Metal Testing Equipment

Description

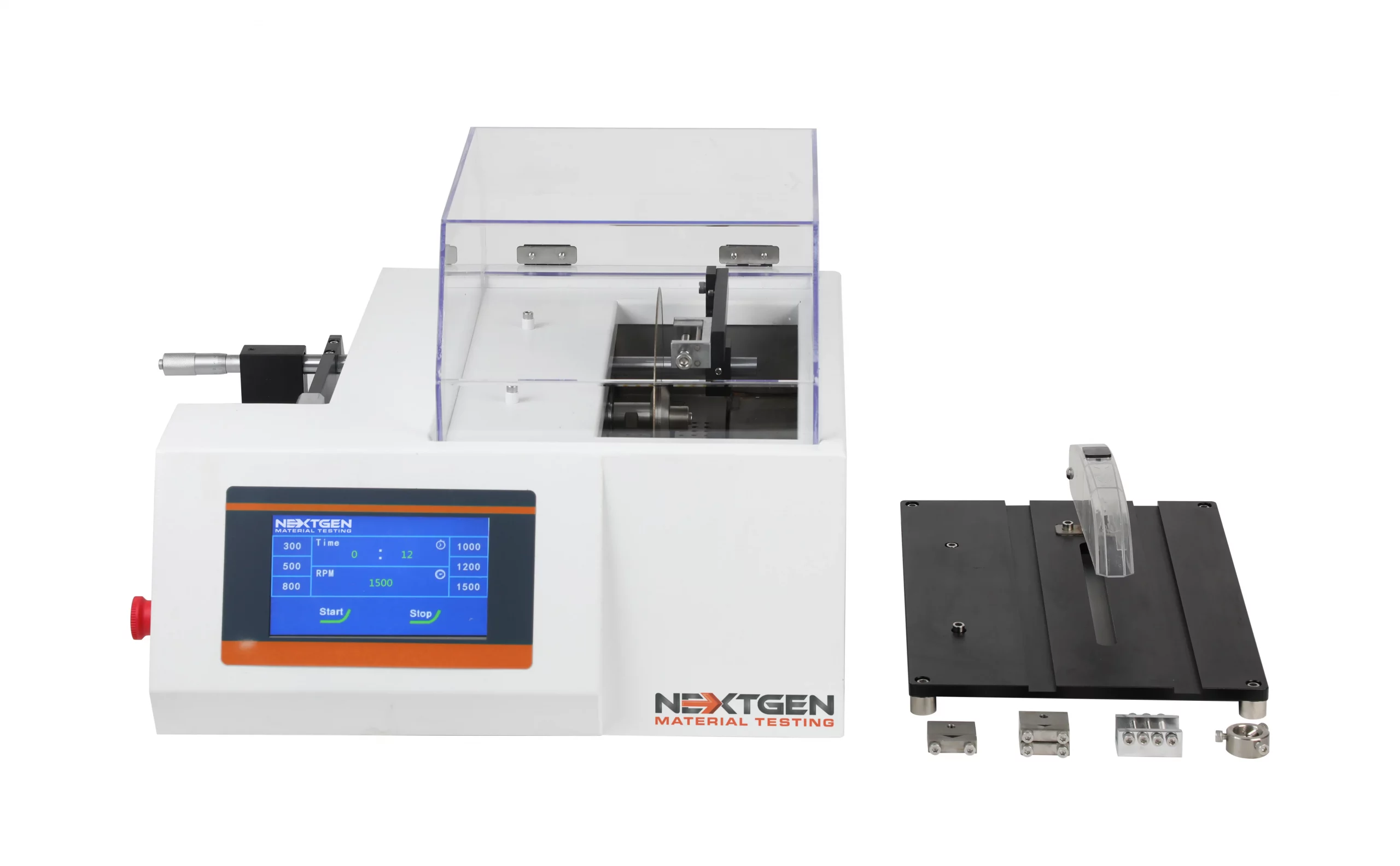

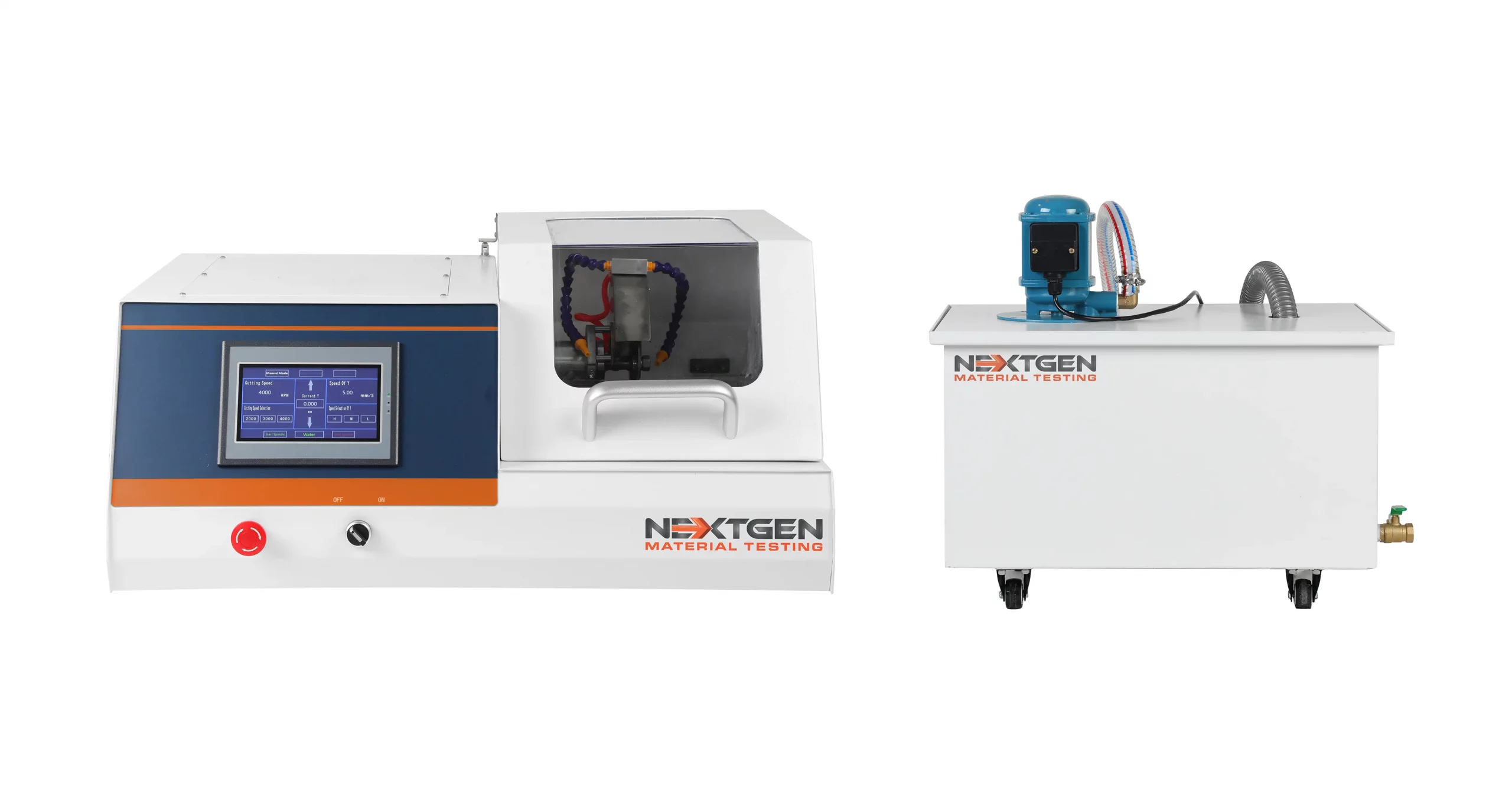

GenCut GL100E & 100 Series low speed advanced automatic precision cut-off saw is well established in the metallography industry. This diamond saw precision cutter is a perfect fit for cutting and sectioning a wide variety of small and delicate samples particularly when the material structure is not homogeneous. This precision cut off saw can accept cutting a cutting wheel of 4”.

GL100E Series metallographic precision cutter has variable speed control from 50-1000 rpm.. Additionally, GenCut GL 100E cut off saw for metallographic sample preparation comes standard with an automatic shut-off function at the end of each cutting cycle. Read more in our MEGA BLOG!

GenCut GL100E Technical Specifications

|

Model |

GenCut GL100E |

|

Cutting Wheel |

Ø200xØ32x0.9mm |

|

Motor |

300W |

|

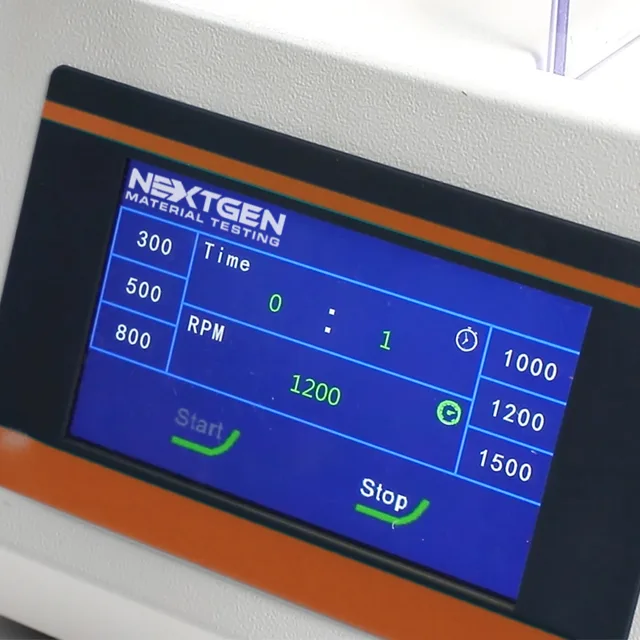

Variable Speed |

100-1500rpm |

|

Cooling Device |

Automatic cycle cooling of cutting fluid (the cutting wheel drives the circulation of the water in the tank to cool down) |

|

Display Panel |

7" Touch Screen Controller |

|

Micrometer Travel Range |

0-25mm |

|

Position Accuracy |

0.01mm |

|

Power Supply |

Single phase, AC220V, 50Hz |

|

Emergency brake

|

Emergency stop switch |

|

Loading weights |

0-450g |

|

Dimensions |

21.65" x 21.65" x 14.96" / 550 x 550 x 380 mm |

|

Weight |

100lbs / 45kg |

Standard Configuration

-

Cutting Saw

-

Single Head Jig

-

Double Head Jig

-

Irregular Sample Jig

-

Flat Clamp

-

Water Drop Jig

-

Wrench for Changing Blade

-

Differential Head

-

Inset Sample Jig

-

Power Cord and Operation Manual

GenCut GL100E Features

-

Two Cutting Modes – Manual or Gravity (weight, counterweight)

-

Digital Touch Screen Control with programmable menu structure for a user-friendly operating experience

-

Precision cutting off with micrometer head control

-

Closed transparent protective cover and safety switch provide protection for operators

-

Features a weight sliding loading system to minimize sample damage

-

Closed loop control cutting to prevent overload of the motor

-

Automatically stops after finishing the cut

-

Built-in Movable Coolant Tank

-

Compact body, small footprint and convenient operation and maintenance

Application

Suitable for cutting small, soft, brittle, special-shaped metal materials, composite materials, plastics, electronic components, biological materials, ceramics, cement, rocks and minerals, etc. It is also commonly used for thin-film sample preparation.

FAQs

The GenCut GL100E works with a diamond cutting wheel sized Ø200 × Ø32 × 0.9 mm. This type of wheel is designed for precision sectioning of metals, ceramics, composites, and other hard or brittle samples. The diamond edge gives a long service life, reducing the need for frequent replacements while maintaining clean, accurate cuts.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL100E is built with a micrometer head that gives a travel range of 0–25 mm. Positioning accuracy is 0.01 mm, allowing for the preparation of very small or delicate specimens with precise depth control. This level of precision helps laboratories carry out repeatable cuts without losing structural detail in the sample.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL100E comes with a closed transparent cover that keeps chips and coolant inside while giving a clear view of the process. A safety switch guarantees the drive cuts off if the cover is opened. The machine features motor overload protection that secures the system by stopping the cut when resistance is too high. An emergency stop button is installed for immediate shutdown.

Click here to learn more about the product or here to receive a personalized quote.

In gravity-feed mode, the GenCut GL100E uses a counterweight system that applies a steady force to the specimen. The weight slides gradually, creating controlled pressure on the cutting wheel. This method results in consistent cutting across the entire sample and is especially useful for delicate specimens where direct manual pressure could cause cracks or deformation.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL100E operates with low-speed cutting that reduces heat and stress on delicate materials. A weight loading system applies a steady force, preventing sudden pressure that could break or deform the specimen. The set of precision jigs, including holders for irregular shapes, keeps samples stable throughout the cut. Together, these elements limit structural changes in fragile or complex specimens and help prepare sections without unnecessary damage.

Click here to learn more about the product or here to receive a personalized quote.

Yes. The GenCut GL100E is not limited to metals and alloys. It is also applied for plastics, composites, ceramics, electronic components, thin films, and biological samples. The combination of a low-speed motor and diamond wheel makes it possible to section brittle or heat-sensitive materials without introducing cracks or deformation.

Non-metallic applications include circuit boards, polymer parts, dental and medical samples, thin-film coatings, and ceramic specimens. The integrated coolant system helps control heat buildup, which is critical when cutting materials with low thermal resistance.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL100E has overall dimensions of 21.65" × 21.65" × 14.96" (550 × 550 × 380 mm) and a weight of about 100 lbs (45 kg). The compact footprint makes it suitable for placement on a standard laboratory bench without taking excessive space. Despite its size, the cutter integrates the motor, cooling system, and touch-screen controller into a single unit, so no external modules are required. This setup keeps the machine practical for laboratories where workspace is limited.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL100E is equipped with a 300 W motor that drives the low-speed diamond wheel. The motor speed is adjustable from 100 to 1500 rpm, which covers both delicate materials that need gentle cutting and harder samples that require higher rotation. Power is supplied by a single-phase AC220V, 50 Hz line, which matches common laboratory setups.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL100E operates in two modes. In manual mode, the operator advances the sample directly. In gravity feed mode, a sliding weight system applies steady pressure to the specimen during cutting. This dual setup makes it possible to handle both routine sections and delicate materials that benefit from controlled, low-force cutting.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL100E is designed for specimens up to 25 mm in diameter. This range covers small and delicate pieces, including brittle materials that require careful sectioning. It is suited for metallographic samples, electronic components, ceramics, and other small specimens where controlled cutting is essential.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL100E uses automatic coolant circulation, where the cutting wheel drives the flow of liquid during operation. A movable coolant tank is integrated into the unit for easy refilling and cleaning. The system runs on water-based cooling, which lowers the heat at the cutting point and reduces the chance of structural damage to delicate samples. This setup keeps both the blade and the specimen stable throughout sectioning.

Click here to learn more about the product or here to receive a personalized quote.

Yes. The GenCut GL100E is equipped with an automatic shut-off that activates once the cutting cycle is completed. This prevents unnecessary wear on the blade and motor. The feature also protects the drive system by stopping power if the machine detects overload during operation.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL100E package includes a single head jig, a double head jig, an irregular sample jig, a flat clamp, a water drop jig, and an inset sample jig for handling different types of specimens. These holders make it possible to secure round, flat, irregular, or delicate samples during sectioning.

The standard delivery also comes with a wrench for blade changes, a differential head, a power cord, and an operation manual. With this set of tools, laboratories can start cutting immediately without the need for extra accessories.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL100E is supplied with a 3-year warranty on mechanical parts and a 1-year warranty on electrical components. This covers the frame, moving assemblies, and optics on the mechanical side, as well as the motor, electronics, and touch screen on the electrical side.

Alongside the warranty, buyers have access to spare parts, consumables, and technical service. This setup protects the investment and makes it possible to keep the cutter in operation without long interruptions.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

GenCut GL100M – Precision Manual Metallographic Sample Cutting Machine with Simple User-Friendly Operation and Large Cutting Capacity Φ100mm

Introducing the GenCut GL100M Manual Cutting Machine, expertly designed for precision metal sample cutting.

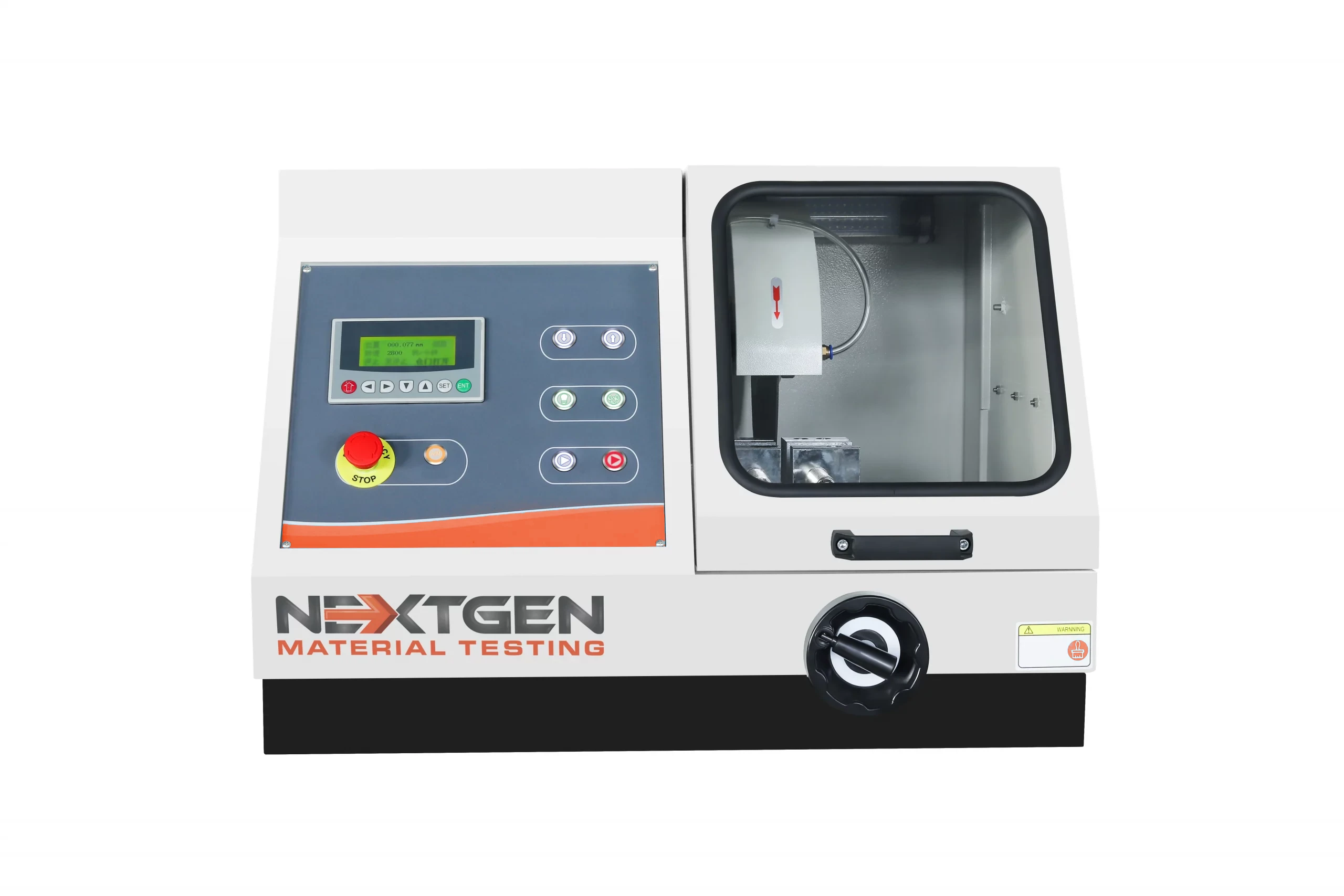

GenCut GL350 – Precision Metallographic Sample Cutting Machine with Simple User-Friendly Operation and Large Cutting Capacity Φ100mm

The GenCut GL350 is a cutting-edge high precision cutting machine equipped with advanced features and capabilities

GenCut GL80A – Precision Metallographic Sample Cutting Machine with Simple User-Friendly Operation and Large Cutting Capacity Φ80mm

Introducing the GenCut GL80A, a highly precise cutting machine offering both automatic and manual work modes.

GenCut GL200E – High Speed Automatic Precision Metallographic Cutter with User-Friendly Touch Screen Interface with max. cutting diameter of 60mm

GenCut GL 200E precision cutting machine includes a touch screen and PLC control, with stable performance and real-time display parameters.

Metallography Consumables

Learn about the full scope of NextGen's cutting, polishing & grinding, mounting and etching metallography consumables. Our consumables are compatible with virtually all global brands, offering a rare combination of exceptional quality, longevity and affordability.