Metal Testing Equipment

Testing the mechanical properties of Metals reveal the elastic and inelastic behaviors of a material when a force is applied. We are able to determine if a Metal can withstand the common stresses for its intended purpose by measuring elasticity, tensile strength, elongation, hardness, fracture toughness, impact resistance, stress rupture and fatigue limit.

The most common testing is done with a Universal Testing Machine for testing the tensile properties of a Metal specimen (ASTM E8). Tension tests provide information on the strength and ductility of materials under uniaxial tensile stress until the point of fracture.

Sub-categories

Metal Hardness Testing Equipment - Bench Top and Portable Solutions

Hardness testing is the measure of how resistant a solid matter is to permanent shape change when an indenter is applied at a known force. Check out our range of Rockwell, Brinell, Micro/Macro Vickers and Knoop Hardness Testers.

Universal Testing Machines for Metal Testing

Universal Testing Machines can be configured for static testing of multiple properties such as tensile, compression, flexure, tearing, peeling, bending and shearing tests. Check out our range of Force Stands, Electromechanical and Servo Hydraulic Universal Testing Machines.

Metallography Sample Preparation Equipment

NextGen metallography equipment is focused on the structure refining of metals and alloys. It specializes in different methods of speci-men preparation including cutting, polishing and grinding.

Pendulum Impact Testers - Charpy and Izod Systems

Pendulum Charpy/Izod Impact Testing is a high strain-rate test to determine the amount of energy absorbed by a material during fracture.

Consumables - Hardness Testing, Metallography, Tensile and More…

NextGen offers a full scope of Hardness Testing Consumables, Metallography Consumables, Tensile Testing Consumables, Tensile Sample Preparation Consumables, Abrasion Testing Consumables and more. You will be able to find an extensive variety of high quality consumables and spare parts at some of lowest pricing in the North American market.

Products

Wedge Tensile Grips for High-Load Metal and Composite Testing

Precision Wedge Grips for High-Strength Tensile Testing NextGen’s wedge tensile grips are engineered to deliver superior performance in tensile strength testing using Universal Testing Machines (UTMs). These grips use a mechanical wedge action that enhances gripping pressure proportionally with the […]

Pneumatic Grips for Fast and Repeatable Clamping

Precision Clamping Solutions with Compressed-Air Actuation from NextGen NextGen’s pneumatic grips are engineered for precise, high-throughput testing applications using universal testing machines (UTMs). These air-actuated systems ensure uniform clamping pressure, reduced operator fatigue, and faster sample mounting, ideal for quality […]

Shoulder Fixtures for Pull-Off and Component Testing

Precision Shoulder Grips for Tensile Testing on NG-EML and SHM Series UTMs NextGen’s shoulder fixtures are specialized tensile grips designed to accommodate specimens with shoulder geometries. These fixtures are critical for standardized testing in accordance with ISO and ASTM protocols […]

Compression Fixtures for Axial Load Testing of Rigid Samples

Precision Compression Test Fixtures for NG-EML and SHM Series UTMs NextGen’s compression fixtures are designed for high-accuracy compression testing of a range of materials including metals, polymers, elastomers, foams, composites, and construction materials. These fixtures are engineered for seamless integration […]

Bending Fixtures for Standard 3-Point Flexural Testing

3-Point and Marker Bending Fixtures for Flexural Testing NextGen’s bending fixtures are engineered for precision flexural testing of various materials, including thermoplastics, composites, metals, and laminated structures. Designed to operate with NG-EML and SHM Universal Testing Machines, these fixtures offer […]

Eccentric Roller Grips for Thin and Flexible Specimens

Optimized Clamping System for Tensile Testing of Sheet Materials and Soft Specimens Eccentric roller grips from NextGen Test are designed to meet the demanding needs of tensile testing applications involving thin, flexible, or soft materials. Utilizing a friction-based clamping mechanism […]

Self-Tightening Grips for Deformable and Elastic Materials

Self-Tightening Grips for Tensile Testing NextGen’s self-tightening grips are engineered for precise tensile testing of deformable and elastic materials such as elastomers, foams, thin plastics, textiles, and biomedical specimens. These grips automatically increase clamping pressure as tensile force is applied, […]

Snubbing Grips for Wire and Cable Tensile Testing

Overview of Snubbing Grips for Tensile Testing of Wires, Cables, Ropes, and Geogrids Snubbing grips (also known as capstan grips) are designed to secure challenging specimens like steel wires, wire ropes, fiber ropes, textile strips, and geogrids during tensile testing. […]

HDT/VICAT Testing Machine – Thermal Analysis for Plastics NG-HDT

Description The HDT/VICAT testing machine offers high precision, reliability, and efficiency for the thermal analysis of thermoplastics and polymers. Engineered with advanced sensors and high-temperature-resistant components, it ensures minimal deformation, fast response, and precise data transmission, delivering consistent and accurate […]

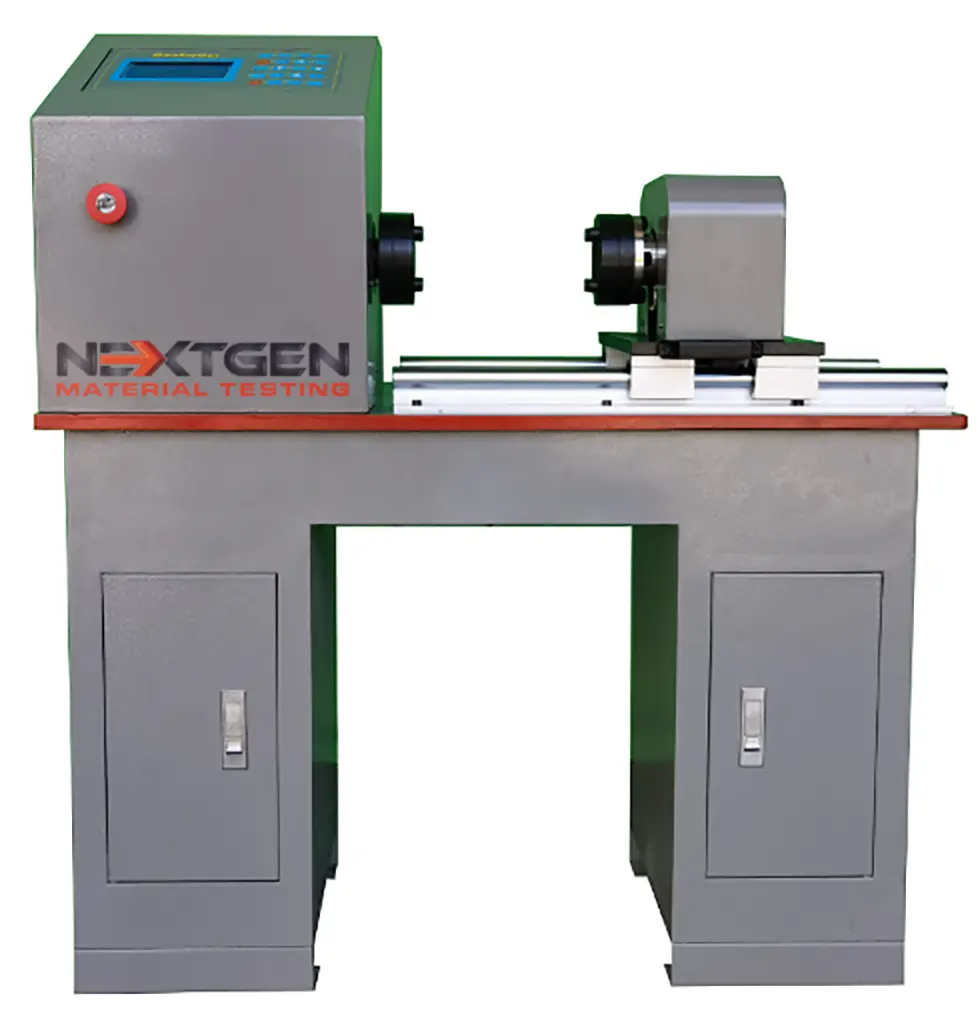

NextGen GenTor Horizontal Torsion Tester

NextGen GenTor Torsion Tester boasts a horizontal type load frame with high stiffness, ensuring accurate and reliable test results.

DWT-1800 Computer Controlled Drop Weight Impact Testing Machine

DWT-1800 Impact Testing Machine is specifically designed for determining the non-plastic transformation temperature of ferritic steel.