Metal Testing Equipment

Description

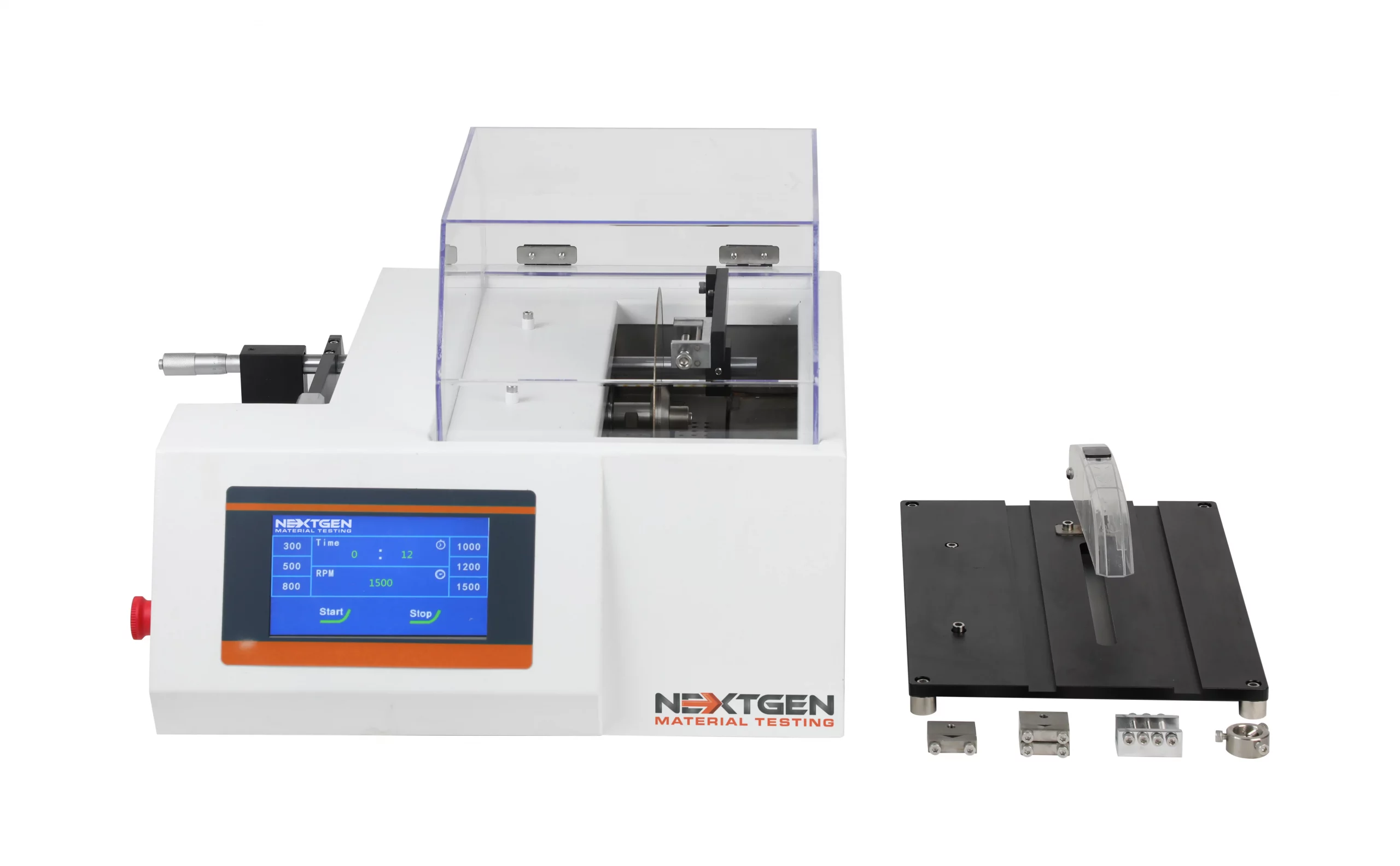

GenCut GL100E & 100 Series low speed advanced automatic precision cut-off saw is well established in the metallography industry. This diamond saw precision cutter is a perfect fit for cutting and sectioning a wide variety of small and delicate samples particularly when the material structure is not homogeneous. This precision cut off saw can accept cutting a cutting wheel of 4”.

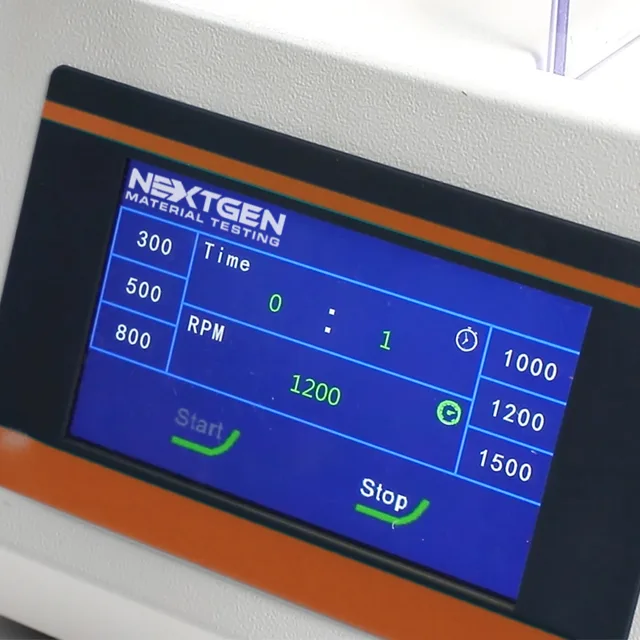

GL100E Series metallographic precision cutter has variable speed control from 50-1000 rpm.. Additionally, GenCut GL 100E cut off saw for metallographic sample preparation comes standard with an automatic shut-off function at the end of each cutting cycle. Read more in our MEGA BLOG!

GenCut GL100E Technical Specifications

|

Model |

GenCut GL100E |

|

Cutting Wheel |

Ø200xØ32x0.9mm |

|

Motor |

300W |

|

Variable Speed |

100-1500rpm |

|

Cooling Device |

Automatic cycle cooling of cutting fluid (the cutting wheel drives the circulation of the water in the tank to cool down) |

|

Display Panel |

7" Touch Screen Controller |

|

Micrometer Travel Range |

0-25mm |

|

Position Accuracy |

0.01mm |

|

Power Supply |

Single phase, AC220V, 50Hz |

|

Emergency brake

|

Emergency stop switch |

|

Loading weights |

0-450g |

|

Dimensions |

21.65" x 21.65" x 14.96" / 550 x 550 x 380 mm |

|

Weight |

100lbs / 45kg |

Standard Configuration

-

Cutting Saw

-

Single Head Jig

-

Double Head Jig

-

Irregular Sample Jig

-

Flat Clamp

-

Water Drop Jig

-

Wrench for Changing Blade

-

Differential Head

-

Inset Sample Jig

-

Power Cord and Operation Manual

GenCut GL100E Features

-

Two Cutting Modes – Manual or Gravity (weight, counterweight)

-

Digital Touch Screen Control with programmable menu structure for a user-friendly operating experience

-

Precision cutting off with micrometer head control

-

Closed transparent protective cover and safety switch provide protection for operators

-

Features a weight sliding loading system to minimize sample damage

-

Closed loop control cutting to prevent overload of the motor

-

Automatically stops after finishing the cut

-

Built-in Movable Coolant Tank

-

Compact body, small footprint and convenient operation and maintenance

Application

Suitable for cutting small, soft, brittle, special-shaped metal materials, composite materials, plastics, electronic components, biological materials, ceramics, cement, rocks and minerals, etc. It is also commonly used for thin-film sample preparation.

Related Products

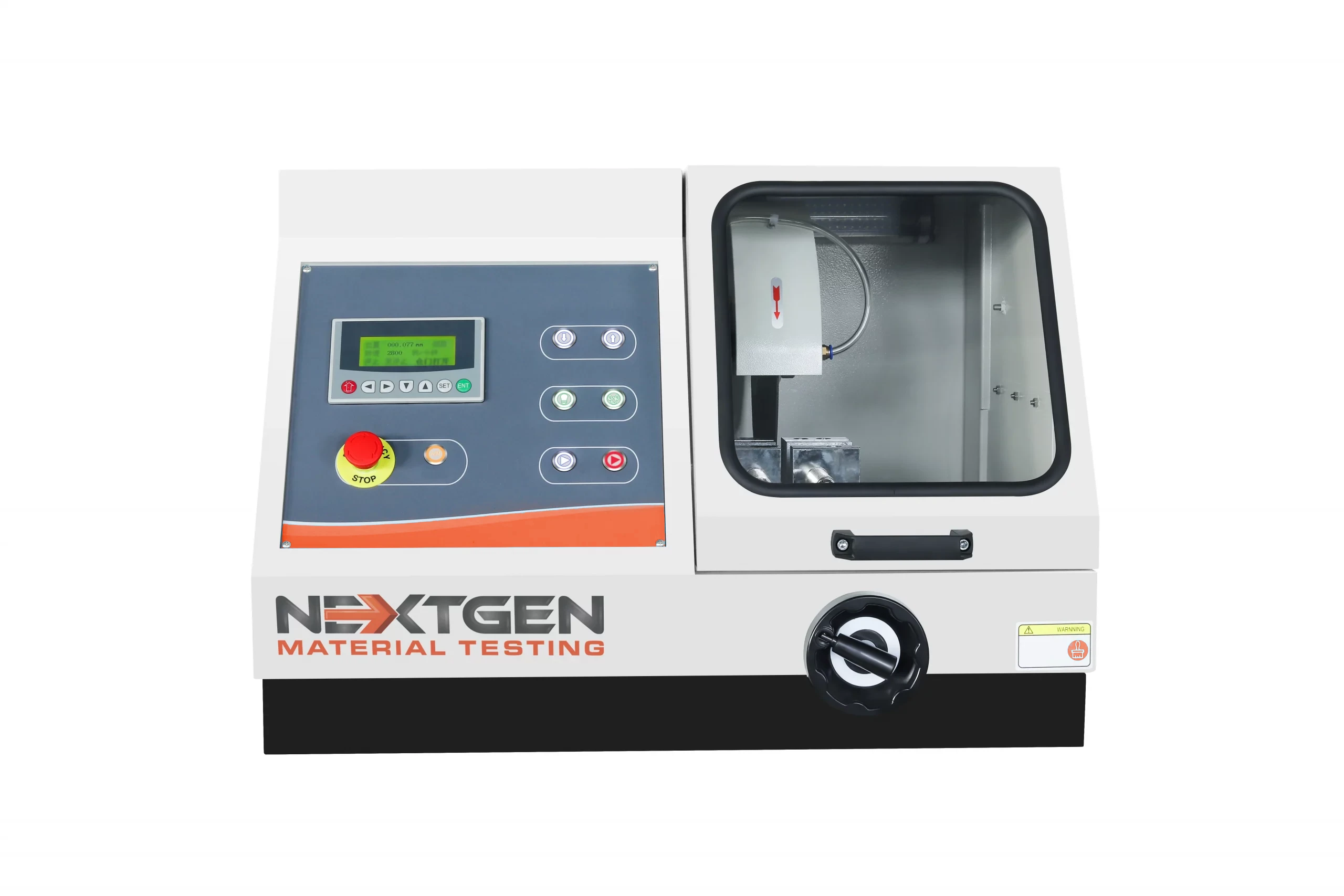

GenCut GL100M – Precision Manual Metallographic Sample Cutting Machine with Simple User-Friendly Operation and Large Cutting Capacity Φ100mm

Introducing the GenCut GL100M Manual Cutting Machine, expertly designed for precision metal sample cutting.

GenCut GL350 – Precision Metallographic Sample Cutting Machine with Simple User-Friendly Operation and Large Cutting Capacity Φ100mm

The GenCut GL350 is a cutting-edge high precision cutting machine equipped with advanced features and capabilities

GenCut GL80A – Precision Metallographic Sample Cutting Machine with Simple User-Friendly Operation and Large Cutting Capacity Φ80mm

Introducing the GenCut GL80A, a highly precise cutting machine offering both automatic and manual work modes.

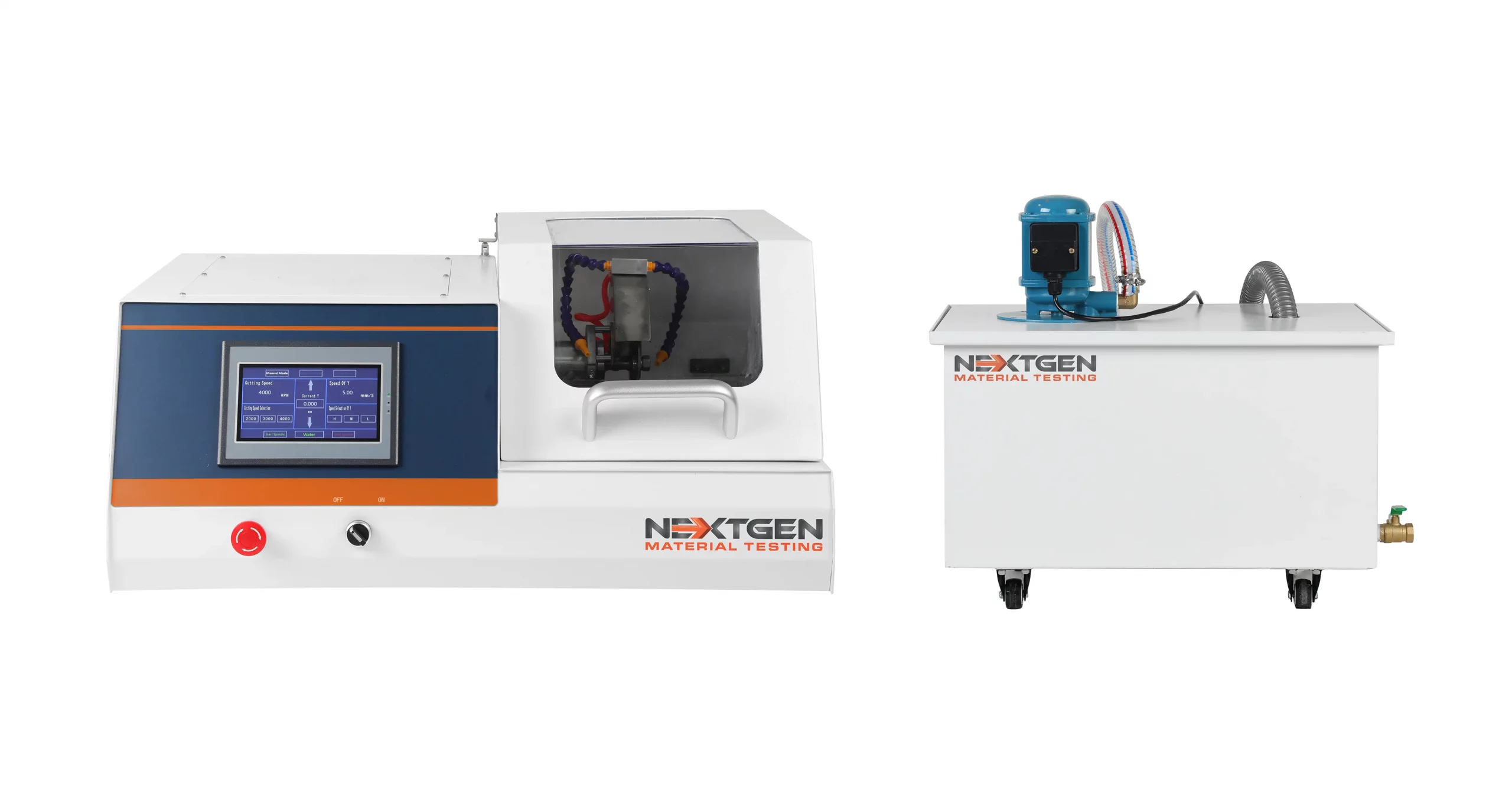

GenCut GL200E – High Speed Automatic Precision Metallographic Cutter with User-Friendly Touch Screen Interface with max. cutting diameter of 60mm

GenCut GL 200E precision cutting machine includes a touch screen and PLC control, with stable performance and real-time display parameters.

Metallography Consumables

Learn about the full scope of NextGen's cutting, polishing & grinding, mounting and etching metallography consumables. Our consumables are compatible with virtually all global brands, offering a rare combination of exceptional quality, longevity and affordability.