Metal Testing Equipment

Standards

ASTM A938, ASTM E143, ISO 7800, GB10128

Description

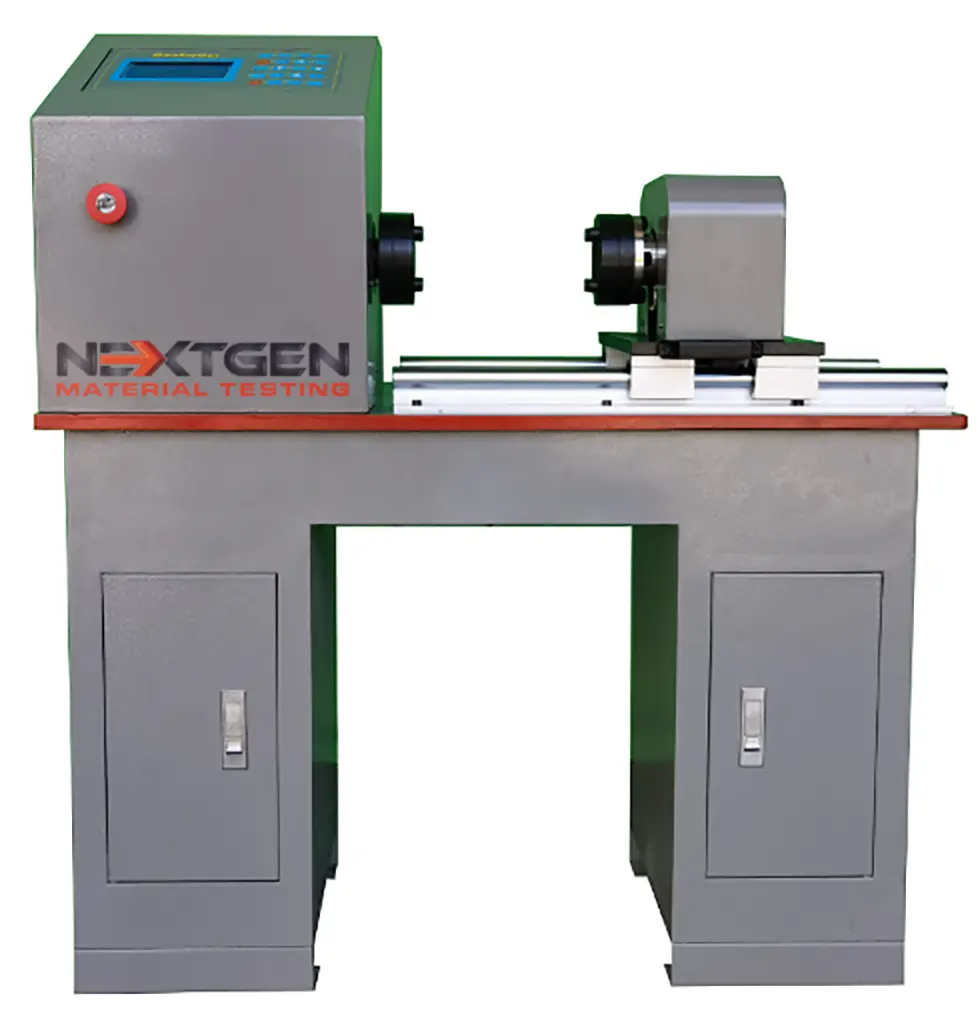

Introducing the NextGen GenTor Torsion Tester, a state-of-the-art computerized machine designed specifically for the torsion testing of a wide range of materials including metals, non-metals, composite materials, and component parts. This testing machine boasts a horizontal type load frame with high stiffness, ensuring accurate and reliable test results. Read more in our latest MEGA BLOG!

Equipped with a high-precision torque sensor, the NextGen GenTor Torsion Tester is able to accurately measure the torque value of the material being tested. Additionally, it features a high-precision torsion angle meter, which accurately measures the torsion angle of the material.

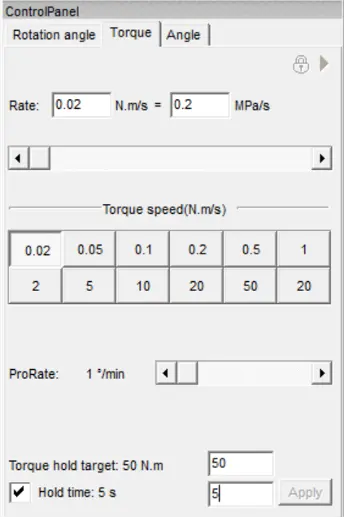

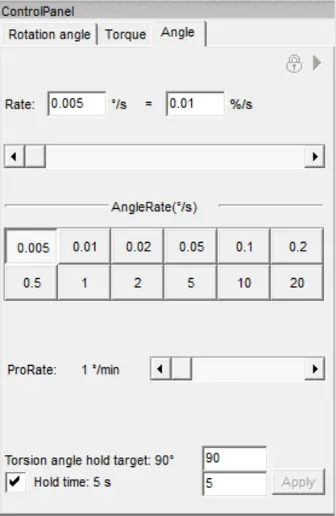

With its various control modes, this torsion tester provides maximum flexibility in testing different types of materials. The machine's computerized real-time display of testing data and various testing curves provide users with a comprehensive and detailed view of the test results.

Whether you're testing metals, non-metals, composite materials, or component parts, the NextGen GenTor Torsion Tester is the perfect tool for achieving accurate and reliable torsion test results.

NextGen GenTor Horizontal Torsion Tester Working Principle

The NextGen GenTor Torsion Tester is a highly advanced testing machine that comprises a host machine, torsion angle measuring device, dedicated measuring system, and a computer. When conducting a test, the computer sends instructions to the control unit, which in turn drives the servo motor to operate. The moving grip rotates along with the reducer, causing the sample to undergo torque. The torque is then transmitted to the fixed grip, and the torque sensor detects this torque, sending a signal to the amplifying circuit of the control unit.

The amplified signal is converted from analog to digital and displayed in real-time on the computer screen. The torque angle is measured using an optical encoder, providing accurate and precise measurement of the torsion angle.

The NextGen GenTor Torsion Tester features computer-controlled English testing software that enables users to control various testing parameters, including torque control, torsion angle control, and deformation control. This software allows for testing speed and other control parameters to be set, while displaying real-time data, such as torque, yield torque, maximum torque, torque strength, angle, and torsion speed.

This highly sophisticated testing machine is perfect for a variety of testing applications, including research and quality control testing. Its advanced features provide reliable and precise results, making the NextGen GenTor Torsion Tester a valuable addition to any testing laboratory.

Test Capacities: 200N.m, 500N.m, 1,000N.m, 2,000N.m, 6,000N.m.

Horizontal Torsion Tester Technical Specifications

| Specifications | NDW-6000 | ||||

|

Max. Torque Capacity (N.m)

|

200 | 500 | 1000 | 2000 | 6000 |

|

Torque Measuring Range (N.m)

|

4-200 | 10-500 | 20-1000 | 40-2000 | 24-6000 |

|

Distance Between Grips (mm)

|

0-500 | 4-1000 | Inquire | ||

|

Min. Torque Reading (N.m)

|

0.01 | ||||

|

Relative Error of Torque

|

≤±1.0% (from 20% of each full range) |

||||

|

Relative Repeatability Error of Torque

|

≤±1.0% (from 20% of each full range)

|

||||

|

Max. Reading of Torsion Angle

|

9999.9°

|

||||

|

Resolution of Torque Angle

|

0.1° | ||||

|

Horizontal Opening (Without Grips) (mm)

|

675 | ||||

|

Maximum Test Speed (RPM)

|

1.5 | ||||

|

Torsion Speed

|

0.1-1000°/min Stepless

|

||||

Horizontal Torsion Tester Testing Software

Close-loop control: it supports constant rotation angle, constant torque control, target hold and hold time.

FAQs

ASTM A938 is a standard specification established by ASTM International, an organization that develops and publishes voluntary consensus standards for various industries. This particular standard specifies the test method for wire specimen torsion.

The ASTM A938 standard outlines the procedure for conducting torsion testing of metallic wire specimens to determine their mechanical properties, such as torsional strength and modulus of elasticity. The standard provides guidelines for sample preparation, testing equipment, testing procedures, and data analysis.

Torsion testing according to this standard involves subjecting a wire specimen to a twisting force until it fractures or reaches a specified deformation. The torque applied and the resulting twist angle is measured during the test. Using these measurements, it is possible to determine a material's ability to withstand torsional loads and how it will behave when subjected to twisting forces.

By following the guidelines of ASTM A938, manufacturers, researchers, and quality control professionals can ensure consistent and reliable testing of wire specimens. The standard helps in comparing the torsional properties of different materials and determining their suitability for specific applications.

NextGen’s GenTor Horizontal Torsion Tester complies with ASTM A938 standard.

Click here to learn more about the product or here to receive a personalized quote.

ASTM E143 is a standard test method established by ASTM International for measuring the modulus of elasticity in torsion. This standard provides guidelines for determining materials' torsional properties, specifically the shear modulus or rigidity modulus.

The standard outlines the procedure for performing torsion tests on cylindrical specimens to measure their shear modulus. The shear modulus is a measure of a material's resistance to shear deformation under torsional forces.

The ASTM E143 test method involves applying torque to a specimen while measuring the resulting angular displacement. The shear modulus is then calculated based on the specimen dimensions and the applied torque.

The standard provides specifications for test setup, specimen preparation, test procedure, and data analysis. It ensures that the torsion test is conducted accurately and consistently across different laboratories and testing facilities.

NextGen GenTor Horizontal Torsion Tester complies with ASTM E143 standard.

Click here to learn more about the product or here to receive a personalized quote.

ISO 7800 is an international standard developed by the International Organization for Standardization (ISO) that provides guidelines for metallic materials torsional testing. This standard specifies the general principles and procedures for conducting torsion tests to determine the torsional properties of metallic specimens.

The standard outlines the test setup, specimen preparation, and testing procedure for measuring metallic materials' torsional properties. It covers a wide range of metallic materials, including ferrous and non-ferrous metals, and provides guidance on the selection of test parameters such as torque levels, test speed, and specimen dimensions.

ISO 7800 promotes the standardization and harmonization of torsional testing practices. This enables accurate comparison of test results across different laboratories and facilitating the exchange of data within the international engineering and manufacturing community. It contributes to the overall quality, safety, and reliability of metallic materials used in various industries, including automotive, aerospace, construction, and manufacturing.

NextGen’s GenTor Horizontal Torsion Tester complies with ISO 7800 standard.

Click here to learn more about the product or here to receive a personalized quote.

GB10128 is a standard for torsion testing of metallic materials. It provides guidelines and requirements for conducting torsion tests on various metallic specimens to determine their torsional properties.

This standard covers the general principles, test methods, and equipment requirements for torsion testing. It specifies the test setup, specimen preparation, and testing procedure to ensure accurate and reliable measurement of metallic materials' torsional properties.

GB10128 outlines the selection and preparation of test specimens, including considerations of sample shape, dimensions, and surface conditions. It also defines testing parameters such as torque levels, test speed, and measurement techniques to be used during the test.

By adhering to these standard guidelines, manufacturers, researchers, and testing laboratories can ensure standardized and consistent torsion testing of metallic materials. The standard helps to ensure the quality, reliability, and safety of metallic components and structures in various industries, including automotive, aerospace, machinery, and construction.

NextGen GenTor Horizontal Torsion Tester complies with GB10128 standard.

Click here to learn more about the product or here to receive a personalized quote.

NextGen’s GenTor Torsion Tester is an exceptional machine that offers unmatched versatility for conducting torsion tests on a wide range of materials. Its capability to evaluate the torsional properties of metals, non-metals, composite materials, and component parts makes it an invaluable tool across various industries, including manufacturing, research and development, and quality control.

With its expansive testing range, NextGen’s GenTor Torsion Tester provides unparalleled flexibility and accuracy in assessing the torsional strength, flexibility, and performance characteristics of different materials. Whether you need to analyze metal components' performance under torsional stress, evaluate the flexibility of non-metal materials, or study composite materials' behaviour in torsion, this advanced testing machine delivers precise and reliable results.

Equipped with high-precision torque measurement and a real-time data display system, NextGen’s GenTor Torsion Tester ensures accurate and consistent test outcomes. The comprehensive data obtained from the testing process empowers engineers, researchers, and quality control professionals to make informed decisions and ensure the highest standards of product quality and reliability.

Click here to learn more about the product or here to receive a personalized quote.

NextGen’s GenTor Torsion Tester is equipped with a horizontal type load frame, which plays a critical role in ensuring accurate and reliable test results. The load frame serves as the structural component of the testing machine and is specifically designed to provide high stiffness.

The horizontal load frame configuration offers several advantages. Firstly, it enhances the stability and balance of the machine during torsion testing, minimizing any potential vibrations or distortions that could affect the accuracy of the results. Secondly, the horizontal orientation allows for uniform distribution of the applied load, ensuring consistent testing conditions across different materials.

The high stiffness of the load frame is crucial for maintaining the testing setup integrity. It prevents any excessive deflection or deformation of the frame when subjected to torsional forces, enabling precise measurement of the torsional properties of the tested materials. This stiffness is achieved through robust materials and precise engineering techniques, ensuring the load frame's durability and reliability.

Click here to learn more about the product or here to receive a personalized quote.

NextGen GenTor Torsion Tester is designed to deliver precise and reliable measurements of torque and torsion angle through its advanced features and high-precision sensors. Equipped with a top-of-the-line torque sensor, this testing machine ensures accurate measurement of the torque value exerted on the material under examination. The torque sensor is specifically engineered to provide precise readings, enabling accurate torsional assessment.

Moreover, NextGen’s GenTor Torsion Tester incorporates a high-precision torsion angle meter that accurately measures the torsion angle of the material. This meter is finely calibrated to capture even the slightest angular changes, offering a detailed understanding of the material's behaviour under torsional stress.

These high-precision sensors synergize with the tester's advanced control system and data processing capabilities. The real-time display of testing data and various testing curves empowers users to closely monitor torque and torsion angle values throughout the testing process, ensuring meticulous measurement accuracy.

Click here to learn more about the product or here to receive a personalized quote.

Yes, NextGen’s GenTor Torsion Tester is designed to provide users with incredible flexibility through its diverse range of control modes. These modes allow operators to conduct tests on various materials with precision and customization, catering to each material's specific requirements.

With the ability to adjust parameters such as torque control, torsion angle control, and deformation control, users can fine-tune the testing process to suit their needs. Whether it involves applying a constant torque, maintaining a particular torsion angle, or controlling the deformation rate, the machine offers versatility and adaptability.

NextGen’s GenTor Torsion Tester features a user-friendly computer interface that displays real-time testing data and various testing curves. This comprehensive visual representation empowers users to closely monitor the test progress and observe how the material responds to torsional stress. This real-time monitoring enhances the analysis and interpretation of the data, enabling a precise evaluation of the material's torsional properties.

Click here to learn more about the product or here to receive a personalized quote.

Yes, NextGen’s GenTor Torsion Tester is equipped with a computerized display that provides real-time testing data and various testing curves. This advanced feature allows users to monitor and analyze test results easily and precisely.

The computerized display offers a comprehensive and detailed view of the test data, providing valuable insights into the material's torsional behaviour. Users can observe torque values, torsion angles, and other relevant parameters recorded in real-time during the test.

The display also presents testing curves, which visually represent the relationship between torque and torsion angle over time. These curves help users identify patterns, trends, and abnormalities in test data, enabling them to make informed decisions and interpretations.

With this computerized display, users can gather accurate and up-to-date information about material performance under torsional stress. It enhances the efficiency and effectiveness of the testing process, allowing for precise analysis and evaluation of the material's torsional properties.

Click here to learn more about the product or here to receive a personalized quote.

NextGen GenTor Torsion Tester is a sophisticated testing machine that consists of four essential components: the host machine, torsion angle measuring device, dedicated measuring system, and computer.

The host machine plays a crucial role as the main structure of the tester, providing stability and support for torsion tests. It is designed to accommodate various mechanisms and sensors necessary for accurate and reliable measurements.

The torsion angle measuring device determines the torsion angle of the material under test. By accurately measuring this angle, users can analyze material behaviour and performance during torsional stress.

In conjunction with the torsion angle measuring device, the dedicated measuring system captures and processes data throughout the testing process. It provides reliable and consistent results by capturing measurements from various sensors accurately.

The computer acts as the central control unit of NextGen’s GenTor Torsion Tester. It receives and processes data from the dedicated measuring system, allowing users to monitor the real-time display of testing data and various testing curves.

Click here to learn more about the product or here to receive a personalized quote.

NextGen’s GenTor Torsion Tester utilizes computer-controlled English testing software, which provides extensive capabilities for controlling and customizing testing parameters. Users can benefit from features such as torque control, torsion angle control, and deformation control.

With torque control, operators can set specific torque levels, ensuring precise torque application to the material under test and maintaining controlled testing conditions.

Torsion angle control allows users to define and maintain specific torsion angles throughout the test, facilitating the study of material behaviour at particular angles and enabling comparative analyses.

Deformation control is a valuable feature that enables users to regulate the rate and extent of deformation in the material. This facilitates the examination of material response under various load and condition scenarios.

Computer-controlled software provides a user-friendly interface, allowing operators to input desired parameters and monitor the testing process in real-time. This enhances operational efficiency and accuracy, enabling precise control over testing variables and ensuring consistent and reliable results.

Click here to learn more about the product or here to receive a personalized quote.

NextGen’s GenTor Torsion Tester offers a versatile solution for torsion testing by providing a range of torque capacities. With options available in 200N.m, 500N.m, 1,000N.m, 2,000N.m, and 6,000N.m, this machine caters to a variety of testing requirements.

The availability of multiple torque capacities ensures that NextGen’s GenTor Torsion Tester can accommodate different material types and testing scenarios. Whether you are working with small or large specimens or examining materials with varying torque resistance, this machine offers the flexibility to meet your specific needs.

By offering a diverse range of torque capacities, NextGen’s GenTor Torsion Tester empowers users across various industries and applications. Whether you are engaged in research and development, quality control, or material characterization, this machine provides the necessary torque options to conduct precise and reliable torsion tests on your materials.

Click here to learn more about the product or here to receive a personalized quote.

NextGen’s GenTor Torsion Tester provides users with a range of torque measuring options to suit different testing needs. The available torque measuring ranges for this machine are 4-200 N.m, 10-500 N.m, 20-1000 N.m, 40-2000 N.m, and 24-6000 N.m.

These torque measuring ranges cater to a wide variety of materials and applications. Whether you are working with smaller, more delicate materials that require lower torque levels or larger, more robust materials that demand higher torque levels, NextGen’s GenTor Torsion Tester has you covered.

By offering multiple torque measuring ranges, this testing machine ensures versatility and accuracy in torsion testing. It allows users to select the appropriate torque range based on specific material properties and testing requirements, resulting in precise and reliable measurement of torsional characteristics.

Click here to learn more about the product or here to receive a personalized quote.

NextGen’s GenTor Torsion Tester offers different options for the distance between grips to accommodate a range of testing requirements. The available distances between grips are 0-500 mm and 4-1000 mm. These options provide flexibility in choosing the appropriate grip distance based on the size and dimensions of the materials being tested.

Adjustable grip distance is essential for accurate and reliable test results. It allows users to accommodate various sample sizes and configurations, ensuring proper alignment and secure gripping during the torsion test.

The wide range of grip distances also enables users to conduct tests on different types of materials, including those of varying lengths or shapes. Whether you are working with shorter samples or longer specimens, NextGen’s GenTor Torsion Tester can be adjusted to meet your specific testing needs.

Having the ability to customize the grip distance enhances the versatility of the testing machine. This makes it suitable for a wide range of applications in industries such as manufacturing, research and development, and quality control.

Click here to learn more about the product or here to receive a personalized quote.

NextGen’s GenTor Torsion Tester offers a minimum torque reading range of 0.01 N.m. This means that it can accurately measure torque values as low as 0.01 N.m during torsion testing.

The ability to measure such low torque values is particularly beneficial when dealing with materials that exhibit delicate or subtle torsional behaviour. It allows for precise analysis and characterization of how the material responds to torsional stress, especially in applications where high sensitivity is required.

With a minimum torque reading range of 0.01 N.m, NextGen’s GenTor Torsion Tester provides researchers, engineers, and quality control professionals with valuable insights into the performance and behaviour of materials under different torsional loads. This information plays a critical role in making informed decisions related to product development, process optimization, and quality assurance.

Click here to learn more about the product or here to receive a personalized quote.

NextGen GenTor Torsion Tester has a relative error of torque that is ≤±1.0%. This means that the measured torque values can deviate from the true values by a maximum of 1.0% within 20% of each full range.

The relative error of torque is a measure of the accuracy and precision of the torque measurements obtained from the testing machine. With a ≤±1.0% relative error, NextGen’s GenTor Torsion Tester provides reliable and consistent torque measurements, ensuring confidence in the accuracy of the test results.

By maintaining a low relative error, the tester enables researchers, engineers, and quality control professionals to obtain precise and trustworthy data regarding materials' torsional properties. This information is crucial for making critical decisions about product design, material selection, and performance evaluation.

Click here to learn more about the product or here to receive a personalized quote.

NextGen’s GenTor Torsion Tester has a relative repeatability error of torque of ≤±1.0% (from 20% of each full range). This specification indicates the level of variation or inconsistency that can occur in torque measurements when performing repeated tests within the specified torque range.

The ≤±1.0% relative repeatability error means that, when conducting multiple tests within 20% of each full range of torque capacity, the measured torque values should remain within a maximum deviation of ±1.0% from the average value. This level of repeatability ensures that the testing results are consistent and reliable, allowing for an accurate assessment of the material's torsional properties.

By minimizing repeatability error, NextGen’s GenTor Torsion Tester enhances torque measurements confidence and precision. This is particularly critical when evaluating materials that require highly accurate and repeatable torque data.

The low relative repeatability error of ≤±1.0% demonstrates the machine's capability to provide reliable and consistent torque measurements, enabling researchers, engineers, and quality control professionals to make informed decisions based on precise and repeatable test results.

Click here to learn more about the product or here to receive a personalized quote.

NextGen’s GenTor Torsion Tester is capable of accurately measuring torsion angles up to 9999.9°. This wide range allows for the evaluation of materials experiencing significant torsional deformation and enables researchers, engineers, and quality control professionals to study material behaviour under high torsional stresses or large angular displacements.

The maximum reading of 9999.9° ensures precise and reliable data capture for comprehensive analysis. This information is vital for understanding materials' torsional properties, assessing their performance under different conditions, and making informed decisions in design, manufacturing, and quality assurance processes.

With its ability to measure high torsion angles, NextGen’s GenTor Torsion Tester offers versatility and accuracy across various industries, including automotive, aerospace, construction, and materials science. It empowers users to explore the mechanical properties of materials subjected to torsional loads and gain valuable insights into their behaviour, ultimately enhancing product development, performance optimization, and quality control efforts.

Click here to learn more about the product or here to receive a personalized quote.

NextGen GenTor Torsion Tester is designed with a high-resolution torque angle measurement capability, offering an impressive precision of 0.1°. This feature allows the machine to accurately detect and display even the slightest changes in torsion angle, providing users with detailed insights into the material's behaviour under torsional stress.

The 0.1° resolution empowers researchers, engineers, and quality control professionals to conduct in-depth analyses of the material's mechanical properties and response to torsional forces. By capturing subtle variations in the torsion angle, it enables a comprehensive understanding of how the material deforms and behaves during testing.

The high-resolution measurement capability of NextGen’s GenTor Torsion Tester equips users with valuable data for making informed decisions. It enables the identification of critical points of deformation and optimizes designs and enhances overall performance.

Click here to learn more about the product or here to receive a personalized quote.

NextGen’s GenTor Torsion Tester horizontal opening (without grips) is 675 mm. This refers to the maximum distance between the two grips of the machine when no additional grips or attachments are installed.

The horizontal opening accommodates different sizes and shapes of test specimens. With a generous 675 mm opening, NextGen’s GenTor Torsion Tester provides ample space for a wide range of materials to be securely held and subjected to torsional forces.

This feature ensures versatility and flexibility in testing various materials, including rods, bars, tubes, and other components. The spacious horizontal opening allows for convenient specimen placement and adjustment, facilitating efficient and accurate testing procedures.

Whether conducting research and development, quality control, or material characterization, NextGen’s GenTor Torsion Tester's generous horizontal opening ensures compatibility with a diverse range of test specimens, making it a reliable and adaptable tool for torsion testing applications.

Click here to learn more about the product or here to receive a personalized quote.

NextGen’s GenTor Torsion Tester has a maximum test speed of 1.5 RPM. This refers to the highest rotational speed at which the machine can perform torsion tests.

Test speed is crucial as it determines the rate of torsional deformation. Higher test speeds enable faster testing, which is beneficial for large-scale experiments or situations where time is limited.

However, it's critical to consider that the appropriate test speed depends on the material's properties and the specific testing requirements. Different materials may behave differently at various speeds, and certain applications may necessitate slower or more controlled testing to accurately evaluate the material's response to torsional stress.

With a maximum test speed of 1.5 RPM, NextGen’s GenTor Torsion Tester offers a versatile range suitable for various applications. It ensures efficient testing while maintaining the necessary control and accuracy to obtain dependable and meaningful results.

Click here to learn more about the product or here to receive a personalized quote.

The torsion speed range of NextGen GenTor Torsion Tester is 0.1-1000°/min, with stepless adjustment. This means that the machine offers a wide range of torsion speeds, allowing users to select any value between 0.1 and 1000 degrees per minute, without predefined increments or steps.

The stepless adjustment feature provides users with precise control over the torsion speed, enabling them to fine-tune the testing conditions based on their specific requirements. This flexibility is particularly valuable when testing different materials with varying torsional properties or when conducting research that necessitates a specific range of torsion speeds.

The ability to adjust the torsion speed within such a broad range empowers researchers, engineers, and quality control professionals to explore a wide spectrum of torsional behaviours. It facilitates detailed investigations into the material's response to different speeds and enables the characterization of its mechanical properties under varying torsional conditions.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

Alignment Device

(NADCAP-Ready Precision Fixture)

NextGen Material Testing’s Alignment Device is a precision-engineered fixture designed to ensure perfect axial alignment in universal testing machines.

G-800E Trinocular Metallurgical Microscope

This inverted metallurgical trincoular microscope is ideal for both industrial or educational metallurgy applications.

HDT/VICAT Testing Machine – Thermal Analysis for Plastics NG-HDT

Description The HDT/VICAT testing machine offers high precision, reliability, and efficiency for the thermal analysis of thermoplastics and polymers. Engineered with advanced sensors and high-temperature-resistant components, it ensures minimal deformation, fast response, and precise data transmission, delivering consistent and accurate […]

Class J - Charpy and Izod Automatic Impact Testing System - 1J - 50J

Class J is widely used for lzod and Charpy impact test on softer metals, plastics and rubber specimens. Equipped with tensile impact pendulum and fixtures, it can carry on tests on plastic film and sheet. The newly enhanced design offers the most cost-effective configuration to address Charpy test from 1J to 50J (0.7 - 37 ft/lbs), and lzod test from 1J to 22J (0.7 - 16 ft/lbs).

Class D Single-Column Charpy Impact Tester – High-Precision Pendulum Testing Machine

NextGen’s Class D Single-Column Charpy Impact Testing System is built for high rigidity and dependable specimen testing across a wide energy range. It supports impact energies from around 150 J (111 ft-lbs) up to around 750 J (553 ft-lbs), covering most standard metal testing needs. The unit includes a digital display and offers a software upgrade option for data plotting. Additional features, such as automated specimen feeding and integrated cooling or heating systems, are available as optional enhancements.

Class G Single-Column Charpy & Izod Impact Tester – High-Precision Pendulum Testing Machine

NextGen's Class G – Single Column Charpy and Izod Impact Testing system provides a high level of rigidity and specimen testing capacity. This Charpy and Izod Impact tester has a minimum capacity of 150 J (111 ft/lbs) and a maximum capacity of 750 J (553 ft/lbs). The system comes standard with a digital display with software upgrade function for data plotting. The Class G impact system can also include automatic specimen feeding, cooling and heating systems as optional upgrades.

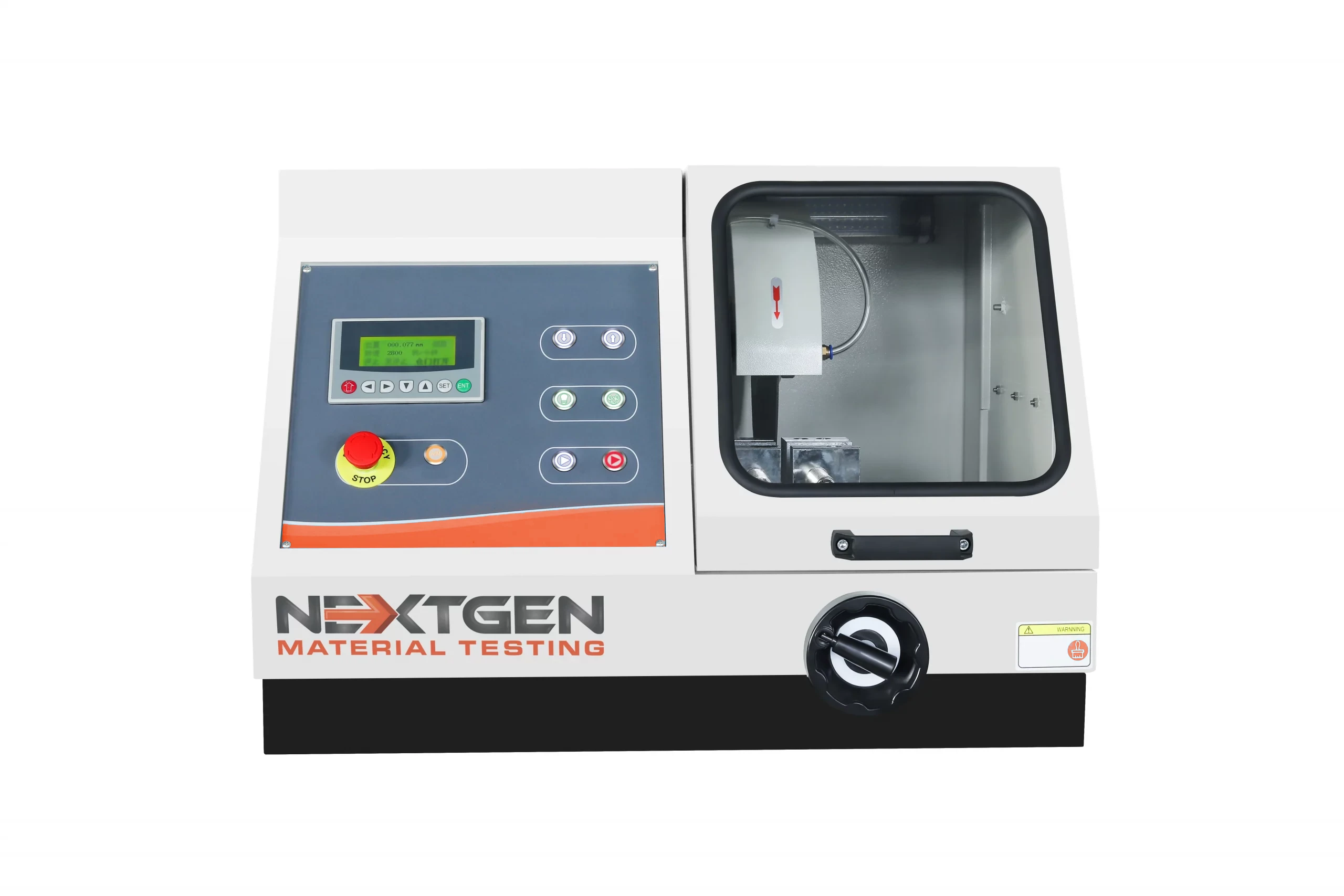

GenCut GL100M – Precision Manual Metallographic Sample Cutting Machine with Simple User-Friendly Operation and Large Cutting Capacity Φ100mm

Introducing the GenCut GL100M Manual Cutting Machine, expertly designed for precision metal sample cutting.

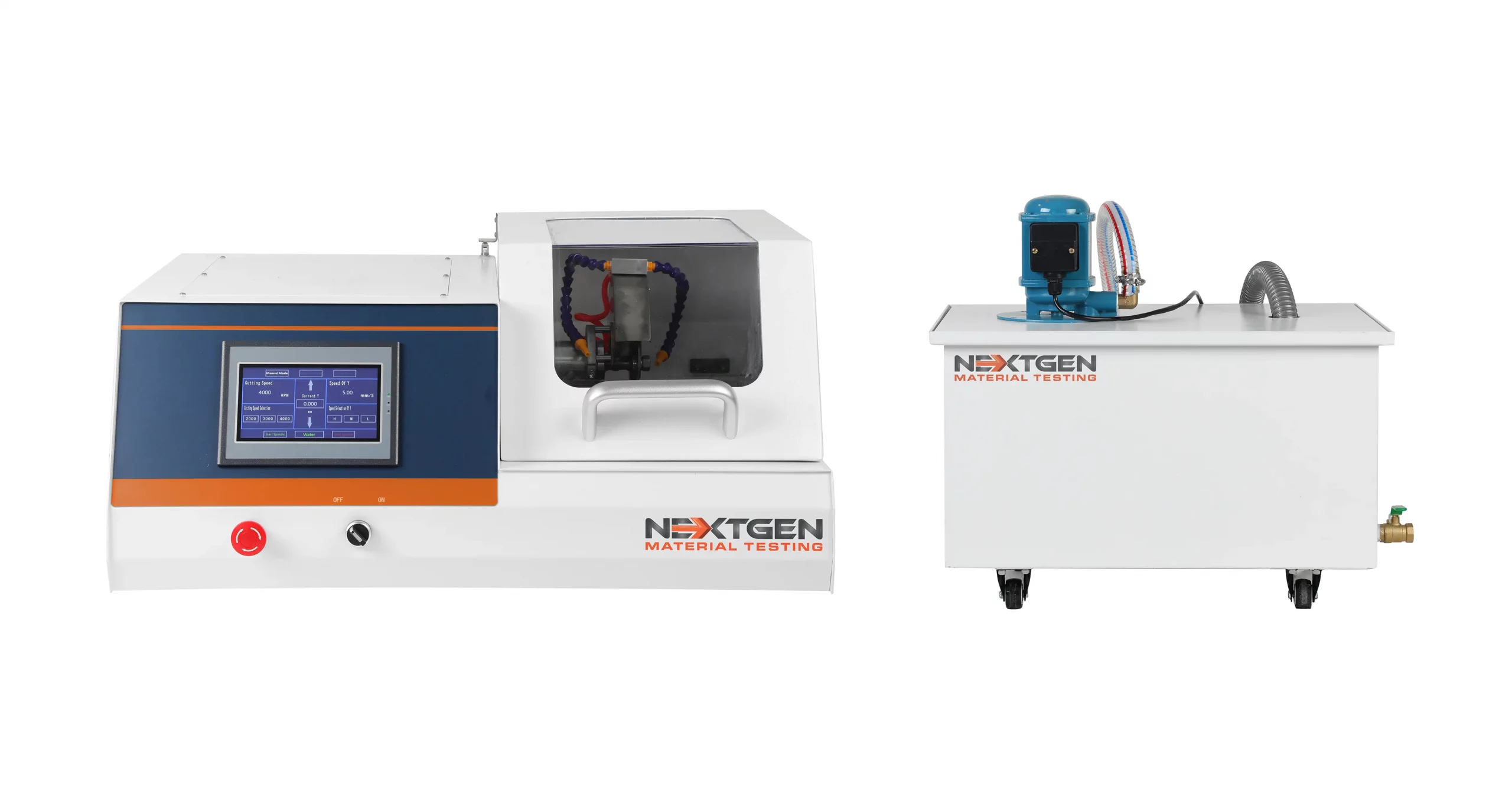

GenCut GL350 – Precision Metallographic Sample Cutting Machine with Simple User-Friendly Operation and Large Cutting Capacity Φ100mm

The GenCut GL350 is a cutting-edge high precision cutting machine equipped with advanced features and capabilities

GenCut GL80A – Precision Metallographic Sample Cutting Machine with Simple User-Friendly Operation and Large Cutting Capacity Φ80mm

Introducing the GenCut GL80A, a highly precise cutting machine offering both automatic and manual work modes.

GenCut GL 170XY – Multi Function Abrasive Cut Off Saw with Touch Screen User Friendly Interface and Large Cutting Capacity – Φ170mm

The GenCut GL 170XY has a large 170mm diameter maximum cutting capacity equipped with a fully automated XY table.

GenCut GL 120XY – Multi Function Abrasive Cut Off Saw with Touch Screen User Friendly Interface and Large Cutting Capacity Φ120mm

The GenCut GL 120XY has a large 120mm diameter maximum cutting capacity equipped with a fully automated XY table.

GenCut GL200E – High Speed Automatic Precision Metallographic Cutter with User-Friendly Touch Screen Interface with max. cutting diameter of 60mm

GenCut GL 200E precision cutting machine includes a touch screen and PLC control, with stable performance and real-time display parameters.

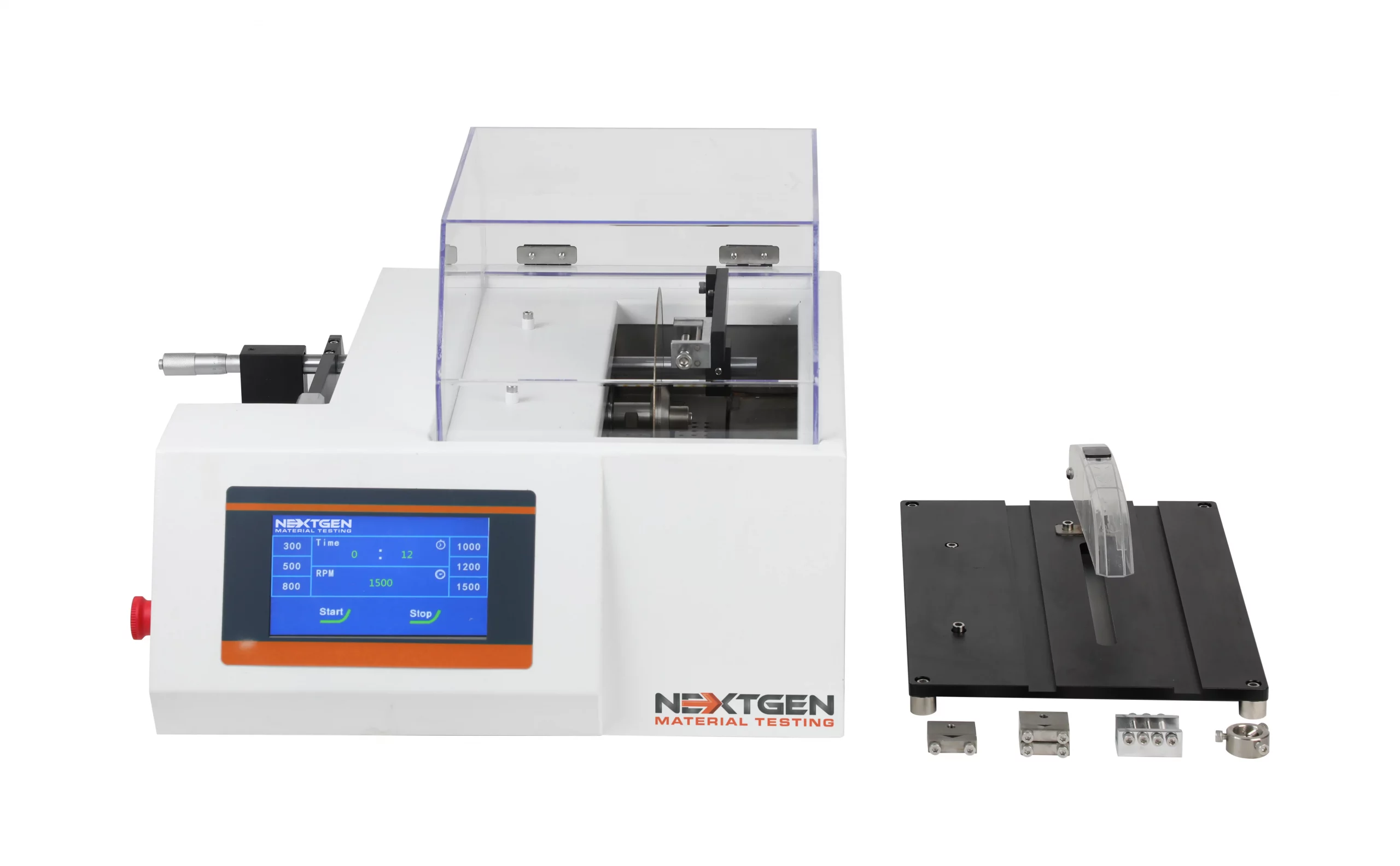

GenCut GL100E – Low Speed Precision Metallographic Automatic Cutter with User-Friendly Touch Screen Interface with max. cutting diameter of 25mm

GenCut GL100E low speed series metallographic precision cutter has variable speed control from 50-1000 rpm.

GenGrind N Series 8” 200S / 10" 250S / 12" 300 S - Advanced Metallographic Grinder & Polisher - Variable Speed 50-1000rpm –Touch Screen Controlled

Introducing the GenGrind N Series metallographic grinders and polishers, offered in sizes 8", 10", or 12" diameter.

GenGrind SA-I 250S 10" Single Wheel Semi Automatic Grinder & Polisher - Variable Speed 100-1000rpm – Individual Force Control - Touch Screen Controlled with Automatic Specimen Mover Power Head – (various wheel sizes available)

Discover the single wheel semi automatic GenGrind 10" SA-I 250S, your ultimate answer to grinding and polishing needs.

GenGrind SA-C 250S 10" Single Wheel Semi Automatic Grinder & Polisher - Variable Speed 100-1000rpm – Central Force Control - Touch Screen Controlled with Automatic Specimen Mover Power Head – (various wheel sizes available)

Introducing the GenGrind SA-C 250S – your ultimate single wheel semi automatic grinding and polishing solution.

GenGrind FA-IC 250D 10" Dual Wheel Fully Automatic Grinder & Polisher - Variable Speed 100-1400rpm – Both Individual and Central Force Control - Touch Screen Controlled with Automatic Specimen Mover Power Head – (various wheel sizes available)

Introducing the GenGrind FA-IC 250D Dual Wheel Polisher and Grinder, a fully automatic metallographic grinding and polishing machine

GenGrind FA-IC 250S 10" Single Wheel Fully Automatic Grinder & Polisher - Variable Speed 100-1400rpm – Both Individual and Central Force Control - Touch Screen Controlled with Automatic Specimen Mover Power Head – (various wheel sizes available)

GenGrind FA-IC 250S Single Wheel Polisher and Grinder, an advanced and fully automatic metallographic grinding and polishing machine

GenPress MFA Dual HYD Fully Automatic Dual Hydraulic Mounting Press – Hydraulic Controlled – 1-2” (25-50mm) Mold Assembly (other sizes available upon request)

GenPress MFA DUAL HYD Metallographic Sample Preparation is an advanced automatic mounting press for compression mounting of material samples

GenPress MFA MOT - Fully Automatic Motorized Mounting Press – Motor Controlled – 1-2” (25-50mm) Mold Assembly (other sizes available upon request)

GenPress MFA MOT mounting press system frees the operator to perform other tasks in the laboratory during the cycle allowing better efficiency

GenPress MFA HYD - Fully Automatic Hydraulic Mounting Press – Hydraulic Controlled – 1-2” (25-50mm) Mold Assembly

GenPress Mounting Press for Metallographic Sample Preparation is an advanced automatic mounting press for compression mounting of material sample

Class H - Servo-Motor Dual Column Charpy Impact Tester - 300J, 450J, 600J or 750J

NextGen's Class H – Servo-Motor Dual Column Charpy Impact Testing system offers of an exceptional combination of versatility and robust build. This impact system provides our most durable options designed with a dual column configuration. The system offers the ultimate versatility of testing 300J (212 ft/lbs), 450J (332 ft/lbs), 600J (442 ft/lbs) and a maximum of 750J (553 ft/lbs) capacities based on both Charpy and Izod test methods. The unit comes standard equipped with a servo motor and is designed to test at any preset angle. The unit comes standard with all the functions of our Class G tester as well as enhanced functionality upgrade of a force transducer inside the strikerwhich enables the determination of characteristic force, energy and displacement parameters such as pre-maximum force energy (Wm), the post maximum force energy, the general yield force (Fgy), the force at brittle fracture initiation (Fbf) and the arrest force (Fa).

Triple Specimen Chamber Motorized Charpy Notch Making Machine

The GenNotch 4000UPG Series is a motorized Charpy & Izod Notch Making Machine with a triple specimen chamber.

NG-EML Series B – Dual Column Bench Top Universal Testing Machine (100 N – 10 kN)

The NG-EML Series B is a high-precision dual-column benchtop universal testing machine engineered for tensile, compression, and flexural testing in the 0.1 kN to 10 kN range. It features Class 0.5 accuracy, a rigid FEM-optimized frame, and a direct-drive servo system with advanced closed-loop control, making it ideal for testing rubber, plastics, metals, composites, and high-performance polymers in both R&D and quality assurance settings.

NG-EML Series C – Dual Column Bench Top and Floor Standing Universal Testing Machine (5 kN – 50 kN)

The NG-EML Series C is a precision-engineered dual-column universal testing machine for tension, compression, and flexural testing of metals, composites, rubbers, and polymers. Available in both bench-top and floor-standing formats, with force capacities from 5 kN to 50 kN and Class 0.5 accuracy.

NG-EML Series D – Floor Standing Universal Testing Machine (50 kN – 1000 kN)

The NG-EML Series D – Floor Standing Universal Testing Machine (50 kN–1000 kN) is a dual-column system for tensile, compression, flexural, shear, and cyclic testing of high-strength metals, composites, polymers, and advanced materials. Available in single-space and dual-space configurations, it meets ASTM E8, ISO 6892-1, ISO 527, and GB/T 228 standards. With closed-loop control, 1200 Hz sampling, ultra-low speeds (0.00005 mm/min), and waveform generation, it is ideal for aerospace, automotive, construction, and research labs.

Grips and Fixtures for NextGen Universal Testing Machines (UTMs)

NextGen's grips and fixtures are precision-engineered accessories that transform universal testing machines into versatile systems capable of tensile, compression, flexural, shear, and other mechanical tests. Designed to meet ASTM and ISO standards, these components ensure accurate, repeatable results across various materials and applications.

GenTest Data Acquisition Software - Advanced Universal Testing Machine Software

Upgrade to GenTest, the latest data acquisition software for universal testing machines. Ensure precise, repeatable material testing with an intuitive interface, powerful analysis tools, and full compliance with ASTM, ISO, DIN, and more.

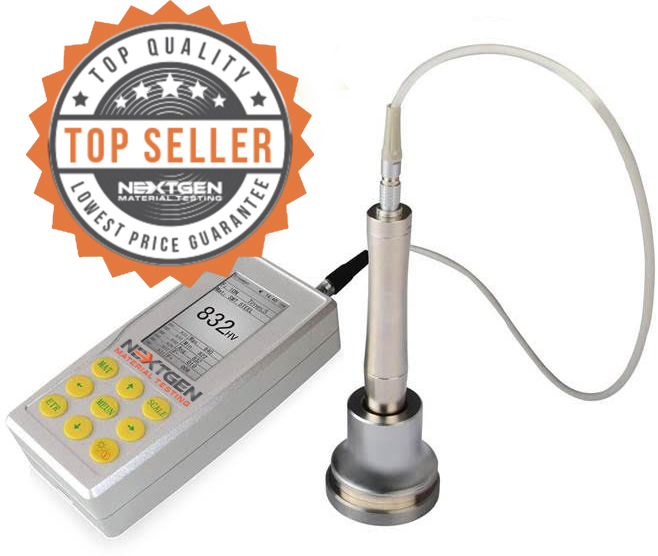

NG - LeebGen 3000 - Leeb Rebound Portable Hardness Tester

LeebGen3000 is a non-destructive precision metal hardness tester developed according to the latest industry standards. LeebGen 3000 is equipped with features which provide the instrument with a combination of a user-friendly interface and exceptional test result accuracy. This in turn allows for ease of operation and an accurate conversion display of virtually any metal hardness testing value.

GenVac MP3 Series - Epoxy Mounting Vacuum Impregnation System for Metallographic Sample Preparation

Experience our enhanced version of the GenVac MP Series. Our user-friendly touch screen interface along with automatic unit conversion and memory modes holds the title of one of the most advanced systems in the marketplace.

TensileTurn CNC XL - Heavy-Duty Round Specimen Preparation

TensileTurn CNC XL is the upgraded version of our TensileTurn CNC classic model. This powerful lathe is capable of turning round, square and irregular stock of tougher materials. The machine comes equipped with a robust tooling fixture, precision tailstock, and a high powered spindle. TensileTurn CNC XL is no doubt the ultimate round tensile test sample preparation machine capable of both tensile specimen preparation and advanced CNC machining. The unit is capable of meeting high capacity and high quantity output requirements for medium to large size laboratories and manufacturing facilities.

Ultrasonic Contact Impedance Hardness Tester - UH200

Welcome to our most advanced and cost-effective Ultrasonic Hardness Testing System. This portable machine is all you need and more!

TensileTurn CNC - Round Tensile Sample Preparation

Featuring a convenient size and high accuracy, the TensileTurn CNC can produce the highest accuracy in round tensile specimens. Able to prepare round tensile specimens, sub-size specimens, threaded tensile specimens, button-head tensile bars, fatigue specimens or any other round testing specimens, the TensileTurn CNC is easy to operate for both experienced and inexperienced operators.

TensileMill CNC XL - Flat Tensile Sample Preparation Equipment

This larger tensile sample preparation machines is the perfect fit for higher tensile sample preparation volumes. Equipped with our tensile software and Carbon Mach4 CNC software combo this machine is both simple to use and versatile for your long-term CNC machining requirements.

NG-SHM CLASS DP - Servo Hydraulic Testing Machine

600kN-2000kN - Servo-Hydraulic Universal Testing Machine - Side Action Wedge Grip 2/4 columns, servo-controlled hydraulic

NG-SHM Class D - Servo Hydraulic Universal Testing Machine

600kN-2000kN - Servo-Hydraulic Universal Testing Machine 2/4 columns, servo-controlled hydraulic

NG-SHM Class C - Servo Hydraulic Testing Machine

600kN-1000kN - Servo-Hydraulic Universal Testing Machine 6 column, servo-controlled hydraulic

NG-SHM Class B - Servo Hydraulic Testing Machine

300kN-3000kN - Servo-Hydraulic Universal Testing Machine 6 column, servo-controlled hydraulic

TensileMill CNC MINI - Compact Flat Tensile Sample Preparation

Despite its small size, the axis of the heavy cast iron frame on which the TensileMill CNC MINI slide on linear rails very smoothly. Its exceptional machining capability is provided by high powered servos and a 24,000 RPM ISO20 spindle.

Specimen Notching/Broaching Machine

NextGen offers an economical solution for Specimen notching and broaching for Charpy and Izod specimens. This certified system complies with ASTM ISO148, EN10045, ASTM E23, DIN 50115 standards. This automated, motorized solution is capable of preparing two specimens at any one given time up to 46 HRC. A variety of broaches are available for different geometries of notches.

Impact Specimen Cooling and Heating Temperature Chamber – GenChamber

NextGen offers a full range of impact specimen cooling and heating chamber designed to meet virtually all Charpy, Izod and Tensile Impact Testing requirements. NextGen's temperature chambers are a combination of user-friendliness, compact and robust build, offering the ultimate versatility of cooling and heating requirements.

Charpy/Izod Notch Verification Projector System NG-NPS-CIS

Enhance your material testing accuracy with our advanced Charpy/Izod Notch Verification Projector System NG-NPS-CIS.

DWT-1800 Computer Controlled Drop Weight Impact Testing Machine

DWT-1800 Impact Testing Machine is specifically designed for determining the non-plastic transformation temperature of ferritic steel.

Low-capacity Vertical Drop Weight Testers Up To 2000J NG-FWT1 & NG-FWT2

Discover NextGen's NG-FWT1 & NG-FWT2 low-capacity drop weight testers up to 2000J (1475 ft/lbs), designed for precise impact resistance testing of metals & non-metals.

GenTest V 2.0: Advanced Testing Software for Servo-Hydraulic Universal Testing Machines

Gentest is designed to enhance your ability to perform accurate and repeatable mechanical testing of materials, components and finished goods across a full spectrum of applications.

NG-SHM Class A - Servo Hydraulic Testing Machine

200kN-2000kN - Servo-Hydraulic Universal Testing Machine 4 or 6 column, servo-controlled hydraulic.

GenGrind Belt BF - Floor Standing Heavy Duty Dual Stage Belt Grinder for Metallographic Sample Preparation

The GenGrind Belt BF Series is a heavy duty dual stage, wet or dry belt grinder offering a robust, floor standing solution for high volume manual belt grinding applications. GenGrind Belt BF - Heavy Duty Dual Stage Belt Grinder for metallographic sample preparation is designed for high material removal of various sample shapes and configurations.

GenGrind Belt BT - Dual Stage Tabletop Belt Grinder for Metallographic Sample Preparation

The GenGrindBelt BT series is a dual stage, wet or dry table top belt grinder offering the most economical solution for manual grinding applications. The GenGrind BT - Dual Stage Belt Grinder for Metallographic Sample Preparation is designed for high material removal of various sample shapes and configurations. The BT - Belt Grinder system is a table top belt grinder suitable for laboratories designed for high material removal.

GenGrind FA-IC Dual Wheel Fully Automatic

Introducing the GenGrind FA-IC, a state-of-the-art single-chip microcomputer controlled grinding and polishing machine.

GenVac MP Series - Epoxy Mounting Vacuum Impregnation System for Metallographic Sample Preparation

GenVac MP2 - Vacuum Impregnator is designed for precision sample impregnation for porous materials. Common applications for vacuum impregnation systems include rocks and minerals, ceramics, electronic circuit boards and other composite materials.

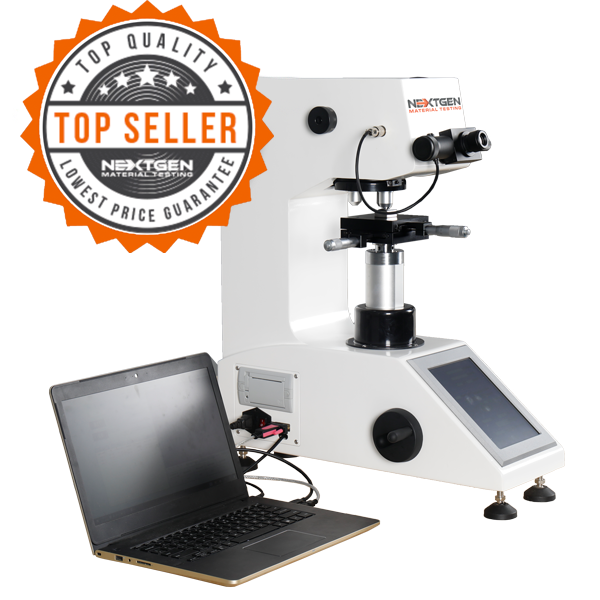

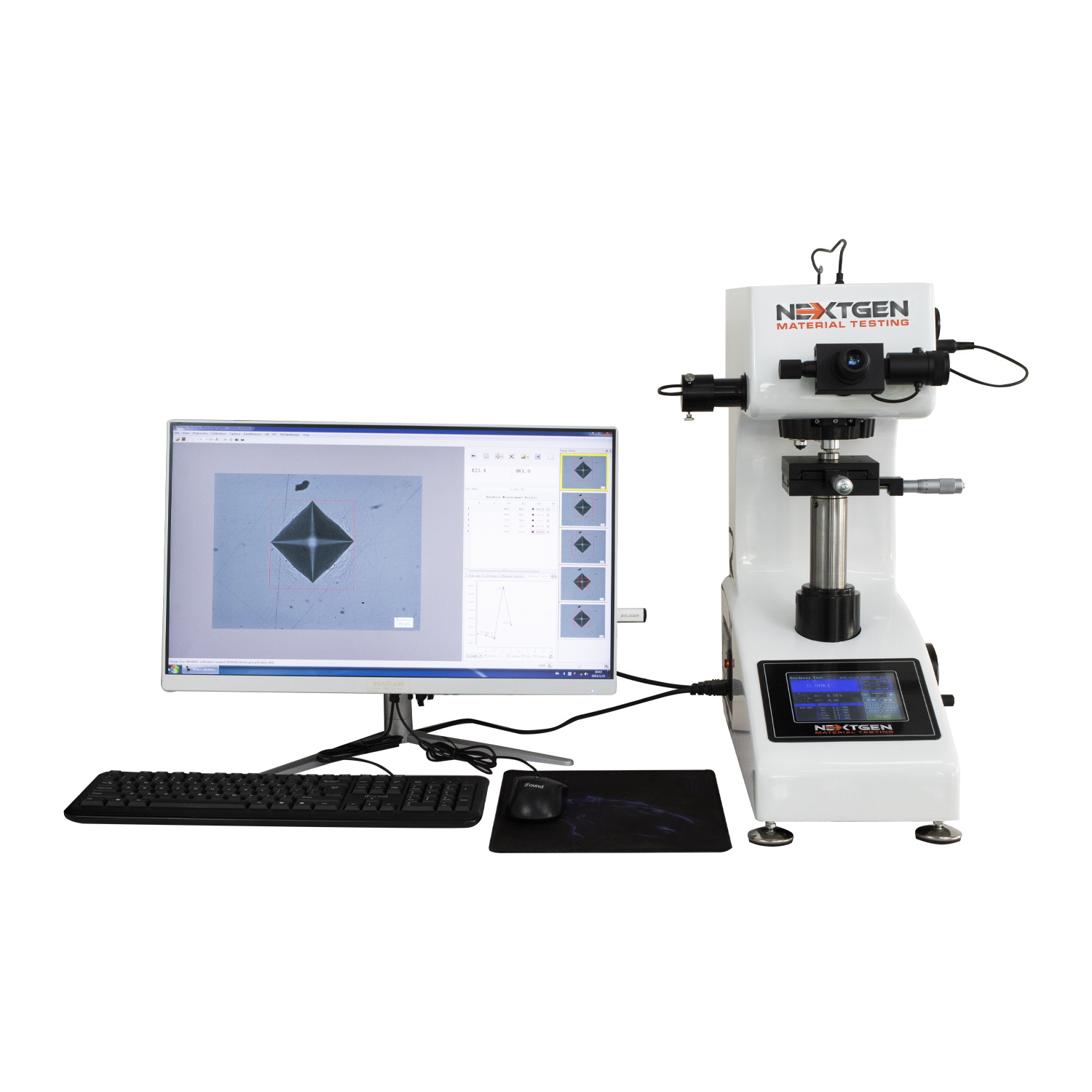

Micro Vickers and Knoop Hardness Tester - Digital and Digital with CCD Optical Analysis Software

NG-1000 Series

NextGen Micro Hardness testers provide solutions for Vickers and Knoop hardness testing with micro loads ranging from 10gf to 1kgf. The NG1000 series is available in Standard Digital, Digital and CCD configurations for Micro Vickers/Knoop testing.

Macro Vickers Hardness Tester - Standard Digital, Digital and Digital with CCD Optical Analysis Software

NG-5000 Series

NextGen Macro Vickers Hardness testers are available with different load capacities and are available in Standard Digital, Digital or CCD configurations. With 5kgf, 10kgf, 30kgf and 50kgf maximum loads available, the NextGen Macro hardness testers can fit all of your Macro testing requirements.

BrinGen - 3000 Series - Digital Brinell and Automatic Brinell Hardness Tester - Closed Loop System

BringGen 3000 is a digital and automatic Brinell testing system equipped with closed loop technology. The forces range from 62.5kgf to 3000kgf and are electronically controlled according to ASTM E10 for precise and repeatable measurements.

BrinGen Scope - Optically Advanced CCD Brinell Measuring Scope for Manual or Digital Brinell Hardness Testing System

BrinGen Scope - is a Optically Advanced CCD Brinell Measuring Scope for Manual or Digital designed as Brinell Hardness Testing automatic scanning system. It is engineered to work with a computer or a laptop to make your testing program faster and more accurate. The Optical Brinell Scope is equipped with real-time result support.

NG-RockGen - Analogue Series Rockwell Hardness Tester - Manual and Electronic Models

The NG-RockGen Analogue Rockwell Hardness Tester is designed to test the hardness of metals by determining the depth of penetration of an indenter under a large load compared to the penetration made by a preload according to the Rockwell regular scales.

NG-RockGen DGEN Series - Digital Rockwell Hardness Tester - Rockwell Regular, Rockwell Superficial and Rockwell TWIN Digital Models

The NG RockGen Digital Series provides an automatic, digital, high accuracy solution to your Rockwell testing requirements. The Digital series is completely automated and is available in Rockwell Regular or Rockwell Superficial scale configurations.

GenRock NG-150 Series - Advanced Rockwell Hardness Tester - Manual and Automatic Rockwell Hardness Testing System

The NG150 GenRock system can be equipped with a variety of accessories to meet all of your hardness testing requirements. A fully motorized stage, Jominy accessories and a wide variety of specimen fixtures are available to configure the NG150 RockGen system to meet your application.

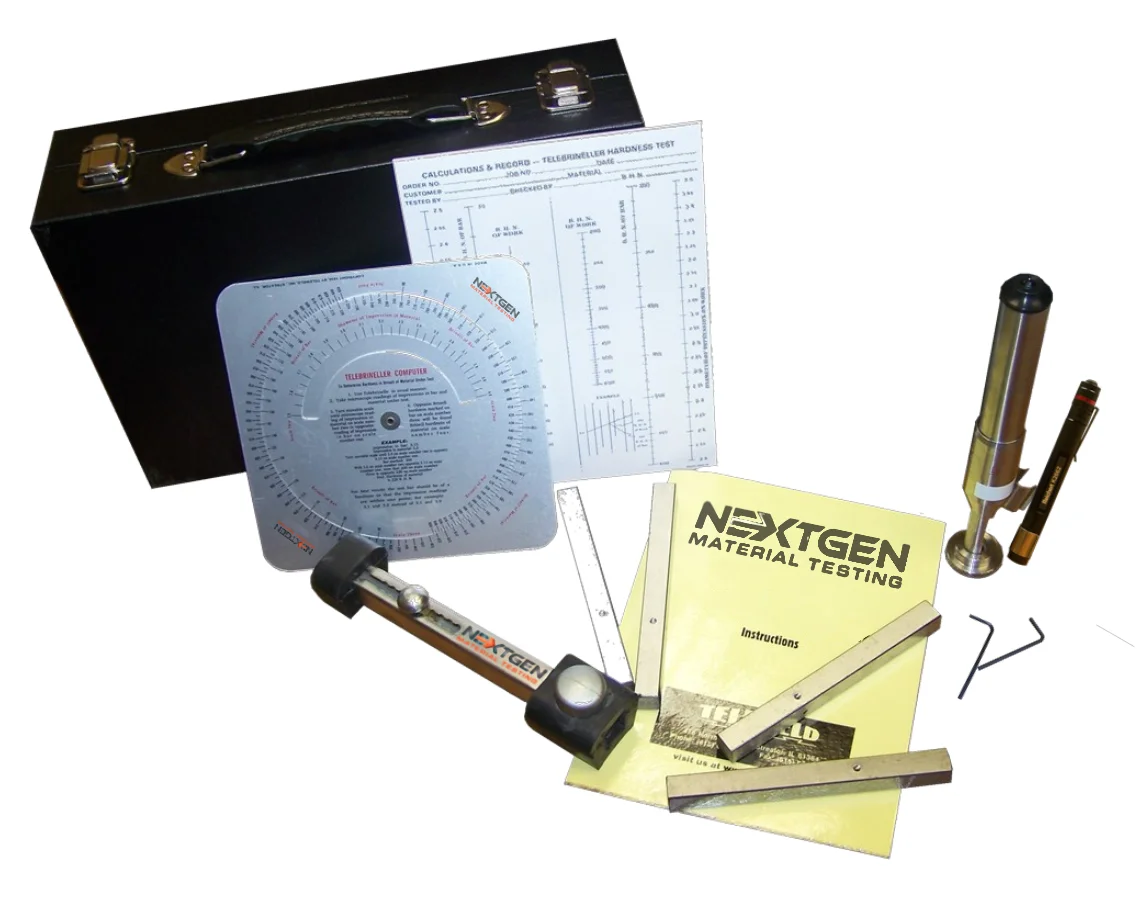

NextGen Telebrineller Brinell Hardness Testing System

The Telebrineller Brinell Hardness Testing System stands out as the best QA solution for ensuring top-notch quality. Developed specifically for welding crews, Telebrineller draws on over fifty years of field experience and solid metallurgical knowledge. Portable and practical, the entire Telebrineller system, housed in a case, weighs less than ten pounds. It's an ideal choice for Brinell hardness testing in any situation.

Surface Roughness Testers

High accuracy surface roughness testing systems for material surface analysis and statistical processing of data. Multiple model variations to help fit your technical and budgetary expectations.

Universal Hardness Tester for Vickers, Rockwell and Brinell

NextGen's Universal Hardness Tester is a closed loop load cell machine with an 8-inch touch screen interface is the ultimate user-friendly solution for your Vickers, Knoop, Rockwell and Brinell Hardness Testing requirements. The measurements are made through optical objective lens and CCD camera to collect indentation images and to generate your hardness reading on the touchscreen LCD.

Hardness Test Blocks, Indenters and Hardness Testing Accessories

Certified Test Blocks are a requirement as a reference material for any type of hardness testing. At NextGen, we understand the importance of a Test Block to ensure the accuracy of your hardness testing procedures.

Metallography Consumables

Learn about the full scope of NextGen's cutting, polishing & grinding, mounting and etching metallography consumables. Our consumables are compatible with virtually all global brands, offering a rare combination of exceptional quality, longevity and affordability.