Metal Testing Equipment

Standards

ISO 148, EN10045, ASTM E23, DIN 50115, ASTM E74 (Class AA)

Description

The GenNotch 4000UPG Series is a triple specimen chamber motorized Charpy Notch Making Machine designed specifically for creating Charpy Test notch specimens. This floor placed stand-alone machine, comes with an easy-to-use interface for simple operation. The GenNotch 4000UPG is built to cut Charpy and Izod notches in both V-type and U-type shapes. It produces industry standards complied top-quality notched samples comparable to those made with a milling machine.

GenNotch 4000UPG Series -Triple Charpy Notch Making Machine Technical Specification

|

GenNotch 4000UPG |

|

|

Broacher Travel |

340±10mm |

|

# of Samples at one cycle time |

3 |

|

Speed |

2-3m/min |

|

Lubrication System |

Lubricating oil circulation, the oil is interchangeable |

|

Hydraulic Oil |

L-HM46 (Anti-wear) |

|

Oil Volume |

20L |

|

Power Consumption |

450W |

|

PowerRequirements |

3-phase, 5-line, AC 220V±10%, 50/60Hz |

|

Machine Dimension (LxWxH) |

27.16 x 25.6 x 61.0-inches / 69 x 65 x 155 cm |

|

Weight |

562lbs / 255kg |

Test Specimens

-

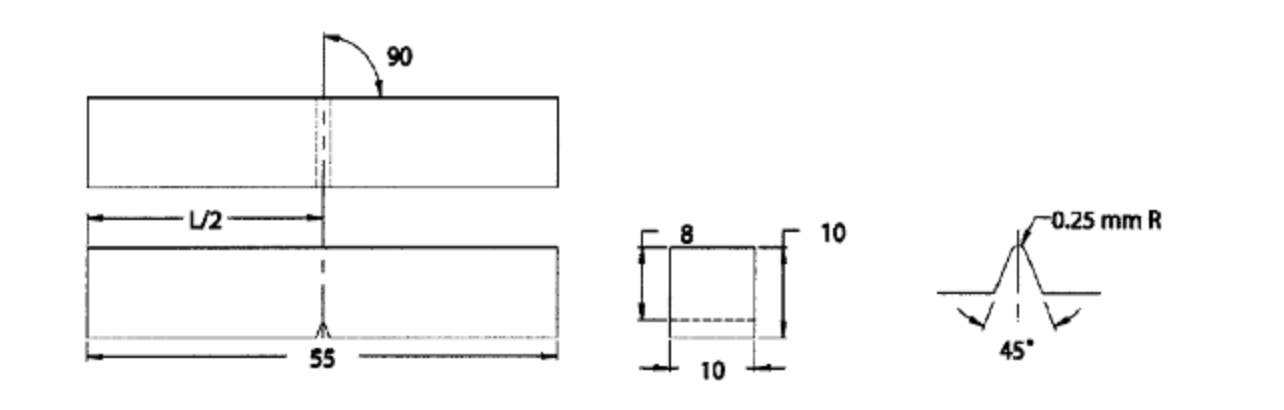

Specimen size: 10x10(7.5, 5, 2.5) x55mm

-

Specimen hardness≤HRC34 Specimen tensile strength: <600MPa

-

If hardness ≤42HRC, M42 material for broacher knife will be used. For higher strength than 600MPa, the broacher knife will be customized and customer need provide specimen.

Notch Type

-

V2 type (ISO148) and Type A (ASTM E23)

-

U5 type (ISO148, GB/T229, Gost 9454) and Type C (ASTM E23), non-standard type, short using life, no warranty

Notching Options

-

U2: depth 2mm, width 2mm, r=1mm±0.05mm, comply with GB/T229, Gost 9454

-

U3: depth 3mm, width 2mm, r=1mm±0.05mm, comply with Gost 9454

FAQs

The GenNotch 4000UPG is specifically designed for preparing Charpy and Izod impact test specimens by cutting precision V- and U-type notches. These notches play a critical role in impact testing, as they act as controlled points of stress concentration that allow engineers to evaluate a material’s toughness, ductility, and energy absorption characteristics under sudden loading conditions.

By using a motorized broaching mechanism, the machine produces uniform and repeatable notches that meet international testing standards such as ISO 148 and ASTM E23. The consistent quality of these notches means that impact test results accurately reflect the true performance of the material, minimizing measurement errors caused by geometric inconsistencies.

Click here to learn more about the product or here to receive a personalized quote.

The GenNotch 4000UPG is equipped with a triple-specimen chamber, allowing three samples to be prepared simultaneously in a single cutting cycle. This configuration significantly improves laboratory productivity by reducing preparation time while maintaining uniform quality across all specimens.

Each specimen is securely positioned within its chamber to ensure precise alignment and consistent notch geometry. The synchronized broaching mechanism applies equal pressure and motion to all three samples, guaranteeing identical results in terms of notch depth, surface finish, and profile accuracy.

Click here to learn more about the product or here to receive a personalized quote.

The GenNotch 4000UPG is designed to accommodate standard Charpy and Izod test specimens used in impact testing worldwide. It supports specimens measuring 0.39 × 0.39 × 2.16 inches (10 × 10 × 55 mm), as well as sub-size samples with reduced thicknesses of 7.5 mm (0.29 in), 5 mm (0.20 in), and 2.5 mm (0.10 in).

These specimen sizes fully comply with international standards such as ISO 148, ASTM E23, and DIN 50115, ensuring compatibility across various testing systems. The machine maintains tight dimensional tolerances and smooth surface finishes to guarantee accurate and repeatable impact results.

Click here to learn more about the product or here to receive a personalized quote.

The GenNotch 4000UPG is capable of producing both V-type and U-type notches that meet international Charpy and Izod testing standards. It supports V-type notches in accordance with ISO 148 and ASTM E23 Type A, ensuring precise geometry for standard impact testing applications. The machine also accommodates U-type notches, compliant with ISO 148, GB/T 229, GOST 9454, and ASTM E23 Type C specifications.

In addition to these standard configurations, the system can produce non-standard U5 notches when required for specialized research or comparative testing. However, because of their deeper geometry and increased tool stress, U5 notches have a shorter tool life and are not covered under warranty.

Click here to learn more about the product or here to receive a personalized quote.

The GenNotch 4000UPG complies with a range of international standards, allowing it to be used confidently in laboratories conducting Charpy and Izod impact testing across the globe. The system fully meets the requirements of ISO 148, EN 10045, ASTM E23, DIN 50115, and ASTM E74 (Class AA).

These standards define the dimensional tolerances, notch geometries, and testing procedures for impact specimens used in metallic material testing. Compliance ensures that the specimens produced by the GenNotch 4000UPG maintain precise notch depth, root radius, and alignment consistent with certified global testing methods.

Click here to learn more about the product or here to receive a personalized quote.

The GenNotch 4000UPG provides a broacher travel distance of 13.38 ± 0.39 inches (340 ± 10 mm), ensuring full and accurate motion for precise notch formation across various specimen sizes. The system operates at a fixed cutting speed of 6.5–9.8 feet per minute (2–3 meters per minute), which has been optimized to balance cutting efficiency and surface quality.

This stable operating speed prevents tool vibration, minimizes heat buildup, and ensures that each notch maintains the correct geometry and smooth finish required by international testing standards.

Click here to learn more about the product or here to receive a personalized quote.

The GenNotch 4000UPG is designed to handle a wide range of metallic materials commonly used in Charpy and Izod impact testing. It can efficiently process specimens with a hardness of up to HRC 34 or a tensile strength below 600 MPa, producing precise V- and U-type notches that comply with international standards.

For materials with higher hardness, up to HRC 42, the system uses an M42 broacher knife, a high-speed steel tool known for its excellent wear resistance and durability. When testing extremely tough or high-strength alloys that exceed these limits, a custom-engineered knife is required. In such cases, the client is asked to provide sample specimens so that NextGen’s engineering team can design and validate the appropriate cutting configuration.

Click here to learn more about the product or here to receive a personalized quote.

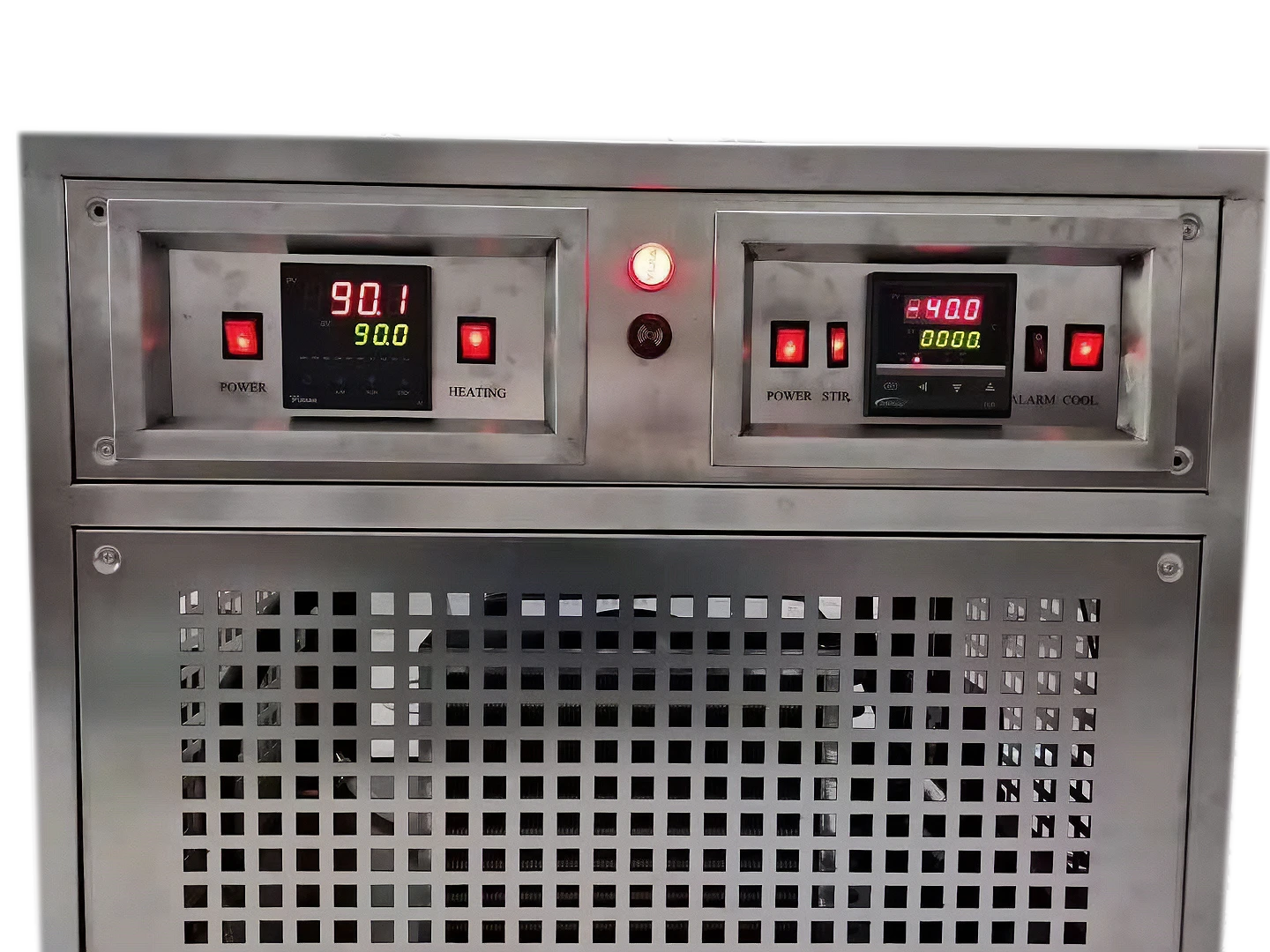

The GenNotch 4000UPG operates on a three-phase, five-line power supply rated at 220 V ±10%, 50/60 Hz, making it suitable for use in laboratories with standard industrial electrical configurations. The system is driven by a 450-watt motor, which provides steady power for the motorized broaching process while maintaining low energy consumption and minimal operational noise.

A stable and properly grounded electrical connection is essential for optimal performance and operator safety. Voltage fluctuations or incorrect wiring can affect cutting precision and system reliability.

It is recommended that installation be carried out by a qualified technician.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenNotch 4000UPG is equipped with a fully automatic circulating lubrication system designed to maintain optimal cutting performance and prolong the life of internal components. The system uses L-HM46 anti-wear hydraulic oil with a total capacity of 5.28 gallons (20 liters), ensuring consistent lubrication throughout each broaching cycle.

This closed-loop oil circulation system minimizes friction between moving parts, keeps the cutting area clean, and helps maintain stable operating pressure. Regular inspection of oil levels and scheduled replacement are recommended to sustain smooth operation and reliable performance over time.

Click here to learn more about the product or here to receive a personalized quote.

The GenNotch 4000UPG is a compact yet durable floor-mounted system designed for stable operation and easy placement in laboratory environments. The machine’s overall dimensions are 27.16 × 25.6 × 61.0 inches (69 × 65 × 155 cm), allowing it to fit comfortably within most testing spaces while providing sufficient room for operator access and maintenance.

It has a total weight of approximately 562 lbs (255 kg), which contributes to its vibration stability during broaching operations. The solid construction ensures consistent notch accuracy even during continuous or heavy-duty use.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenNotch 4000UPG is fully compatible with a wide range of Charpy and Izod impact testing systems that adhere to international standards such as ISO 148, ASTM E23, and DIN 50115. The specimens produced by this machine maintain precise notch geometry and surface finish, allowing seamless integration with both NextGen’s own pendulum impact testers and other compliant testing instruments.

This compatibility means that laboratories can prepare samples using the GenNotch 4000UPG and test them across various certified impact testing machines without adjustment or reconfiguration.

Click here to learn more about the product or here to receive a personalized quote.

The accuracy of notches produced by the GenNotch 4000UPG can be verified through precise optical measurement and projection methods. Laboratories typically use optical profile projectors, measuring microscopes, or digital image analysis systems to assess notch geometry, including depth, angle, and root radius. These tools allow for non-destructive verification and provide highly detailed visual confirmation of compliance with international standards such as ISO 148 and ASTM E23.

NextGen offers optical measurement systems and certified accessories specifically designed for Charpy and Izod specimen validation. These instruments help laboratories confirm that each notch meets the required dimensional tolerances before conducting impact testing.

Click here to learn more about the product or here to receive a personalized quote.

Routine maintenance of the GenNotch 4000UPG is essential to preserve precision, reliability, and long-term performance. Operators should regularly check hydraulic oil levels, inspect the oil’s clarity, and replace it approximately every six to twelve months, depending on usage and environmental conditions. Maintaining clean, properly circulated oil helps prevent system wear and ensures smooth broaching motion.

The broacher assembly and cutting chamber should be cleaned periodically to remove metal shavings or residue that could affect cutting accuracy. The broacher knife must also be examined for sharpness and replaced when signs of dulling or uneven wear appear.

Lubrication is a key factor in consistent operation. The integrated oil-circulation system should be monitored for proper flow and pressure to guarantee stable performance.

Click here to learn more about the product or here to receive a personalized quote.

The service life of the broacher knife depends primarily on the hardness and tensile strength of the specimens being processed. Under standard operating conditions, typically with specimens below HRC 34, a single knife can produce several thousand notched samples before requiring replacement. Consistent lubrication, proper alignment, and regular cleaning further extend tool life and maintain notch precision.

When working with harder materials or specimens that approach the upper hardness limits, wear on the cutting edges increases, leading to shorter operational cycles. In such cases, the knife should be inspected more frequently for dullness or surface damage.

NextGen offers replacement broacher knives manufactured from high-performance materials such as M42 tool steel, which provides excellent wear resistance and maintains sharpness even under demanding conditions.

Click here to learn more about the product or here to receive a personalized quote.

Yes, NextGen supplies a full range of replacement knives and consumables for the GenNotch 4000UPG to maintain consistent cutting quality and system reliability. All consumables are precision-manufactured and tested to ensure compatibility with the original machine specifications.

Available items include replacement broacher knives, hydraulic oils, seals, and key mechanical components such as filters and lubrication fittings. For laboratories requiring verified quality control, NextGen also provides NIST-certified consumables, ensuring traceability and compliance with international standards.

Customers can order parts directly through NextGen’s technical sales team or authorized distributors. Stocked items are typically available for quick shipment, minimizing downtime and allowing laboratories to maintain uninterrupted operation of their notch preparation and testing processes.

Click here to learn more about the product or here to receive a personalized quote.

NextGen provides lifetime technical support for all GenNotch 4000UPG systems, ensuring continuous performance and reliability throughout the equipment’s service life. Customers have access to dedicated support specialists who assist with troubleshooting, maintenance guidance, and system optimization.

Technical assistance includes help with diagnostics, spare parts replacement, and remote consultations for resolving operational or calibration issues. In addition, NextGen supplies detailed technical documentation, including manuals, service guides, and reference materials, to assist laboratory personnel in maintaining proper operation.

For new installations or staff onboarding, on-site or remote operator training sessions can be arranged to familiarize users with system operation, maintenance routines, and safety best practices.

Click here to learn more about the product or here to receive a personalized quote.

Yes, NextGen provides professional calibration and certification services to ensure that every testing setup meets international accuracy and traceability standards. The company performs calibration for impact testing systems, force-measuring instruments, and related accessories in accordance with recognized procedures and reference materials.

All calibration work is carried out using equipment traceable to NIST (National Institute of Standards and Technology), guaranteeing verified measurement accuracy. This allows laboratories to maintain full compliance with standards such as ISO 148, ASTM E23, and ASTM E74.

In addition to calibration, NextGen offers certified consumables and verification specimens that help users validate machine performance over time. Each calibration service is accompanied by detailed documentation, including certificates of conformity and measurement uncertainty data, supporting complete audit and accreditation requirements.

Click here to learn more about the product or here to receive a personalized quote.

Although the GenNotch 4000UPG is designed with a simple and intuitive control interface, operator training is highly recommended to achieve consistent and reliable results. Training helps users understand proper specimen alignment, notch positioning, and system operation, ensuring that each sample meets international testing standards.

During the training process, operators learn how to monitor broaching speed, verify notch geometry, and maintain optimal lubrication and oil levels. They are also instructed on routine cleaning, tool replacement, and safety procedures to prevent operational errors or equipment wear.

For new installations, NextGen can provide on-site or remote training sessions tailored to the laboratory’s workflow and testing requirements. This structured instruction allows operators to become confident in using the machine effectively while maintaining precision, safety, and long-term system reliability.

Click here to learn more about the product or here to receive a personalized quote.

The GenNotch 4000UPG is equipped with several built-in safety features designed to protect both the operator and the machine during operation. The cutting process takes place within a fully enclosed chamber that prevents accidental contact with moving components and contains metal fragments or oil mist produced during broaching.

Automatic pressure regulation ensures stable hydraulic performance and prevents system overload, reducing the risk of mechanical failure. The integrated oil-circulation control continuously monitors lubrication flow and temperature, maintaining safe operating conditions and extending component life.

Additionally, the machine includes emergency stop functionality, electrical overload protection, and interlock systems that prevent operation if the chamber door is open or improperly secured.

Click here to learn more about the product or here to receive a personalized quote.

The GenNotch 4000UPG should be installed on a stable, level surface capable of supporting its total weight of approximately 562 lbs (255 kg). The installation area must provide enough clearance on all sides for daily operation, inspection, and maintenance tasks. It is recommended to keep at least 24 inches (60 cm) of free space around the machine to ensure safe specimen handling and proper ventilation.

A stable three-phase power supply of AC 220 V ±10%, 50/60 Hz is required for consistent performance. The electrical circuit must be properly grounded to prevent voltage fluctuations and ensure safe operation. Clean oil circulation is also critical, so the surrounding area should remain free from excessive dust, humidity, or chemical vapors that could contaminate the lubrication system.

Click here to learn more about the product or here to receive a personalized quote.

Under normal laboratory operating conditions, the hydraulic oil in the GenNotch 4000UPG should be replaced approximately every 6 to 12 months. This interval may vary depending on the frequency of use, ambient temperature, and cleanliness of the working environment.

Regular oil maintenance is essential to preserve the efficiency of the lubrication and hydraulic systems. Over time, oil can accumulate fine metal particles and impurities that reduce its protective properties and increase component wear. Before each replacement, the oil level and clarity should be inspected through the system’s viewing port or dipstick.

When performing an oil change, it is recommended to use the specified L-HM46 anti-wear hydraulic oil or an equivalent grade to maintain smooth broacher motion and stable pressure control. Proper oil management not only extends the service life of internal components but also ensures consistent cutting precision and smooth operation.

Click here to learn more about the product or here to receive a personalized quote.

The GenNotch 4000UPG should be operated in a clean, dry, and stable laboratory environment to maintain optimal performance and longevity. The recommended ambient temperature range is between 10 °C and 35 °C, with relative humidity kept at moderate levels to prevent condensation or corrosion on metal components.

The machine should be placed on a solid, level surface away from sources of vibration, dust, or direct airflow from air-conditioning systems. Excessive humidity, unstable voltage, or strong mechanical shocks may affect cutting precision and wear resistance of the broacher knife.

For storage, the system should be kept covered in a temperature-controlled room, ideally between 5 °C and 40 °C. Before extended periods of non-use, it is recommended to drain the oil, clean the cutting chamber, and apply a thin layer of protective lubricant to prevent oxidation of critical parts.

Click here to learn more about the product or here to receive a personalized quote.

Yes, NextGen offers complete installation and setup services for the GenNotch 4000UPG to ensure proper system operation from the very beginning. Upon delivery, qualified technicians can perform on-site installation, alignment, and initial calibration to verify that the system is functioning according to specifications.

During installation, operators receive familiarization training covering machine operation, maintenance procedures, and safety guidelines. This helps laboratory staff quickly gain confidence in using the equipment and maintain optimal performance during routine operation.

For international customers or facilities with remote locations, NextGen also provides virtual installation support. Through video guidance and detailed documentation, the technical team assists clients step-by-step with setup and configuration.

Click here to learn more about the product or here to receive a personalized quote.

The choice of knife depends on the hardness and tensile strength of the specimen material. For most standard applications, where specimen hardness does not exceed HRC 42, an M42 broacher knife is the ideal choice. This tool steel offers excellent wear resistance and maintains sharpness through repeated use, ensuring precise and smooth notch formation.

When working with materials that exceed 600 MPa in tensile strength or have higher hardness values, a customized knife configuration is recommended. In such cases, NextGen’s engineering team analyzes the provided specimen samples to design a broacher knife with the appropriate material composition, geometry, and cutting angle.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenNotch 4000UPG is fully compatible with low-temperature testing setups commonly used in impact testing laboratories. Specimens prepared with this system can be conditioned in cryogenic or sub-zero temperature chambers before being tested on Charpy or Izod impact testers.

The precision of the notches produced by the GenNotch 4000UPG ensures that results remain consistent and reliable even when tests are performed under extreme temperature conditions. The specimens meet the dimensional and surface finish requirements outlined in ISO 148 and ASTM E23, which regulate low-temperature impact testing procedures.

Click here to learn more about the product or here to receive a personalized quote.

The GenNotch 4000UPG stands apart from manual or single-specimen notch cutters through its advanced automation, productivity, and precision. Its motorized broaching mechanism delivers a uniform cutting speed that ensures consistent notch geometry across all specimens, reducing variability caused by manual operation.

The triple-specimen chamber allows three samples to be processed simultaneously, significantly increasing throughput and minimizing preparation time in high-volume testing environments. The integrated oil-circulation system keeps the cutting area lubricated, improving surface finish, extending tool life, and reducing the need for frequent maintenance.

In contrast to manual machines, which rely heavily on operator skill and physical effort, the GenNotch 4000UPG provides stable, repeatable performance with minimal user input.

Click here to learn more about the product or here to receive a personalized quote.

The standard delivery package of the GenNotch 4000UPG includes all essential components required for immediate installation and operation. Each system comes with the main unit, an integrated control system, and a complete oil circulation assembly to maintain optimal lubrication during cutting.

A factory-calibrated broacher knife set is provided to ensure precise notch formation from the first use. The package also contains a starter spare parts kit with commonly replaced components and a detailed operation manual with setup, maintenance, and safety instructions.

For laboratories requiring additional accessories or consumables, extra broacher knives, oils, or replacement parts can be ordered separately. This comprehensive package enables users to begin producing standardized notched specimens immediately after installation, minimizing setup time.

Click here to learn more about the product or here to receive a personalized quote.

NextGen provides comprehensive after-sales support to guarantee long-term reliability and user confidence in every installed unit. Clients benefit from lifetime product assistance, meaning technical help is always available for troubleshooting, maintenance, or performance optimization.

The company maintains a steady inventory of consumables and spare parts, allowing quick replacement and minimal downtime during operation. Each customer also receives access to NextGen’s technical specialists, who can assist remotely or on-site with installation, calibration, and operator training.

In addition to this, all systems are covered by a global warranty program that reflects NextGen’s commitment to product quality and ongoing customer care. This combination of lifetime support, stocked consumables, and professional guidance ensures that laboratories can operate the GenNotch 4000UPG efficiently and confidently for years to come.

Click here to learn more about the product or here to receive a personalized quote.

No, the GenNotch 4000UPG does not require any external software integration. It is a fully self-contained, floor-mounted system designed for direct and independent operation. The built-in control interface allows operators to manage all cutting parameters, speed adjustments, and specimen cycles without the need for a connected computer or additional software.

This simplified design minimizes setup time and eliminates compatibility concerns that can arise with third-party software. It also enhances reliability, as all operations are handled directly through the system’s intuitive control panel.

Click here to learn more about the product or here to receive a personalized quote.

Yes, NextGen offers upgraded versions of the GenNotch 4000UPG series that provide higher levels of automation, control, and operator safety. These modernized systems are designed to deliver faster specimen preparation, reduced maintenance, and improved consistency for high-volume testing environments.

The newer-generation models include refined motorized components, enhanced lubrication systems, and advanced control panels with intuitive digital interfaces. They also feature updated safety enclosures and more efficient energy management, ensuring long-term reliability and compliance with current laboratory standards.

Customers can contact NextGen’s technical sales team to receive recommendations on the most suitable upgraded model for their testing requirements, including details on performance improvements, available configurations, and integration options with existing laboratory equipment.

Click here to learn more about the product or here to receive a personalized quote.

Yes, NextGen can fully adapt the GenNotch 4000UPG to meet unique operational or research needs. Each customization begins with an assessment of the client’s testing objectives, sample types, and production environment. From there, NextGen’s engineering team develops tailored solutions to enhance efficiency, precision, or automation levels.

Custom configurations may include special broacher knife geometries, adjustable cutting depths, or reinforced cutting assemblies for working with harder or unconventional materials. For high-volume laboratories, the system can also be equipped with automated sample handling, integrated oil-circulation monitoring, or digital data tracking for seamless workflow integration.

Click here to learn more about the product or here to receive a personalized quote.

Yes, NextGen provides worldwide delivery for all equipment, accessories, and consumables. Every shipment includes complete export documentation, such as CE certification, conformity paperwork, and detailed operation manuals.

The products are securely packaged according to international freight and safety standards, ensuring safe transport by air, sea, or ground. NextGen’s logistics team coordinates with global freight partners to handle customs clearance, insurance, and tracking, offering clients a smooth and transparent delivery experience.

Click here to learn more about the product or here to receive a personalized quote.

The GenNotch 4000UPG stands out for its combination of precision, productivity, and international compliance. It features a triple-specimen chamber, allowing simultaneous preparation of three Charpy or Izod samples in one cycle, greatly improving efficiency and repeatability. Its motorized broaching system provides uniform notch geometry and consistent cutting speed, reducing operator influence and human error. The integrated oil-lubricated mechanism ensures smooth operation, extended tool life, and reduced maintenance requirements.

Beyond mechanical performance, the GenNotch 4000UPG is fully compliant with ISO 148, EN 10045, ASTM E23, DIN 50115, and ASTM E74 (Class AA) standards, guaranteeing global test compatibility. This makes it a dependable choice for both production and research laboratories seeking reliable notch accuracy, long-term operational stability, and traceable results that meet international quality expectations.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenNotch 4000UPG is capable of producing notched specimens whose geometry and force-related preparation steps align with calibration practices consistent with ASTM E74, including the more stringent demands of Class AA verified range standards. Its precise machining and control systems support producing specimens whose associated force calibrations can satisfy the lower uncertainty limits demanded by Class AA.

ASTM E74 is a standard that defines practices for calibration and verification of static force-measuring instruments (such as load cells, dynamometers, and force transducers) used in materials testing machines. In the context of Class AA, instruments must maintain a lower limit factor (LLF) whose error does not exceed 0.05 % of applied force, and the verified loading range must begin at 2000 × LLF up to the full capacity. The standard ensures high accuracy and traceability to primary force standards, minimizing measurement uncertainty in critical calibration steps.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenNotch 4000UPG is engineered to support specimen notches and tolerances consistent with DIN 50115 requirements, enabling preparation of notched specimens in line with that German impact testing standard.

DIN 50115 is a German standard for notched bar impact bending tests on metallic materials (Kerbschlagbiegeversuch). It defines specimen dimensions, notch types (V and U), test conditions, energy absorption measurement, and procedures for conducting the impact test. DIN 50115 has historically aligned with ISO/R 83 and ISO/R 148 formats, prescribing impact hammer speeds (e.g. about 5 to 5.5 m/s for certain energy ranges), specimen placement, and reporting of absorbed energy. Over time, DIN 50115 has been withdrawn and replaced by international standards (notably ISO 148 series) but remains relevant when dealing with legacy test data or conformity to formerly adopted German norms.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenNotch 4000UPG is designed to produce notched specimens that conform to EN 10045-1 test method requirements, allowing you to perform Charpy impact tests under that European standard.

EN 10045-1 (1990) is the European standard defining the Charpy impact test method (with U- and V-notches) for metallic materials. It specifies the required specimen geometry (standard length of 55 mm, square cross-section 10 × 10 mm or reduced widths of 7.5 mm or 5 mm), the notch types (V notch, U notch) and their dimensions and tolerances, and machine test conditions such as striker energy, specimen placement, and reporting. It also pairs with EN 10045-2, which addresses verification of the pendulum impact testing machines. Because EN 10045-1 has been made inactive or superseded in many regions (often replaced by ISO 148 series), it is commonly regarded as historically important and still relevant for interpreting older test data and legacy compliance.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenNotch 4000UPG is designed to fully comply with ISO 148-1 (Metallic materials — Charpy pendulum impact test, Part 1: Test method). It prepares V- and U-notches meeting the dimensional and positional tolerances stipulated in that standard, ensuring the specimens produced are suitable for ISO-compliant Charpy impact testing.

The ISO 148-1 standard defines the methodology for conducting Charpy impact tests on metallic materials. It specifies standard specimen dimensions (for example, 55 mm length, 10 × 10 mm cross-section for full size, and alternate thicknesses of 7.5, 5.0 or 2.5 mm), the placement and geometry of V and U notches, and requirements for temperature control and time limits during specimen transfer to the impact tester. The standard ensures that tests across different labs are comparable by standardizing specimen preparation, notch geometry, test temperature conditions, and procedural timing. The GenNotch 4000UPG’s capabilities align with these requirements to deliver consistent ISO-conformant notched specimens.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

Impact Specimen Cooling Temperature Chamber – NG-ISCC Series

The NG-ISCC Low Temperature Chamber is built to cool and stabilize Charpy impact specimens before testing. It supports conditioning from +30°C down to -60°C, -80°C, -100°C, or -196°C depending on the model. NG-ISCC-60 and NG-ISCC-80 use compressor-based refrigeration, while NG-ISCC-100 and NG-ISCC-196 use liquid nitrogen cooling to achieve ultra-low setpoints. Temperature control accuracy is ≤ ±0.5°C with a 0.01°C instrument resolution, using ethanol or another non-freezing solution as the cooling medium. It is widely used in materials testing and quality control programs to evaluate low-temperature toughness of metals and alloys.

Class J - Charpy and Izod Automatic Impact Testing System - 1J - 50J

Class J is widely used for lzod and Charpy impact test on softer metals, plastics and rubber specimens. Equipped with tensile impact pendulum and fixtures, it can carry on tests on plastic film and sheet. The newly enhanced design offers the most cost-effective configuration to address Charpy test from 1J to 50J (0.7 - 37 ft/lbs), and lzod test from 1J to 22J (0.7 - 16 ft/lbs).

Class D Single-Column Charpy Impact Tester – High-Precision Pendulum Testing Machine

NextGen’s Class D Single-Column Charpy Impact Testing System is built for high rigidity and dependable specimen testing across a wide energy range. It supports impact energies from around 150 J (111 ft-lbs) up to around 750 J (553 ft-lbs), covering most standard metal testing needs. The unit includes a digital display and offers a software upgrade option for data plotting. Additional features, such as automated specimen feeding and integrated cooling or heating systems, are available as optional enhancements.

Class G Single-Column Charpy & Izod Impact Tester – High-Precision Pendulum Testing Machine

NextGen's Class G – Single Column Charpy and Izod Impact Testing system provides a high level of rigidity and specimen testing capacity. This Charpy and Izod Impact tester has a minimum capacity of 150 J (111 ft/lbs) and a maximum capacity of 750 J (553 ft/lbs). The system comes standard with a digital display with software upgrade function for data plotting. The Class G impact system can also include automatic specimen feeding, cooling and heating systems as optional upgrades.

Class H - Servo-Motor Dual Column Charpy Impact Tester - 300J, 450J, 600J or 750J

NextGen's Class H – Servo-Motor Dual Column Charpy Impact Testing system offers of an exceptional combination of versatility and robust build. This impact system provides our most durable options designed with a dual column configuration. The system offers the ultimate versatility of testing 300J (212 ft/lbs), 450J (332 ft/lbs), 600J (442 ft/lbs) and a maximum of 750J (553 ft/lbs) capacities based on both Charpy and Izod test methods. The unit comes standard equipped with a servo motor and is designed to test at any preset angle. The unit comes standard with all the functions of our Class G tester as well as enhanced functionality upgrade of a force transducer inside the strikerwhich enables the determination of characteristic force, energy and displacement parameters such as pre-maximum force energy (Wm), the post maximum force energy, the general yield force (Fgy), the force at brittle fracture initiation (Fbf) and the arrest force (Fa).

Specimen Notching/Broaching Machine

NextGen offers an economical solution for Specimen notching and broaching for Charpy and Izod specimens. This certified system complies with ASTM ISO148, EN10045, ASTM E23, DIN 50115 standards. This automated, motorized solution is capable of preparing two specimens at any one given time up to 46 HRC. A variety of broaches are available for different geometries of notches.

Impact Specimen Cooling and Heating Temperature Chamber – GenChamber

NextGen offers a full range of impact specimen cooling and heating chamber designed to meet virtually all Charpy, Izod and Tensile Impact Testing requirements. NextGen's temperature chambers are a combination of user-friendliness, compact and robust build, offering the ultimate versatility of cooling and heating requirements.

Charpy/Izod Notch Verification Projector System NG-NPS-CIS

Enhance your material testing accuracy with our advanced Charpy/Izod Notch Verification Projector System NG-NPS-CIS.

DWT-1800 Computer Controlled Drop Weight Impact Testing Machine

DWT-1800 Impact Testing Machine is specifically designed for determining the non-plastic transformation temperature of ferritic steel.