Metal Testing Equipment

Standards

ASTM E8, ASTM A370, ISO 6892-1, DIN 50125, JIS Z 2241, ASTM E646, ASTM E345, ISO 6892-2, GB/T 228.1

Description

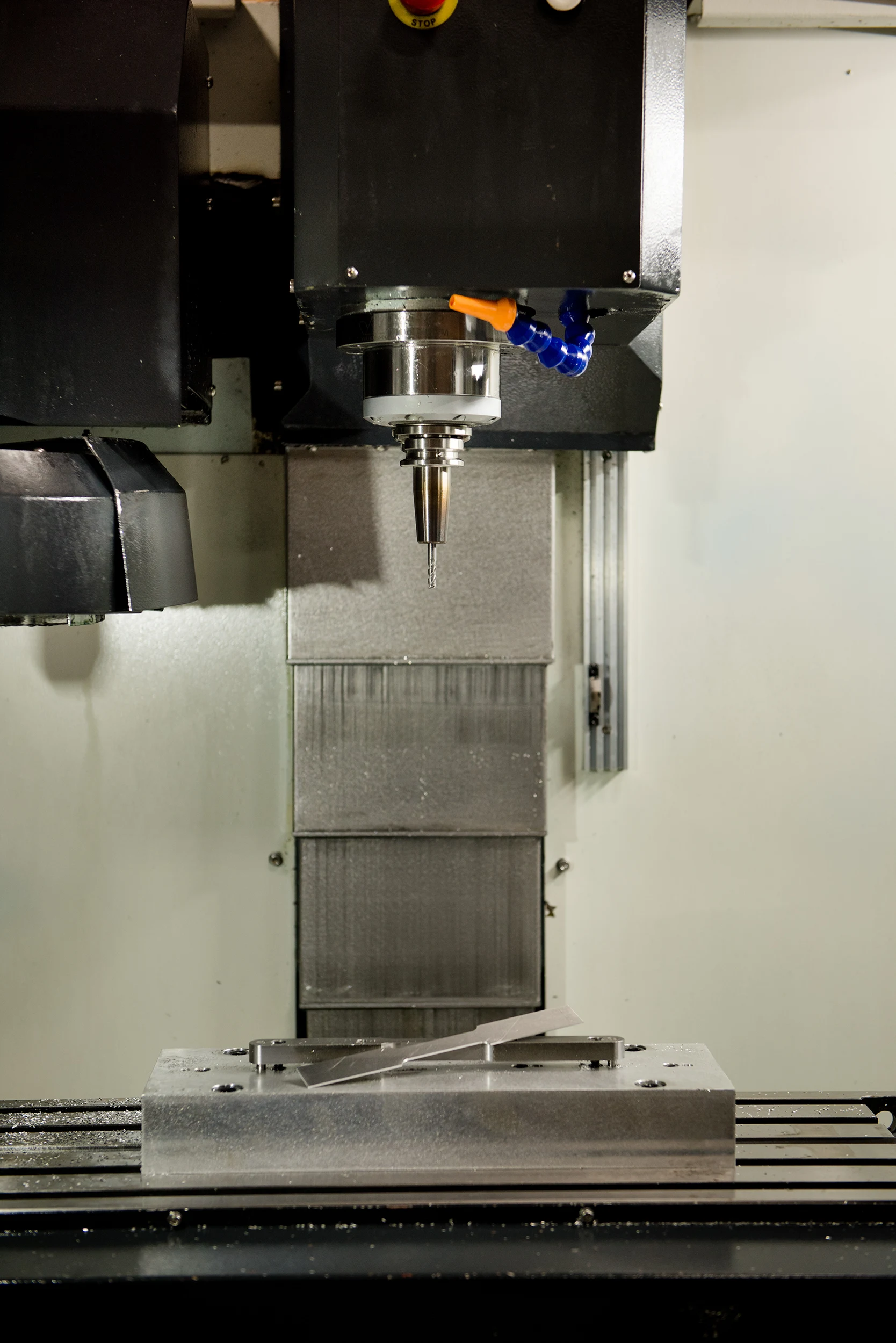

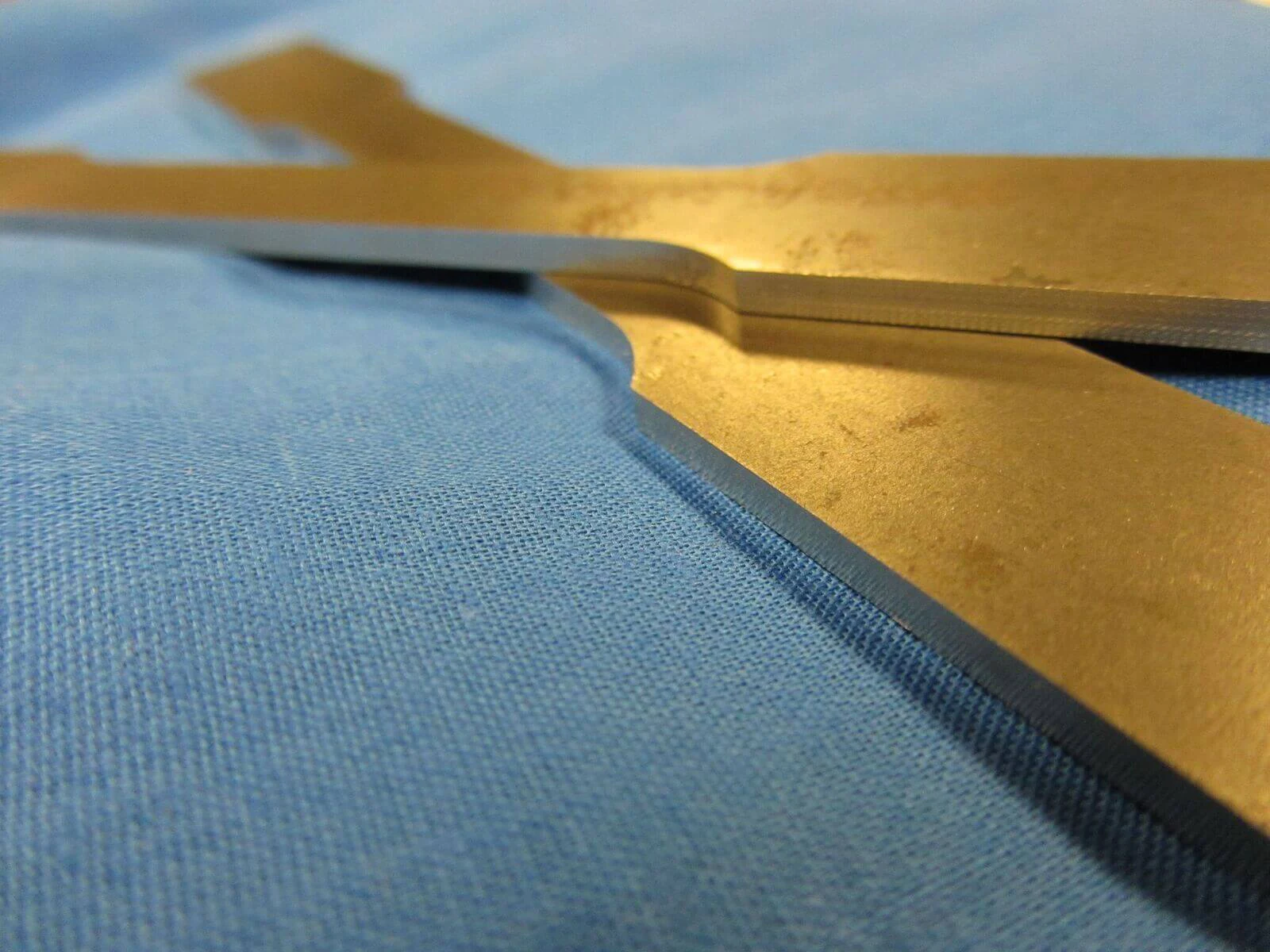

The TensileMill CNC XL – Flat Tensile Specimen Preparation Machine is an advanced and powerful CNC machining system designed for laboratories and production environments that require high-volume, precision sample preparation. As an enhanced version of the classic TensileMill CNC model, the XL system delivers extended table dimensions, greater travel distance, and increased spindle power—making it ideal for processing larger or tougher materials while maintaining exceptional dimensional accuracy.

Equipped with a high-speed spindle and precision servo motors, the TensileMill CNC XL achieves fast material removal rates and consistent surface finishes across steel, aluminum, composite, and polymer specimens. The system operates on the Mach4-based control platform, which supports complex machining programs and allows users to create custom pockets, contours, hole patterns, and engraved markings directly from the touchscreen interface.

Despite its industrial-grade performance, the TensileMill CNC XL maintains a compact footprint, making it suitable for both research facilities and production floors. The intuitive TensileSoft™ interface enables users with minimal CNC experience to select or customize ASTM-, ISO-, or DIN-compliant parameters for immediate machining. The result is a fully automated, turnkey solution that prepares flat tensile specimens with repeatable accuracy and minimal operator involvement.

From light sheet metals to heavy-duty alloys, the TensileMill CNC XL offers a scalable solution for any laboratory looking to improve throughput, shorten lead times, and maintain strict compliance with global testing standards such as ASTM E8, ASTM A370, ISO 6892-1, and DIN 50125.

Key Features

The TensileMill CNC XL – Flat Tensile Specimen Preparation Machine combines industrial-grade strength with advanced CNC precision to deliver reliable and repeatable specimen preparation performance. Every component is designed to support stability, speed, and long-term accuracy in demanding laboratory or production environments.

- Heavy-Duty Construction: A rigid cast iron frame and linear guideways provide vibration-free operation and stability during high-speed machining.

- Precision Drive System: Equipped with 20 mm ball screws on the X and Y axes and a 25 mm ball screw on the Z axis for smooth motion and high repeatability.

- Powerful Servo Spindle: A belt-driven 5 hp (3.7 kW) servo spindle running up to 10,000 RPM with BT30 taper delivers efficient material removal on metals and composites.

- Advanced Tool Control: Servo spindle with full synchronous position control, disc-spring clamping, collet-style gripper, and air-over-hydraulic release ensure rapid, secure tool changes.

- Automated Tool Changer: A 10-station umbrella-style automatic tool changer allows flexible setup, with any tool assignable to any position.

- Integrated CNC Center: Designed as a 30 Taper CNC machining center with a simple, ergonomic control panel, large touchscreen interface, and MPG handwheel for precise manual adjustments.

- Intelligent Mach4 Software: Powered by Mach4 control software, compatible with Fanuc G-code and Macro B, featuring built-in graphical wizards for on-machine programming.

- High-Performance Computing: Runs on an industrial-grade PC with a 5th-generation 64-bit Intel Broadwell processor, 64 GB SSD, and 4 GB RAM for fast program execution.

- Modern Connectivity: Includes Wi-Fi and Bluetooth capability for seamless data transfer and remote monitoring.

Advanced Controller and Software System

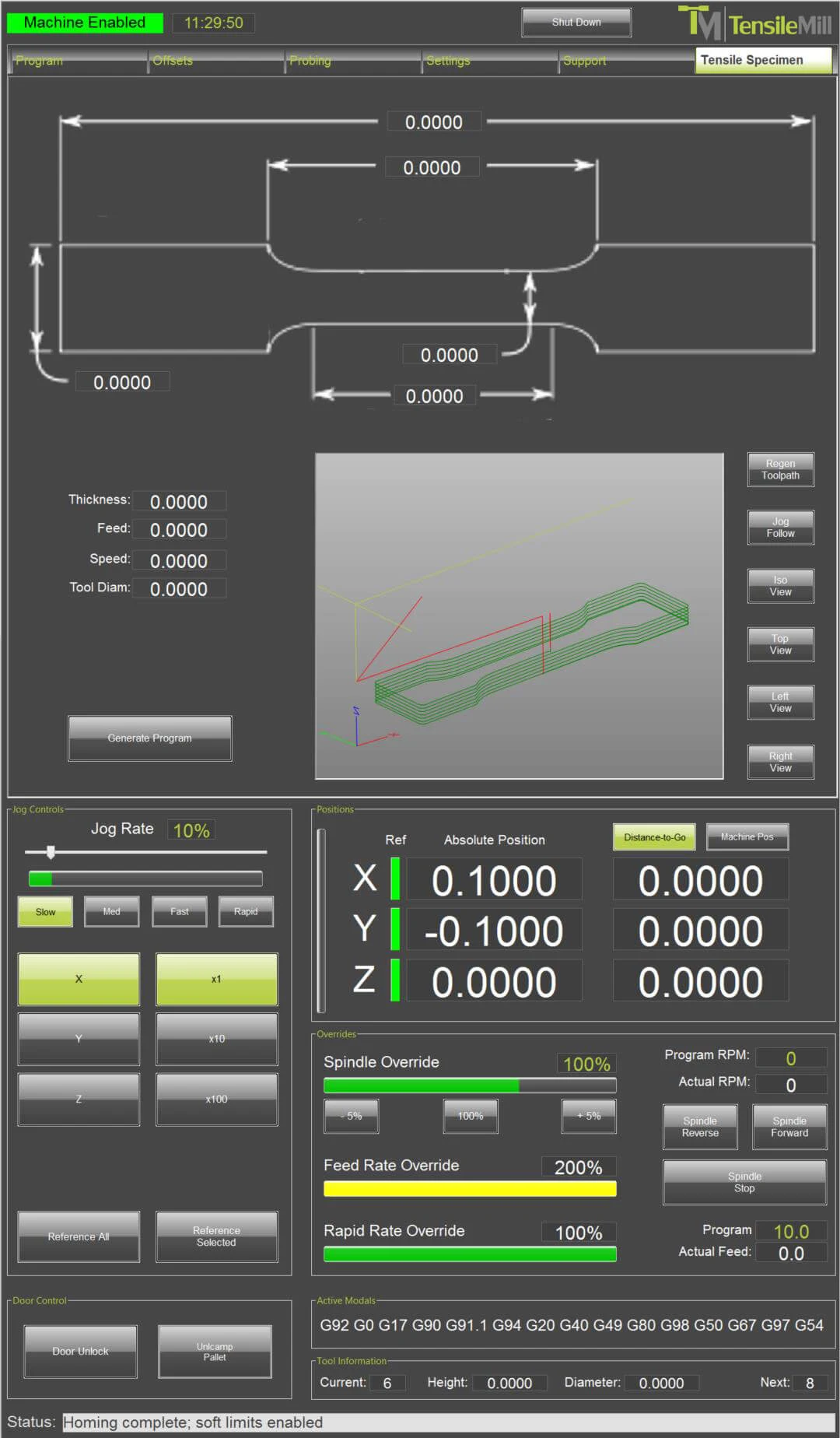

The TensileMill CNC XL – Flat Tensile Specimen Preparation Machine is powered by an intuitive touchscreen controller integrated with the Carbon™ CNC software suite. Designed for both precision and usability, this control system delivers professional-grade machining functions while remaining accessible to operators of all experience levels.

The Carbon™ software platform provides a seamless balance between automation and customization. It includes advanced features such as macro B programming, helical interpolation, drilling canned cycles, and dual-mode cutter compensation for complex specimen geometries. Operators can easily access both TensileSoft™ for specimen preparation and Mach4 Industrial CNC Software for general machining operations.

Service Plan and Support

NextGen Material Testing offers a comprehensive Service Plan for all TensileMill CNC specimen preparation systems, including the TensileMill CNC XL – Flat Tensile Specimen Preparation Machine. This plan is designed to maintain peak system performance, extend equipment life, and preserve long-term testing accuracy through regular Preventive Maintenance (PM) and professional technical support.

Our service plan includes:

- Scheduled preventive maintenance to minimize downtime and detect potential issues early.

- Expert operator training and retraining to help your team stay proficient and fully utilize the system’s capabilities.

- Performance verification and calibration checks to maintain compliance with ASTM, ISO, and DIN standards.

- Priority technical assistance for troubleshooting, software updates, and replacement parts.

Whether integrating new operators or optimizing existing workflows, this ongoing support ensures consistent performance and reliability. Contact our team to discuss a customized service plan that best fits your operational needs and testing schedule.

Technical Specifications

| Parameter | Specification |

|---|---|

| Overall Dimensions (D × W × H) | 66.1 × 75.79 × 86.54 in / 1680 × 1925 × 2198 mm |

| Table Size | 31.5 × 10.24 in / 800 × 260 mm |

| Load Capacity | 330 lb / 150 kg |

| T-Slot Size | 0.63 in / 16 mm |

| Machine Weight | 2976 lb / 1350 kg |

| Working Travel (X / Y / Z) | 15.75 / 9.1 / 15.75 in — 400 / 230 / 400 mm |

Spindle

| Parameter | Specification |

|---|---|

| Speed | 10,000 RPM |

| Power | 5 hp / 3.7 kW |

| Torque | 10.8 lb-ft / 14.6 Nm |

| Lubrication | High-speed grease |

| Bearings | Angular contact ball bearings |

Auto Tool Changer

| Parameter | Specification |

|---|---|

| Taper | BT30 |

| Pull Stud | MAS P30T-1 |

| Max Tool Diameter | 3.14 in / 80 mm |

| Max Tool Weight | 13.2 lb / 6 kg |

| Tool Change Type | Umbrella style |

| Tool Numbering | Random pot assignment |

| Tool Change Time | 6 seconds |

Servos

| Parameter | Specification |

|---|---|

| Servo Power | 1.75 hp / 1.3 kW |

| Servo Torque | 1175.4 / 3299.6 oz-in |

| Maximum Feedrate | 1000 ipm / 25.4 m/min |

| Ball Screws | PMI double nut: 20 mm (X/Y), 25 mm (Z) |

Power

| Parameter | Specification |

|---|---|

| Input Voltage | 220 V, 3-phase |

Additional Features

| Parameter | Specification |

|---|---|

| Position Repeatability Accuracy | 0.01 mm |

| Motor Drive | Servo |

| Drive Mechanism | Precision ball screw |

| Frame | Cast iron |

| Connection Requirements | Pneumatic (optional) |

Control System

| Parameter | Specification |

|---|---|

| Control Type | PC-based Mach4 control |

| Processor | 64-bit, 5th Generation Intel Broadwell |

| Program Storage | 64 GB SSD, unlimited program capacity |

| Memory | 4 GB (upgradable) |

| Display | Full-color multi-touch (glove compatible) |

| Operating Modes | Auto / MDI / Jog, automatic switching |

| Wizards | Built-in graphical wizards for on-machine programming |

| Units | Inch / Metric |

| Overrides | Feed: 0–150%, Spindle: 50–150%, Rapid: 0–100% (configurable) |

| G-Code Compatibility | Fanuc-compatible, Mach3-compatible |

| Custom Macro Support | Fanuc Macro B |

| External Communication | TCP Modbus |

| M-Codes | Unlimited user-defined, 5 inputs & 5 outputs (upgradeable) |

FAQs

If you want to pinpoint the exact quantity of specimens that can be prepared in one cycle, we advise that you speak with one of our Product Consultants to further discuss your application. Flat tensile mill quantity samples and the time it takes to complete the machining process will usually depend largely on the material type, the hardness, and the thickness of your material. Submit your request or call us today for any additional details!

The TensileMill CNC XL will be supplied with all of your necessary end-mills and tooling fixtures for any long term operations. Additional fixtures can be very easily acquired from TensileMill CNC. Request a quote today.

Even though the tooling fixtures are designed to last a lifetime with the proper maintenance, if you wish too, additional fixtures can also be purchased along the road.

The capacity offered by TensileMill CNC XL is better and more superior than both the Classic and the MINI. The machine offers a much bigger and better frame which is capable of handling tougher and larger samples. The standard tool charger allows for automation of tensile sample preparation needs. The unit is able to be programmed for tensile sample preparation and for advanced CNC machining requirements with the on-of-a-kind software that comes standard with the unit.

The longest Tensile specimen that can be prepared using the TensileMill XL will depend with the working travel distance of (X by Y by Z) 15.75 by 15.75 by 9.1. This machine is ideal for dynamic and skillful tensile sample preparation. The unit can handle large stacking volumes of various material hardness with ease. If you have a laboratory which requires a high volume of tensile preparation, the XL will be the perfect fit for you. Request quote today to learn more.

The XL model is a versatile machine which offers the best of both worlds when it comes to tensile specimen preparation and general purpose CNC machining. The unit can be equipped with a few options for tensile clamping fixtures:

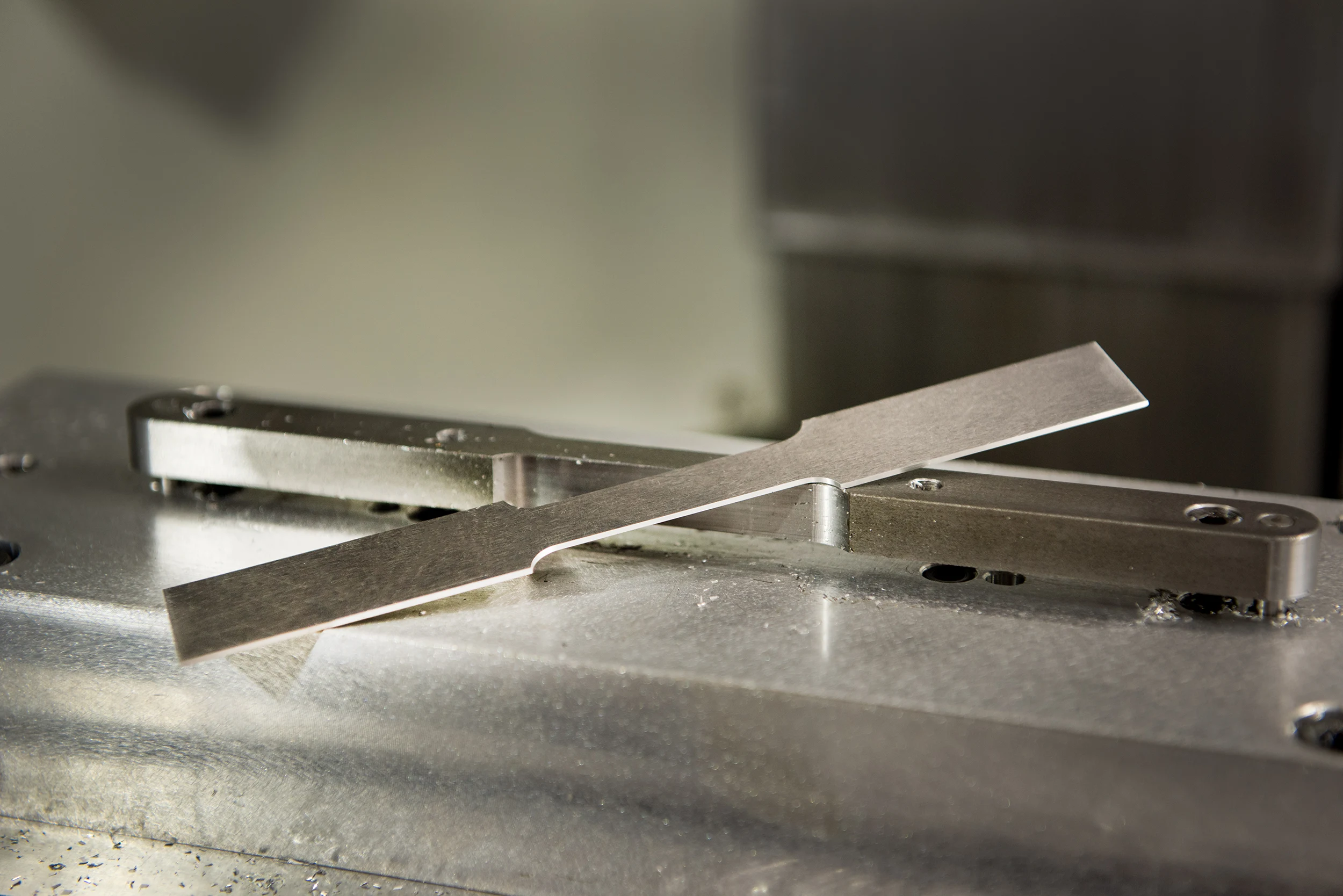

Double Clamping Fixture (Standard) TensileMill CNC XL comes with a standard double clamping fixture.

Technical Details:

This option offers you the ability to prepare 2 stacks of up to 12" long, 2" wide, and up to 1" thick (note that this depends on the material).

Triple Clamping Fixture (Upgrade):

The triple fixture is an upgrade option that is commonly used for specimen preparations for higher volume, regular, and/or sub-size specimen preparations.

Technical Details:

This option offers you the ability to prepare 3 stacks of specimens that go up to 12" long, 1" wide, and up to 1" thick (again this depends on the material). The side fixtures can also be removed to prepare a thicker specimen in the middle fixture. These offers add versatility to the user.

Custom Clamping Fixture:

Sheet metal fixtures, tube fixtures, and others are available based on your specific technical requirements. TensileMill CNC Inc. is also very capable of designing a specialty fixture based on your needs.

TensileMill CNC XL will in fact be supplied with all of your necessary end-mills and tooling fixtures for long term operation. Additional end-mills and fixtures can be easily acquired from TensileMill CNC requesting a quote today.

The tooling fixtures are designed to last a lifetime including proper maintenance, additional fixtures can also be purchased down the road.

Following the basic preventative maintenance procedures is the general rule for all quality control equipment. Keeping your unit clean and keeping the lube tank full is a little bit of a special recommendation. Contact us if you have any other questions.

The XLis a specialty unit which can be customized to your specific needs. The base price of the XL includes the turnkey solutions based on your technical requirements. Base fixtures, clamping fixtures, ER collets, End Mills, ISO 20 Spindle Upgrade and more are also a part of this upgraded version of the Classic unit.

Related Products

TensileMill CNC Classic Upgrade – Flat Tensile and Charpy/Izod Impact Specimen Preparation System

The TensileMill CNC Classic Upgrade is a hybrid CNC system for preparing standardized flat tensile and Charpy/Izod impact test specimens in-house. It supports ASTM E8, ASTM E23, ISO, DIN, and JIS geometry formats and provides stable machining accuracy for consistent batch-to-batch results.

TensileMill CNC MINI – Compact Flat Tensile Specimen Preparation System

The TensileMill CNC MINI is a compact CNC system designed for preparing standardized flat tensile test specimens. It supports specimen geometries based on ASTM E8, ASTM A370 / E370, ISO 6892-1, DIN 50125, and JIS Z2201. The system uses a cast iron frame, linear guideways, and a guided TensileSoft™ interface to support consistent specimen dimensions. Operators can select preloaded standard profiles or enter custom dimensions directly into the control interface. The MINI is suitable for routine testing workflows, training environments, and production quality control applications.