Metal Testing Equipment

Metal testing equipment is used to assess the mechanical and structural performance of metals during manufacturing, processing, and final quality control. These systems assess hardness, tensile strength, ductility, impact resistance, and other performance indicators of materials, thereby guaranteeing that they comply with stringent engineering and safety standards.

At NextGen Material Testing, we offer a comprehensive selection of certified metal testing machines that are engineered to guarantee precision, repeatability, and adherence to international standards such as ASTM, ISO, and DIN. Our material testing systems are capable of supporting a diverse array of applications, including advanced analysis in research laboratories and quality control on the factory floor.

NextGen provides fully integrated solutions that are customized to meet your operational needs, including hardness testing systems, universal testing machines (UTMs), impact testers, metallography preparation tools, and tensile specimen milling equipment.

Sub-categories

Metal Hardness Testing Equipment - Bench Top and Portable Solutions

Hardness testing is the measure of how resistant a solid matter is to permanent shape change when an indenter is applied at a known force. Check out our range of Rockwell, Brinell, Micro/Macro Vickers and Knoop Hardness Testers.

Universal Testing Machines for Metal Testing

Universal Testing Machines can be configured for static testing of multiple properties such as tensile, compression, flexure, tearing, peeling, bending and shearing tests. Check out our range of Force Stands, Electromechanical and Servo Hydraulic Universal Testing Machines.

Metallography Sample Preparation Equipment

NextGen metallography equipment is focused on the structure refining of metals and alloys. It specializes in different methods of speci-men preparation including cutting, polishing and grinding.

Tensile Sample Preparation Equipment

NextGen Material Testing, in partnership with TensileMill CNC Inc., offers equipment for preparing both flat (dog-bone) and round (cylindrical) tensile specimens. The machines in this category are available in different sizes and capacities to match laboratory research, routine quality control, and continuous production testing. Users can select the required specimen dimensions or standard and prepare consistent samples with a simple, guided workflow.

Pendulum Impact Testers - Charpy and Izod Systems

Pendulum Charpy/Izod Impact Testing is a high strain-rate test to determine the amount of energy absorbed by a material during fracture.

Consumables - Hardness Testing, Metallography, Tensile and More…

NextGen offers a full scope of Hardness Testing Consumables, Metallography Consumables, Tensile Testing Consumables, Tensile Sample Preparation Consumables, Abrasion Testing Consumables and more. You will be able to find an extensive variety of high quality consumables and spare parts at some of lowest pricing in the North American market.

Products

Impact Specimen Cooling Temperature Chamber – NG-ISCC Series

The NG-ISCC Low Temperature Chamber is built to cool and stabilize Charpy impact specimens before testing. It supports conditioning from +30°C down to -60°C, -80°C, -100°C, or -196°C depending on the model. NG-ISCC-60 and NG-ISCC-80 use compressor-based refrigeration, while NG-ISCC-100 and NG-ISCC-196 use liquid nitrogen cooling to achieve ultra-low setpoints. Temperature control accuracy is ≤ ±0.5°C with a 0.01°C instrument resolution, using ethanol or another non-freezing solution as the cooling medium. It is widely used in materials testing and quality control programs to evaluate low-temperature toughness of metals and alloys.

Automatic Longitudinal Polisher System for Tensile Specimens – NG-AutoPol

The NG-AutoPol Automatic Longitudinal Polisher System by NextGen Material Testing Inc. is engineered to minimize grinding stress and residual surface stress that often remain after initial machining operations such as turning or milling. This advanced machine delivers precise longitudinal polishing […]

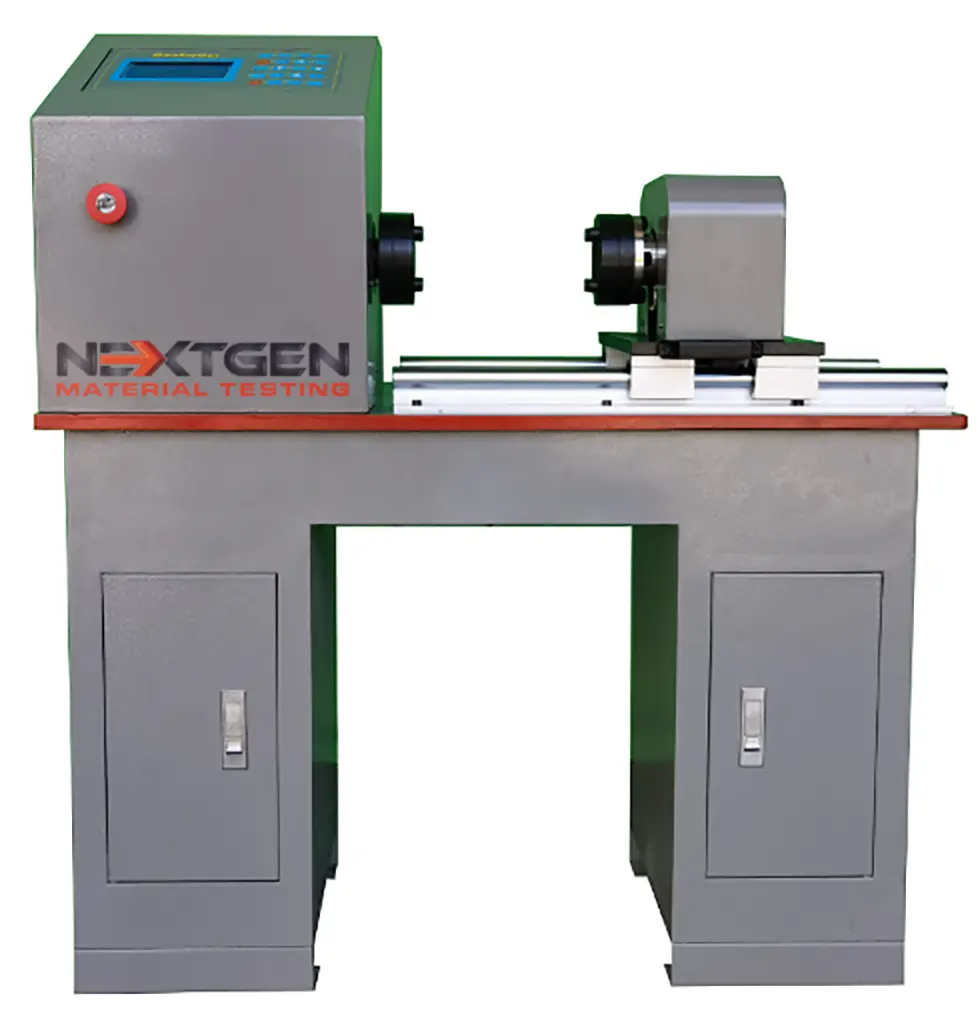

NextGen GenTor Horizontal Torsion Tester

NextGen GenTor Torsion Tester boasts a horizontal type load frame with high stiffness, ensuring accurate and reliable test results.

DWT-1800 Computer Controlled Drop Weight Impact Testing Machine

DWT-1800 Impact Testing Machine is specifically designed for determining the non-plastic transformation temperature of ferritic steel.

Drop Weight (Falling Weight Impact) Tester – NG-FWT1 & NG-FWT2 (Up to 2000 J)

NG-FWT1 and NG-FWT2 are low-capacity vertical drop weight impact testers for controlled impact testing up to 2000 J. They let you set drop height, impact speed, and energy to reproduce repeatable real-world impact events. Operation is available via an integrated touchscreen with DROPTest-S or a PC with DROPTest-BASIC for advanced evaluation and data management. Optional instrumentation supports high-speed measurement up to 4 MHz for force and impact analysis. The platform can be expanded with temperature-controlled testing and robotic automation for higher throughput and consistency.

Metallography plays a critical role in understanding the internal structure and grain behavior of metals. Before any microstructural analysis or surface testing can take place, samples must be properly prepared. NextGen offers a complete suite of

Metallography plays a critical role in understanding the internal structure and grain behavior of metals. Before any microstructural analysis or surface testing can take place, samples must be properly prepared. NextGen offers a complete suite of  Proper specimen preparation directly affects the reliability of tensile test results. Deviations in specimen dimensions or surface finish can result in misleading data and failed certifications. At NextGen, we supply advanced flat and round

Proper specimen preparation directly affects the reliability of tensile test results. Deviations in specimen dimensions or surface finish can result in misleading data and failed certifications. At NextGen, we supply advanced flat and round  Impact testing is used to measure how materials respond to fast, high-energy loading conditions. It’s a vital method for assessing toughness, ductility, and the tendency of a material to fail in brittle or ductile modes—particularly in safety-critical applications. NextGen provides high-performance Charpy and Izod

Impact testing is used to measure how materials respond to fast, high-energy loading conditions. It’s a vital method for assessing toughness, ductility, and the tendency of a material to fail in brittle or ductile modes—particularly in safety-critical applications. NextGen provides high-performance Charpy and Izod