Metal Testing Equipment

Standards

Description

Class C

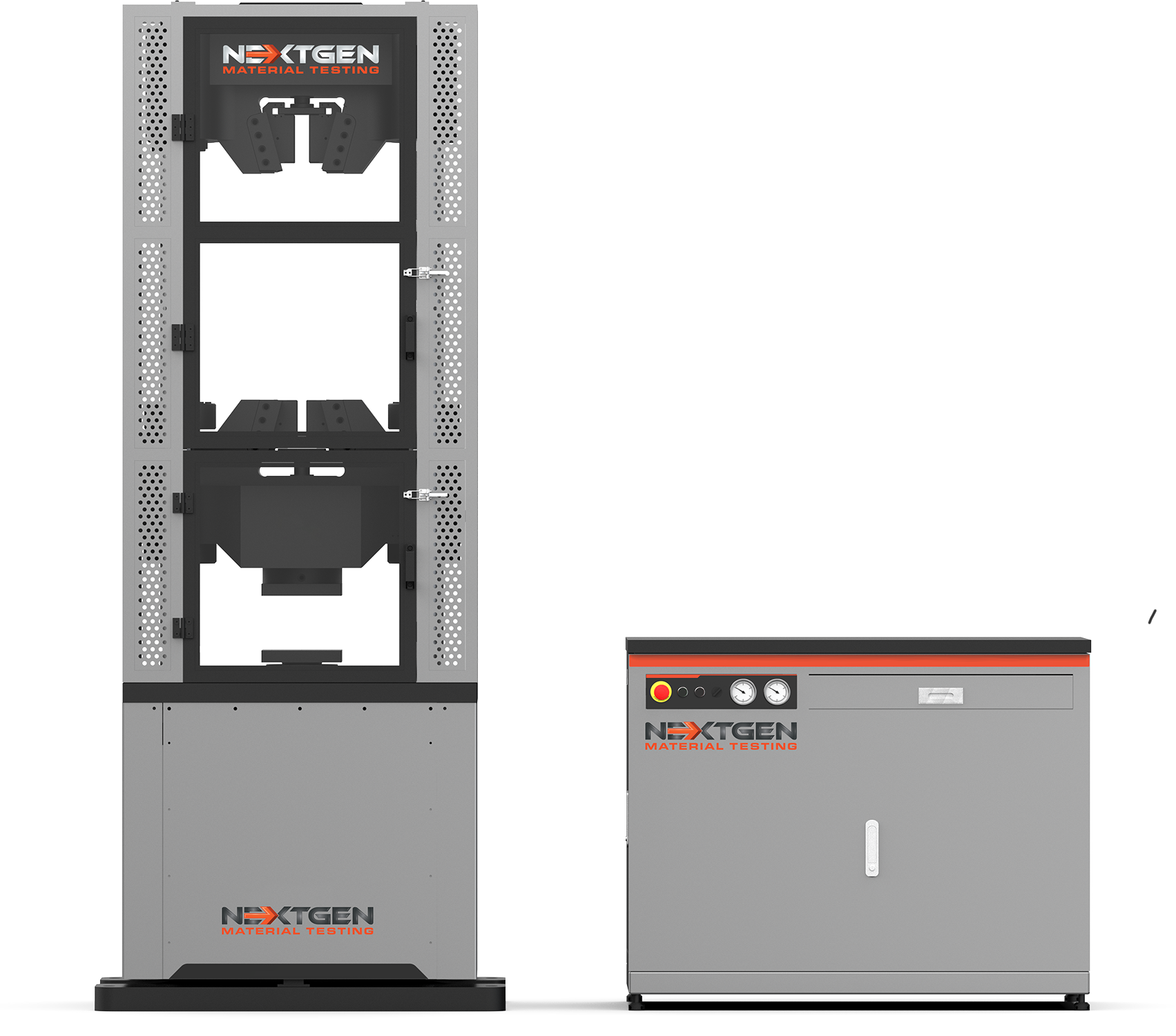

The NG-SHM Class C series is designed to provide a solution for your high-force mechanical testing of a diverse range of materials covering many different industries. Class C has been designed specifically with a longer jaw face for tensile testing of steel wire.

Force Capacity: 600kN (134885.36 lbf), 1000kN (224808.94 lbf)

Load Frame Configuration: 6 column, servo-controlled hydraulic

Test Space: Dual zone (tension on top, compression on bottom)

Typical Specimens: Fasteners, rebar, chain, welds, castings, stranded steel wire

Load Frame

- Specifically designed with a longer jaw face for tensile testing of stranded steel wire

- Lead screw driven crosshead to adjust the test space

- Durable 6-column load frame design incorporates 3-position crosshead, adjustable specimen positioning, precision guide columns, thick crosshead and a base beam minimizes the load frames stored energy while producing reliable, stable, accurate loads, strain and modulus values.

- Ergonomically designed load frames ensure safety, reduce operator fatigue, and provide the highest level of flexibility.

- Standard Dual Zone Test Space for reducing setup time

- "Quick Return" hydraulic valve for higher throughput

- Automatic limit checking for crosshead position, overload, over temperature, over voltage, etc.

- The system can return automatically, the oil cylinder can return to the original position manually or automatically after finishing testing

- Positive specimen holding is ensured by the wedge action hydraulic operated grips

- Encoder mounted on the seat is for position measurement of the crosshead to provide higher accuracy

- Servo valve provides high stability and reliability

Load Cell

- Uses strain gauge load cell technology to measure the force being applied to your specimen. The load cell is located in the lower grip and is used to directly measure tensile force.

- Precise load cell measures and captures sensitively tension and compression force, high accuracy load measurement resolution reaches 1/350000.

- Quality load cell ensures high precision and repeatability.

NG-SHM Class C - Servo Hydraulic Testing Machine Technical Specifications

| Servo-Hydraulic Universal Testing Machine | ||

|---|---|---|

| Model | SHM605 | SHM106 |

| Class | Class C | |

| Capacity | 600kN (134885.36 lbf) | 1000kN (224808.94 lbf) |

| Calibration accuracy | Class 1 / Class 0.5 | |

| Force range | 1% - 100%FS | |

| Force accuracy | Better than ±1%/±0.5% | |

| Extension Range | 1% - 100%FS | |

| Extension Accuracy | Better than ±1%/±0.5% | |

| Extension Resolution | 1/350000 of max extension | |

| Actuator (piston) speed (mm/min) |

0 - 140 | 0 - 100 |

| Force Loading Speed | 0.02% - 2% FS /s | |

| Column Number | 6 | 6 |

| Column Spacing (test space width) (cm) |

41 | 43 |

| Maximum Tension Space(cm) | 110 | 110 |

| Maximum Compression Space (cm) |

95 | 95 |

| Diameter of Round Specimens (mm) |

Ø9 - Ø18 | Ø9 - Ø18 |

| Diameter of Threaded Steel (mm) |

Ø10 - Ø30 | Ø10 - Ø45 |

| Thickness of Flat Specimens (mm) |

2 - 20 | 2 - 40 |

| Compression Platens (cm) | ?15 | 20 x 20 |

| Actuator (piston) Stroke (cm) |

25 | 25 |

| Frame Dimensions (l x w x h) (cm) |

94 x 65 x 294 | 102 x 67 x 305 |

| Hydraulic Power Unit Dimensions (l x w x h) (cm) |

45.5" x 24" x 35.5" / 115 x 60 x 90 cm | |

| Power Consumption (kW) | 6 | 6 |

| Frame Weight |

6613.868 lbs / 3000 kg | 11023.11 lbs / 5000 kg |

FAQs

The NG-SHM Class C Servo Hydraulic Testing Machine was developed to provide long-term precision and stability. However, it is recommended that you conduct regular calibration annually or as required by your quality control system or applicable standards (such as ISO 7500-1 or ASTM E4). Proper usage and scheduled service checks are required for maintaining Class 1 or Class 0.5 calibration accuracy.

NextGen's technical support team provides on-site maintenance and calibration services. In order to reduce downtime, certified technicians can conduct system checks, recalibrations, and adjustments on-site. Remote support and guidance are also accessible to assist with basic maintenance tasks between service intervals, providing additional convenience.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the NG-SHM Class C – Servo Hydraulic Testing Machine fully complies with ISO 7500-1.

ISO 7500-1 is a recognized international standard that defines verification requirements for force measuring systems for uniaxial testing machines. It guarantees that the equipment provides reliable, traceable, and precise force readings during tension and compression tests. Machines certified under ISO 7500-1 must undergo calibration and verification procedures using standard force-measuring devices to confirm their accuracy over the full range of operations.

The NG-SHM Class C series meets this standard with a force measurement system verified for Class 1 and Class 0.5 accuracy. This makes it suitable for demanding testing applications where data precision and repeatability are essential. ISO 7500-1 compliance assures laboratories and quality control environments that the test results obtained from the machine are valid and in accordance with international testing protocols.

Click here to learn more about the product or here to receive a personalized quote.

The NG-SHM Class C – Servo Hydraulic Testing Machine is equipped with a standard dual-zone test space, which includes a tension zone at the top and a compression zone at the bottom. This layout allows both test types to be performed on the same machine without major reconfiguration.

By separating the zones, the operator does not have to remove and reinstall fixtures when switching between tension and compression tests. Each zone remains ready for its specific function, simplifying test preparation.

This configuration also reduces setup errors and improves workflow efficiency. Operators can complete more tests in less time, especially in high-throughput environments. The dual-zone structure improves usability while maintaining precise alignment and accurate force application throughout both testing modes.

Click here to learn more about the product or here to receive a personalized quote.

The NG-SHM Class C – Servo Hydraulic Testing Machine includes automatic limit checking to monitor critical system parameters during operation. These checks prevent damage to the machine and improve operator safety.

The system constantly monitors the crosshead position to avoid movement beyond safe travel limits. It also detects overload conditions where applied forces exceed the rated capacity, which risks both specimens and equipment. Additionally, it checks for abnormal temperature rises, excessive voltage, and other faults that could affect performance or cause equipment failure.

If any limit is exceeded, the machine automatically halts operation or adjusts as needed to protect its internal systems. This built-in monitoring allows for safer testing, extends machine life, and makes certain that every test is conducted within defined and secure operating parameters. It reduces error chances and supports consistent, trouble-free performance over time.

Click here to learn more about the product or here to receive a personalized quote.

The NG-SHM Class C – Servo Hydraulic Testing Machine is an ideal solution for professionals and organizations that require high-force, precision mechanical testing of metallic materials. It is especially beneficial for quality control engineers, research institutions, testing laboratories, and manufacturers who need to validate the mechanical properties of components under both tension and compression.

This equipment is highly suitable for industries such as construction, automotive, aerospace, shipbuilding, steel production, infrastructure, and energy. Typical applications include testing rebar, bolts, welded joints, structural chains, and stranded steel wire used in cables and tension elements.

The system’s dual-zone configuration, high accuracy, and broad capacity range make it a valuable tool for assuring safety, performance, and compliance with international material testing standards. Whether used for certification, research, or routine inspection, the NG-SHM Class C provides dependable results for professionals working with critical structural materials.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

NG-SHM Series A — Servo-Hydraulic Universal Testing Machines (300 kN – 3000 kN)

NG-SHM Series A is a high-force servo-hydraulic UTM for static tensile and compression testing of metals. Capacity options from 300 to 3000 kN support oversized round and flat specimens beyond electromechanical limits. The dual-zone configuration enables tension on the upper head and compression on the lower platen without fixture changeover. GenTest software offers standards-based method libraries, real-time curves, automatic calculations, and exportable reports. The system is built for ASTM/ISO metal strength testing in heavy industrial and research environments.

NG-SHM CLASS DP - Servo Hydraulic Testing Machine

600kN-2000kN - Servo-Hydraulic Universal Testing Machine - Side Action Wedge Grip 2/4 columns, servo-controlled hydraulic

NG-SHM Class D - Servo Hydraulic Universal Testing Machine

600kN-2000kN - Servo-Hydraulic Universal Testing Machine 2/4 columns, servo-controlled hydraulic

NG-SHM Class B - Servo Hydraulic Testing Machine

300kN-3000kN - Servo-Hydraulic Universal Testing Machine 6 column, servo-controlled hydraulic

GenTest v3.0 Software for Universal Testing Machines

GenTest Software is developed for testing facilities that require controlled execution on universal testing machines. The method-driven workflow keeps setup parameters, recorded data, calculations, and reporting connected in a single record. The software supports standards-based programs aligned with ASTM, ISO, DIN, EN, and BS and is used for tensile, compression, bending, and shear testing. It helps teams produce consistent results and documentation for QA/QC and customer reporting.