Metal Testing Equipment

Standards

ISO 148, ASTM E23, ASTM E74 (Class AA)

Description

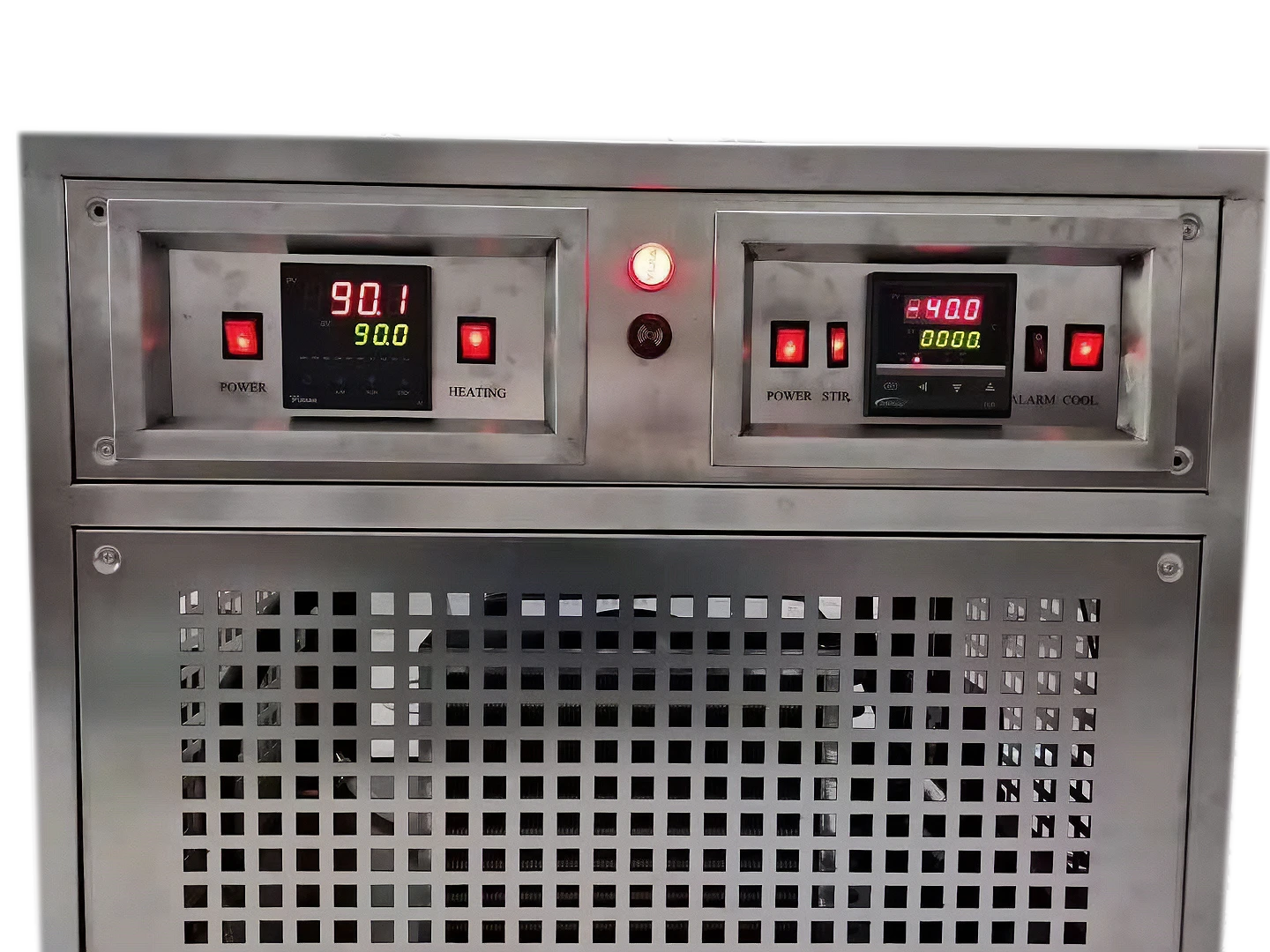

The Impact Specimen Cooling and Heating Temperature Chamber – GenChamber is a high-performance dual-function system engineered for precise temperature conditioning of Charpy and Izod impact specimens. Designed to meet the requirements of ISO 148-1 and ASTM E23, this chamber supports both low-temperature soaking and high-temperature stabilization for metallic materials prior to impact testing.

The low-temperature mode uses an advanced compressor-based refrigeration system combined with thermal equilibrium and circulating stirring mechanisms, delivering automatic cooling and uniform temperature control down to -80°C. This ensures consistent preparation of impact notch specimens and supports repeatable, reliable test results. Built-in safety protections guard against overheating and overcurrent conditions. Additionally, an integrated alarm notifies the user when the target temperature is reached, guaranteeing precise timing for specimen preparation.

The high-temperature function features a durable stainless-steel electric heating system with forced air circulation and internal ventilation for uniform heat distribution. The system is equipped with PID temperature control and offers high-resolution monitoring with a 0.1°C display accuracy, maintaining stable conditions throughout the heating process. A centrifugal fan ensures continuous airflow and temperature uniformity, meeting industry-standard temperature gradient requirements.

This temperature conditioning chamber is ideally suited for materials testing laboratories, research and development facilities, and quality control departments that require consistent and reliable preparation of Charpy and Izod impact test specimens.

Technical Parameters

| Model | GenChamber |

|---|---|

| Range of Control Temperature | Low temperature: +30℃ to -80℃ (ambient temperature ≤ 25°C) High temperature: +30℃ to 100℃ (ambient temperature ≤ 25°C) |

| Temperature Control Accuracy | Low temperature: ≤ ±0.5°C High temperature: < ±1°C |

| Display Resolution | 0.1°C |

| Cooling Speed | +30°C to 0°C: approx. 2°C/min 0°C to -20°C: approx. 1.5°C/min -20°C to -60°C: approx. 1°C/min -60°C to -80°C: approx. 0.7°C/min |

| Heating Speed | +20°C to +50°C: approx. 2°C/min +50°C to +100°C: approx. 3°C/min |

| Working Area (L × W × H) | Low Temperature Chamber: 5.9 × 5.5 × 4.7 in (150 × 140 × 120 mm) High Temperature Chamber: 5.9 × 5.5 × 4.7 in (150 × 140 × 120 mm) |

| Specimen Capacity | 60–120 specimens (Standard size: 10 × 10 × 55 mm) |

| Outer Dimensions (L × W × H) | 25.6 × 20.0 × 29.9 in (650 × 510 × 760 mm) |

| Timer | 1 to 99 minutes, 1-second resolution |

| Cooling Medium | Cooling chamber: Ethyl alcohol (≥ 99.5% purity recommended) Heating chamber: Air |

| Stirring Motor Power | 23 W |

| Power Supply | Single-phase, 110 V, 60 Hz, 2.5 kW |

Standard Configuration

| Model | GenChamber |

|---|---|

| Main Unit | One set |

| Cooling Compressor | One set |

| Stainless Steel Heating Pipes | One set |

| High-Precision Intelligent Temperature Controller | One set |

| Stainless-Steel Inner Chamber | Corrosion-resistant and anti-aging |

| Sample Baskets | 3 pieces for the high-temperature chamber 3 pieces for the low-temperature chamber |

| Power Transformer | Included (110V input to 220V output) |

FAQs

The GenChamber is a temperature conditioning chamber developed for preparing Charpy and Izod impact specimens before testing. It combines low-temperature soaking down to –80 °C with high-temperature stabilization up to +100 °C, allowing materials to be tested under a full range of thermal conditions.

This system is widely used in materials testing laboratories, R&D facilities, and quality control departments. Conditioning specimens before fracture provides reliable data on how metals and other materials behave in both extreme cold and elevated heat, supporting compliance with standards such as ISO 148 and ASTM E23.

Click here to learn more about the product or here to receive a personalized quote.

The GenChamber functions as a dual-purpose system that prepares Charpy and Izod specimens through both cooling and heating cycles. In low-temperature mode, a compressor-based refrigeration system combined with an ethanol cooling medium and stirring mechanism lowers specimens to as cold as –80 °C. In high-temperature mode, stainless steel heating elements with forced air circulation raise specimens up to +100 °C.

The principle is straightforward: specimens are brought to a defined thermal state before impact testing, ensuring that the fracture behavior reflects actual service conditions. By delivering precise and uniform temperature conditioning, the GenChamber allows laboratories to produce consistent and repeatable impact test results across different batches and materials.

Click here to learn more about the product or here to receive a personalized quote.

The GenChamber is manufactured in line with ISO 148, which sets the procedure for Charpy impact testing of metallic materials, and ASTM E23, the widely used American standard for notched-bar impact testing. It also complies with ASTM E74 (Class AA), covering calibration procedures for impact testing equipment to ensure traceable accuracy.

Together, these standards form the backbone of international impact testing practice. Compliance means the chamber can be used in laboratories worldwide without modification, supporting industries that require verified test results for product certification, regulatory approval, and material research.

Click here to learn more about the product or here to receive a personalized quote.

The GenChamber is built for preparing Charpy and Izod impact specimens before testing. It accommodates the standard size of 10 × 10 × 55 mm, which is commonly used across international standards.

The chamber is primarily applied to metallic materials, conditioning impact notch samples to either low or high temperatures before they are fractured under a pendulum impact tester. By stabilizing specimens in controlled environments, the GenChamber helps laboratories achieve repeatable results that align with ISO 148, ASTM E23, and related methods.

Click here to learn more about the product or here to receive a personalized quote.

The GenChamber offers controlled temperature transitions tailored for impact specimen preparation. In cooling mode, the rate varies with the target range: about 2 °C/min from +30 °C to 0 °C, 1.5 °C/min from 0 °C to –20 °C, 1 °C/min from –20 °C to –60 °C, and around 0.7 °C/min from –60 °C to –80 °C.

In heating mode, the system raises the temperature at approximately 2 °C/min between +20 °C and +50 °C and 3 °C/min between +50 °C and +100 °C. These controlled gradients help specimens reach equilibrium without thermal shock.

Click here to learn more about the product or here to receive a personalized quote.

The GenChamber relies on a compressor-based refrigeration system that works with ethyl alcohol as the cooling medium. A stirring mechanism circulates the liquid continuously, helping specimens reach uniform temperatures without localized cold spots.

This system enables cooling down to –80 °C, with stepwise gradients from ambient conditions. The combination of controlled refrigeration, ethanol circulation, and stirring stability makes the chamber suitable for preparing Charpy and Izod specimens in line with ISO and ASTM low-temperature testing requirements.

Click here to learn more about the product or here to receive a personalized quote.

The GenChamber uses a stainless-steel electric heating system paired with forced air circulation to deliver stable and uniform heat. A PID controller regulates temperature changes with high precision, while a centrifugal fan keeps air moving continuously inside the chamber.

This setup prevents localized hot zones and maintains uniform heat distribution across all specimens. The combination of durable heating elements and controlled airflow supports reliable conditioning up to +100 °C, meeting international impact testing requirements.

Click here to learn more about the product or here to receive a personalized quote.

The GenChamber is delivered as a complete system with all the main components required for operation. The cooling compressor handles low-temperature conditioning, while the stainless steel heating pipes manage high-temperature cycles. A high-precision intelligent temperature controller is included for accurate monitoring and adjustment.

For handling specimens, the package provides three baskets for the cooling chamber and three baskets for the heating chamber, allowing batch preparation. The unit also comes with a stainless-steel inner chamber for durability and a power transformer for installations where 220 V conversion is needed.

Click here to learn more about the product or here to receive a personalized quote.

The GenChamber is equipped with a programmable timer that can be set from 1 to 99 minutes with a 1-second resolution. This feature allows operators to define precise soaking times for both cooling and heating cycles, ensuring specimens remain at the required temperature for the correct duration.

Once the programmed time elapses, the chamber completes the cycle automatically, removing the need for manual monitoring. This automation helps laboratories maintain consistent specimen preparation and reduces the risk of variability between batches.

Click here to learn more about the product or here to receive a personalized quote.

The GenChamber includes an integrated alarm system that activates once the target temperature has been reached. This notification alerts the operator that specimens are conditioned and ready for transfer to the impact tester.

The alarm also helps with precise timing, since the interval between reaching the set temperature and starting the impact test is critical for consistent results. By signaling exactly when the chamber is stable, the system reduces guesswork and allows laboratories to follow ISO and ASTM requirements more confidently.

Click here to learn more about the product or here to receive a personalized quote.

The GenChamber maintains temperature consistency through a combination of forced air circulation and a centrifugal fan in the heating chamber, along with a stirring motor in the cooling section. These systems keep air and coolant moving continuously, preventing hot or cold spots from forming around the specimens.

This uniform distribution ensures that all samples inside the chamber reach the same thermal state, whether during rapid cooling down to –80 °C or heating up to +100 °C.

Click here to learn more about the product or here to receive a personalized quote.

The GenChamber features a 0.1 °C display resolution, giving operators fine control over temperature settings and clear visibility of even small fluctuations. In cooling mode, the system maintains accuracy within ±0.5 °C, while in heating mode, it holds stability within ±1 °C.

This level of precision is supported by the chamber’s PID temperature controller and continuous circulation systems, which distribute cold or hot air evenly across the specimen load. As a result, every sample in the chamber experiences the same conditions.

Click here to learn more about the product or here to receive a personalized quote.

The GenChamber runs on a single-phase 110 V, 60 Hz power source with a load capacity of 2.5 kW. This makes it compatible with standard laboratory electrical setups in regions using 110 V mains.

For installations in areas operating on 220 V, a step-down transformer is supplied as part of the standard configuration, so no additional modifications are needed. The system’s electrical design ensures stable performance for both the refrigeration unit and the heating chamber, supporting precise specimen conditioning across the full temperature range.

Click here to learn more about the product or here to receive a personalized quote.

The GenChamber can handle between 60 and 120 specimens in a single cycle, depending on how the baskets are loaded. This capacity is based on the standard Charpy and Izod specimen size of 10 × 10 × 55 mm (0.39 × 0.39 × 2.17 in).

Each chamber is equipped with dedicated sample baskets, allowing multiple specimens to be placed securely during heating or cooling. This setup enables laboratories to prepare large batches consistently, which is especially useful for production testing or certification work where many samples must be processed under identical temperature conditions.

Click here to learn more about the product or here to receive a personalized quote.

Both the high-temperature and low-temperature sections of the GenChamber have identical internal dimensions of 5.9 × 5.5 × 4.7 in (150 × 140 × 120 mm). The chambers are built with a stainless-steel inner structure, which resists corrosion and aging even under repeated exposure to extreme conditions.

This working space is designed to hold multiple Charpy or Izod specimens simultaneously, allowing operators to condition entire batches under the same thermal profile. The combination of uniform chamber size and durable stainless-steel construction helps maintain consistent performance while extending service life.

Click here to learn more about the product or here to receive a personalized quote.

The GenChamber measures 25.6 × 20.0 × 29.9 in (650 × 510 × 760 mm). Its size allows it to sit comfortably on a standard laboratory bench without the need for dedicated floor space. The relatively compact footprint is an advantage for quality control labs and R&D facilities, where multiple instruments often need to be arranged in a limited area.

Both the cooling chamber and the heating chamber have identical internal working spaces of 5.9 × 5.5 × 4.7 in (150 × 140 × 120 mm), large enough to hold between 60 and 120 standard Charpy or Izod specimens at once. This means a lab can prepare an entire batch of samples under controlled conditions in one cycle, improving workflow efficiency.

Click here to learn more about the product or here to receive a personalized quote.

Regular upkeep of the GenChamber is straightforward but important for consistent performance. The coolant in the low-temperature chamber should be checked and replaced periodically to maintain purity and cooling efficiency. Filters and circulation components need routine inspection to prevent blockages that could disrupt airflow or coolant flow. The stainless-steel inner chamber should be wiped clean after use to avoid residue buildup, especially when specimens release particles. A general inspection schedule covering seals, connections, and sensors helps detect wear early, keeping the chamber dependable during repeated test cycles.

Click here to learn more about the product or here to receive a personalized quote.

After purchasing the GenChamber, customers receive access to a full range of after-sales services. This includes availability of spare parts to keep the system running without long downtime, and technical assistance for troubleshooting, calibration, or operator training. The chamber is supported with stocked consumables such as cooling media and accessories, so replacements are easy to source. These service options help laboratories keep the unit in reliable working condition over many years of use.

Click here to learn more about the product or here to receive a personalized quote.

The GenChamber is built with multiple layers of protection to keep both users and specimens safe. It features overheat protection to stop the heating system if the temperature rises beyond set limits, and overcurrent protection to shield electrical components from power surges. The chamber itself has a closed stainless-steel design, keeping the operator separated from the cooling medium and heated space during operation. An integrated alarm system signals when the set temperature is reached or if conditions deviate, giving clear feedback to the user and preventing misuse.

Click here to learn more about the product or here to receive a personalized quote.

The GenChamber includes a warranty that covers both mechanical and electrical components. Mechanical parts, such as door mechanisms, chamber body, and moving joints, are protected under this warranty. Electrical items like the controller, sensors, motor, and display are covered for a defined period as well.

After sales, users have access to technical assistance, spare parts, and service options. These cover repairs, component replacement, and support for calibration or compliance verification.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

Impact Specimen Cooling Temperature Chamber – NG-ISCC Series

The NG-ISCC Low Temperature Chamber is built to cool and stabilize Charpy impact specimens before testing. It supports conditioning from +30°C down to -60°C, -80°C, -100°C, or -196°C depending on the model. NG-ISCC-60 and NG-ISCC-80 use compressor-based refrigeration, while NG-ISCC-100 and NG-ISCC-196 use liquid nitrogen cooling to achieve ultra-low setpoints. Temperature control accuracy is ≤ ±0.5°C with a 0.01°C instrument resolution, using ethanol or another non-freezing solution as the cooling medium. It is widely used in materials testing and quality control programs to evaluate low-temperature toughness of metals and alloys.

Class J - Charpy and Izod Automatic Impact Testing System - 1J - 50J

Class J is widely used for lzod and Charpy impact test on softer metals, plastics and rubber specimens. Equipped with tensile impact pendulum and fixtures, it can carry on tests on plastic film and sheet. The newly enhanced design offers the most cost-effective configuration to address Charpy test from 1J to 50J (0.7 - 37 ft/lbs), and lzod test from 1J to 22J (0.7 - 16 ft/lbs).

Class D Single-Column Charpy Impact Tester – High-Precision Pendulum Testing Machine

NextGen’s Class D Single-Column Charpy Impact Testing System is built for high rigidity and dependable specimen testing across a wide energy range. It supports impact energies from around 150 J (111 ft-lbs) up to around 750 J (553 ft-lbs), covering most standard metal testing needs. The unit includes a digital display and offers a software upgrade option for data plotting. Additional features, such as automated specimen feeding and integrated cooling or heating systems, are available as optional enhancements.

Class G Single-Column Charpy & Izod Impact Tester – High-Precision Pendulum Testing Machine

NextGen's Class G – Single Column Charpy and Izod Impact Testing system provides a high level of rigidity and specimen testing capacity. This Charpy and Izod Impact tester has a minimum capacity of 150 J (111 ft/lbs) and a maximum capacity of 750 J (553 ft/lbs). The system comes standard with a digital display with software upgrade function for data plotting. The Class G impact system can also include automatic specimen feeding, cooling and heating systems as optional upgrades.

Class H - Servo-Motor Dual Column Charpy Impact Tester - 300J, 450J, 600J or 750J

NextGen's Class H – Servo-Motor Dual Column Charpy Impact Testing system offers of an exceptional combination of versatility and robust build. This impact system provides our most durable options designed with a dual column configuration. The system offers the ultimate versatility of testing 300J (212 ft/lbs), 450J (332 ft/lbs), 600J (442 ft/lbs) and a maximum of 750J (553 ft/lbs) capacities based on both Charpy and Izod test methods. The unit comes standard equipped with a servo motor and is designed to test at any preset angle. The unit comes standard with all the functions of our Class G tester as well as enhanced functionality upgrade of a force transducer inside the strikerwhich enables the determination of characteristic force, energy and displacement parameters such as pre-maximum force energy (Wm), the post maximum force energy, the general yield force (Fgy), the force at brittle fracture initiation (Fbf) and the arrest force (Fa).

Triple Specimen Chamber Motorized Charpy Notch Making Machine

The GenNotch 4000UPG Series is a motorized Charpy & Izod Notch Making Machine with a triple specimen chamber.

Specimen Notching/Broaching Machine

NextGen offers an economical solution for Specimen notching and broaching for Charpy and Izod specimens. This certified system complies with ASTM ISO148, EN10045, ASTM E23, DIN 50115 standards. This automated, motorized solution is capable of preparing two specimens at any one given time up to 46 HRC. A variety of broaches are available for different geometries of notches.

Charpy/Izod Notch Verification Projector System NG-NPS-CIS

Enhance your material testing accuracy with our advanced Charpy/Izod Notch Verification Projector System NG-NPS-CIS.

DWT-1800 Computer Controlled Drop Weight Impact Testing Machine

DWT-1800 Impact Testing Machine is specifically designed for determining the non-plastic transformation temperature of ferritic steel.