Metal Testing Equipment

Description

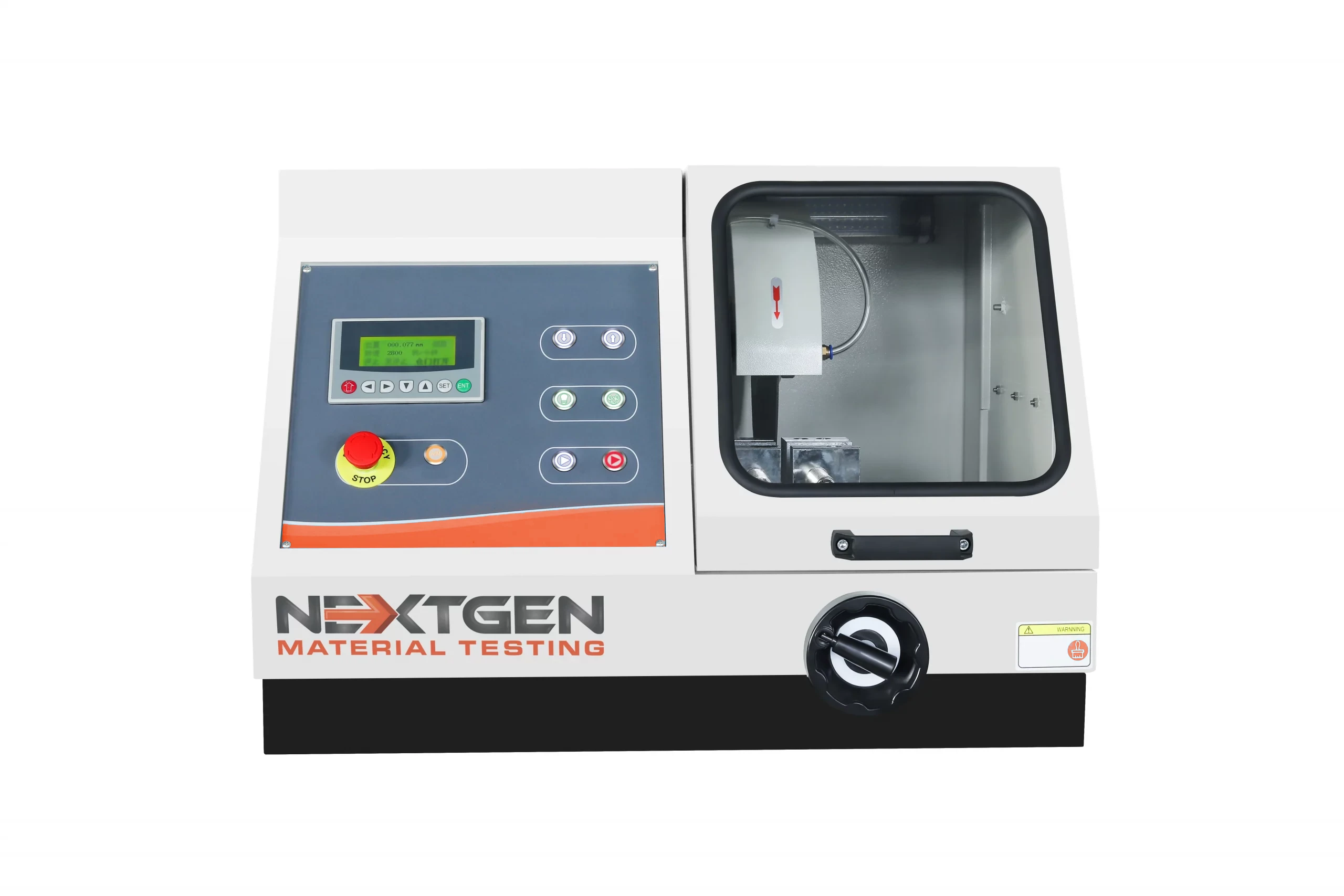

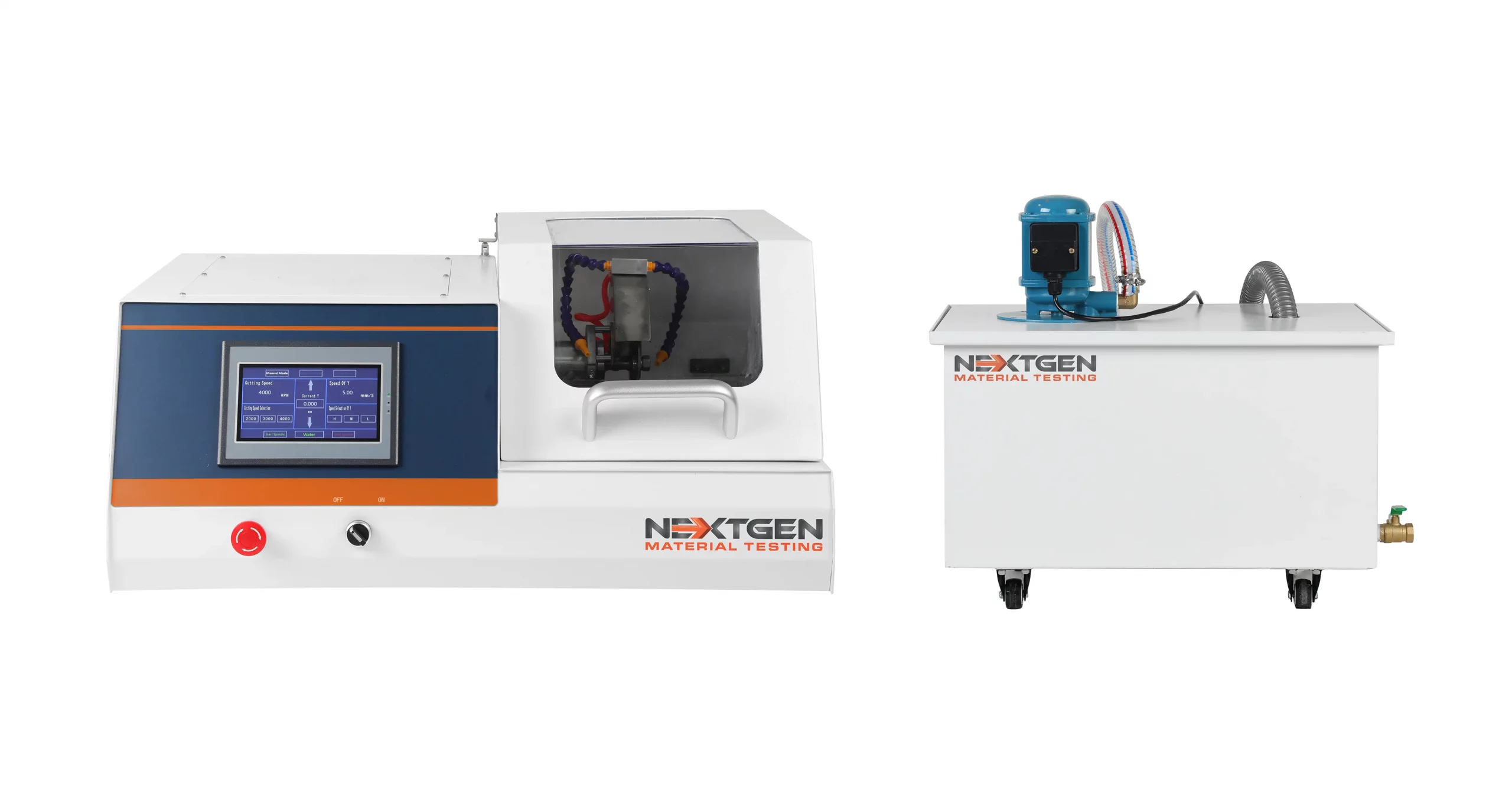

Introducing the GenCut GL100M Cutting Machine, expertly designed for precision metal sample cutting. Embracing a secure closed structure with a spacious observation window, prioritizing user safety. Benefit from its swift clamping mechanism, ensuring effortless sample securing. The dedicated cooling water tank facilitates efficient circulating cooling liquid.

Crafted with durability in mind, essential elements like the jaw and work surface are composed of stainless materials, guaranteeing an extended service life. Elevate your cutting experience with the GL100M - your solution for precise and safe metal sample cutting. Read more in our MEGA BLOG!

GenCut GL100M Technical Specifications

|

Model |

GenCut GL100M |

|

Cutting Wheel |

Φ350×2.0×Φ32mm |

|

Maximum Cutting Section |

Φ100mm |

|

Speed |

2800rpm |

|

Y Axis Cutting Range |

100mm (3.937") |

|

Motor Power |

3.0kW |

|

Cutting Room Light |

Low Voltage DC Led Lighting |

|

Voltage |

220V / 60Hz / 3 Phase |

|

Dimensions |

28.75” x 27.5” x 20.5” / 730 x 700 x 520mm |

|

Weight |

Cutter – 396lbs (180kg) Tank – 55 lbs (25kg) |

GenCut GL100M Standard Configuration

-

GenCut GL100M Manual Metallographic Cutting Saw

-

Coolant Tank

-

Coolant Pump

-

Wrench 14#-17#

-

Wrench 24-27#

-

Water Inlet Tube

-

Drain Pipe

-

Cutting Wheel

-

Φ350 x 2.0 x Φ32mm

-

Fast Clamps and Operation Manual

GenCut GL100M Features

-

Handwheel Operation for Y Axis Control

-

Smooth Operation of the Working Table

-

More control over the samples movement when compared to “slot machine” type manual machines

Important Note:

Check out our consumables catalogue starting on Page 1 for Saw consumables. Or speak with your NextGen representative for our best recommendation on consumables to include for your cutting applications!

FAQs

The main purpose of the GenCut GL100M – Precision Manual Metallographic Sample Cutting Machine is to cut metal samples for metallographic analysis. This machine is designed to provide accurate and clean cuts, a necessity for preparing samples that will be subjected to detailed microscopic examination and other metallurgical tests.

The GenCut GL100M offers high precision cutting, maintaining sample integrity, and resulting in reliable test results. Its advanced features include a securely closed structure for greater safety, a spacious observation window for clear visibility during the cutting process, and a swift clamping mechanism for efficient and secure sample securing. These features collectively improve the machine's performance, making it an ideal tool for laboratories and industrial settings requiring precise metal sample preparation.

Additionally, the GenCut GL100M has a dedicated cooling water tank, which facilitates efficient liquid circulation. This is necessary for maintaining optimal temperatures during cutting, preventing overheating, and prolonging the cutting wheel's and other components' lifespan.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL100M – Precision Manual Metallographic Sample Cutting Machine offers user safety through its secure closed structure and spacious observation window. The closed structure provides a protective barrier, significantly reducing the risk of exposure to potential hazards such as flying debris and sparks during the cutting process. This robust design makes sure that users are shielded from the cutting area, thus creating a safe working environment.

The machine also features a spacious observation window, allowing users to clearly monitor the cutting operation without sacrificing safety. This window is designed to provide optimal visibility, enabling users to make precise adjustments and control the cutting process effectively. The clear view of the cutting area improves operational accuracy while keeping the user safe from the moving cutting wheel.

Furthermore, the GenCut GL100M includes a swift clamping mechanism that securely holds samples in place. This prevents any movement that could pose a safety risk. The combination of these safety features provides smooth and efficient machine operation, minimizing potential dangers.

Click here to learn more about the product or here to receive a personalized quote

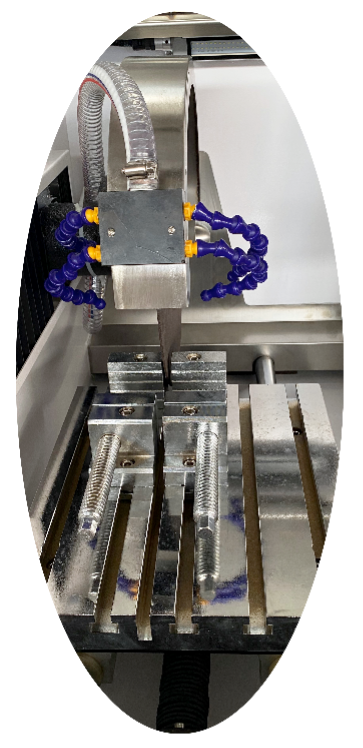

The GenCut GL100M – Precision Manual Metallographic Sample Cutting Machine provides efficient sample securing through its swift clamping mechanism. This feature allows users to secure samples quickly and easily, thereby increasing the cutting process efficiency. The swift clamping mechanism is designed to hold samples firmly in place, preventing any movement during cutting that could compromise the precision of the cuts.

The mechanism's ease of use reduces setup time, enabling operators to focus more on cutting tasks rather than on securing samples. This efficiency is particularly beneficial in high-throughput environments where time is of the essence. The secure clamping provided by the GenCut GL100M guarantees that each sample remains stable throughout the cutting process.

Additionally, the swift clamping mechanism increases user safety by minimizing the risk of sample slippage or movement, which can lead to accidents or suboptimal cutting results. The reliability of the clamping system provides assurance that users can consistently achieve high-quality cuts without constant adjustments or re-clamping.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL100M – Precision Manual Metallographic Sample Cutting Machine maintains optimal temperatures during operation through its dedicated cooling water tank, which facilitates efficient circulation of cooling liquid. This system is necessary for preventing overheating of the cutting wheel and other critical components.

The dedicated cooling water tank continuously supplies cooling liquid to the cutting area, absorbing the heat generated by the cutting process. This efficient cooling mechanism not only protects the equipment from thermal damage but also helps maintain the integrity of metal samples by reducing thermal distortion. By keeping the cutting area cool, the system increases the precision and quality of the cuts.

Moreover, the circulating cooling liquid helps extend the lifespan of the cutting wheel and other components by preventing excessive wear and tear due to high temperatures. This contributes to the overall durability and reliability of the GenCut GL100M, making it a cost-effective solution for laboratories and industrial environments that require consistent and precise sample cutting.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL100M – Precision Manual Metallographic Sample Cutting Machine offers durability and extended service life by using high-quality stainless materials for elements such as the jaw and work surface. Stainless steel is renowned for its strength, resistance to corrosion, and long-lasting performance, making it an ideal choice for components that undergo frequent use and exposure to harsh conditions.

The use of stainless materials in the construction of the jaw and work surface guarantees that these critical parts can withstand continuous operation without degrading. This robust construction not only extends the machine's longevity but also maintains the precision and reliability of the cutting process over time.

Additionally, the GenCut GL100M's durability is further supported by its overall design, which focuses on robustness and stability. The combination of durable materials and sturdy construction means that the machine can endure heavy-duty use in demanding laboratory and industrial environments. This resilience reduces the need for frequent maintenance and replacement of parts, making the GenCut GL100M a cost-effective investment for facilities requiring reliable metallographic sample cutting.

Click here to learn more about the product or here to receive a personalized quote.

The cutting wheel used in the GenCut GL100M – Precision Manual Metallographic Sample Cutting Machine has specific dimensions that contribute to its effectiveness and precision in cutting metal samples. The wheel measures 350 millimeters in diameter, 2.0 millimeters in thickness, and has a central bore diameter of 32 millimeters (Φ350×2.0×Φ32mm).

These dimensions were carefully selected to provide optimal cutting performance. The 350mm diameter allows for substantial cutting depth, making it suitable for a wide array of sample sizes. The 2.0mm thickness guarantees that the wheel can make precise and clean cuts without compromising its structural integrity. The 32mm central bore diameter fits securely onto the machine’s spindle.

Cutting wheel size and design play an important role in high-precision metallographic sample preparation. By providing clean and accurate cuts, the wheel helps maintain the integrity of the samples, which is necessary for subsequent analysis and testing. Additionally, the robust construction of the cutting wheel guarantees that it can withstand the stresses of cutting different types of metal.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL100M – Precision Manual Metallographic Sample Cutting Machine has a maximum cutting section capacity of 100 millimeters diameter (Φ100mm). This capacity indicates the largest diameter of a metal sample that the machine can effectively cut, making it suitable for a wide spectrum of sample sizes used in metallographic analysis.

The ability to cut samples up to 100mm in diameter means that the GenCut GL100M can handle different types of metals and sample dimensions. This capacity is notably beneficial in industrial and laboratory settings where diverse sample sizes are common.

The 100mm maximum cutting section is achieved without adversely affecting precision and quality. The machine's robust construction and advanced features, such as the swift clamping mechanism and dedicated cooling water tank, support its ability to cut larger samples accurately and efficiently. These features guarantee that even the largest samples are held securely and remain cool during the cutting process.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL100M - Precision Manual Metallographic Sample Cutting Machine operates at 2800 revolutions per minute (rpm). The machine must operate at a high speed to make sure that precise and efficient cuts are made on metal samples. In addition, it must guarantee that the machine can cut a wide range of materials with consistency and accuracy.

The 2800rpm speed allows the cutting wheel to operate at an optimal rate, facilitating clean and precise cuts while minimizing the risk of overheating and deformation of the samples. This speed is well-suited to metallographic sample preparation, where maintaining the integrity of the sample's microstructure is necessary for accurate analysis and testing.

Additionally, the high speed contributes to the machine's overall efficiency, reducing the time required to cut samples. This increases productivity in laboratory and industrial settings. The combination of speed and precision ensures that the GenCut GL100M consistently delivers high-quality results.

Click here to learn more about the product or here to receive a personalized quote.

The Y-axis cutting range of the GenCut GL100M – Precision Manual Metallographic Sample Cutting Machine is 100 millimeters, equivalent to 3.937 inches. This range refers to the maximum distance the cutting mechanism can move along the Y-axis.

The 100mm Y-axis cutting range provides substantial flexibility in handling different sample sizes and shapes. This capability makes certain that users can accurately position their samples for optimal cutting, which is important for maintaining sample integrity during metallographic analysis.

Having a significant Y-axis cutting range enhances the versatility of the GenCut GL100M. As a result, it is suitable for a wide range of applications, both in laboratory and industrial settings. It allows the cutting of larger and more complex samples without repositioning them multiple times.

The machine's design includes smooth handwheel operation for controlling the Y-axis movement, which provides users with fine control over the sample's positioning. Precision control is necessary for clean, accurate cuts and preparing high-quality samples for further analysis.

Click here to learn more about the product or here to receive a personalized quote.

The motor power of the GenCut GL100M – Precision Manual Metallographic Sample Cutting Machine is 3.0 kilowatts (kW). This substantial motor power provides the machine with the required strength and efficiency to perform precise and clean cuts through different types of metal samples.

A 3.0kW motor guarantees that the GenCut GL100M can handle demanding cutting tasks easily, delivering consistent and reliable performance. This high power output enables the cutting wheel to maintain steady speed and torque, even when cutting through tougher or thicker materials.

The powerful motor also contributes to the machine's overall efficiency. With 3.0kW of power, the GenCut GL100M can complete cutting operations faster, reducing sample preparation time. This efficiency is particularly valuable in high-throughput environments where large numbers of samples need to be processed promptly.

Moreover, the motor's power ensures that the machine operates reliably over extended periods, minimizing the risk of mechanical failures or interruptions. Durability and reliability make the GenCut GL100M an excellent choice for laboratories and industrial settings where precision and efficiency are of fundamental importance.

Click here to learn more about the product or here to receive a personalized quote.

The cutting room of the GenCut GL100M – Precision Manual Metallographic Sample Cutting Machine is equipped with low-voltage DC LED lighting. This type of lighting is chosen for its numerous benefits that increase both safety and efficiency during operation.

Low-voltage DC LED lighting provides bright and clear illumination of the cutting area, allowing operators to see their work with precision. This greater visibility is necessary for achieving accurate cuts and careful sample preparation, as it helps in closely monitoring the cutting process and making proper adjustments.

LED lights are known for their energy efficiency, consuming less power than traditional lighting options while providing superior brightness. This efficiency helps reduce the overall energy consumption of the machine, making it more economical to operate. The low voltage requirement further guarantees that the lighting system is safe, minimizing the risk of electrical hazards.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL100M – Precision Manual Metallographic Sample Cutting Machine operates on a voltage requirement of 220 volts (V), with a frequency of 60 hertz (Hz), and is powered by a 3-phase power supply. These specifications are standard for industrial-grade equipment, enabling the machine to receive a stable, sufficient power supply for optimum performance.

The 220V, 60Hz, 3-phase power setup provides several advantages. Firstly, it makes sure that the machine can deliver consistent power to its 3.0kW motor. This supports the robust performance needed for precise and efficient metal sample cutting. The 3-phase power supply is particularly beneficial for industrial applications as it provides a more balanced and reliable flow of electricity, reducing the risk of power fluctuations that could affect machine performance.

Using a 3-phase power system also increases the efficiency of the GenCut GL100M, as it allows the machine to operate more smoothly and with greater stability.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL100M - Precision Manual Metallographic Sample Cutting Machine has dimensions of 28.75 inches in height, 27.5 inches in width, and 20.5 inches in depth. These measurements can also be expressed in metric units as 730 millimeters in height, 700 millimeters in width, and 520 millimeters in depth.

These dimensions indicate that the GenCut GL100M is compact enough to fit into standard laboratory and industrial workspaces. It also provides sufficient internal capacity for a range of sample-cutting tasks. The machine’s size balances space efficiency with operational capability, making it suitable for locations where space is limited.

The GenCut GL100M's compact footprint allows it to be easily integrated into existing setups without significant rearrangement. Despite its compact size, the machine is robustly built to handle metallographic sample preparation.

Well-considered dimensions also contribute to machine stability during operation. The sturdy construction and balanced design help maintain precision and accuracy while cutting, preventing unwanted movement that could affect sample quality.

Click here to learn more about the product or here to receive a personalized quote.

The weight of the GenCut GL100M – Precision Manual Metallographic Sample Cutting Machine is divided into two main components: the cutter and the tank. The cutter itself weighs 396 pounds, equivalent to 180 kilograms. The tank, which houses the cooling system, weighs 55 pounds, or 25 kilograms.

The cutter's substantial weight reflects its robust construction, designed to provide stability and durability during operation. This weight minimizes vibrations and movements, which are crucial for precise and accurate cuts. A stable machine is required for high-quality metallographic samples, as any movement during the cutting process can compromise the sample integrity.

In total, the GenCut GL100M cutter weighs 396 pounds (180 kg), and the tank weighs 55 pounds (25 kg), reflecting the machine's robust and stable construction that provides precise, reliable, and efficient metallographic sample preparation.

Click here to learn more about the product or here to receive a personalized quote.

The standard configuration of the GenCut GL100M – Precision Manual Metallographic Sample Cutting Machine includes components for accurate and efficient sample cutting. These components are:

-

GenCut GL100M Manual Metallographic Cutting Saw: The core unit of the machine, designed for precision cutting of metal samples.

-

Coolant Tank: This component holds the cooling liquid, which is crucial for maintaining optimal temperatures during the cutting process to prevent overheating.

-

Coolant Pump: This pump circulates the cooling liquid from the coolant tank to the cutting area.

-

Wrenches (14#-17# and 24-27#): These wrenches are provided for the machine assembly and maintenance.

-

Water Inlet Tube: This tube connects to the water supply, allowing for the proper flow of cooling liquid into the coolant tank.

-

Drain Pipe: Used for draining the cooling liquid from the machine, facilitating easy maintenance and cleaning of the cooling system.

-

Cutting Wheel (Φ350 x 2.0 x Φ32mm): The cutting wheel, with 350mm diameter, 2.0mm thickness, and 32mm central bore.

-

Fast Clamps: These clamps securely hold samples in place during cutting.

-

Operation Manual: A comprehensive guide that provides detailed instructions on the setup, operation, and maintenance of the GenCut GL100M.

Click here to learn more about the product or here to receive a personalized quote.

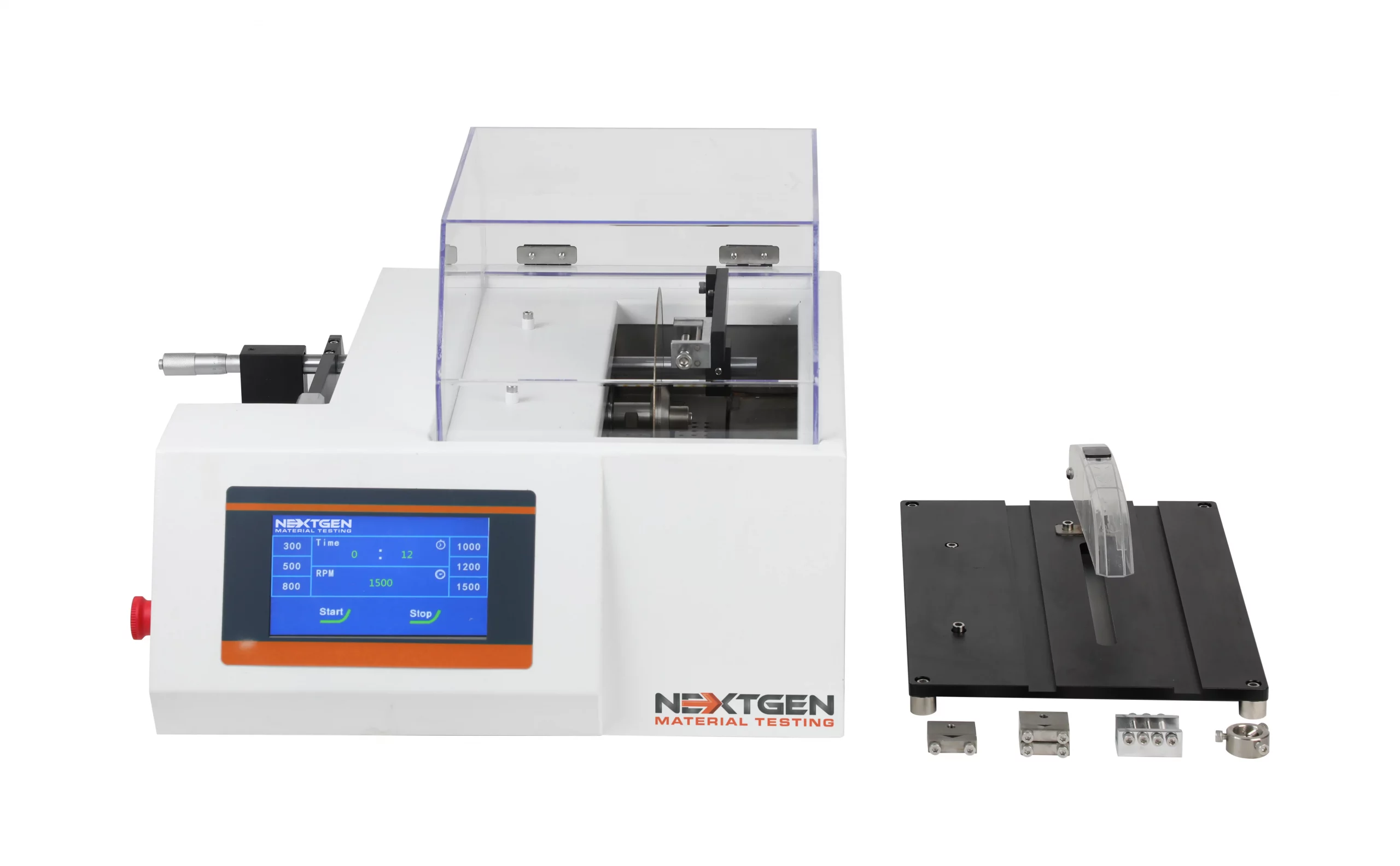

The GenCut GL100M – Precision Manual Metallographic Sample Cutting Machine features handwheel operation with Y-axis control. This handwheel allows users to precisely adjust the position of the cutting mechanism along the Y-axis, providing fine control over the movement and positioning of the metal samples.

Handwheel operation is crucial for accurate cuts, as it enables users to make incremental adjustments with high precision. This level of control is necessary for preparing metallographic samples that require exact dimensions and smooth edges. By turning the handwheel, operators can smoothly and steadily move the cutting mechanism.

This manual control method also enhances the user’s ability to manage the cutting process, offering a tactile and responsive means of adjusting the cutting position. Unlike automated systems, the handwheel allows immediate feedback and corrections.

The handwheel for Y-axis control contributes to the GenCut GL100M's versatility and usability. It guarantees that operators can handle a range of cutting tasks with precision and ease, making it suitable for different metallographic applications in both laboratory and industrial settings. Fine adjustments manually allow increased flexibility and control.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL100M – Precision Manual Metallographic Sample Cutting Machine offers smooth working table operation through its well-engineered design and high-quality construction. The working table is a crucial component where metal samples are placed and maneuvered during cutting.

One of the key features that contribute to smooth operation is high-precision bearings and guides. These components minimize friction and allow the table to move smoothly. This makes it possible for samples to be positioned accurately without jerky movements or resistance.

Additionally, the working table is constructed from durable, low-friction materials that further enhance its smooth operation. These materials were chosen for their ability to withstand frequent use while maintaining a consistent, easy-moving surface. This durability makes certain that the table remains smooth and reliable over time, even in demanding laboratory and industrial environments.

Click here to learn more about the product or here to receive a personalized quote.

The GenCut GL100M – Precision Manual Metallographic Sample Cutting Machine offers significantly more control over sample movement than "slot machine" type manual machines through its advanced design and operational features. Unlike the slot machine type, which often relies on less precise mechanisms for moving samples, the GenCut GL100M incorporates several key elements that increase precision and control.

Firstly, the GenCut GL100M uses handwheel operation for Y-axis control. This handwheel allows users to make fine, incremental adjustments to the sample position with high precision. This level of control is necessary for verifying that each cut is made exactly as required, which is highly relevant for metallographic sample preparation where accuracy is very important.

Additionally, the smooth operation of the working table further enhances sample movement control. The working table is designed with high-precision bearings and low-friction materials, allowing effortless movement. This smooth movement allows samples to be positioned and adjusted accurately without jerky or uneven motions, which are common on less advanced machines.

Click here to learn more about the product or here to receive a personalized quote.

Related Products

GenCut GL350 – Precision Metallographic Sample Cutting Machine with Simple User-Friendly Operation and Large Cutting Capacity Φ100mm

The GenCut GL350 is a cutting-edge high precision cutting machine equipped with advanced features and capabilities

GenCut GL80A – Precision Metallographic Sample Cutting Machine with Simple User-Friendly Operation and Large Cutting Capacity Φ80mm

Introducing the GenCut GL80A, a highly precise cutting machine offering both automatic and manual work modes.

GenCut GL200E – High Speed Automatic Precision Metallographic Cutter with User-Friendly Touch Screen Interface with max. cutting diameter of 60mm

GenCut GL 200E precision cutting machine includes a touch screen and PLC control, with stable performance and real-time display parameters.

GenCut GL100E – Low Speed Precision Metallographic Automatic Cutter with User-Friendly Touch Screen Interface with max. cutting diameter of 25mm

GenCut GL100E low speed series metallographic precision cutter has variable speed control from 50-1000 rpm.

Metallography Consumables

Learn about the full scope of NextGen's cutting, polishing & grinding, mounting and etching metallography consumables. Our consumables are compatible with virtually all global brands, offering a rare combination of exceptional quality, longevity and affordability.