Metal Testing Equipment

Versatile Side-Entry Clamping for a Wide Range of Materials

Side action grips are tensile fixtures that clamp specimens from the sides, allowing quick and secure holding of various materials in a universal testing machine (UTM). NextGen’s side-action grips come in both manual lever-action designs for rapid sample insertion and screw-action designs for precise clamping force control. All models in this category use a standard 10 mm diameter pin connection for compatibility with NextGen UTMs, and they are built to industry standards to ensure accurate, repeatable results. Below is a detailed overview of each side-action grip model, including specifications, materials/applications, jaw configurations, and relevant test standards.

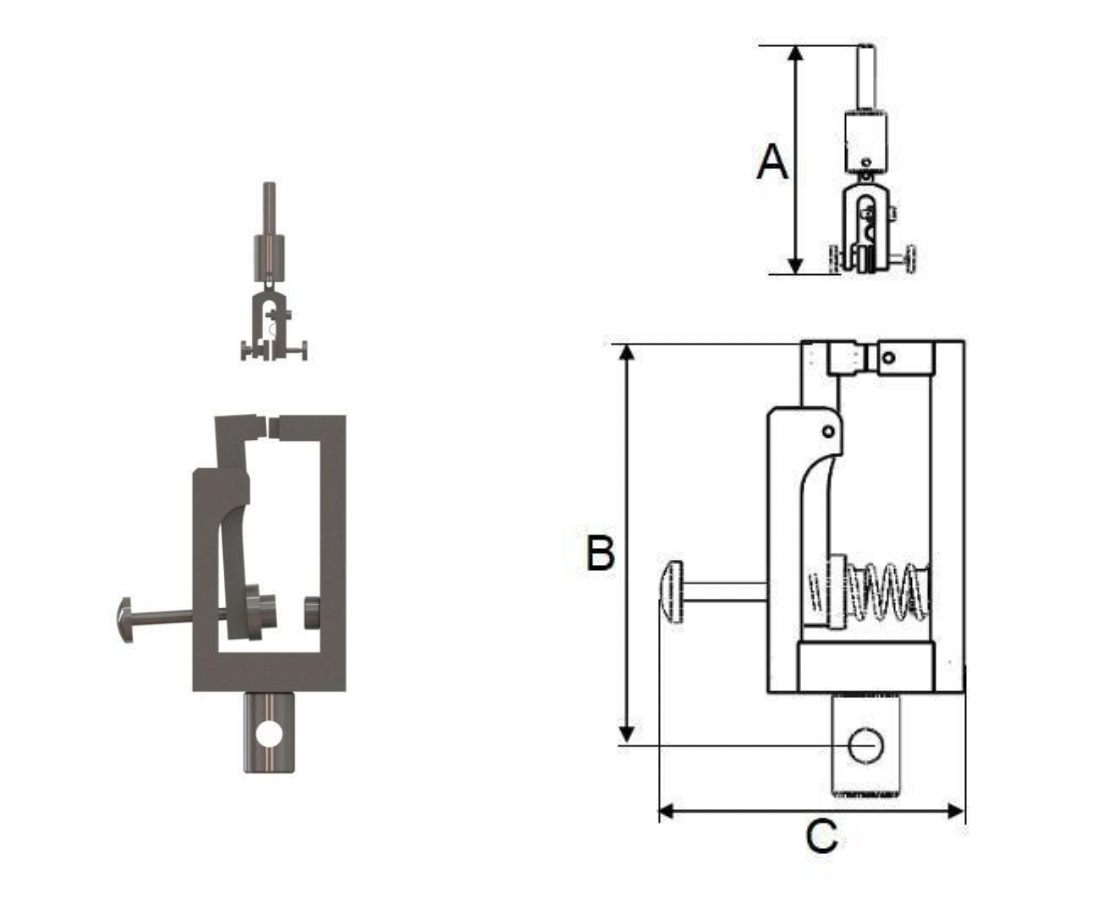

NGA201A – Manual Side-Action Grip (20 N Capacity)

Model NGA201A is a low-force manual side-action grip intended for extremely delicate tensile tests, such as those on fine polymer filaments (e.g. polyurethane fibers). Despite its small size, it provides secure clamping for specimens and a maximum load capacity of 20 N . The NGA201A features a lightweight, compact design and is ideal for micro-scale specimens where minimal grip weight and gentle clamping are critical.

- Maximum Load: ≤20 N (approximately 2 kgf) capacity for micro-tensile applications

- Specimen Application: Designed for very thin, flexible specimens like polyurethane monofilaments and similar fine fibers

- Connection: Attaches via 10 mm diameter pin on both upper and lower grip components – compatible with standard UTM clevis adapters

- Dimensions: Upper grip height 68 mm, lower grip height 136 mm, with a grip body width of 90 mm

- Working Temperature: Ambient (room temperature) operation

- Grip Weight: ~0.2 kg per grip half (very lightweight for minimal influence on low-force measurements)

- Applicable Standards: Suitable for single-fiber tensile tests such as ASTM D3822 (tensile properties of single textile fibers), ensuring gentle clamping without slippage for compliance with such methods.

| Specifications | |

|---|---|

| Application | Tension test for polyurethane filament |

| Maximum force | ≤20N |

| Connection | Upper grip – Φ10mm pin |

| Lower grip – Φ10mm pin | |

| Height | Upper grip (A) – 68mm |

| Lower grip (B) – 136mm | |

| Grip body width (C) | 90mm |

| Working temperature | Ambient |

| Grip weight | 200g |

NGA501A – Manual Side-Action Grip (50 N Capacity)

Model NGA501A is a manual side-action tensile grip for slightly higher forces (up to 50 N) and is tailored to thin sheets and flexible materials. It is commonly used for tensile testing of plastic films, thin polymer sheets, paper or strips, fine wires/threads, textiles, and other soft specimens . The NGA501A features flat jaws lined with a 1 mm thick rubber coating to improve friction and protect delicate samples from damage.

- Maximum Load: ≤50 N capacity (approx. 5 kgf) for low-force tension tests

- Specimen Applications: Plastic films, thin sheets, strips, fine threads, fabrics, and other soft or flexible materials

- Jaw Faces: Flat jaws, size 24 mm (H) × 32 mm (W), with 1 mm thick rubber coating to prevent slippage and avoid specimen damage

- Specimen Thickness: Accommodates specimens up to 5 mm thick

- Connection: 10 mm pin coupling on both upper and lower grips for mounting to the machine

- Dimensions: 76 mm grip height, 47 mm grip body width, and 83 mm overall width – a compact form factor for small samples

- Weight: ~0.16 kg (upper grip) and 0.25 kg (lower grip), keeping the fixture lightweight

- Applicable Standards: Facilitates tensile tests according to standards like ASTM D882 (plastic film tensile properties) and ISO 13934-1 (textile strip tensile strength), where rubber-coated flat grips are recommended for avoiding stress concentrations.

| Specifications | |

|---|---|

| Application | Tension test for plastic sheet, film, strip, fine thread, fabric, and soft materials |

| Maximum force | ≤50N |

| Connection | Upper grip: Φ10mm pin |

| Lower grip: Φ10mm pin | |

| Height (A) | 76mm |

| Grip body width (B) | 47mm |

| Overall width (C) | 83mm |

| Working temperature | Ambient |

| Grip weight | Upper grip: 0.16kg |

| Lower grip: 0.25kg | |

| Grip jaw | 24(H)mm × 32(W)mm |

| Specimen thickness | ≤5mm |

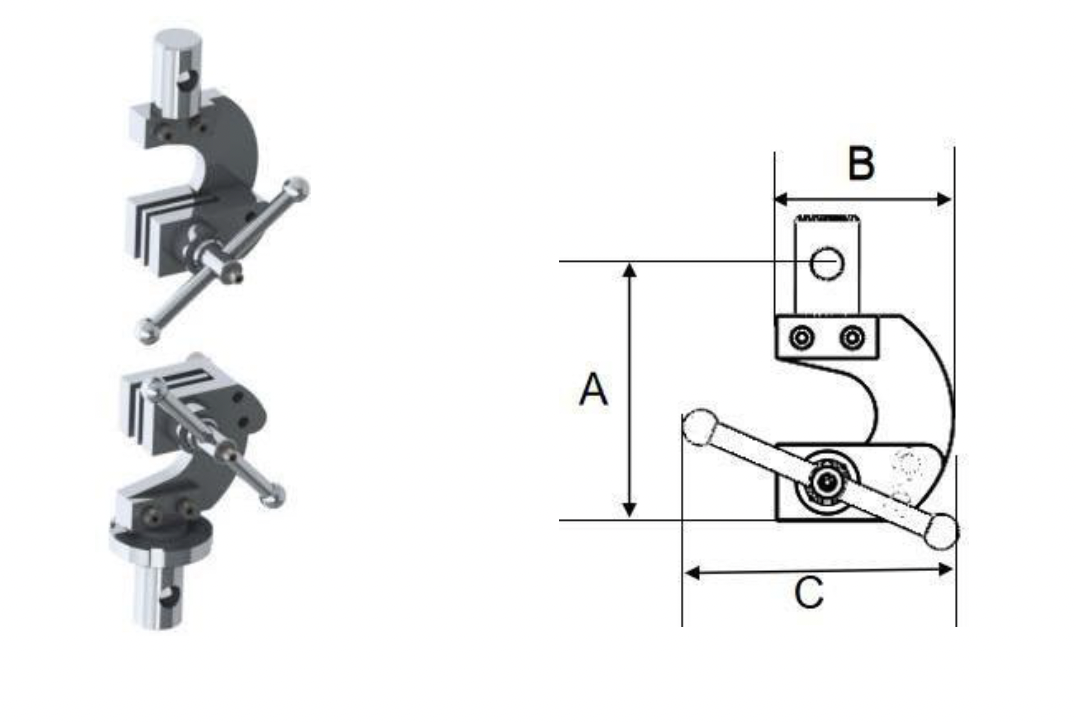

NGA502A & NGA502B – Manual Side-Action Grips (500 N Capacity)

Models NGA502A and NGA502B are higher-capacity manual side-action grips rated for forces up to 500 N . They are suited for the same range of specimen types as the NGA501A (films, flexible plastics, fabrics, fine wires, etc.), but with a sturdier build to handle greater loads . The two variants differ primarily in material and temperature rating: the NGA502A is constructed from alloy steel for standard ambient laboratory use, whereas the NGA502B is made of stainless steel and is engineered for testing in extreme temperatures from –70 °C up to +350 °C (ideal for environmental chamber testing). Both variants share the same general design and dimensions.

- Maximum Load: ≤500 N capacity (50 kgf) for medium low-force tensile tests

- Specimen Applications: Plastic films, polymer sheets, strips, fine threads, textiles, and other soft materials (same as NGA501 series, but accommodating higher forces)

- Grip Material: High-strength alloy steel for NGA502A; corrosion-resistant stainless steel for NGA502B (Stainless steel construction allows NGA502B to operate across a wide temperature range without losing strength)

- Temperature Range: NGA502A: Ambient conditions; NGA502B: –70 °C to +350 °C for cryogenic or high-temperature testing environments

- Jaw Faces: Flat faces, 24 mm × 32 mm, with a 1 mm rubber coating for secure gripping of smooth or delicate specimens (Both A and B variants use the same jaw size and coating; rubber inserts may be removed for high-temperature testing on NGA502B)

- Specimen Thickness: Up to 5 mm thick

- Connection: 10 mm diameter pin (upper and lower) for mounting

- Dimensions: ~80 mm overall height, 48 mm grip body width, and 80 mm overall width – a compact grip with a robust build

- Weight: Approximately 0.44 kg (upper grip) and 0.55 kg (lower grip) per unit (roughly 0.5 kg each)

- Applicable Standards: Suitable for tests in accordance with ASTM D882 / ISO 527 (plastic films and thin sheets) and relevant fabric testing standards. NGA502B enables compliance with standards requiring conditioning at high or low temperatures (e.g., ASTM D5035), without compromising grip performance.

| Specifications | ||

|---|---|---|

| Model | NGA502A | NGA502B |

| Application | Tension test for plastic sheet, film, strip, fine thread, fabric, and soft materials | |

| Maximum force | ≤500N | |

| Grip material | Alloy steel | Stainless steel |

| Grip weight | Upper grip: 0.44kg | Upper grip: 0.43kg |

| Lower grip: 0.55kg | Lower grip: 0.54kg | |

| Connection | Upper grip: Φ10mm pin | Upper grip: Φ10mm pin |

| Lower grip: Φ10mm pin | Lower grip: Φ10mm pin | |

| Height (A) | 80mm | |

| Grip body width (B) | 48mm | |

| Overall width (C) | 80mm | |

| Working temperature | Ambient | -70°C – +350°C |

| Grip jaw | 24(H)mm × 32(W)mm | |

| Specimen thickness | ≤5mm | |

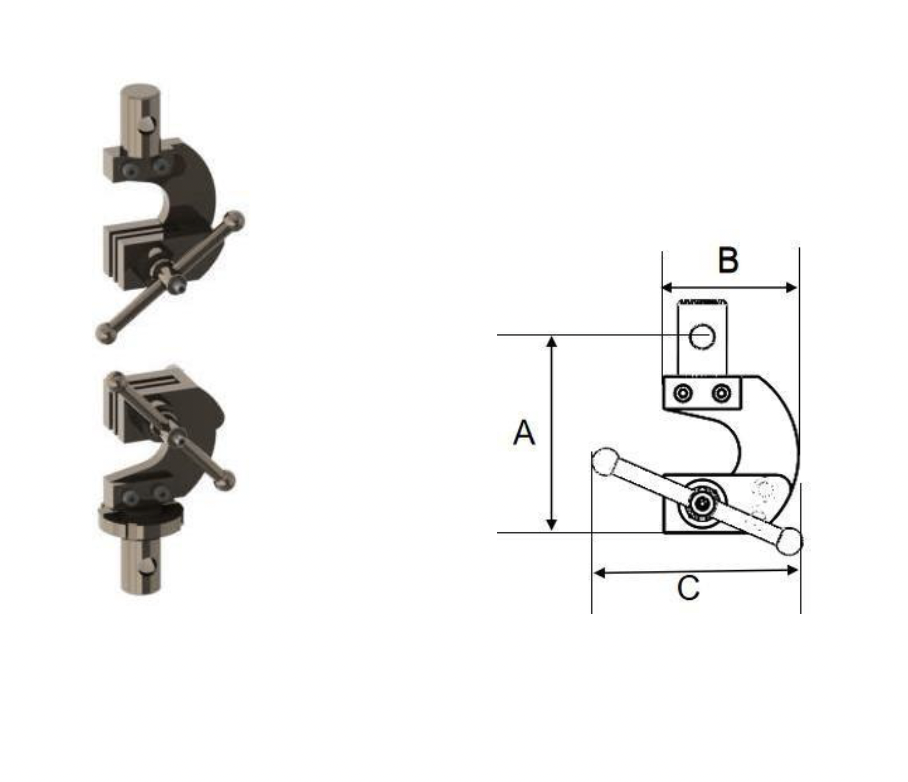

NGA503 Series (Models NGA503A/C/D/E) – Manual Side-Action Grips (5 kN Capacity)

NGA503 Series manual side-action grips are medium-duty clamps designed for a broad array of sheet and fabric materials, with a maximum tensile capacity of 5 kN . These grips feature a robust construction and large clamping surfaces to securely hold flexible or planar specimens such as waterproofing membrane rolls, polymer films, textile fabrics, rubber sheets, and alkali-resistant fiberglass mesh fabrics . Each NGA503 grip has an oversized jaw face area of 46 mm (height) × 80 mm (width) to distribute pressure evenly and prevent tearing . The grips can accommodate specimen thicknesses up to 10 mm and operate at ambient temperatures. All variants in this series use the standard 10 mm pin connections and weigh approximately 2.32 kg per grip half , reflecting their sturdy all-steel design for handling higher forces.

Four jaw face profile options are available under different model numbers, each optimized for a specific material type :

- NGA503A: Equipped with wave-profile (wavy surface) jaw faces for gripping waterproof rolls such as bitumen or polymer roofing membranes. The wave-profile jaws conform to surface irregularities of waterproofing materials, ensuring a secure hold without slippage.

- NGA503C: Uses wave-profile jaw faces, like the A variant, but intended for plastic films and textile fabrics. The contoured wave pattern provides gentle but firm clamping for flexible films and cloth, minimizing stress concentrations on these materials.

- NGA503D: Features trapezoidal-profile (sawtooth-like) jaw faces tailored for rubber sheets and other elastomeric materials. The trapezoidal serration bites into rubbery specimens to prevent them from slipping out as they elongate under load.

- NGA503E: Utilizes trapezoidal-profile jaw faces optimized for coarse or stiff fabrics like alkali-resistant fiberglass mesh (used in construction). The aggressive profile securely grips the mesh without allowing the strands to pull free during testing.

Common Specifications: All NGA503 variants share the same base specifications – a 5 kN maximum load, 46 × 80 mm jaw size, up to 10 mm specimen thickness capacity, and ambient working temperature . Each grip (upper or lower) weighs ~2.32 kg , indicating a heavy-duty build. The connection to the machine is via 10 mm diameter pins on both ends .

Applicable Standards: The NGA503 series is compatible with a variety of testing standards for the materials it covers. For example, it can be used for tensile tests of roofing membranes per EN 12311-1 (bitumen/polymer roll roofing tensile strength), for plastic films per ASTM D882 / ISO 527-3, for rubber sheet tensile tests per ASTM D412 / ISO 37, and for textile fabrics per ASTM D5035 / ISO 13934-1. The interchangeable jaw profiles ensure that each variant meets the gripping requirements of these standards, providing reliable results without specimen slippage or damage.

| Specifications | ||||

|---|---|---|---|---|

| Model | NGA503A | NGA503C | NGA503D | NGA503E |

| Application | Tension test for waterproof rolls, film and textile fabric, rubber and Alkali-resistant mesh fabric etc. | |||

| Maximum force | ≤5kN | |||

| Grip weight | Upper grip: 2.32kg | Upper grip: 2.32kg | Upper grip: 2.32kg | Upper grip: 2.32kg |

| Lower grip: 2.32kg | Lower grip: 2.32kg | Lower grip: 2.32kg | Lower grip: 2.32kg | |

| Connection | Upper grip: Φ10mm pin | Upper grip: Φ10mm pin | Upper grip: Φ10mm pin | Upper grip: Φ10mm pin |

| Lower grip: Φ10mm pin | Lower grip: Φ10mm pin | Lower grip: Φ10mm pin | Lower grip: Φ10mm pin | |

| Height (A) | 105mm | |||

| Grip body width (B) | 80mm | |||

| Overall width (C) | 120mm | |||

| Specimen thickness | ≤10mm | |||

| Working temperature | Ambient | |||

| Grip jaw | 46(H)mm × 80(W)mm | |||

| Jaw face type | Wave-profile | Wave-profile | Trapezoid-profile | Trapezoid-profile |

| Specimen material | Waterproof rolls | Film and textile fabric | Rubber | Alkali-resistant mesh fabric |

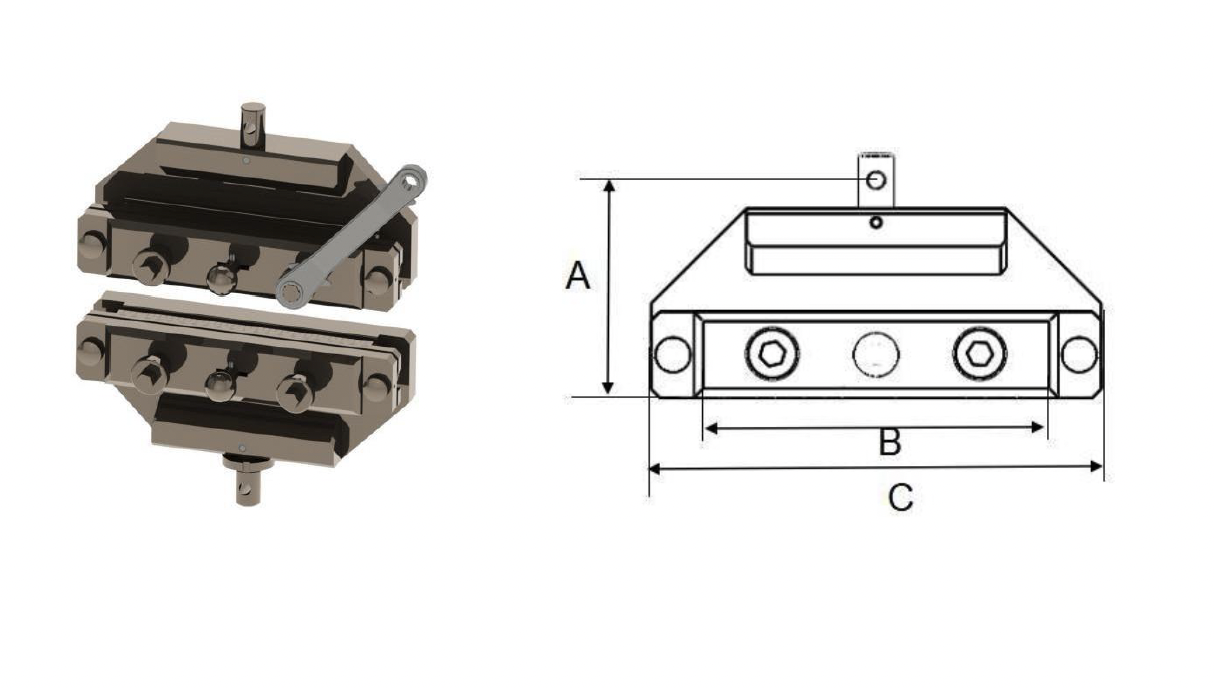

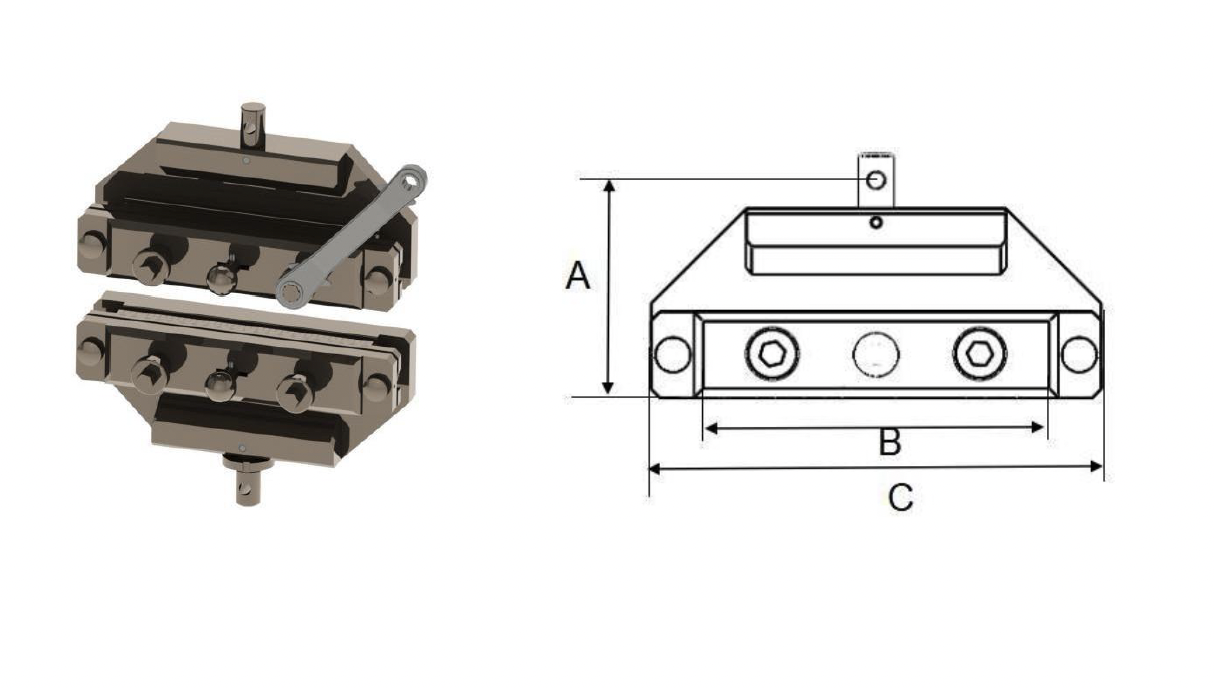

NGA204C – Manual Side-Action Grip (20 kN Capacity)

Model NGA204C is a heavy-duty manual side-action grip engineered for high-force testing of wide textile specimens, notably geotextiles and geosynthetics, up to 20 kN of tensile force . This grip is characterized by its exceptionally wide jaw faces (50 mm × 210 mm) with a wave-profile serrated surface . The large, wave-pattern jaws allow secure clamping of broad fabric specimens (such as geotextile strips) without concentrating stress on any one point, thereby preventing premature tearing. NGA204C’s design aligns with the requirements of wide-width geotextile tensile tests, providing the necessary grip width and force capacity to test heavy geotextile materials in compliance with industry standards.

- Maximum Load: ≤20 kN capacity (approximately 2,000 kgf) for high-strength tensile specimens

- Primary Application: Wide-width tensile testing of geotextiles and geomembranes (e.g. geotextile fabric strips used in civil engineering)

- Jaw Face: Extra-large 50 mm (H) × 210 mm (W) wave-profile jaw faces (serrated) for maximum contact area and grip on broad specimens. The wave-profile surface provides high friction over a large area, critical for holding geotextiles without slippage.

- Specimen Capacity: Handles specimen widths up to 210 mm and thickness up to 10 mm, per wide-width strip test requirements.

- Connection: 10 mm pin mount (both upper and lower) to attach securely to the UTM crossheads

- Dimensions: Approximately 127 mm in height, 210 mm body width, and 260 mm overall width. The expansive width accommodates the required specimen size for geotextile standards.

- Weight: ~8.8 kg per grip half (upper 8.74 kg, lower 8.85 kg) – a very robust assembly reflecting its all-steel construction for high loads.

- Applicable Standards: Specifically designed for tests like ASTM D4595 and ISO 10319 (wide-width strip tensile test methods for geotextiles), which mandate wide gripping surfaces. The NGA204C’s jaw width and wave-serrated faces enable compliance with these standards, ensuring accurate determination of tensile strength and strain in geotextile materials.

| Specifications | |

|---|---|

| Application | Tension test for geo-textile |

| Maximum force | ≤20kN |

| Connection | Upper grip Φ10mm pin |

| Lower grip Φ10mm pin | |

| Height (A) | 127mm |

| Grip body width (B) | 210mm |

| Overall width (C) | 260mm |

| Working temperature | Ambient |

| Grip weight | Upper grip 8.74kg |

| Lower grip 8.85kg | |

| Wave-profile jaw face | 50(H)mm x 210(W)mm |

| Specimen thickness | ≤10mm |

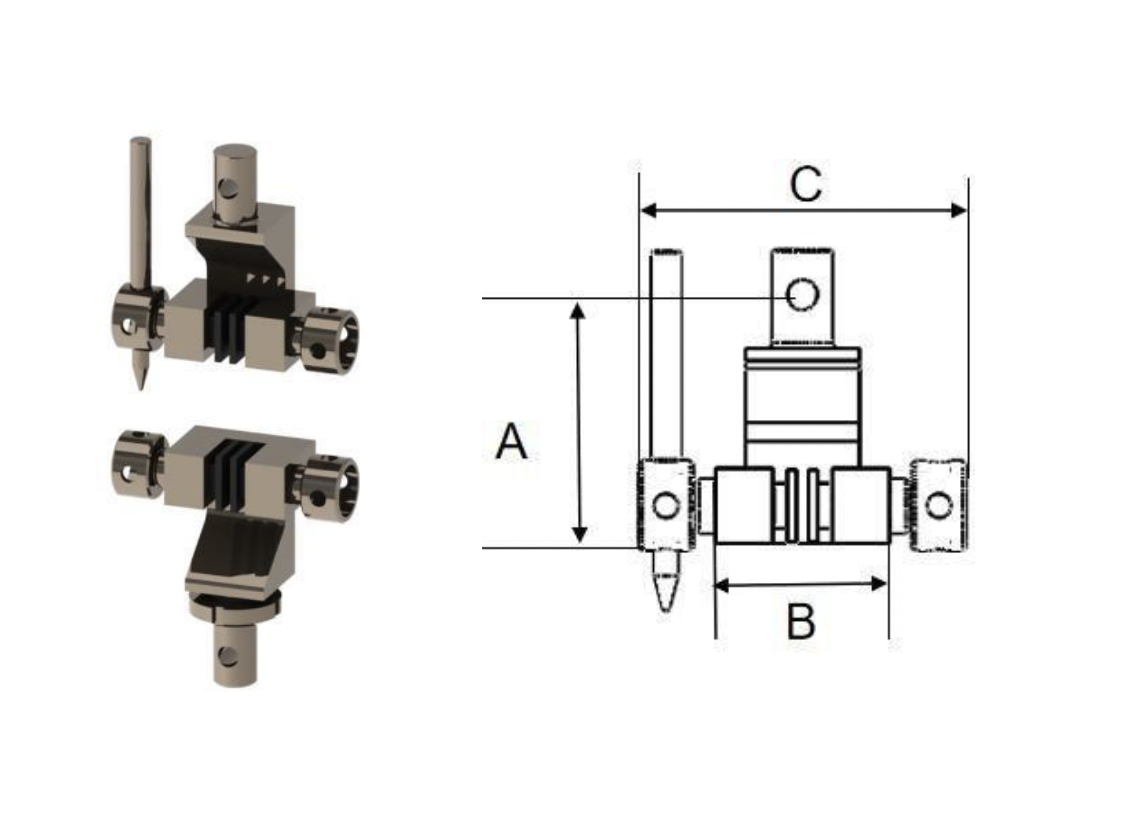

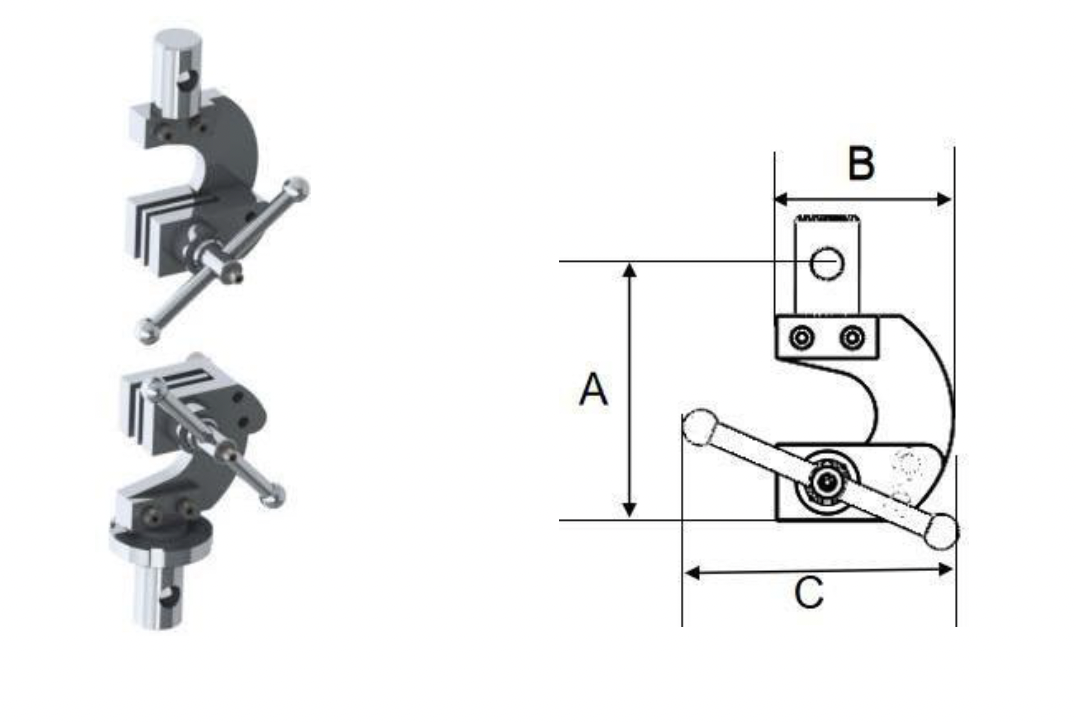

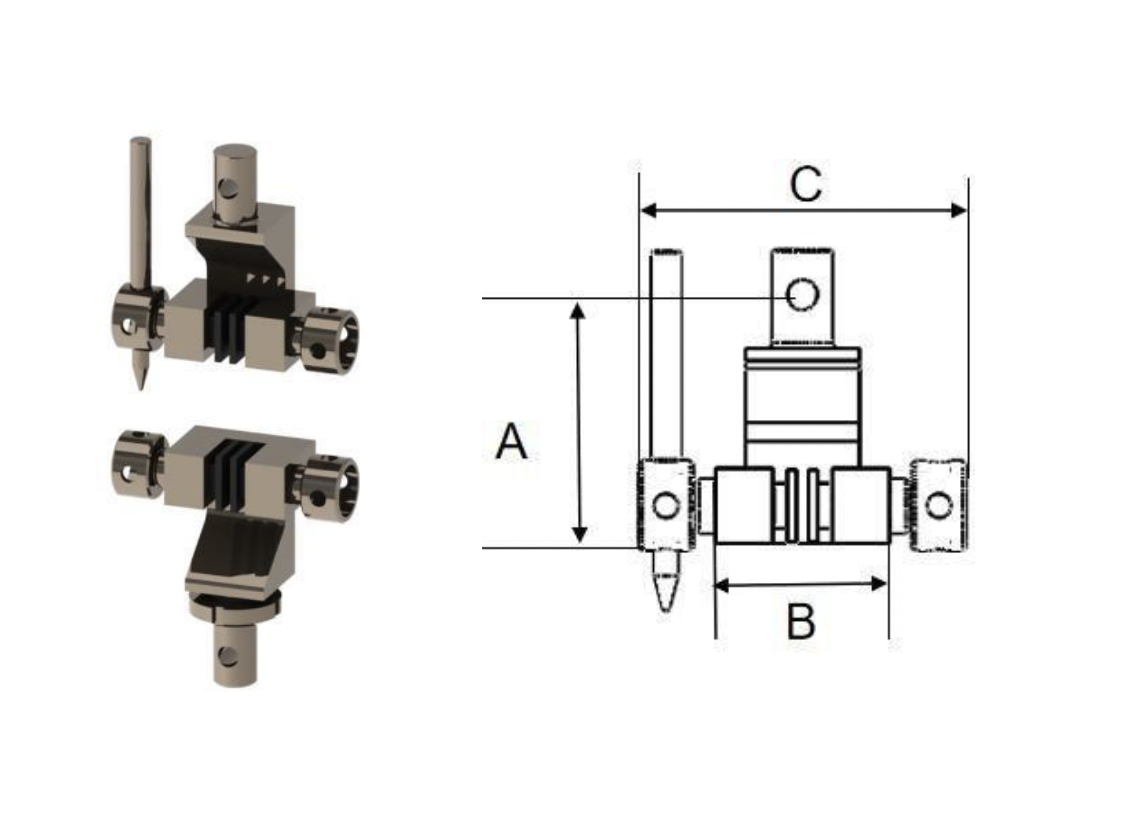

NGB103A – Manual Side-Action Grip (1 kN Capacity)

Model NGB103A is a light-duty manual side-action grip (lever or quick-clamp style) designed for tensile forces up to 1 kN . It is well-suited for testing small samples of plastics and textiles, such as plastic films, thin sheets, and fabric strips . The NGB103A features interchangeable jaw inserts to accommodate different material types: a diamond-pattern serrated jaw set for gripping textile fabrics, and a smooth flat jaw set for gripping plastics or other delicate surfaces . Operators can select the appropriate jaw face to prevent specimen slippage or damage based on the material being tested.

- Maximum Load: ≤1 kN (100 kgf) capacity

- Specimen Applications: Thin plastic films and sheets, as well as textile samples (e.g. fabric strips) requiring gentle but firm clamping

- Jaw Faces: 24 mm × 26 mm jaw faces, supplied in two types – diamond serrated (for fabrics and other woven materials) and flat/smooth (for plastics and delicate samples). The serrated jaws have a fine pyramid grip pattern to bite into fabric without slipping, while the flat jaws (with optional thin rubber interfacing, if needed) avoid puncturing or imprinting on soft plastics.

- Specimen Thickness: Up to 14 mm thick can be clamped, allowing a wide range of sample geometries (including multiple layers of thin material if required).

- Connection: Standard 10 mm pin (upper and lower) for mounting to the test frame

- Dimensions: 75 mm overall grip height, 60 mm body width, 110 mm overall width – a compact size for table-top UTM applications

- Weight: ~0.92 kg (upper grip) and 0.97 kg (lower grip)

- Note: The diamond serrated jaws should be used for textile specimens, and the flat jaws for plastic films/sheets, as recommended. This ensures compliance with appropriate testing standards (for example, using serrated jaws for fabric strip tests per ASTM D5035 to prevent slippage, and flat/rubber-faced jaws for film tests per ASTM D882 to avoid stress risers).

| Specifications | |

|---|---|

| Application | Tension test for textile, plastic film and sheet |

| Maximum force | ≤1kN |

| Connection | Upper grip: Φ10mm pin |

| Lower grip: Φ10mm pin | |

| Height (A) | 75mm |

| Grip body width (B) | 60mm |

| Overall width (C) | 110mm |

| Working temperature | Ambient |

| Grip weight | Upper grip: 0.92kg |

| Lower grip: 0.97kg | |

| Diamond jaw face | 24(H)mm x 26(W)mm |

| Flat jaw face | 24(H)mm x 26(W)mm |

| Specimen thickness | ≤14mm |

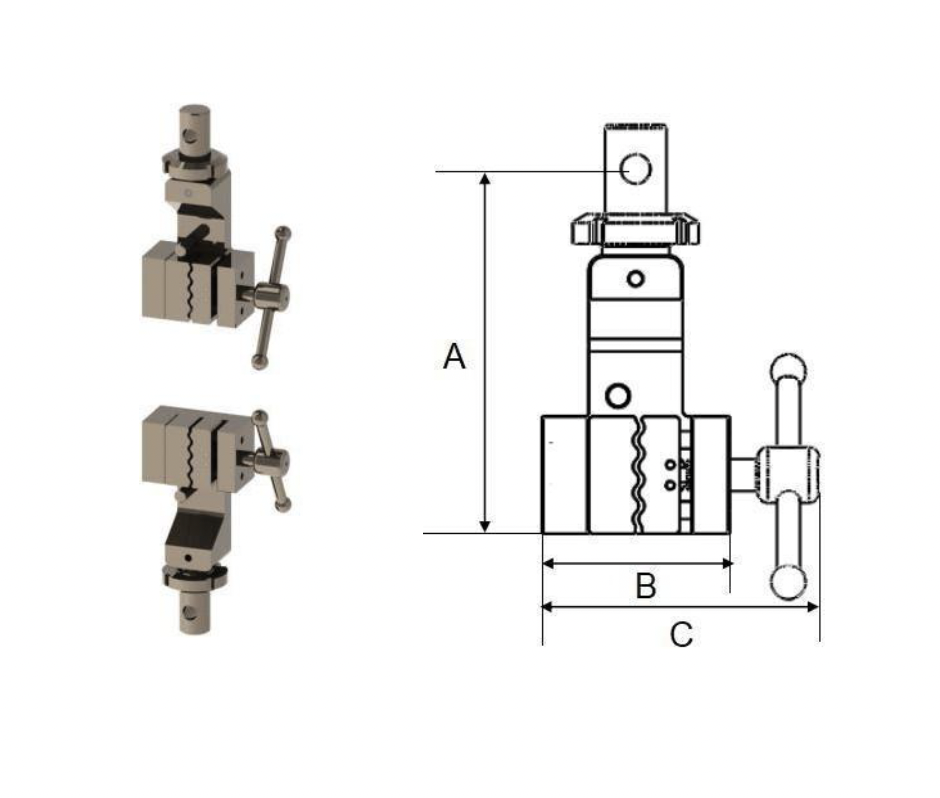

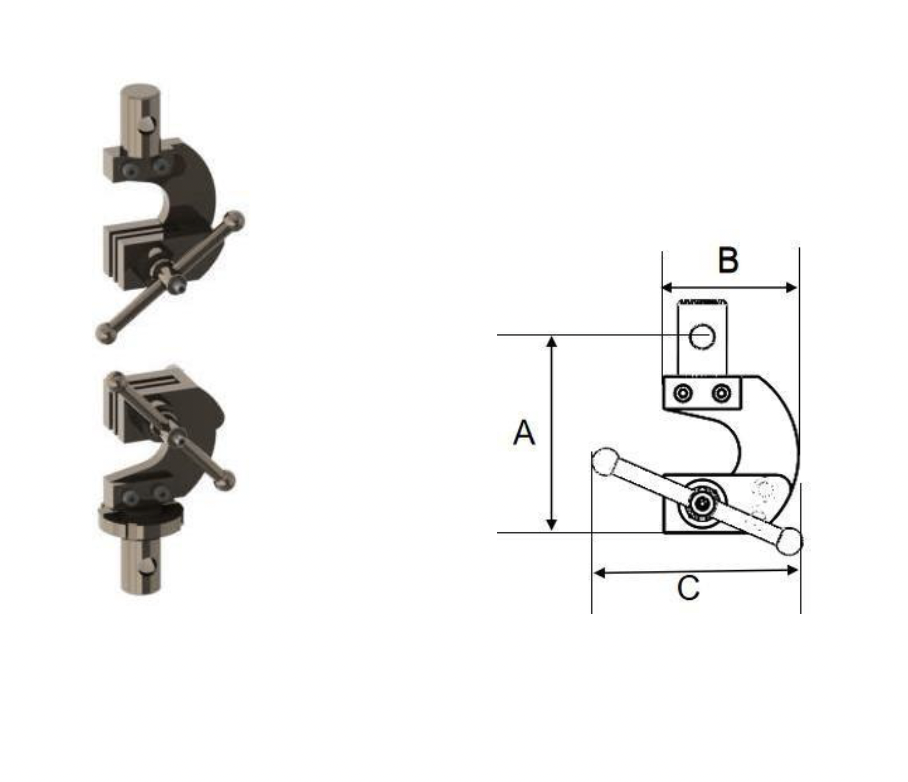

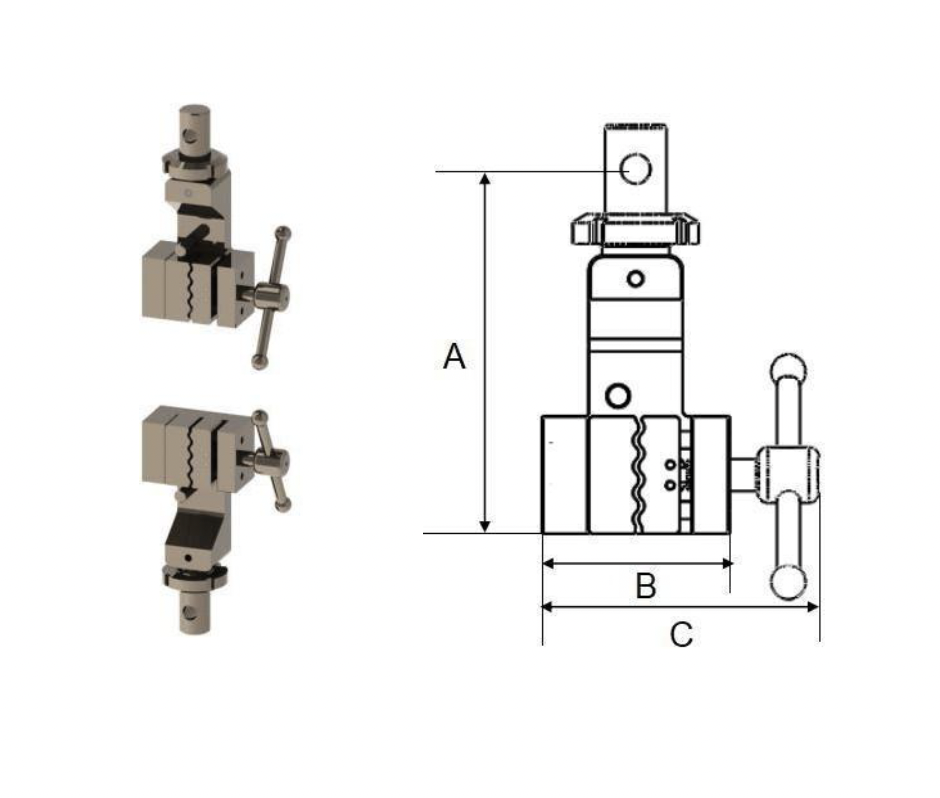

NGB103B – Screw Side-Action Grip (1 kN Capacity)

Model NGB103B is a screw-driven side-action grip with a 1 kN maximum force rating, offering more controlled clamping than the quick-action NGB103A. It employs a threaded tightening knob to apply clamping pressure, which is beneficial for delicate or high-precision tests where gradual, uniform jaw pressure is needed. NGB103B is used for similar specimen types as NGB103A – thin plastics and textiles – and includes two interchangeable jaw faces to match the material: a wave-profile serrated jaw for fabrics, and a smooth flat jaw for films .

- Maximum Load: ≤1 kN (100 kgf)

- Specimen Applications: Textile fabrics and plastic films (and other thin, flexible materials)

- Clamping Mechanism: Screw side-action – a manual screw knob tightens the jaws, allowing fine control of clamping force and alignment. This mechanism prevents sudden jerks on the specimen and is ideal for brittle or sensitive samples.

- Jaw Faces: 40 mm jaw height, provided as two types – wave-profile serrated jaws (40 mm × 26 mm) for gripping textiles, and flat jaws (40 mm × 22 mm) for gripping plastic films. The wave-profile jaw has a sinusoidal serration that grips fabric securely across the width without cutting fibers, while the flat jaw presents a smooth surface (which can be used with a rubber pad if needed) for materials that must not be scored.

- Specimen Thickness: Up to 6 mm thick material can be accommodated between the jaws

- Connection: 10 mm pin (upper & lower) for mounting to load frame

- Dimensions: 125 mm total height, 60 mm body width, and 95 mm overall width. (The larger height compared to NGB103A accounts for the screw mechanism assembly.)

- Weight: ~1.22 kg for each grip (upper and lower are identical in weight)

- Applicable Standards: Enables compliance with the same standards as NGB103A (ASTM D882 for films, ASTM D5035 / ISO 13934-1 for fabrics, etc.), but with the added benefit of precise torque control on the specimen. This can be important for test methods requiring gradual loading or specific clamping pressure to avoid specimen damage.

| Specifications | |

|---|---|

| Application | Tension test for textile, plastic film |

| Maximum force | ≤1kN |

| Connection | Upper grip – Φ10mm pin |

| Lower grip – Φ10mm pin | |

| Height (A) | 125mm |

| Grip body width (B) | 60mm |

| Overall width (C) | 95mm |

| Working temperature | Ambient |

| Grip weight | Upper grip – 1.22kg |

| Lower grip – 1.22kg | |

| Wave-profile jaw face | 40(H)mm x 26(W)mm |

| Flat jaw face | 40(H)mm x 22(W)mm |

| Specimen thickness | ≤6mm |

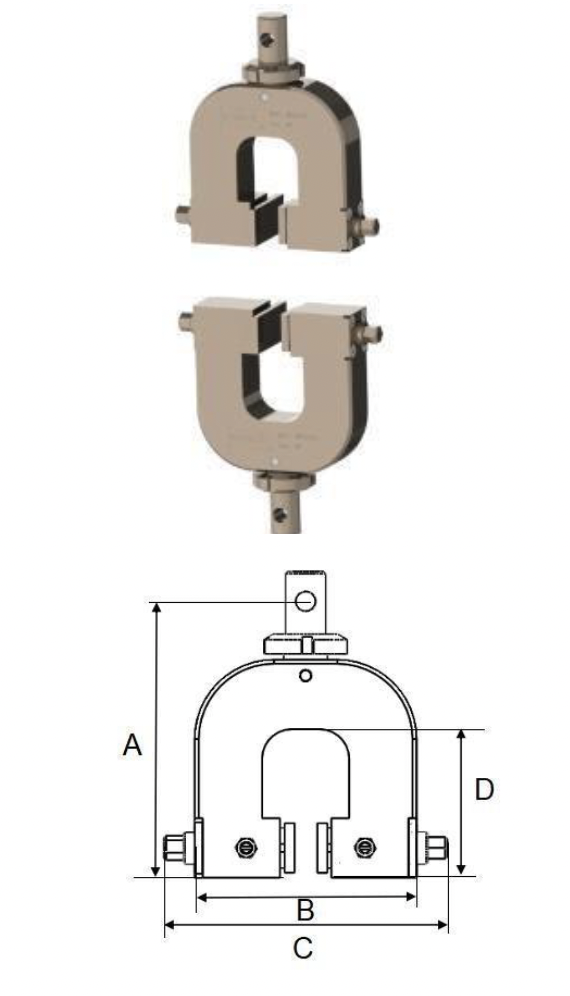

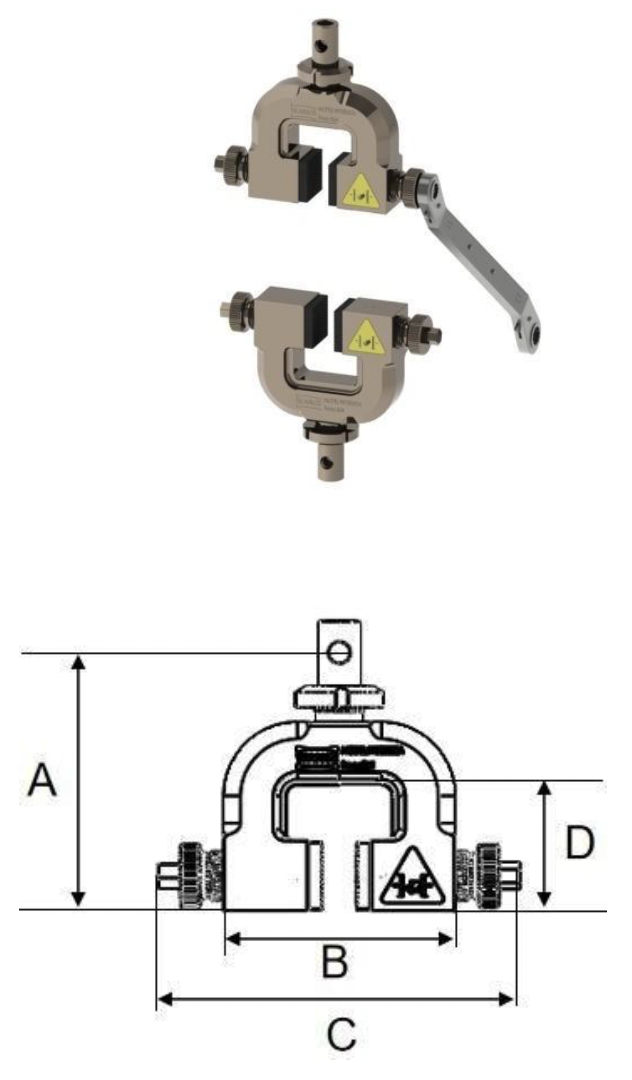

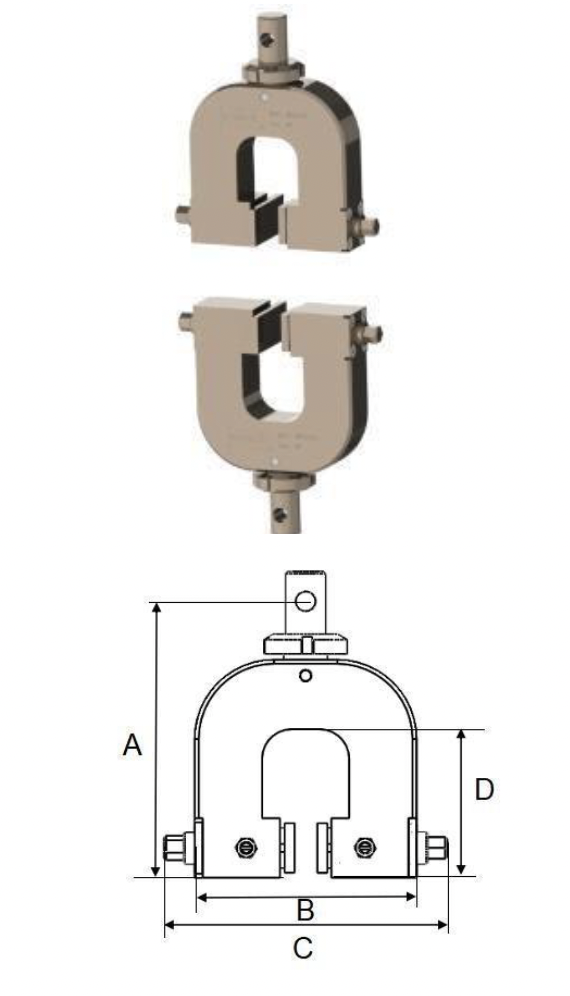

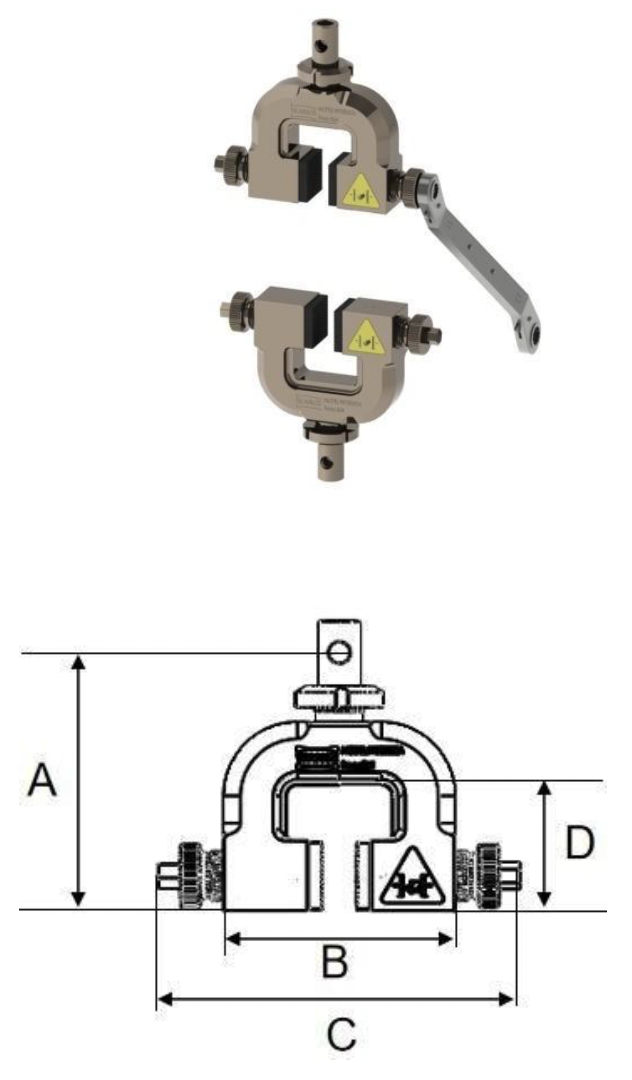

NGB303A – Screw Side-Action Grip (3 kN Capacity)

Model NGB303A is a mid-range screw side-action grip rated for tensile loads up to 3 kN . It is designed to hold medium-sized specimens such as heavier fabric strips, composite strips, or plastic sheets that require more clamping force than the 1 kN grips. The NGB303A features a deep, robust frame (75 mm throat depth) and comes standard with two sets of flat jaw inserts of different heights (25 mm and 50 mm) . This dual-jaw-height design provides versatility: the user can choose a shorter jaw face for small specimens or a taller jaw face for larger specimens to increase the gripping area. For materials that are prone to slipping (like fabrics), optional serrated jaw inserts in both 25 mm and 50 mm heights are available .

- Maximum Load: ≤3 kN (300 kgf) capacity

- Specimen Applications: Stiffer textiles (industrial fabrics, webbing, belts) and plastic sheets or strips that require moderate clamping force. This grip is often used for tests on materials such as canvas, heavy non-wovens, thick polymer films, etc.

- Jaw Configuration: Flat jaw faces in two interchangeable sizes – 25 mm height and 50 mm height (both 25 mm width). The grip can be fitted with either pair of jaws depending on specimen size. The larger 50 mm jaws provide more contact area for wider or more slippery samples, while the 25 mm jaws are useful for narrower specimens or when required by specific test standards. Additionally, optional serrated jaws (with 25 mm or 50 mm face heights) can be used in place of the flat jaws for high-friction gripping of textiles. This flexibility in jaw faces allows one grip to cover a range of material types and standards.

- Specimen Thickness: Capable of clamping specimens up to 16 mm thick, accommodating multiple layers or thick materials.

- Connection: 10 mm pin coupling (upper and lower) for mounting to the test machine

- Dimensions: 135 mm height, 110 mm body width, 140 mm overall width; jaw throat depth ~75 mm. The relatively wide frame and deep throat allow gripping of larger sample widths and prevent jaw deflection at high loads.

- Weight: ~2.38 kg per grip half (upper or lower), reflecting a solid steel construction for durability under 3 kN loads.

- Applicable Standards: The NGB303A grip supports a variety of standard test methods. For instance, it can be used for textile strip tests such as ASTM D5035 or ISO 13934-1 (which often specify ~25 mm wide jaw faces), as well as for plastic sheet tests like ASTM D882 (where larger jaws can be beneficial for thicker specimens). The availability of both 25 mm and 50 mm jaw faces means the grip can easily conform to different standard requirements for jaw contact area.

| Specifications | |

|---|---|

| Application | Tension test for textile, plastic film and sheet |

| Maximum force | ≤3kN |

| Connection | Upper grip – Φ10mm pin |

| Lower grip – Φ10mm pin | |

| Height (A) | 135mm |

| Grip body width (B) | 110mm |

| Overall width (C) | 140mm |

| Depth (D) | 75mm |

| Working temperature | Ambient |

| Grip weight | |

| Upper grip | 2.38kg |

| Lower grip | 2.38kg |

| Flat jaw face (left) | 25(H)mm x 25(W)mm |

| Flat jaw face (right) | 50(H)mm x 25(W)mm |

| Specimen thickness | ≤16mm |

| Jaw face (Option) | |||

|---|---|---|---|

| No. | Length (A) mm | Width (B) mm | Type |

| NGB303A-11 | 25 | 25 | Serrated |

| NGB303A-12 | 50 | 25 | Serrated |

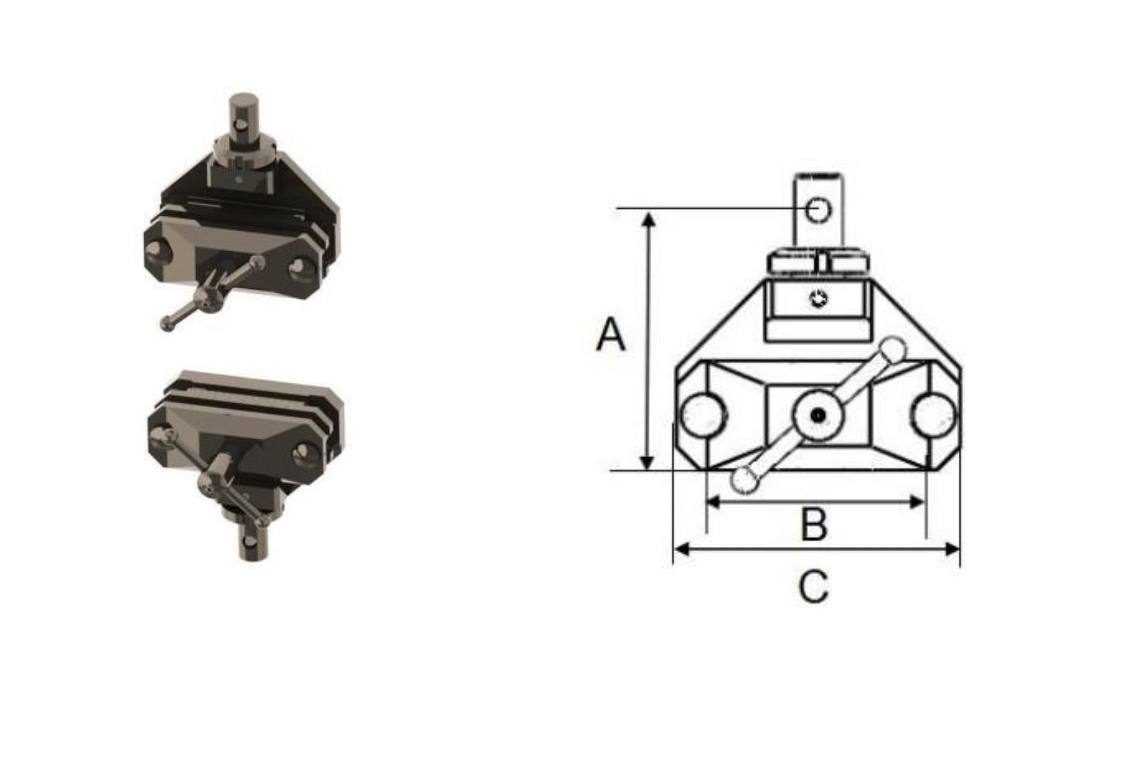

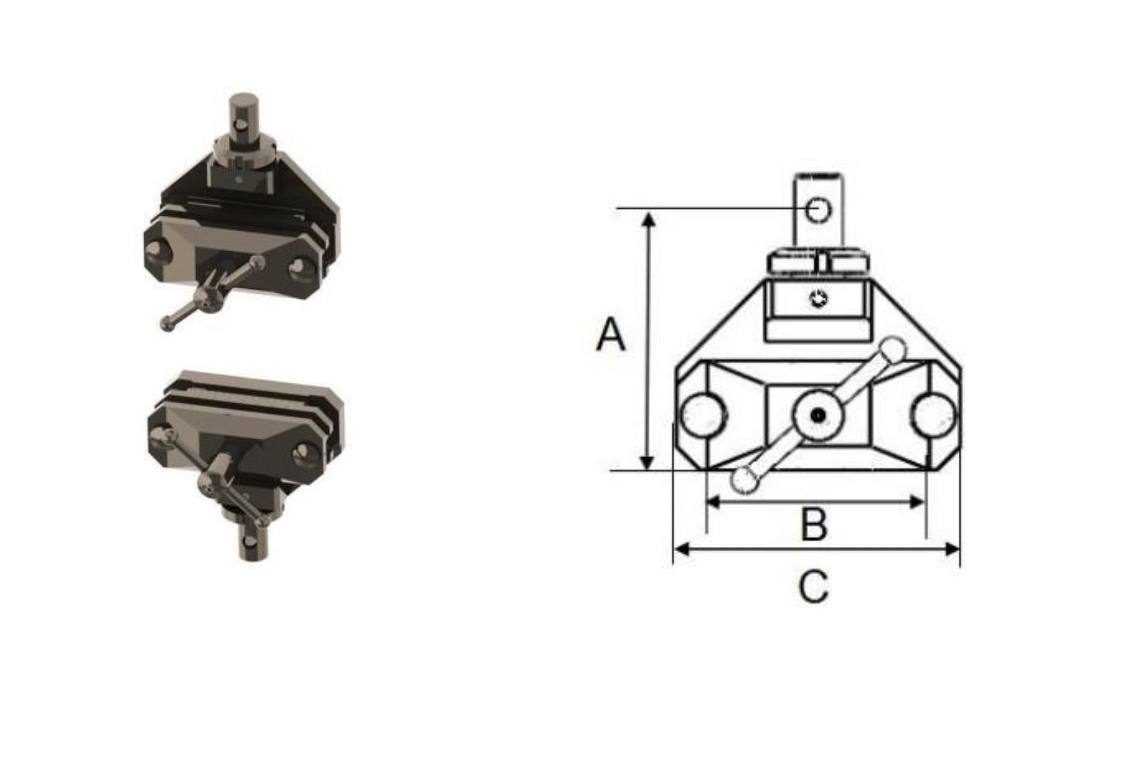

NGB503A – Screw Side-Action Grip (5 kN Capacity)

Model NGB503A is the highest-capacity screw-operated side-action grip in this category, with a maximum load rating of 5 kN . It is built for robust tensile testing of a wide range of materials, from strong textiles to tough plastics. The NGB503A has a symmetrical jaw design featuring 32 mm × 32 mm square clamping faces on both sides. The standard configuration includes flat jaw inserts that are rubber-coated, providing excellent grip on smooth specimens like plastic sheets without causing stress concentrations . To accommodate various test requirements, NextGen offers multiple optional jaw sets for the NGB503A: serrated (tooth) jaws, diamond-pattern jaws, and wave-profile jaws, each designed for specific materials (e.g., textiles, rubber, plastic films, etc.) .

- Maximum Load: ≤5 kN (500 kgf) capacity

- Specimen Applications: Versatile use for higher-strength fabrics (industrial textiles, geotextile samples that are narrower than those requiring NGA204C), polymer sheets and plates, plastic packaging materials (plastic bags, strapping, etc.), and other sheet or film materials up to the 5 kN range. This grip is often utilized in testing where specimens may be stronger or thicker than what the NGA503 series handles, but still require a side-action clamping mechanism.

- Jaw Faces (Standard): Two flat jaw faces, each 32 mm (H) × 32 mm (W), with a rubber-coated surface. The rubber coating on the flats provides a high-friction, non-marring grip suitable for smooth or delicate surfaces (like plastic film or paperboard), preventing slip without tearing the specimen.

- Optional Jaw Faces: A range of interchangeable jaw inserts is available for NGB503A to tailor the grip to specific materials:

- Diamond-Serrated Jaws (70 mm × 32 mm): For rubbery or highly elastic materials (e.g., rubber sheets, elastomer specimens) where a sharp, penetrating grip is needed to prevent slippage. The diamond pattern effectively bites into tough surfaces like rubber.

- Coarse Serrated Jaws (70 mm × 32 mm): For rigid plastic sheets, plates, or composites that can tolerate an aggressive grip. These serrated jaws ensure no slipping when testing high-strength plastics or thick sheet materials.

- Wave-Profile Jaws (32 mm × 32 mm): For flexible items such as textile straps, webbing, or plastic bags that benefit from a distributed clamping profile. The wave-profile (sometimes called “wave serrated”) jaw spreads the clamping force and prevents cut-through on very pliable specimens.

- Specimen Thickness: Up to 16 mm thickness capacity, allowing this grip to handle relatively thick materials or multiple-layer specimens.

- Connection: 10 mm pin interface on both upper and lower grip bodies

- Dimensions: 120 mm overall height, 110 mm body width, 170 mm overall width; jaw throat depth ~60 mm. This size provides a rigid frame to withstand 5 kN loads while accommodating a variety of specimen sizes.

- Weight: ~2.19 kg per grip half (upper or lower)

- Applicable Standards: The NGB503A’s flexibility with jaw faces makes it suitable for many standard test methods at the 5 kN load level. For instance, it can be used for textile grab tests (e.g., ASTM D5034 or ISO 13934-2) by employing serrated or wave-profile jaws that mimic required grip conditions. It also supports plastic sheet and film tests (like ASTM D882) using the flat rubber-coated jaws for proper load introduction. Additionally, for packaging materials such as plastic strapping or bags, it meets the needs of standards (e.g., ASTM D6775 for strap tensile testing) by allowing the appropriate jaw selection. In all cases, the screw-driven clamping and the variety of jaw options ensure that specimens are held according to the standard’s stipulations, preventing slippage and jaw-induced failures.

| Specifications | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Application | Tension test for textile, plastic film and sheet | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Maximum force | ≤5kN | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Specifications | |

|---|---|

| Application | Tension test for polyurethane filament |

| Maximum force | ≤20N |

| Connection | Upper grip – Φ10mm pin |

| Lower grip – Φ10mm pin | |

| Height | Upper grip (A) – 68mm |

| Lower grip (B) – 136mm | |

| Grip body width (C) | 90mm |

| Working temperature | Ambient |

| Grip weight | 200g |

NGA501A – Manual Side-Action Grip (50 N Capacity)

Model NGA501A is a manual side-action tensile grip for slightly higher forces (up to 50 N) and is tailored to thin sheets and flexible materials. It is commonly used for tensile testing of plastic films, thin polymer sheets, paper or strips, fine wires/threads, textiles, and other soft specimens . The NGA501A features flat jaws lined with a 1 mm thick rubber coating to improve friction and protect delicate samples from damage.

- Maximum Load: ≤50 N capacity (approx. 5 kgf) for low-force tension tests

- Specimen Applications: Plastic films, thin sheets, strips, fine threads, fabrics, and other soft or flexible materials

- Jaw Faces: Flat jaws, size 24 mm (H) × 32 mm (W), with 1 mm thick rubber coating to prevent slippage and avoid specimen damage

- Specimen Thickness: Accommodates specimens up to 5 mm thick

- Connection: 10 mm pin coupling on both upper and lower grips for mounting to the machine

- Dimensions: 76 mm grip height, 47 mm grip body width, and 83 mm overall width – a compact form factor for small samples

- Weight: ~0.16 kg (upper grip) and 0.25 kg (lower grip), keeping the fixture lightweight

- Applicable Standards: Facilitates tensile tests according to standards like ASTM D882 (plastic film tensile properties) and ISO 13934-1 (textile strip tensile strength), where rubber-coated flat grips are recommended for avoiding stress concentrations.

| Specifications | |

|---|---|

| Application | Tension test for plastic sheet, film, strip, fine thread, fabric, and soft materials |

| Maximum force | ≤50N |

| Connection | Upper grip: Φ10mm pin |

| Lower grip: Φ10mm pin | |

| Height (A) | 76mm |

| Grip body width (B) | 47mm |

| Overall width (C) | 83mm |

| Working temperature | Ambient |

| Grip weight | Upper grip: 0.16kg |

| Lower grip: 0.25kg | |

| Grip jaw | 24(H)mm × 32(W)mm |

| Specimen thickness | ≤5mm |

NGA502A & NGA502B – Manual Side-Action Grips (500 N Capacity)

Models NGA502A and NGA502B are higher-capacity manual side-action grips rated for forces up to 500 N . They are suited for the same range of specimen types as the NGA501A (films, flexible plastics, fabrics, fine wires, etc.), but with a sturdier build to handle greater loads . The two variants differ primarily in material and temperature rating: the NGA502A is constructed from alloy steel for standard ambient laboratory use, whereas the NGA502B is made of stainless steel and is engineered for testing in extreme temperatures from –70 °C up to +350 °C (ideal for environmental chamber testing). Both variants share the same general design and dimensions.

- Maximum Load: ≤500 N capacity (50 kgf) for medium low-force tensile tests

- Specimen Applications: Plastic films, polymer sheets, strips, fine threads, textiles, and other soft materials (same as NGA501 series, but accommodating higher forces)

- Grip Material: High-strength alloy steel for NGA502A; corrosion-resistant stainless steel for NGA502B (Stainless steel construction allows NGA502B to operate across a wide temperature range without losing strength)

- Temperature Range: NGA502A: Ambient conditions; NGA502B: –70 °C to +350 °C for cryogenic or high-temperature testing environments

- Jaw Faces: Flat faces, 24 mm × 32 mm, with a 1 mm rubber coating for secure gripping of smooth or delicate specimens (Both A and B variants use the same jaw size and coating; rubber inserts may be removed for high-temperature testing on NGA502B)

- Specimen Thickness: Up to 5 mm thick

- Connection: 10 mm diameter pin (upper and lower) for mounting

- Dimensions: ~80 mm overall height, 48 mm grip body width, and 80 mm overall width – a compact grip with a robust build

- Weight: Approximately 0.44 kg (upper grip) and 0.55 kg (lower grip) per unit (roughly 0.5 kg each)

- Applicable Standards: Suitable for tests in accordance with ASTM D882 / ISO 527 (plastic films and thin sheets) and relevant fabric testing standards. NGA502B enables compliance with standards requiring conditioning at high or low temperatures (e.g., ASTM D5035), without compromising grip performance.

| Specifications | ||

|---|---|---|

| Model | NGA502A | NGA502B |

| Application | Tension test for plastic sheet, film, strip, fine thread, fabric, and soft materials | |

| Maximum force | ≤500N | |

| Grip material | Alloy steel | Stainless steel |

| Grip weight | Upper grip: 0.44kg | Upper grip: 0.43kg |

| Lower grip: 0.55kg | Lower grip: 0.54kg | |

| Connection | Upper grip: Φ10mm pin | Upper grip: Φ10mm pin |

| Lower grip: Φ10mm pin | Lower grip: Φ10mm pin | |

| Height (A) | 80mm | |

| Grip body width (B) | 48mm | |

| Overall width (C) | 80mm | |

| Working temperature | Ambient | -70°C – +350°C |

| Grip jaw | 24(H)mm × 32(W)mm | |

| Specimen thickness | ≤5mm | |

NGA503 Series (Models NGA503A/C/D/E) – Manual Side-Action Grips (5 kN Capacity)

NGA503 Series manual side-action grips are medium-duty clamps designed for a broad array of sheet and fabric materials, with a maximum tensile capacity of 5 kN . These grips feature a robust construction and large clamping surfaces to securely hold flexible or planar specimens such as waterproofing membrane rolls, polymer films, textile fabrics, rubber sheets, and alkali-resistant fiberglass mesh fabrics . Each NGA503 grip has an oversized jaw face area of 46 mm (height) × 80 mm (width) to distribute pressure evenly and prevent tearing . The grips can accommodate specimen thicknesses up to 10 mm and operate at ambient temperatures. All variants in this series use the standard 10 mm pin connections and weigh approximately 2.32 kg per grip half , reflecting their sturdy all-steel design for handling higher forces.

Four jaw face profile options are available under different model numbers, each optimized for a specific material type :

- NGA503A: Equipped with wave-profile (wavy surface) jaw faces for gripping waterproof rolls such as bitumen or polymer roofing membranes. The wave-profile jaws conform to surface irregularities of waterproofing materials, ensuring a secure hold without slippage.

- NGA503C: Uses wave-profile jaw faces, like the A variant, but intended for plastic films and textile fabrics. The contoured wave pattern provides gentle but firm clamping for flexible films and cloth, minimizing stress concentrations on these materials.

- NGA503D: Features trapezoidal-profile (sawtooth-like) jaw faces tailored for rubber sheets and other elastomeric materials. The trapezoidal serration bites into rubbery specimens to prevent them from slipping out as they elongate under load.

- NGA503E: Utilizes trapezoidal-profile jaw faces optimized for coarse or stiff fabrics like alkali-resistant fiberglass mesh (used in construction). The aggressive profile securely grips the mesh without allowing the strands to pull free during testing.

Common Specifications: All NGA503 variants share the same base specifications – a 5 kN maximum load, 46 × 80 mm jaw size, up to 10 mm specimen thickness capacity, and ambient working temperature . Each grip (upper or lower) weighs ~2.32 kg , indicating a heavy-duty build. The connection to the machine is via 10 mm diameter pins on both ends .

Applicable Standards: The NGA503 series is compatible with a variety of testing standards for the materials it covers. For example, it can be used for tensile tests of roofing membranes per EN 12311-1 (bitumen/polymer roll roofing tensile strength), for plastic films per ASTM D882 / ISO 527-3, for rubber sheet tensile tests per ASTM D412 / ISO 37, and for textile fabrics per ASTM D5035 / ISO 13934-1. The interchangeable jaw profiles ensure that each variant meets the gripping requirements of these standards, providing reliable results without specimen slippage or damage.

| Specifications | ||||

|---|---|---|---|---|

| Model | NGA503A | NGA503C | NGA503D | NGA503E |

| Application | Tension test for waterproof rolls, film and textile fabric, rubber and Alkali-resistant mesh fabric etc. | |||

| Maximum force | ≤5kN | |||

| Grip weight | Upper grip: 2.32kg | Upper grip: 2.32kg | Upper grip: 2.32kg | Upper grip: 2.32kg |

| Lower grip: 2.32kg | Lower grip: 2.32kg | Lower grip: 2.32kg | Lower grip: 2.32kg | |

| Connection | Upper grip: Φ10mm pin | Upper grip: Φ10mm pin | Upper grip: Φ10mm pin | Upper grip: Φ10mm pin |

| Lower grip: Φ10mm pin | Lower grip: Φ10mm pin | Lower grip: Φ10mm pin | Lower grip: Φ10mm pin | |

| Height (A) | 105mm | |||

| Grip body width (B) | 80mm | |||

| Overall width (C) | 120mm | |||

| Specimen thickness | ≤10mm | |||

| Working temperature | Ambient | |||

| Grip jaw | 46(H)mm × 80(W)mm | |||

| Jaw face type | Wave-profile | Wave-profile | Trapezoid-profile | Trapezoid-profile |

| Specimen material | Waterproof rolls | Film and textile fabric | Rubber | Alkali-resistant mesh fabric |

NGA204C – Manual Side-Action Grip (20 kN Capacity)

Model NGA204C is a heavy-duty manual side-action grip engineered for high-force testing of wide textile specimens, notably geotextiles and geosynthetics, up to 20 kN of tensile force . This grip is characterized by its exceptionally wide jaw faces (50 mm × 210 mm) with a wave-profile serrated surface . The large, wave-pattern jaws allow secure clamping of broad fabric specimens (such as geotextile strips) without concentrating stress on any one point, thereby preventing premature tearing. NGA204C’s design aligns with the requirements of wide-width geotextile tensile tests, providing the necessary grip width and force capacity to test heavy geotextile materials in compliance with industry standards.

- Maximum Load: ≤20 kN capacity (approximately 2,000 kgf) for high-strength tensile specimens

- Primary Application: Wide-width tensile testing of geotextiles and geomembranes (e.g. geotextile fabric strips used in civil engineering)

- Jaw Face: Extra-large 50 mm (H) × 210 mm (W) wave-profile jaw faces (serrated) for maximum contact area and grip on broad specimens. The wave-profile surface provides high friction over a large area, critical for holding geotextiles without slippage.

- Specimen Capacity: Handles specimen widths up to 210 mm and thickness up to 10 mm, per wide-width strip test requirements.

- Connection: 10 mm pin mount (both upper and lower) to attach securely to the UTM crossheads

- Dimensions: Approximately 127 mm in height, 210 mm body width, and 260 mm overall width. The expansive width accommodates the required specimen size for geotextile standards.

- Weight: ~8.8 kg per grip half (upper 8.74 kg, lower 8.85 kg) – a very robust assembly reflecting its all-steel construction for high loads.

- Applicable Standards: Specifically designed for tests like ASTM D4595 and ISO 10319 (wide-width strip tensile test methods for geotextiles), which mandate wide gripping surfaces. The NGA204C’s jaw width and wave-serrated faces enable compliance with these standards, ensuring accurate determination of tensile strength and strain in geotextile materials.

| Specifications | |

|---|---|

| Application | Tension test for geo-textile |

| Maximum force | ≤20kN |

| Connection | Upper grip Φ10mm pin |

| Lower grip Φ10mm pin | |

| Height (A) | 127mm |

| Grip body width (B) | 210mm |

| Overall width (C) | 260mm |

| Working temperature | Ambient |

| Grip weight | Upper grip 8.74kg |

| Lower grip 8.85kg | |

| Wave-profile jaw face | 50(H)mm x 210(W)mm |

| Specimen thickness | ≤10mm |

NGB103A – Manual Side-Action Grip (1 kN Capacity)

Model NGB103A is a light-duty manual side-action grip (lever or quick-clamp style) designed for tensile forces up to 1 kN . It is well-suited for testing small samples of plastics and textiles, such as plastic films, thin sheets, and fabric strips . The NGB103A features interchangeable jaw inserts to accommodate different material types: a diamond-pattern serrated jaw set for gripping textile fabrics, and a smooth flat jaw set for gripping plastics or other delicate surfaces . Operators can select the appropriate jaw face to prevent specimen slippage or damage based on the material being tested.

- Maximum Load: ≤1 kN (100 kgf) capacity

- Specimen Applications: Thin plastic films and sheets, as well as textile samples (e.g. fabric strips) requiring gentle but firm clamping

- Jaw Faces: 24 mm × 26 mm jaw faces, supplied in two types – diamond serrated (for fabrics and other woven materials) and flat/smooth (for plastics and delicate samples). The serrated jaws have a fine pyramid grip pattern to bite into fabric without slipping, while the flat jaws (with optional thin rubber interfacing, if needed) avoid puncturing or imprinting on soft plastics.

- Specimen Thickness: Up to 14 mm thick can be clamped, allowing a wide range of sample geometries (including multiple layers of thin material if required).

- Connection: Standard 10 mm pin (upper and lower) for mounting to the test frame

- Dimensions: 75 mm overall grip height, 60 mm body width, 110 mm overall width – a compact size for table-top UTM applications

- Weight: ~0.92 kg (upper grip) and 0.97 kg (lower grip)

- Note: The diamond serrated jaws should be used for textile specimens, and the flat jaws for plastic films/sheets, as recommended. This ensures compliance with appropriate testing standards (for example, using serrated jaws for fabric strip tests per ASTM D5035 to prevent slippage, and flat/rubber-faced jaws for film tests per ASTM D882 to avoid stress risers).

| Specifications | |

|---|---|

| Application | Tension test for textile, plastic film and sheet |

| Maximum force | ≤1kN |

| Connection | Upper grip: Φ10mm pin |

| Lower grip: Φ10mm pin | |

| Height (A) | 75mm |

| Grip body width (B) | 60mm |

| Overall width (C) | 110mm |

| Working temperature | Ambient |

| Grip weight | Upper grip: 0.92kg |

| Lower grip: 0.97kg | |

| Diamond jaw face | 24(H)mm x 26(W)mm |

| Flat jaw face | 24(H)mm x 26(W)mm |

| Specimen thickness | ≤14mm |

NGB103B – Screw Side-Action Grip (1 kN Capacity)

Model NGB103B is a screw-driven side-action grip with a 1 kN maximum force rating, offering more controlled clamping than the quick-action NGB103A. It employs a threaded tightening knob to apply clamping pressure, which is beneficial for delicate or high-precision tests where gradual, uniform jaw pressure is needed. NGB103B is used for similar specimen types as NGB103A – thin plastics and textiles – and includes two interchangeable jaw faces to match the material: a wave-profile serrated jaw for fabrics, and a smooth flat jaw for films .

- Maximum Load: ≤1 kN (100 kgf)

- Specimen Applications: Textile fabrics and plastic films (and other thin, flexible materials)

- Clamping Mechanism: Screw side-action – a manual screw knob tightens the jaws, allowing fine control of clamping force and alignment. This mechanism prevents sudden jerks on the specimen and is ideal for brittle or sensitive samples.

- Jaw Faces: 40 mm jaw height, provided as two types – wave-profile serrated jaws (40 mm × 26 mm) for gripping textiles, and flat jaws (40 mm × 22 mm) for gripping plastic films. The wave-profile jaw has a sinusoidal serration that grips fabric securely across the width without cutting fibers, while the flat jaw presents a smooth surface (which can be used with a rubber pad if needed) for materials that must not be scored.

- Specimen Thickness: Up to 6 mm thick material can be accommodated between the jaws

- Connection: 10 mm pin (upper & lower) for mounting to load frame

- Dimensions: 125 mm total height, 60 mm body width, and 95 mm overall width. (The larger height compared to NGB103A accounts for the screw mechanism assembly.)

- Weight: ~1.22 kg for each grip (upper and lower are identical in weight)

- Applicable Standards: Enables compliance with the same standards as NGB103A (ASTM D882 for films, ASTM D5035 / ISO 13934-1 for fabrics, etc.), but with the added benefit of precise torque control on the specimen. This can be important for test methods requiring gradual loading or specific clamping pressure to avoid specimen damage.

| Specifications | |

|---|---|

| Application | Tension test for textile, plastic film |

| Maximum force | ≤1kN |

| Connection | Upper grip – Φ10mm pin |

| Lower grip – Φ10mm pin | |

| Height (A) | 125mm |

| Grip body width (B) | 60mm |

| Overall width (C) | 95mm |

| Working temperature | Ambient |

| Grip weight | Upper grip – 1.22kg |

| Lower grip – 1.22kg | |

| Wave-profile jaw face | 40(H)mm x 26(W)mm |

| Flat jaw face | 40(H)mm x 22(W)mm |

| Specimen thickness | ≤6mm |

NGB303A – Screw Side-Action Grip (3 kN Capacity)

Model NGB303A is a mid-range screw side-action grip rated for tensile loads up to 3 kN . It is designed to hold medium-sized specimens such as heavier fabric strips, composite strips, or plastic sheets that require more clamping force than the 1 kN grips. The NGB303A features a deep, robust frame (75 mm throat depth) and comes standard with two sets of flat jaw inserts of different heights (25 mm and 50 mm) . This dual-jaw-height design provides versatility: the user can choose a shorter jaw face for small specimens or a taller jaw face for larger specimens to increase the gripping area. For materials that are prone to slipping (like fabrics), optional serrated jaw inserts in both 25 mm and 50 mm heights are available .

- Maximum Load: ≤3 kN (300 kgf) capacity

- Specimen Applications: Stiffer textiles (industrial fabrics, webbing, belts) and plastic sheets or strips that require moderate clamping force. This grip is often used for tests on materials such as canvas, heavy non-wovens, thick polymer films, etc.

- Jaw Configuration: Flat jaw faces in two interchangeable sizes – 25 mm height and 50 mm height (both 25 mm width). The grip can be fitted with either pair of jaws depending on specimen size. The larger 50 mm jaws provide more contact area for wider or more slippery samples, while the 25 mm jaws are useful for narrower specimens or when required by specific test standards. Additionally, optional serrated jaws (with 25 mm or 50 mm face heights) can be used in place of the flat jaws for high-friction gripping of textiles. This flexibility in jaw faces allows one grip to cover a range of material types and standards.

- Specimen Thickness: Capable of clamping specimens up to 16 mm thick, accommodating multiple layers or thick materials.

- Connection: 10 mm pin coupling (upper and lower) for mounting to the test machine

- Dimensions: 135 mm height, 110 mm body width, 140 mm overall width; jaw throat depth ~75 mm. The relatively wide frame and deep throat allow gripping of larger sample widths and prevent jaw deflection at high loads.

- Weight: ~2.38 kg per grip half (upper or lower), reflecting a solid steel construction for durability under 3 kN loads.

- Applicable Standards: The NGB303A grip supports a variety of standard test methods. For instance, it can be used for textile strip tests such as ASTM D5035 or ISO 13934-1 (which often specify ~25 mm wide jaw faces), as well as for plastic sheet tests like ASTM D882 (where larger jaws can be beneficial for thicker specimens). The availability of both 25 mm and 50 mm jaw faces means the grip can easily conform to different standard requirements for jaw contact area.

| Specifications | |

|---|---|

| Application | Tension test for textile, plastic film and sheet |

| Maximum force | ≤3kN |

| Connection | Upper grip – Φ10mm pin |

| Lower grip – Φ10mm pin | |

| Height (A) | 135mm |

| Grip body width (B) | 110mm |

| Overall width (C) | 140mm |

| Depth (D) | 75mm |

| Working temperature | Ambient |

| Grip weight | |

| Upper grip | 2.38kg |

| Lower grip | 2.38kg |

| Flat jaw face (left) | 25(H)mm x 25(W)mm |

| Flat jaw face (right) | 50(H)mm x 25(W)mm |

| Specimen thickness | ≤16mm |

| Jaw face (Option) | |||

|---|---|---|---|

| No. | Length (A) mm | Width (B) mm | Type |

| NGB303A-11 | 25 | 25 | Serrated |

| NGB303A-12 | 50 | 25 | Serrated |

NGB503A – Screw Side-Action Grip (5 kN Capacity)

Model NGB503A is the highest-capacity screw-operated side-action grip in this category, with a maximum load rating of 5 kN . It is built for robust tensile testing of a wide range of materials, from strong textiles to tough plastics. The NGB503A has a symmetrical jaw design featuring 32 mm × 32 mm square clamping faces on both sides. The standard configuration includes flat jaw inserts that are rubber-coated, providing excellent grip on smooth specimens like plastic sheets without causing stress concentrations . To accommodate various test requirements, NextGen offers multiple optional jaw sets for the NGB503A: serrated (tooth) jaws, diamond-pattern jaws, and wave-profile jaws, each designed for specific materials (e.g., textiles, rubber, plastic films, etc.) .

- Maximum Load: ≤5 kN (500 kgf) capacity

- Specimen Applications: Versatile use for higher-strength fabrics (industrial textiles, geotextile samples that are narrower than those requiring NGA204C), polymer sheets and plates, plastic packaging materials (plastic bags, strapping, etc.), and other sheet or film materials up to the 5 kN range. This grip is often utilized in testing where specimens may be stronger or thicker than what the NGA503 series handles, but still require a side-action clamping mechanism.

- Jaw Faces (Standard): Two flat jaw faces, each 32 mm (H) × 32 mm (W), with a rubber-coated surface. The rubber coating on the flats provides a high-friction, non-marring grip suitable for smooth or delicate surfaces (like plastic film or paperboard), preventing slip without tearing the specimen.

- Optional Jaw Faces: A range of interchangeable jaw inserts is available for NGB503A to tailor the grip to specific materials:

- Diamond-Serrated Jaws (70 mm × 32 mm): For rubbery or highly elastic materials (e.g., rubber sheets, elastomer specimens) where a sharp, penetrating grip is needed to prevent slippage. The diamond pattern effectively bites into tough surfaces like rubber.

- Coarse Serrated Jaws (70 mm × 32 mm): For rigid plastic sheets, plates, or composites that can tolerate an aggressive grip. These serrated jaws ensure no slipping when testing high-strength plastics or thick sheet materials.

- Wave-Profile Jaws (32 mm × 32 mm): For flexible items such as textile straps, webbing, or plastic bags that benefit from a distributed clamping profile. The wave-profile (sometimes called “wave serrated”) jaw spreads the clamping force and prevents cut-through on very pliable specimens.

- Specimen Thickness: Up to 16 mm thickness capacity, allowing this grip to handle relatively thick materials or multiple-layer specimens.

- Connection: 10 mm pin interface on both upper and lower grip bodies

- Dimensions: 120 mm overall height, 110 mm body width, 170 mm overall width; jaw throat depth ~60 mm. This size provides a rigid frame to withstand 5 kN loads while accommodating a variety of specimen sizes.

- Weight: ~2.19 kg per grip half (upper or lower)

- Applicable Standards: The NGB503A’s flexibility with jaw faces makes it suitable for many standard test methods at the 5 kN load level. For instance, it can be used for textile grab tests (e.g., ASTM D5034 or ISO 13934-2) by employing serrated or wave-profile jaws that mimic required grip conditions. It also supports plastic sheet and film tests (like ASTM D882) using the flat rubber-coated jaws for proper load introduction. Additionally, for packaging materials such as plastic strapping or bags, it meets the needs of standards (e.g., ASTM D6775 for strap tensile testing) by allowing the appropriate jaw selection. In all cases, the screw-driven clamping and the variety of jaw options ensure that specimens are held according to the standard’s stipulations, preventing slippage and jaw-induced failures.

| Specifications | |

|---|---|

| Application | Tension test for textile, plastic film and sheet |

| Maximum force | ≤5kN |

| Connection | Upper grip – Φ10mm pin |

| Lower grip – Φ10mm pin | |

| Height (A) | 120mm |

| Grip body width (B) | 110mm |

| Overall width (C) | 170mm |

| Depth (D) | 60mm |

| Working temperature | Ambient |

| Grip weight | |

| Upper grip | 2.19kg |

| Lower grip | 2.19kg |

| Flat jaw face (rubber coated) | 32(H)mm x 32(W)mm |

| Flat jaw face | 32(H)mm x 32(W)mm |

| Specimen thickness | ≤16mm |

| Jaw face (Option) | ||||

|---|---|---|---|---|

| No. | Length (A) mm | Width (B) mm | Type | Specimen |

| WDSB503A-09/10 | 70 | 32 | Diamond | Rubber |

| WDSB503A-11/12 | 70 | 32 | Serrated | Plastic sheet |

| WDSB503A-15 | 32 | 32 | Wave-profile | Textile, plastic bag |

| WDSB503A-16 | 70 | 32 | ||

| WDSB503A-18 | 70 | 32 | ||

| Jaw face (Option) | ||||

|---|---|---|---|---|

| No. | Length (A) mm | Width (B) mm | Type | Specimen |

| WDSB503A-09/10 | 70 | 32 | Diamond | Rubber |

| WDSB503A-11/12 | 70 | 32 | Serrated | Plastic sheet |

| WDSB503A-15 | 32 | 32 | Wave-profile | Textile, plastic bag |

| WDSB503A-16 | 70 | 32 | ||

| WDSB503A-18 | 70 | 32 | ||

Related Products

Specialized Grips and Fixtures for Tear, Peel, and Puncture Testing

Specialized Accessories for Unique and Complex Testing Applications NextGen Material Testing Inc. provides a comprehensive selection of specialized grips and fixtures engineered for advanced testing applications that extend beyond traditional tensile and compression methods. Designed for seamless integration with our […]

TestStar® Series Grips and Fixtures for Hydraulic UTM Integration

Versatile, High-Performance Fixtures for Advanced Mechanical Testing NextGen’s TestStar® grips and fixtures are purpose-built to deliver superior mechanical testing performance in demanding industrial applications. These high-precision components are engineered to integrate seamlessly with our universal testing machines (UTMs), offering broad […]

Composite Grips and Fixtures for Tensile, Shear, and Delamination Tests

NextGen Material Testing, Inc. offers a complete portfolio of advanced grips and fixtures specifically engineered for composite material testing with universal testing machines. These solutions meet a wide array of international testing standards including ASTM D3039, ISO 527, ASTM D2344, […]

Grips and Fixtures for Tensile, Shear, and Flexural Testing of Wood

Specialized Grips and Fixtures for Wood Tensile, Shear, Bending, and Fastener Withdrawal Testing NextGen offers a robust line of specialized grips and fixtures for wood material testing, supporting universal testing machines (UTM) across industrial and academic laboratories. These components are […]

3-Point and 4-Point Bending Fixtures for Uniform Moment Flexural Testing

Precision 3-Point and 4-Point Bending Fixtures for NextGen Universal Testing Machines NextGen’s bending fixtures are precision-engineered to enable accurate flexural testing of various materials, including metals, ceramics, composites, concrete, bricks, and construction products. These accessories are optimized for seamless integration […]

Wedge Tensile Grips for High-Load Metal and Composite Testing

Precision Wedge Grips for High-Strength Tensile Testing NextGen’s wedge tensile grips are engineered to deliver superior performance in tensile strength testing using Universal Testing Machines (UTMs). These grips use a mechanical wedge action that enhances gripping pressure proportionally with the […]

Pneumatic Grips for Fast and Repeatable Clamping

Precision Clamping Solutions with Compressed-Air Actuation from NextGen NextGen’s pneumatic grips are engineered for precise, high-throughput testing applications using universal testing machines (UTMs). These air-actuated systems ensure uniform clamping pressure, reduced operator fatigue, and faster sample mounting, ideal for quality […]

Shoulder Fixtures for Pull-Off and Component Testing

Precision Shoulder Grips for Tensile Testing on NG-EML and SHM Series UTMs NextGen’s shoulder fixtures are specialized tensile grips designed to accommodate specimens with shoulder geometries. These fixtures are critical for standardized testing in accordance with ISO and ASTM protocols […]

Compression Fixtures for Axial Load Testing of Rigid Samples

Precision Compression Test Fixtures for NG-EML and SHM Series UTMs NextGen’s compression fixtures are designed for high-accuracy compression testing of a range of materials including metals, polymers, elastomers, foams, composites, and construction materials. These fixtures are engineered for seamless integration […]

Bending Fixtures for Standard 3-Point Flexural Testing

3-Point and Marker Bending Fixtures for Flexural Testing NextGen’s bending fixtures are engineered for precision flexural testing of various materials, including thermoplastics, composites, metals, and laminated structures. Designed to operate with NG-EML and SHM Universal Testing Machines, these fixtures offer […]

Eccentric Roller Grips for Thin and Flexible Specimens

Optimized Clamping System for Tensile Testing of Sheet Materials and Soft Specimens Eccentric roller grips from NextGen Test are designed to meet the demanding needs of tensile testing applications involving thin, flexible, or soft materials. Utilizing a friction-based clamping mechanism […]

Self-Tightening Grips for Deformable and Elastic Materials

Self-Tightening Grips for Tensile Testing NextGen’s self-tightening grips are engineered for precise tensile testing of deformable and elastic materials such as elastomers, foams, thin plastics, textiles, and biomedical specimens. These grips automatically increase clamping pressure as tensile force is applied, […]

Snubbing Grips for Wire and Cable Tensile Testing

Overview of Snubbing Grips for Tensile Testing of Wires, Cables, Ropes, and Geogrids Snubbing grips (also known as capstan grips) are designed to secure challenging specimens like steel wires, wire ropes, fiber ropes, textile strips, and geogrids during tensile testing. […]