Metal Testing Equipment

Grips and fixtures are critical components for universal testing machines (UTMs), enabling precise application of tensile, compression, flexural, shear, peel, and puncture forces. Designed to securely hold specimens during testing, these accessories guarantee accurate load transmission and compliance with ASTM, ISO, and other international standards.

NextGen Material Testing offers a comprehensive selection of grips and fixtures compatible with electromechanical and servo-hydraulic UTMs. Each unit is engineered to suit specific material types and testing modes, ranging from rubber and plastic films to hardened metals and composite laminates. Available solutions include wedge grips for high-strength metals, pneumatic grips for efficient clamping, and flexural fixtures for 3-point and 4-point bending tests.

Our grips and fixtures support an extensive range of specimen geometries and dimensions, helping laboratories and manufacturers achieve optimal alignment, repeatability, and safety. Many models feature self-tightening mechanisms, interchangeable jaw faces (smooth, serrated, rubber-coated), and high-strength alloys to prevent specimen damage or slippage during high-load applications.

With the right combination of grips and fixtures, your UTM becomes a flexible testing platform suitable for R&D, quality control, and standard-compliant material testing. Whether conducting ASTM E8 tensile tests, ASTM D695 compression tests, or ISO 178 flexural testing, NextGen’s accessories are built to deliver consistent, traceable, and accurate results within all applications.

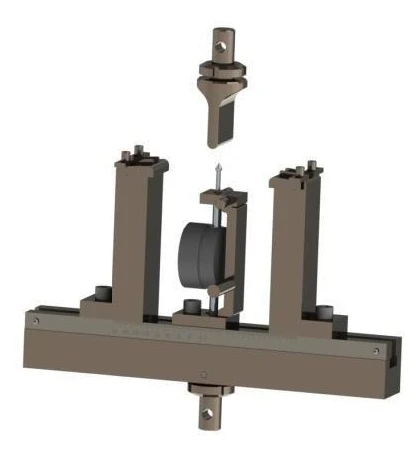

Side Action Tensile Grips for Versatile Clamping Applications

Side Action Tensile Grips for Versatile Clamping Applications

Side action grips are versatile mechanical clamps designed for tensile testing of plastics, metals, textiles, rubber, and composite specimens. These manually operated grips apply lateral pressure through dual jaws, tightened using screws or levers, to hold the specimen securely without causing surface damage.

Ideal for medium-load tensile applications, side action grips are commonly used in quality control and research environments. They are especially valued for their adaptability—interchangeable jaw faces (smooth, serrated, rubber-coated) allow precise matching to different material types and surface conditions, helping reduce slippage during testing.

This type of grip is a cost-effective and reliable choice for laboratories performing standardized tensile tests across a wide range of specimen geometries, where firm, controlled clamping is required without the complexity of powered gripping systems.

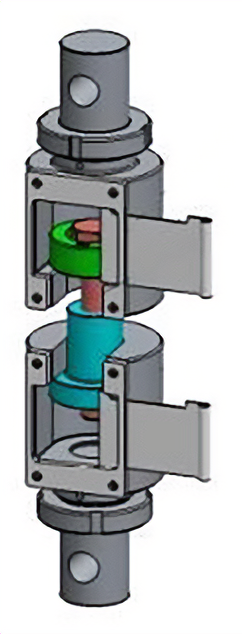

Snubbing Grips for Wire and Cable Tensile Testing

Snubbing Grips for Wire and Cable Tensile Testing

Wire and cable snubbing grips—also referred to as capstan or bollard grips—are specialized fixtures for tensile testing of wires, ropes, fiber bundles, and electrical cables with high slip risk. These grips use a curved mandrel or capstan around which the specimen is wrapped multiple times to generate friction and distribute the load evenly across its length.

This design prevents localized failure at the jaw and allows accurate measurement of the specimen’s full tensile strength, especially for high-strength steel cables, braided wires, and reinforced conductors. The free end is typically secured using a clamp or wedge, ensuring stable loading throughout the test.

These grips are essential for test laboratories, cable manufacturers, and infrastructure or construction quality control teams requiring compliance with ASTM, ISO, or other international standards for cable and wire testing. They offer a non-damaging, high-holding solution for tensile testing of flexible yet high-capacity specimens.

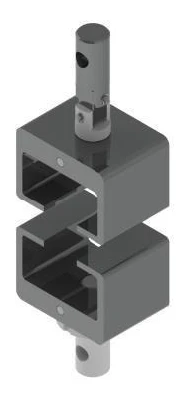

Self-Tightening Grips for Deformable and Elastic Materials

Self-Tightening Grips for Deformable and Elastic Materials

Self-tightening grips are designed to automatically increase clamping pressure as tensile force is applied, making them ideal for materials that elongate, thin, or deform during testing. Commonly used for elastomers, thin plastics, foams, fabrics, and biomedical specimens, these grips adapt to changing specimen dimensions without manual adjustment.

Popular designs include scissor grips, eccentric cam grips, and lever-action jaws, all of which tighten progressively under load. This mechanism minimizes slippage, eliminates the need for excessive pre-tightening, and prevents damage to delicate specimens at the start of the test.

These grips are well-suited for quality control laboratories, textile and rubber manufacturers, and research environments conducting standardized tensile tests on soft, elastic, or low-friction materials. They improve test repeatability and maintain reliable alignment and gripping force throughout the loading cycle.

Eccentric Roller Grips for Thin and Flexible Specimens

Eccentric roller grips are self-tightening fixtures specifically designed for tensile testing of thin films, rubber sheets, flexible plastics, and other delicate or low-strength materials. They feature an off-center cam roller that clamps the specimen against a fixed anvil. As the tensile load increases, the roller rotates further, automatically increasing the grip force.

This self-energizing mechanism ensures that even as the specimen elongates or necks, it remains securely held without slippage or tearing. To protect sensitive materials, the gripping surfaces are often coated with rubber or non-cutting materials.

These grips are ideal for R&D labs, quality control environments, and manufacturers working with soft or flexible specimens. Their tool-free, lever-actuated design allows for quick specimen loading while maintaining stable clamping pressure throughout the test. Eccentric roller grips comply with relevant ASTM and ISO standards for elastomer and film testing, ensuring accurate and repeatable results.

Bending Fixtures for Standard 3-Point Flexural Testing

Bending fixtures—also known as flexural test fixtures—are used with universal testing machines to perform 3-point and 4-point bend tests. These tests evaluate flexural strength, modulus of elasticity, and modulus of rupture in materials such as plastics, metals, wood, and composites.

The fixtures consist of lower support anvils and upper loading noses (or rollers), with adjustable spans to accommodate different specimen sizes and geometries. They are engineered to meet test requirements defined by standards such as ASTM D790 for plastics and ASTM C393 for sandwich structures. The design ensures precise alignment and minimal friction or torsion during loading.

Manufacturers, research facilities, and testing labs use bending fixtures to simulate real-world flexural stress scenarios under controlled conditions. Constructed from high-strength steel or rigid aluminum, these fixtures maintain structural integrity even under high loads, ensuring that force is applied directly to the specimen without deflection or misalignment.

Compression Fixtures for Axial Load Testing of Rigid Samples

Compression fixtures are essential accessories for universal testing machines used to apply axial compressive loads in a stable and aligned manner. The standard configuration includes flat compression platens—precision-machined steel plates that ensure even force distribution across the specimen surface.

For high-precision or high-force testing, one platen may feature a spherically seated base to self-align with the specimen, reducing the risk of eccentric loading and improving result accuracy. Additional configurations include compression cages or four-post assemblies for testing large samples like foam blocks, packaging materials, or structural components, ensuring specimens do not buckle or shift during loading.

NextGen's compression fixtures are available in a range of sizes and capacities, suitable for testing plastics (ASTM D695), concrete cubes, metals, composites, and paperboard products. These fixtures are ideal for materials testing laboratories, construction quality control, and packaging validation, providing a rigid, compliant platform for reliable compressive strength measurements.

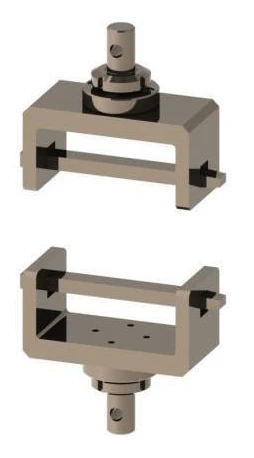

Shoulder Fixtures for Pull-Off and Component Testing

Shoulder fixtures—also known as shoulder grips or ledge grips—are specialized testing accessories designed to hold specimens with an enlarged end, flange, or head that cannot be gripped using standard jaws. These fixtures are essential for performing pull-off, push-out, and component integrity tests where force must be applied through the specimen’s shoulder to simulate real-world use conditions.

Common applications include testing bolt heads, cable terminations, syringe plungers, anchors, buttons, bottle caps, and fastener pull-outs. The specimen typically rests on a recessed ledge or collar, while the opposing end is subjected to axial force by the UTM.

Shoulder fixtures are widely used in medical device testing, automotive component validation, packaging durability, and construction anchoring systems, where it’s critical to assess how parts behave under tensile or compressive loads applied through their structural features. Built in various sizes and configurations, these grips ensure even load distribution across the shoulder area, preventing bending and enabling accurate, repeatable test results in accordance with ASTM and ISO standards.

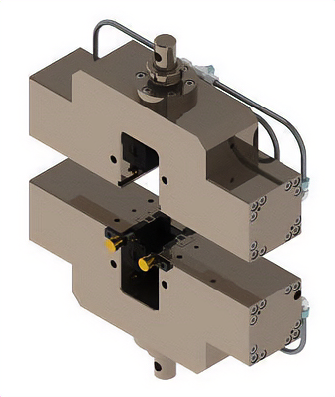

Pneumatic Grips for Fast and Repeatable Clamping

Pneumatic Grips for Fast and Repeatable Clamping

Pneumatic grips use air pressure to apply quick, uniform, and adjustable clamping force to test specimens. Activated by a button or foot pedal, these grips feature built-in air cylinders that close the jaws with precisely controlled pressure—ideal for testing materials that require consistent gripping without surface damage.

They are widely used for rubber, plastics, textiles, and other soft or flexible specimens where accurate pressure control is essential. Users can fine-tune the clamping force to prevent slippage or crushing, especially during standardized tensile tests.

Thanks to their fast operation, pneumatic grips are preferred in high-throughput testing laboratories, quality control departments, and manufacturing facilities. Variants like pneumatic side-action grips are commonly used for mid-range force applications up to 20 kN, offering repeatable and self-centering clamping across different test setups.

These grips support a wide range of material tests and can be adapted to meet requirements from ASTM, ISO, and other international standards, ensuring consistent, safe, and efficient performance in demanding test environments.

Wedge Tensile Grips for High-Load Metal and Composite Testing

Wedge tensile grips use a self-tightening wedge-action mechanism that increases clamping force as tensile load rises. Each grip includes an internal wedge-shaped slider with serrated or knurled jaws that grip the specimen more firmly as tension is applied.

These grips are ideal for high-strength materials such as metals and composites, particularly in high-load testing applications. Their design ensures secure holding without slippage or jaw damage, even under peak loads. Available in both manual and hydraulic configurations, wedge grips accommodate a wide force range—from a few kilonewtons to over 500 kN.

They are commonly used in material testing laboratories, aerospace and automotive industries, and research institutions performing ASTM E8, ISO 6892, or other metal tensile tests. The grips maintain axial alignment during testing, making them essential for precise tensile strength measurements of hard, structural specimens.

3-Point and 4-Point Bending Fixtures for Uniform Moment Flexural Testing

3-point and 4-point bending fixtures are specialized tools used in flexural testing to apply two evenly spaced loads across a specimen, creating a constant moment region between the load points. This configuration eliminates shear forces in the central section, enabling accurate measurement of flexural modulus and modulus of elasticity.

These fixtures are particularly suited for testing brittle materials, plastics, composites, and concrete beams, where minimizing stress concentration is essential. Typical applications include tests based on ASTM D6272 for plastics and ASTM C78 for third-point loading of concrete specimens.

The fixture consists of two upper loading rollers and two lower supports with adjustable span distances to accommodate different specimen sizes and meet specific standard requirements. It is widely used by construction material labs, composite manufacturers, and research institutions aiming to observe failure modes or deflection behavior under pure bending conditions.

Grips and Fixtures for Tensile, Shear, and Flexural Testing of Wood

Wood testing grips and fixtures are specially designed to accommodate the anisotropic, variable nature of wood and timber specimens. These solutions support a full range of mechanical tests defined by standards such as ASTM D143 and ASTM D4761, covering tensile, shear, compression, nail/screw withdrawal, and flexural testing.

For tensile tests parallel to grain, grips with flat or serrated jaws or shouldered clamps are used to hold dogbone-shaped specimens without crushing. For perpendicular-to-grain tests, fixtures with bonded metal brackets are applied. Block shear fixtures allow testing of shear strength along the grain under tension or compression. Nail and screw withdrawal fixtures are designed to pull fasteners axially from wood blocks to assess withdrawal resistance.

Compression testing is performed using oversized or self-aligning compression platens, while 3-point and 4-point bending fixtures are used for measuring modulus of rupture and modulus of elasticity in lumber and beams.

These fixtures are widely used by wood product manufacturers, construction material testing labs, and furniture and fastener industries, ensuring accurate, repeatable testing while compensating for wood’s natural variability. All fixtures are built to prevent grip-induced failure and ensure compliance with wood testing standards.

Composite Grips and Fixtures for Tensile, Shear, and Delamination Tests

Composite Grips and Fixtures for Tensile, Shear, and Delamination Tests

Composite grips and fixtures are engineered for the complex mechanical testing of composite materials, including carbon fiber reinforced polymers, fiberglass, and laminates. These materials require specialized handling to avoid premature failure, misalignment, or stress concentrations during testing.

For tensile testing, hydraulic wedge grips with treated jaw surfaces are used to prevent slippage or crushing of composite laminates. In compression testing, fixtures such as the Combined Loading Compression (CLC) and IITRI types hold specimens with side supports or end tabs to ensure proper failure modes.

Shear testing of interlaminar strength is typically performed using short-beam shear fixtures (per ASTM D2344), Iosipescu shear fixtures (ASTM D5379), and rail shear devices (ASTM D7078) for in-plane shear. Fracture toughness evaluation includes double cantilever beam fixtures (ASTM D5528) for Mode I and end notch flexure or mixed-mode bending fixtures for Mode II delamination.

Additional solutions include picture frame fixtures and bias extensometer setups for fabric in-plane shear, as well as floating roller peel (ASTM D3167) and climbing drum peel fixtures (ASTM D1781) for testing bonded laminate assemblies.

Specialized Grips and Fixtures for Tear, Peel, and Puncture Testing

Special-purpose grips and fixtures cover a wide range of non-standard mechanical tests including peel, tear, puncture, pull-through, buckle, and custom shear testing. These solutions are designed for materials and configurations that cannot be tested using conventional grips, allowing flexible adaptation to specialized requirements.

Examples include 90-degree peel fixtures and climbing drum peel fixtures for adhesive bond strength testing of tapes, laminates, and bonded assemblies. Tear test grips hold plastic films or fabrics for propagation tear evaluation. Puncture fixtures include systems for geomembranes under ASTM D4833 and ball burst tests for textiles in accordance with ASTM D3787. Other options include tear propagation fixtures, eyelet pull-through grips, and buckle test fixtures.

Custom shear fixtures are available for adhesive lap joint testing, such as those conforming to ASTM D4501. These solutions are commonly used by packaging developers, textile manufacturers, material testing labs, and industrial product engineers requiring accurate test configurations beyond standard tensile or compression applications.

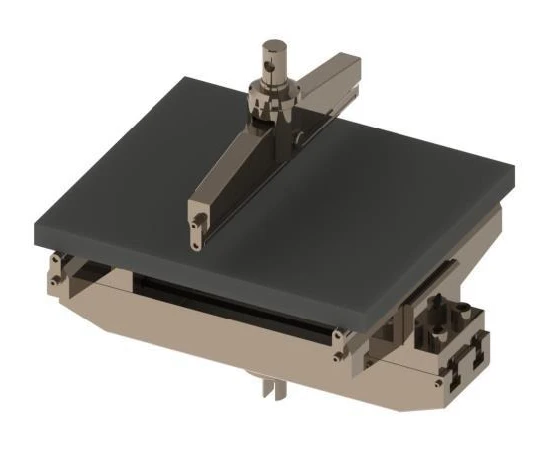

TestStar® Series Grips and Fixtures for Hydraulic UTM Integration

TestStar® series grips and fixtures are designed specifically for use with NextGen’s TestStar universal testing machines, which are high-performance systems equipped with hydraulic actuation. These accessories offer the same core functionality as standard grips but are fully compatible with TestStar mounting, force capacity, and control systems.

TestStar® series grips and fixtures are designed specifically for use with NextGen’s TestStar universal testing machines, which are high-performance systems equipped with hydraulic actuation. These accessories offer the same core functionality as standard grips but are fully compatible with TestStar mounting, force capacity, and control systems.

The range includes manual and pneumatic snubbing grips for testing wires and cables using the capstan method, side action grips for general-purpose tensile testing, wedge-action grips for high-strength metals, and dedicated compression and bending fixtures. Fixtures such as 3-point flexural setups are available for testing plastics, metals, and composites, utilizing the full capabilities of the TestStar frame.

These grips are ideal for test laboratories, heavy industrial applications, and materials R&D, particularly when working with large specimens or high-force testing requirements. Hydraulic variants are available for high-capacity setups.

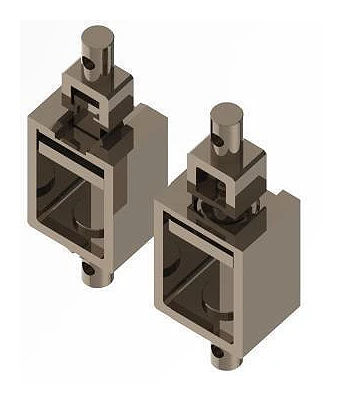

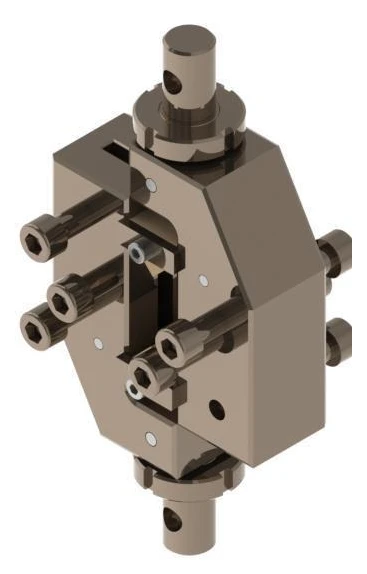

Dual-Action Hydraulic Grips with Wedge Clamping for High-Capacity Tests

Dual-Action Hydraulic Grips with Wedge Clamping for High-Capacity Tests

Dual side action/wedge hydraulic grips are designed for high-capacity tensile testing, combining parallel hydraulic clamping with wedge-action self-tightening. In side-action mode, the jaws close symmetrically from both sides using hydraulic pressure, ensuring even, balanced force on flat or wide specimens without introducing bending stress.

The wedge-action mode uses angled jaw slides that increase clamping force as tensile load rises. This mechanism provides additional holding strength for large metal specimens, steel rods, and fasteners, making these grips ideal for testing applications involving forces in the hundreds of kilonewtons. The hydraulic actuation allows pre-set pressure control for safe and consistent specimen engagement.

These grips are commonly used on servo-hydraulic universal testing machines in construction materials labs, metal testing facilities, and industrial manufacturing environments, where conventional manual or pneumatic grips are insufficient. Their robust construction supports maximum machine loads, making them essential for rebar, bolt, and structural metal testing.

Threaded Grips for Bolt and Nut Tensile Testing

Threaded Grips for Bolt and Nut Tensile Testing

Bolt and nut tensile grips (also known as threaded grips) are specialized fixtures for axial tension testing of bolts, screws, studs, and nuts. These grips use threaded adapters or holders rather than clamping jaws, allowing direct engagement with the specimen's threads. The setup replicates real-world loading conditions by applying tensile force through the bolt head and nut.

These grips are essential for measuring the tensile strength, yield behavior, and proof load capacity of fasteners, in accordance with standards such as ASTM F606. In a typical proof load test, a nut is mounted on a hardened test mandrel and loaded to a specified tension to verify thread integrity and load-bearing capacity without failure. NextGen’s grips include interchangeable threaded inserts to accommodate various thread sizes.

Widely used in automotive, aerospace, construction, and mechanical engineering laboratories, these grips are built from high-strength steel to handle forces exceeding 100 kN. They enable reliable, repeatable testing of threaded fasteners and provide critical data for quality control and product certification in structural and mechanical applications.

Grips and Fixtures for Hydraulic Universal Testing Machines

Grips and Fixtures for Hydraulic Universal Testing Machines

Within the hydraulic machine accessories category, the tensile grips and fixtures segment covers all devices for applying tension using a high-force system. This includes large hydraulic grips—both side-acting and wedge types—for straight-pulling of metal coupons or bars. It also encompasses special tensile fixtures like the tensile shear fixture, which may be used to test shear strength in tension (for example, pulling on a single-lap joint to induce shear failure), and proof load fixtures for nuts, as commonly needed in fastener testing.

A nut proof load fixture usually involves a loading mandrel (a hardened threaded rod) that the nut is fastened onto, paired with a support so the nut can be pulled without movement. The nut is stressed in tension via the mandrel up to a specified force to ensure it can hold that load without stripping. In the hydraulic context, these fixtures are built to withstand very high forces, since large nuts and fasteners can require hundreds of kilonewtons in proof tests. Tensile grips for hydraulic machines also often feature quick-change jaw inserts and heavy-duty construction, such as bolt grips with larger thread sizes or split collar grips for large diameter specimens.

Everything in this category is about handling large tensile forces safely and accurately. The fixtures are designed to maintain perfect alignment in the vertical direction, as off-axis loads at high force can be catastrophic. With NextGen’s tensile grips and fixtures for hydraulic frames, users can perform standard tension tests (like ASTM E8 for metals, ASTM A370 for rebar, etc.) and specialized tension-based tests (fastener proof tests, shear in tension, etc.) with confidence that the equipment can handle the load. Each fixture meets the relevant standard (such as wedge grips fulfilling the grip requirements of ASTM E8, or nut testers meeting ASTM F606) and interfaces properly with the high-capacity load cells and actuators of the hydraulic machine.

Products

NG-EML Series A – Single Column Bench Top Universal Testing Machine (50 N – 5 kN)

The NG-EML Series A – Single Column Bench Top UTM (50 N–5 kN) is a precision electromechanical system designed for tension, compression, and flexural testing of low-force specimens. Featuring GenTest™ software, a high-speed servo drive, Class 0.5 accuracy, and USB/Ethernet control, this compact tabletop unit supports ASTM, ISO, and EN standards. Ideal for testing plastics, rubber, foams, films, composites, and thin metals.

NG-EML Series B – Dual Column Bench Top Universal Testing Machine (100 N – 10 kN)

The NG-EML Series B is a high-precision dual-column benchtop universal testing machine engineered for tensile, compression, and flexural testing in the 0.1 kN to 10 kN range. It features Class 0.5 accuracy, a rigid FEM-optimized frame, and a direct-drive servo system with advanced closed-loop control, making it ideal for testing rubber, plastics, metals, composites, and high-performance polymers in both R&D and quality assurance settings.

NG-EML Series C – Dual Column Bench Top and Floor Standing Universal Testing Machine (5 kN – 50 kN)

The NG-EML Series C is a precision-engineered dual-column universal testing machine for tension, compression, and flexural testing of metals, composites, rubbers, and polymers. Available in both bench-top and floor-standing formats, with force capacities from 5 kN to 50 kN and Class 0.5 accuracy.

NG-EML Series D – Floor Standing Universal Testing Machine (50 kN – 1000 kN)

The NG-EML Series D – Floor Standing Universal Testing Machine (50 kN–1000 kN) is a dual-column system for tensile, compression, flexural, shear, and cyclic testing of high-strength metals, composites, polymers, and advanced materials. Available in single-space and dual-space configurations, it meets ASTM E8, ISO 6892-1, ISO 527, and GB/T 228 standards. With closed-loop control, 1200 Hz sampling, ultra-low speeds (0.00005 mm/min), and waveform generation, it is ideal for aerospace, automotive, construction, and research labs.