Metal Testing Equipment

Standards

ASTM E1820, ASTM E2298, ASTM E23, ASTM E74 (Class AA), EN10045, ISO 148

Description

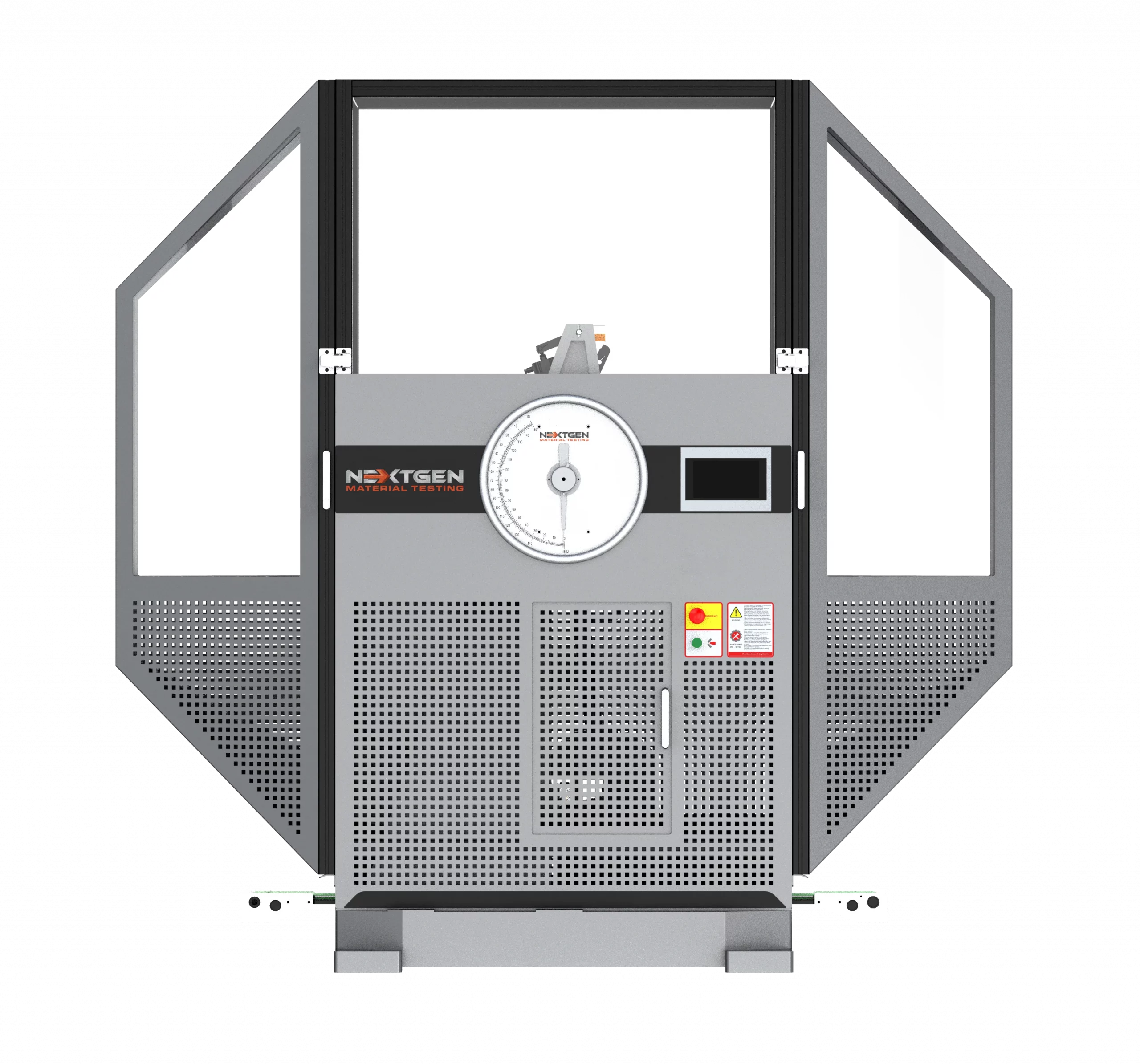

The Class D Single-Column Charpy Impact Tester is a high-precision pendulum impact testing machine developed to perform Charpy impact testing on metals in strict compliance with international standards, including ASTM E23, ISO 148, and EN100 45. This floor-standing system is available in two primary models with maximum impact energy capacities of 450 J (332 ft-lbs) and 750 J (553 ft-lbs), covering a wide range of test requirements.

Each unit supports interchangeable pendulums rated at 150 J, 300 J, 450 J, and 600 J, offering flexibility for various energy levels. The 450 J model is commonly used in educational institutions, research laboratories, and government testing centers. The 750 J model is suited for demanding industrial applications, including aerospace, steel production, and heat treatment operations.

The system includes a fully enclosed safety frame and offers optional automation features, such as a PC-controlled specimen feeding mechanism and an integrated cooling system for testing at temperatures as low as -180°C. As a reliable and adaptable Charpy impact tester, the Class D system is ideal for laboratories and production facilities seeking to meet rigorous testing standards while enhancing efficiency and operator safety.

These systems can be configured with an automatic cooling and feeder solution that supports a streamlined, operator-friendly workflow. In simple terms, specimens can be brought down to the required test temperature using an integrated cooling solution, then automatically fed into the tester for consistent positioning and testing. This reduces manual handling, improves repeatability, and helps maintain temperature control from cooling through impact testing.

For customers looking to take automation even further, a fully automated robotic solution is also available. This option can be designed to handle end-to-end specimen handling, including loading, temperature conditioning, feeding, testing, and sorting, with minimal operator involvement. If you would like to explore a fully automated configuration, please let us know your target sample volume, specimen dimensions, and temperature requirements, and we will propose the most practical automation layout for your application.

Metals Impact Tester – Class D – Single-Column Charpy Impact Tester (Up to 750 J)

The Class D system supports impact energy levels of 150 J (111 ft-lbs), 300 J (221 ft-lbs), 450 J (332 ft-lbs), 600 J (442 ft-lbs), and 750 J (553 ft-lbs). It features both analog and digital displays for precise readings and includes an optional PC connection for advanced data processing through dedicated software.

This high-energy solution is built for long-term use, with the flexibility to incorporate automation or low-temperature testing enhancements as needed.

Learn more in our blog post on how pendulum impact testers support accurate and compliant material testing.

Single-Column Charpy Impact Tester Main Features

The Class D Single-Column Charpy Impact Tester is equipped with a comprehensive set of standard and optional features

Key features include:

- Heavy cast iron base engineered to eliminate vibrations during testing.

- Rigid single-column frame (front and rear) for enhanced structural stability in high-energy tests.

- Standard PLC-based touchscreen control system for streamlined operation.

- Digital and analog display options, with optional PC connectivity for software-based data analysis.

- Motorized pendulum lifting system with automatic return after impact.

- The electromagnetic pendulum locking mechanism ensures test security and repeatability.

- Fully enclosed impact chamber for operator protection during testing.

- Precisely calculated pendulum height and mass to ensure optimal test accuracy.

- Tool-free striker replacement system to comply with ISO and ASTM specifications.

- High-precision bearings to reduce friction and improve measurement consistency.

- Aerodynamically rounded pendulum edges to minimize wind resistance and external interference.

- Optional computer control with semi-automatic operation (manual specimen change only).

- When combined with software control, an optional automated specimen feeding system enables complete automation.

- Optional environmental cooling system for testing at temperatures as low as -180°C.

High-Precision Pendulum Testing Machine Charpy Technical Specifications

| NG-Impact Class D | ||

|---|---|---|

| Model | NG452 Class D | NG752 Class D |

| Maximum Impact Energy | 450 J | 750 J (553 ft/lbs) |

| Optional Pendulum | 150 J (111 ft/lbs), 300 J (221 ft/lbs) | 300 J (221 ft/lbs), 450 J (332 ft/lbs), 600 J (442 ft/lbs) |

| Angle Resolution | 0.025° | |

| Angle of Striking | 150° ±1° | |

| Velocity of Striker | 5.24 m/s | |

| Support Span | 40 mm | |

| Radius of Curvature of Supports | 1 mm | |

| Angle of Slope of Supports | 0° | |

| Angle of Taper of Supports | 11° ± 1° | |

| Radius of Striking Edge | 2 mm | |

| Angle of Striking Tip | 30° | |

| Width of Striking Edge | 16 mm | |

| Specimen Dimensions | 55 × 10 × 10 mm, 55 × 10 × 7.5 mm, 55 × 10 × 5 mm | |

| Overall Dimensions | 84.6 × 33.5 × 82.7 in / 215 × 85 × 210 cm | |

| Weight | 1875 lbs / 900 kg | |

| Power Consumption | 1.5 kW | |

Model-Specific Configurations and Included Components

| Name | Description | Model | |||||

|---|---|---|---|---|---|---|---|

| Machine Frame | NG452/752 Class D | NG452 D-2 | NG752 D-2 | NG452 D-3 | NG752 D-3 | NG452 D-4 | NG752 D-4 |

| Framework | Frame | X | X | X | |||

| Pendulum Lock/Release System | X | X | X | ||||

| Driving System | X | X | X | ||||

| Angle Measurement | X | X | X | ||||

| PLC | X | X | X | ||||

| Dial Gauge Display | X | X | X | ||||

| Touch Screen | X | X | X | ||||

| Motor | X | X | X | ||||

| Software | X | X | |||||

| Accessories | Span Block Specimen Centering Block Centering Tongs Standard Tools Anchor Bolts Wedge Block | X | X | X | |||

| PC Connection | RS232 | X | X | ||||

| Instrumented Impact System | Force transducer in a pendulum for quick plotting of the force-time graph Access to more testing parameters on the GenTest software | X | |||||

High-Precision Pendulum Testing Machine – Specimen Collection and Filtering Device

A motorized collection device is available to automate the removal of broken specimens following impact testing. This system prevents potential obstructions that could interfere with the striker mechanism by removing the need for manual cleaning. The unit also includes an advanced filtering function that automatically differentiates between qualified and unqualified specimens, directing them to separate collection bins for efficient post-test sorting.FAQs

Yes, the Class D Single-Column Charpy Impact Tester is fully compliant with the ISO 148 standard. It is designed in accordance with the technical specifications required for standardized Charpy impact testing of metallic materials.

ISO 148 outlines procedures for measuring a material’s energy absorption during impact, helping assess its resistance to sudden fracture. The standard specifies critical testing parameters such as specimen size, striker geometry, support span, and energy calculation methods.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Class D Single-Column Charpy Impact Tester is fully compliant with the EN 10045 standard. It is engineered to meet the European testing requirements for conducting Charpy impact tests on metallic materials.

EN 10045 specifies the procedures and criteria for testing toughness and fracture behaviour using a notched specimen impacted by a pendulum hammer. The Class D tester aligns with all critical parameters, including support spacing, striker shape, impact angle, and specimen dimensions.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Class D Single-Column Charpy Impact Tester is designed in full accordance with the ASTM E23 standard. It adheres to all specified requirements for conducting Charpy impact testing on metallic specimens.

ASTM E23 sets strict parameters for equipment, specimen dimensions, striker configuration, and test procedures to evaluate the energy absorbed by a material during fracture. The Class D tester meets these conditions precisely, including impact velocity, striking angle, support span, and notch alignment.

Click here to learn more about the product or here to receive a personalized quote.

The Class D Single-Column Charpy Impact Tester is equipped with a range of interchangeable pendulum energy options, including 150 J, 300 J, 450 J, 600 J, and 750 J. These configurations enable accurate Charpy testing across a wide spectrum of materials and testing standards.

Each pendulum corresponds to a specific impact energy level, allowing operators to match the setup with their material’s expected toughness and the applicable standard requirements. Lower energy pendulums (150 J, 300 J) are ideal for testing less rigid or smaller specimens, while higher capacities (600 J, 750 J) accommodate high-strength metals and components used in industrial and structural applications.

Click here to learn more about the product or here to receive a personalized quote.

The 450 J model of the Class D Single-Column Charpy Impact Tester is frequently used in academic institutions, certification bodies, and research laboratories for standardized Charpy impact testing.

In universities and technical colleges, this model supports instruction in materials science and mechanical engineering courses, allowing students to explore fracture mechanics and understand material behaviour under impact loading.

Government testing centers and regulatory agencies use the 450 J system to validate material toughness for public works and safety-related applications. Its compliance with ASTM and ISO standards ensures trustworthy testing for certification purposes.

Click here to learn more about the product or here to receive a personalized quote.

The 750 J model of the Class D Single-Column Charpy Impact Tester is primarily used in demanding industrial settings where high-energy impact testing is essential. Common application areas include aerospace manufacturing, steel production plants, and heat treatment facilities.

In aerospace manufacturing, the system supports rigorous testing of structural metals to verify fracture resistance and material performance under extreme impact loads. This ensures compliance with critical safety and reliability standards.

Steel producers rely on the 750 J model to evaluate the toughness and energy absorption characteristics of different steel grades used in construction, transportation, and infrastructure components.

In heat treatment operations, the tester helps assess the mechanical integrity of thermally processed materials, confirming that they retain the necessary ductility and strength after treatment.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Class D Single-Column Charpy Impact Tester is built to minimize vibration effects during impact testing. It features a robust cast iron base that delivers high structural stability and effectively dampens vibrations that could influence the accuracy of results.

This solid base construction helps absorb mechanical shock and external vibrations, ensuring a stable platform throughout the testing process. Such design considerations are critical for achieving consistent, high-precision measurements.

By reducing vibration-related interferences, the Class D tester maintains test integrity, allowing for repeatable and dependable impact energy readings—particularly important when assessing material behaviour under high-energy conditions.

Click here to learn more about the product or here to receive a personalized quote.

The Class D Single-Column Charpy Impact Tester is a precision-engineered system equipped with a wide array of standard features to support reliable and efficient impact testing. Built with a fully enclosed frame, it ensures operator safety and consistent test conditions.

The system includes both analog and digital displays for accurate energy measurement. For users requiring data management capabilities, an optional PC connection is available to enable advanced analysis through dedicated software.

Key features include a rigid single-column design with a cast iron base for vibration control, a PLC touchscreen interface for streamlined operation, and a secure pendulum locking mechanism. A motorized pendulum lift with automatic return simplifies the testing cycle.

Click here to learn more about the product or here to receive a personalized quote.

The Class D Single-Column Charpy Impact Tester is built with a rigid, floor-mounted single-column frame designed to withstand high-impact forces up to 750 J. The system’s robust structural design incorporates a precision-machined base and reinforced column that minimize vibrations and deflection during testing.

This added rigidity ensures accurate energy transfer to the specimen and consistent striker motion, which are critical for reliable results in high-energy testing scenarios. The durable construction also improves repeatability and stability, even under intense operational loads, making the Class D model suitable for rigorous testing environments and compliance with ASTM and ISO standards.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Class D Single-Column Charpy Impact Tester features a straightforward and user-friendly design that allows for easy exchange of the striking knife. This enables quick adaptation between ISO and ASTM testing configurations.

The system is engineered for efficient maintenance and standard flexibility. The striking knife can be replaced with minimal effort, reducing downtime and ensuring continued compliance with international testing protocols.

Click here to learn more about the product or here to receive a personalized quote.

The Class D Single-Column Charpy Impact Tester is designed to minimize the effects of wind resistance during testing, supporting consistent and accurate impact energy measurements.

To reduce aerodynamic interference, the tester features a pendulum with a streamlined profile and rounded edges. This design decreases the surface area exposed to airflow, allowing the pendulum to move through the air with reduced drag.

While it is not possible to eliminate wind resistance entirely, the machine’s engineering significantly limits its impact. For optimal accuracy, it is still recommended to perform tests in a controlled environment with minimal ambient air movement.

Click here to learn more about the product or here to receive a personalized quote.

The Class D Single-Column Charpy Impact Tester is equipped with a high-performance PLC (Programmable Logic Controller) that is specifically configured to support accurate and reliable pendulum operation.

This controller uses advanced logic and control algorithms to manage key functions such as pendulum elevation, release, and return with high precision. It ensures that test parameters like striker velocity and striking angle remain consistent and within required tolerances.

The system features a user-friendly digital interface, allowing operators to monitor test progress in real time, adjust settings as needed, and access recorded data with clarity and ease.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Class D Single-Column Charpy Impact Tester supports semi-automatic operation when paired with computer and software control. In this configuration, the operator manually places each specimen, while the software handles the rest of the testing cycle.

The integrated software enables precise control of critical parameters such as pendulum lift, striking angle, and velocity. This results in consistent and repeatable test conditions, aligned with standardized impact testing procedures.

The computer interface provides a clear and intuitive environment for managing tests, viewing live data, and handling automated data logging and analysis. This helps reduce manual errors and improves overall workflow accuracy.

Click here to learn more about the product or here to receive a personalized quote.

Is an optional specimen feeding system available for the Class D Single-Column Charpy Impact Tester?

Yes, the Class D Single-Column Charpy Impact Tester can be configured with an optional specimen feeding system that automates the handling and positioning of specimens during testing.

This feature streamlines the testing process by reducing the need for manual loading, thereby improving efficiency and minimizing the potential for user error. It ensures consistent specimen alignment and repeatable impact conditions across a large number of tests.

When integrated with PC-based software control, the specimen feeding system enables fully automated operation—managing everything from specimen loading to test execution. This allows the operator to focus on oversight and data review rather than manual tasks.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Class D Single-Column Charpy Impact Tester can be equipped with an optional cooling system designed to facilitate low-temperature testing of specimens, with capabilities down to -180 °C.

This feature is particularly useful for evaluating material behavior under extreme cold conditions, which is critical in industries such as aerospace, automotive, and advanced materials research. The system ensures specimens are consistently maintained at the required temperature prior to impact.

The cooling unit delivers precise thermal control, supporting accurate and repeatable test results while complying with standards that require sub-zero specimen conditioning.

Click here to learn more about the product or here to receive a personalized quote.

The NG452 Class D Single-Column Charpy Impact Tester offers optional pendulum energy levels of 150 J, 300 J, 450 J, and 600 J. These configurations provide the flexibility needed to match testing conditions to a wide range of material properties.

The 150 J and 300 J options are best suited for evaluating materials with lower impact strength, offering accurate measurements under lighter loading conditions. For more robust materials or applications requiring higher energy absorption, the 450 J and 600 J pendulums deliver the force necessary to conduct reliable, high-energy impact testing.

This range of pendulum capacities makes the NG452 Class D model adaptable for everything from routine testing to advanced material research, allowing users to select the most appropriate configuration for precise and consistent test results.

Click here to learn more about the product or here to receive a personalized quote.

The NG752 Class D Single-Column Charpy Impact Tester supports optional pendulum energy configurations of 300 J, 450 J, and 600 J. These options allow users to tailor the system to meet specific testing requirements across a variety of materials and applications.

The 300 J pendulum is well-suited for evaluating materials with moderate impact resistance, offering precise and repeatable testing conditions. For more demanding scenarios, the 450 J and 600 J pendulums provide higher energy levels needed to assess the performance of structural metals and other high-strength materials.

This range of optional configurations increases the versatility of the NG752 Class D tester, enabling users to select the appropriate energy level for accurate fracture analysis and impact performance evaluation.

Click here to learn more about the product or here to receive a personalized quote.

The Class D Single-Column Charpy Impact Tester offers an angle resolution of 0.025°, enabling highly accurate measurement of the pendulum's movement during impact testing.

This fine level of resolution allows the system to detect even minimal variations in the angle of swing, ensuring that every detail of the impact event is precisely captured. Such precision is especially important for analyzing material fracture behavior and verifying the consistency of impact energy readings.

The 0.025° resolution supports advanced material evaluation, helping engineers and researchers identify subtle differences in performance across specimens and improve product design or quality control processes.

Click here to learn more about the product or here to receive a personalized quote.

The Class D Single-Column Charpy Impact Tester operates with a striker velocity of 5.24 m/s. This is the speed at which the pendulum impacts the specimen during testing and is a critical factor in determining the energy absorbed upon fracture.

Maintaining a constant velocity of 5.24 m/s ensures repeatable and standardized testing conditions in accordance with Charpy testing protocols. This consistent velocity is essential for obtaining accurate and reliable impact energy readings.

The selected striker speed supports compliance with international testing standards and helps assess a material’s resistance to sudden impact loads. It enables clear comparisons between different materials, making it useful for quality control, design validation, and research.

Click here to learn more about the product or here to receive a personalized quote.

The Class D Single-Column Charpy Impact Tester operates with a striker velocity of 5.24 m/s. This is the speed at which the pendulum impacts the specimen during testing and is a critical factor in determining the energy absorbed upon fracture.

Maintaining a constant velocity of 5.24 m/s ensures repeatable and standardized testing conditions in accordance with Charpy testing protocols. This consistent velocity is essential for obtaining accurate and reliable impact energy readings.

The selected striker speed supports compliance with international testing standards and helps assess a material’s resistance to sudden impact loads. It enables clear comparisons between different materials, making it useful for quality control, design validation, and research.

Click here to learn more about the product or here to receive a personalized quote.

The Class D Single-Column Charpy Impact Tester has a support span of 40 mm. This measurement refers to the fixed distance between the two supports where the specimen rests during testing.

A 40 mm span is the standardized value used in Charpy impact testing and ensures consistent placement and alignment of specimens across all tests. This uniform setup supports accurate energy absorption measurements and minimizes errors caused by misalignment or uneven loading.

The fixed support span is suitable for testing a range of specimen geometries, contributing to both testing flexibility and compliance with international standards.

Click here to learn more about the product or here to receive a personalized quote.

The Class D Single-Column Charpy Impact Tester is equipped with supports that have a curvature radius of 1 mm. This specific radius is designed to ensure accurate, uniform contact with the specimen during impact testing.

A 1 mm radius helps distribute the applied load evenly across the support surface, minimizing stress concentrations that could distort results. This is especially important when testing materials that are thin, brittle, or sensitive to uneven loading.

This curvature value aligns with standardized Charpy testing requirements and supports reliable energy absorption measurements across a variety of sample types.

Click here to learn more about the product or here to receive a personalized quote.

The Class D Single-Column Charpy Impact Tester is built with supports that have a slope angle of 0°. This flat configuration ensures the specimen sits evenly and securely during testing, helping to maintain consistency across all test conditions.

A 0° slope eliminates any tilt that could affect the alignment of the specimen, reducing the risk of measurement errors caused by uneven loading. This contributes to the repeatability and accuracy of test results, particularly in high-precision Charpy impact evaluations.

This design choice is essential for maintaining controlled conditions when analyzing material behaviour under dynamic loading. It ensures uniform energy transfer and reliable comparisons between different specimens.

Click here to learn more about the product or here to receive a personalized quote.

The Class D Single-Column Charpy Impact Tester is designed with support anvils that feature a taper angle of 11° ± 1°. This specific range ensures that the specimen is held securely and in precise alignment during impact testing.

The tapered design of the supports plays a vital role in maintaining consistent test conditions by minimizing the risk of misalignment or shifting during the test. The 11° taper provides optimal contact with the specimen and helps distribute the applied force uniformly across the support span.

Allowing for a tolerance of ±1° ensures that slight manufacturing or setup variations do not compromise testing accuracy or repeatability.

Click here to learn more about the product or here to receive a personalized quote.

The Class D Single-Column Charpy Impact Tester features a striking edge with a radius of 2 mm. This rounded edge is a critical design element that affects how impact energy is delivered to the notched specimen during testing.

A 2 mm radius provides a controlled contact point, concentrating force in a consistent area and enabling accurate measurement of absorbed energy. This geometry helps standardize stress distribution at the moment of impact, which is essential for generating repeatable and meaningful test data.

The selected radius aligns with established Charpy testing standards, ensuring comparability of results across different machines and testing conditions.

Click here to learn more about the product or here to receive a personalized quote.

The Class D Single-Column Charpy Impact Tester is equipped with a striking tip set at a 30° angle. This angle is precisely defined to deliver a standardized and consistent impact during Charpy testing procedures.

The 30° angle helps ensure optimal contact between the striking edge and the notched specimen, supporting accurate energy transfer and repeatable test outcomes. It reflects commonly accepted testing standards and is critical for maintaining measurement reliability.

This fixed-angle configuration contributes to uniform testing conditions across specimens and materials, enabling valid comparisons and dependable assessments of material toughness and fracture behavior.

Click here to learn more about the product or here to receive a personalized quote.

The Class D Single-Column Charpy Impact Tester features a striking edge with a thickness of 16 mm. This dimension refers to the width of the impact surface that contacts the specimen during testing.

A 16 mm striking edge is specifically engineered to deliver consistent force transfer and simulate real-world impact conditions in accordance with standardized testing procedures. Its thickness ensures the proper distribution of impact energy without compromising the integrity of the component.

This standardized thickness meets common Charpy testing specifications and supports accurate, repeatable evaluations of material toughness and fracture behavior. It allows for valid comparisons across different tests and materials.

The robust design of the striking edge also contributes to the system’s long-term performance and reliability in both routine and high-energy impact testing applications.

Click here to learn more about the product or here to receive a personalized quote.

The Class D Single-Column Charpy Impact Tester supports a range of standardized specimen dimensions: 55×10×10 mm, 55×10×7.5 mm, and 55×10×5 mm. This flexibility allows for precise testing across a variety of materials and sample thicknesses.

Each of these specimen sizes maintains a consistent length of 55 mm and width of 10 mm, while the thickness can vary depending on the specific testing requirements or standard being followed.

This range of dimensions enables users to conduct impact tests on materials with different cross-sections, making the system suitable for both basic and advanced research applications. It supports accurate evaluation of fracture characteristics and impact performance.

The ability to work with multiple specimen sizes enhances the Class D tester’s adaptability in testing metals, alloys, and other engineering materials under controlled and repeatable conditions.

Click here to learn more about the product or here to receive a personalized quote.

The Class D Single-Column Charpy Impact Tester has overall dimensions of approximately 84.6 × 33.5 × 82.7 inches (length × width × height), or 215 × 85 × 210 cm. These measurements reflect the system’s assembled footprint and the space needed for safe and efficient operation.

Despite its structural strength, the Class D tester features a compact layout that fits well within laboratory or industrial testing areas. Its size is optimized to support pendulum operation, impact force delivery, and specimen handling while remaining space-efficient.

The 84.6-inch length accommodates the full arc of the pendulum, the 33.5-inch width ensures stability, and the 82.7-inch height provides sufficient clearance for vertical movement.

This balanced footprint makes the Class D tester a practical choice for use in academic environments, research labs, and production facilities, where both performance and floor space efficiency are important.

Click here to learn more about the product or here to receive a personalized quote.

The Class D Single-Column Charpy Impact Tester weighs approximately 1984 lbs. (900 kg). This considerable mass reflects the machine’s robust construction and plays a key role in ensuring testing stability and measurement accuracy.

The heavy-duty frame reduces the transmission of vibrations during high-energy testing, helping to maintain consistent contact and alignment between the striker and the specimen. This results in more precise and repeatable impact energy measurements.

The 1984 lbs. (900 kg) weight also highlights the system’s durability under frequent or demanding usage, making it a dependable tool for laboratories, universities, government facilities, and industrial environments.

Its solid build contributes to long-term mechanical integrity and provides confidence in test results by preventing unwanted machine movement during operation.

Click here to learn more about the product or here to receive a personalized quote.

The Class D Single-Column Charpy Impact Tester has a power consumption rating of 1.5 kW. This figure indicates the typical electrical power required for the machine to perform impact testing efficiently and reliably.

This power level supports all essential components of the system, including the motorized pendulum lift, control electronics, touchscreen interface, and optional automation features. The 1.5 kW rating ensures that the machine can deliver the force and velocity necessary for accurate Charpy impact tests.

While actual power usage may vary slightly depending on system configuration and use conditions, the 1.5 kW specification provides a reliable reference for planning energy requirements in a laboratory or industrial setting.

This level of consumption reflects an effective balance between performance and efficiency, making the Class D tester well-suited for consistent, high-precision testing.

Click here to learn more about the product or here to receive a personalized quote.

The Class D Single-Column Charpy Impact Tester is equipped with high-precision ball bearings to support smooth and accurate pendulum movement during impact testing.

These bearings are engineered to reduce friction and allow precise rotation of critical moving parts such as the pendulum and striker. The design ensures consistent motion by using a set of small, hardened steel balls positioned between polished inner and outer rings.

This configuration enhances measurement accuracy by minimizing mechanical resistance and eliminating unnecessary variation caused by irregular motion. The result is a stable, repeatable swing path—critical for capturing reliable energy readings during Charpy testing.

The inclusion of precision bearings reflects the Class D tester’s focus on mechanical integrity and testing accuracy, supporting dependable results in research, quality control, and industrial applications.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Class D Single-Column Charpy Impact Tester includes a touchscreen display that can optionally be connected to a PC for advanced data analysis. This integration allows users to control the system through dedicated software, providing greater flexibility and improved data processing.

Through PC connectivity, users can perform deeper analysis, visualize impact curves, and generate detailed test reports. The software interface supports efficient parameter adjustments, real-time monitoring, and organized data storage—all from a centralized platform.

The combination of touchscreen control and PC integration offers a well-rounded solution for precise Charpy impact testing. This feature is particularly valuable in quality control, research, and testing laboratories where detailed material performance insights are essential.

Click here to learn more about the product or here to receive a personalized quote.

The Class D Single-Column Charpy Impact Tester is engineered with several user-oriented features that simplify operation and improve usability across various testing environments.

At the core of its design is an intuitive PLC touchscreen interface, allowing operators to quickly navigate through setup steps and perform tests with minimal training. Clear on-screen instructions and responsive controls make the testing process straightforward and efficient.

To reduce operator workload, the system can be optionally configured with automation features such as an automatic specimen feeding unit and a low-temperature cooling cycle. These additions help streamline repetitive tasks and improve overall workflow.

The integrated touchscreen enhances user interaction by enabling real-time monitoring of test data, easy adjustment of parameters, and quick access to built-in analysis tools.

Additionally, the Class D tester features a fully enclosed testing area with built-in safety interlocks to protect the user during operation. Its ergonomic design supports comfortable specimen loading and unloading, making it suitable for both routine and high-throughput testing.

Click here to learn more about the product or here to receive a personalized quote.

The Class D Single-Column Charpy Impact Tester comes with lifetime product support, ensuring long-term access to expert assistance for as long as the equipment is in use.

This comprehensive support includes help with machine installation, operation, calibration, and routine maintenance. Users can rely on technical specialists for guidance on aligning with relevant standards such as ASTM E23, ISO 148, and EN 10045, while keeping the system running at peak performance.

In addition to hands-on support, users may also receive software updates, manuals, and training materials to help them stay current with best practices and product improvements.

With lifetime product support, users benefit from continued reliability, peace of mind, and professional help when needed—whether for daily operation or advanced troubleshooting.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

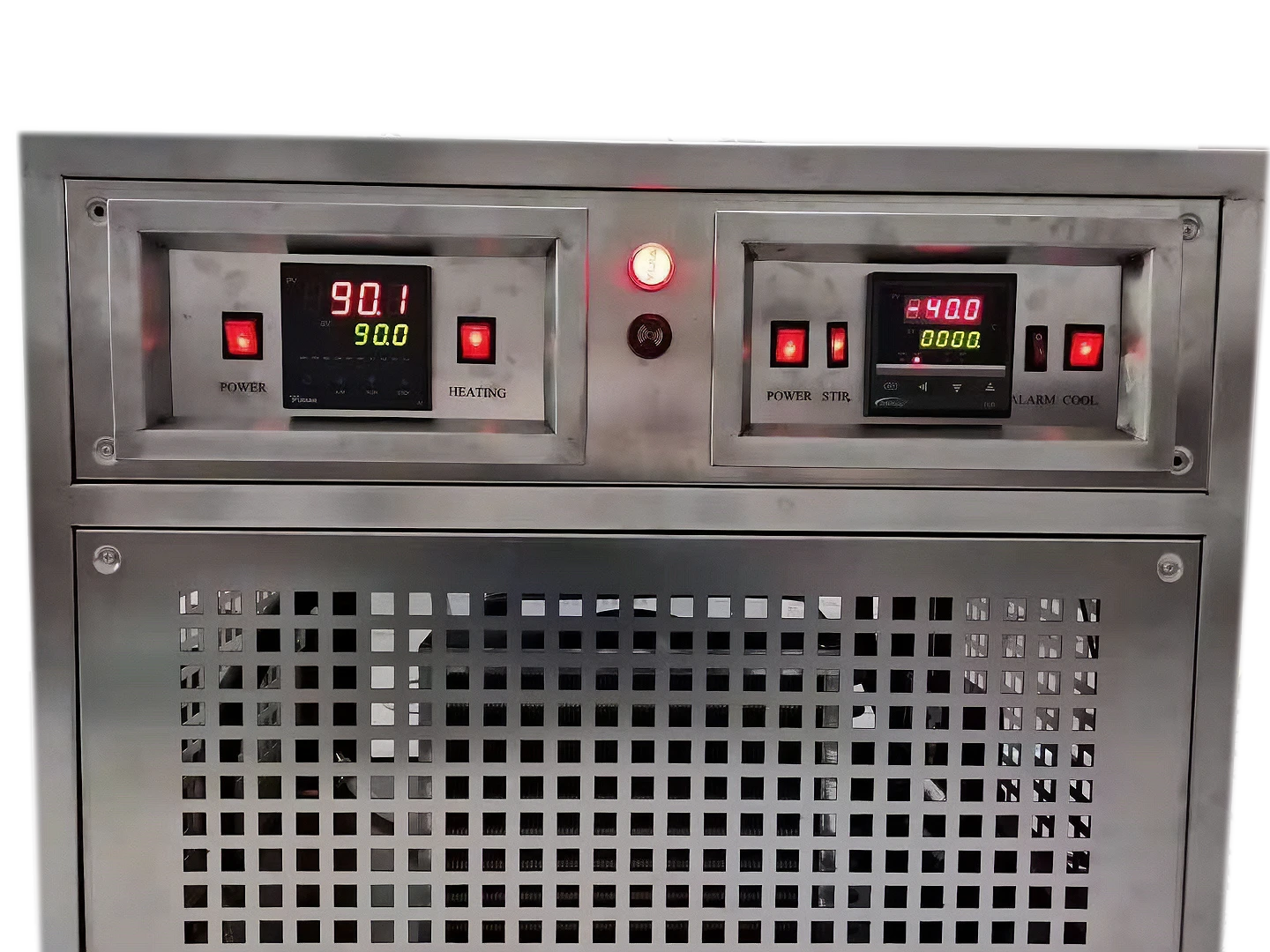

Impact Specimen Cooling Temperature Chamber – NG-ISCC Series

The NG-ISCC Low Temperature Chamber is built to cool and stabilize Charpy impact specimens before testing. It supports conditioning from +30°C down to -60°C, -80°C, -100°C, or -196°C depending on the model. NG-ISCC-60 and NG-ISCC-80 use compressor-based refrigeration, while NG-ISCC-100 and NG-ISCC-196 use liquid nitrogen cooling to achieve ultra-low setpoints. Temperature control accuracy is ≤ ±0.5°C with a 0.01°C instrument resolution, using ethanol or another non-freezing solution as the cooling medium. It is widely used in materials testing and quality control programs to evaluate low-temperature toughness of metals and alloys.

Class J - Charpy and Izod Automatic Impact Testing System - 1J - 50J

Class J is widely used for lzod and Charpy impact test on softer metals, plastics and rubber specimens. Equipped with tensile impact pendulum and fixtures, it can carry on tests on plastic film and sheet. The newly enhanced design offers the most cost-effective configuration to address Charpy test from 1J to 50J (0.7 - 37 ft/lbs), and lzod test from 1J to 22J (0.7 - 16 ft/lbs).

Class G Single-Column Charpy & Izod Impact Tester – High-Precision Pendulum Testing Machine

NextGen's Class G – Single Column Charpy and Izod Impact Testing system provides a high level of rigidity and specimen testing capacity. This Charpy and Izod Impact tester has a minimum capacity of 150 J (111 ft/lbs) and a maximum capacity of 750 J (553 ft/lbs). The system comes standard with a digital display with software upgrade function for data plotting. The Class G impact system can also include automatic specimen feeding, cooling and heating systems as optional upgrades.

Class H - Servo-Motor Dual Column Charpy Impact Tester - 300J, 450J, 600J or 750J

NextGen's Class H – Servo-Motor Dual Column Charpy Impact Testing system offers of an exceptional combination of versatility and robust build. This impact system provides our most durable options designed with a dual column configuration. The system offers the ultimate versatility of testing 300J (212 ft/lbs), 450J (332 ft/lbs), 600J (442 ft/lbs) and a maximum of 750J (553 ft/lbs) capacities based on both Charpy and Izod test methods. The unit comes standard equipped with a servo motor and is designed to test at any preset angle. The unit comes standard with all the functions of our Class G tester as well as enhanced functionality upgrade of a force transducer inside the strikerwhich enables the determination of characteristic force, energy and displacement parameters such as pre-maximum force energy (Wm), the post maximum force energy, the general yield force (Fgy), the force at brittle fracture initiation (Fbf) and the arrest force (Fa).

Triple Specimen Chamber Motorized Charpy Notch Making Machine

The GenNotch 4000UPG Series is a motorized Charpy & Izod Notch Making Machine with a triple specimen chamber.

Specimen Notching/Broaching Machine

NextGen offers an economical solution for Specimen notching and broaching for Charpy and Izod specimens. This certified system complies with ASTM ISO148, EN10045, ASTM E23, DIN 50115 standards. This automated, motorized solution is capable of preparing two specimens at any one given time up to 46 HRC. A variety of broaches are available for different geometries of notches.

Impact Specimen Cooling and Heating Temperature Chamber – GenChamber

NextGen offers a full range of impact specimen cooling and heating chamber designed to meet virtually all Charpy, Izod and Tensile Impact Testing requirements. NextGen's temperature chambers are a combination of user-friendliness, compact and robust build, offering the ultimate versatility of cooling and heating requirements.

Charpy/Izod Notch Verification Projector System NG-NPS-CIS

Enhance your material testing accuracy with our advanced Charpy/Izod Notch Verification Projector System NG-NPS-CIS.

DWT-1800 Computer Controlled Drop Weight Impact Testing Machine

DWT-1800 Impact Testing Machine is specifically designed for determining the non-plastic transformation temperature of ferritic steel.