Metal Testing Equipment

Servo-hydraulic static universal testing machines use a closed-loop hydraulic system to apply and control load during material and component testing. These systems are typically used when testing requires higher force levels than those commonly handled by electromechanical universal testing machines.

Servo-hydraulic UTMs are applied in static test methods such as tensile, compression, and flexural testing, particularly for metals and other high-strength materials. Hydraulic actuation allows stable load control under high forces and supports the use of hydraulic grips and large-capacity fixtures.

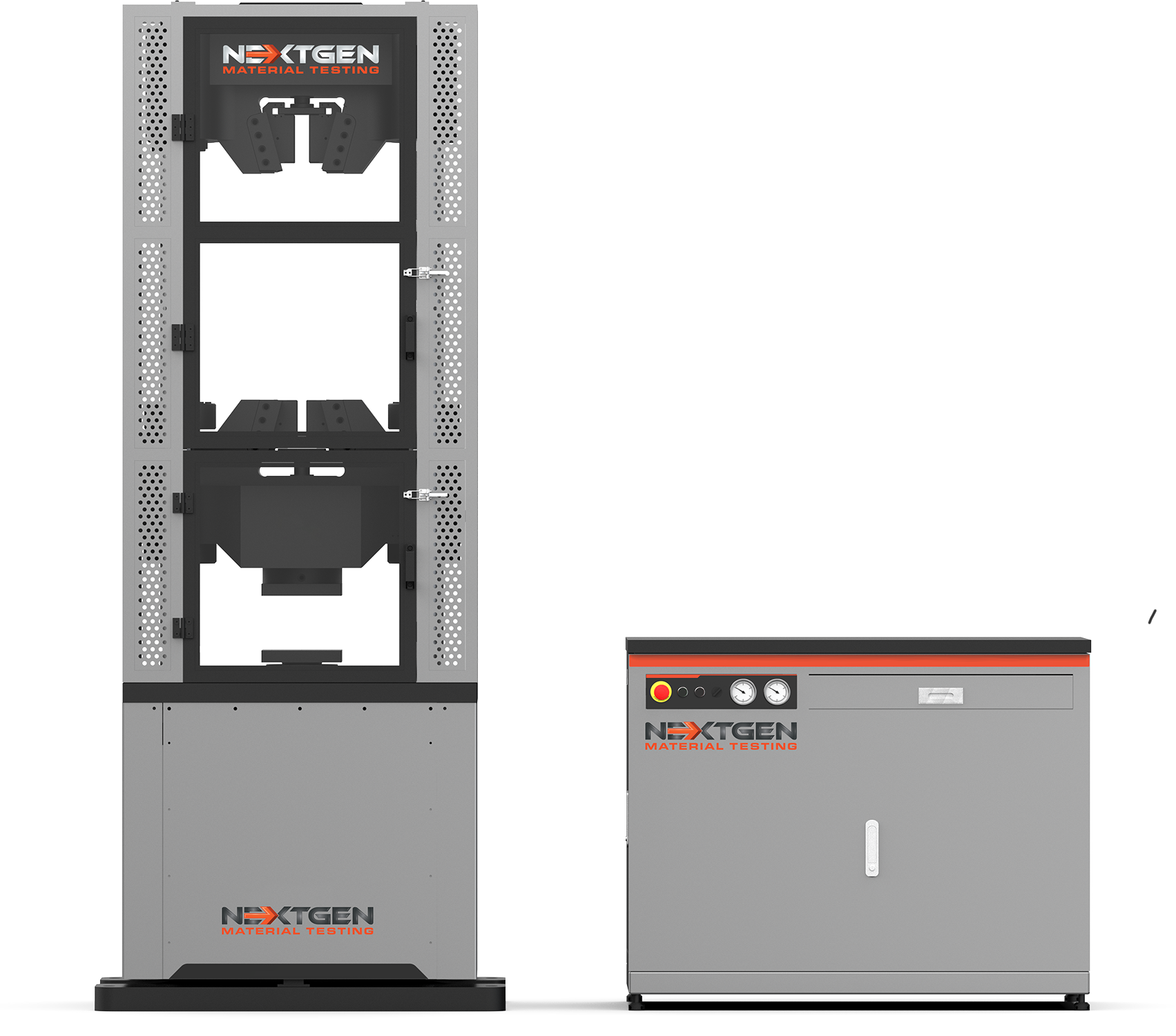

NextGen servo-hydraulic systems can be configured with different frame capacities, hydraulic power units, and control components. The machines are compatible with hydraulic and mechanical grips, bending fixtures, compression platens, and application-specific accessories for testing metals, composites, and other structural materials.

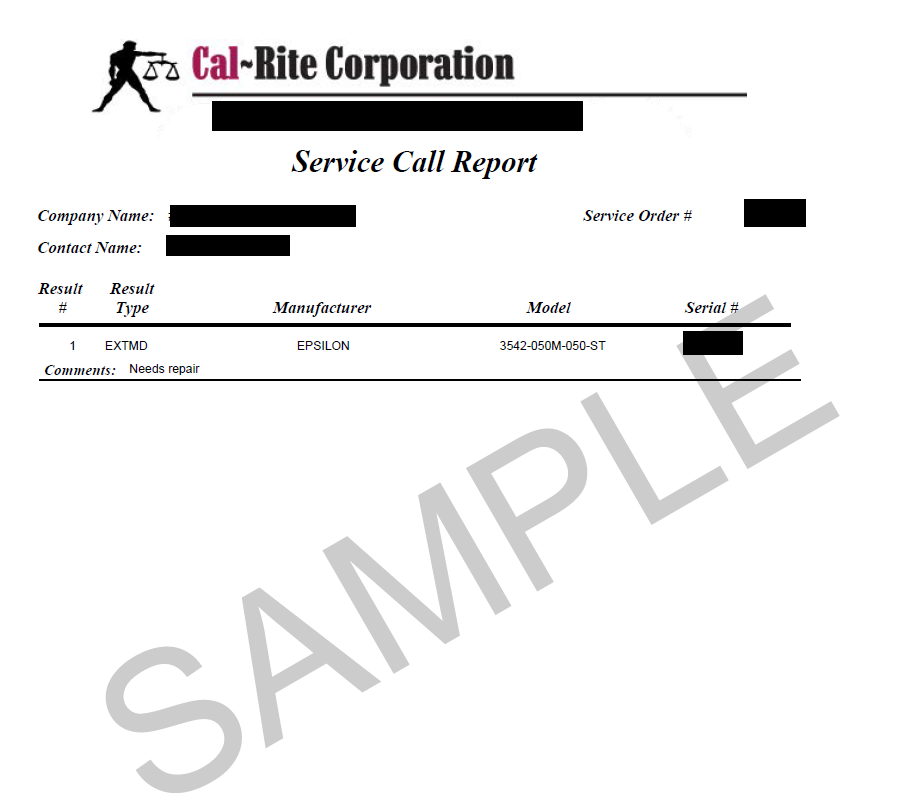

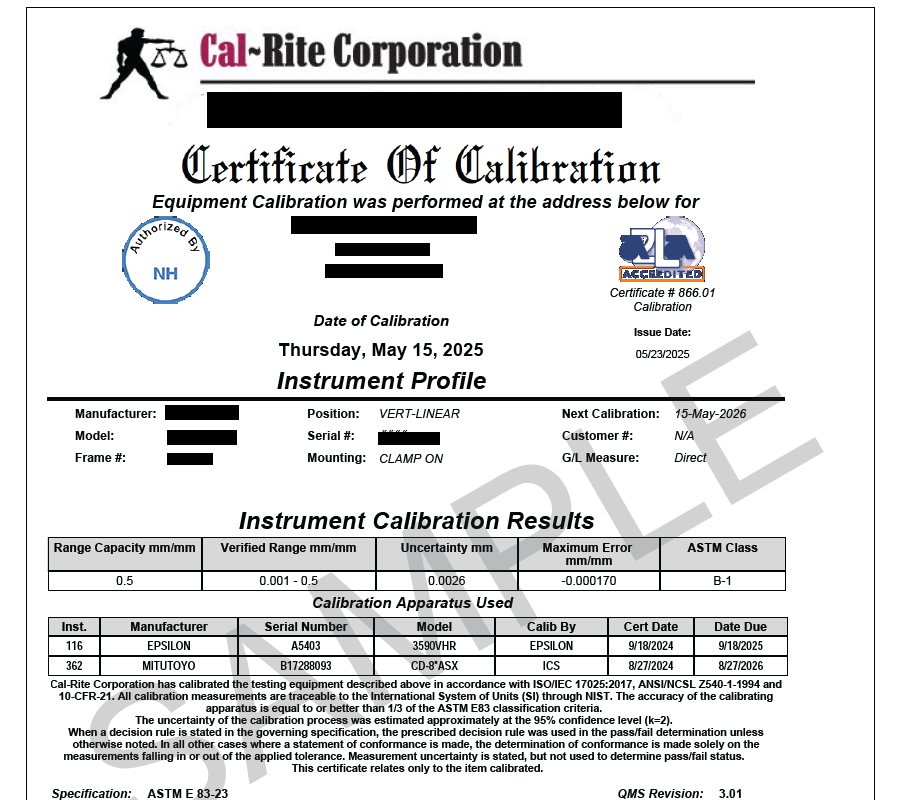

In addition to equipment supply, NextGen provides calibration and certification services for both NextGen systems and third-party universal testing machines. Certification is performed in accordance with applicable standards and can include force, displacement, and system verification. Examples of available certificates are shown below:

Products

NG-SHM Series A — Servo-Hydraulic Universal Testing Machines (300 kN – 3000 kN)

NG-SHM Series A is a high-force servo-hydraulic UTM for static tensile and compression testing of metals. Capacity options from 300 to 3000 kN support oversized round and flat specimens beyond electromechanical limits. The dual-zone configuration enables tension on the upper head and compression on the lower platen without fixture changeover. GenTest software offers standards-based method libraries, real-time curves, automatic calculations, and exportable reports. The system is built for ASTM/ISO metal strength testing in heavy industrial and research environments.

NG-SHM CLASS DP - Servo Hydraulic Testing Machine

600kN-2000kN - Servo-Hydraulic Universal Testing Machine - Side Action Wedge Grip 2/4 columns, servo-controlled hydraulic

NG-SHM Class D - Servo Hydraulic Universal Testing Machine

600kN-2000kN - Servo-Hydraulic Universal Testing Machine 2/4 columns, servo-controlled hydraulic

NG-SHM Class C - Servo Hydraulic Testing Machine

600kN-1000kN - Servo-Hydraulic Universal Testing Machine 6 column, servo-controlled hydraulic

NG-SHM Class B - Servo Hydraulic Testing Machine

300kN-3000kN - Servo-Hydraulic Universal Testing Machine 6 column, servo-controlled hydraulic

GenTest v3.0 Software for Universal Testing Machines

GenTest Software is developed for testing facilities that require controlled execution on universal testing machines. The method-driven workflow keeps setup parameters, recorded data, calculations, and reporting connected in a single record. The software supports standards-based programs aligned with ASTM, ISO, DIN, EN, and BS and is used for tensile, compression, bending, and shear testing. It helps teams produce consistent results and documentation for QA/QC and customer reporting.

FAQs

Here are some fundamental differences between Class A and Class DP Servo Hydraulic Universal Tensile Testers:

- Class A can only perform tension or compression test, while Class DP can perform tension and compression cyclical test.

- Class DP is much heavier system than Class A. It is a robust machine equipped with a heavier bottom platen and top platen. It also has a much larger cylinder.

- Class DP tensile tester uses I type load cell. This is an more advanced, precise and reliable load cell relative to Class A system.

- During specimen clamping Class DP Servo Hydraulic machine has smaller initial force than Class A. That means that Class DP has smaller rate of damage on specimens during clamping.

- Class DP system is shock absorbent allowing for a minimum ground shock upon tensile specimen break.

- Class DP is easier for tensile testing in general. It is more user friendly, accessible and accurate. When it comes to Class A tensile tester, the operator needs to use a small ladder when loading the specimens, because the tensile test space is in the upper section of the tester.

Learn more by contacting us today or submit quote request.