Metal Testing Equipment

Standards

Description

Servo Hydraulic Tensile Testing System – Class A

The SHM class A Series addresses the needs of standardized and routine testing, providing the user high quality and exceptionally affordable price. This multi-column testing system is suited for a full range of testing applications, including tension, compression, shearing, bending, and more.

The NG-SHM Class A series is designed to provide a solution for your high-force mechanical testing of a diverse range of materials covering many different industries.

Force Capacity: 200kN, 300kN, 500kN, 600kN, 1000kN, 2000kN and 3000kN

Load Frame Configuration: 4 or 6 column, servo-controlled hydraulic

Test Space: Dual zone (tension on top, compression on bottom)

Load Frame

- Lead screw driven crosshead to adjust the test space

- Durable 6-column load frame design incorporates 3-position crosshead, adjustable specimen positioning, precision guide columns, thick crosshead and a base beam minimizes the load frames stored energy while producing reliable, stable, accurate loads, strain and modulus values.

- Ergonomically designed load frames ensure safety, reduce operator fatigue, and provide the highest level of flexibility.

- Standard Dual Zone Test Space for reducing setup time

- "Quick Return" hydraulic valve for higher throughput

- Automatic limit checking for crosshead position, overload, over temperature, over voltage, etc.

- The system can return automatically, the oil cylinder can return to the original position manually or automatically after finishing testing

- Positive specimen holding is ensured by the wedge action hydraulic operated grips

- Encoder mounted on the seat is for position measurement of the crosshead to provide higher accuracy

- Servo valve provides high stability and reliability

Load Cell Resolution

- Uses strain gauge load cell technology to measure the force being applied to your specimen. The load cell is located in the lower grip and is used to directly measure tensile force.

- Precise load cell measures and captures sensitively tension and compression force, high accuracy load measurement resolution reaches 1/500000.

- Quality load cell ensures high precision and repeatability for your Tensile Testing System

NG-SHM Class A - Servo Hydraulic Testing Machine Technical Specifications

| Servo-Hydraulic Universal Testing Machine | ||||||

|---|---|---|---|---|---|---|

| Model | SHM205 SHM305 |

SHM505 SHM605 |

SHM1006 | SHM2006 | SHM3006 | |

| Class | Class A | |||||

| Capacity | 200kN 300kN |

500kN 600kN |

1000kN | 2000kN | 3000kN | |

| Calibration accuracy | Class 1 / Class 0.5 | |||||

| Force range | 1% - 100%FS | |||||

| Force accuracy | Better than ±1%/±0.5% | |||||

| Extension Range | 1% - 100%FS | |||||

| Extension Accuracy | Better than ±1%/±0.5% | |||||

| Extension Resolution | 1/350000 of max extension | |||||

| Actuator (piston) speed (mm/min) |

0 - 180 | 0 - 140 | 0 - 90 | 0 - 70 | 0 - 100 | |

| Force Loading Speed | 0.02% - 2% FS /s | |||||

| Column Number | 4 | 6 | 6 | 6 | 6 | |

| Column Spacing (test space width) (cm) |

40.5 | 43 | 45 | 73 | 53 | |

| Maximum Tension Space (cm) |

52 | 71 | 75 | 90 | 120 | |

| Maximum Compression Space (cm) |

52 | 70 | 66 | 75 | 100 | |

| Diameter of Round Specimens (mm) |

Φ10 - Φ32 | Φ10 - Φ18 Φ18 - Φ29 Φ29 - Φ40 | Φ15 - Φ30 Φ30 - Φ45 Φ45 - Φ55 | Φ15 - Φ70 | Φ30 - Φ110 | |

| Thickness of Flat Specimens (mm) |

2 - 25 | 2 - 16 16 - 30 | 2 - 20 20 - 40 | 2 - 70 | 10 - 100 | |

| Compression Platens (cm) | Φ12 | Φ15 | 20 x 20 | Φ24 | Φ28 | |

| Actuator (piston) Stroke (cm) |

15 | 25 | 25 | 25 | 30 | |

| Frame Dimensions (l x w x h) (cm) |

82 x 57 x 195.5 | 94 x 65 x 240 | 102 x 67 x 260 | 137 x 82 x 330 | 132 x 95 x 395.8 | |

| Hydraulic Power Unit Dimensions (l x w x h) (cm) |

115 x 60 x 90cm | |||||

| Hydraulic Power Unit Weight (kg) |

300 | 380 | ||||

| Power Consumption (kW) | 3.5 | 4 | 6 | 6 | 6 | |

| Power Supply | 3 Phase, AC380V, 50Hz | |||||

| Frame Weight (kg) | 1500 | 2500 | 3500 | 8000 | 8000 | |

| Main Cylinder Hoses Length | 2.4m x 1 | 2.4m x 1 | 2.6m x 1 | 2.6m x 1 | 2.6m x 1 | |

| Upper Grip Hoses Length | 3.6m x 2 | 4.0m x 2 | 4.2m x 2 | 4.6m x 2 | 5.4m x 2 | |

| Lower Grip Hoses Length | 3.1m x 2 | 3.35m x 2 | 3.35m x 2 | 3.9m x 2 | 4.7m x 2 | |

| Optional Bending Fixture | Support Span (cm) | 3 - 35 | 3 - 40 | 3 - 40 | 6 - 50 | 6 - 50 |

| Bending Nose Diameter (Φ, mm) |

3 - 65 | 3 - 200 | 3 - 300 | 3 - 300 | 3 - 300 | |

FAQs

The hydraulic wedge-action gripping system in the NG-SHM Class A – Servo Hydraulic Testing Machine is designed to reduce variables that could affect material deformation and fracture behavior, allowing test results to accurately reflect the material’s true mechanical properties.

One of the key concerns in tensile and compression testing is specimen slippage or improper clamping, which can lead to uneven force distribution and inaccurate strain measurements. The wedge-action mechanism addresses this by automatically increasing clamping force as load is applied, securing the specimen with a uniform grip. This prevents premature deformation or micro-movements that could alter stress distribution and strain analysis.

Additionally, hydraulic operation provides precise and repeatable clamping pressure, reducing inconsistencies caused by manual adjustments. By maintaining stable specimen positioning, the system allows for accurate force application, making sure that load values, elongation, and failure characteristics align with the material’s actual mechanical performance.

This level of control is particularly important for high-precision applications in aerospace, automotive, and metallurgical research, where understanding true material behavior is key for material qualification, safety assessments, and failure analysis.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

NG-SHM CLASS DP - Servo Hydraulic Testing Machine

600kN-2000kN - Servo-Hydraulic Universal Testing Machine - Side Action Wedge Grip 2/4 columns, servo-controlled hydraulic

NG-SHM Class D - Servo Hydraulic Universal Testing Machine

600kN-2000kN - Servo-Hydraulic Universal Testing Machine 2/4 columns, servo-controlled hydraulic

NG-SHM Class C - Servo Hydraulic Testing Machine

600kN-1000kN - Servo-Hydraulic Universal Testing Machine 6 column, servo-controlled hydraulic

NG-SHM Class B - Servo Hydraulic Testing Machine

300kN-3000kN - Servo-Hydraulic Universal Testing Machine 6 column, servo-controlled hydraulic

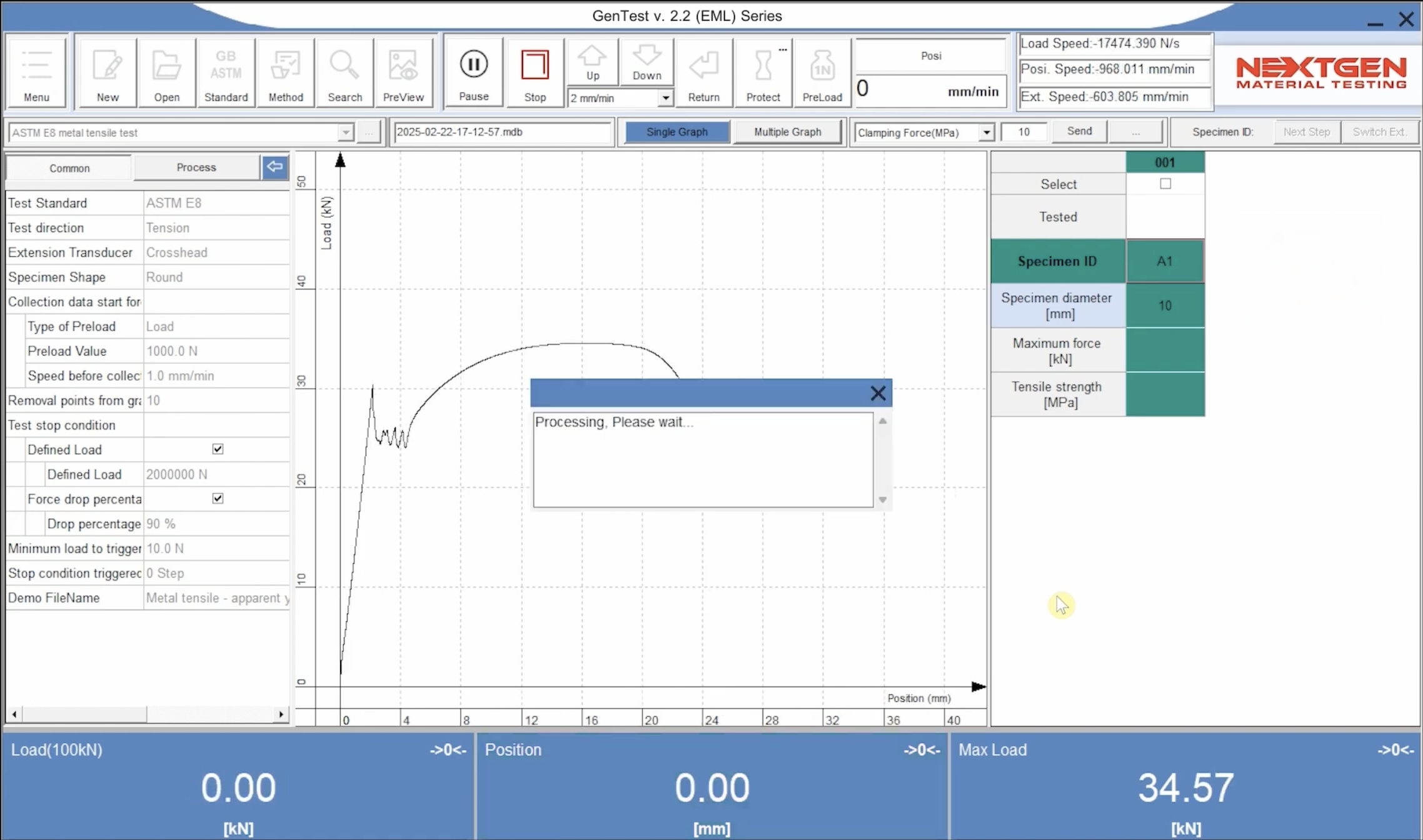

GenTest V 2.0: Advanced Testing Software for Servo-Hydraulic Universal Testing Machines

Gentest is designed to enhance your ability to perform accurate and repeatable mechanical testing of materials, components and finished goods across a full spectrum of applications.