Metal Testing Equipment

Description

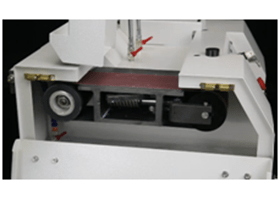

The GenGrind Belt BF Series is a heavy duty dual stage, wet or dry belt grinder offering a robust, floor standing solution for high volume manual belt grinding applications. GenGrind Belt BF - Heavy Duty Dual Stage Belt Grinder for metallographic sample preparation is designed for high material removal of various sample shapes and configurations. The BF series - belt grinder is a floor standing, ruggedly designed unit for laboratory or production shop environments. A recirculation system is built in to the front cabinet of the GenGrind BT for lubrication and cleaning of your specimens. With a wide variety of consumables available, the GenGrind BF Heavy Duty Dual Stage Belt Grinder is your ideal choice for manual grinding operations.

- Included recirculation unit for coolant supply and filtering

- Adjustable coolant supplies for ideal positioning of your lubricant

- User friendly and accessible controls for quick changes to your grinding procedures

- Side access to the individual belts for quick removal and replacement belt procedures

- Variable belt speed from 50-600 RPM through the front access controls

- Compatible with a standard 4" x 36" grinding belt

Dual Stage Belt Grinder Technical Specifications

| Specifications | GenGrind Belt BF |

|---|---|

| Belt Size (Inch) | 4“ x 36“ |

| Machine Size (WxLxH) |

29.5" x 25.6" x 42" 75 x 65 x 105 |

| Power Supply | 220V 50/60Hz 1Ph |

| Motor Power | 370W |

| Weight | 406 lbs / 184 kg |

| Maximum Sample Size (cm) | 16-21 square |

FAQs

The GenGrind Belt BF is engineered for manual metallographic sample preparation, focusing on high-material removal. Its main purpose is to provide a heavy-duty grinding solution that can handle an array of sample shapes and sizes, particularly in high-volume laboratory or production environments. It supports both wet and dry grinding processes, which makes it suitable for various types of materials and applications.

This machine is ideal for the initial stages of sample preparation, where aggressive grinding is required to shape and smooth specimens before fine polishing. With its robust construction and dual-stage setup, the GenGrind Belt BF allows users to perform sequential grinding tasks efficiently, helping improve workflow and preparation consistency in metallurgical labs and industrial settings.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind Belt BF operates as a manual, floor-standing dual-stage grinder designed to remove material from samples through a rotating abrasive belt. Users guide the sample against the moving belt to achieve the desired surface removal level. The grinder allows for two grinding stages, which can be used consecutively for coarse and medium grinding without switching machines.

It features adjustable belt speed from 50 to 600 RPM, giving users control over grinding intensity based on material type. The built-in coolant recirculation system delivers lubrication to the belt surface, reducing heat and improving sample finishes. It is simple to access and control the system from the front panel, making operation straightforward and flexible for a broad range of sample preparation applications.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenGrind Belt BF is equipped with a built-in recirculation unit specifically created for cooling supply and filtering. This feature provides a steady flow of coolant during grinding operations, helping to manage heat and maintain sample surface quality. It is particularly useful in wet grinding applications where temperature control is a requirement.

The unit also filters the used coolant, removing particles and debris before reusing it. This reduces waste, extends coolant life, and minimizes maintenance needs. By providing continuous lubrication and cleaning, the recirculation unit supports efficient grinding, keeps the work area clean, and enhances the overall reliability of the machine during high-volume or intensive use.

Click here to learn more about the product or here to receive a personalized quote.

How does the GenGrind Belt BF allow users to control the positioning of the coolant during grinding?

The GenGrind Belt BF includes adjustable coolant supplies, allowing users to position lubricant flow precisely where it is needed during grinding. This flexibility helps to assure that the coolant effectively reaches the contact point between the sample and the belt, which is critical for controlling heat and removing grinding debris.

Proper coolant placement improves grinding efficiency by reducing friction and preventing samples from overheating. It also supports better surface quality and extends the life of both the abrasive belt and the coolant itself. This feature is especially useful when working with samples of different shapes and sizes, offering improved control and consistency in manual grinding tasks.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind Belt BF features user-friendly and easily accessible controls that simplify operation and allow for quick adjustments to grinding procedures. These controls are located on the front panel of the machine, enabling users to manage settings such as belt speed and coolant flow without interrupting workflow.

This design supports fast, responsive changes based on the specific requirements of each sample, making the grinder more efficient and adaptable to busy lab or production environments. By reducing setup time and simplifying adjustments, the control layout allows for smooth operation and consistent results regardless of grinding tasks.

Click here to learn more about the product or here to receive a personalized quote.

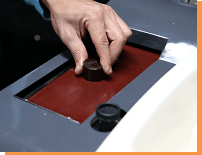

The GenGrind Belt BF is designed with side access to each grinding belt, making removal and replacement fast and straightforward. This feature allows users to change belts without dismantling other parts of the machine, reducing downtime and improving overall efficiency during operation.

Quick belt replacement is especially important in high-volume settings where different abrasives types may be used frequently. Side access saves time and maintains safety and ease of use. It guarantees that the grinder remains ready for continuous use with minimal interruption, supporting both productivity and convenience in laboratory and production environments.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind Belt BF offers a variable belt speed ranging from 50 to 600 revolutions per minute (RPM), allowing users to adjust the grinding speed to suit different materials and preparation requirements. This flexibility is necessary for optimizing performance, whether performing aggressive material removal or a more controlled surface preparation.

Speed adjustments are made through the front access controls, which are positioned for easy and quick operation. This setup allows users to change settings without pausing the process or making complex adjustments. By offering precise speed control, the GenGrind Belt BF helps achieve consistent results and better adaptation to an array of grinding tasks.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind Belt BF is compatible with standard 4" x 36" grinding belts, which are widely available and commonly used in industrial and laboratory settings. This standard size makes it easy for users to source replacement belts and provides an extensive selection of abrasive types and grit sizes for different material preparation needs.

Using a standard belt size also simplifies inventory management and reduces downtime, as users can quickly replace worn belts with readily available options. This compatibility supports both flexibility and cost-effectiveness, making the machine practical for frequent use in high-demand sample preparation environments.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind Belt BF has overall dimensions of 29.5 inches in width, 25.6 inches in length, and 42 inches in height (equivalent to 75 x 65 x 105 cm). As a floor-standing unit, its compact yet sturdy design makes it suitable for both laboratory and production shop environments where space and workflow efficiency are important.

The machine’s size allows it to handle demanding grinding tasks while remaining manageable within a standard workspace layout. Its vertical build helps conserve floor space, and its accessible design ensures that users can operate and maintain the unit comfortably. As a result, it is an excellent choice for areas that prepare samples on a regular basis.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind Belt BF operates on a 220V, 50/60Hz, single-phase power supply. This standard electrical configuration is commonly available in laboratory and industrial settings, making installation straightforward without specialized wiring.

Single-phase design supports stable and efficient performance while keeping energy consumption manageable. This setup provides assurance that the grinder can run reliably under continuous use, which is necessary for environments where consistent grinding and high sample throughput are required.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind Belt BF is powered by a 370-watt motor, which provides sufficient torque and speed for effective material removal during metallographic sample preparation. This motor power supports stable belt rotation across the full speed range of 50 to 600 RPM, guaranteeing reliable grinding performance under varying load conditions.

The 370W rating is well-suited to manual, heavy-duty use, delivering the force needed for both coarse and fine grinding tasks. It balances power efficiency with durability, enabling it to be used regularly in laboratories and production environments without consuming excessive amounts of energy.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind Belt BF weighs approximately 406 pounds or 184 kilograms. This substantial weight provides excellent stability during grinding operations, reducing vibration and ensuring consistent performance. In heavy-duty grinding, where machine movement may affect precision and safety, this is particularly important.

While the unit is not designed for frequent relocation, its weight and floor-standing design make it ideal for fixed installation in laboratories or production areas. Once positioned, it remains securely in place, supporting safe and efficient manual operation for long periods of use.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind Belt BF can handle samples up to 16 to 21 square centimeters. This capacity allows users to prepare various types of specimen shapes and dimensions, which makes the machine suitable for a variety of metallographic applications that require high material removal rates.

This sample size range supports flexibility in manual grinding tasks, including both standard and irregularly shaped specimens. It enables effective surface preparation for further analysis without equipment modifications. The ability to handle large samples also contributes to grinder usefulness in high-throughput and diverse laboratory environments.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind Belt BF features a dual-stage design, which allows users to perform two grinding steps in sequence on a single machine. It is an ideal setup for processes that require both coarse and medium grinding stages. Changing equipment or adjusting settings between steps is no longer necessary.

Having two grinding belts available side-by-side increases efficiency and saves time during sample preparation. It also improves consistency, as users can move directly from one belt to the next without interrupting workflow. In high-volume environments, this design is particularly useful for metallographic analysis that requires repeatable results and rapid processing.

Click here to learn more about the product or here to receive a personalized quote.

Yes, the GenGrind Belt BF supports both wet and dry grinding operations, offering greater flexibility for different sample types and preparation needs. Wet grinding is often preferred for reducing heat and minimizing dust, which helps preserve the sample's structural integrity and improves the surface finish. It is particularly useful when working with heat-sensitive materials.

Dry grinding, on the other hand, can be more convenient for quick material removal and water use. The ability to switch between wet and dry modes makes the GenGrind Belt BF adaptable to a range of metallographic tasks. This dual capability allows users to choose the most suitable method for each application, improving efficiency and result quality.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind Belt BF is built with rugged, floor-standing construction well-suited to both laboratory use and demanding production environments. Its heavy-duty frame provides the stability needed for high-intensity grinding, while its compact footprint fits comfortably within standard lab or workshop layouts.

This sturdy build guarantees reliable performance during extended use and supports accurate manual control over sample preparation. Its durable materials and practical design resist wear, helping it maintain consistent output over time. Whether in a research lab or industrial setting, the GenGrind Belt BF delivers dependable operation and long-term usability.

Click here to learn more about the product or here to receive a personalized quote.

The GenGrind Belt BF is ideal for metallographic sample preparation professionals working in many different industries. This includes material testing laboratories, metallurgical research facilities, academic institutions, and production quality control departments. It is particularly beneficial for users who need high-volume manual grinding with consistent results.

Technicians handling tough or irregularly shaped samples will find the dual-stage and wet/dry capabilities especially useful. Its durable design and efficient operation also make it a reliable choice in production environments where repeatable surface preparation is required before further analysis. Whether for educational, industrial, or research use, this machine supports precise and flexible grinding operations.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

GenGrind N Series 8” 200S / 10" 250S / 12" 300 S - Advanced Metallographic Grinder & Polisher - Variable Speed 50-1000rpm –Touch Screen Controlled

Introducing the GenGrind N Series metallographic grinders and polishers, offered in sizes 8", 10", or 12" diameter.

GenGrind SA-I 250S 10" Single Wheel Semi Automatic Grinder & Polisher - Variable Speed 100-1000rpm – Individual Force Control - Touch Screen Controlled with Automatic Specimen Mover Power Head – (various wheel sizes available)

Discover the single wheel semi automatic GenGrind 10" SA-I 250S, your ultimate answer to grinding and polishing needs.

GenGrind SA-C 250S 10" Single Wheel Semi Automatic Grinder & Polisher - Variable Speed 100-1000rpm – Central Force Control - Touch Screen Controlled with Automatic Specimen Mover Power Head – (various wheel sizes available)

Introducing the GenGrind SA-C 250S – your ultimate single wheel semi automatic grinding and polishing solution.

GenGrind FA-IC 250D 10" Dual Wheel Fully Automatic Grinder & Polisher - Variable Speed 100-1400rpm – Both Individual and Central Force Control - Touch Screen Controlled with Automatic Specimen Mover Power Head – (various wheel sizes available)

Introducing the GenGrind FA-IC 250D Dual Wheel Polisher and Grinder, a fully automatic metallographic grinding and polishing machine

GenGrind FA-IC 250S 10" Single Wheel Fully Automatic Grinder & Polisher - Variable Speed 100-1400rpm – Both Individual and Central Force Control - Touch Screen Controlled with Automatic Specimen Mover Power Head – (various wheel sizes available)

GenGrind FA-IC 250S Single Wheel Polisher and Grinder, an advanced and fully automatic metallographic grinding and polishing machine

GenGrind Belt BT - Dual Stage Tabletop Belt Grinder for Metallographic Sample Preparation

The GenGrindBelt BT series is a dual stage, wet or dry table top belt grinder offering the most economical solution for manual grinding applications. The GenGrind BT - Dual Stage Belt Grinder for Metallographic Sample Preparation is designed for high material removal of various sample shapes and configurations. The BT - Belt Grinder system is a table top belt grinder suitable for laboratories designed for high material removal.

GenGrind FA-IC Dual Wheel Fully Automatic

Introducing the GenGrind FA-IC, a state-of-the-art single-chip microcomputer controlled grinding and polishing machine.

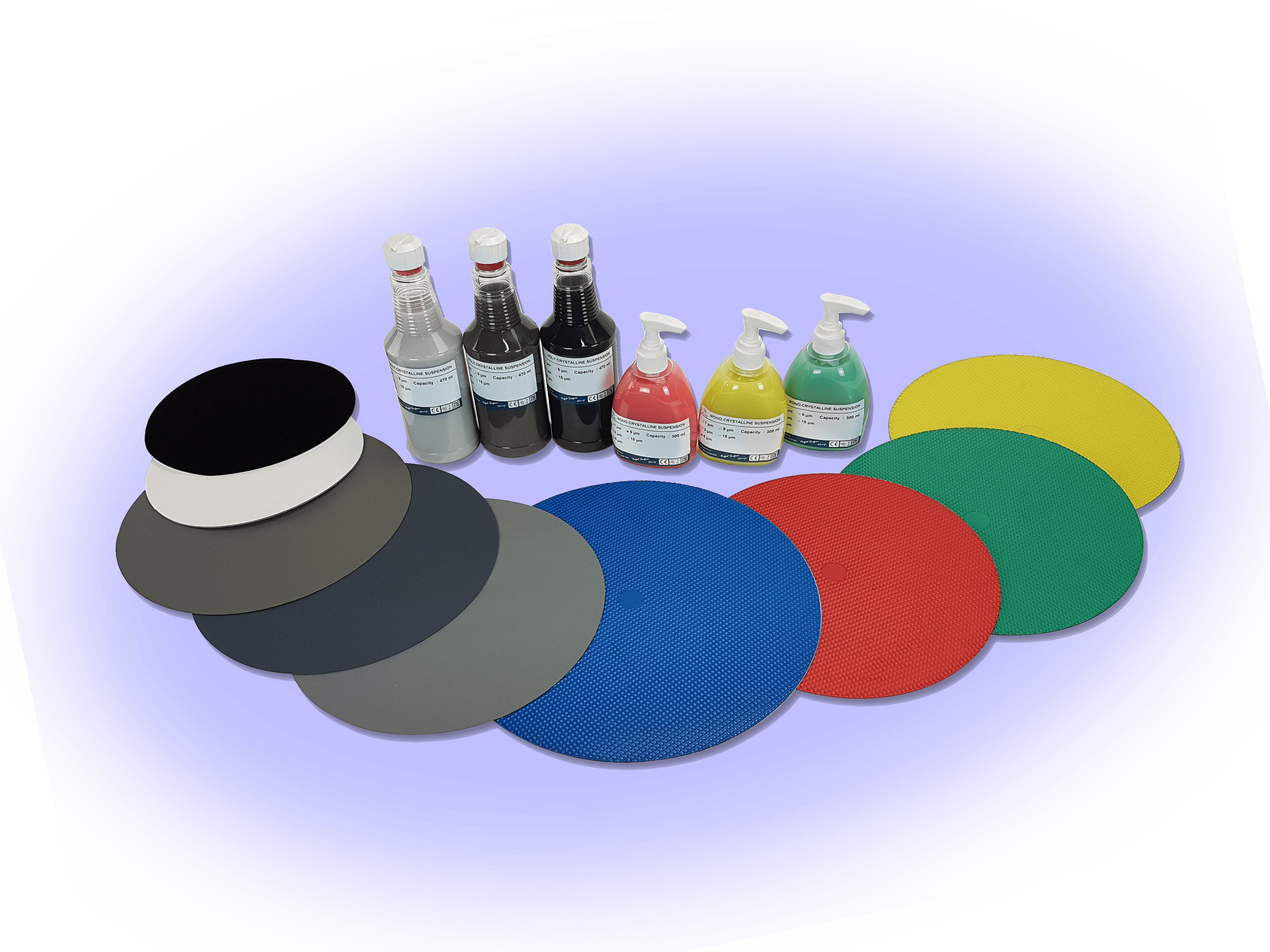

Metallography Consumables

Learn about the full scope of NextGen's cutting, polishing & grinding, mounting and etching metallography consumables. Our consumables are compatible with virtually all global brands, offering a rare combination of exceptional quality, longevity and affordability.