Metal Testing Equipment

Standards

ISO 148, EN10045, ASTM E23, ASTM E1820, ASTM E2298, ASTM E74 (Class AA)

Description

The Class H Metals Impact Tester is a dual column impact testing system designed for Charpy Impact testing according to ASTM E23, ASTM E1820, ASTM E2298, ISO 148 and EN10045 industry standards. Class H is designed for high volume and especially hard materials. This unit has the highest accuracy and can be equipped with a force transducer for precise data sampling and complete measurement system. The Class H has a peak capacity of 750J (553 ft/lbs) with optional pendulums for 300J (221 ft/lbs), 450J (332 ft/lbs), 600J (442 ft/lbs) and 750J (553 ft/lbs). Class Hcomes standard as a fully enclosed system and allows for impact testing at any pre-set angle.

Metals Impact Tester - Class H 750J - Dual Column Charpy Impact Tester

Impact Energy

300J (212 ft/lbs), 450J (332 ft/lbs), 600J (442 ft/lbs) or 750J (553 ft/lbs)

This system comes standard with an analog and digital readout for higher accuracy along with the option to add the ability to connectthe system to a computer for use with our analysis software. Class H-4 is an instrumented type meaning there is a force transducer inside the strikerwhich enables the determination of characteristic force, energy and displacement parameters such as pre-maximum force energy (Wm), the post maximum force energy, the general yield force (Fgy), the force at brittle fracture initiation (Fbf) and the arrest force (Fa). Lear more about Pendulum Impact Testers and Testing.

Main Features

- The heavy cast iron base is mechanically designed to avoid any vibrations having an effect on impact testing results.

- Dual column impact frame

- Standard touch screen display and optional connectivity to a PC for software analysis

- Motor-driven raising of the hammer with auto-return after completion of a test

- Electromagnet locks the pendulum securely

- Fully enclosed testing area for the highest safety while undergoing impact testing

- The pendulum height and weight are precisely designed to ensure high accuracy

- Simple and easy design to exchange the striking knife to meet ISO or ASTM standards

- Designed with a high precision bearing for the most accurate impact results

- Quality PLC controller for precision pendulum testing

- Optional computer with software control is available for a semi-automatic operation. The operator must only change the specimens while the rest is controlled by the PC.

- Optional instrumented version with force transducer within the pendulum for detailed software analysis - enables the user to determine the highest amount of data on their specimens

Technical Specifications

| NG-Impact Class H | |

|---|---|

| Model | NG752 Class H and Class G |

| Maximum Impact Energy | 750J (553 ft/lbs) |

| Optional Pendulum | 300J (221 ft/lbs), 450J (332 ft/lbs), 600J (442 ft/lbs) and 750J (553 ft/lbs) |

| Angle Resolution | 0.025° |

| Angle of Striking | 30°-150° ±1° - Adjustable |

| Distance from Axis of Support to Center of Percussion | 29.5" 750 mm |

| Velocity of Striker | 5.24 m/s |

| Support Span | 1.58" 40 mm |

| Radius of Curvature of Supports | 1 mm |

| Angle of Taper of Supports | 11° ± 1° |

| Radius of Striking Edge | 2 mm (R2) and 8 mm (R8) |

| Angle of Striking Tip | 30° |

| Thickness of Striking | 0.63" 16 mm |

| Force Transducer | 30kN, 50kN |

| A/D Sampling Resolution | 16bits |

| Maximum Sampling Frequency | 1.25MHz |

| Frequency Band Width | 500kHz |

| Specimen Dimensions | 2.16x0.4x0.4", 2.16x0.4x0.3", 2.16x0.4x0.2" 55x10x10 mm, 55x10x7.5 mm, 55x10x5mm |

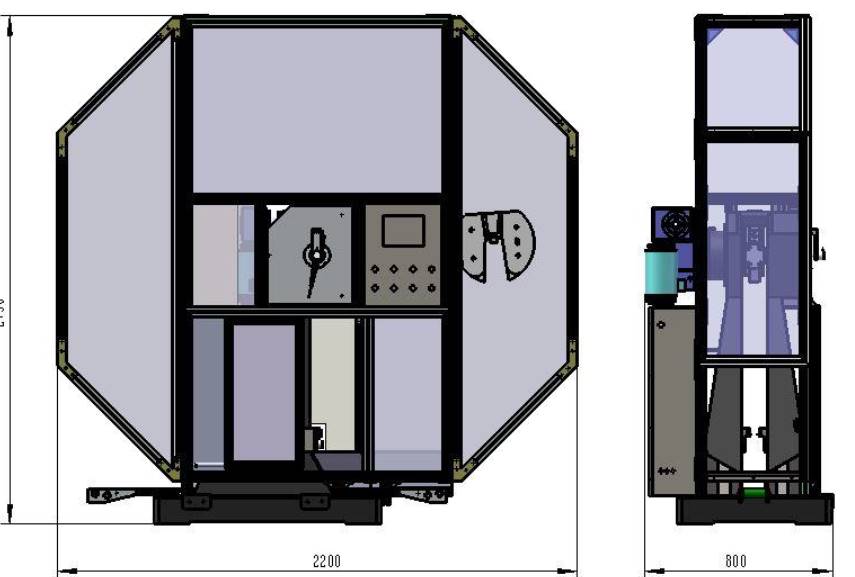

| Overall Dimensions | 7.72 x 2.7 x 7.88" 196 x 68 x 200 cm |

| Weight | 1765lbs 800 kg |

| Power | AC220V±10%, 50Hz, 100W |

Configurations

| Name | Description | Model | ||

|---|---|---|---|---|

| Machine Frame | NG752 Class H | NG752 H-2 | NG752 H-3 | NG752 H-4 |

| Framework | Frame | X | X | X |

| Pendulum Lock/Release System | X | X | X | |

| Driving System | X | X | X | |

| Angle Measurement | X | X | X | |

| PLC | X | X | X | |

| Dial Gauge Display | X | X | X | |

| Touch Screen | X | X | X | |

| Full Protection Shield | X | X | X | |

| Servo Motor | X | X | X | |

| Software | Gentest | X | X | |

| Accessories | Span Block Specimen Centering Block Centering Tongs Standard Tools Anchor Bolts Wedge Block |

X | X | X |

| PC Connection | RS232 | X | X | |

| Instrumented Impact System | Force Transducer in Pendulum for quick plotting of the force-time graph Access to more testing parameters on Gentest software |

X | ||

FAQs

The Class H impact tester is used to measure the impact toughness of metallic specimens using the Charpy method. It swings a pendulum of known energy into a notched specimen and records how much energy is absorbed during fracture. This helps engineers and quality teams understand how a material behaves under sudden loading, especially at different temperatures or after heat treatment and welding.

With available pendulums up to 750 J, the system is suited for high-strength steels and other materials that absorb significant energy before breaking. It is used for tasks such as batch release testing, procedure qualification, weld qualification, and research into ductile-to-brittle transition behavior.

In its instrumented version, the tester also captures force–time data, so labs can look beyond a single energy number and study crack initiation and growth in more depth.

Click here to learn more about the product or here to receive a personalized quote.The Class H tester is aimed at labs that work with structural and high-strength metals. Typical users include steel mills, forging and heat-treatment shops, pipe and plate producers, automotive and truck component manufacturers, power generation suppliers and heavy equipment builders. Any facility that needs Charpy testing for welds, heat affected zones or base materials can use this system in daily QA and procedure qualification.

On the personnel side, it is normally operated by lab technicians, QC and QA engineers and test engineers. Lab managers and quality managers rely on its results and reports to approve batches and qualify processes. In engineering organizations, R&D or materials engineers also use the instrumented version to study fracture behavior in more detail, especially when comparing alloys or testing new heat treatments.

Click here to learn more about the product or here to receive a personalized quote.The Class H Charpy impact tester is built around the main international standards used for metallic impact testing. It supports Charpy testing in line with ASTM E23, which is the core reference for many metal producers and labs. On top of that, it can be used for fracture-toughness related testing according to ASTM E1820 and instrumented impact work per ASTM E2298 when the instrumented configuration is installed.

For labs that work under European or mixed standards, the system also supports ISO 148 and EN 10045 Charpy requirements. Energy measurement hardware can be calibrated against ASTM E74 Class AA procedures for high-level accuracy.

Because the frame, pendulum, striker geometry and support span are all specified with these documents in mind, labs can qualify procedures, run routine QA work and support certification testing without redesigning their methods around the machine.

Click here to learn more about the product or here to receive a personalized quote.The Class H system supports a full range of Charpy impact energies so labs can match the machine to their material requirements. It is available with pendulums rated at 300 J, 450 J, 600 J and 750 J, covering everything from general steel testing to high-toughness and heat-treated alloys. The 750 J pendulum is the highest-capacity option and is suitable for demanding applications where materials absorb large amounts of energy before fracture.

Each pendulum is designed and balanced for its specific energy level, ensuring the swing path and impact velocity remain consistent. Labs can start with one capacity and add others later if their test range changes. The machine’s frame and components are built to handle the full range safely, so switching to a higher-energy pendulum does not require a structural upgrade.

Click here to learn more about the product or here to receive a personalized quote.The dual-column frame gives the Class H tester the rigidity it needs to handle high-energy impacts without frame movement or deformation. During a Charpy strike, a large amount of force travels through the machine. With two structural columns, the load is distributed evenly, preventing twisting or bending that could affect the pendulum’s path or starting angle.

This layout also keeps the supports and striker aligned over long-term use. A single-column design can shift slightly over time, especially when repeatedly testing high-hardness materials. The dual-column structure stays stable even at 600 J or 750 J, helping maintain accurate, repeatable readings.

Another benefit is reduced vibration. When the impact occurs, the two-column frame transfers energy into the heavy cast iron base more efficiently. This reduces noise, improves accuracy and extends the lifespan of bearings and mechanical parts. For labs processing large batches, the dual-column design ensures consistency from the first test of the day to the last.

Click here to learn more about the product or here to receive a personalized quote.The servo-motor lift replaces manual pendulum raising, which removes a major source of human variation. It brings the pendulum to the exact same starting angle for every test, with no overshoot and no gradual drift. Because the absorbed energy depends directly on the pendulum’s starting height, this consistent lift is a key factor in repeatable results.

The motor moves smoothly, without jerks or uneven acceleration, so the potential energy at the starting point is always the same. Once the angle is reached, the electromagnetic lock holds the pendulum still, ensuring the release happens under identical conditions from test to test.

This automation is especially valuable in high-volume labs, where manual lifting would introduce fatigue and increasing variation across the shift. By keeping every cycle uniform, the servo-motor system helps maintain accuracy at all energy levels, including demanding tests near 750 J.

Click here to learn more about the product or here to receive a personalized quote.The Class H tester uses a fully enclosed impact chamber to keep operators protected during every strike. The enclosure surrounds the pendulum, supports and specimen so no debris or fractured pieces can leave the test zone. This is important when testing high-hardness materials, where broken fragments can fly at high speed.

The doors are equipped with interlocks that prevent the pendulum from moving unless the enclosure is closed and secured. If the door is opened at any point, the machine will not allow a test cycle to start. This removes the possibility of accidental release while loading a specimen.

The electromagnetic lock adds another safety layer by holding the pendulum firmly at the top position until the system confirms all conditions are safe. Lights and on-screen notices guide the operator through each step so there is no confusion about machine status. Together, these features create a controlled environment that protects the operator even during high-energy tests.

Click here to learn more about the product or here to receive a personalized quote.The Class H tester is designed for metallic materials, especially those with high hardness or high toughness that require energy levels up to 750 J. Common materials include carbon steels, alloy steels, tool steels, stainless steels, cast irons, welded joints, heat-treated components and structural metals used in construction or manufacturing. Because the frame is rigid and the pendulum delivers consistent impact energy, the system handles demanding samples without losing accuracy.

Sub-size specimens are also supported, which makes the machine suitable for materials with limited sample availability or for applications where thickness varies. Although the system is optimized for metals, labs sometimes use it for research on certain non-metals or specialized composites as long as the sample dimensions match Charpy standards and the energy range is appropriate.

Click here to learn more about the product or here to receive a personalized quote.In the instrumented Class H-4 version, the striker is built with an integrated force transducer that measures the impact force throughout the entire strike instead of recording only the final absorbed-energy value. When the pendulum hits the sample, the sensor captures force at high speed and sends the signal to the controller and PC software. The system then builds a detailed force–time or force–displacement curve showing how the material reacts at every stage of the fracture.

The transducer detects the initial elastic response, the start of crack formation, the peak load, crack growth, and the point where the specimen fully breaks. Because the sensor collects data continuously, the operator can see subtle events that a traditional Charpy tester would never record.

This setup is especially valuable for comparing materials, assessing brittle vs ductile behavior, or validating heat treatments. It gives engineers far deeper insight than a single energy value and turns the impact test into a full dynamic-fracture analysis tool.

Click here to learn more about the product or here to receive a personalized quote.With the instrumented Class H-4 configuration, the striker contains a built-in force transducer that records the full force–time history during impact. This allows the system to measure much more than just absorbed energy. The software can capture the maximum force reached during the strike, the energy absorbed before that maximum (pre-maximum energy Wm) and the energy absorbed after the maximum as the crack continues to grow.

It can also determine characteristic forces linked to different parts of the fracture process, such as general yield force, brittle fracture initiation force and arrest force. These values help engineers see whether a material behaves more ductile or brittle and how the crack propagates under dynamic loading.

By combining these parameters with the traditional energy value, the instrumented setup gives a detailed picture of fracture behavior that is useful for R&D, material comparison, and critical applications where simple energy numbers are not enough.

Click here to learn more about the product or here to receive a personalized quote.When the Class H tester is connected to a PC, the system moves from a simple energy-only machine to a full digital impact workstation. Through the software, the tester can store test results automatically, generate reports, and keep a clear history of samples, batches and operators. Instead of reading values off the dial or display and typing them into spreadsheets, the operator gets data recorded and saved directly from the instrument.

The software can show force–time or energy–time curves for instrumented versions, allow zooming and comparison between samples, and mark key points on each curve. It also lets users add sample IDs, material grades, heat numbers and other traceability fields. Reports can be printed or exported in common formats for internal QA use or for customers.

Click here to learn more about the product or here to receive a personalized quote.The Class H tester is built around the standard Charpy specimen sizes used in ISO 148 and ASTM E23. It supports full-size specimens of 2.16 x 0.40 x 0.40 inches (55 x 10 x 10 mm), which are the most common dimensions for metallic impact testing. The machine also accepts sub-size specimens such as 2.16 x 0.40 x 0.30 inches (55 x 10 x 7.5 mm) and 2.16 x 0.40 x 0.20 inches (55 x 10 x 5 mm).

The support span, striker geometry and frame layout are designed to match these dimensions, so operators can switch between full-size and sub-size bars without needing a different machine. Centering blocks and tongs help position each specimen correctly over the supports and under the striker.

Click here to learn more about the product or here to receive a personalized quote.The Class H uses a servo-motor drive to handle all pendulum movement, so the operator does not waste time on manual lifting. After the specimen is loaded and the door is closed, the motor brings the pendulum up to the preset starting angle within a few seconds. The starting angle can be set anywhere in the working range, and the system repeats that angle from test to test without drift.

Right after impact, the pendulum continues its swing, and the system calculates the absorbed energy. The machine then brings the pendulum back to a safe locked position automatically. In routine work, the time between pressing start and having the pendulum ready for the next specimen is very short, which keeps the line moving.

Click here to learn more about the product or here to receive a personalized quote.The Class H system is built to handle demanding workloads, especially when labs test large quantities of high-hardness metals such as alloy steels, heat-treated components or structural materials. The dual-column frame provides strong lateral stability, which prevents the structure from flexing during high-energy impacts. Combined with a heavy cast iron base, the machine absorbs each strike without shifting, even during long test cycles.

The servo-motor lift speeds up workflow by raising the pendulum quickly and consistently to the preset angle. Because the operator does not manually lift the pendulum, productivity remains high throughout the shift and operator fatigue is reduced. The automatic return after impact allows the next specimen to be loaded almost immediately, which is ideal for labs running dozens or hundreds of samples per day.

The fully enclosed testing area and electromagnetic lock keep operation safe during fast-paced testing. The machine’s precision bearings, rigid frame and consistent release mechanism maintain accuracy even when repeatedly striking high-strength materials that generate strong vibrations. This combination of strength, speed and stability makes the Class H a suitable choice for intensive, high-hardness material testing.

Click here to learn more about the product or here to receive a personalized quote.Changing the striking knife is a simple process, but it must be done with the machine completely secured. The pendulum should remain locked by the electromagnetic hold so it cannot move while the operator works. After opening the protective enclosure, the operator loosens the bolts that keep the current knife attached to the striker head. These bolts sit at the front of the assembly, making them easy to reach with the supplied wrench set.

Once the old knife is removed, the new one (ASTM or ISO) is positioned directly on the machined reference surfaces. The radius of the knife, such as R2 or R8, must match the chosen test standard. The operator then tightens the bolts evenly to ensure proper alignment. A clean contact surface is important, because even a small tilt can affect impact behavior.

After installation, it is recommended to run a quick verification with reference specimens before returning to regular testing. This helps confirm that the new knife is mounted correctly and that the energy values fall within the expected tolerance range.

Click here to learn more about the product or here to receive a personalized quote.Most day-to-day care for the Class H tester is simple: keep the test area clean, check that supports and striker faces are free of burrs, and verify that the enclosure, locks and interlocks work correctly. Operators should visually inspect the pendulum, bearings and striking edge on a regular basis, especially in high-volume labs. Any damage to the knife or supports should be addressed before more tests are run.

Calibration is mainly handled through indirect verification with certified impact reference specimens in line with ASTM E23 and ISO 148. Labs typically perform these checks at set intervals and after any mechanical changes. For instrumented versions, the force sensor and data chain should be verified according to the service instructions so the force–time curves remain reliable.

A full service visit is usually recommended on a yearly basis. During this, a technician checks the angle system, electronics, mechanical alignment and safety systems, and documents the results for the lab’s quality records.

Click here to learn more about the product or here to receive a personalized quote.The standard Class H configuration includes the core accessories needed for everyday Charpy testing. These typically include the span block and specimen centering block that help position samples correctly on the supports. Centering tongs are supplied to make loading faster and ensure the notch orientation is consistent from test to test.

The machine also comes with the required striking knife for the chosen standard, along with the corresponding support anvils. Standard tools for basic adjustments, routine checks and installation are included as well. Anchor bolts are provided so the system can be secured to the floor, which is important for stability during high-energy impacts.

Some accessories vary slightly depending on the exact model (H-2, H-3 or H-4), but the base package always includes the components necessary to run compliant ASTM and ISO Charpy tests immediately after installation. Additional pendulums, knives or software options can be added if the lab needs expanded capability.

Click here to learn more about the product or here to receive a personalized quote.The Class H tester uses a high-resolution angle encoder that tracks the pendulum’s starting position with very fine accuracy. Because the absorbed energy is based on the difference between the starting and ending angles, even small errors can affect the final value. The encoder reads the pendulum’s lift position precisely and sends the data directly to the controller, removing guesswork and eliminating the variability that can come from manual angle scales.

The servo-motor lift also plays a role in accuracy. It raises the pendulum smoothly to the exact preset angle every time, without overshooting or drifting. This ensures that each test begins with the same amount of potential energy. Combined with the electromagnetic lock, which holds the pendulum completely still before release, the starting angle remains consistent across long test runs.

Click here to learn more about the product or here to receive a personalized quote.The Class H tester is a large floor-standing system, so the lab should reserve enough room for safe operation and access. The machine itself measures roughly 77.2 x 26.8 x 78.8 inches (196 x 68 x 200 cm) and weighs about 1765 lbs (800 kg). Because of this weight, the machine should be placed on a solid, stable floor capable of supporting heavy equipment. A small buffer zone around the frame is recommended so operators can load specimens, check the enclosure and access the pendulum area without obstruction.

For power, the unit requires a standard AC 220V ±10%, 50Hz, 100W supply. Labs in regions with different power standards may need a compatible electrical line or transformer. The machine does not require high current, but it should have a dedicated, stable power source to avoid voltage drops during operation.

Good ventilation, controlled indoor temperature and minimal vibration near the installation area help maintain consistent test performance and protect the mechanical components over long-term use.

Click here to learn more about the product or here to receive a personalized quote.After installation, the Class H tester is supported through a full service network so the machine stays reliable for many years. Customers can access technical assistance for operation questions, troubleshooting, routine checks and software-related issues if the system is connected to a PC. Support is available by phone, email or remote diagnostics, depending on what the lab needs.

Consumables include striking knives, support anvils, centering tools and small mechanical parts that wear over time. For instrumented versions, replacement striker tips and sensor-related components are also stocked. These items are normally kept available for quick shipment, so high-volume labs do not experience long downtime.

Larger parts such as pendulums, shields or electronics modules can be supplied if aging or accidental damage occurs. Because all replacement components match the original specifications, the machine maintains its accuracy and stays compliant with ASTM and ISO methods. Extended service plans are available for labs that want structured long-term maintenance and priority support.

Click here to learn more about the product or here to receive a personalized quote.High accuracy at high energy comes from a combination of structural stability, precisely machined components and controlled motion. The dual-column frame provides rigidity so the pendulum swings along the intended path without unwanted flex or distortion, even at 750 J. The heavy cast iron base absorbs impact shock and reduces external vibration, which helps maintain a consistent starting angle and impact geometry.

The servo-motor lift raises the pendulum smoothly to the exact preset angle, giving each test the same initial potential energy. The electromagnetic lock ensures that the pendulum is fully secured until the controlled release, removing operator influence. The bearings in the striker assembly are high precision, which minimizes friction and energy loss during the swing.

For instrumented units, the integrated force transducer captures clean, high-resolution force data so the software can verify the mechanical performance of each strike. Together, these factors allow the Class H to deliver stable, repeatable measurements at the highest energies used in Charpy impact testing.

Click here to learn more about the product or here to receive a personalized quote.The three configurations differ mainly in automation level and data capability. The Class H-2 version is the standard mechanical configuration with all core components: dual-column frame, servo-motor lift, electromagnetic lock, full safety enclosure, touch screen, and both analog and digital energy readouts. It performs accurate Charpy testing but is not designed for instrumented data capture.

The Class H-3 configuration adds PC connectivity through RS232 and access to GenTest software. This allows digital data storage, automated reporting, easier batch documentation, and optional integration with lab workflows. The mechanical testing process remains the same, but the digital workflow becomes more efficient.

The Class H-4 configuration includes everything from H-3 but adds an instrumented striker with an integrated force transducer. This enables high-speed force-time data, detailed fracture analysis and advanced parameters such as maximum force, pre- and post-maximum energy, brittle-fracture initiation force and arrest force. H-4 is intended for labs that require deeper insight into fracture behavior, R&D accuracy or high-level QA documentation.

Click here to learn more about the product or here to receive a personalized quote.The Class H system is primarily designed for Charpy impact testing according to ASTM E23, ISO 148 and EN10045. Its dual-column frame, support span and striker geometry are optimized for Charpy specimens and the horizontal impact configuration these standards require.

Izod testing uses a different specimen position, support setup and impact direction. Because of this, the standard Class H configuration does not switch between Charpy and Izod without modification. Some components, such as the striking orientation and support assembly, would need to be reconfigured to follow the Izod method correctly.

For labs that need both Charpy and Izod capabilities, it is usually recommended to use a dedicated system or confirm with the supplier whether a compatible Izod attachment is available for the Class H frame. This ensures correct alignment, accurate energy readings and full compliance with the required standards.

Click here to learn more about the product or here to receive a personalized quote.The PLC controller acts as the core control unit for the Class H system. It manages all automatic movements and safety checks during each test cycle. When the operator loads a specimen and selects the test settings, the PLC handles the pendulum lift, monitors the starting angle and confirms that the enclosure is closed before any motion begins. This keeps operator actions simple while the internal logic maintains consistent test conditions.

During the strike, the PLC tracks the pendulum’s release, movement and return path. It ensures that the swing completes correctly and that the pendulum comes back to a safe locked position after the impact. Because the PLC executes the sequence the same way each time, the machine repeats tests with high consistency, even in busy labs.

The controller also manages communication with the touch screen and optional software. It provides stable data for the digital and analog readouts and ensures that the operating sequence remains reliable over thousands of tests.

Click here to learn more about the product or here to receive a personalized quote.The electromagnetic lock holds the pendulum firmly in its raised position until the operator is ready to run the test. Because the lock releases only when the machine is in a safe and confirmed state, there is no risk of the pendulum dropping accidentally or slipping during setup. This prevents sudden movement that could injure an operator or damage the striker and supports.

The lock engages automatically after each test when the pendulum returns to its starting position. This removes the need for manual latching and keeps hands away from the pendulum path. When the operator loads the next specimen, the pendulum is completely immobilized and cannot move until the system receives the command to begin the test.

This controlled release and secure hold make daily operation safer and more predictable. In high-volume labs, where operators repeat the same motions many times per shift, the electromagnetic lock significantly reduces the chance of accidents and keeps the workflow smooth.

Click here to learn more about the product or here to receive a personalized quote.Yes. Labs can use certified impact verification specimens and alignment tools to confirm that the Class H tester continues to meet ASTM E23 and ISO 148 requirements. These reference specimens have known absorbed-energy values, and when the machine tests them, the results must fall within the allowed tolerance range. Using these specimens regularly helps verify that the pendulum, supports and striker remain in proper condition.

In addition to reference bars, labs can use angle-check tools, support-span gauges and striker-radius templates to confirm that the mechanical setup matches the standard. For instrumented versions, verification also includes checking the force sensor’s response with a basic calibration routine to make sure the signal is stable and accurate.

All tools are available through the same supplier network that provides the machine. Keeping a small set of verification items in the lab makes routine checks easier and supports stable, repeatable testing throughout the year.

Click here to learn more about the product or here to receive a personalized quote.A standard Charpy test cycle on the Class H system is fast, especially when processing multiple samples. Loading the specimen and checking the notch orientation usually takes only a few seconds. Once the sample is in position, the pendulum is raised by the servo-motor automatically, removing the need for manual lifting. The machine reaches the preset starting angle quickly, and the operator initiates the strike.

The impact itself happens instantly. The energy value appears on the display right after the pendulum completes the swing, and the auto-return brings it back to the safe position without operator effort. In most cases, the entire sequence from placing the specimen to seeing the final energy result takes less than 10 to 15 seconds.

If the machine is instrumented, the software requires a moment to process the force–time curve, but even then the total cycle remains very short. This speed makes the Class H well suited for high-volume labs that test dozens or hundreds of samples daily.

Click here to learn more about the product or here to receive a personalized quote.New operators usually need only a short introduction to begin using the Class H tester effectively. The machine is designed for straightforward operation, so most of the workflow is guided by the touch screen and the built-in controls. A typical onboarding session covers how to select the correct striking knife for ASTM or ISO work, how to position and center the specimen, how to set the starting angle and how to run a safe impact cycle. This takes little time because the machine handles the heavy steps automatically, including raising the pendulum and returning it after the strike.

For labs using the instrumented version or connecting the tester to analysis software, additional training may be helpful. This includes learning how to read force–time graphs, how to interpret advanced fracture parameters and how to export or store digital results. Even here the process stays simple, and operators often become confident within a few sessions. The system’s layout and instructions are designed so that new users can reach consistent, repeatable results without needing deep prior experience in impact testing.

Click here to learn more about the product or here to receive a personalized quote.The touch-screen interface simplifies the routine workflow by putting the main controls directly in front of the operator. Instead of navigating through physical buttons or multi-level menus, the operator selects the test type, checks the angle, confirms the pendulum state and starts the test through clear on-screen options. This reduces setup time, especially when multiple batches must be processed in a single shift.

The screen also shows key information in real time, such as the starting angle, test status and final energy values. Because everything is displayed visually, operators spend less time checking gauges or switching between instruments. If the machine is connected to software, the screen can guide the user with prompts, making the process even smoother.

This direct, simple interface helps prevent common mistakes, supports new operators and speeds up repetitive tasks. For high-volume labs, the touch screen becomes a practical advantage that keeps testing moving without unnecessary delays.

Click here to learn more about the product or here to receive a personalized quote.Yes. The Class H tester is designed so labs can integrate it into their current data workflows without rebuilding their entire system. Even in its basic configuration, the machine can output results in formats that most QA and QC teams already use, such as digital readouts, printed summaries or exported data through the PC software option. When connected to analysis software, the system can generate structured files that match common reporting practices inside metal testing labs.

Many laboratories use simple folder-based systems or shared drives for documentation. In these cases, the exported files can be saved directly into the existing structure. For more advanced environments, such as labs with LIMS or centralized data hubs, the software can output results in formats that are easy to map into external systems. This includes energy values, ID information, time stamps and instrumented-force data when available.

Click here to learn more about the product or here to receive a personalized quote.The Class H tester should be installed in a stable lab environment where temperature and vibration remain controlled. A typical recommended range is standard room temperature, without rapid swings that could affect the metal frame, bearings or electronics. Large temperature changes can slightly shift mechanical alignment or influence sensor behavior, so a steady indoor environment is ideal.

Vibration control is equally important. The machine should not be placed near heavy presses, mills, compressors or equipment that produces floor vibration. Even periodic shaking can influence the pendulum's starting angle or cause small shifts in the supports. A solid floor is preferred, and the machine should be anchored according to the installation instructions.

Airflow should not hit the pendulum area directly, and the machine should have enough space for safe operation and access to both sides. A calm, stable environment helps ensure consistent readings and protects the mechanical components over years of heavy use.

Click here to learn more about the product or here to receive a personalized quote.The cast iron base helps stabilize the entire impact system by adding mass and damping. Because it has a high density, the base absorbs a significant amount of the shock generated during each strike. This prevents the frame from flexing or shifting when the pendulum hits the specimen. A lighter frame would transmit more vibration into the machine structure, which could affect the angle reading, striker path or energy calculation.

Cast iron also has natural vibration-damping properties. When external vibrations come from nearby equipment, foot traffic or building structure, the base minimizes how much of that movement reaches the pendulum. This keeps the machine steady so the swing angle, starting position and impact conditions remain consistent across tests.

For labs running many samples per day or working with high-hardness materials, this stability helps maintain repeatable test conditions and reduces noise in the readings. Overall, the heavy cast iron foundation plays an important role in test accuracy and long-term reliability.

Click here to learn more about the product or here to receive a personalized quote.Yes. The Class H system is built so that a non-instrumented machine can be upgraded to an instrumented setup as long as the frame and electronics match the required configuration. The upgrade involves replacing the standard striker with a striker that contains an integrated force transducer and connecting it to the appropriate signal-conditioning hardware. Once installed, the machine can record force–time data and provide parameters such as maximum force, pre-maximum energy, post-maximum energy, brittle-fracture initiation force and arrest force.

Before an upgrade, the lab usually shares the machine’s model version, serial number and controller details so the technical team can confirm compatibility. After installation, a short verification is done to make sure the new sensor responds correctly and the software reads the signal without drift or noise.

This upgrade option is useful for labs that start with basic energy measurements and later need deeper fracture analysis or more advanced reporting.

Click here to learn more about the product or here to receive a personalized quote.Most errors come from small alignment issues that directly affect the absorbed-energy reading. A common mistake is placing the specimen off-center on the supports, which changes the impact position and leads to inconsistent results. Another frequent issue is using the wrong support span or the wrong striker radius for the selected standard. If the operator switches between ASTM and ISO samples and forgets to adjust the striking knife, the results will not match the method requirements.

Surface contamination is another problem, especially when gloves, oil or dust get on the fracture area. This can change how the specimen behaves at the moment of impact. Incorrect orientation of the notch, or choosing the wrong side to face the striker, also leads to invalid tests.

Rushed installation is usually the cause, so good habits matter. Taking a moment to verify centering, notch direction, support span and striker type prevents most issues and keeps the results usable for QA and audits.

Click here to learn more about the product or here to receive a personalized quote.For long-term use, consumables and spare parts for the Class H tester are supplied through the same channel as the machine itself. Typical consumables include striking knives, anvils or supports, specimen centering parts and small mechanical items that wear with heavy use. Instrumented versions may also need replacement striker tips or sensor-related parts over time.

Most common items are kept in stock, so they can be shipped quickly when a lab needs them. For critical environments, many customers keep at least one spare striking knife and basic hardware on site to avoid downtime during intensive test campaigns.

Larger components, such as pendulums, shields or electronics modules, are available as service parts if damage or aging appears after years of operation. All parts are matched to the original design so the machine keeps its accuracy and stays aligned with ASTM and ISO method requirements.

Click here to learn more about the product or here to receive a personalized quote.To stay compliant with ASTM E23 and ISO 148, labs should run regular indirect verification using certified reference specimens. In practice this means testing impact reference bars with known absorbed energy and comparing the measured values to the certified range. If the results stay inside the allowed tolerance, the machine is considered fit for use.

Routine checks also include confirming the pendulum starting angle, checking the zero position, and verifying that the energy scale and digital readout agree. On instrumented versions, the force signal should be checked with the appropriate procedures so that force–time data is reliable.

These verifications are typically done at defined intervals, for example annually by an accredited service provider and more frequently as internal checks. Results should be recorded with date, operator, reference bar batch and observed values. This documentation is important for audits, customer requirements and internal quality records.

Click here to learn more about the product or here to receive a personalized quote.Class H is a heavy, floor standing system with a listed weight of about 800 kg and a frame height close to 2 m. For international shipment it is normally packed in a reinforced wooden crate that supports the weight, protects the dual columns and shields the pendulum and enclosure from vibration and impact. Critical components such as the pendulum, striker, electronics and accessories are locked or braced during transport to prevent movement.

Because of the size and weight, loading and unloading require a forklift or crane rated for the full crate mass. Door widths, freight elevator limits and access paths at the destination site should be checked in advance.

Export documentation, basic insurance and, when needed, fumigation or IPPC marking for the crate can be arranged through standard freight channels. Many customers also request that the machine is installed and checked on site after arrival to confirm calibration and proper operation before routine testing begins.

Click here to learn more about the product or here to receive a personalized quote.Class H is supplied with a standard range of pendulum capacities: 300 J, 450 J, 600 J and 750 J. This covers typical Charpy energy levels required by ASTM E23, ISO 148 and EN10045. The machine is also designed to work with R2 and R8 striking radii and a 30° striking angle, so most standard applications are already covered out of the box.

For labs with special materials or internal procedures, custom options can be discussed. In many cases this means adapting the pendulum to a specific energy window inside the 300 J to 750 J range, or providing a different striking edge geometry that still respects safe operation and the frame design. Such requests are considered case by case, taking into account machine limits, dynamic performance and safety.

If a project requires a non-standard configuration, the best approach is to share the target standard, specimen size and desired energy level so the technical team can confirm what is practical and safe.

Click here to learn more about the product or here to receive a personalized quote.The Class H system typically includes a standard manufacturer warranty that covers the main mechanical structure, electronics and core components for a defined period. During this time, customers receive assistance for any defects, operational issues or unexpected faults that are not caused by misuse or improper installation.

Long-term support includes access to technical help, troubleshooting guidance and remote assistance. Spare parts, consumables and accessories are stocked and can be supplied quickly to keep the machine running without long downtime. For labs that want predictable operation, optional extended support plans are available. These can include priority service, calibration assistance, and periodic checks to confirm that the machine remains compliant with ASTM and ISO requirements.

Software support is also part of the package if the user connects the tester to a PC. This includes help with installation, updates and guidance on analysis workflows. The overall goal is to give labs reliable, long-term operation with minimal interruption.

Click here to learn more about the product or here to receive a personalized quote.When the Class H tester is connected to analysis software, the operator gets much more information than a simple absorbed-energy value. The software records the full force–time or force–displacement profile from the moment the pendulum hits the specimen until the pendulum completes the swing. This curve shows how the material reacts during each stage of fracture: initial contact, elastic response, crack initiation, crack growth and final break.

With instrumented pendulums, the software can highlight key points such as maximum force, pre- and post-maximum energy, arrest force and brittle-fracture initiation force. These markers help engineers understand whether a material fails in a ductile, semi-ductile or brittle mode.

The ability to zoom, compare curves, and overlay multiple samples also helps identify batch variation, heat-treatment problems or anomalies in production materials. In short, software analysis turns a single number into a detailed fracture signature, giving labs clearer insight into real material behavior.

Click here to learn more about the product or here to receive a personalized quote.Related Products

Class J - Charpy and Izod Automatic Impact Testing System - 1J - 50J

Class J is widely used for lzod and Charpy impact test on softer metals, plastics and rubber specimens. Equipped with tensile impact pendulum and fixtures, it can carry on tests on plastic film and sheet. The newly enhanced design offers the most cost-effective configuration to address Charpy test from 1J to 50J (0.7 - 37 ft/lbs), and lzod test from 1J to 22J (0.7 - 16 ft/lbs).

Class D Single-Column Charpy Impact Tester – High-Precision Pendulum Testing Machine

NextGen’s Class D Single-Column Charpy Impact Testing System is built for high rigidity and dependable specimen testing across a wide energy range. It supports impact energies from around 150 J (111 ft-lbs) up to around 750 J (553 ft-lbs), covering most standard metal testing needs. The unit includes a digital display and offers a software upgrade option for data plotting. Additional features, such as automated specimen feeding and integrated cooling or heating systems, are available as optional enhancements.

Class G Single-Column Charpy & Izod Impact Tester – High-Precision Pendulum Testing Machine

NextGen's Class G – Single Column Charpy and Izod Impact Testing system provides a high level of rigidity and specimen testing capacity. This Charpy and Izod Impact tester has a minimum capacity of 150 J (111 ft/lbs) and a maximum capacity of 750 J (553 ft/lbs). The system comes standard with a digital display with software upgrade function for data plotting. The Class G impact system can also include automatic specimen feeding, cooling and heating systems as optional upgrades.

Triple Specimen Chamber Motorized Charpy Notch Making Machine

The GenNotch 4000UPG Series is a motorized Charpy & Izod Notch Making Machine with a triple specimen chamber.

Specimen Notching/Broaching Machine

NextGen offers an economical solution for Specimen notching and broaching for Charpy and Izod specimens. This certified system complies with ASTM ISO148, EN10045, ASTM E23, DIN 50115 standards. This automated, motorized solution is capable of preparing two specimens at any one given time up to 46 HRC. A variety of broaches are available for different geometries of notches.

Impact Specimen Cooling and Heating Temperature Chamber – GenChamber

NextGen offers a full range of impact specimen cooling and heating chamber designed to meet virtually all Charpy, Izod and Tensile Impact Testing requirements. NextGen's temperature chambers are a combination of user-friendliness, compact and robust build, offering the ultimate versatility of cooling and heating requirements.

Charpy/Izod Notch Verification Projector System NG-NPS-CIS

Enhance your material testing accuracy with our advanced Charpy/Izod Notch Verification Projector System NG-NPS-CIS.

DWT-1800 Computer Controlled Drop Weight Impact Testing Machine

DWT-1800 Impact Testing Machine is specifically designed for determining the non-plastic transformation temperature of ferritic steel.