Metal Testing Equipment

Heavy-Duty Splitting Fixtures for Rock and Composite Shear Testing

NextGen’s category of high-capacity splitting fixtures is engineered for shear and splitting tests on rock, concrete, and composite specimens. These fixtures are purpose-built for use with hydraulic universal testing machines in demanding environments such as geotechnical labs, mining research centers, and structural materials testing facilities. Designed for compatibility with international standards like GB/T 23561.11, they ensure precise and repeatable performance under loads up to 2000 kN or more.

Each fixture in this category features rugged construction, secure mounting systems (including flanges and positioning pins), and flexible specimen accommodation—supporting standard sizes such as Φ50×50 mm and 50×50×50 mm. Whether testing natural rock or engineered composites, these solutions provide the mechanical stability and test consistency required for accurate material analysis.

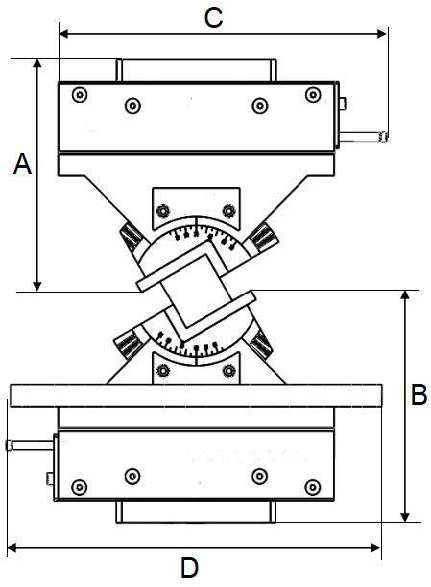

NGA206B – Rock Shear Fixture

The NGA206B Rock Shear Fixture is a high-capacity splitting system designed specifically for shear strength testing of rock specimens. With a rated capacity of ≤ 2000 kN, it supports both cylindrical and cubic sample formats, ensuring versatility across geological testing laboratories. The fixture conforms to GB/T 23561.11 standards and is designed for use under ambient temperature conditions. Its dual-grip system (flange on top and positioning pin on bottom) ensures stability and accuracy throughout each test cycle.

The NGA206B Rock Shear Fixture is a high-capacity splitting system designed specifically for shear strength testing of rock specimens. With a rated capacity of ≤ 2000 kN, it supports both cylindrical and cubic sample formats, ensuring versatility across geological testing laboratories. The fixture conforms to GB/T 23561.11 standards and is designed for use under ambient temperature conditions. Its dual-grip system (flange on top and positioning pin on bottom) ensures stability and accuracy throughout each test cycle.

- Application: Shear testing for rocks.

- Maximum Capacity: ≤2000 kN load.

- Weight:

- Upper Grip: 26 kg

- Lower Grip: 28 kg

- Connection:

- Upper Grip: Flange

- Lower Grip: Positioning pin

- Working Temperature: Ambient.

- Standard Compliance: GB/T 23561.11.

- Grip Dimensions:

- Height (A / B): 210 mm (Upper and Lower)

- Width (C): 310 mm (Upper Grip)

- Width (D): 350 mm (Lower Grip)

- Minimum Test Space: 450 mm.

- Specimen Size Supported:

- Cylindrical: Φ50 × 50 mm

- Cubic: 50 × 50 × 50 mm

Technical Specifications – NGA206B Rock Shear Fixture

| Parameter | Specification |

|---|---|

| Application | Shear test for rocks |

| Maximum Force | ≤2000 kN |

| Weight | Upper Grip: 26 kg Lower Grip: 28 kg |

| Connection | Upper: FlangeLower: Positioning pin |

| Working Temperature | Ambient |

| Standard | GB/T 23561.11 |

| Height (A / B) | 210 mm (Upper and Lower) |

| Width (C / D) | Upper: 310 mm Lower: 350 mm |

| Minimum Test Space | 450 mm |

| Specimen Size | Φ50 × 50 mm 50 × 50 × 50 mm |

NextGen’s splitting fixture line offers trusted performance for advanced shear and splitting applications under high loads. With robust design, seamless compatibility with hydraulic UTMs, and adherence to global standards, these fixtures are essential for laboratories and industries focused on evaluating the structural integrity of tough materials. Contact NextGen Material Testing Inc. to find the right splitting fixture setup for your testing needs.

Related Products

Impact Specimen Cooling Temperature Chamber – NG-ISCC Series

The NG-ISCC Low Temperature Chamber is built to cool and stabilize Charpy impact specimens before testing. It supports conditioning from +30°C down to -60°C, -80°C, -100°C, or -196°C depending on the model. NG-ISCC-60 and NG-ISCC-80 use compressor-based refrigeration, while NG-ISCC-100 and NG-ISCC-196 use liquid nitrogen cooling to achieve ultra-low setpoints. Temperature control accuracy is ≤ ±0.5°C with a 0.01°C instrument resolution, using ethanol or another non-freezing solution as the cooling medium. It is widely used in materials testing and quality control programs to evaluate low-temperature toughness of metals and alloys.

TensileMill CNC Classic Upgrade – Flat Tensile and Charpy/Izod Impact Specimen Preparation System

The TensileMill CNC Classic Upgrade is a hybrid CNC system for preparing standardized flat tensile and Charpy/Izod impact test specimens in-house. It supports ASTM E8, ASTM E23, ISO, DIN, and JIS geometry formats and provides stable machining accuracy for consistent batch-to-batch results.

Automatic Longitudinal Polisher System for Tensile Specimens – NG-AutoPol

The NG-AutoPol Automatic Longitudinal Polisher System by NextGen Material Testing Inc. is engineered to minimize grinding stress and residual surface stress that often remain after initial machining operations such as turning or milling. This advanced machine delivers precise longitudinal polishing […]

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

Alignment Device

(NADCAP-Ready Precision Fixture)

NextGen Material Testing’s Alignment Device is a precision-engineered fixture designed to ensure perfect axial alignment in universal testing machines.

G-800E Trinocular Metallurgical Microscope

This inverted metallurgical trincoular microscope is ideal for both industrial or educational metallurgy applications.

Class J - Charpy and Izod Automatic Impact Testing System - 1J - 50J

Class J is widely used for lzod and Charpy impact test on softer metals, plastics and rubber specimens. Equipped with tensile impact pendulum and fixtures, it can carry on tests on plastic film and sheet. The newly enhanced design offers the most cost-effective configuration to address Charpy test from 1J to 50J (0.7 - 37 ft/lbs), and lzod test from 1J to 22J (0.7 - 16 ft/lbs).

Class D Single-Column Charpy Impact Tester – High-Precision Pendulum Testing Machine

NextGen’s Class D Single-Column Charpy Impact Testing System is built for high rigidity and dependable specimen testing across a wide energy range. It supports impact energies from around 150 J (111 ft-lbs) up to around 750 J (553 ft-lbs), covering most standard metal testing needs. The unit includes a digital display and offers a software upgrade option for data plotting. Additional features, such as automated specimen feeding and integrated cooling or heating systems, are available as optional enhancements.

Class G Single-Column Charpy & Izod Impact Tester – High-Precision Pendulum Testing Machine

NextGen's Class G – Single Column Charpy and Izod Impact Testing system provides a high level of rigidity and specimen testing capacity. This Charpy and Izod Impact tester has a minimum capacity of 150 J (111 ft/lbs) and a maximum capacity of 750 J (553 ft/lbs). The system comes standard with a digital display with software upgrade function for data plotting. The Class G impact system can also include automatic specimen feeding, cooling and heating systems as optional upgrades.

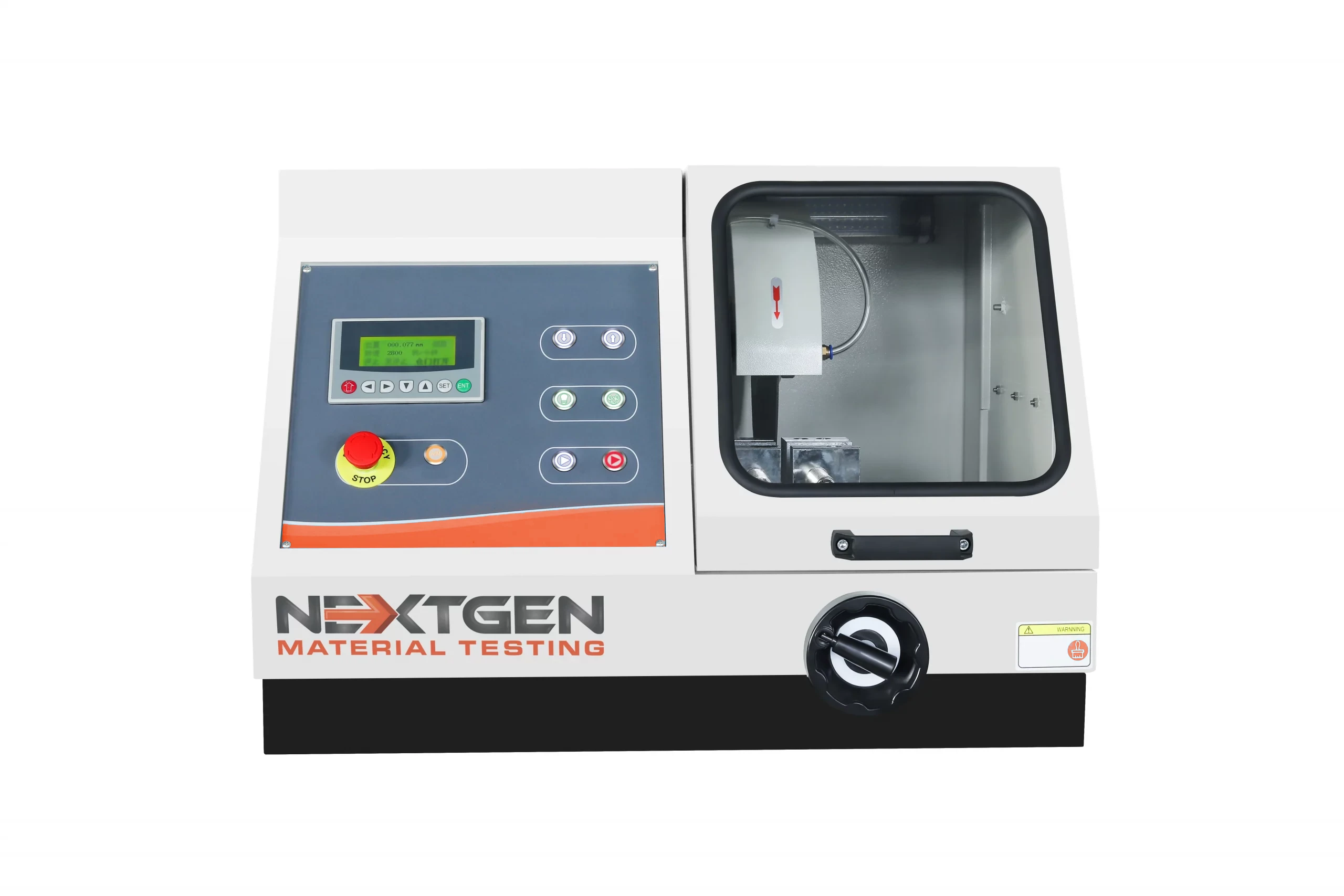

GenCut GL100M – Precision Manual Metallographic Sample Cutting Machine with Simple User-Friendly Operation and Large Cutting Capacity Φ100mm

Introducing the GenCut GL100M Manual Cutting Machine, expertly designed for precision metal sample cutting.

GenCut GL350 – Precision Metallographic Sample Cutting Machine with Simple User-Friendly Operation and Large Cutting Capacity Φ100mm

The GenCut GL350 is a cutting-edge high precision cutting machine equipped with advanced features and capabilities

GenCut GL80A – Precision Metallographic Sample Cutting Machine with Simple User-Friendly Operation and Large Cutting Capacity Φ80mm

Introducing the GenCut GL80A, a highly precise cutting machine offering both automatic and manual work modes.

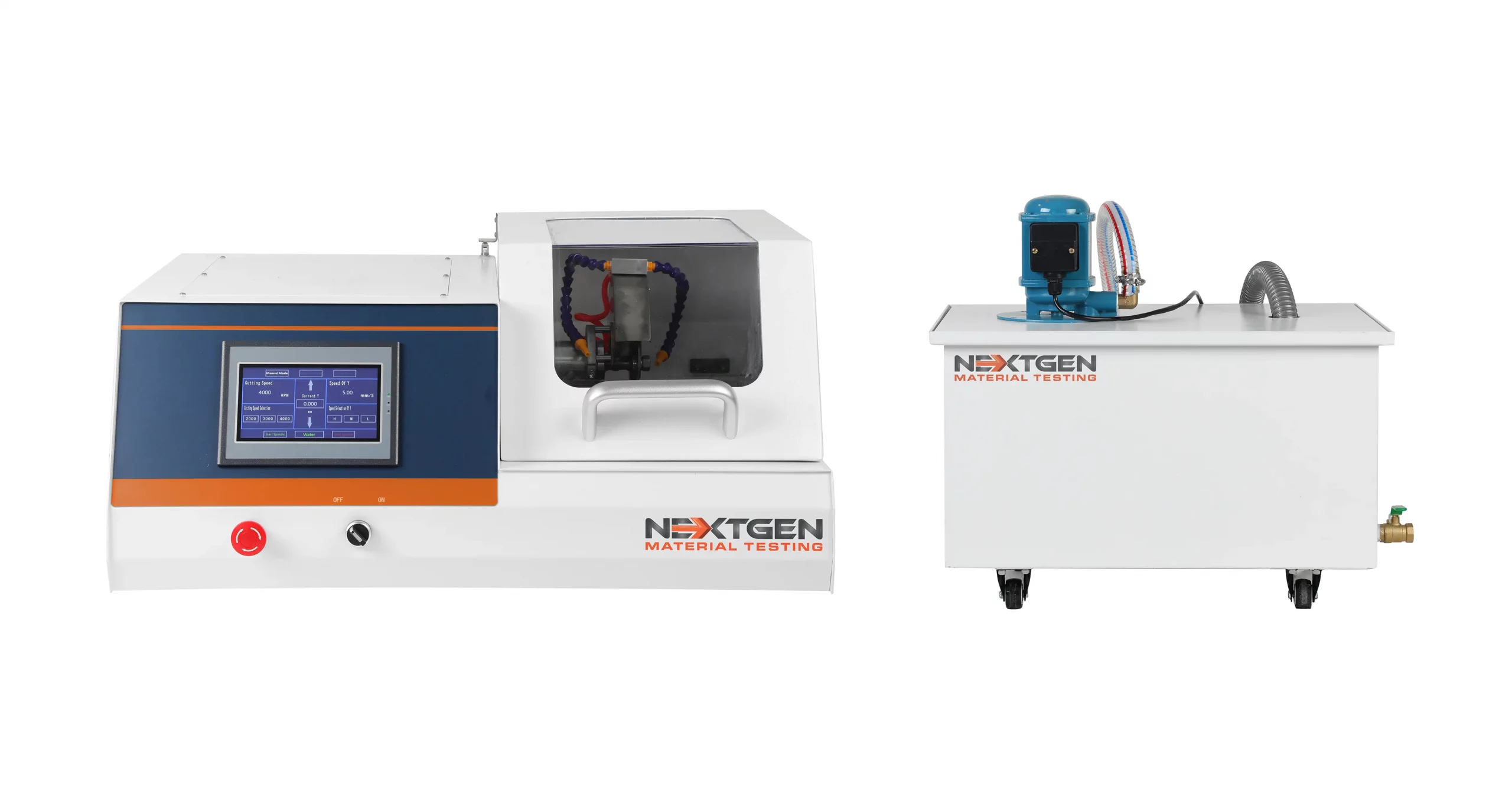

GenCut GL 170XY – Multi Function Abrasive Cut Off Saw with Touch Screen User Friendly Interface and Large Cutting Capacity – Φ170mm

The GenCut GL 170XY has a large 170mm diameter maximum cutting capacity equipped with a fully automated XY table.

GenCut GL 120XY – Multi Function Abrasive Cut Off Saw with Touch Screen User Friendly Interface and Large Cutting Capacity Φ120mm

The GenCut GL 120XY has a large 120mm diameter maximum cutting capacity equipped with a fully automated XY table.

GenCut GL200E – High Speed Automatic Precision Metallographic Cutter with User-Friendly Touch Screen Interface with max. cutting diameter of 60mm

GenCut GL 200E precision cutting machine includes a touch screen and PLC control, with stable performance and real-time display parameters.

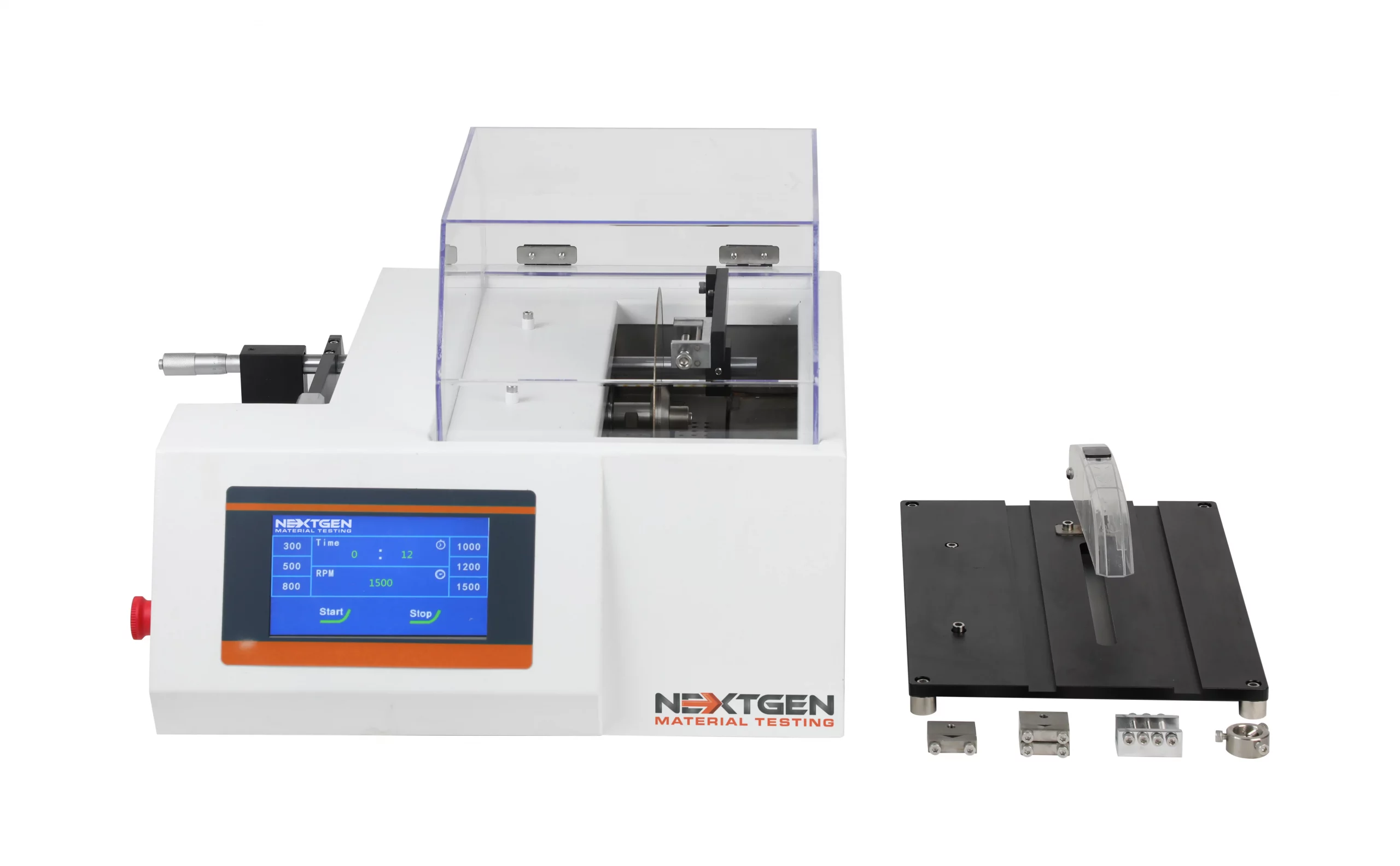

GenCut GL100E – Low Speed Precision Metallographic Automatic Cutter with User-Friendly Touch Screen Interface with max. cutting diameter of 25mm

GenCut GL100E low speed series metallographic precision cutter has variable speed control from 50-1000 rpm.

GenGrind N Series 8” 200S / 10" 250S / 12" 300 S - Advanced Metallographic Grinder & Polisher - Variable Speed 50-1000rpm –Touch Screen Controlled

Introducing the GenGrind N Series metallographic grinders and polishers, offered in sizes 8", 10", or 12" diameter.

GenGrind SA-I 250S 10" Single Wheel Semi Automatic Grinder & Polisher - Variable Speed 100-1000rpm – Individual Force Control - Touch Screen Controlled with Automatic Specimen Mover Power Head – (various wheel sizes available)

Discover the single wheel semi automatic GenGrind 10" SA-I 250S, your ultimate answer to grinding and polishing needs.

GenGrind SA-C 250S 10" Single Wheel Semi Automatic Grinder & Polisher - Variable Speed 100-1000rpm – Central Force Control - Touch Screen Controlled with Automatic Specimen Mover Power Head – (various wheel sizes available)

Introducing the GenGrind SA-C 250S – your ultimate single wheel semi automatic grinding and polishing solution.

GenGrind FA-IC 250D 10" Dual Wheel Fully Automatic Grinder & Polisher - Variable Speed 100-1400rpm – Both Individual and Central Force Control - Touch Screen Controlled with Automatic Specimen Mover Power Head – (various wheel sizes available)

Introducing the GenGrind FA-IC 250D Dual Wheel Polisher and Grinder, a fully automatic metallographic grinding and polishing machine

GenGrind FA-IC 250S 10" Single Wheel Fully Automatic Grinder & Polisher - Variable Speed 100-1400rpm – Both Individual and Central Force Control - Touch Screen Controlled with Automatic Specimen Mover Power Head – (various wheel sizes available)

GenGrind FA-IC 250S Single Wheel Polisher and Grinder, an advanced and fully automatic metallographic grinding and polishing machine

GenPress MFA Dual HYD Fully Automatic Dual Hydraulic Mounting Press – Hydraulic Controlled – 1-2” (25-50mm) Mold Assembly (other sizes available upon request)

GenPress MFA DUAL HYD Metallographic Sample Preparation is an advanced automatic mounting press for compression mounting of material samples

GenPress MFA MOT - Fully Automatic Motorized Mounting Press – Motor Controlled – 1-2” (25-50mm) Mold Assembly (other sizes available upon request)

GenPress MFA MOT mounting press system frees the operator to perform other tasks in the laboratory during the cycle allowing better efficiency

GenPress MFA HYD - Fully Automatic Hydraulic Mounting Press – Hydraulic Controlled – 1-2” (25-50mm) Mold Assembly

GenPress Mounting Press for Metallographic Sample Preparation is an advanced automatic mounting press for compression mounting of material sample

Class H - Servo-Motor Dual Column Charpy Impact Tester - 300J, 450J, 600J or 750J

NextGen's Class H – Servo-Motor Dual Column Charpy Impact Testing system offers of an exceptional combination of versatility and robust build. This impact system provides our most durable options designed with a dual column configuration. The system offers the ultimate versatility of testing 300J (212 ft/lbs), 450J (332 ft/lbs), 600J (442 ft/lbs) and a maximum of 750J (553 ft/lbs) capacities based on both Charpy and Izod test methods. The unit comes standard equipped with a servo motor and is designed to test at any preset angle. The unit comes standard with all the functions of our Class G tester as well as enhanced functionality upgrade of a force transducer inside the strikerwhich enables the determination of characteristic force, energy and displacement parameters such as pre-maximum force energy (Wm), the post maximum force energy, the general yield force (Fgy), the force at brittle fracture initiation (Fbf) and the arrest force (Fa).

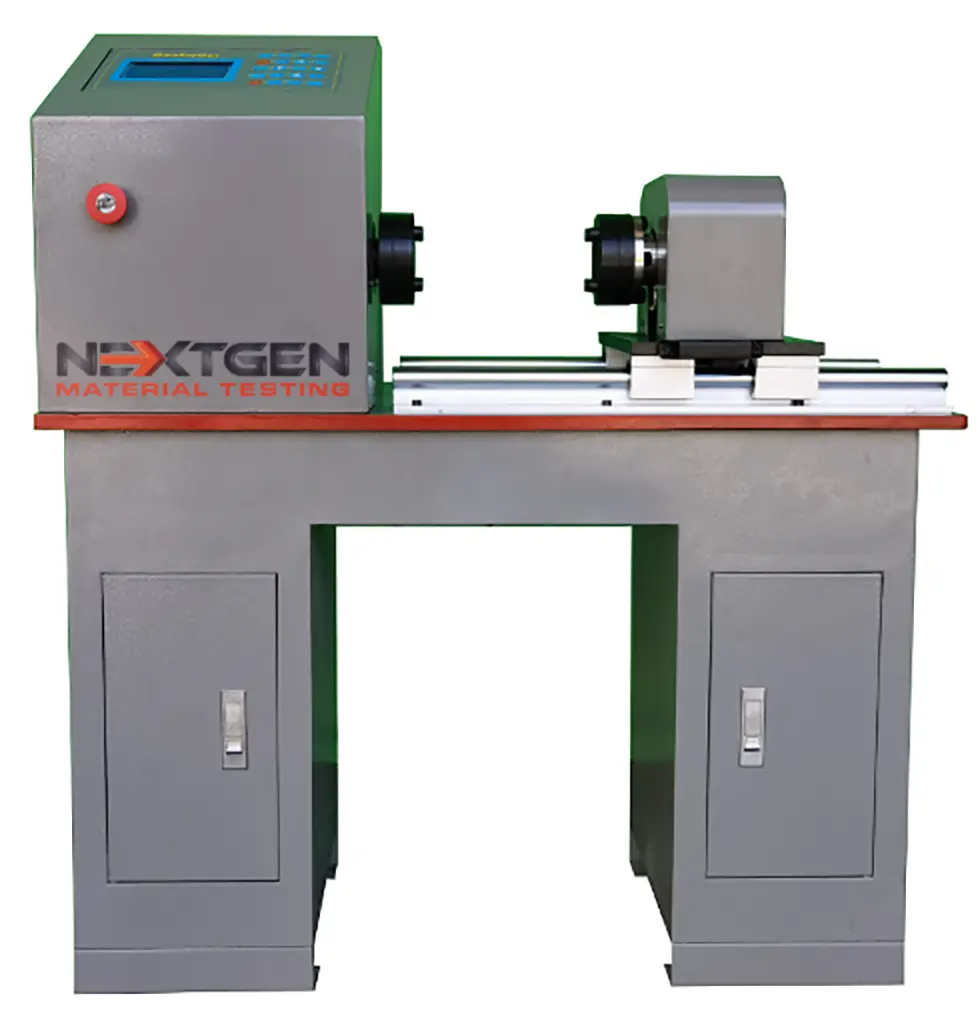

NextGen GenTor Horizontal Torsion Tester

NextGen GenTor Torsion Tester boasts a horizontal type load frame with high stiffness, ensuring accurate and reliable test results.

Triple Specimen Chamber Motorized Charpy Notch Making Machine

The GenNotch 4000UPG Series is a motorized Charpy & Izod Notch Making Machine with a triple specimen chamber.

NG-EML Series B – Dual Column Bench Top Universal Testing Machine (100 N – 10 kN)

The NG-EML Series B is a high-precision dual-column benchtop universal testing machine engineered for tensile, compression, and flexural testing in the 0.1 kN to 10 kN range. It features Class 0.5 accuracy, a rigid FEM-optimized frame, and a direct-drive servo system with advanced closed-loop control, making it ideal for testing rubber, plastics, metals, composites, and high-performance polymers in both R&D and quality assurance settings.

NG-EML Series C – Dual Column Bench Top and Floor Standing Universal Testing Machine (5 kN – 50 kN)

The NG-EML Series C is a precision-engineered dual-column universal testing machine for tension, compression, and flexural testing of metals, composites, rubbers, and polymers. Available in both bench-top and floor-standing formats, with force capacities from 5 kN to 50 kN and Class 0.5 accuracy.

NG-EML Series D – Floor Standing Universal Testing Machine (50 kN – 1000 kN)

The NG-EML Series D – Floor Standing Universal Testing Machine (50 kN–1000 kN) is a dual-column system for tensile, compression, flexural, shear, and cyclic testing of high-strength metals, composites, polymers, and advanced materials. Available in single-space and dual-space configurations, it meets ASTM E8, ISO 6892-1, ISO 527, and GB/T 228 standards. With closed-loop control, 1200 Hz sampling, ultra-low speeds (0.00005 mm/min), and waveform generation, it is ideal for aerospace, automotive, construction, and research labs.

Grips and Fixtures for NextGen Universal Testing Machines (UTMs)

NextGen's grips and fixtures are precision-engineered accessories that transform universal testing machines into versatile systems capable of tensile, compression, flexural, shear, and other mechanical tests. Designed to meet ASTM and ISO standards, these components ensure accurate, repeatable results across various materials and applications.

GenTest – Advanced UTM Testing Software

GenTest Software provides test control and data acquisition for universal testing machine workflows used in quality control and materials testing. It combines method templates, step-based sequencing, live curve monitoring, and built-in calculations in one environment. The software supports standards-based testing programs aligned with ASTM, ISO, DIN, EN, and BS. Results and reports remain linked to the method and specimen inputs for consistent review, auditing, and customer documentation.

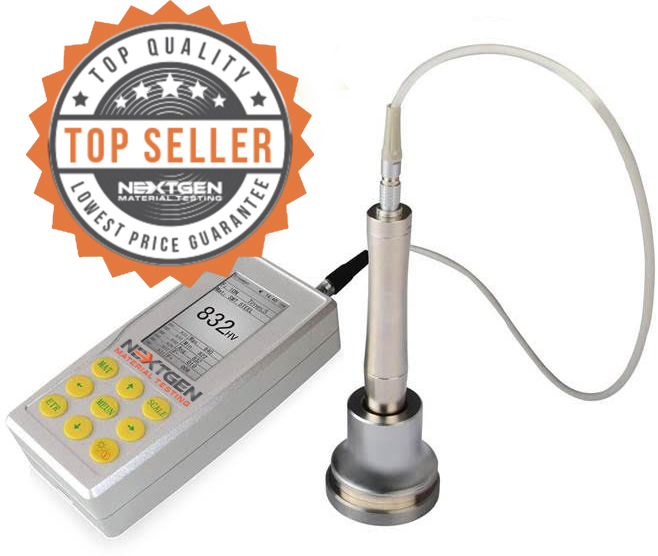

NG - LeebGen 3000 - Leeb Rebound Portable Hardness Tester

LeebGen3000 is a non-destructive precision metal hardness tester developed according to the latest industry standards. LeebGen 3000 is equipped with features which provide the instrument with a combination of a user-friendly interface and exceptional test result accuracy. This in turn allows for ease of operation and an accurate conversion display of virtually any metal hardness testing value.

GenVac MP3 Series - Epoxy Mounting Vacuum Impregnation System for Metallographic Sample Preparation

Experience our enhanced version of the GenVac MP Series. Our user-friendly touch screen interface along with automatic unit conversion and memory modes holds the title of one of the most advanced systems in the marketplace.

TensileTurn CNC – Classic Upgrade – Round Tensile Specimen Preparation Machine

The TensileTurn CNC – Classic Upgrade is engineered specifically for preparing round tensile specimens with controlled gauge dimensions and stable repeatability. The system allows operators to select standardized geometry from ASTM, ISO, or DIN libraries or input custom parameters when required. Materials up to 55 HRC can be processed, including common engineering metals and specialty alloys used in research and production. Its compact footprint and guided interface support both experienced machinists and users without CNC backgrounds.

Ultrasonic Contact Impedance Hardness Tester - UH200

Welcome to our most advanced and cost-effective Ultrasonic Hardness Testing System. This portable machine is all you need and more!

TensileTurn CNC – Industrial Upgrade – Round Tensile Sample Preparation Machine

The TensileTurn CNC – Industrial Upgrade Model is a compact round tensile specimen preparation system designed for accurate and repeatable machining results. Operators can select specimen dimensions from preloaded ASTM, ISO, and DIN standard libraries or enter custom parameters directly through the touchscreen interface. The system supports a wide range of materials and specimen types, including standard round bars, button-head samples, and threaded tensile specimens. Its dedicated CNC control environment enables independent sample preparation without relying on external machine shop resources.

TensileMill CNC XL – Flat Tensile Specimen Preparation Machine

The TensileMill CNC XL – Flat Tensile Specimen Preparation Machine is an advanced CNC system built for accurate and repeatable flat specimen machining. Designed for high-volume testing environments, it supports ASTM E8, ASTM A370, ISO 6892-1, and DIN 50125 standards. Its powerful 5 hp spindle, Mach4-based Carbon™ control, and automatic tool changer deliver fast material processing across metals, polymers, and composites. The heavy cast iron frame ensures vibration-free precision, while the intuitive TensileSoft™ interface allows both trained and new operators to achieve consistent results.

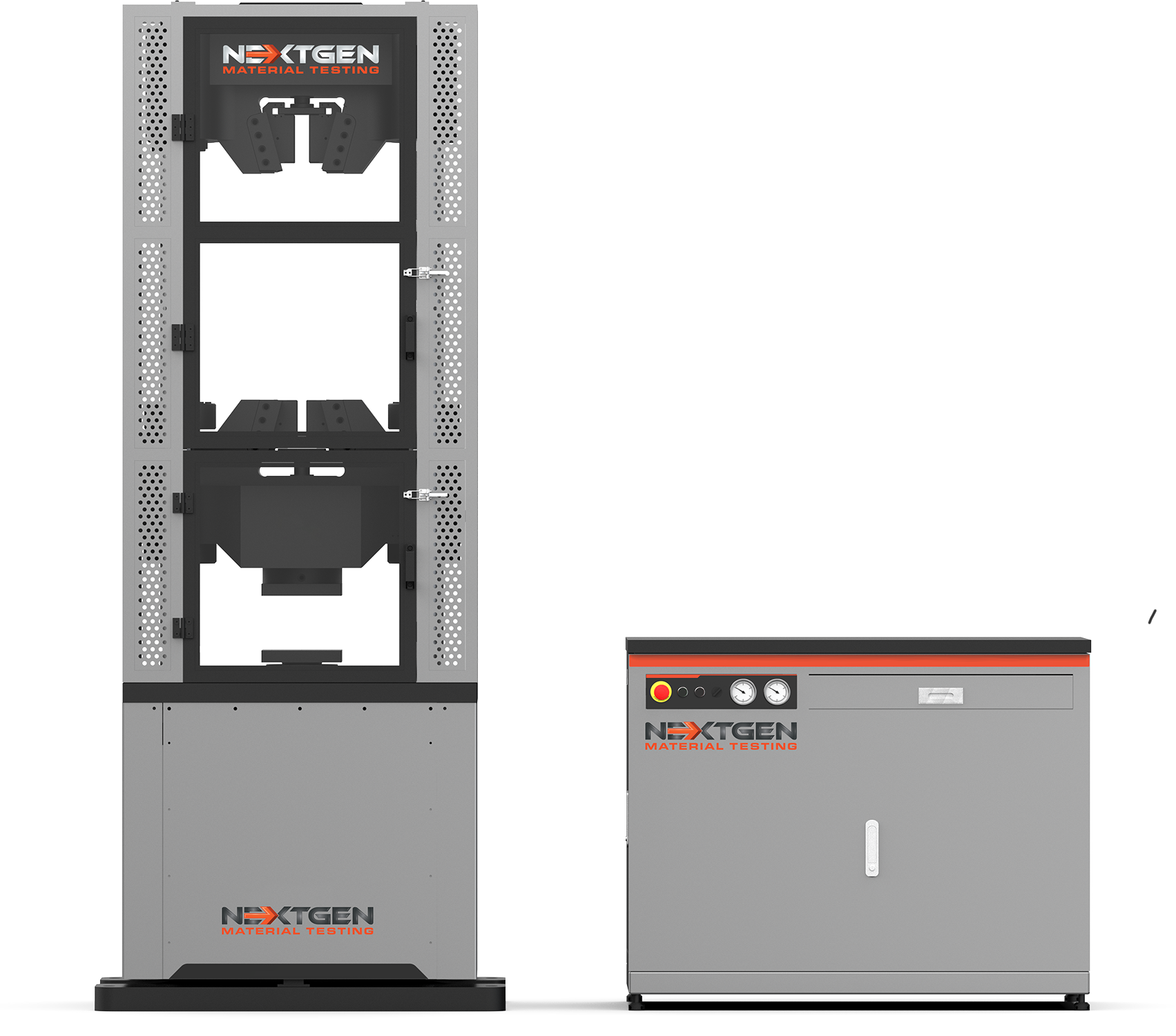

NG-SHM Series A — Servo-Hydraulic Universal Testing Machines (300 kN – 3000 kN)

NG-SHM Series A is a high-force servo-hydraulic UTM for static tensile and compression testing of metals. Capacity options from 300 to 3000 kN support oversized round and flat specimens beyond electromechanical limits. The dual-zone configuration enables tension on the upper head and compression on the lower platen without fixture changeover. GenTest software offers standards-based method libraries, real-time curves, automatic calculations, and exportable reports. The system is built for ASTM/ISO metal strength testing in heavy industrial and research environments.

NG-SHM CLASS DP - Servo Hydraulic Testing Machine

600kN-2000kN - Servo-Hydraulic Universal Testing Machine - Side Action Wedge Grip 2/4 columns, servo-controlled hydraulic

NG-SHM Class D - Servo Hydraulic Universal Testing Machine

600kN-2000kN - Servo-Hydraulic Universal Testing Machine 2/4 columns, servo-controlled hydraulic

NG-SHM Class C - Servo Hydraulic Testing Machine

600kN-1000kN - Servo-Hydraulic Universal Testing Machine 6 column, servo-controlled hydraulic

TensileMill CNC MINI – Compact Flat Tensile Specimen Preparation System

The TensileMill CNC MINI is a compact CNC system designed for preparing standardized flat tensile test specimens. It supports specimen geometries based on ASTM E8, ASTM A370 / E370, ISO 6892-1, DIN 50125, and JIS Z2201. The system uses a cast iron frame, linear guideways, and a guided TensileSoft™ interface to support consistent specimen dimensions. Operators can select preloaded standard profiles or enter custom dimensions directly into the control interface. The MINI is suitable for routine testing workflows, training environments, and production quality control applications.

Specimen Notching/Broaching Machine

NextGen offers an economical solution for Specimen notching and broaching for Charpy and Izod specimens. This certified system complies with ASTM ISO148, EN10045, ASTM E23, DIN 50115 standards. This automated, motorized solution is capable of preparing two specimens at any one given time up to 46 HRC. A variety of broaches are available for different geometries of notches.

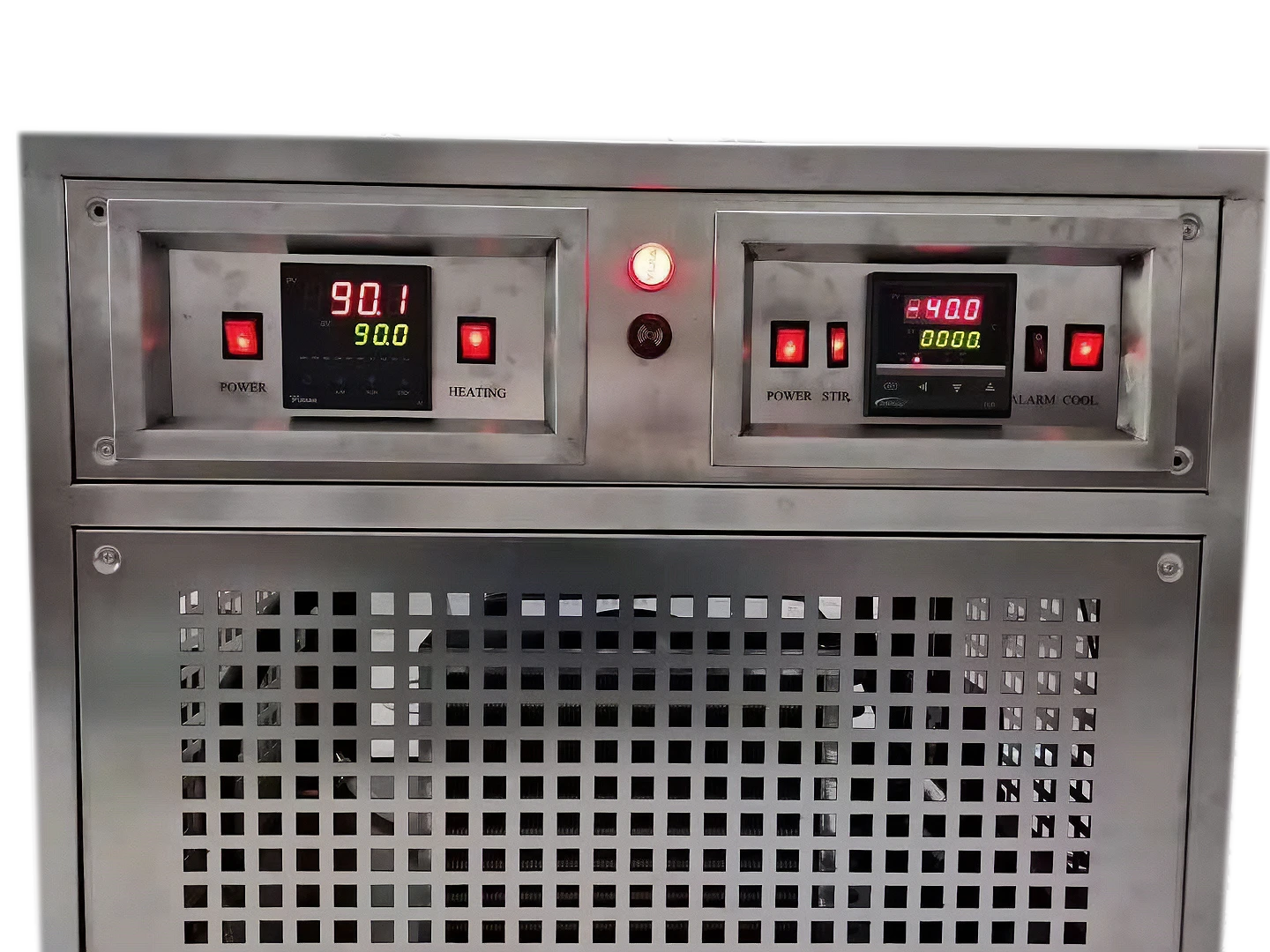

Impact Specimen Cooling and Heating Temperature Chamber – GenChamber

NextGen offers a full range of impact specimen cooling and heating chamber designed to meet virtually all Charpy, Izod and Tensile Impact Testing requirements. NextGen's temperature chambers are a combination of user-friendliness, compact and robust build, offering the ultimate versatility of cooling and heating requirements.

Charpy/Izod Notch Verification Projector System NG-NPS-CIS

Enhance your material testing accuracy with our advanced Charpy/Izod Notch Verification Projector System NG-NPS-CIS.

DWT-1800 Computer Controlled Drop Weight Impact Testing Machine

DWT-1800 Impact Testing Machine is specifically designed for determining the non-plastic transformation temperature of ferritic steel.

Drop Weight (Falling Weight Impact) Tester – NG-FWT1 & NG-FWT2 (Up to 2000 J)

NG-FWT1 and NG-FWT2 are low-capacity vertical drop weight impact testers for controlled impact testing up to 2000 J. They let you set drop height, impact speed, and energy to reproduce repeatable real-world impact events. Operation is available via an integrated touchscreen with DROPTest-S or a PC with DROPTest-BASIC for advanced evaluation and data management. Optional instrumentation supports high-speed measurement up to 4 MHz for force and impact analysis. The platform can be expanded with temperature-controlled testing and robotic automation for higher throughput and consistency.

NG-SHM Class B - Servo Hydraulic Testing Machine

300kN-3000kN - Servo-Hydraulic Universal Testing Machine 6 column, servo-controlled hydraulic

GenTest v3.0 Software for Universal Testing Machines

GenTest Software is developed for testing facilities that require controlled execution on universal testing machines. The method-driven workflow keeps setup parameters, recorded data, calculations, and reporting connected in a single record. The software supports standards-based programs aligned with ASTM, ISO, DIN, EN, and BS and is used for tensile, compression, bending, and shear testing. It helps teams produce consistent results and documentation for QA/QC and customer reporting.

GenGrind Belt BF - Floor Standing Heavy Duty Dual Stage Belt Grinder for Metallographic Sample Preparation

The GenGrind Belt BF Series is a heavy duty dual stage, wet or dry belt grinder offering a robust, floor standing solution for high volume manual belt grinding applications. GenGrind Belt BF - Heavy Duty Dual Stage Belt Grinder for metallographic sample preparation is designed for high material removal of various sample shapes and configurations.

GenGrind Belt BT - Dual Stage Tabletop Belt Grinder for Metallographic Sample Preparation

The GenGrindBelt BT series is a dual stage, wet or dry table top belt grinder offering the most economical solution for manual grinding applications. The GenGrind BT - Dual Stage Belt Grinder for Metallographic Sample Preparation is designed for high material removal of various sample shapes and configurations. The BT - Belt Grinder system is a table top belt grinder suitable for laboratories designed for high material removal.

GenGrind FA-IC Dual Wheel Fully Automatic

Introducing the GenGrind FA-IC, a state-of-the-art single-chip microcomputer controlled grinding and polishing machine.

GenVac MP Series - Epoxy Mounting Vacuum Impregnation System for Metallographic Sample Preparation

GenVac MP2 - Vacuum Impregnator is designed for precision sample impregnation for porous materials. Common applications for vacuum impregnation systems include rocks and minerals, ceramics, electronic circuit boards and other composite materials.

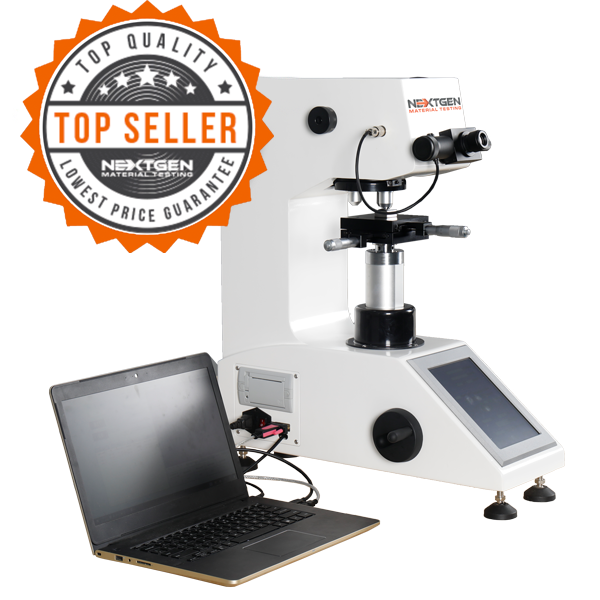

Micro Vickers and Knoop Hardness Tester - Digital and Digital with CCD Optical Analysis Software

NG-1000 Series

NextGen Micro Hardness testers provide solutions for Vickers and Knoop hardness testing with micro loads ranging from 10gf to 1kgf. The NG1000 series is available in Standard Digital, Digital and CCD configurations for Micro Vickers/Knoop testing.

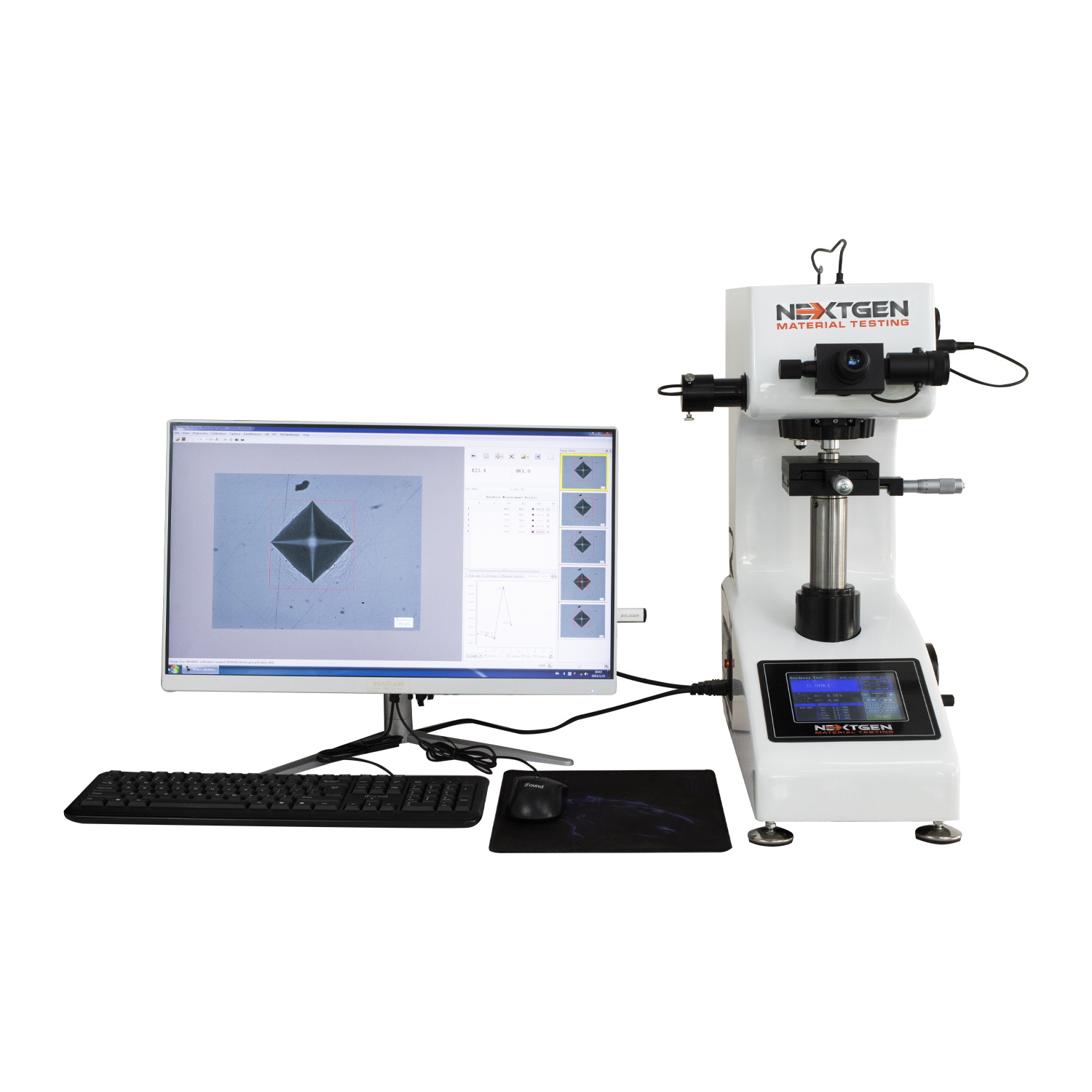

Macro Vickers Hardness Tester - Standard Digital, Digital and Digital with CCD Optical Analysis Software

NG-5000 Series

NextGen Macro Vickers Hardness testers are available with different load capacities and are available in Standard Digital, Digital or CCD configurations. With 5kgf, 10kgf, 30kgf and 50kgf maximum loads available, the NextGen Macro hardness testers can fit all of your Macro testing requirements.

BrinGen - 3000 Series - Digital Brinell and Automatic Brinell Hardness Tester - Closed Loop System

BringGen 3000 is a digital and automatic Brinell testing system equipped with closed loop technology. The forces range from 62.5kgf to 3000kgf and are electronically controlled according to ASTM E10 for precise and repeatable measurements.

BrinGen Scope - Optically Advanced CCD Brinell Measuring Scope for Manual or Digital Brinell Hardness Testing System

BrinGen Scope - is a Optically Advanced CCD Brinell Measuring Scope for Manual or Digital designed as Brinell Hardness Testing automatic scanning system. It is engineered to work with a computer or a laptop to make your testing program faster and more accurate. The Optical Brinell Scope is equipped with real-time result support.

NG-RockGen - Analogue Series Rockwell Hardness Tester - Manual and Electronic Models

The NG-RockGen Analogue Rockwell Hardness Tester is designed to test the hardness of metals by determining the depth of penetration of an indenter under a large load compared to the penetration made by a preload according to the Rockwell regular scales.

NG-RockGen DGEN Series - Digital Rockwell Hardness Tester - Rockwell Regular, Rockwell Superficial and Rockwell TWIN Digital Models

The NG RockGen Digital Series provides an automatic, digital, high accuracy solution to your Rockwell testing requirements. The Digital series is completely automated and is available in Rockwell Regular or Rockwell Superficial scale configurations.

GenRock NG-150 Series - Advanced Rockwell Hardness Tester - Manual and Automatic Rockwell Hardness Testing System

The NG150 GenRock system can be equipped with a variety of accessories to meet all of your hardness testing requirements. A fully motorized stage, Jominy accessories and a wide variety of specimen fixtures are available to configure the NG150 RockGen system to meet your application.

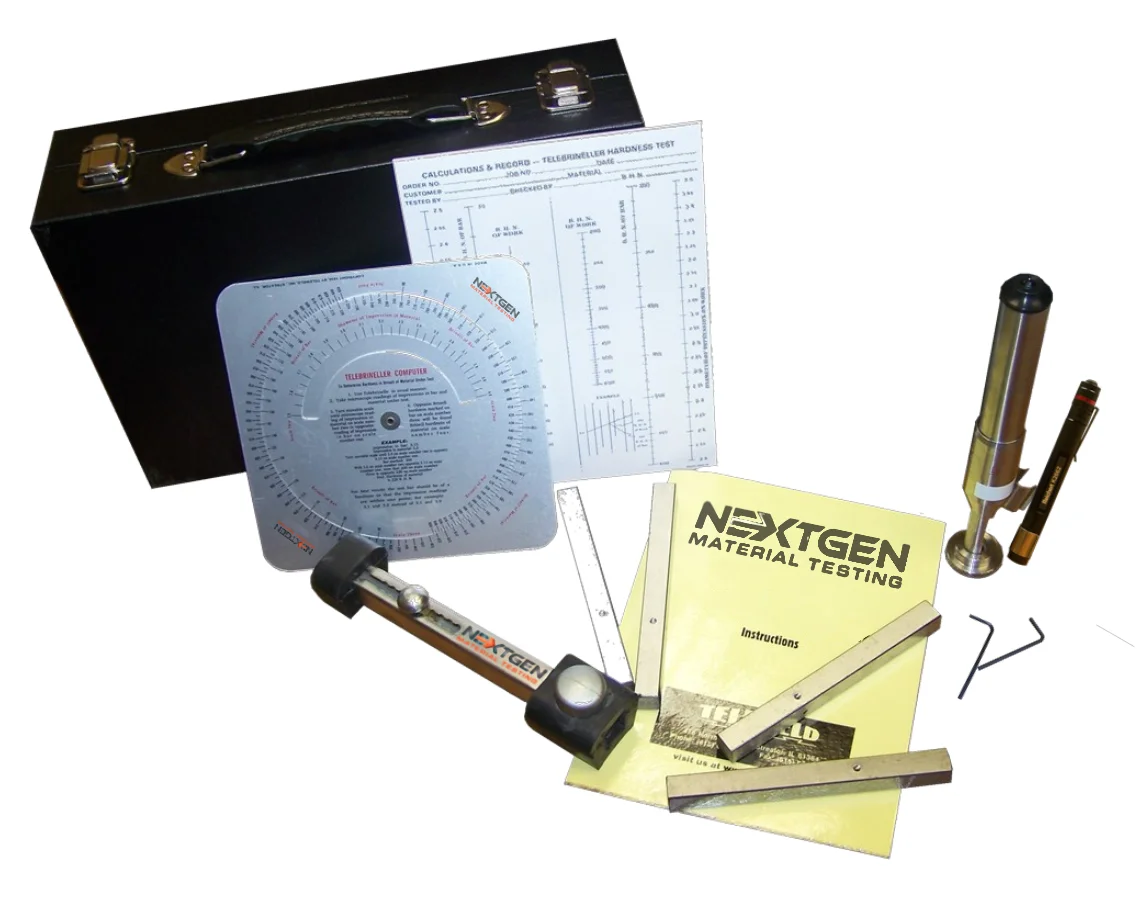

NextGen Telebrineller Brinell Hardness Testing System

The Telebrineller Brinell Hardness Testing System stands out as the best QA solution for ensuring top-notch quality. Developed specifically for welding crews, Telebrineller draws on over fifty years of field experience and solid metallurgical knowledge. Portable and practical, the entire Telebrineller system, housed in a case, weighs less than ten pounds. It's an ideal choice for Brinell hardness testing in any situation.

Surface Roughness Testers

High accuracy surface roughness testing systems for material surface analysis and statistical processing of data. Multiple model variations to help fit your technical and budgetary expectations.

UniGen Universal Hardness Tester – Rockwell, Vickers & Brinell Hardness Testing System

NextGen's Universal Hardness Tester is a closed loop load cell machine with an 8-inch touch screen interface is the ultimate user-friendly solution for your Vickers, Knoop, Rockwell and Brinell Hardness Testing requirements. The measurements are made through optical objective lens and CCD camera to collect indentation images and to generate your hardness reading on the touchscreen LCD.

Hardness Test Blocks, Indenters and Hardness Testing Accessories

Certified Test Blocks are a requirement as a reference material for any type of hardness testing. At NextGen, we understand the importance of a Test Block to ensure the accuracy of your hardness testing procedures.

Metallography Consumables

Learn about the full scope of NextGen's cutting, polishing & grinding, mounting and etching metallography consumables. Our consumables are compatible with virtually all global brands, offering a rare combination of exceptional quality, longevity and affordability.