Rubber Testing Equipment

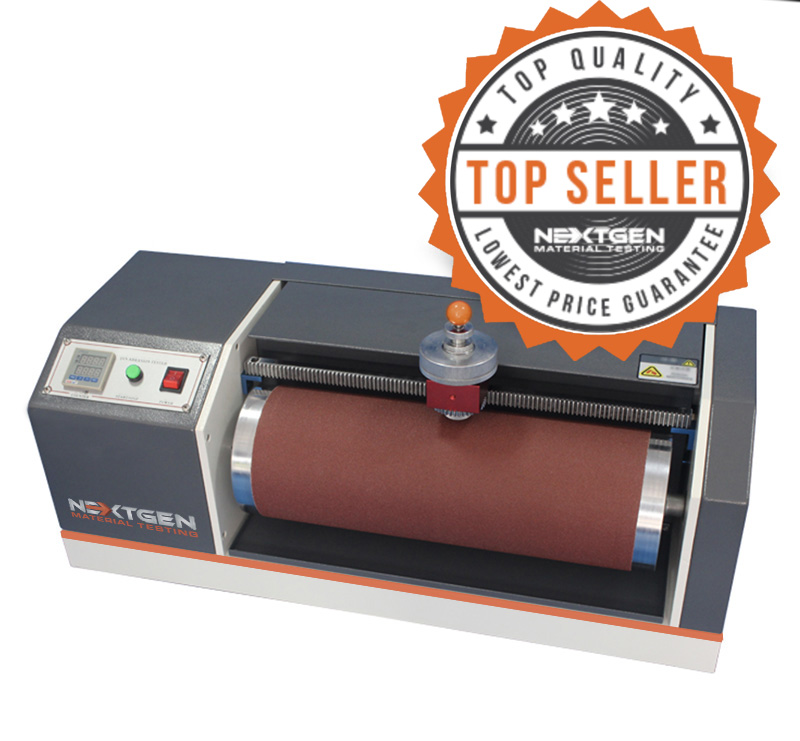

GenKron is used together with a special balance for testing the abrasive consumption of materials. The measurements are done through volumetric loss of a rotating specimen exposed to the action of a standard grinding wheel. It is especially suited for testing harder materials such as shoe soles, tires and other rubber materials.

Specifications

| Type | GenKron-A | GenKron-B |

|---|---|---|

| Grinding Wheel | Granularity: 36 | Granularity: 40 |

| Rubber Wheel Speed | 76±2 rpm | |

| Grinding Speed | 34±1 rpm | |

| Angle of Inclination | 0 - 35° adjustable | |

| Counter | LCD 0 - 999.999 | |

| Load | 26.7N ± 0.2N | 1.81kg, 5.43 kg |

| Dimensions (W X D X H) | 60 X 45 X 40cm | |

| Weight | 60 kg | |

| Power | AC 110V / 50Hz 0.2 kW | |

FAQs

Both the GenBurst-AD and GenBurst-A models of the Burst Strength Tester for Fabric have a capacity range of 0-100 kgf/cm². This capacity enables the tester to apply substantial pressure, suitable for assessing the burst strength of various materials, including fabric, leather, and paper. The broad range makes it versatile for different applications, allowing it to handle both lightweight and heavy-duty materials effectively.

The capacity range of this test allows precise control over the pressure applied to the specimen, resulting in accurate and reliable data regarding the material's rupture resistance when subjected to varying levels of pressure.

Click here to learn more about the product or here to receive a personalized quote.

Both the GenBurst-AD and GenBurst-A models operate at an oil pressure speed of 170±10 ml/min. This consistent oil flow rate helps maintain stable pressure during burst testing, resulting in accurate results across different materials. Controlled oil pressure speed is crucial for applying uniform force to the specimen, preventing abrupt pressure changes that could affect the accuracy of the burst strength measurement.

As a result of this setting of oil pressure speed, both models are capable of performing reliably during continuous testing, making them ideal for applications that require steady and repeatable conditions for the operation.

Click here to learn more about the product or here to receive a personalized quote.

In terms of weight, the GenBurst-AD model weighs approximately 132 lbs (60 kg), making it relatively easy to handle and suitable for laboratories that need to move their equipment from time to time.

GenBurst-A is slightly lighter than the GenBurst-C model, and weighs around 110 lbs (50 kg), despite offering additional features such as the PLC touch screen and micro-printer, despite being slightly larger in size. As a result of this weight difference, users have the ability to choose a model that matches the space and mobility needs of their lab, balancing portability and functionality at the same time.

Click here to learn more about the product or here to receive a personalized quote.

Both the GenBurst-AD and GenBurst-A models of the Burst Strength Tester for Fabric support dual voltage options of 110V/60Hz or 220V/50Hz. This dual compatibility enables the machine to operate in diverse lab environments worldwide, whether in North America or internationally, without needing specialized converters or adaptors.

Dual power standards are particularly useful for facilities that need to relocate equipment across regions or serve clients globally. It also simplifies installation, as the tester can be integrated smoothly into numerous setups, guaranteeing its functionality and adaptability to multiple laboratory standards. This capability makes GenBurst suitable for international laboratories, quality control departments, and research centers, making it more versatile across different testing environments.

Click here to learn more about the product or here to receive a personalized quote.

NextGen’s Akron Abrasion Tester standard configuration includes: GenKron-B Akron Abrasion Tester, 3x Grinding Wheels NO36 or NO40), Steel Brush, Power Cord and Instruction Manual. It can be used to perform various abrasion tests.

Taber Abrasion is a simple and affordable process to compare the mass-loss and wear rate of one or more materials or coatings. In a standard Taber abrasion test, wear is measured by placing a disk-shaped specimen in continual contact with an abrasive wheel while applying predetermined forces over a predetermined number of cycles. The ASTM D4060, ASTM F1978-12, and MIL-A-8625 standards are the most frequently utilized for these testing. It also provides sufficient comparative data. It provides side-by-side comparisons of a number of materials or coatings to assess which material has greater wear resistance under simulated, accelerated wear circumstances.

The lead PO time for Akron Abrasion Tester is a few weeks depending on when the PO is placed.

Click here to request a personal quote from our specialists.

It's critical to evaluate wear and abrasion properties during the product development stage because many rubber or plastic materials repeatedly come into contact with different surfaces in their service environment. Abrasion testing can be performed to assess and forecast the material's overall durability as it would function in practical applications.

Rotary Abrasion Drum (DIN Abrasion)

This test method calculates the volume loss brought on by the abrasive action by rubbing a test item over a sheet of a given grade of abrasive material. An abrasion resistance index or a relative volume loss might be used to express the outcome.

The Taber Abrasion

This test procedure assesses a material's resistance to abrasive wear when subjected to the pressure of abrasive wheels. A variety of abrasive wheels, speeds, and test loadings are available from us.

NBS Abrasion

Using a downward force, this test method evaluates the rubber's resistance. This technique is most frequently used to assess footwear components' abrasion resistance, including rubber heels and soles.

NextGen’s Akron Abrasion Tester is 60 X 45 X 40cm and weights 60kgs.

Click here to request a personal quote from our specialists.

It is crucial to understand that while these two characteristics can be reliable signs of an abrasion-resistant rubber, they are not absolute proof. The most precise way to gauge how well a tough rubber handles abrasive conditions is by a volume loss measurement or an adjusted abrasion resistance index %.

Although abrasion-resistant rubber can be tested under controlled circumstances, the outcomes are not necessarily a precise predictor of how a tested protective rubber would perform in settings and conditions encountered in the real world. Because no two wearing processes are precisely the same, abrasion is particularly application-specific. In the case of rubber, several external factors, such as the temperature, pressure, or velocity present in any given application, might influence the degree of abrasion. The outcomes of a test like the ASTM D5963 might not always coincide with actual outcomes due to the factors at play. In some cases, a protective rubber that performs well in a controlled rubber abrasion resistance assessment may not match the characteristics of a highly abrasion-resistant rubber in other environments.

NextGen’s Akron Abrasion Tester counter parameter is LCD 0 - 999.999.

Click here to request a personal quote from our specialists.

It is possible to convert the volume loss measurement into an abrasion resistance index %. A higher number on the index percentage denotes a better outcome and more abrasion-resistant rubber material. Other organizations' standardized rubber abrasion resistance tests have also employed this testing procedure. These include the ISO 4649 test and the DIN 53516 test, which stands for "Testing of Rubber and Elastomers; Determination of Abrasion Resistance" (Rubber, vulcanized or thermoplastic - Determination of abrasion resistance using a rotating cylindrical drum device).

The level of resistance of abrasion-resistant rubber is affected by several properties of the material. The harder and denser the rubber is the higher its durometer. A high-durometer rubber will typically be more resistant to abrasions and indentation. Rubber's tensile strength can potentially impact rubber's resistance to abrasion significantly.

The Angle of Inclination of NextGen’s Akron Abrasion Tester is 0 - 35° adjustable.

Click here to request a personal quote from our specialists.

Abrasion-resistant rubber is put through several standard tests to determine its resistance level. These studies look at the material to determine which rubber varieties are the most resistant to abrasions. The American Society for Testing and Materials developed one such test, the ASTM D5963, to measure rubber's abrasion resistance. This test entails applying pressure on the material to examine how it responds while documenting the outcomes. A specialized machine with a rotating drum and abrasive surface is set up. The machine is outfitted with a rubber material sample, which is mechanically rotated around the drum.

To provide a fair and consistent reading, the machine is programmed to apply the same amount of pressure to each sample. After the test, the material's volume loss is calculated in cubic millimetres. The reading number will be lower for a tough rubber with a high level of rubber abrasion resistance.

The grinding speed of NextGen’s Akron Abrasion Tester is 34±1 rpm.

Click here to request a personal quote from our specialists.

One of the most important factors when working with various varieties of rubber is rubber abrasion resistance. A rubber resistant to abrasion may be required in applications with high physical demands. Knowing what abrasion-resistant rubber is, how it is assessed, and how this resistance affects performance in high-stress environments will help you choose and use the best material in an abrasive environment.

Abrasion refers explicitly to the wear that a material experiences due to friction when it comes into contact with another object. Numerous distinct processes may be at blame for this wear. These can involve a variety of actions, such as grinding, sliding, scuffing, and repeated collisions.

Rubber's capacity to endure such abrasive wear is known as rubber abrasion resistance. Certain types of strong rubber are ideal for certain jobs because they excel at protecting against abrasions. Abrasion is typically more likely to happen when motion is present since this causes a higher rate of friction-induced wear. By giving you a highly protective rubber surface, abrasion-resistant rubber can be the secret to success in this type of application.

Click here to request a personal quote from our specialists.

The abrasion test procedure (ISO 4649 / DIN 53516) is fairly straightforward. By rubbing a test piece of rubber across the surface of an abrasive sheet mounted on a rotating drum, abrasion resistance is measured. It is expressed as a reduction in volume measured in cubic millimetres, such as 150 mm3.

The most crucial thing to remember when analyzing the abrasion test results is that higher numbers indicate a weaker resistance to abrasion due to a greater loss of surface rubber. The stronger the wear resistance, however, the lower the figure. A single belt with strong abrasion resistance can frequently outlast two or even three 'budget' belts of lesser grade.

Numerous applications call for materials that can withstand abrasive conditions and difficulties, particularly in industrial settings. Rubber that can withstand abrasion is the ideal substance. Make sure you are aware of how rubber abrasion resistance is evaluated, and choose a protective rubber that performs well under the harsh conditions of a rotating drum. This will assist you in selecting the best material forms to withstand the roughest situations.

The rubber wheel speed of NextGen’s Akron Abrasion Tester is 76±2 rpm.

Click here to request a personal quote from our specialists.

To provide a consistent outflow of light, the abrasive method involves utilizing an abrasive substance to produce mechanical surface flaws in the fibre. Abrasives may be sprayed on the surface to be abraded, or mechanical tools (such as a knife or sandpaper) may be used (sanding, etc.). For instance, by creating brilliant reflections at the fibre edges, the latter treatment of the fibres, most notably by sanding, produces patterns.

By modifying the optical sheath's surface, making "micro-perforations" or rough patches, using an abrasive, producing surface flaws, and allowing light to leak out along the fibres, it is possible to change the way that optical fibres conduct light. The original optical fibre then transmits the light radiation from one end of the fibre to the other while according to the laws of waveguides.

The luminous surface flux is maintained constant by administering a progressive treatment along the optical fibres, which is confirmed by observing the radiation that can be seen on the fabric.

NextGen’s Akron Abrasion Tester is especially suited for testing harder materials such as shoe soles, tires and other rubber materials.

Click here to request a personal quote from our specialists.

In traditional pneumatic conveying systems, only bulk particle materials with particular qualities may be transported in dense phase and hence at low velocity. The term "conventional pneumatic conveying systems" refers to those where the material is supplied in the pipeline at a constant rate and is blown or sucked through the pipeline with a constant flow of air. In traditional pneumatic conveying systems, materials with strong air retention may typically be transported relatively naturally at low velocity in a moving bed-type of dense phase flow. Good permeability materials may typically be transported at low velocities as well, albeit in a dense phase flow mode similar to a slug or plug in traditional pneumatic conveying systems.

But most bulk particle materials that need to be pneumatically transported typically don't have enough air retention or permeability for low-velocity dense phase conveying, thus, they can only be delivered in a traditional pneumatic conveying system using a dilute phase suspension flow.

The measurements, in Akron Abrasion Tester, are done through volumetric loss of a rotating specimen exposed to the action of a standard grinding wheel.

Click here to request a personal quote from our specialists.

Abrasive material machining is becoming increasingly significant across many different businesses and not only the engineering sector. Tight tolerances are possible due to the procedures employed to manufacture well-controlled surfaces of high quality. Tough materials can also be machined.

The individual cutting edges in abrasive machining have a random distribution and direction in contrast to conventional cutting techniques. Since microscopic particles provide the cutting edge, the depth of engagement must also be minimal. These characteristics lead to varied chip production since any given grain may come into contact with the work at a positive, zero, or, in most cases, a negative rake angle. As a result, particles may simply distort the surface, plough into it, or produce chips.

GenKron – Akron Abrasion Tester is used together with a special balance for testing the abrasive consumption of materials.

Click here to request a personal quote from our specialists.

Related Products

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

ICI / Mace Snag Tester

Discover the Fabric Textile ICI / Mace Snag Tester, a reliable tool for assessing fabric snagging under normal wear conditions.

Moving Die Rheometer (MDR)

Introducing the NG-MDR Moving Die Rheometer, your solution for accurately assessing the curing and processing characteristics of vulcanized rubber compounds. Designed for precision, this state-of-the-art rheometer captures the characteristic curve and parameters of rubber vulcanization by measuring the torque applied to the oscillating die.

Aging Oven

Our aging oven is well-suited for performing drying, baking, wax melting, and sterilization experiments in industrial and mining enterprises, as well as in laboratories, colleges, and research institutions.

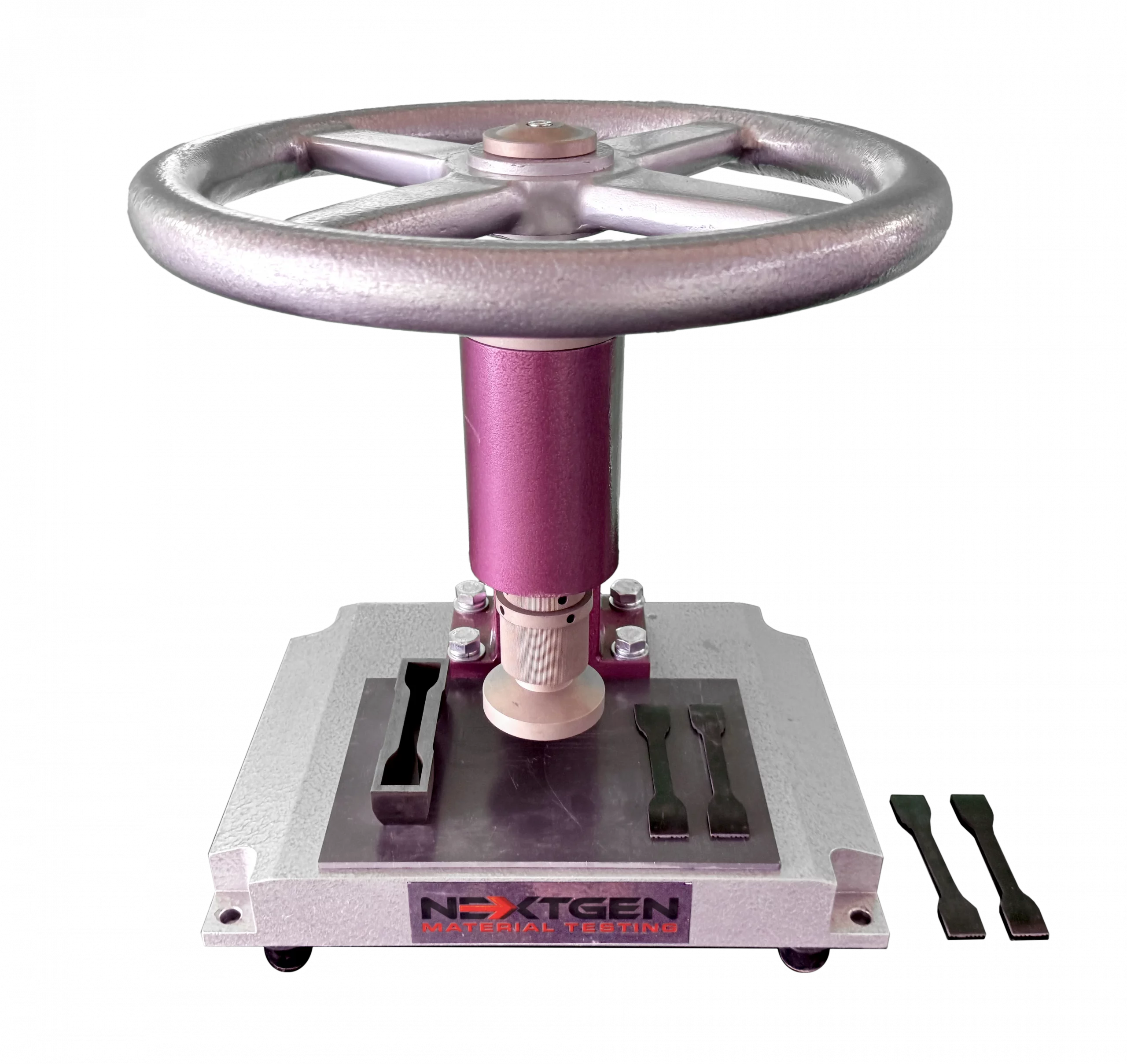

NG-T-Press M Series - Manual Cutting Press System for Rubber Tensile Specimens

Our newest manual cutting press system is suitable for laboratories to create specimens from rubber, tape, and special materials.

Rotary Abrasion Tester Single & Dual Wheel

GenRotary used evaluate abrasion resistance. It can conduct tests on a wide range of materials such as: cloth, paper, paint, plywood, leather, tile, glass, rubber etc. It tests the specimen by rotating it while in contact with the grinding wheel and applying the required pressure. The Joss of weight reflects on the change in weight of the specimen. The unit also has an intelligent power failure recovery function.

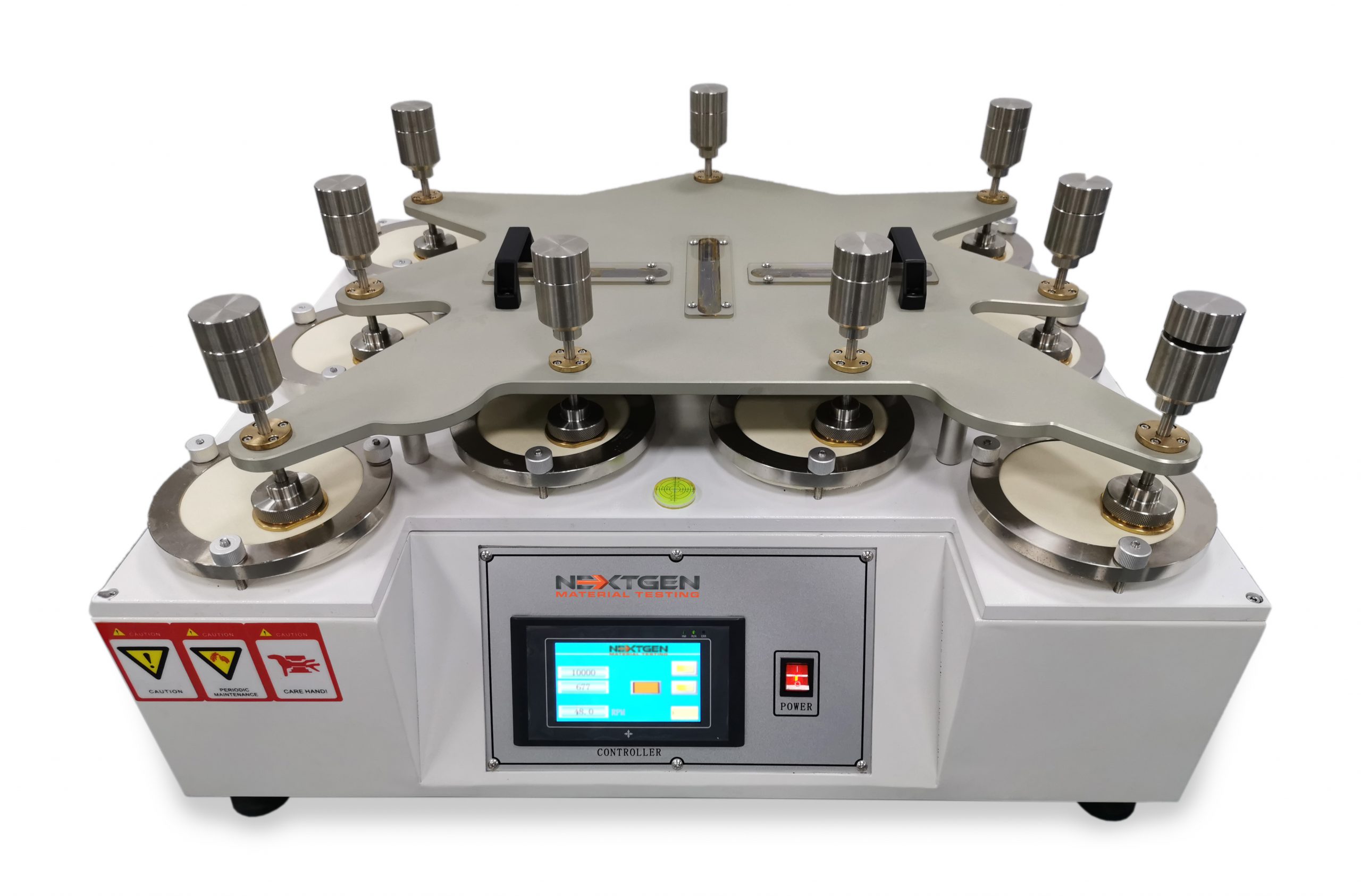

9-Station Martindale Abrasion Tester

The GenDale - Martindale Abrasion Tester is mainly used to test shoe fabric, shoe lining, and many other types of shoe related materials.

GenRoss-CH - Ross Flex Tester with Low Temperature Chamber

GenRoss-CH is an advanced Ross Flex Tester designed for assessing the cold resistance of materials in low temperature environments.

Linear Taber Abrasion Tester

NextGen's linear abrasion meters evaluate the abrasion and scratch resistance of products, along with color transmission.

NextGen Environmental Chambers NG-EC 100,150,225,408,1000

The temperature and humidity NextGen Environmental Chambers features a sturdy cabinet made of cold-rolled steel and stainless steel.

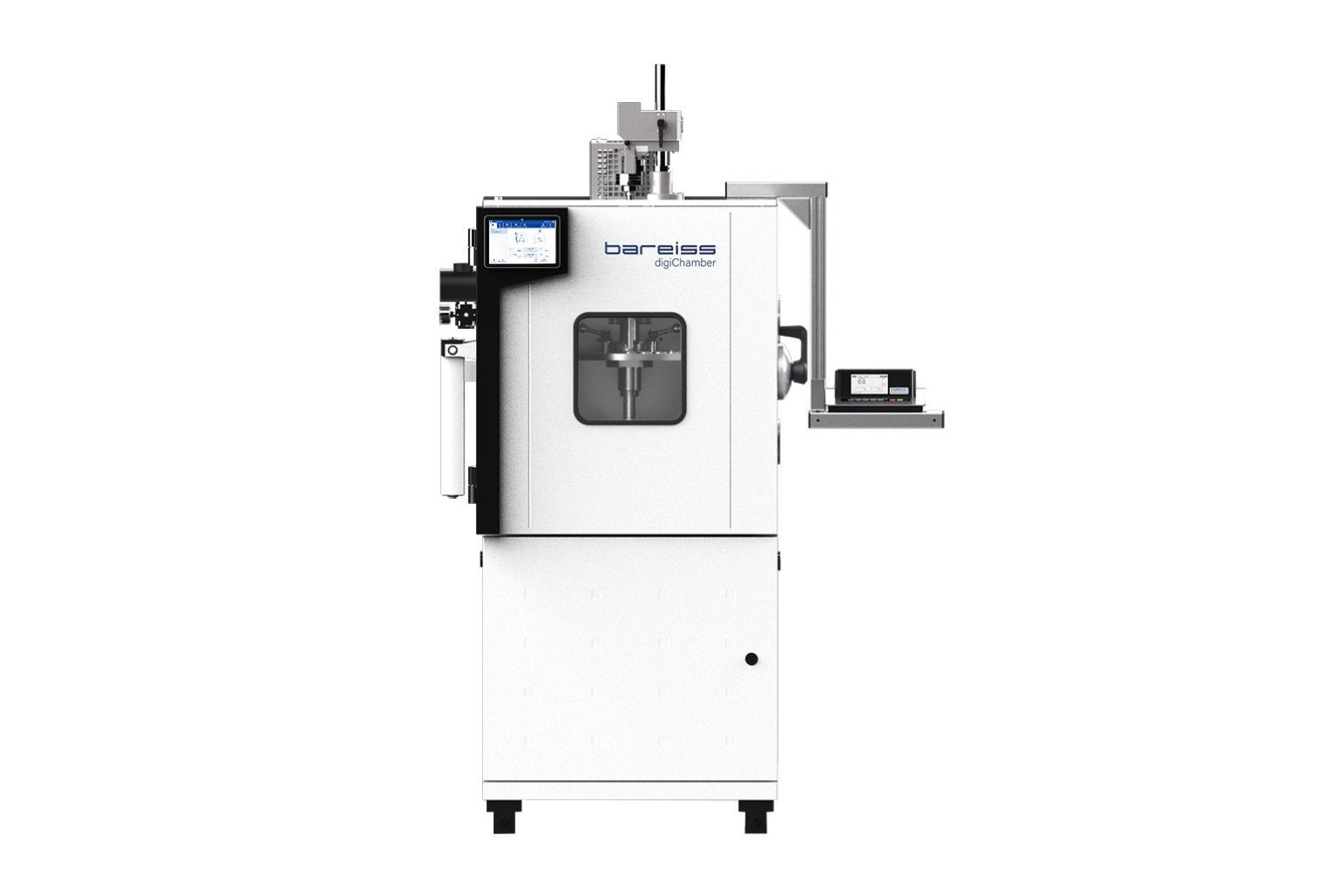

digiChamber - Temperature Controlled Hardness Testing

Discover digiChamber from NextGen Material Testing, the advanced temperature-controlled hardness tester developed by Bareiss.

HDA 120 - Hardness and Density Automation Test System

The HDA 120 test system is a versatile solution for semi-automatic detection of sample hardness and density.

RPA Ultra - Advanced Rubber Process Analyzer Rheometer

RPA Ultra is an advanced rubber process analyzer rheometer that measures the dynamic and static characteristics of raw rubber compounds

NG-EML Series B – Dual Column Bench Top Universal Testing Machine (100 N – 10 kN)

The NG-EML Series B is a high-precision dual-column benchtop universal testing machine engineered for tensile, compression, and flexural testing in the 0.1 kN to 10 kN range. It features Class 0.5 accuracy, a rigid FEM-optimized frame, and a direct-drive servo system with advanced closed-loop control, making it ideal for testing rubber, plastics, metals, composites, and high-performance polymers in both R&D and quality assurance settings.

NG-EML Series C – Dual Column Bench Top and Floor Standing Universal Testing Machine (5 kN – 50 kN)

The NG-EML Series C is a precision-engineered dual-column universal testing machine for tension, compression, and flexural testing of metals, composites, rubbers, and polymers. Available in both bench-top and floor-standing formats, with force capacities from 5 kN to 50 kN and Class 0.5 accuracy.

NG-EML Series D – Floor Standing Universal Testing Machine (50 kN – 1000 kN)

The NG-EML Series D – Floor Standing Universal Testing Machine (50 kN–1000 kN) is a dual-column system for tensile, compression, flexural, shear, and cyclic testing of high-strength metals, composites, polymers, and advanced materials. Available in single-space and dual-space configurations, it meets ASTM E8, ISO 6892-1, ISO 527, and GB/T 228 standards. With closed-loop control, 1200 Hz sampling, ultra-low speeds (0.00005 mm/min), and waveform generation, it is ideal for aerospace, automotive, construction, and research labs.

GenTest Data Acquisition Software - Advanced Universal Testing Machine Software

Upgrade to GenTest, the latest data acquisition software for universal testing machines. Ensure precise, repeatable material testing with an intuitive interface, powerful analysis tools, and full compliance with ASTM, ISO, DIN, and more.

Automatic Shore, IRHD and VLRH Hardness Testing System

NextGen is proud to present our German line of fully-automatic Shore, IRHD and VLRH hardness testing system for plastic materials, plastic and foam compounds for the ultimate precision, accuracy and repeatability, exceptional ease-of-use and maintenance. Experience the industry leader for specimen testing including rubbers, plastics, foams, composites, o-rings, and more.

Advanced Portable Shore Durometer System with Test Stand Options

HPEIII is NextGen's advanced German line of equipment that is the new generation of HPE systems ideal for various plastic and plastic compound testing. The new system enhancements offer advantages including temperature sensor, reading values of ambient temperature and humidity, historical hardness value display, larger LCD display, standard USB connection and much more. These advanced portable systems can be paired up with either manual or automatic motorized test stands to help eliminate the human error factor and maximize accuracy and repeatability between test when switching from one operator to the next.

Classic Analogue Shore Durometer with Test Stand Options

This German-manufactured system has been the global benchmark of Shore hardness testing systems since 1954. With ever enhanced ergonomic design, the HP Shore Hardness Tester is both visually appealing and precise rubber and plastic testing system as it has been for nearly 50 years.

Burst Strength Tester for Fabric

GenBurst is the Burst Strength Tester designed to test anti-rupture strength of variety of materials such as leather, paper and fabric.

DIN Abrasion Tester

GenDin, is designed to conform to the ASTM D5963 and IS0 4649 standards. This top quality and highly popular abrasion tester will allow you to measure the abrasion resistance of rubbers (vulcanized thermo set rubbers and thermoplastic elastomers) that are subject to abrasive/frictional wear on their actual service. Since wear is always a result of abrasion, different test methods have been developed for the simulation of long term wear.

Demattia Flex Cracking Tester

GenFlex tests the ability of rubber products to withstand repeated flexing without developing cracks is of prime importance where such products are used in conditions undergoing repeated flexing. Flexing endurance of rubber products is determined by simulating in laboratory the action of flexing repeatedly under standard conditions of speed, mode, and degree of flexing.

Discoloration Meter

The machine is used to simulate an environment of sunlight radiation on a specimen to identify the resistance of fabric to discoloration.

Electric Crocking Tester - GenCrock

The machine is used to test the dyeing of the fabric, and the fade degree of the leather after dry or wet rubbing. The test method involves the specimen to be fastened to the base of the crocking meter and rubbed with an abrasive hammer attached to a wet or a dry cloth under controlled conditions. The transfer of colour is then measured using a scale to evaluate the rating of the specimen's dyeing grade.

Freezing Tester - GenFreeze

GenFreeze is specially designed to test the characteristics of various materials in a cold environment to ensure suitability for use in a cold climate. Based on the testing demand, adjust the beater and flexing grip, then load to the desired position. It can be used to test rubbers, leather, and plastics, PU leather etc. The unit can be adjusted to meet different requirements.

Martindale Abrasion Tester - GenDale

GenDale is mainly used to test shoe fabric, shoe lining, and many other types of shoe related materials. The unit can test up to four specimens at the same time for abrasion. The fabric specimen is measured by having rubbing applied on it via a complex direction of back and forth motion. The accuracy of abrasion strength is determined by the specific number of cycles conducted until a hole appears in the test area of the fabric specimen.

Mooney Viscosity Testing Machine - GenMooney

GenMooney is a viscosity testing machine is applied to measure the viscosity of the unmixed or mixed unvulcanized natural rubber, synthetic rubber and regenerated rubber .This tester has many functions such as fast warming, maintaining temperature, data stability, etc. It is equipped with an automated calibration feature for a simple data calibration of each experiment.

NBS Rubber Abrasion Tester - GenNBS

GenNBS is used to test the abrasion resistance of vulcanized rubber or other rubber compounds. It is commonly used for the soles and heels of footwear. It has an intelligent power failure recovery system. The unit conducts measurements through volumetric loss of specimens exposed to the action of a normalized abrasive medium secured to a rotations cylinder.

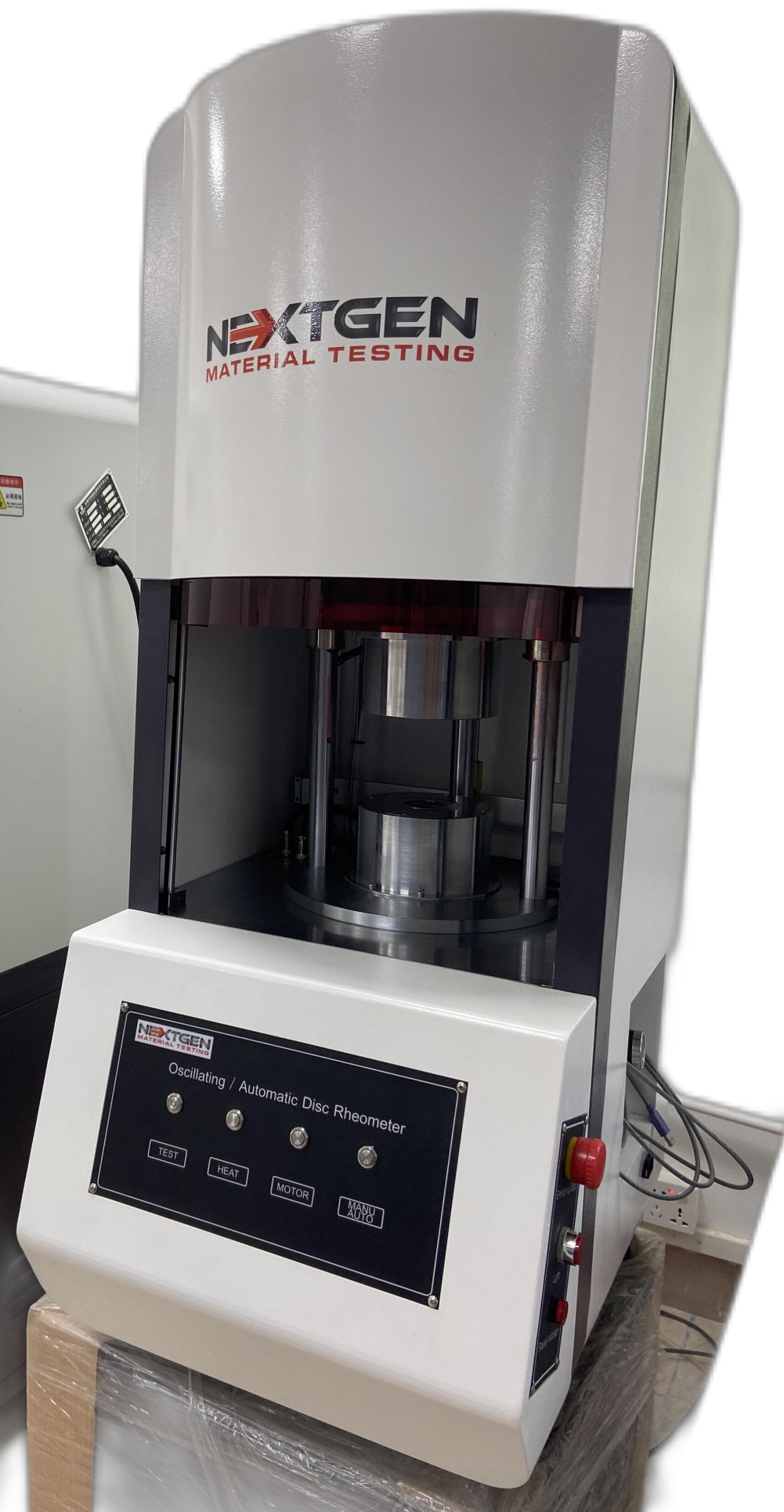

Oscillating / Automatic Disc Rheometer (ODR)

This machine is designed to get the characteristic curve and characteristic parameters of rubber vulcanization by measuring the applied moment of rubber to the oscillating dye body. NG-ODR rotor-free vulcameter has an excellent stability of results. The data and diagrams can be used as a reference for development, research and production quality.

Salt Spray Tester - GenSalt

GenSalt is designed to test the surface of different materials for resistance to corrosion. The unit is commonly used to test coated materials of a metallic nature in a controlled corrosive environment. The test can be used on rust-proof painting, anodizing, electroplating and rust-proof of grease. The machine imitates expedited corrosion process via salt spraying on a given test sample to identify the corrosion (oxides) resistance. Test results are based on the longevity of time a material can resist visible corrosion on the test sample.

Wyzenbeek Abrasion Tester - GenWyze

The machine is designed to test the abrasion resistance of fabrics and metals. The abrasion of fabrics is tested when the specimen is pulled over the frame and rubbed against an abradant over a curved surface. The number of cycles, also known as double rubs, conducted on the specimen before the fabric shows visible wear is used to determine the rating of abrasion.

Vertical Rebound Resilience Tester - GenRebound

GenRebound tests the resilience of rubber compounds. The machine must be adjusted in a horizontal position and the plunger raised at a specific height. The plunger is then released onto the specimen for a given number of impacts. The measurements are based on the 4th, 5th, and 6th impacts. The average of the three (3) measurements is then calculated for the test result. The machine is highly useful in production of compounds designed to absorb vibration or shock according to the ASTM standards.

Digital Densimeter Systems

Description The NG-DM-A Series offers high-accuracy digital Densimeters designed for a wide variety of material testing needs. These elegant and compact densimeter systems offer capacity ranges from 150g to 3000g with accuracy of 0.001g/cm3 down to 0.0002g/cm3. Advanced Densimeter System […]

Ross Flex Tester

Ross Flex Tester is designed to determine the resistance of vulcanized or synthetic elastomers to cut growth. The system does so under continuously bend flexing in 90°.