Metal Testing Equipment

Description

This inverted metallurgical trincoular microscope is ideal for both industrial or educational metallurgy applications. The trinocular head allows for the addition of any c-mount microscope camera. The microscope comes standard with infinity plan achromat LWD 10x, 20x, 50x, and 80x objectives and includes a pair of 10x eyepieces an a separate eyepiece with reticle installed.

Trinocular Metallurgical Microscope Technical Specifications

| Model | G-800E |

| Head | Trinocular w/ 1x C-Mount |

| Eyepieces | 10x 20mm FOV (Pair) 10x w/ Reticle |

| Nosepiece | Quintuple |

| Objectives | Infinity Plan Achromat Long Working Distance 10x, 20x, 50x, 80x |

| Polarizing | Simple Polarizer & Analyzer |

| Focusing | Coarse & Fine Focus |

| Accessories | Blue Filter, Yellow Filter, Green Filter, Dust Cover, Power Cord, Manual |

| Warranty | 3 Year Mechanical & 1 Year Electrical |

FAQs

The G-800E is a metallurgical microscope designed for examining the microstructure of metals, alloys, and other industrial materials. It features a trinocular head, allowing operators to observe samples directly while also connecting a camera for imaging or live projection.

The system is widely used in industrial applications such as quality control, failure analysis, and process verification, where accurate assessment of grain size, inclusions, and surface treatments is required. It is also a reliable tool in educational labs, where students and researchers learn metallography and practice structural analysis techniques.

Click here to learn more about the product or here to receive a personalized quote.

The G-800E is an inverted metallurgical microscope, meaning the objectives are positioned beneath the stage while the sample rests face down. This setup makes it easier to examine large or mounted specimens without additional preparation. The microscope uses reflected light illumination, where light is directed onto the polished surface of the sample and the reflected image is captured through the optics.

The trinocular system allows simultaneous viewing through eyepieces and connection of a camera for optical analysis and documentation. This principle makes the G-800E practical for both direct observation and digital recording of metallographic structures.

Click here to learn more about the product or here to receive a personalized quote.

The G-800E is designed for metals and alloys, making it suitable for metallographic studies such as grain size, phase distribution, and heat-treatment effects. It is also used for polished sections of industrial materials, coatings, and layered structures where microstructure evaluation is required. Typical applications include steels, aluminum, copper, and other alloys, as well as composite or treated surfaces. Its optical system is optimized for examining opaque samples that rely on reflected light rather than transmitted light.

Click here to learn more about the product or here to receive a personalized quote.

The G-800E supports brightfield observation, which is the standard method for routine metallography, and it also includes polarization capability for highlighting grain boundaries, inclusions, and different phases. The microscope uses reflected light illumination, making it suitable for opaque materials such as metals and alloys.

Click here to learn more about the product or here to receive a personalized quote.

The G-800E is supplied with infinity plan achromat long working distance objectives in 10x, 20x, 50x, and 80x. Combined with the 10x eyepieces, this gives a practical magnification range from 100x up to 800x. The long working distance design allows comfortable observation of mounted or polished samples without risk of damaging either the specimen or the optics. This range covers both general surface inspection and detailed microstructural analysis.

Click here to learn more about the product or here to receive a personalized quote.

The G-800E is an inverted metallurgical microscope, which means samples are placed face down on the stage. This design is more convenient for examining large, polished, or mounted specimens since they do not need to be cut down to fit under an upright frame. Inverted models like the G-800E also provide easier handling of heavy or irregular samples.

Click here to learn more about the product or here to receive a personalized quote.

The G-800E is commonly applied in metallurgy and material testing, where it is used to study grain size, inclusions, and heat-treatment effects. Industrial R&D labs rely on it for developing new alloys and coatings. It is also used in academic laboratories for training students in metallography and related sciences. These fields benefit from the microscope’s balance of durability, precision, and adaptability to different sample types.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the G-800E is well-suited for QC applications in industrial metallurgy. It is used to examine polished samples for grain structure, inclusions, coatings, and defects that affect product performance. The microscope supports routine checks, failure analysis, and microstructure evaluation, giving manufacturers reliable data for material certification and process control.

Click here to learn more about the product or here to receive a personalized quote.

The G-800E is designed with practicality in mind. Its compact frame fits easily into standard lab benches without taking up unnecessary space. Controls for focus, illumination, and stage movement are arranged for comfortable use, reducing operator fatigue during long sessions. The ergonomic layout makes routine metallographic work straightforward, supporting smooth workflow in both industrial and educational laboratories.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the G-800E is often used as a teaching tool in universities and technical institutes. Its trinocular design allows connection of cameras and projectors, which is helpful for classroom demonstrations. The simple controls, stable focusing, and durable mechanics make it suitable for student training in metallurgy and material science. It provides both hands-on practice and clear visual presentations for group learning.

Click here to learn more about the product or here to receive a personalized quote.

The G-800E is supplied with full after-sales support. Customers have access to stocked spare parts, certified consumables, and technical assistance for installation, operation, and maintenance. Lifetime product support is available, meaning service, updates, and help remain accessible long after the initial purchase. This structure makes the microscope a secure investment for labs that rely on stable long-term performance.

Click here to learn more about the product or here to receive a personalized quote.

The G-800E works with a full range of metallography consumables, including certified calibration slides, filters, and optical accessories. These items are available with NIST certification, confirming their accuracy and traceability. Replacement parts and consumables are stocked to keep the microscope in service without long delays, which is important for both production labs and research facilities.

Click here to learn more about the product or here to receive a personalized quote.

The G-800E is made for heavy, repeated use in both industrial and teaching labs. Its metal frame and precise mechanics give stability during long sessions, while quality optics keep performance consistent over time. The microscope is built to handle daily operation without losing accuracy.

Click here to learn more about the product or here to receive a personalized quote.

The G-800E is supplied with a trinocular head fitted with a 1x C-Mount. This makes it ready for connection to a wide range of microscope cameras used for digital imaging. Laboratories can capture both still images and video, store results for documentation, or project live images for teaching and presentations. The design allows camera use alongside direct viewing through the eyepieces, so imaging does not interrupt routine work.

Click here to learn more about the product or here to receive a personalized quote.

The G-800E comes with a pair of 10x eyepieces offering a 20 mm field of view, providing a wide and clear image for routine metallographic observation. In addition, a dedicated 10x eyepiece with a reticle is included for measurement tasks, making it possible to take direct size or position readings during analysis.

Click here to learn more about the product or here to receive a personalized quote.

The G-800E is equipped with a quintuple nosepiece, which means it can hold five objectives simultaneously. In its standard configuration, it comes with long working distance infinity plan achromat objectives at 10x, 20x, 50x, and 80x. The fifth slot can be fitted with an additional lens if required.

This arrangement lets operators move quickly between magnifications without interrupting work, which is especially valuable in metallography where you start with a general overview and then zoom into microstructural details. The ability to mount five objectives at once gives the microscope flexibility for both routine quality control and advanced research tasks.

Click here to learn more about the product or here to receive a personalized quote.

The G-800E features a coarse and fine focusing system, allowing users to make quick adjustments for general positioning and then refine the image with precise control. This dual mechanism provides both speed and accuracy, which is essential when working at higher magnifications.

The focusing system is built for stability and ergonomic handling, making sure that once the sample is in focus, it remains steady without drift.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the G-800E is equipped with a simple polarizer and analyzer, which allow users to perform polarizing observations. This feature is particularly valuable in metallography, where polarization helps highlight grain boundaries, phases, and inclusions that may not be visible under standard brightfield conditions.

By improving contrast and material differentiation, polarizing observation makes it easier to identify microstructural details and assess the quality of metals and alloys. This capability supports both routine laboratory analysis and advanced research where precise structural information is required.

Click here to learn more about the product or here to receive a personalized quote.

The G-800E comes equipped with a full set of accessories to support immediate use in laboratory or classroom settings. The package includes blue, yellow, and green filters to enhance image contrast during different types of metallographic observations. A dust cover is supplied to protect the optics and body when the microscope is not in use.

Practical items such as a power cord and user manual are also included, giving operators everything needed for setup and operation. With these accessories, the microscope is ready for routine metallography work right out of the box, without requiring additional purchases.

Click here to learn more about the product or here to receive a personalized quote.

The G-800E microscope is supplied with a 3-year warranty for mechanical components and a 1-year warranty for electrical parts. This structure gives users confidence in both the durability of the optical and structural design and the reliability of the electronic systems.

In addition to warranty coverage, product support continues after purchase. Spare parts, consumables, and technical assistance remain available, ensuring that laboratories and institutions can keep the microscope in service without long interruptions. The warranty and support package is designed to protect investment and provide long-term usability in demanding industrial and educational environments.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

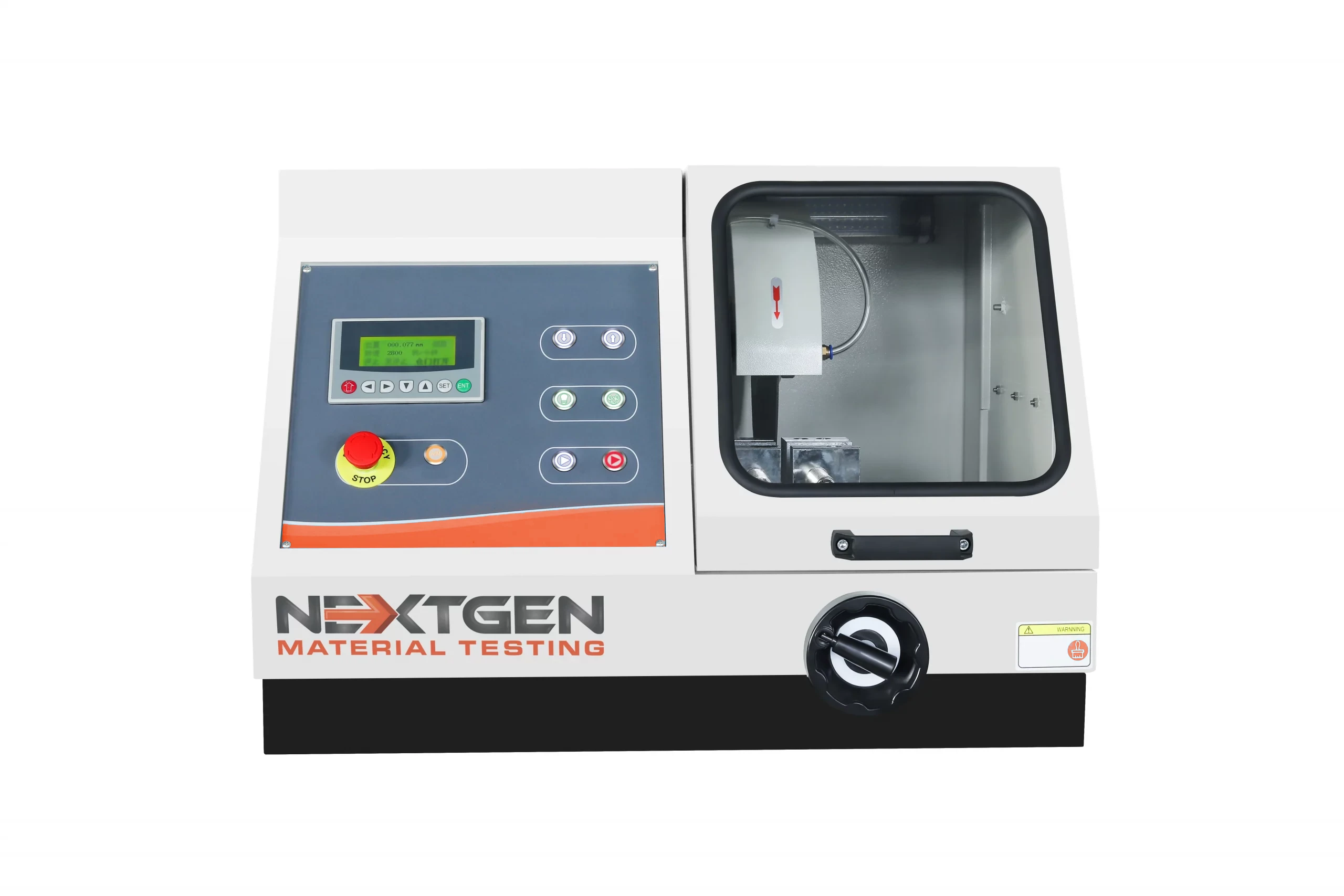

GenCut GL100M – Precision Manual Metallographic Sample Cutting Machine with Simple User-Friendly Operation and Large Cutting Capacity Φ100mm

Introducing the GenCut GL100M Manual Cutting Machine, expertly designed for precision metal sample cutting.

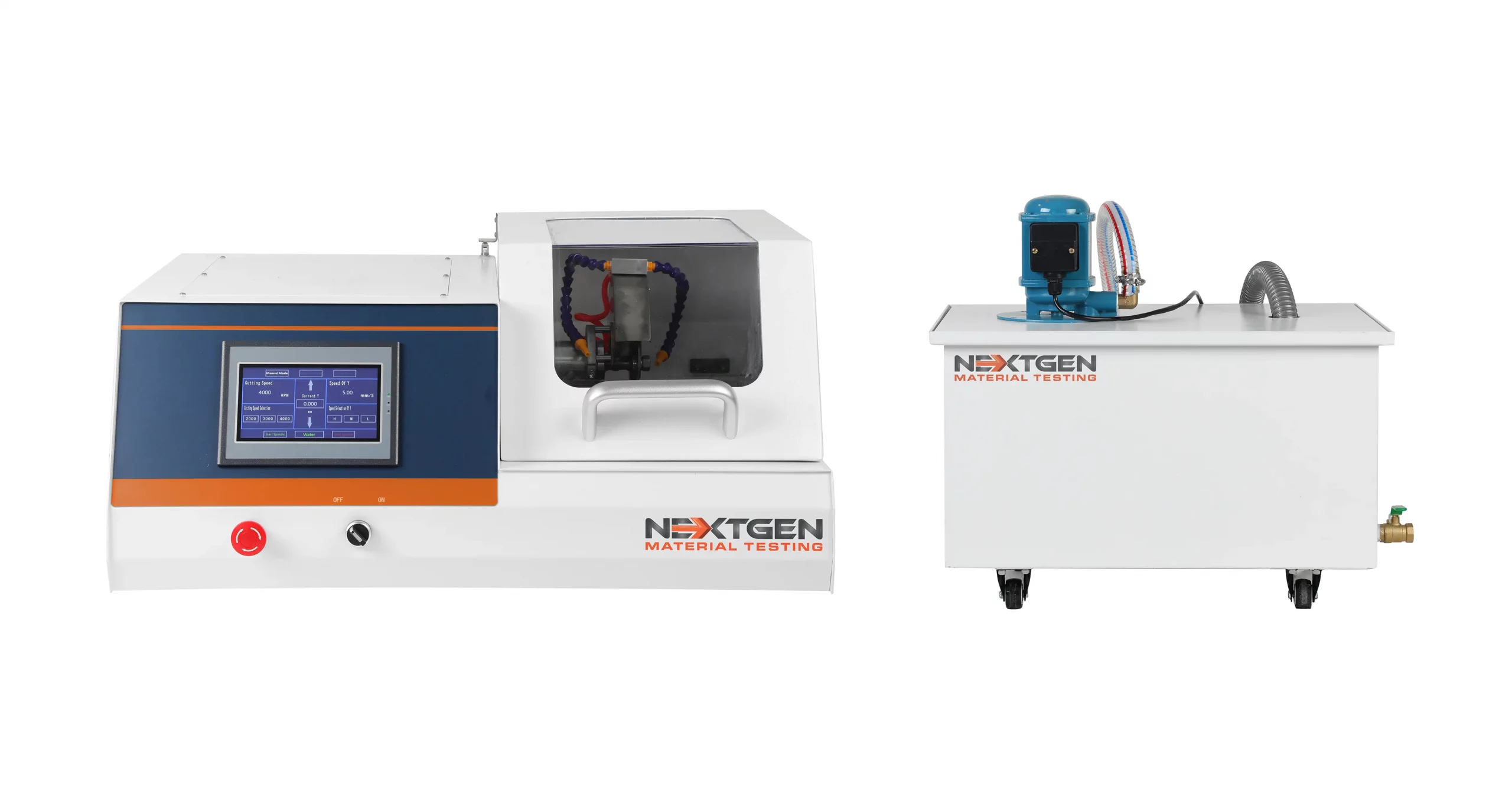

GenCut GL350 – Precision Metallographic Sample Cutting Machine with Simple User-Friendly Operation and Large Cutting Capacity Φ100mm

The GenCut GL350 is a cutting-edge high precision cutting machine equipped with advanced features and capabilities

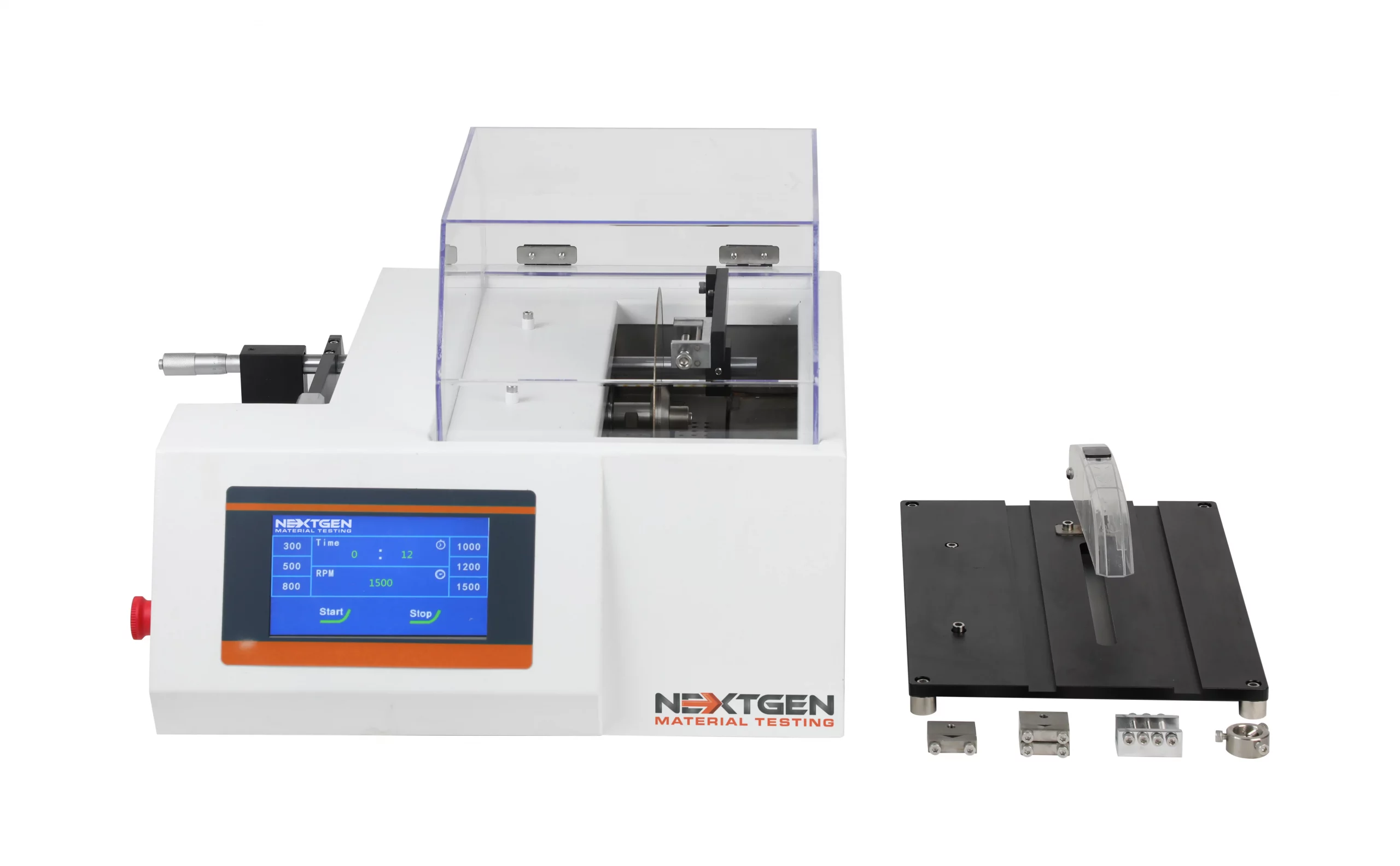

GenCut GL80A – Precision Metallographic Sample Cutting Machine with Simple User-Friendly Operation and Large Cutting Capacity Φ80mm

Introducing the GenCut GL80A, a highly precise cutting machine offering both automatic and manual work modes.

GenCut GL 170XY – Multi Function Abrasive Cut Off Saw with Touch Screen User Friendly Interface and Large Cutting Capacity – Φ170mm

The GenCut GL 170XY has a large 170mm diameter maximum cutting capacity equipped with a fully automated XY table.

GenCut GL 120XY – Multi Function Abrasive Cut Off Saw with Touch Screen User Friendly Interface and Large Cutting Capacity Φ120mm

The GenCut GL 120XY has a large 120mm diameter maximum cutting capacity equipped with a fully automated XY table.

GenCut GL200E – High Speed Automatic Precision Metallographic Cutter with User-Friendly Touch Screen Interface with max. cutting diameter of 60mm

GenCut GL 200E precision cutting machine includes a touch screen and PLC control, with stable performance and real-time display parameters.

GenCut GL100E – Low Speed Precision Metallographic Automatic Cutter with User-Friendly Touch Screen Interface with max. cutting diameter of 25mm

GenCut GL100E low speed series metallographic precision cutter has variable speed control from 50-1000 rpm.

GenGrind N Series 8” 200S / 10" 250S / 12" 300 S - Advanced Metallographic Grinder & Polisher - Variable Speed 50-1000rpm –Touch Screen Controlled

Introducing the GenGrind N Series metallographic grinders and polishers, offered in sizes 8", 10", or 12" diameter.

GenGrind SA-I 250S 10" Single Wheel Semi Automatic Grinder & Polisher - Variable Speed 100-1000rpm – Individual Force Control - Touch Screen Controlled with Automatic Specimen Mover Power Head – (various wheel sizes available)

Discover the single wheel semi automatic GenGrind 10" SA-I 250S, your ultimate answer to grinding and polishing needs.

GenGrind SA-C 250S 10" Single Wheel Semi Automatic Grinder & Polisher - Variable Speed 100-1000rpm – Central Force Control - Touch Screen Controlled with Automatic Specimen Mover Power Head – (various wheel sizes available)

Introducing the GenGrind SA-C 250S – your ultimate single wheel semi automatic grinding and polishing solution.

GenGrind FA-IC 250D 10" Dual Wheel Fully Automatic Grinder & Polisher - Variable Speed 100-1400rpm – Both Individual and Central Force Control - Touch Screen Controlled with Automatic Specimen Mover Power Head – (various wheel sizes available)

Introducing the GenGrind FA-IC 250D Dual Wheel Polisher and Grinder, a fully automatic metallographic grinding and polishing machine

GenGrind FA-IC 250S 10" Single Wheel Fully Automatic Grinder & Polisher - Variable Speed 100-1400rpm – Both Individual and Central Force Control - Touch Screen Controlled with Automatic Specimen Mover Power Head – (various wheel sizes available)

GenGrind FA-IC 250S Single Wheel Polisher and Grinder, an advanced and fully automatic metallographic grinding and polishing machine

GenPress MFA Dual HYD Fully Automatic Dual Hydraulic Mounting Press – Hydraulic Controlled – 1-2” (25-50mm) Mold Assembly (other sizes available upon request)

GenPress MFA DUAL HYD Metallographic Sample Preparation is an advanced automatic mounting press for compression mounting of material samples

GenPress MFA MOT - Fully Automatic Motorized Mounting Press – Motor Controlled – 1-2” (25-50mm) Mold Assembly (other sizes available upon request)

GenPress MFA MOT mounting press system frees the operator to perform other tasks in the laboratory during the cycle allowing better efficiency

GenPress MFA HYD - Fully Automatic Hydraulic Mounting Press – Hydraulic Controlled – 1-2” (25-50mm) Mold Assembly

GenPress Mounting Press for Metallographic Sample Preparation is an advanced automatic mounting press for compression mounting of material sample

GenVac MP3 Series - Epoxy Mounting Vacuum Impregnation System for Metallographic Sample Preparation

Experience our enhanced version of the GenVac MP Series. Our user-friendly touch screen interface along with automatic unit conversion and memory modes holds the title of one of the most advanced systems in the marketplace.

GenGrind Belt BF - Floor Standing Heavy Duty Dual Stage Belt Grinder for Metallographic Sample Preparation

The GenGrind Belt BF Series is a heavy duty dual stage, wet or dry belt grinder offering a robust, floor standing solution for high volume manual belt grinding applications. GenGrind Belt BF - Heavy Duty Dual Stage Belt Grinder for metallographic sample preparation is designed for high material removal of various sample shapes and configurations.

GenGrind Belt BT - Dual Stage Tabletop Belt Grinder for Metallographic Sample Preparation

The GenGrindBelt BT series is a dual stage, wet or dry table top belt grinder offering the most economical solution for manual grinding applications. The GenGrind BT - Dual Stage Belt Grinder for Metallographic Sample Preparation is designed for high material removal of various sample shapes and configurations. The BT - Belt Grinder system is a table top belt grinder suitable for laboratories designed for high material removal.

GenGrind FA-IC Dual Wheel Fully Automatic

Introducing the GenGrind FA-IC, a state-of-the-art single-chip microcomputer controlled grinding and polishing machine.

GenVac MP Series - Epoxy Mounting Vacuum Impregnation System for Metallographic Sample Preparation

GenVac MP2 - Vacuum Impregnator is designed for precision sample impregnation for porous materials. Common applications for vacuum impregnation systems include rocks and minerals, ceramics, electronic circuit boards and other composite materials.

Hardness Test Blocks, Indenters and Hardness Testing Accessories

Certified Test Blocks are a requirement as a reference material for any type of hardness testing. At NextGen, we understand the importance of a Test Block to ensure the accuracy of your hardness testing procedures.

Metallography Consumables

Learn about the full scope of NextGen's cutting, polishing & grinding, mounting and etching metallography consumables. Our consumables are compatible with virtually all global brands, offering a rare combination of exceptional quality, longevity and affordability.