Metal Testing Equipment

Description

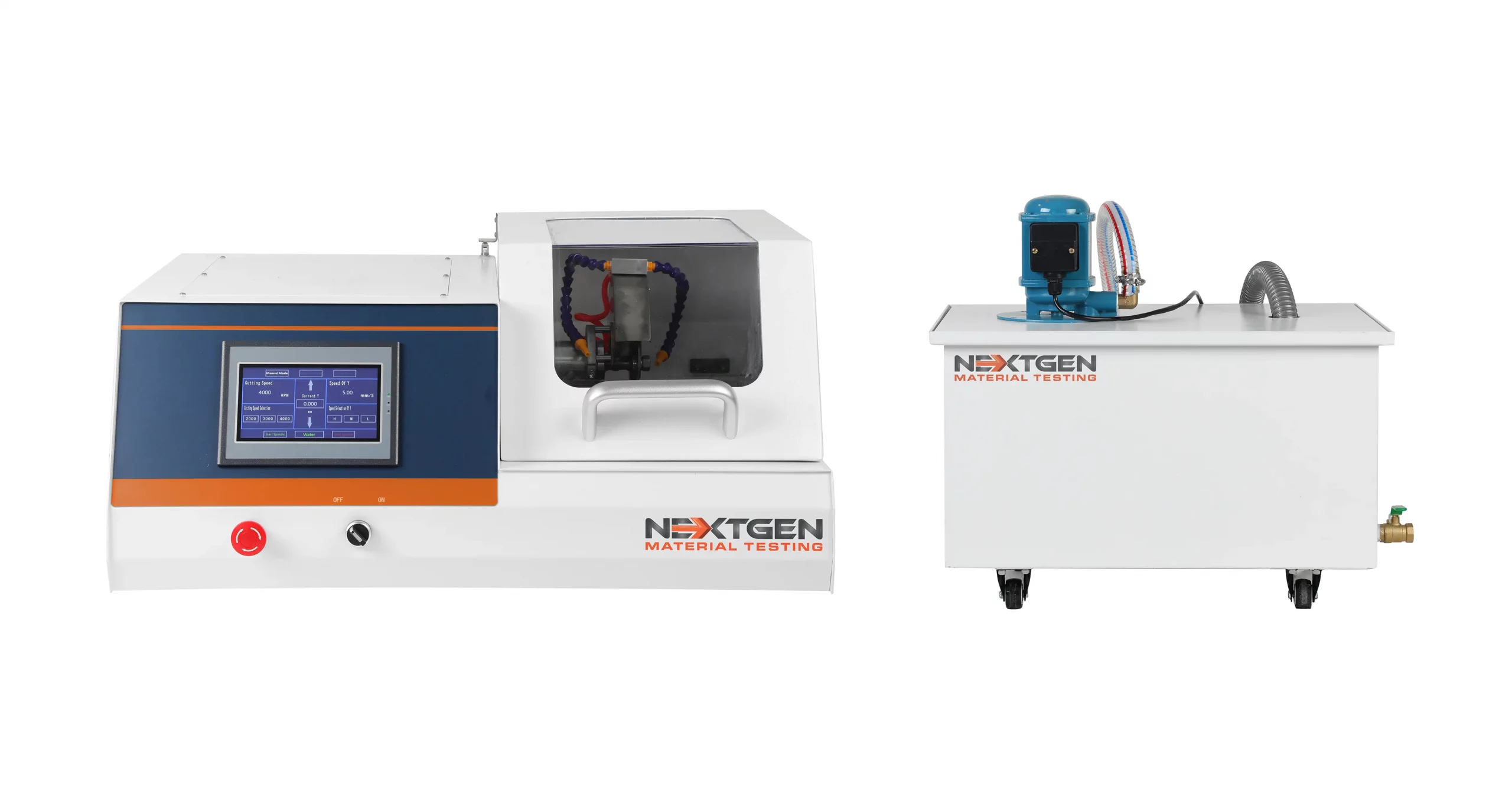

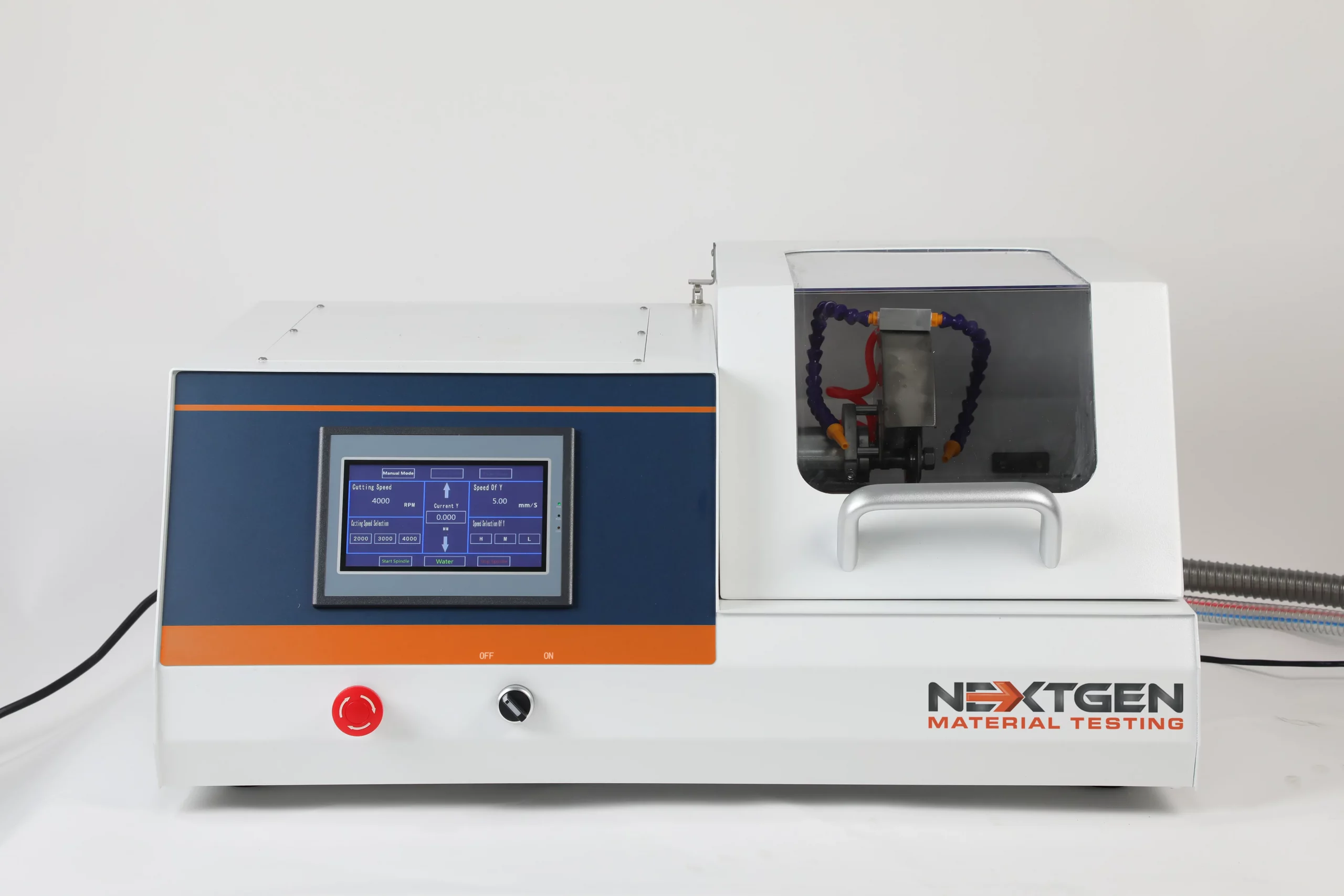

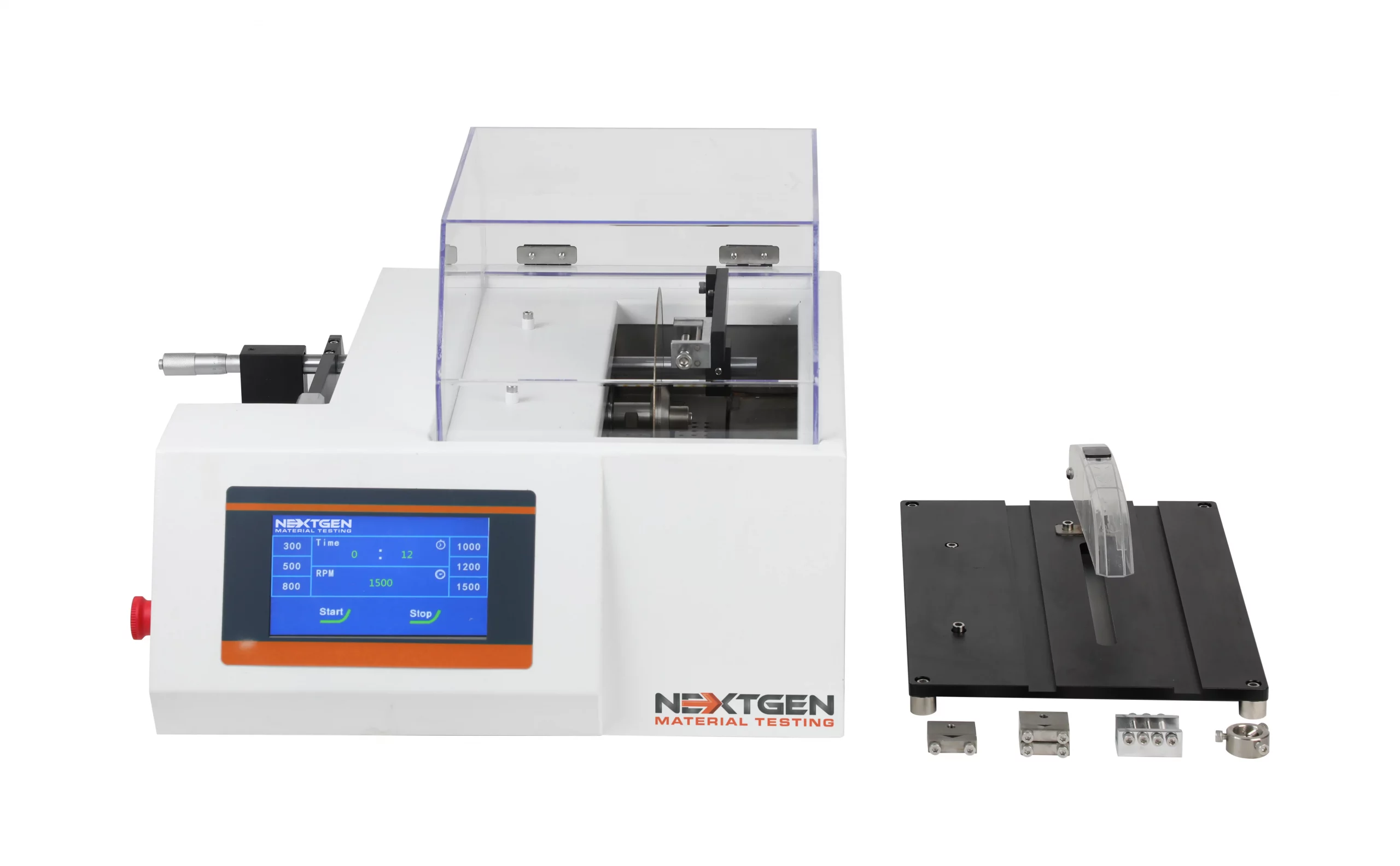

GenCut GL200E high-speed precision cutting machine includes a touch screen and PLC control, with stable performance and real-time display of cutting parameters. The GenCut GL 200E features Y-axis automatic feed cutting, with high position accuracy, large speed range and high cutting capacity; the cutting chamber is a fully enclosed structure with transparent protective cover for observation during cutting. It is equipped with a circulating cooling system allowing for the surface of the cut specimen to be bright and flat without burns.

The GenCut GL 200E is especially suitable for precision deformation-free cutting of metals, electronic components, ceramic materials, crystals, hard alloys, rock and ore, concrete, organic materials, biological materials (teeth, bone) and other materials, and is ideal for automatic precision cutting on the table. Read more in our MEGA BLOG!

GenCut GL200E Technical Specifications

|

Model |

GenCut GL200E |

|

Cutting Method |

Automatic spindle Y-feed (automatic return when cutting is complete), manual feed, pulse feed (automatic return when cutting is complete) |

|

Feed Speed |

0-600mm/min (Adjustment steps of 0.01mm) |

|

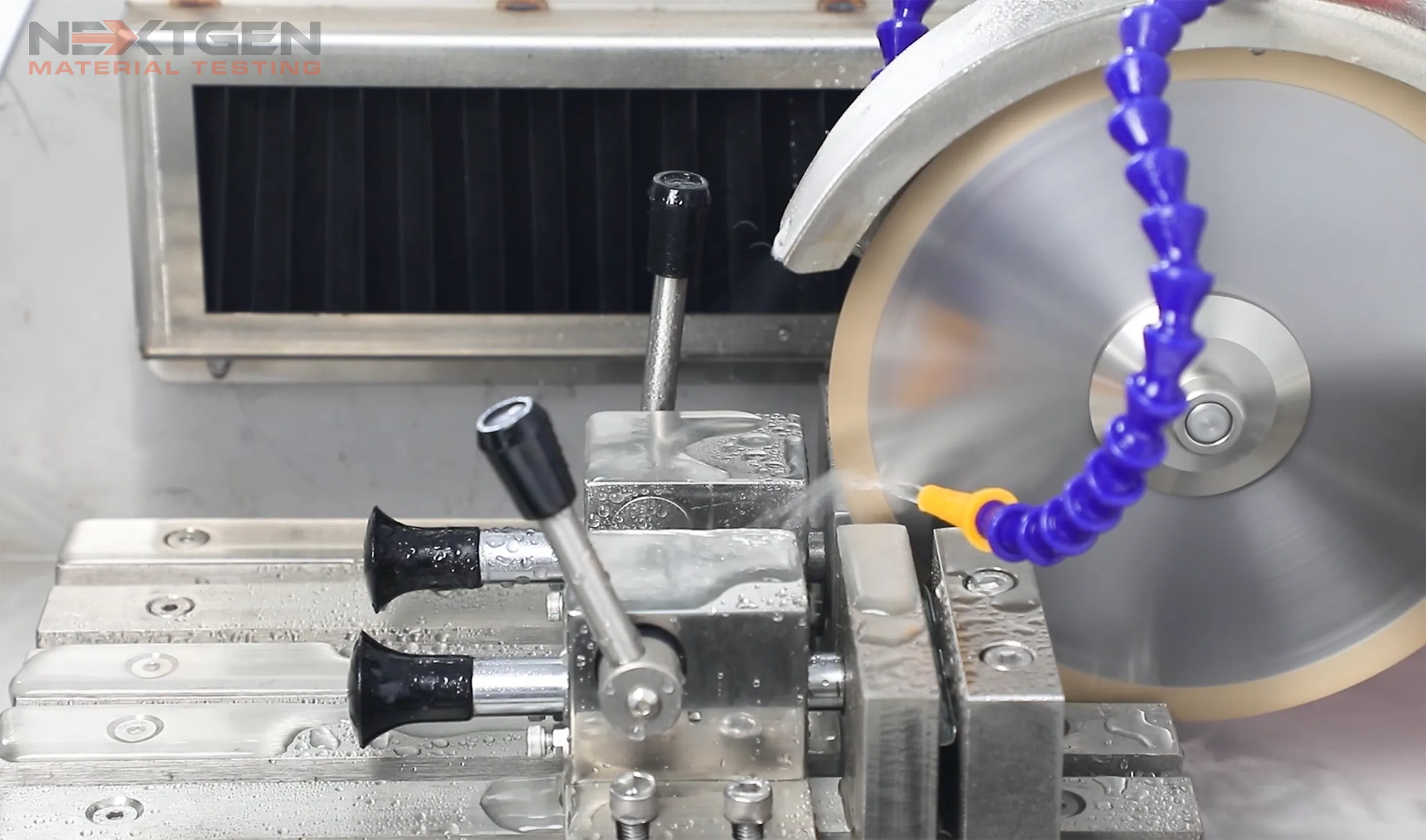

Cutting Wheel Size |

Φ200 x 1.0 x Φ32mm |

|

Spindle Speed |

500-5000rpm |

|

Y-Axis Travel |

260mm |

|

Maximum Cutting Diameter |

Φ60mm |

|

Motor Power |

1500W |

|

Input Power |

220V 50/60Hz 1 Phase |

|

Display and Control |

Touch Screen |

|

Cutting Platform Dimensions |

225 x 320mm |

|

Cutting Fixture |

Quick Clamp |

|

Dimensions & Weight |

33” x 32” x 16”; 287lbs / 830 x 820 x 410 mm; 130kg |

|

Transverse Clamping Width |

225mm |

|

Longitudinal Clamping Length |

150mm |

Standard Configuration

-

GenCut GL200E Cutting Saw

-

Coolant Chamber

-

Wrench 13#-15#

-

Wrench 17#-19#

-

Internal Hexagonal Wrench 6mm and 8mm

-

Water Inlet Tube

-

Drain Pipe

-

Diamond Cutting Wheel Φ200 x 1.0 x Φ32mm and Operation Manual

GenCut GL200E Features

-

Digital Touch Screen Control with programmable menu structure for a user-friendly operating experience

-

Precision cutting off with micrometer head control

-

Closed transparent protective cover and safety switch provide protection for operators

-

Closed loop control cutting to prevent overload of the motor

-

Automatically stops after finishing the cut

-

Built-in Movable Coolant Tank

-

Compact body, small footprint and convenient operation and maintenance

FAQs

The main purpose of the GenCut GL200E – High-Speed Automatic Precision Metallographic Cutter is to provide high-speed, precision cutting for a diverse range of materials used in metallographic sample preparation. This machine handles metals, electronic components, ceramic materials, crystals, hard alloys, rock and ore, concrete, organic materials, and biological materials such as teeth and bone. It provides deformation-free cutting, producing bright and flat surfaces without burning.

Featuring both automatic and manual feed options, the GenCut GL200E is ideally suited to precision and efficient cutting operations, as it offers both automatic and manual feed options. Its user-friendly touchscreen interface and PLC control allow for real-time display and adjustment of cutting parameters, enhancing accuracy and ease of use. The High-Speed Automatic Precision Metallographic Cutter is ideally suited for laboratories and industries that require reliable and high-quality cutting results.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL200E – High-Speed Automatic Precision Metallographic Cutter is highly suitable for precision deformation-free cutting of a wide array of materials. These include metals, electronic components, ceramic materials, crystals, hard alloys, rock and ore, concrete, organic materials, and biological materials such as teeth and bones. Its flexible design handles various sample types effectively.

There is no better way to cut metal than with the high-speed automatic precision metallographic cutter. It is ideal for automatic precision cutting on a table. Due to its ability to cut through different materials with ease and precision, it is highly versatile and plays a vital role in metallographic analysis due to its versatility. By using the GenCut GL200E, you can rest assured that your samples will be prepared accurately and efficiently, preserving their structural integrity for further examination.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL200E – High-Speed Automatic Precision Metallographic Cutter offers multiple cutting methods to meet different needs and preferences. It includes an automatic spindle Y-feed, which automatically moves the cutting wheel along the Y-axis and returns to its original position once the cutting is complete. The method used here makes certain that the cuts are consistent and precise without the need for manual intervention.

Additionally, the GenCut GL200E features a manual feed option, allowing users to control the feed rate manually for more customized cutting tasks. This mode is beneficial for intricate or specific cuts that require hands-on work.

Lastly, the machine offers a pulse feed option, which cuts in pulses and automatically returns to its original position upon completion. This method is ideal for materials that benefit from incremental cutting approaches.

Click here to learn more about the product or here to receive a personalized quote.

The feed speed range of the GenCut GL200E - High-Speed Automatic Precision Metallographic Cutter is adjustable from 0 to 600 millimeters per minute. With such an extensive range of options, users are able to precisely control the speed of the cutting process to suit different materials and cutting needs. By adjusting the feed rate in steps of 0.01mm, you are able to achieve fine-tuned control over the cutting speed, resulting in high accuracy and optimal results when cutting different materials.

With this capability to adjust the feed speed precisely, it is possible to use the GenCut GL200E to process a wide range of materials, from delicate specimens that require slower speeds to more durable materials that can be processed at higher speeds.

Click here to learn more about the product or here to receive a personalized quote.

The cutting wheel used in the GenCut GL200E - High-Speed Automatic Precision Metallographic Cutter has dimensions of Φ200mm in diameter, 1.0mm in thickness, and a central bore of Φ32mm. This specific size is designed to provide precise and efficient cutting performance. In addition to metals, ceramics, and biological specimens, this machine is suitable for a wide range of materials.

The 200mm diameter allows for significant cutting depth, making it suitable for different sample sizes. The 1.0mm thickness ensures minimal material waste while providing the strength needed for clean and accurate cuts. The 32mm central bore provides a secure fit onto the spindle, maintaining stability during high-speed operations up to 5000rpm. This cutting wheel size is optimized for the machine’s capabilities, contributing to the precision and reliability of the GenCut GL200E in metallographic sample preparation.

Click here to learn more about the product or here to receive a personalized quote.

The spindle speed range of the GenCut GL200E - High-Speed Automatic Precision Metallographic Cutter spans from 500 to 5000 revolutions per minute (RPM). This extensive range of speeds allows for optimal adjustment according to the material being cut and the specific requirements of the cutting task. Lower speeds around 500rpm are suitable for delicate or soft materials, reducing the risk of damage. Higher speeds up to 5000rpm are ideal for harder materials, resulting in efficient and clean cuts.

The ability to fine-tune the spindle speed increases the machine's functionality and precision, making the GenCut GL200E a reliable choice for a range of metallographic sample preparations. This feature makes it possible that the cutting process can be customized to achieve the best results for different types of specimens, maintaining their integrity and quality.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL200E - High-Speed Automatic Precision Metallographic Cutter features a Y-axis travel distance of 260mm, greatly optimizing its cutting capabilities. It is because of this extended range of sizes that we are able to handle different sample sizes in a more flexible and efficient manner, allowing us to process even larger specimens accurately and efficiently.

As a result of its substantial Y-axis travel, precise positioning of the cutting table is possible, which is necessary in order to guarantee consistent and accurate cuts. This capability is particularly useful when working with complex or elongated samples that require precise adjustments during the cutting process, such as those that are complex or elongated. The 260mm travel distance supports diverse applications in metallographic sample preparation, making the GenCut GL200E an adaptable and reliable tool for laboratories and industries requiring meticulous cutting performance.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL200E - High-Speed Automatic Precision Metallographic Cutter has a maximum cutting diameter of Φ60mm. This capacity allows the machine to handle relatively large samples, enabling it to be used in a variety of applications across different industries. Whether you are cutting metals, ceramics, biological specimens, or other materials, the ability to accommodate samples up to 60mm in diameter offers versatility and efficiency.

This significant cutting diameter is especially beneficial in laboratories and industrial settings where a wide range of sample sizes are processed. The GenCut GL200E's capability to cut larger specimens accurately and efficiently reduces the need for additional cutting equipment, thereby simplifying sample preparation. The precise and clean cuts achieved with this maximum diameter improve the quality and reliability of metallographic analyses, making sure that even substantial samples can be prepared with the same high standards of precision and care.

Click here to learn more about the product or here to receive a personalized quote.

The motor in the GenCut GL200E - High-Speed Automatic Precision Metallographic Cutter has 1500 watts. This robust motor power allows the machine can handle demanding cutting tasks with ease. It provides sufficient force to cut through a variety of materials including metals, ceramics, and biological specimens. The 1500W motor contributes to the cutter's high-speed operation, allowing for efficient and precise operation even in tough materials.

As a result of this level of motor power, the machine is able to perform and be reliable. This makes certain that it can maintain consistent cutting speeds and accuracy over extended periods of use. For laboratories and industrial applications, the 1500W motor guarantees that the GenCut GL200E can meet rigorous sample preparation requirements, providing the necessary power to achieve clean and accurate cuts.

Click here to learn more about the product or here to receive a personalized quote.

The input power requirements for the GenCut GL200E - High-Speed Automatic Precision Metallographic Cutter are 220V, operating at 50/60Hz in a single-phase configuration. This standard electrical specification makes the machine compatible with common power systems found in laboratory and industrial settings. Single-phase power allows the cutter to be easily integrated into existing electrical setups without specialized equipment or modifications.

An input voltage of 220V provides a stable and reliable energy source, enabling high-speed and precise cutting operations to be carried out. This voltage level powers the cutter's 1500W motor, which provides efficient and effective performance across a wide range of cutting tasks with its 1500W motor. Dual frequency compatibility (50/60Hz) further enhances the machine's adaptability, allowing it to be used in different regions with different electrical standards.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL200E - High-Speed Automatic Precision Metallographic Cutter features a modern touchscreen display and control interface. By using this intuitive touchscreen, users can navigate through menus easily, set cutting parameters, and monitor real-time data during the cutting process. The user-friendly interface of the machine makes it easy for anyone to operate it, regardless of their skill level in terms of technical knowledge.

By allowing quick adjustments to cutting speed, feed rate, and other critical settings, touchscreen control improves precision and efficiency in machine operation. This digital interface provides clear and immediate feedback, helping users maintain optimal control over cutting operations. The programmable menu structure of the touchscreen allows customization and storage of specific cutting protocols, simplifying repetitive tasks and improving workflow efficiency.

Click here to learn more about the product or here to receive a personalized quote.

The cutting platform on the GenCut GL200E - High-Speed Automatic Precision Metallographic Cutter measures 225mm by 320mm. These dimensions provide a spacious and stable surface for securing various sample sizes during cutting. The ample platform size allows samples can be positioned accurately, facilitating precise and consistent cuts.

A larger cutting platform, such as the one on the GenCut GL200E, is particularly advantageous for handling larger or more complex specimens. It allows better maneuverability and positioning, which is crucial for high-quality cuts. The stability provided by the 225mm by 320mm platform minimizes vibrations and movements during cutting.

This generous cutting area contributes to the versatility of the GenCut GL200E, making it suitable for a broad range of metallographic sample preparations. Whether working with metals, ceramics, or biological materials, the substantial cutting platform dimensions ensure that the machine can accommodate diverse sample sizes easily.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL200E - High-Speed Automatic Precision Metallographic Cutter includes a quick clamp cutting fixture. This quick clamp mechanism allows for rapid and secure sample fastening to the cutting platform. This reduces setup time and enhances overall workflow efficiency. The quick clamp guarantees that samples are held firmly in place during the cutting process, preventing any movement that could compromise the precision and quality of the cuts.

The quick clamp fixture is particularly beneficial in high-throughput environments where time is critical, as it allows operators to swiftly change samples and maintain a steady pace of operations. Secure clamping also enhances safety by making certain that samples do not shift during cutting, which could otherwise lead to accidents or inconsistent results.

The inclusion of a quick clamp cutting fixture makes the GenCut GL200E a versatile and efficient tool for metallographic sample preparation, providing both convenience and reliability in securing samples for precise cutting.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL200E - High-Speed Automatic Precision Metallographic Cutter has dimensions of 33 inches in length, 32 inches in width, and 16 inches in height. In metric units, these dimensions are 830 mm in length, 820 mm in width, and 410 mm in height. This compact size makes it possible for the machine to fit comfortably in a range of laboratory and industrial settings, making efficient use of space.

The relatively small footprint of the GenCut GL200E makes it ideal for environments where space is limited, while still offering ample cutting capabilities. Its design balances functionality with space efficiency, allowing easy integration into existing workflows. Despite its compact size, the machine is robust and capable of handling a number of metallographic sample preparation tasks.

These dimensions highlight the machine's adaptability, making it suitable for an array of applications where high-speed, precise cutting is required without occupying excessive space. The GenCut GL200E's thoughtful design provides assurance that it can deliver high performance in a user-friendly and space-efficient package.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL200E - High-Speed Automatic Precision Metallographic Cutter weighs 287 pounds, equivalent to 130 kilograms. This substantial weight reflects the machine's robust construction, assuring stability and durability during operation. The solid build minimizes vibrations and movement, which is important for maintaining precision and accuracy in cutting tasks.

The GenCut GL200E's weight also indicates its ability to handle demanding metallographic sample preparation tasks reliably. It guarantees that the machine remains securely in place during use, providing a steady platform for cutting a wide range of materials. This stability is particularly important for consistent and high-quality cuts, especially when working with hard or dense materials.

Despite its heavy-duty construction, the GenCut GL200E is designed to be user-friendly and efficient, combining its robust weight with features that enhance performance and ease of use. The machine's weight, coupled with its compact dimensions, makes it a dependable and useful tool for laboratories and industrial settings focused on precise metallographic analysis.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL200E - High-Speed Automatic Precision Metallographic Cutter has a 225mm clamping width. This width allows for secure and stable clamping of a variety of sample sizes and shapes, assuring that they are firmly held in place during the cutting process. The generous clamping width enhances the machine's flexibility, enabling it to handle wider samples efficiently.

Having a transverse clamping width of 225mm is particularly beneficial for preparing larger or more complex samples, providing ample space to position and secure them accurately. This feature ensures that samples do not move or shift during cutting, which is crucial for maintaining precision and high-quality cuts. The stable clamping mechanism minimizes vibrations and inconsistencies, contributing to the GenCut GL200E's overall reliability and performance.

This substantial clamping width makes the GenCut GL200E an ideal tool for a wide range of metallographic sample preparations, ensuring that samples of various sizes can be handled with ease and precision. It underscores the machine's adaptability and effectiveness in meeting diverse cutting requirements in both laboratory and industrial settings.

Click here to learn more about the product or here to receive a personalized quote.

The longitudinal clamping length of the GenCut GL200E - High-Speed Automatic Precision Metallographic Cutter is 150mm. This length allows for secure and stable clamping of samples along the cutting platform. The 150mm clamping length is particularly advantageous for handling elongated samples, providing the necessary support to achieve precise and consistent cuts.

The substantial longitudinal clamping length enhances the machine's versatility, allowing it to accommodate a large variety of sample sizes and shapes. By securely holding the samples in place, the clamping mechanism minimizes movement and vibrations. This is essential for maintaining accuracy and high-quality cuts. This feature is crucial for applications that require precise longitudinal sample positioning.

The 150mm longitudinal clamping length of the GenCut GL200E contributes to its reliability and effectiveness in metallographic sample preparation, thereby making it a valuable tool in both laboratory and industrial settings where precision cutting is essential.

Click here to learn more about the product or here to receive a personalized quote.

The standard configuration of the GenCut GL200E - High-Speed Automatic Precision Metallographic Cutter includes all the key components and accessories needed for efficient operation and precise cutting. This setup makes certain that users have everything required to start using the machine immediately.

Included in the standard configuration are:

-

GenCut GL200E Cutting Saw: The main unit of the machine, is designed for high-speed and precise cutting.

-

Coolant Chamber: Provides effective cooling of the cutting area to prevent overheating and maintain sample integrity.

-

Wrench 13#-15#: A wrench for various assembly and maintenance tasks.

-

Wrench 17#-19#: Another wrench that can be used for assembly and maintenance needs.

-

Internal Hexagonal Wrench 6mm and 8mm: Hex wrenches for precise adjustments and component assembly.

-

Water Inlet Tube: Facilitates the connection of the coolant system to the water supply.

-

Drain Pipe: Used for draining the coolant system.

-

Diamond Cutting Wheel (Φ200 x 1.0 x Φ32mm): A high-quality cutting wheel designed for precise and clean cuts.

-

Operation Manual: A detailed guide to assist users in setting up, operating, and maintaining the machine.

With this standard configuration, the GenCut GL200E is ready for immediate use, providing users with the tools and accessories required for reliable metallographic sample preparation.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL200E - High-Speed Automatic Precision Metallographic Cutter achieves precision cutting through micrometer head control. This advanced feature allows for extremely fine adjustments to the cutting position so that each cut is made with a high degree of accuracy. The micrometer head control provides precise measurement and control over the cutting process. This allows users to make incremental adjustments as small as fractions of a millimeter.

This level of precision is crucial for metallographic sample preparation, where maintaining the integrity and exact dimensions of the sample is essential. By using micrometer head control, the GenCut GL200E can handle delicate and complex cutting tasks with exceptional accuracy. This feature is particularly beneficial when working with materials that require meticulous handling, such as metals, ceramics, and biological specimens.

The micrometer head control enhances the machine’s ability to produce high-quality, deformation-free cuts, making it a reliable tool for precise metallographic analysis. This capability guarantees that the GenCut GL200E meets rigorous laboratory and industrial standards.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL200E - High-Speed Automatic Precision Metallographic Cutter offers operator safety through a closed transparent protective cover and a safety switch. The closed transparent protective cover encloses the cutting area, preventing direct contact with moving parts. This allows operators to monitor the cutting process. This visibility provides assurance that users can oversee operations without exposing themselves to potential hazards.

The safety switch further enhances protection by automatically shutting off the machine when the protective cover is opened. This interlock mechanism prevents the machine from operating when the cover is not securely in place, reducing the risk of accidents and injuries. The combination of these safety features guarantees that the GenCut GL200E provides a secure working environment, allowing operators to perform precise cutting tasks confidently and safely.

These safety measures are particularly important in laboratory and industrial settings, where maintaining a high level of safety is crucial. By implementing these features, the GenCut GL200E not only delivers high-performance cutting capabilities but also prioritizes users' well-being.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL200E - High-Speed Automatic Precision Metallographic Cutter prevents motor overload through its closed-loop control cutting system. This advanced feature continuously monitors the motor's performance and adjusts the cutting parameters in real time to provide optimal operation. By maintaining a constant feedback loop, the system can detect any signs of excessive load or strain on the motor. It can make immediate adjustments to avoid overload.

This closed-loop control system manages cutting speed and feed rate dynamically so that the motor operates within safe limits. This not only protects the motor from damage due to overheating or overexertion but also enhances the overall efficiency and longevity of the machine. Motor overload prevention is particularly important in demanding cutting tasks where maintaining consistent performance is critical.

By incorporating closed-loop control, the GenCut GL200E offers reliable and safe operation, providing users with confidence in the machine's ability to handle different materials and cutting conditions without risking motor damage. This feature makes the cutter an ideal tool for precise and high-quality metallographic sample preparation.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenCut GL200E - High-Speed Automatic Precision Metallographic Cutter stops automatically after finishing the cut. The purpose of this feature is to increase workflow efficiency by making sure that the machine ceases to operate immediately after it performs a cutting operation. As a result of the automatic stop function, operators no longer require manual intervention in order to halt the machine, allowing them to quickly move on to the next sample or task at hand.

This automatic stopping capability saves time and protects the machine from unnecessary wear, contributing to its durability and longevity. Additionally, it enhances safety by reducing the risk of accidents if the machine continues to run unattended. The automatic stop feature is a crucial aspect of the GenCut GL200E, providing optimal performance, efficiency, and safety in metallographic sample preparation.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenCut GL200E - High-Speed Automatic Precision Metallographic Cutter has a built-in movable coolant tank. This feature significantly improves machine usability and efficiency. The movable coolant tank facilitates easy maintenance and refilling so that the cooling system operates effectively to prevent overheating and maintain the integrity of the samples during cutting.

It is important to note that the built-in design of the coolant tank allows for seamless integration with the machine, eliminating the need for external coolant systems and reducing the overall footprint of the machine. Moreover, due to the tank's mobility, it is easy to clean and reposition it as needed, further improving the efficiency of workflow. The built-in movable coolant tank contributes significantly to the precise, burn-free cutting needed for the preparation of high-quality metallographic samples by providing efficient cooling of the cutting process.

Click here to learn more about the product or here to receive a personalized quote.

GenCut GL200E - High-Speed Automatic Precision Metallographic Cutter features a compact body and small footprint, improving its operation and maintenance. The compact design allows the machine to fit easily into various laboratory and industrial environments, making efficient use of available space without compromising its cutting capabilities.

The small footprint ensures that the GenCut GL200E can be conveniently placed on workbenches or in designated cutting areas, facilitating easy access and operation. This design reduces clutter and space requirements typically associated with larger cutting machines.

Additionally, the machine's compact and user-friendly design simplifies maintenance tasks. Key components, such as the built-in movable coolant tank, are easily accessible, making routine maintenance and cleaning straightforward. This ease of maintenance helps to guarantee that the machine operates smoothly and reliably, reducing downtime and extending its service life.

Click here to learn more about the product or here to receive a personalized quote.

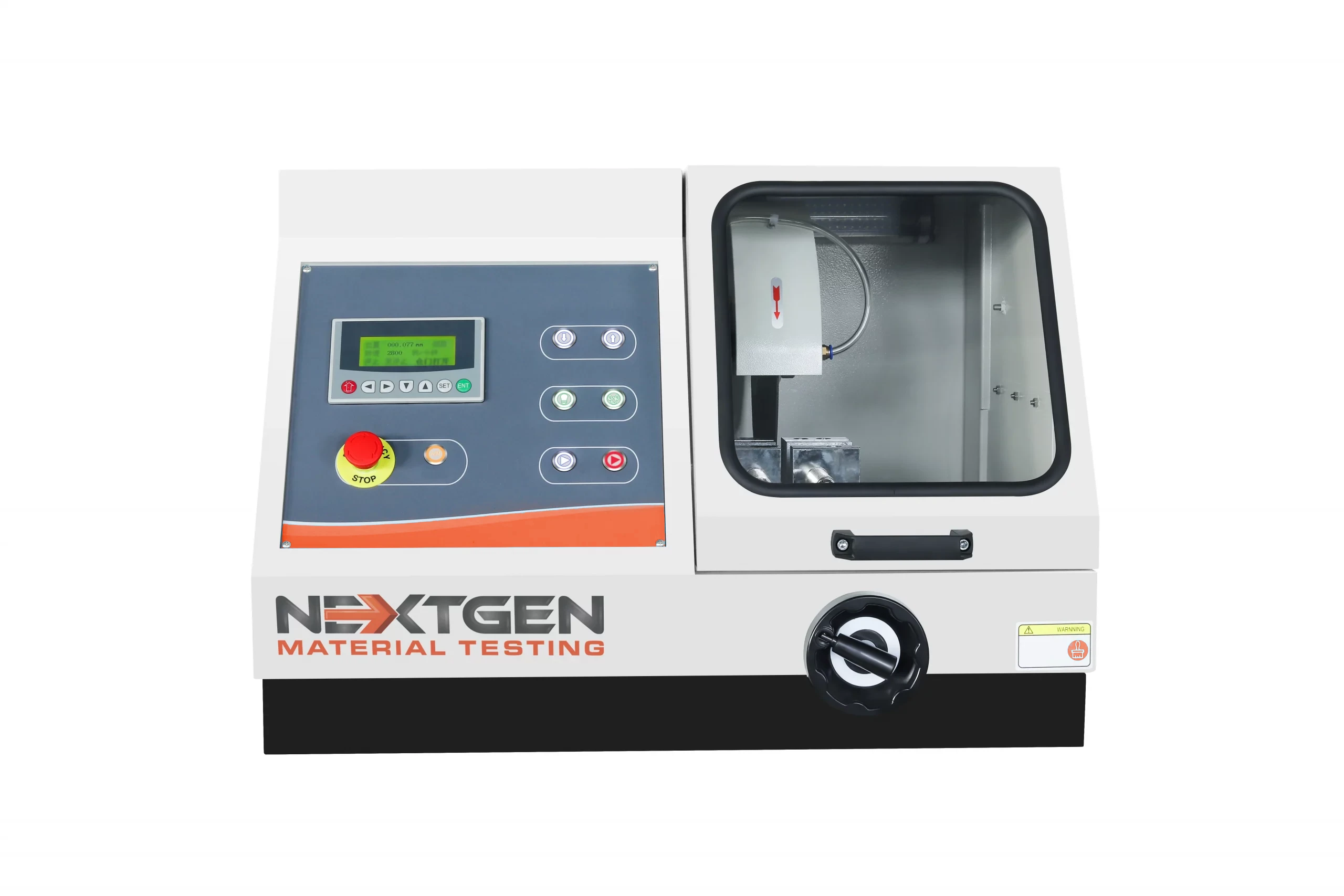

Related Products

GenCut GL100M – Precision Manual Metallographic Sample Cutting Machine with Simple User-Friendly Operation and Large Cutting Capacity Φ100mm

Introducing the GenCut GL100M Manual Cutting Machine, expertly designed for precision metal sample cutting.

GenCut GL350 – Precision Metallographic Sample Cutting Machine with Simple User-Friendly Operation and Large Cutting Capacity Φ100mm

The GenCut GL350 is a cutting-edge high precision cutting machine equipped with advanced features and capabilities

GenCut GL80A – Precision Metallographic Sample Cutting Machine with Simple User-Friendly Operation and Large Cutting Capacity Φ80mm

Introducing the GenCut GL80A, a highly precise cutting machine offering both automatic and manual work modes.

GenCut GL100E – Low Speed Precision Metallographic Automatic Cutter with User-Friendly Touch Screen Interface with max. cutting diameter of 25mm

GenCut GL100E low speed series metallographic precision cutter has variable speed control from 50-1000 rpm.

Metallography Consumables

Learn about the full scope of NextGen's cutting, polishing & grinding, mounting and etching metallography consumables. Our consumables are compatible with virtually all global brands, offering a rare combination of exceptional quality, longevity and affordability.