Metal Testing Equipment

Standards

Descriptions

Improve the accuracy and efficiency of your impact testing procedures with the NG-NPS-CIS Charpy/Izod Notch Verification Projector System—a high-precision optical measurement solution engineered to meet the demanding requirements of modern materials testing laboratories. Designed in full compliance with GB/T229 – 2007 “Metal Charpy Impact Test Method”, this system enables precise verification of U-type and V-type notch geometries through optical projection and comparison against certified reference templates. The system is equipped with an integrated GenDRN Digital Readout Module to assist with real-time positioning and measurement visibility.

The projector features a 50× magnification lens and a large Φ200 mm screen, allowing operators to clearly assess notch conformity with maximum clarity. Its robust platform offers ±10 mm vertical and horizontal table displacement, ±12 mm height adjustment, and 360° table rotation, ensuring full flexibility during specimen alignment and inspection. A powerful halogen and tungsten light source (12 V, 100 W) guarantees bright and consistent illumination across the measurement area.

Whether you are performing impact specimen verification, notch inspection, or general metallographic quality control, the NG-NPS-CIS projector system provides a reliable, repeatable, and user-friendly platform to help achieve compliance with international standards and deliver high-quality test results.

Charpy/Izod Notch Verification Projector System Technical Specifications

| Model | NG-NPS-CIS |

| Magnification | x50 |

| Projector Screen Size | Φ200 mm |

| Table Displacement | Vertical ±10 mm, Horizontal ±10 mm |

| Table Height Adjustment | ±12 mm |

| Table Rotation Range | 0-360° |

| Light Source | Halogen and Tungsten, 12 V, 100 W |

| Dimensions | 28 x 28 x 18 in (711 x 711 x 457 mm) |

| Weight | 84 lbs (38 kg) |

Advanced Digital Readout System for Real-Time Measurement Accuracy

The NG-NPS-CIS is equipped with the GenDRN Digital Readout (DRO), a precision-driven module that has been developed to improve the accuracy, usability, and control of the system during notch verification. This system enables users to manually assign precise coordinates when necessary, recover mistakenly reset values, and zero positions at any point with real-time coordinate tracking across up to three axes.

With built-in linear error compensation, inch-metric conversion, and a center-finding function, the DRO guarantees that measurements are consistent and complies with strict testing standards. The system also includes a power-off memory feature that automatically restores the last used coordinates after unexpected shutdowns, thereby reducing test interruption and enhancing workflow reliability.

Compliance and Certification

The NG-NPS-CIS Charpy/Izod Notch Verification Projector System is engineered in full compliance with ASTM E23, ISO 148, and GB/T229 – 2007 standards. Each unit includes a formal Certificate of Compliance, confirming verified calibration accuracy, environmental test conditions, and traceability to certified measurement instruments.

During inspection and verification, the system undergoes a rigorous calibration process using high-precision tools such as micrometers, digital meters, and universal measuring microscopes. Testing is performed under stable temperature and humidity to ensure the highest level of reliability.

The optical system’s 50× magnification lens is evaluated for accuracy in key performance areas, including:

-

Notch width and depth

-

Grid graduation resolution

-

V-notch angle accuracy

-

Root radius conformity

All measured values fall within strict uncertainty thresholds as required by international standards. Calibration results are traceable and repeatable, assuring that the projector system delivers consistent, audit-ready outcomes.

To maintain long-term accuracy and compliance, annual recalibration is recommended as part of a regular quality control protocol.

This certification-backed process confirms that the NG-NPS-CIS system is ready for precision-critical applications such as notch inspection, impact specimen verification, and metallographic quality control, helping laboratories meet global testing standards with confidence.

FAQs

In order to make certain that the NG-NPS-CIS system remains in compliance with international testing standards and maintains long-term accuracy, it is advised that the system be recalibrated annually. Routine recalibration is required for guaranteeing that critical measurements—including notch width, depth, angle, and radius—remain within acceptable uncertainty thresholds.

In regulated environments where audit readiness is critical, annual calibration additionally assures consistent performance in applications such as notch inspection and impact specimen verification.

Click here to learn more about the product or here to receive a personalized quote.

Yes, each NG-NPS-CIS Charpy/Izod Notch Verification Projector System comes with a Certificate of Compliance. This document outlines the equipment’s verified calibration parameters, environmental conditions during testing, and traceability to certified reference instruments. It is a confirmation that the unit has been calibrated under controlled laboratory conditions using precision tools, including digital meters and micrometers.

This certificate guarantees that the system satisfies the ASTM E23, ISO 148, and GB/T229 – 2007 standards. This makes sure laboratories and quality control teams can work with confidence, as they depend on traceable, repeatable measurement results.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenDRN DRO offers inch-metric conversion at the push of a button, allowing you to switch between millimeters and inches based on your testing standard.

It also supports multiple resolution settings (from 0.1 µm to 10 µm), giving you the flexibility to adapt to different testing requirements without compromising precision.

Click here to learn more about the product or here to receive a personalized quote.

The NG-NPS-CIS is equipped with the GenDRN Digital Readout Module, which includes a power-off memory function. If power is interrupted, the DRO automatically restores the last used coordinate data when the system restarts.

This feature prevents lost alignment settings, saving time and minimizing disruption in high-throughput testing labs.

Click here to learn more about the product or here to receive a personalized quote.

Absolutely. The NG-NPS-CIS is equipped with a 12 V, 100 W halogen and tungsten light source, providing bright and consistent illumination across the entire screen.

This high-intensity lighting makes it easy to view even the finest notch details, regardless of room lighting conditions. A clear and evenly lit projection ensures reliable notch comparison and verification.

Click here to learn more about the product or here to receive a personalized quote.

The system includes a rotatable and fully adjustable stage, making it easy to align the notch exactly where it needs to be. Smooth controls allow for fine adjustments, helping the operator achieve precise positioning quickly and intuitively.

Accurate alignment is critical in impact testing, and this notch verification projector helps minimize human error by providing a stable and ergonomic inspection platform.

Click here to learn more about the product or here to receive a personalized quote.

The NG-NPS-CIS uses optical projection at 50× magnification to evaluate U-type and V-type notches with exceptional accuracy. The specimen’s notch is projected onto a large Φ200 mm screen for comparison against certified reference templates.

This method allows you to detect even small deviations in notch depth, angle, or shape that could compromise the accuracy of Charpy or Izod impact test results. It’s an essential part of any quality-driven impact testing setup.

Click here to learn more about the product or here to receive a personalized quote.

The Charpy/Izod Notch Verification Projector System - NG-NPS-CIS is specifically designed to verify the accuracy and compliance of notches in Charpy and Izod impact test specimens. These notches are critical because they directly influence the results of impact resistance tests, which are used to evaluate materials' toughness and durability.

The NG-NPS-CIS magnifies the test specimen notch profiles and projects them onto a screen. This allows operators to carefully compare the notches against standardized reference charts to confirm that they meet the required specifications, such as those outlined in ASTM E23 and ISO 148. By verifying the precision of these notches, the system guarantees that the impact tests produce reliable and consistent data, which is essential for assessing materials' mechanical properties in industries like aerospace, automotive, and construction.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Charpy/Izod Notch Verification Projector System - NG-NPS-CIS fully complies with ASTM E23, the standard method for conducting Charpy impact tests on metallic materials. ASTM E23 outlines the specific requirements for the dimensions and shape of notches in Charpy test specimens, as these are critical to obtaining accurate and reliable results in impact resistance testing.

The NG-NPS-CIS is designed to ensure that the U-type and V-type notches in Charpy and Izod specimens meet these stringent requirements. By projecting the notch profiles onto a screen with high magnification, the system allows operators to check the notches against ASTM E23 standards. This guarantees that all notches are within acceptable tolerances, which is essential for the integrity of the impact tests and for producing consistent, dependable data.

Compliance with ASTM E23 is crucial for industries that require rigorous material testing, as it guarantees accurate results and can be reliably used for assessing material toughness and performance in real-world applications.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the Charpy/Izod Notch Verification Projector System - NG-NPS-CIS complies with ISO 148, which is the international standard for conducting Charpy impact tests on metallic materials. ISO 148 specifies the requirements for the dimensions, shape, and quality of notches in Charpy test specimens, making sure that they are consistent and accurate for reliable impact resistance testing.

The NG-NPS-CIS system verifies that the notches in both Charpy and Izod specimens meet these strict standards. By projecting the notch profiles onto a screen at high magnification, the system allows for precise comparison against ISO 148 specifications, which can be used to determine whether any deviations from the requirements are present. This level of compliance is essential for maintaining the integrity of impact tests and for providing consistent, reliable data on materials' toughness and durability.

Click here to learn more about the product or here to receive a personalized quote.

The Charpy/Izod Notch Verification Projector System - NG-NPS-CIS is engineered to meet the stringent requirements of the GB/T 229-2007 standard, which governs the Charpy impact testing method for metallic materials in China. This standard emphasizes the precise measurement and conformity of U-type and V-type notches in test specimens, as these notches are critical to accurate impact resistance data.

The NG-NPS-CIS system achieves this by using optical projection technology to magnify the notch profiles and project them onto a screen. This process allows operators to compare the projected notch images against a standard reference map, to verify that the notches are within the acceptable dimensional tolerances specified by GB/T 229-2007. By confirming that the notches adhere to these precise requirements, the system ensures that the impact test results are both accurate and reliable, maintaining the integrity of the testing process according to this national standard.

Click here to learn more about the product or here to receive a personalized quote.

What is the magnification level of the Charpy/Izod Notch Verification Projector System - NG-NPS-CIS?

The Charpy/Izod Notch Verification Projector System - NG-NPS-CIS features a x50 magnification level. This high magnification is crucial for accurately examining the U-type and V-type notches in Charpy and Izod impact test specimens. At x50 magnification, the notch profiles are enlarged sufficiently to allow for detailed inspection and comparison with standard reference maps.

This level of magnification ensures that even the smallest deviations from the required notch dimensions are visible, enabling precise verification that the notches meet the strict tolerances set by standards such as ASTM E23, ISO 148, and GB/T 229-2007. Accurate notch verification is essential for the reliability of impact resistance tests, as it ensures that the specimens are correctly prepared, leading to consistent and dependable test results that are crucial for assessing materials toughness and durability.

Click here to learn more about the product or here to receive a personalized quote.

The Charpy/Izod Notch Verification Projector System - NG-NPS-CIS features a projector screen with a diameter of 200mm (Ф200mm). This screen size is significant because it provides ample space for the magnified projection of notch profiles, allowing operators to clearly and accurately assess the dimensions and shapes of the notches in Charpy and Izod impact test specimens.

With a 200mm diameter screen, the system guarantees that the entire notch profile is visible and easy to compare against standard reference maps. This is crucial for verifying that the notches conform to the required specifications set by standards like ASTM E23, ISO 148, and GB/T 229-2007. The large screen size enhances visibility and precision in the verification process, contributing to the overall reliability and accuracy of the impact resistance tests performed on the specimens.

Click here to learn more about the product or here to receive a personalized quote.

The Charpy/Izod Notch Verification Projector System - NG-NPS-CIS features a table displacement of ±10mm both vertically and horizontally. These displacement specifications are important because they allow for the precise positioning of test specimens under the projector system. The ability to adjust the table vertically and horizontally allows the notches on the Charpy and Izod specimens can be aligned perfectly with the optical projection system.

It is important that the notch profiles are projected accurately onto the screen in order for detailed inspections to be carried out, so this adjustability is crucial. Upon fine-tuning the specimen's position, the operator can ensure that the entire notch is clearly visible and aligned with the reference maps that are used to verify the position of the specimen.

Click here to learn more about the product or here to receive a personalized quote.

The adjustment range in the Charpy/Izod Notch Verification Projector System - NG-NPS-CIS is ±12mm vertically, allowing precise positioning of the test specimen relative to the projector’s optical system. This range is crucial because it ensures that the notch on the Charpy or Izod specimen is perfectly aligned with the projector's field of view. Proper alignment is essential for accurate notch verification, as it allows the notch profile to be clearly and accurately projected onto the screen.

This precision is vital for comparing notch dimensions to standard reference charts. Without this fine adjustment capability, even minor misalignments could lead to inaccuracies in the measurement process, potentially compromising the reliability of the impact test results. Therefore, the ±12mm adjustment range is an integral feature that supports the accuracy, consistency, and overall integrity of the notch verification process.

Click here to learn more about the product or here to receive a personalized quote.

The table in the Charpy/Izod Notch Verification Projector System - NG-NPS-CIS has a full rotation range of 0-360 degrees. This complete rotation capability is necessary for maximum test specimen positioning flexibility. With the ability to rotate the table through a full 360 degrees, operators can easily adjust the orientation of the specimen to make sure that the notch is perfectly aligned with the projector’s optical system.

This range of rotation is particularly significant for accurately projecting and analyzing the notch profile from any angle. It allows the notch can be viewed and verified without needing to reposition the entire specimen, thereby saving time and improving the efficiency of the verification process. The 0-360 degree rotation also allows for thorough notch inspection from all perspectives.

Click here to learn more about the product or here to receive a personalized quote.

The Charpy/Izod Notch Verification Projector System - NG-NPS-CIS uses halogen and tungsten lighting with 12V, 100W specification. This type of lighting provides bright, consistent illumination in order to project and view the notch profiles of test specimens from Charpy and Izod in a precise and accurate manner.

It is commonly known that halogen and tungsten lights provide stable and high-intensity light, which is ideal for ensuring that the notches are clearly visible when projected onto the screen, as a result of their stable and high-intensity light output. Clarity is important when measuring and comparing the notches against standard reference charts as this ensures the precise measurement and comparison of the notches. Consistent and bright illumination helps prevent shadows or dim areas on the projection, which could lead to inaccuracies in the verification process.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

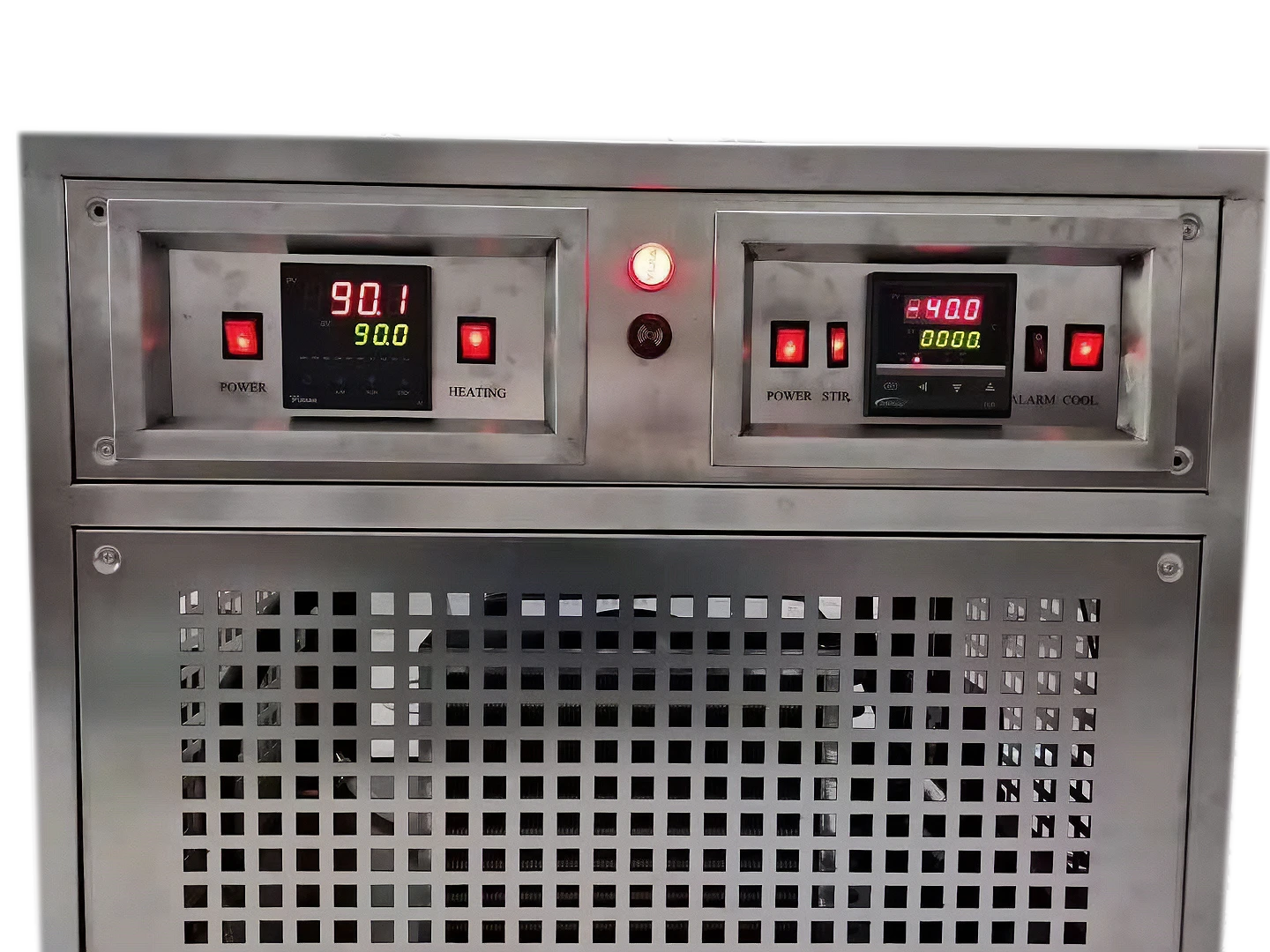

Impact Specimen Cooling Temperature Chamber – NG-ISCC Series

The NG-ISCC Low Temperature Chamber is built to cool and stabilize Charpy impact specimens before testing. It supports conditioning from +30°C down to -60°C, -80°C, -100°C, or -196°C depending on the model. NG-ISCC-60 and NG-ISCC-80 use compressor-based refrigeration, while NG-ISCC-100 and NG-ISCC-196 use liquid nitrogen cooling to achieve ultra-low setpoints. Temperature control accuracy is ≤ ±0.5°C with a 0.01°C instrument resolution, using ethanol or another non-freezing solution as the cooling medium. It is widely used in materials testing and quality control programs to evaluate low-temperature toughness of metals and alloys.

Class J - Charpy and Izod Automatic Impact Testing System - 1J - 50J

Class J is widely used for lzod and Charpy impact test on softer metals, plastics and rubber specimens. Equipped with tensile impact pendulum and fixtures, it can carry on tests on plastic film and sheet. The newly enhanced design offers the most cost-effective configuration to address Charpy test from 1J to 50J (0.7 - 37 ft/lbs), and lzod test from 1J to 22J (0.7 - 16 ft/lbs).

Class D Single-Column Charpy Impact Tester – High-Precision Pendulum Testing Machine

NextGen’s Class D Single-Column Charpy Impact Testing System is built for high rigidity and dependable specimen testing across a wide energy range. It supports impact energies from around 150 J (111 ft-lbs) up to around 750 J (553 ft-lbs), covering most standard metal testing needs. The unit includes a digital display and offers a software upgrade option for data plotting. Additional features, such as automated specimen feeding and integrated cooling or heating systems, are available as optional enhancements.

Class G Single-Column Charpy & Izod Impact Tester – High-Precision Pendulum Testing Machine

NextGen's Class G – Single Column Charpy and Izod Impact Testing system provides a high level of rigidity and specimen testing capacity. This Charpy and Izod Impact tester has a minimum capacity of 150 J (111 ft/lbs) and a maximum capacity of 750 J (553 ft/lbs). The system comes standard with a digital display with software upgrade function for data plotting. The Class G impact system can also include automatic specimen feeding, cooling and heating systems as optional upgrades.

Class H - Servo-Motor Dual Column Charpy Impact Tester - 300J, 450J, 600J or 750J

NextGen's Class H – Servo-Motor Dual Column Charpy Impact Testing system offers of an exceptional combination of versatility and robust build. This impact system provides our most durable options designed with a dual column configuration. The system offers the ultimate versatility of testing 300J (212 ft/lbs), 450J (332 ft/lbs), 600J (442 ft/lbs) and a maximum of 750J (553 ft/lbs) capacities based on both Charpy and Izod test methods. The unit comes standard equipped with a servo motor and is designed to test at any preset angle. The unit comes standard with all the functions of our Class G tester as well as enhanced functionality upgrade of a force transducer inside the strikerwhich enables the determination of characteristic force, energy and displacement parameters such as pre-maximum force energy (Wm), the post maximum force energy, the general yield force (Fgy), the force at brittle fracture initiation (Fbf) and the arrest force (Fa).

Triple Specimen Chamber Motorized Charpy Notch Making Machine

The GenNotch 4000UPG Series is a motorized Charpy & Izod Notch Making Machine with a triple specimen chamber.

Specimen Notching/Broaching Machine

NextGen offers an economical solution for Specimen notching and broaching for Charpy and Izod specimens. This certified system complies with ASTM ISO148, EN10045, ASTM E23, DIN 50115 standards. This automated, motorized solution is capable of preparing two specimens at any one given time up to 46 HRC. A variety of broaches are available for different geometries of notches.

Impact Specimen Cooling and Heating Temperature Chamber – GenChamber

NextGen offers a full range of impact specimen cooling and heating chamber designed to meet virtually all Charpy, Izod and Tensile Impact Testing requirements. NextGen's temperature chambers are a combination of user-friendliness, compact and robust build, offering the ultimate versatility of cooling and heating requirements.

DWT-1800 Computer Controlled Drop Weight Impact Testing Machine

DWT-1800 Impact Testing Machine is specifically designed for determining the non-plastic transformation temperature of ferritic steel.