an advanced rubber process analyzer rheometer that measures the dynamic and static characteristics of raw rubber compounds

NG-EML Series B – Dual Column Bench Top Universal Testing Machine (100 N – 10 kN)

The NG-EML Series B is a high-precision dual-column benchtop universal testing machine engineered for tensile, compression, and flexural testing in the 0.1 kN to 10 kN range. It features Class 0.5 accuracy, a rigid FEM-optimized frame, and a direct-drive servo system with advanced closed-loop control, making it ideal for testing rubber, plastics, metals, composites, and high-performance polymers in both R&D and quality assurance settings.

NG-EML Series C – Dual Column Bench Top and Floor Standing Universal Testing Machine (5 kN – 50 kN)

The NG-EML Series C is a precision-engineered dual-column universal testing machine for tension, compression, and flexural testing of metals, composites, rubbers, and polymers. Available in both bench-top and floor-standing formats, with force capacities from 5 kN to 50 kN and Class 0.5 accuracy.

NG-EML Series D – Floor Standing Universal Testing Machine (50 kN – 1000 kN)

The NG-EML Series D – Floor Standing Universal Testing Machine (50 kN–1000 kN) is a dual-column system for tensile, compression, flexural, shear, and cyclic testing of high-strength metals, composites, polymers, and advanced materials. Available in single-space and dual-space configurations, it meets ASTM E8, ISO 6892-1, ISO 527, and GB/T 228 standards. With closed-loop control, 1200 Hz sampling, ultra-low speeds (0.00005 mm/min), and waveform generation, it is ideal for aerospace, automotive, construction, and research labs.

GenTest Data Acquisition Software - Advanced Universal Testing Machine Software

Upgrade to GenTest, the latest data acquisition software for universal testing machines. Ensure precise, repeatable material testing with an intuitive interface, powerful analysis tools, and full compliance with ASTM, ISO, DIN, and more.

Automatic Shore, IRHD and VLRH Hardness Testing System

NextGen is proud to present our German line of fully-automatic Shore, IRHD and VLRH hardness testing system for plastic materials, plastic and foam compounds for the ultimate precision, accuracy and repeatability, exceptional ease-of-use and maintenance. Experience the industry leader for specimen testing including rubbers, plastics, foams, composites, o-rings, and more.

Advanced Portable Shore Durometer System with Test Stand Options

HPEIII is NextGen's advanced German line of equipment that is the new generation of HPE systems ideal for various plastic and plastic compound testing. The new system enhancements offer advantages including temperature sensor, reading values of ambient temperature and humidity, historical hardness value display, larger LCD display, standard USB connection and much more. These advanced portable systems can be paired up with either manual or automatic motorized test stands to help eliminate the human error factor and maximize accuracy and repeatability between test when switching from one operator to the next.

Classic Analogue Shore Durometer with Test Stand Options

This German-manufactured system has been the global benchmark of Shore hardness testing systems since 1954. With ever enhanced ergonomic design, the HP Shore Hardness Tester is both visually appealing and precise rubber and plastic testing system as it has been for nearly 50 years.

Akron Abrasion Tester

GenKron is used together with a special balance for testing the abrasive consumption of materials. The measurements are done through volumetric loss of a rotating specimen exposed to the action of a standard grinding wheel. It is especially suited for testing harder materials such as shoe soles, tires and other rubber materials.

Burst Strength Tester for Fabric

GenBurst is the Burst Strength Tester designed to test anti-rupture strength of variety of materials such as leather, paper and fabric.

DIN Abrasion Tester

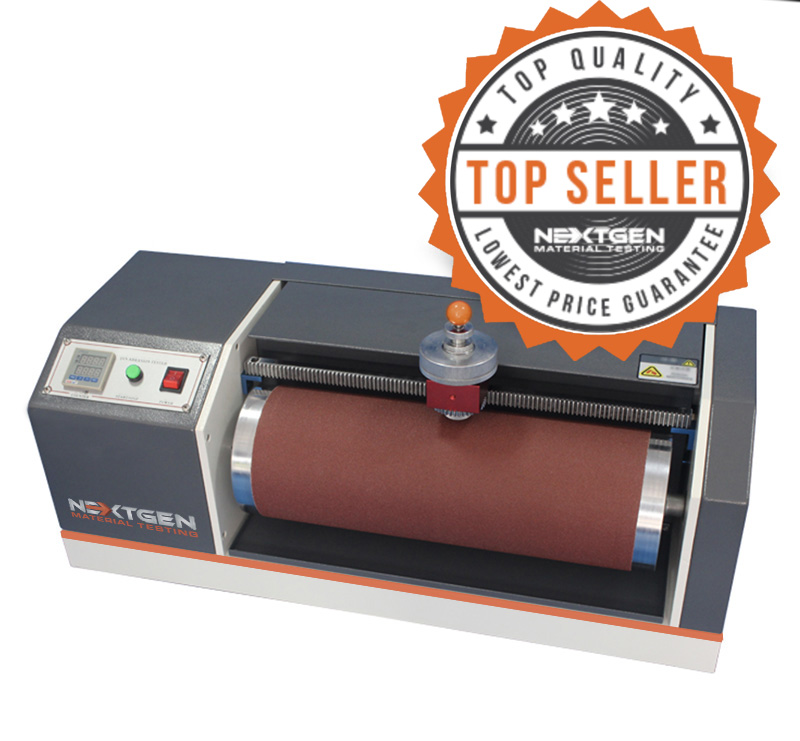

GenDin, is designed to conform to the ASTM D5963 and IS0 4649 standards. This top quality and highly popular abrasion tester will allow you to measure the abrasion resistance of rubbers (vulcanized thermo set rubbers and thermoplastic elastomers) that are subject to abrasive/frictional wear on their actual service. Since wear is always a result of abrasion, different test methods have been developed for the simulation of long term wear.

Demattia Flex Cracking Tester

GenFlex tests the ability of rubber products to withstand repeated flexing without developing cracks is of prime importance where such products are used in conditions undergoing repeated flexing. Flexing endurance of rubber products is determined by simulating in laboratory the action of flexing repeatedly under standard conditions of speed, mode, and degree of flexing.

Discoloration Meter

The machine is used to simulate an environment of sunlight radiation on a specimen to identify the resistance of fabric to discoloration.

Electric Crocking Tester - GenCrock

The machine is used to test the dyeing of the fabric, and the fade degree of the leather after dry or wet rubbing. The test method involves the specimen to be fastened to the base of the crocking meter and rubbed with an abrasive hammer attached to a wet or a dry cloth under controlled conditions. The transfer of colour is then measured using a scale to evaluate the rating of the specimen's dyeing grade.

Freezing Tester - GenFreeze

GenFreeze is specially designed to test the characteristics of various materials in a cold environment to ensure suitability for use in a cold climate. Based on the testing demand, adjust the beater and flexing grip, then load to the desired position. It can be used to test rubbers, leather, and plastics, PU leather etc. The unit can be adjusted to meet different requirements.

Martindale Abrasion Tester - GenDale

GenDale is mainly used to test shoe fabric, shoe lining, and many other types of shoe related materials. The unit can test up to four specimens at the same time for abrasion. The fabric specimen is measured by having rubbing applied on it via a complex direction of back and forth motion. The accuracy of abrasion strength is determined by the specific number of cycles conducted until a hole appears in the test area of the fabric specimen.

Mooney Viscosity Testing Machine - GenMooney

GenMooney is a viscosity testing machine is applied to measure the viscosity of the unmixed or mixed unvulcanized natural rubber, synthetic rubber and regenerated rubber .This tester has many functions such as fast warming, maintaining temperature, data stability, etc. It is equipped with an automated calibration feature for a simple data calibration of each experiment.

NBS Rubber Abrasion Tester - GenNBS

GenNBS is used to test the abrasion resistance of vulcanized rubber or other rubber compounds. It is commonly used for the soles and heels of footwear. It has an intelligent power failure recovery system. The unit conducts measurements through volumetric loss of specimens exposed to the action of a normalized abrasive medium secured to a rotations cylinder.

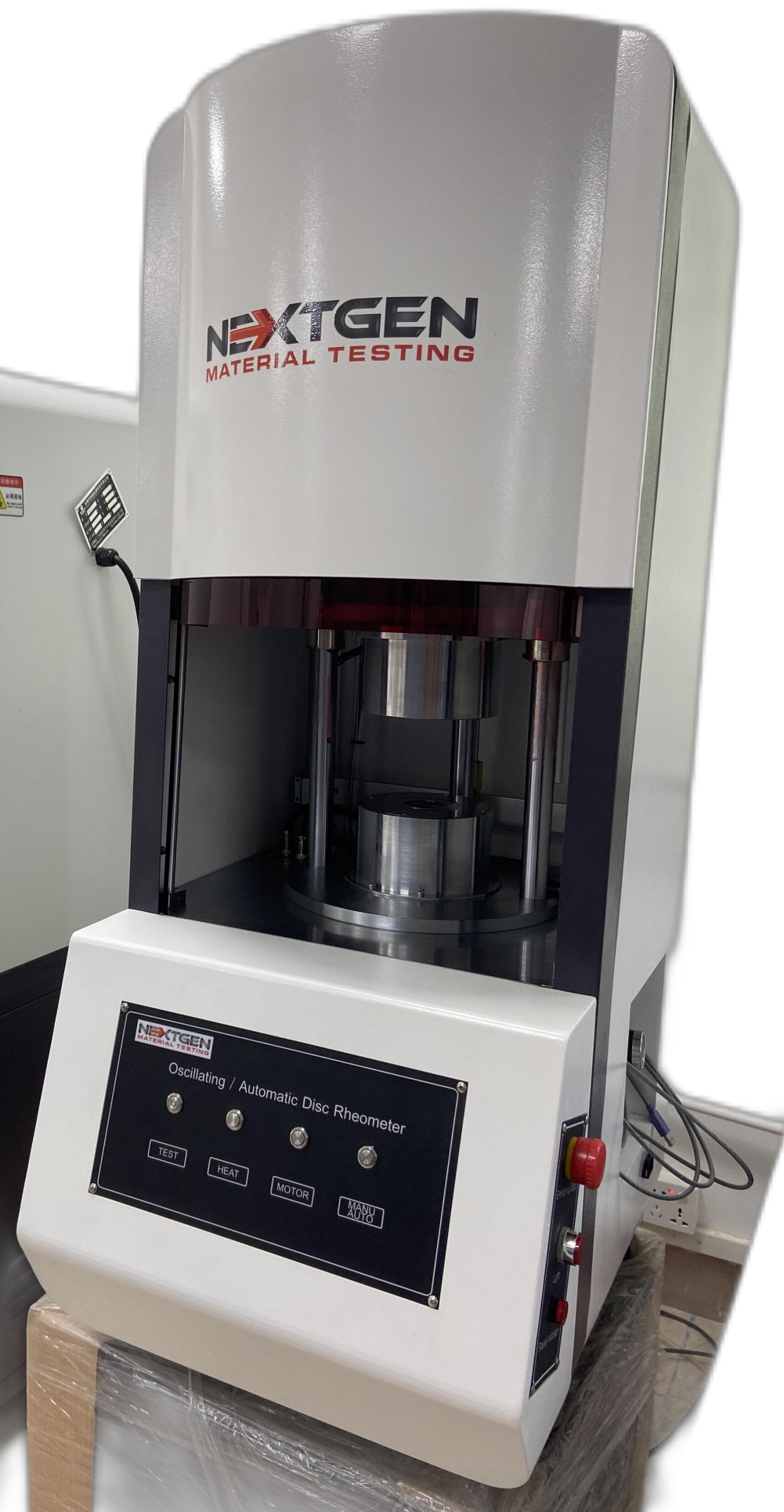

Oscillating / Automatic Disc Rheometer (ODR)

This machine is designed to get the characteristic curve and characteristic parameters of rubber vulcanization by measuring the applied moment of rubber to the oscillating dye body. NG-ODR rotor-free vulcameter has an excellent stability of results. The data and diagrams can be used as a reference for development, research and production quality.

Salt Spray Tester - GenSalt

GenSalt is designed to test the surface of different materials for resistance to corrosion. The unit is commonly used to test coated materials of a metallic nature in a controlled corrosive environment. The test can be used on rust-proof painting, anodizing, electroplating and rust-proof of grease. The machine imitates expedited corrosion process via salt spraying on a given test sample to identify the corrosion (oxides) resistance. Test results are based on the longevity of time a material can resist visible corrosion on the test sample.

Wyzenbeek Abrasion Tester - GenWyze

The machine is designed to test the abrasion resistance of fabrics and metals. The abrasion of fabrics is tested when the specimen is pulled over the frame and rubbed against an abradant over a curved surface. The number of cycles, also known as double rubs, conducted on the specimen before the fabric shows visible wear is used to determine the rating of abrasion.

Vertical Rebound Resilience Tester - GenRebound

GenRebound tests the resilience of rubber compounds. The machine must be adjusted in a horizontal position and the plunger raised at a specific height. The plunger is then released onto the specimen for a given number of impacts. The measurements are based on the 4th, 5th, and 6th impacts. The average of the three (3) measurements is then calculated for the test result. The machine is highly useful in production of compounds designed to absorb vibration or shock according to the ASTM standards.

Digital Densimeter Systems

Description The NG-DM-A Series offers high-accuracy digital Densimeters designed for a wide variety of material testing needs. These elegant and compact densimeter systems offer capacity ranges from 150g to 3000g with accuracy of 0.001g/cm3 down to 0.0002g/cm3. Advanced Densimeter System […]

Ross Flex Tester

Ross Flex Tester is designed to determine the resistance of vulcanized or synthetic elastomers to cut growth. The system does so under continuously bend flexing in 90°.