Metal Testing Equipment

Reliable Fixturing Solutions for High-Force Hydraulic UTMs

Hydraulic Universal Testing Machines (UTMs) from NextGen are engineered for high-force material testing across demanding industries like aerospace, automotive, construction, and metallurgy. To match the force and complexity of these applications, specialized grips and fixtures are required to deliver safe, accurate, and repeatable results. NextGen’s fixturing solutions for hydraulic UTMs are designed in full compliance with ASTM, ISO, DIN, and JIS standards, covering a wide range of tests including tensile shear, proof load, flexural bending, and rock or composite splitting.

Hydraulic Universal Testing Machines (UTMs) from NextGen are engineered for high-force material testing across demanding industries like aerospace, automotive, construction, and metallurgy. To match the force and complexity of these applications, specialized grips and fixtures are required to deliver safe, accurate, and repeatable results. NextGen’s fixturing solutions for hydraulic UTMs are designed in full compliance with ASTM, ISO, DIN, and JIS standards, covering a wide range of tests including tensile shear, proof load, flexural bending, and rock or composite splitting.

Each fixture is fully compatible with NextGen’s hydraulic UTM systems, ensuring smooth integration and high durability even under daily intensive use. Whether you are testing fasteners, composites, or structural components, these grips and fixtures provide the reliability and performance necessary to meet modern testing demands.

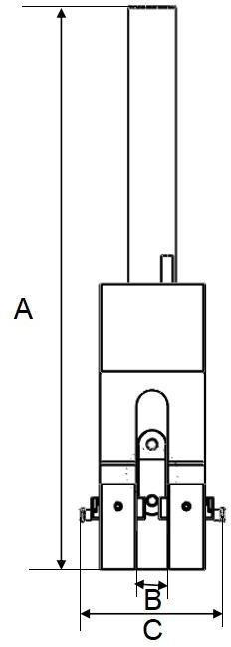

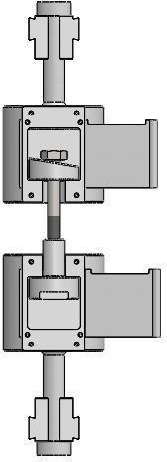

NGA106A – Tensile Shear Fixture

The NGA106A Tensile Shear Fixture is designed for shear testing of steel welding mesh. With a maximum load capacity of up to 1000 kN, this fixture offers precise and repeatable performance for suspended clamping applications. It features hydraulic clamping from the upper grip and supports a variety of standard specimen diameters. The fixture conforms to GB/T 1499.3 and is engineered for use under ambient test conditions.

The NGA106A Tensile Shear Fixture is designed for shear testing of steel welding mesh. With a maximum load capacity of up to 1000 kN, this fixture offers precise and repeatable performance for suspended clamping applications. It features hydraulic clamping from the upper grip and supports a variety of standard specimen diameters. The fixture conforms to GB/T 1499.3 and is engineered for use under ambient test conditions.

- Application: Shear tests for steel welding mesh.

- Maximum Capacity: ≤1000 kN load.

- Connection: Clamped by upper hydraulic grip.

- Grip Weight: 10 kg (22 lbs).

- Connecting Rod Diameter: Φ32 mm.

- Grip Dimensions:

- Length (A): 15.6 in / 395 mm

- Groove Width (B): 0.87 in / 22 mm

- Grip Width (C): 4 in / 101 mm

- Working Temperature: Ambient.

- Standard Compliance: GB/T 1499.3.

- Clamping Mode: Suspended.

- Minimum Test Space Requirement: 425 mm.

- Supported Specimen Diameters: Φ6, Φ8, Φ10, Φ12, Φ16 mm.

Technical Specifications – NGA106A Tensile Shear Fixture

| Parameter | Specification |

|---|---|

| Application | Shear test for steel welding mesh |

| Maximum Force | ≤1000 kN |

| Grip Weight | 10 kg |

| Connection | Clamped by upper hydraulic grip |

| Connecting Rod Diameter | Φ32 mm |

| Grip Length (A) | 395 mm |

| Groove Width (B) | 22 mm |

| Grip Width (C) | 101 mm |

| Working Temperature | Ambient |

| Standard | GB/T 1499.3 |

| Clamping Mode | Suspended |

| Minimum Test Space | 425 mm |

| Specimen Diameter | Φ6, Φ8, Φ10, Φ12, Φ16 mm |

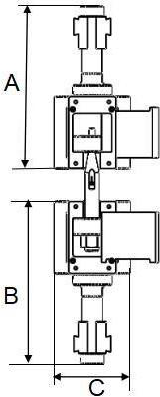

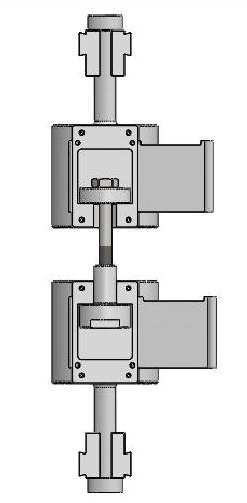

NGA605A – Proof Load Test for Nuts

The NGA605A Proof Load Test Fixture is engineered for verifying the proof load strength of nuts under controlled tensile loading. Capable of handling up to 600 kN, this fixture complies with GB/T 3098.2-2010 and ISO 898-2012 standards. It is suitable for suspended clamping via hydraulic grips and supports a wide range of both standard and optional nut sizes, including fine thread options. This fixture is ideal for ensuring compliance with nut property class ≤10 specifications.

The NGA605A Proof Load Test Fixture is engineered for verifying the proof load strength of nuts under controlled tensile loading. Capable of handling up to 600 kN, this fixture complies with GB/T 3098.2-2010 and ISO 898-2012 standards. It is suitable for suspended clamping via hydraulic grips and supports a wide range of both standard and optional nut sizes, including fine thread options. This fixture is ideal for ensuring compliance with nut property class ≤10 specifications.

- Application: Proof load test for nuts.

- Maximum Capacity: ≤600 kN load.

- Connection: Clamped by hydraulic grip.

- Weight: 12 kg (upper grip), 12 kg (lower grip).

- Grip Dimensions:

- Upper Grip Height (A): 290 mm

- Lower Grip Height (B): 290 mm

- Grip Width (C): 67.5 mm

- Working Temperature: Ambient.

- Standard Compliance: GB/T 3098.2-2010, ISO 898-2012.

- Clamping Mode: Suspended.

- Nut Property Class: ≤10.

- Standard Accessories (Nut Sizes): M6, M12, M16, M20.

- Optional Accessories (Nut Sizes): M5, M7, M8, M10, M14, M18, M22, M24, M27, and M5–M27 with fine pitch threads.

Technical Specifications – NGA605A Proof Load Test Fixture for Nuts

| Parameter | Specification |

|---|---|

| Application | Proof load test for nuts |

| Maximum Force | ≤600 kN |

| Weight | Upper Grip: 12 kg Lower Grip: 12 kg |

| Connection | Clamped by hydraulic grip |

| Height (A / B) | Upper: 290 mm Lower: 290 mm |

| Grip Width (C) | 67.5 mm |

| Working Temperature | Ambient |

| Standard | GB/T 3098.2-2010ISO 898-2012 |

| Clamping Mode | Suspended |

| Nut Property Class | ≤10 |

| Standard Accessories | M6, M12, M16, M20 |

| Optional Accessories | M5, M7, M8, M10, M14, M18, M22, M24, M27,M5–M27 with fine pitch thread |

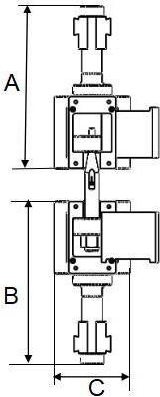

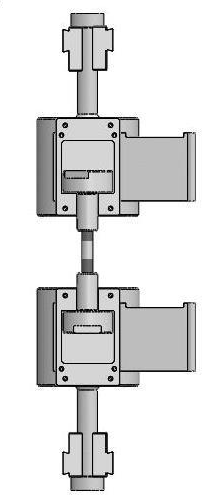

NGA206A – Proof Load Test for Nuts

The NGA206A Proof Load Test Fixture is designed for testing the tensile proof load capacity of nuts in compliance with GB/T 3098.2-2010 and ISO 898-2012 standards. With a robust load capacity of up to 2000 kN, this fixture accommodates larger nut sizes and higher force applications. It uses a hydraulic clamping system and operates under ambient conditions. The system supports both standard and optional thread sizes, including fine-pitch configurations, for broad testing coverage.

The NGA206A Proof Load Test Fixture is designed for testing the tensile proof load capacity of nuts in compliance with GB/T 3098.2-2010 and ISO 898-2012 standards. With a robust load capacity of up to 2000 kN, this fixture accommodates larger nut sizes and higher force applications. It uses a hydraulic clamping system and operates under ambient conditions. The system supports both standard and optional thread sizes, including fine-pitch configurations, for broad testing coverage.

- Application: Proof load test for nuts.

- Maximum Capacity: ≤2000 kN load.

- Connection: Clamped by hydraulic grip.

- Weight: 24 kg (upper grip), 24 kg (lower grip).

- Grip Dimensions:

- Upper Grip Height (A): 375 mm

- Lower Grip Height (B): 375 mm

- Grip Width (C): 78 mm

- Working Temperature: Ambient.

- Standard Compliance: GB/T 3098.2-2010, ISO 898-2012.

- Clamping Mode: Suspended.

- Nut Property Class: ≤10.

- Standard Accessories (Nut Sizes): M16, M20, M27, M36.

- Optional Accessories (Nut Sizes): M5, M6, M7, M8, M10, M12, M14, M18, M22, M24, M30, M33, M39, and M5–M39 with fine pitch threads.

Technical Specifications – NGA206A Proof Load Test Fixture for Nuts

| Parameter | Specification |

|---|---|

| Application | Proof load test for nuts |

| Maximum Force | ≤2000 kN |

| Weight | Upper Grip: 24 kg Lower Grip: 24 kg |

| Connection | Clamped by hydraulic grip |

| Height (A / B) | Upper: 375 mm Lower: 375 mm |

| Grip Width (C) | 78 mm |

| Working Temperature | Ambient |

| Standard | GB/T 3098.2-2010ISO 898-2012 |

| Clamping Mode | Suspended |

| Nut Property Class | ≤10 |

| Standard Accessories | M16, M20, M27, M36 |

| Optional Accessories | M5–M39 incl. fine pitch: M5, M6, M7, M8, M10, M12, M14,M18, M22, M24, M30, M33, M39 and all fine threads |

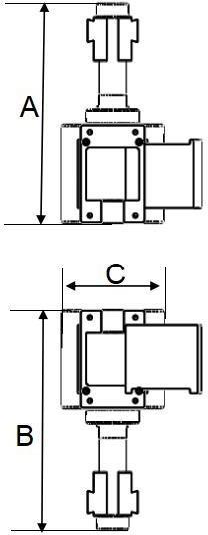

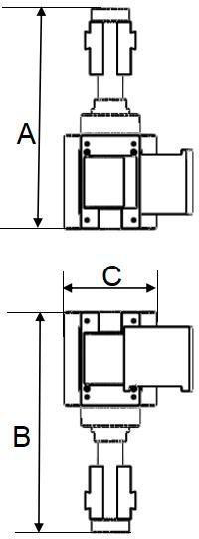

NGB605A – Bolt and Nut Tensile Grip

The NGB605A Bolt and Nut Tensile Grip is a multifunctional fixture designed for tension, proof load, and wedge load testing of bolts and nuts. Engineered to handle up to 600 kN of force, it conforms to GB/T 3098.2-2010 and ISO 898-2012 standards. The system is suspended and clamped hydraulically for secure and accurate testing. It supports a wide variety of thread sizes, including both standard and fine pitch configurations, and is suitable for nut property class ≤10.9.

The NGB605A Bolt and Nut Tensile Grip is a multifunctional fixture designed for tension, proof load, and wedge load testing of bolts and nuts. Engineered to handle up to 600 kN of force, it conforms to GB/T 3098.2-2010 and ISO 898-2012 standards. The system is suspended and clamped hydraulically for secure and accurate testing. It supports a wide variety of thread sizes, including both standard and fine pitch configurations, and is suitable for nut property class ≤10.9.

- Application: Tension, proof load, and wedge load tests for bolts and nuts.

- Maximum Capacity: ≤600 kN load.

- Connection: Clamped by hydraulic grip.

- Weight: 12 kg (upper grip), 12 kg (lower grip).

- Grip Dimensions:

- Upper Grip Height (A): 290 mm

- Lower Grip Height (B): 290 mm

- Grip Width (C): 67.5 mm

- Working Temperature: Ambient.

- Standard Compliance: GB/T 3098.2-2010, ISO 898-2012.

- Clamping Mode: Suspended.

- Nut Property Class: ≤10.9.

- Standard Accessories (Nut Sizes): M6, M12, M16, M20.

- Optional Accessories (Nut Sizes): M4, M5, M7, M8, M10, M14, M18, M22, M24, M27 and M4–M27 with fine pitch threads.

Technical Specifications – NGB605A Bolt and Nut Tensile Grip

| Parameter | Specification |

|---|---|

| Application | Tension, proof load, and wedge load test for bolts and nuts |

| Maximum Force | ≤600 kN |

| Weight | Upper Grip: 12 kg Lower Grip: 12 kg |

| Connection | Clamped by hydraulic grip |

| Height (A / B) | Upper: 290 mm Lower: 290 mm |

| Grip Width (C) | 67.5 mm |

| Working Temperature | Ambient |

| Standard | GB/T 3098.2-2010ISO 898-2012 |

| Clamping Mode | Suspended |

| Nut Property Class | ≤10.9 |

| Standard Accessories | M6, M12, M16, M20 |

| Optional Accessories | M4–M27 incl. fine threads: M4, M5, M7, M8, M10, M14,M18, M22, M24, M27 and fine-pitch M4–M27 |

Minimum Required Bolt Specimen Lengths

The table below shows the shortest acceptable specimen length (in mm) for various bolt thread specifications when performing wedge load, tensile, or stud tension tests. These lengths ensure the sample fits securely and performs accurately under load.

| Specification | M4 | M5 | M6 | M7 | M8 | M9 | M10 | M12 |

|---|---|---|---|---|---|---|---|---|

| Specimen Length (mm) | 9 | 10 | 11 | 19 | 20 | 21 | 22 | 32 |

| Specification | M14 | M16 | M18 | M20 | M22 | M24 | M27 |

|---|---|---|---|---|---|---|---|

| Specimen Length (mm) | 39 | 41 | 93 | 100 | 102 | 104 | 107 |

Load Configurations

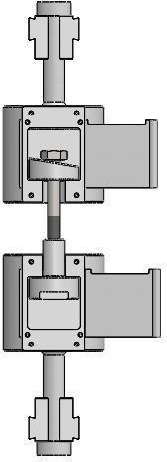

The illustrations below depict the different configurations supported by the fixture for bolt and nut testing:

|

|

|

| Fig. 1 – Wedge Load | Fig. 2 – Bolt Tension | Fig. 3 – Stud Tension |

- Fig. 1 – Wedge Load: Applied angular load to evaluate bolt integrity under shear forces.

- Fig. 2 – Bolt Tension: Direct tensile load applied along the axis of the bolt.

- Fig. 3 – Stud Tension: Axial tensile loading applied to threaded studs without heads.

NGB206A – Bolt and Nut Tensile Grip

The NGB206A Bolt and Nut Tensile Grip is designed for high-force testing applications including tension, proof load, and wedge load testing of bolts and nuts. Supporting loads up to 2000 kN, this system is ideal for testing large-diameter fasteners in compliance with GB/T 3098.2-2010 and ISO 898-2012. With hydraulic clamping and suspended test mode, it ensures safe and repeatable results under ambient conditions. This grip supports nut property classes up to 12.9 and accommodates a wide range of standard and optional accessories.

The NGB206A Bolt and Nut Tensile Grip is designed for high-force testing applications including tension, proof load, and wedge load testing of bolts and nuts. Supporting loads up to 2000 kN, this system is ideal for testing large-diameter fasteners in compliance with GB/T 3098.2-2010 and ISO 898-2012. With hydraulic clamping and suspended test mode, it ensures safe and repeatable results under ambient conditions. This grip supports nut property classes up to 12.9 and accommodates a wide range of standard and optional accessories.

- Application: Tension, proof load, and wedge load testing for bolts and nuts.

- Maximum Capacity: ≤2000 kN load.

- Connection: Clamped by hydraulic grip.

- Weight: 24 kg (upper grip), 24 kg (lower grip).

- Grip Dimensions:

- Upper Grip Height (A): 375 mm

- Lower Grip Height (B): 375 mm

- Grip Width (C): 78 mm

- Working Temperature: Ambient.

- Standard Compliance: GB/T 3098.2-2010, ISO 898-2012.

- Clamping Mode: Suspended.

- Nut Property Class: ≤12.9.

- Standard Accessories (Nut Sizes): M16, M120, M27, M36.

- Optional Accessories (Nut Sizes): M5, M6, M7, M8, M10, M12, M14, M18, M22, M24, M30, M33, M39 and M5–M39 with fine pitch threads.

Technical Specifications – NGB206A Bolt and Nut Tensile Grip

| Parameter | Specification |

|---|---|

| Application | Tension, proof load, wedge load test for bolts and nuts |

| Maximum Force | ≤2000 kN |

| Weight | Upper Grip: 24 kg Lower Grip: 24 kg |

| Connection | Clamped by hydraulic grip |

| Height (A / B) | Upper: 375 mm Lower: 375 mm |

| Grip Width (C) | 78 mm |

| Working Temperature | Ambient |

| Standard | GB/T 3098.2-2010ISO 898-2012 |

| Clamping Mode | Suspended |

| Nut Property Class | ≤12.9 |

| Standard Accessories | M16, M120, M27, M36 |

| Optional Accessories | M5–M39 incl. fine threads: M5, M6, M7, M8, M10, M12, M14,M18, M22, M24, M30, M33, M39 and all fine pitch M5–M39 |

Minimum Required Specimen Lengths for Bolt Testing

| Specification | M4 | M5 | M6 | M7 | M8 | M9 | M10 | M12 | M14 | M16 |

|---|---|---|---|---|---|---|---|---|---|---|

| Specimen Length (mm) | 9 | 10 | 11 | 19 | 20 | 21 | 22 | 42 | 49 | 51 |

| Specification | M18 | M20 | M22 | M24 | M27 | M30 | M33 | M36 | M39 |

|---|---|---|---|---|---|---|---|---|---|

| Specimen Length (mm) | 103 | 110 | 112 | 114 | 117 | 130 | 133 | 136 | 139 |

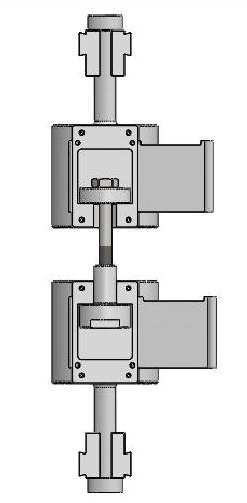

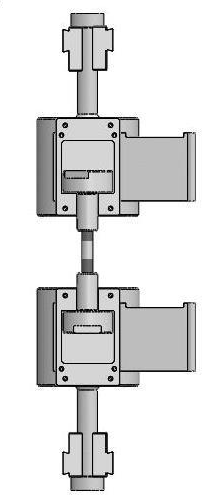

Load Test Configuration Illustrations

|

|

|

| Fig. 1 – Wedge Load | Fig. 2 – Bolt Tension | Fig. 3 – Stud Tension |

- Fig.1 – Wedge Load: Applies a shear force through angular alignment to evaluate bolt strength under inclined stress.

- Fig.2 – Bolt Tension: Applies direct axial tension through standard bolt grip interface.

- Fig.3 – Stud Tension: Applies axial force to threaded studs using dual-threaded support blocks.

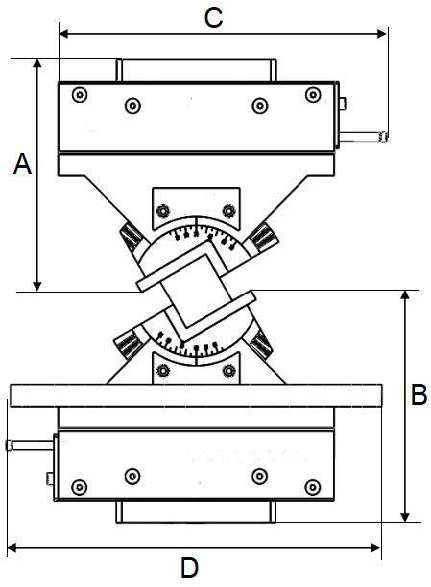

NGA206B – Rock Shear Fixture

The NGA206B Rock Shear Fixture is a high-capacity splitting system designed specifically for shear strength testing of rock specimens. With a rated capacity of ≤ 2000 kN, it supports both cylindrical and cubic sample formats, ensuring versatility across geological testing laboratories. The fixture conforms to GB/T 23561.11 standards and is designed for use under ambient temperature conditions. Its dual-grip system (flange on top and positioning pin on bottom) ensures stability and accuracy throughout each test cycle.

The NGA206B Rock Shear Fixture is a high-capacity splitting system designed specifically for shear strength testing of rock specimens. With a rated capacity of ≤ 2000 kN, it supports both cylindrical and cubic sample formats, ensuring versatility across geological testing laboratories. The fixture conforms to GB/T 23561.11 standards and is designed for use under ambient temperature conditions. Its dual-grip system (flange on top and positioning pin on bottom) ensures stability and accuracy throughout each test cycle.

- Application: Shear testing for rocks.

- Maximum Capacity: ≤2000 kN load.

- Weight:

- Upper Grip: 26 kg

- Lower Grip: 28 kg

- Connection:

- Upper Grip: Flange

- Lower Grip: Positioning pin

- Working Temperature: Ambient.

- Standard Compliance: GB/T 23561.11.

- Grip Dimensions:

- Height (A / B): 210 mm (Upper and Lower)

- Width (C): 310 mm (Upper Grip)

- Width (D): 350 mm (Lower Grip)

- Minimum Test Space: 450 mm.

- Specimen Size Supported:

- Cylindrical: Φ50 × 50 mm

- Cubic: 50 × 50 × 50 mm

Technical Specifications – NGA206B Rock Shear Fixture

| Parameter | Specification |

|---|---|

| Application | Shear test for rocks |

| Maximum Force | ≤2000 kN |

| Weight | Upper Grip: 26 kg Lower Grip: 28 kg |

| Connection | Upper: FlangeLower: Positioning pin |

| Working Temperature | Ambient |

| Standard | GB/T 23561.11 |

| Height (A / B) | 210 mm (Upper and Lower) |

| Width (C / D) | Upper: 310 mm Lower: 350 mm |

| Minimum Test Space | 450 mm |

| Specimen Size | Φ50 × 50 mm 50 × 50 × 50 mm |

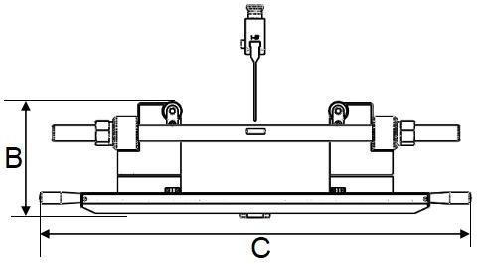

NGA206A – Bending Fixture

The NGA206A Bending Fixture is designed for performing high-force bending tests on metal, ceramic, and composite materials. Engineered for a capacity of up to 2000 kN, it complies with key standards such as GB/T 232, GB1499.1, and GB1499.2. The system uses a fixed block on the upper side and a positioning pin on the lower side, ensuring a secure and stable setup during testing. The fixture includes a robust lower support platform with multiple mandrel size options, making it adaptable for various test configurations.

The NGA206A Bending Fixture is designed for performing high-force bending tests on metal, ceramic, and composite materials. Engineered for a capacity of up to 2000 kN, it complies with key standards such as GB/T 232, GB1499.1, and GB1499.2. The system uses a fixed block on the upper side and a positioning pin on the lower side, ensuring a secure and stable setup during testing. The fixture includes a robust lower support platform with multiple mandrel size options, making it adaptable for various test configurations.

- Application: Bending tests for metals, ceramics, and composites.

- Maximum Capacity: ≤2000 kN load.

- Weight:

- Lower Grip: 86 kg

- Connection:

- Upper Grip: Fixing block

- Lower Grip: Positioning pin

- Working Temperature: Ambient.

- Standard Compliance: GB/T 232, GB1499.1, GB1499.2.

- Grip Dimensions:

- Lower Grip Height (B): 225 mm

- Lower Grip Width (C): 846 mm

- Minimum Test Space: 480 mm

- Included Mandrel Diameters: Φ32, Φ60, Φ88, Φ160

- Optional Mandrels: Full list below

Technical Specifications – NGA206A Bending Fixture

| Parameter | Specification |

|---|---|

| Application | Bending test for metal, composite, ceramic, etc. |

| Maximum Force | ≤2000 kN |

| Lower Grip Weight | 86 kg |

| Connection | Upper: Fixing block Lower: Positioning pin |

| Working Temperature | Ambient |

| Standard | GB/T 232, GB1499.1, GB1499.2 |

| Lower Grip Height (B) | 225 mm |

| Lower Grip Width (C) | 846 mm |

| Minimum Test Space | 480 mm |

| Mandrel Diameter (included) | Φ32, Φ60, Φ88, Φ160 |

Optional Mandrels

| Φ1 | Φ2 | Φ3 | Φ4 | Φ5 | Φ6 | Φ6.5 | Φ8 | Φ9 | Φ10 |

|---|---|---|---|---|---|---|---|---|---|

| Φ12 | Φ13.5 | Φ14 | Φ15 | Φ16 | Φ16.5 | Φ18 | Φ19.5 | Φ20 | Φ21 |

| Φ22 | Φ22.5 | Φ24 | Φ25 | Φ25.5 | Φ27 | Φ28 | Φ28.5 | Φ30 | Φ31.5 |

| Φ33 | Φ34.5 | Φ36 | Φ38 | Φ40 | Φ42 | Φ44 | Φ46 | Φ48 | Φ50 |

| Φ54 | Φ56 | Φ64 | Φ66 | Φ70 | Φ72 | Φ75 | Φ80 | Φ84 | Φ90 |

| Φ92 | Φ95 | Φ98 | Φ100 | Φ108 | Φ110 | Φ112 | Φ120 | Φ125 | Φ130 |

| Φ132 | Φ135 | Φ140 | Φ144 | Φ150 | Φ154 | Φ155 | Φ160 | Φ165 | Φ170 |

| Φ175 | Φ180 | Φ192 | Φ196 | Φ200 | Φ210 | Φ216 | Φ224 | Φ240 | Φ242 |

| Φ250 | Φ252 | Φ256 | Φ280 |

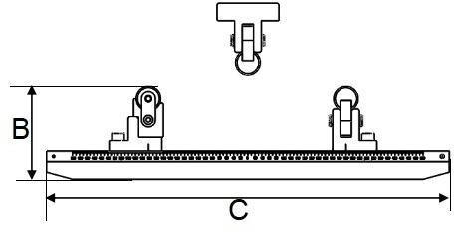

NGA206B – Flexure Fixture

The NGA206B Flexure Fixture is designed for high-capacity flexure testing of metallic, ceramic, and composite specimens. With a rated capacity of ≤2000 kN, this fixture provides reliable three-point or four-point bending evaluations using roller supports. The system is compliant with standards such as GB/T2542, GB/T4111, and JC/T 239, and features a lightweight lower grip and precision mandrel and roller components for adaptable testing.

The NGA206B Flexure Fixture is designed for high-capacity flexure testing of metallic, ceramic, and composite specimens. With a rated capacity of ≤2000 kN, this fixture provides reliable three-point or four-point bending evaluations using roller supports. The system is compliant with standards such as GB/T2542, GB/T4111, and JC/T 239, and features a lightweight lower grip and precision mandrel and roller components for adaptable testing.

- Application: Flexure testing for metal, composite, and ceramic materials.

- Maximum Capacity: ≤2000 kN load.

Weight:

Weight:

- Lower Grip: 23 kg

- Connection:

- Upper Grip: Fixing block and screw

- Lower Grip: Positioning pin

- Working Temperature: Ambient.

- Standard Compliance: GB/T2542, GB/T4111, JC/T 239.

- Grip Dimensions:

- Lower Grip Height (B): 130 mm

- Lower Grip Width (C): 574 mm

- Minimum Test Space: 280 mm

- Loading & Support Rollers:

- Roller 1: Φ35 × 210 mm

- Roller 2: Φ30 × 160 mm

- Included Mandrel Diameters: Φ32, Φ60, Φ88, Φ160

Technical Specifications – NGA206B Flexure Fixture

| Parameter | Specification |

|---|---|

| Application | Flexure test for metal, composite, ceramic, etc. |

| Maximum Force | ≤ 2000 kN |

| Lower Grip Weight | 23 kg |

| Connection | Upper: Fixing block and screw Lower: Positioning pin |

| Working Temperature | Ambient |

| Standard | GB/T2542, GB/T4111, JC/T 239 |

| Lower Grip Height (B) | 130 mm |

| Lower Grip Width (C) | 574 mm |

| Minimum Test Space | 280 mm |

| Roller 1 (Φ × Length) | Φ35 × 210 mm |

| Roller 2 (Φ × Length) | Φ30 × 160 mm |

| Mandrel Diameter (included) | Φ32, Φ60, Φ88, Φ160 |

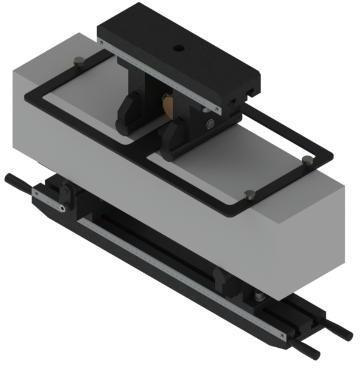

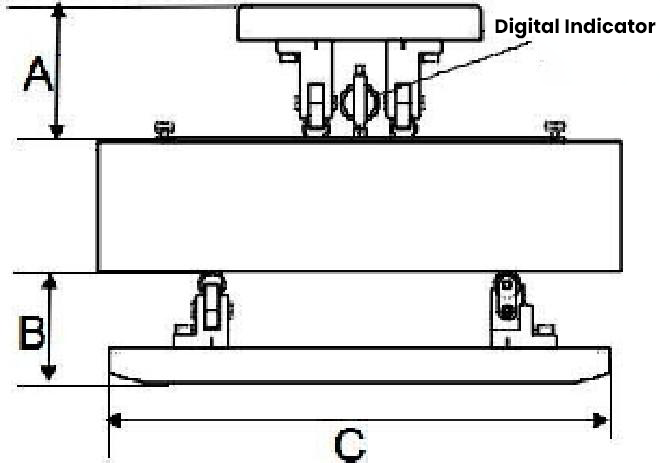

NGB206A – 4-Point Flexure Fixture

The NGB206A 4-Point Flexure Fixture is engineered for precise flexural testing of composite materials, concrete, and construction components. Designed to handle forces up to 2000 kN, this fixture complies with GB/T 50081 and offers fully adjustable lower and upper spans for flexible specimen sizing. It supports large concrete specimens and is optionally equipped with a digital indicator and elasticity modulus measurement device, making it suitable for both R&D and quality control applications.

The NGB206A 4-Point Flexure Fixture is engineered for precise flexural testing of composite materials, concrete, and construction components. Designed to handle forces up to 2000 kN, this fixture complies with GB/T 50081 and offers fully adjustable lower and upper spans for flexible specimen sizing. It supports large concrete specimens and is optionally equipped with a digital indicator and elasticity modulus measurement device, making it suitable for both R&D and quality control applications.

- Application: Flexure testing of composite, concrete, and construction materials.

- Maximum Capacity: ≤2000 kN load.

- Weight:

- Upper Grip: 12 kg

- Lower Grip: 20 kg

Connection:Upper Grip: Fixing block and screw

Connection:Upper Grip: Fixing block and screw

- Lower Grip: Positioning pin

- Working Temperature: Ambient.

- Standard Compliance: GB/T 50081.

- Grip Dimensions:

- Upper Grip Height (A): 157 mm

- Lower Grip Height (B): 127 mm

- Lower Grip Width (C): 574 mm

- Adjustable Span Ranges:

- Lower Span: 60–480 mm

- Upper Span: 60–180 mm

- Minimum Test Space: 450 mm

- Compatible Concrete Specimens:

- 150 × 150 × 600 mm

- 150 × 150 × 550 mm

- 100 × 100 × 400 mm

- Optional Features: Digital indicator and elasticity modulus measurement system

Technical Specifications – NGB206A 4-Point Flexure Fixture

| Parameter | Specification |

|---|---|

| Application | Flexure test for composite, concrete, construction material |

| Maximum Force | ≤ 2000 kN |

| Upper Grip Weight | 12 kg |

| Lower Grip Weight | 20 kg |

| Connection | Upper: Fixing block and screw Lower: Positioning pin |

| Working Temperature | Ambient |

| Standard | GB/T 50081 |

| Upper Grip Height (A) | 157 mm |

| Lower Grip Height (B) | 127 mm |

| Lower Grip Width (C) | 574 mm |

| Lower Span (adjustable) | 60–480 mm |

| Upper Span (adjustable) | 60–180 mm |

| Minimum Test Space | 450 mm |

| Concrete Specimen Sizes | 150×150×600 mm 150×150×550 mm 100×100×400 mm |

| Optional Add-ons | Digital indicator & elasticity modulus device |

NextGen’s grips and fixtures for hydraulic universal testing machines are built to perform under extreme conditions while maintaining full compliance with leading international standards. These high-load solutions empower manufacturers, laboratories, and research institutions to conduct critical mechanical property evaluations with precision and confidence.

Whether you're upgrading existing systems or setting up a new testing lab, investing in advanced hydraulic fixturing from NextGen ensures long-term accuracy, reliability, and global testing compliance. Reach out to NextGen Material Testing Inc. today to enhance your testing capabilities.

Related Products

NG-SHM CLASS DP - Servo Hydraulic Testing Machine

600kN-2000kN - Servo-Hydraulic Universal Testing Machine - Side Action Wedge Grip 2/4 columns, servo-controlled hydraulic

NG-SHM Class D - Servo Hydraulic Universal Testing Machine

600kN-2000kN - Servo-Hydraulic Universal Testing Machine 2/4 columns, servo-controlled hydraulic

NG-SHM Class C - Servo Hydraulic Testing Machine

600kN-1000kN - Servo-Hydraulic Universal Testing Machine 6 column, servo-controlled hydraulic

NG-SHM Class B - Servo Hydraulic Testing Machine

300kN-3000kN - Servo-Hydraulic Universal Testing Machine 6 column, servo-controlled hydraulic

GenTest V 2.0: Advanced Testing Software for Servo-Hydraulic Universal Testing Machines

Gentest is designed to enhance your ability to perform accurate and repeatable mechanical testing of materials, components and finished goods across a full spectrum of applications.

NG-SHM Class A - Servo Hydraulic Testing Machine

200kN-2000kN - Servo-Hydraulic Universal Testing Machine 4 or 6 column, servo-controlled hydraulic.