Metal Testing Equipment

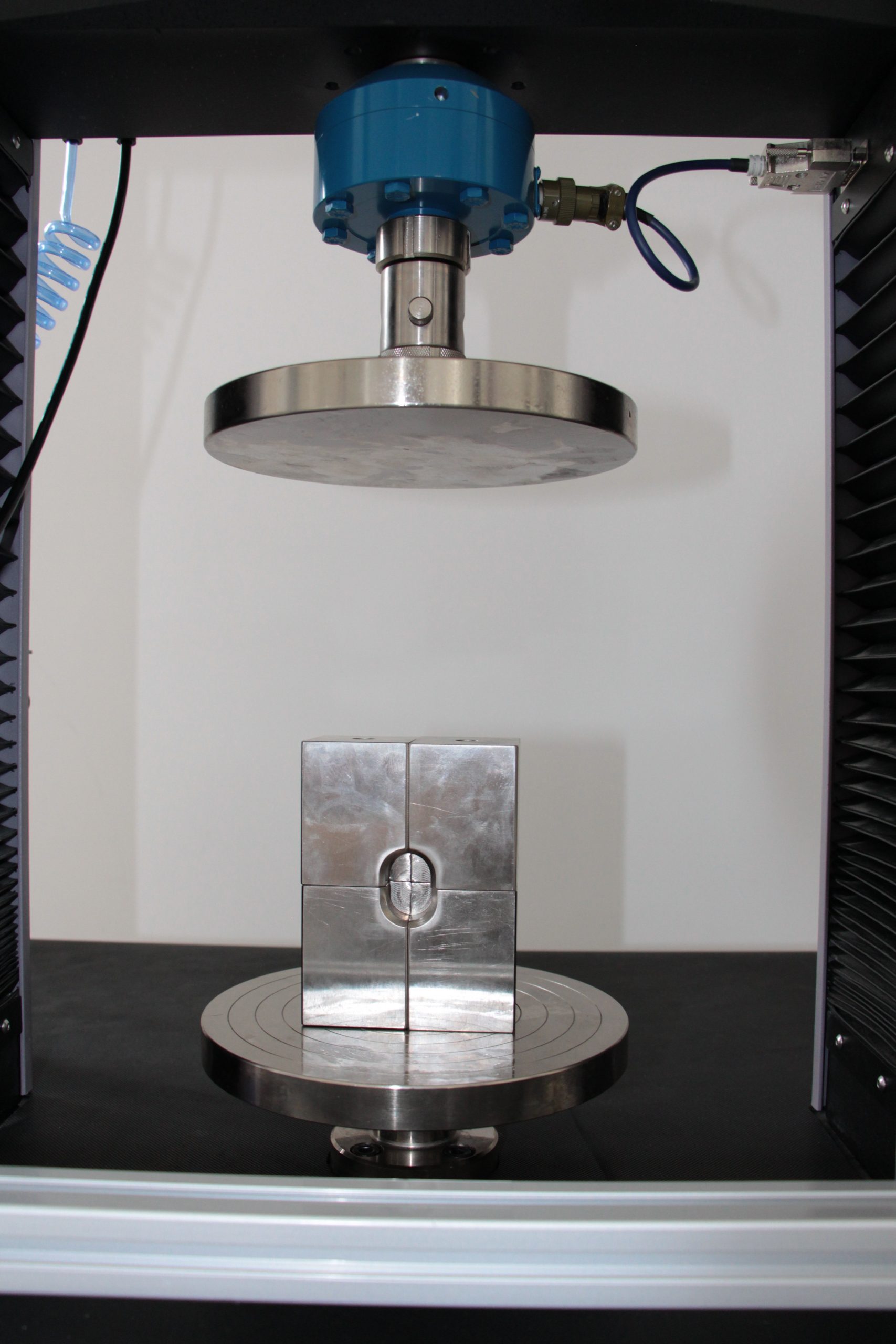

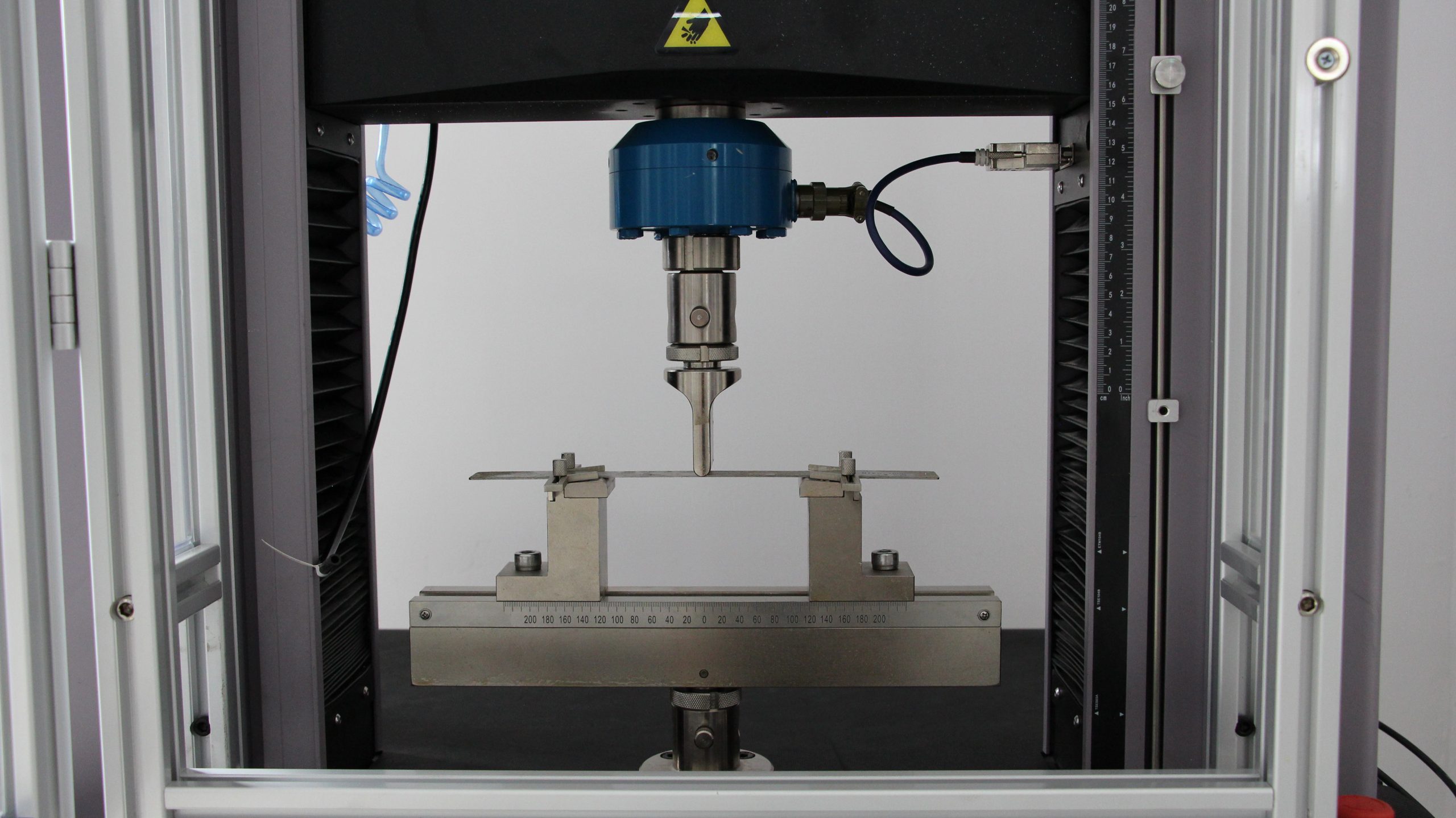

Standards

ASTM E8, ISO 7500-1, ASTM E4, ISO 6892

Description

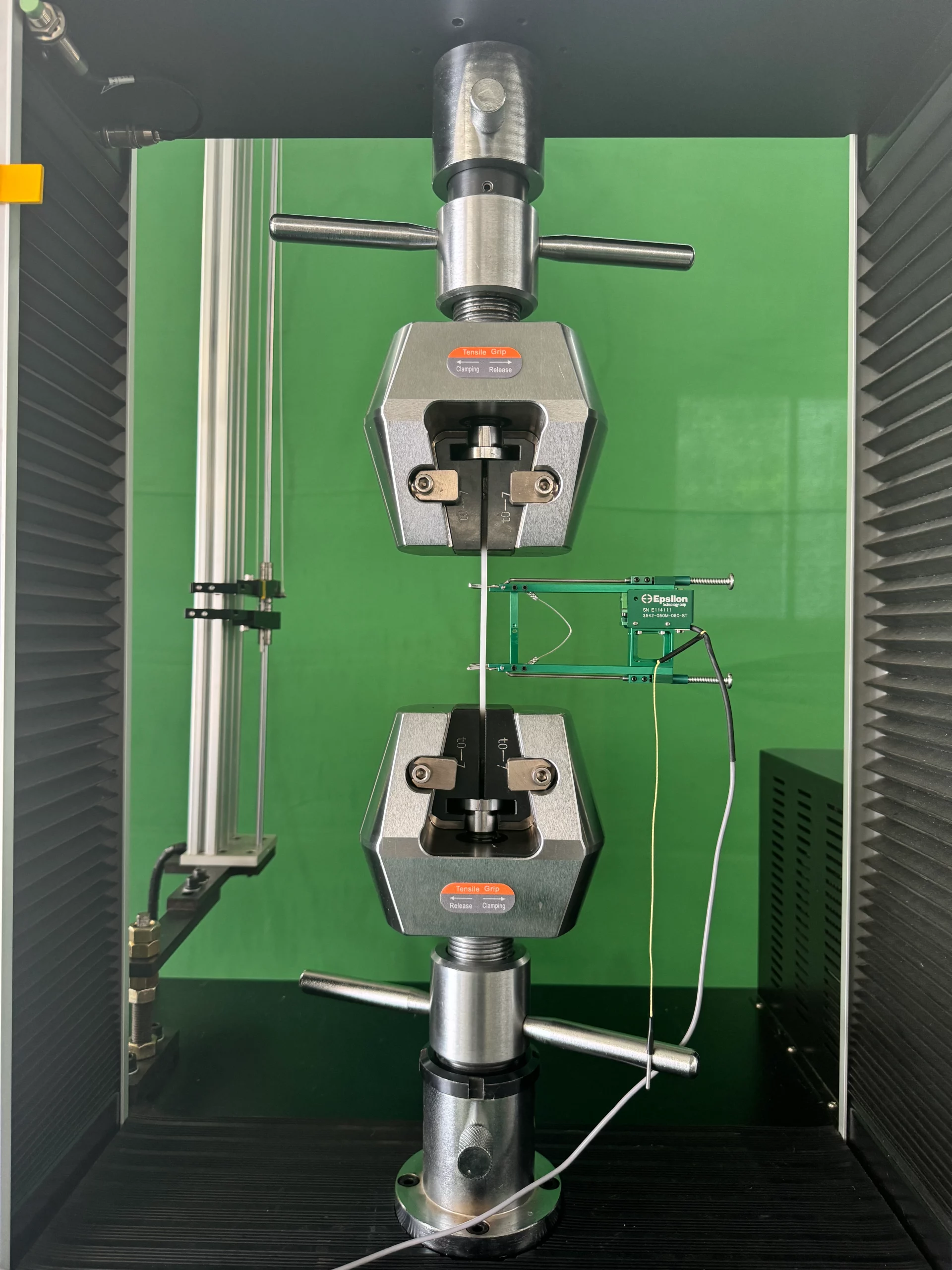

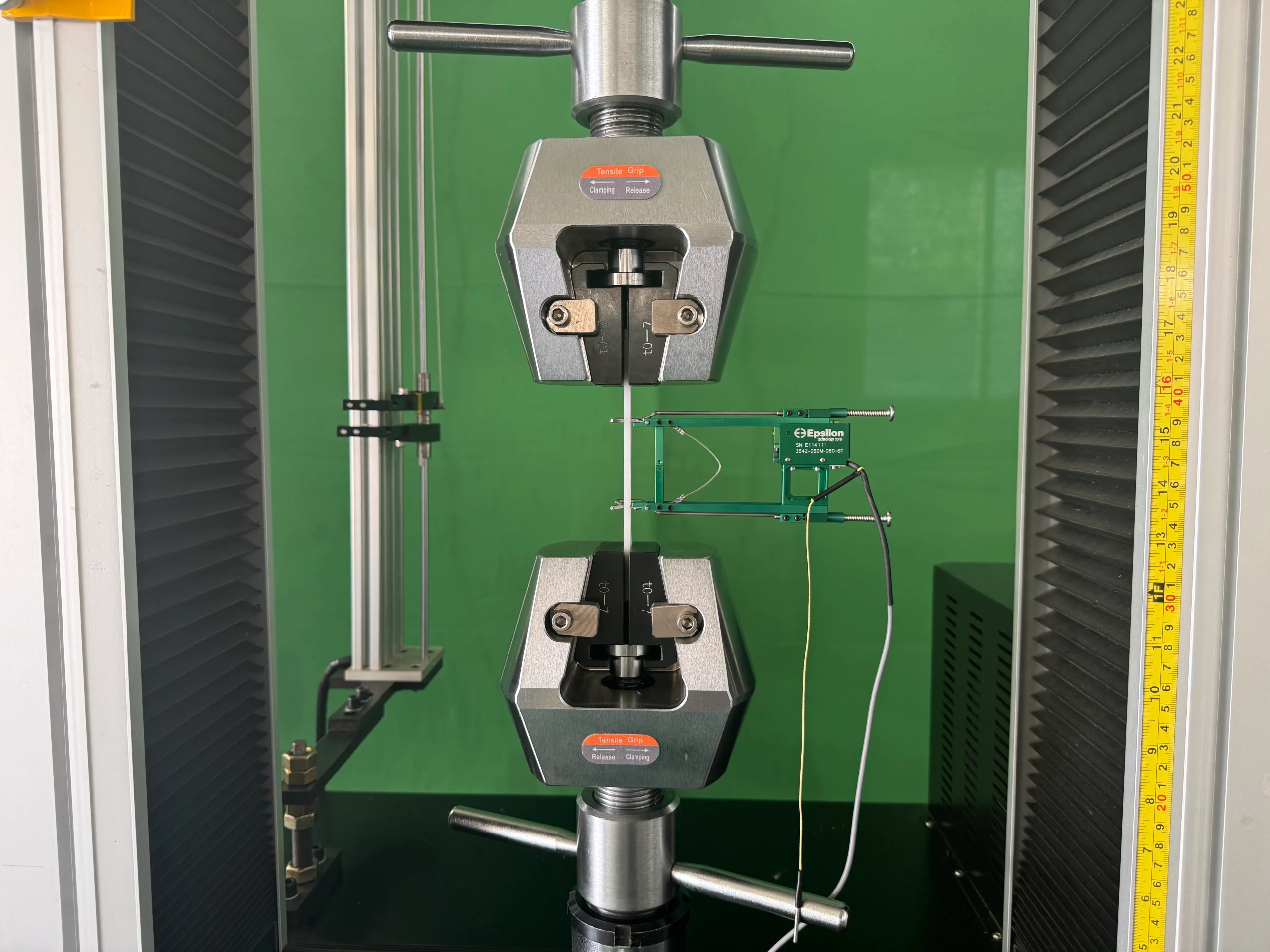

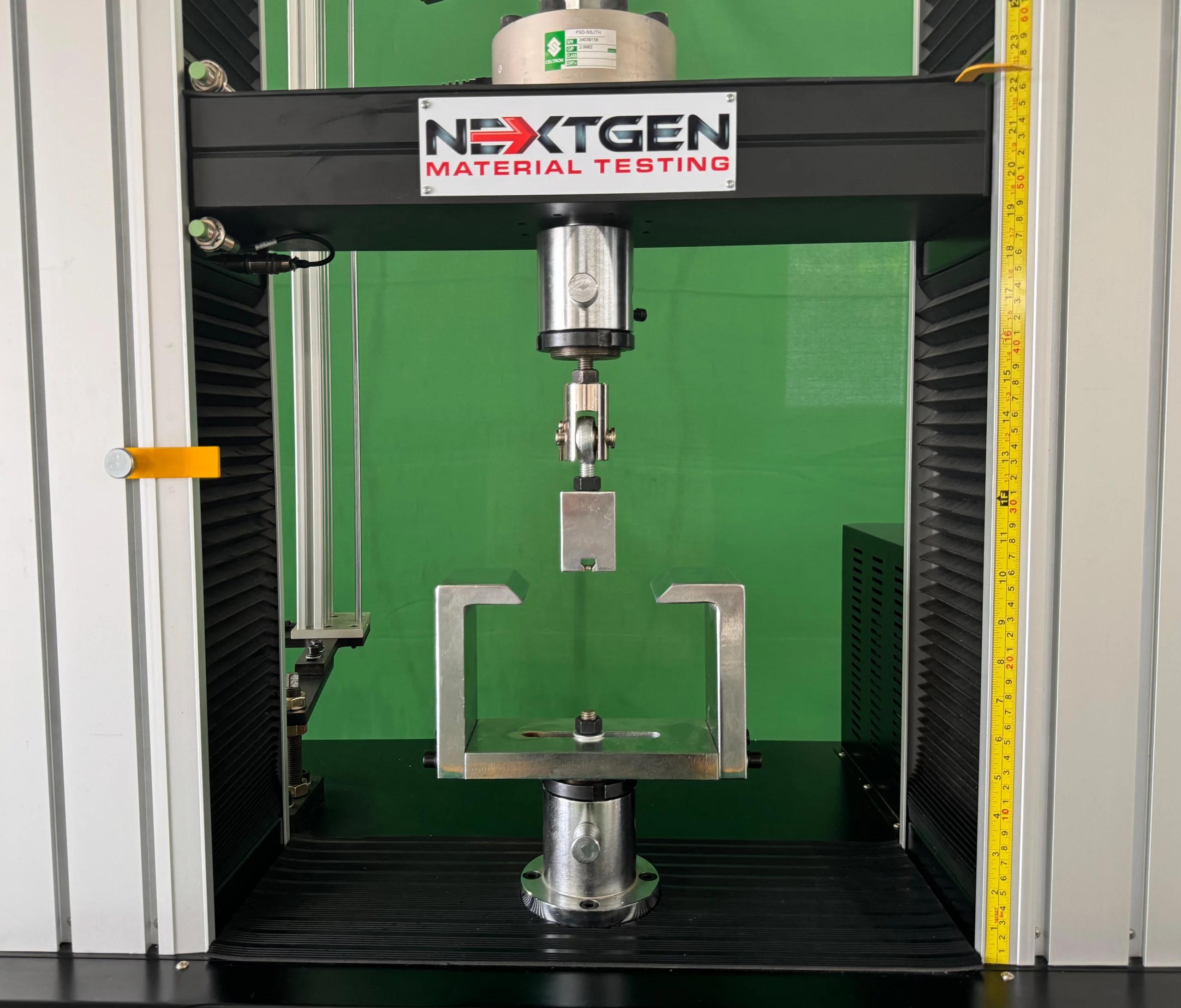

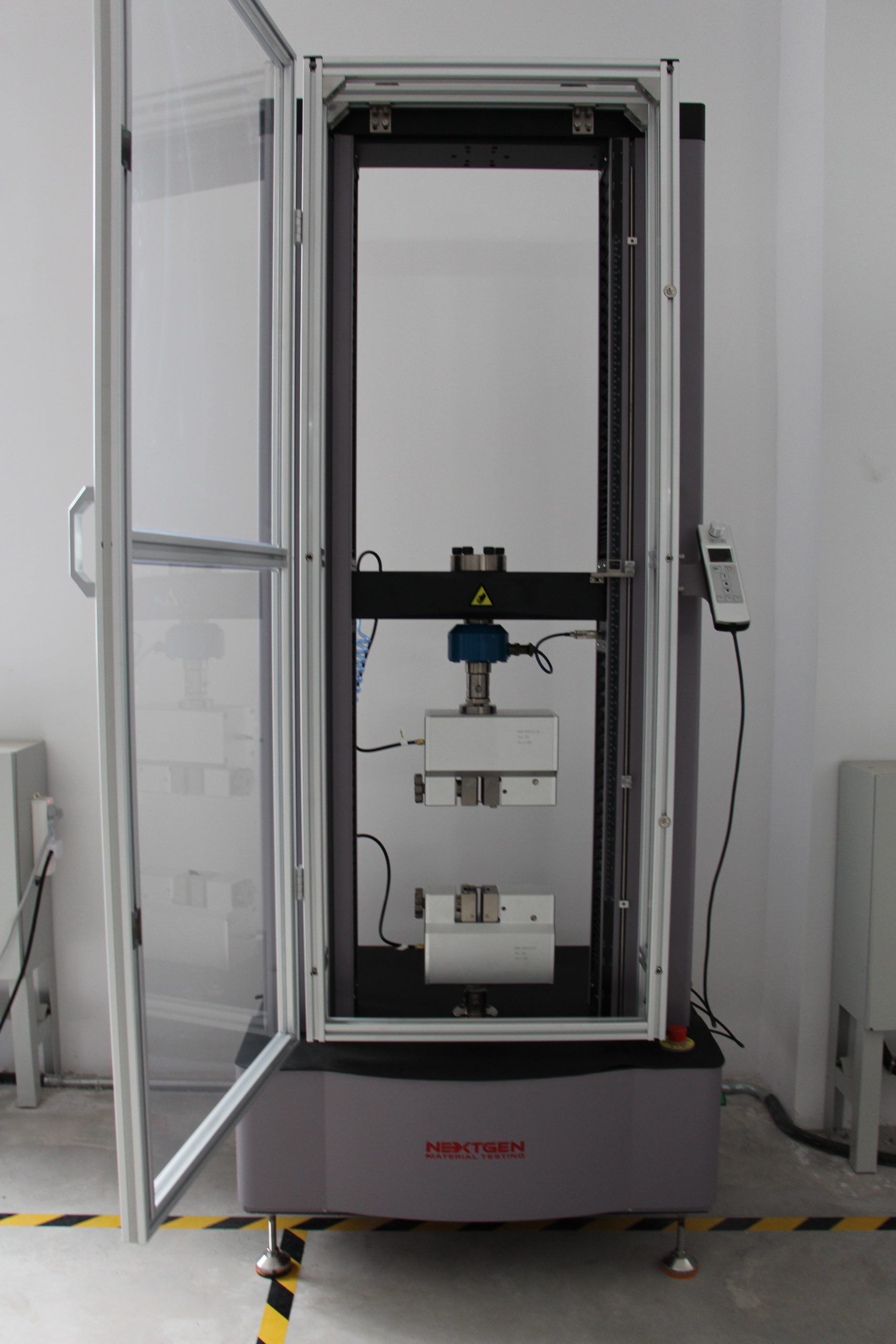

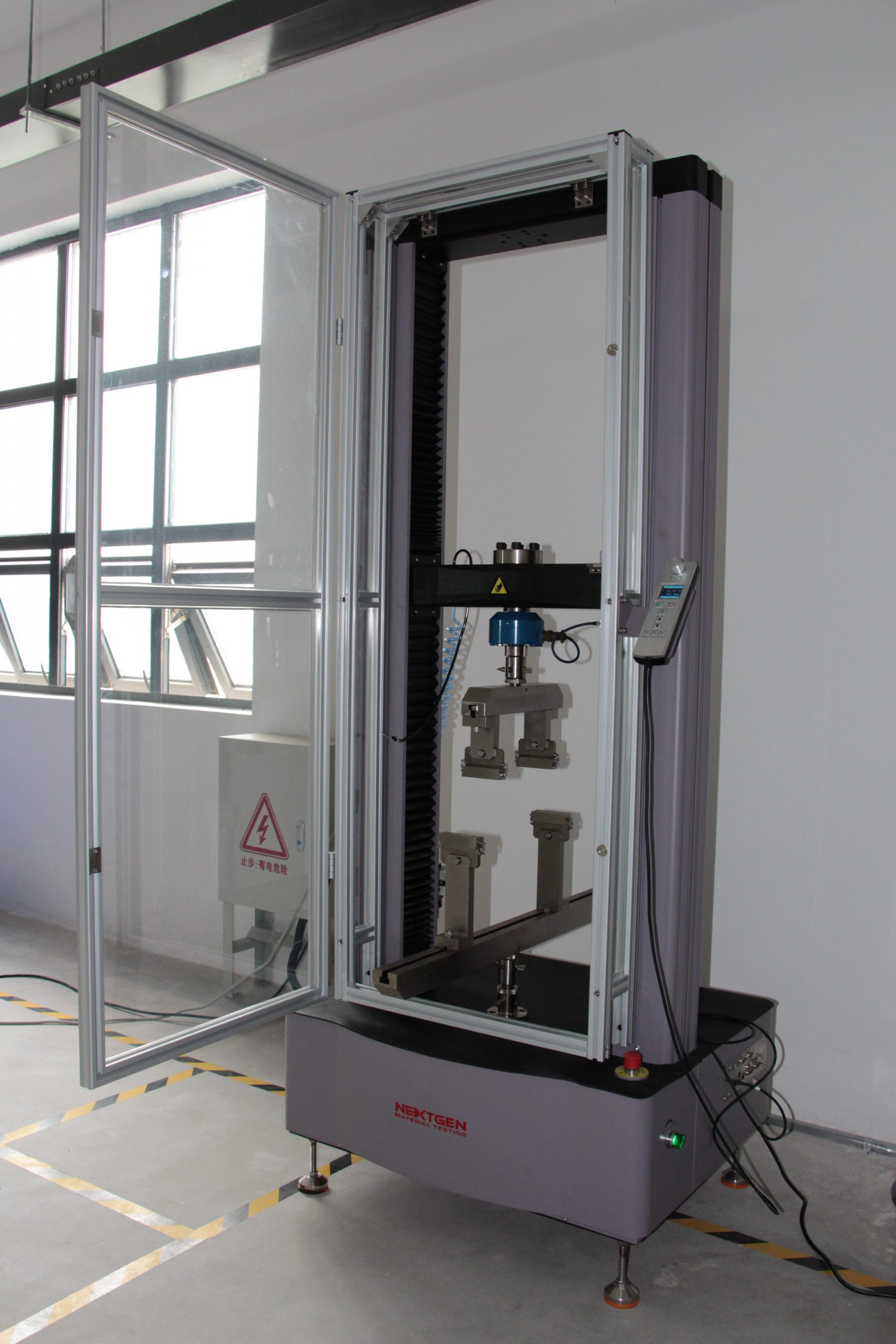

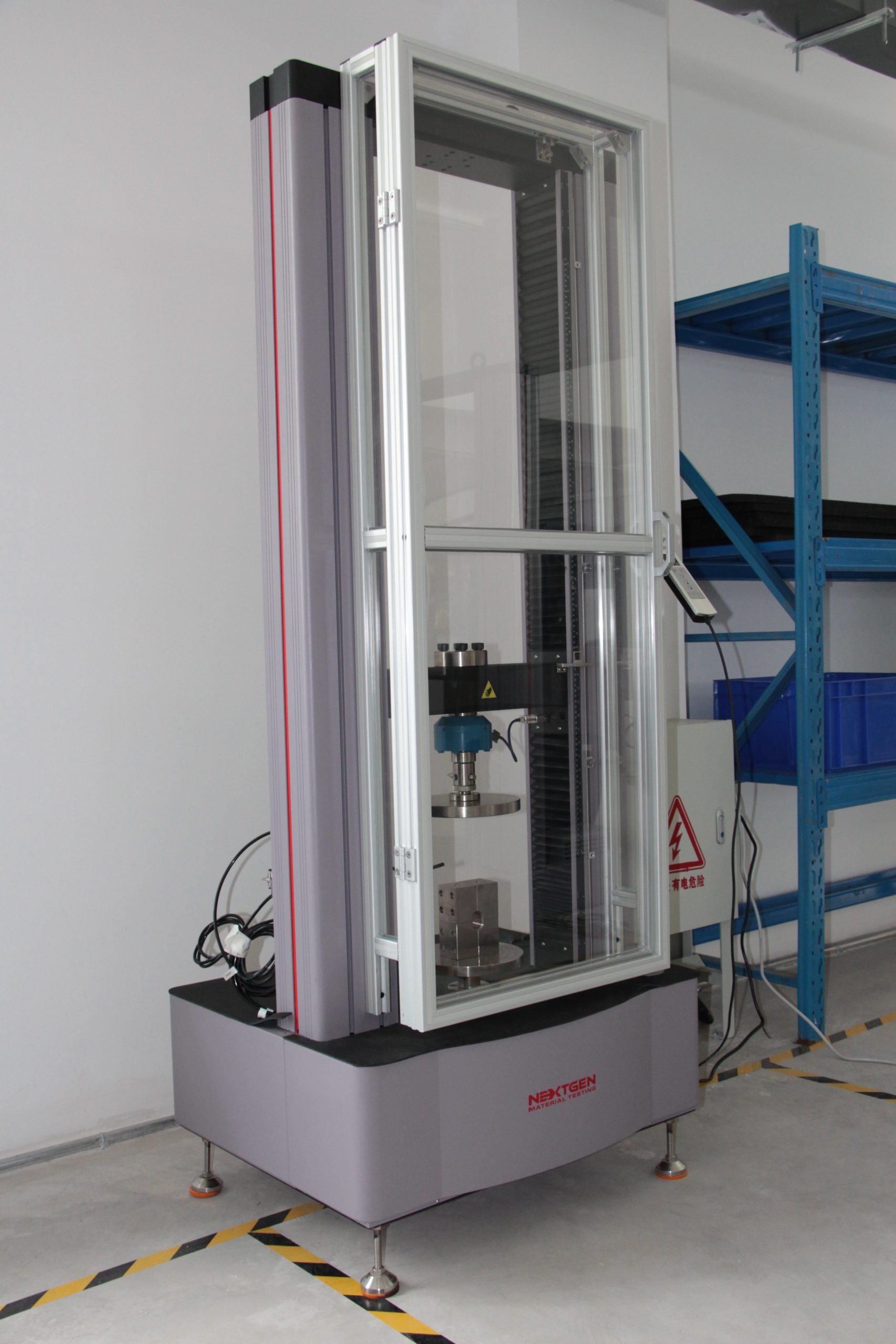

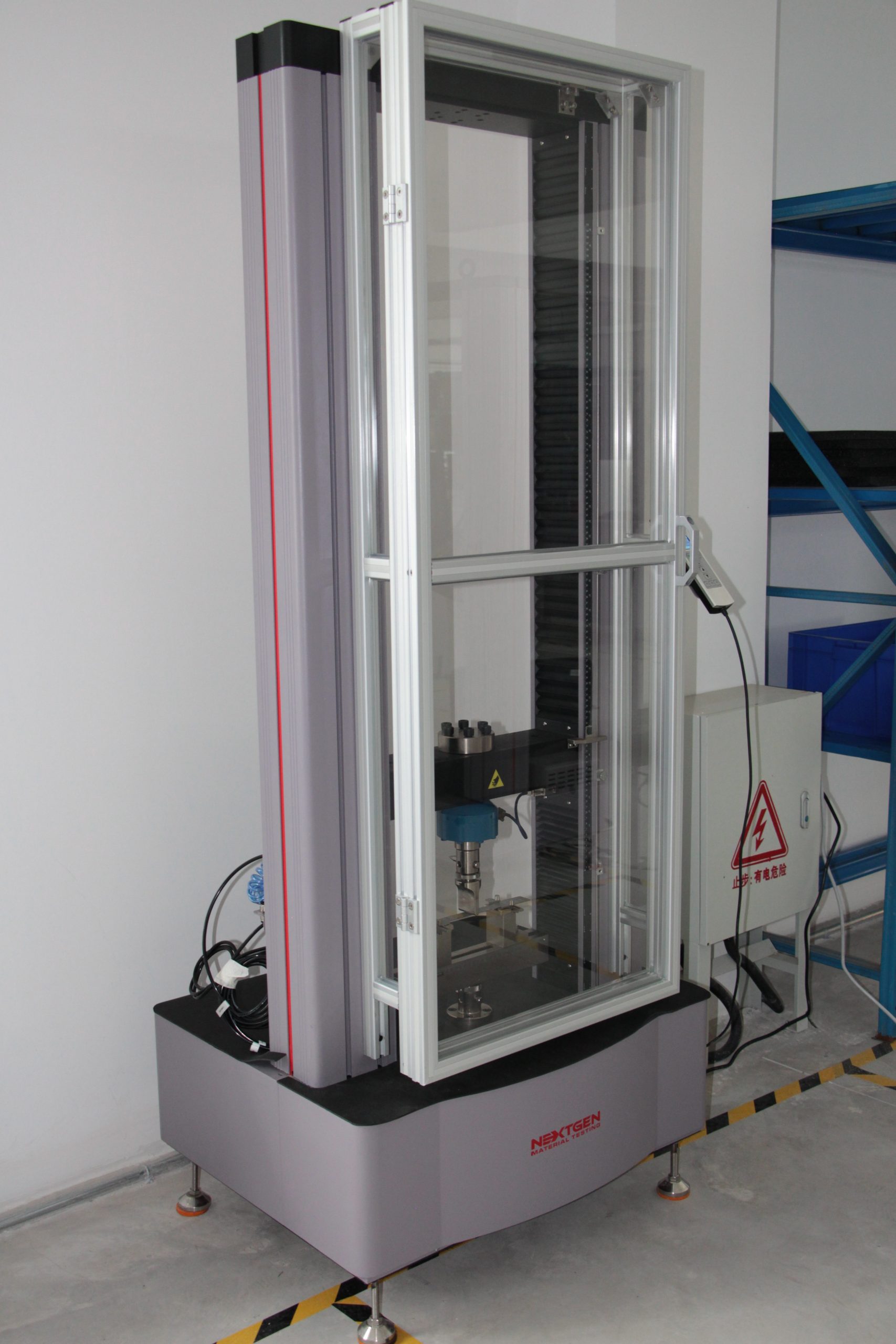

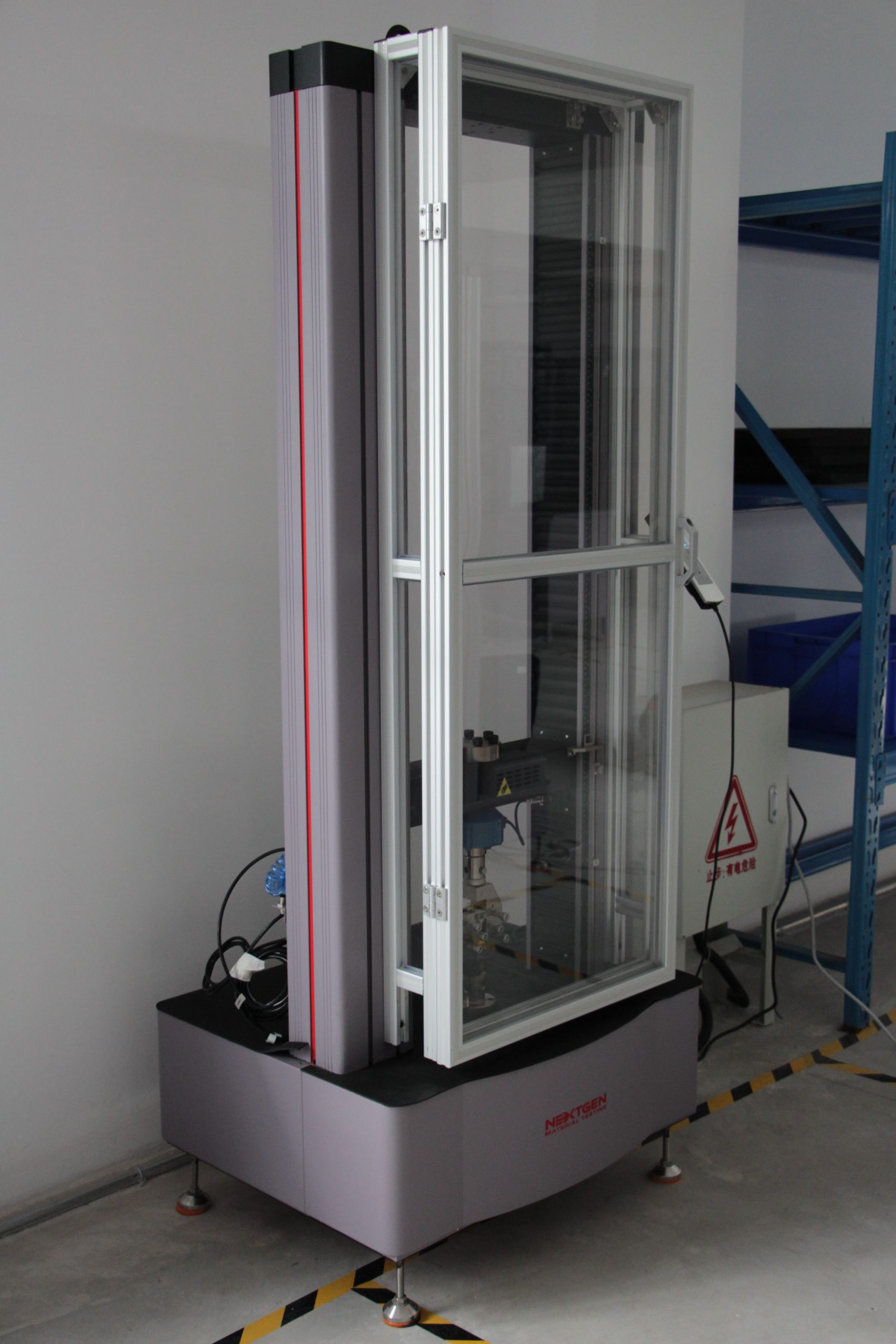

The NG-EML Dual Column Bench Top and Floor Standing – Universal Testing Machine (5 kN – 50 kN) is a next-generation electromechanical system developed for precise and reliable testing across a wide range of materials. Engineered with a servo direct-drive system, FEM-optimized frame, and high-rigidity dual-column structure, the machine delivers superior accuracy, higher stiffness, and faster control response.

The system is designed to meet the growing demands of testing advanced composites, high-strength steels, high-temperature alloys, and other complex materials. With minimized vibration and high alignment stability, it is ideal for determining elastic modulus, yield strength, tensile strength, and more.

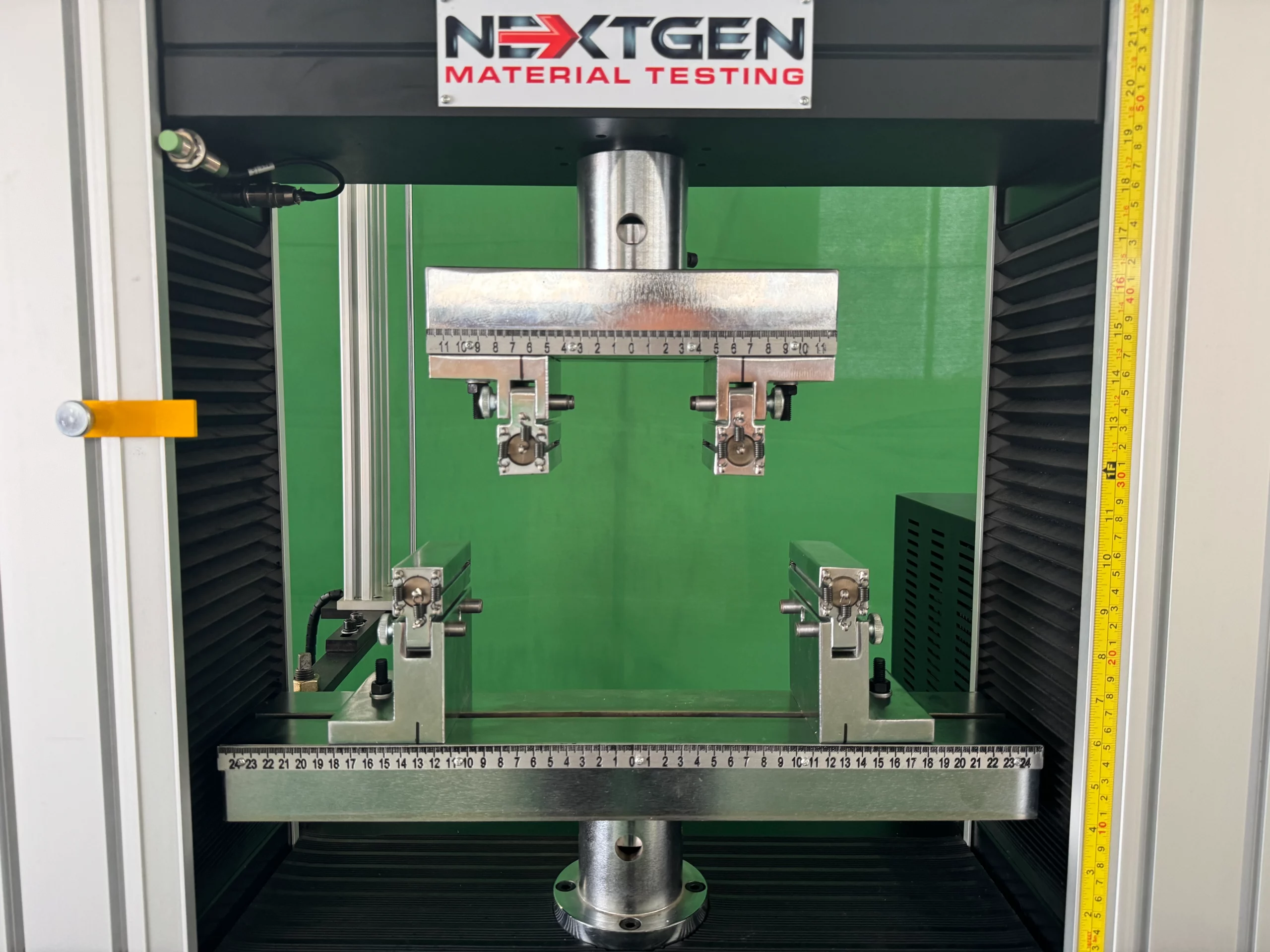

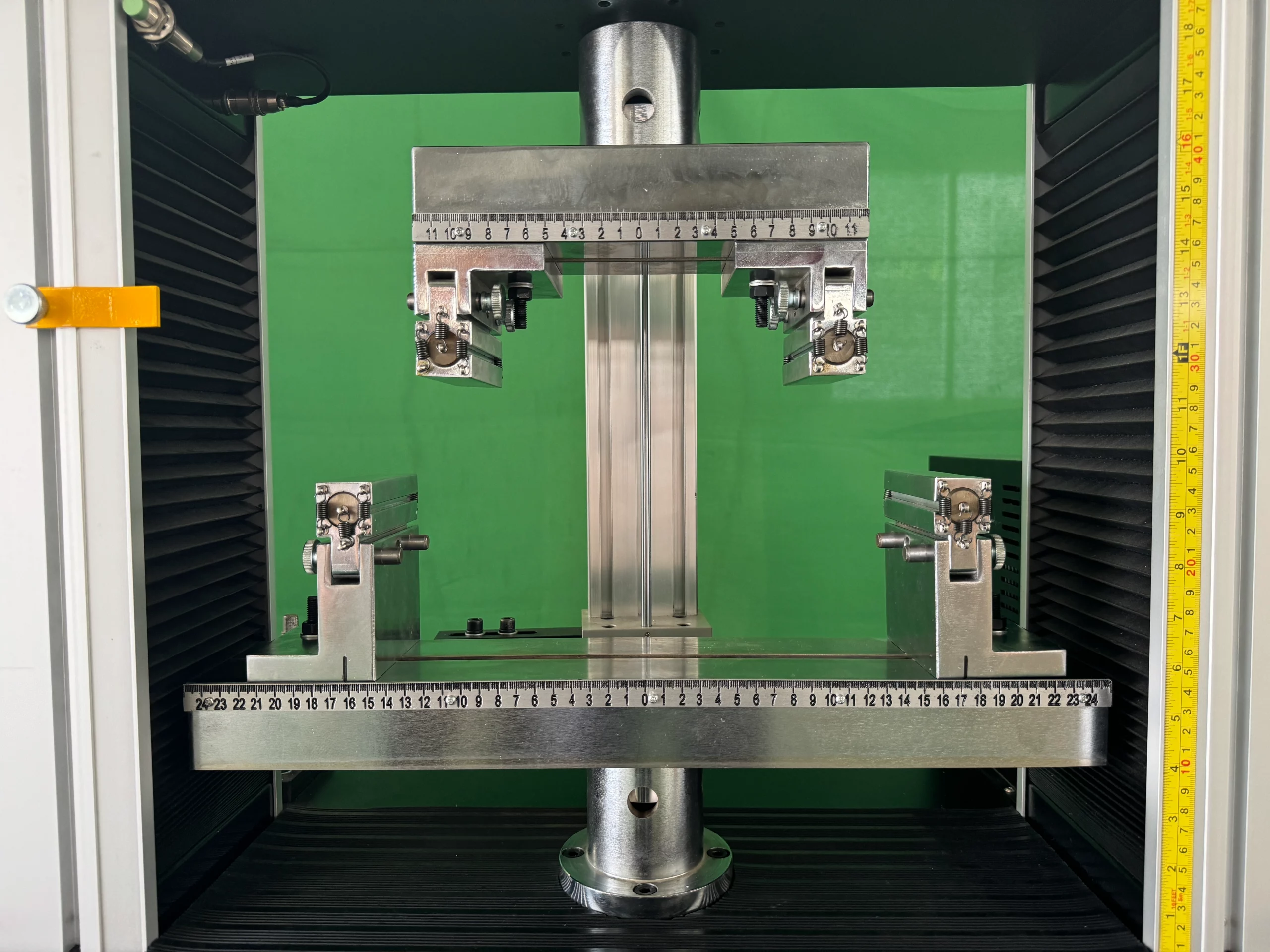

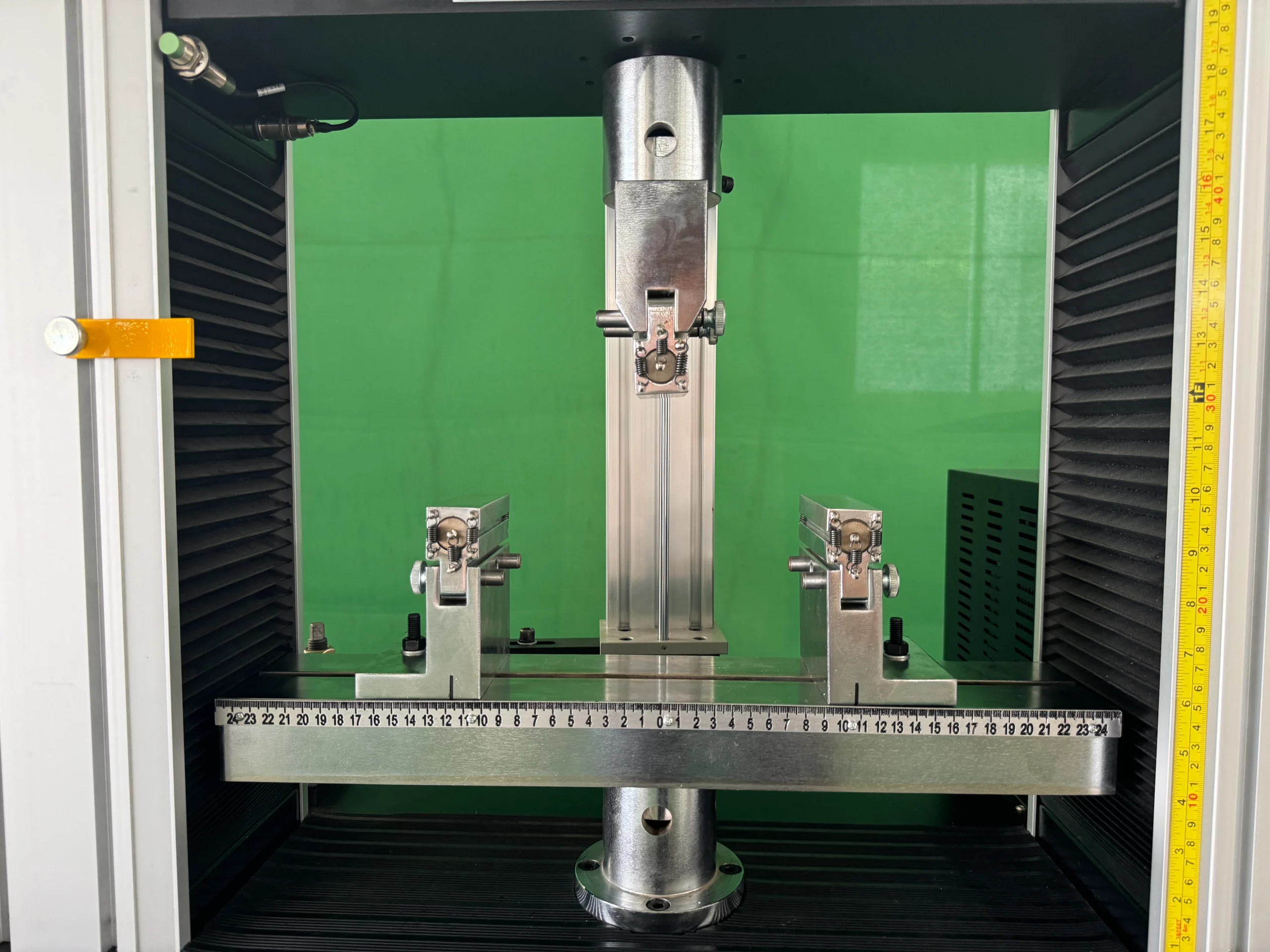

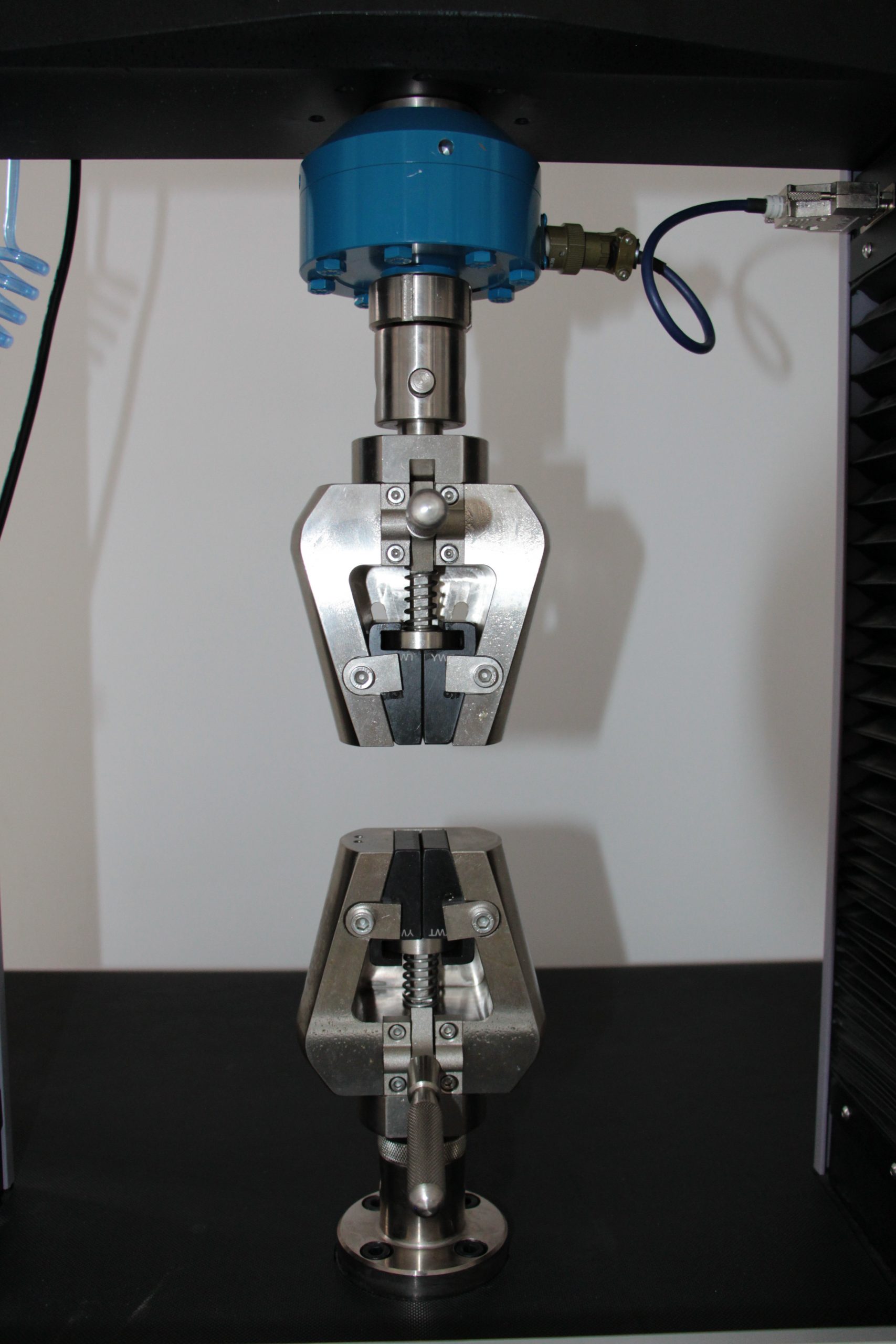

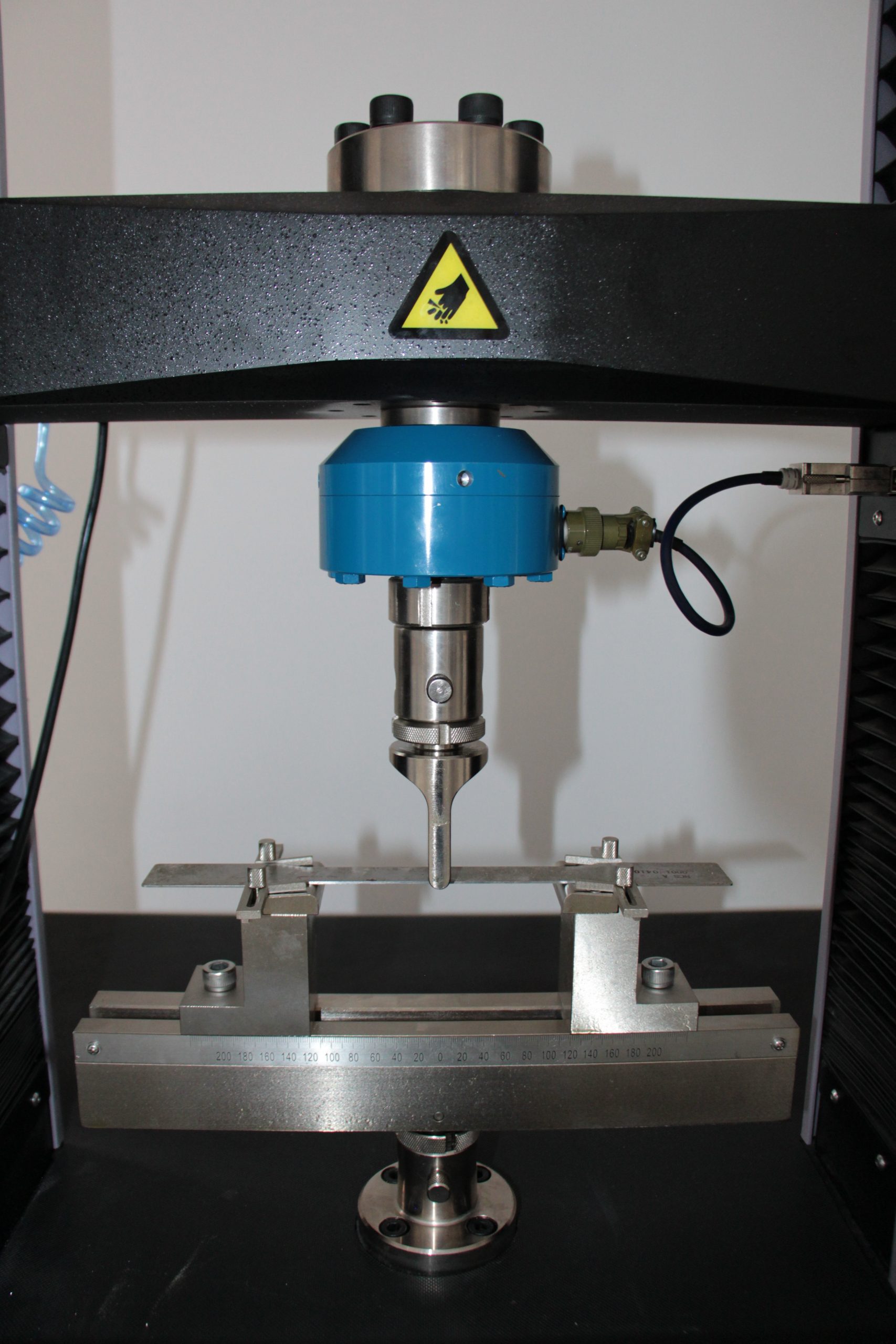

This versatile machine supports a broad array of test configurations, including tension, compression, flexural, and cyclic loading, and is suitable for both standardized routine testing and research-level material development.

Force Capacity: 20kN (4496.17 lbf), 30KN (6744.26 lbf), 50kN (11240.44 lbf)

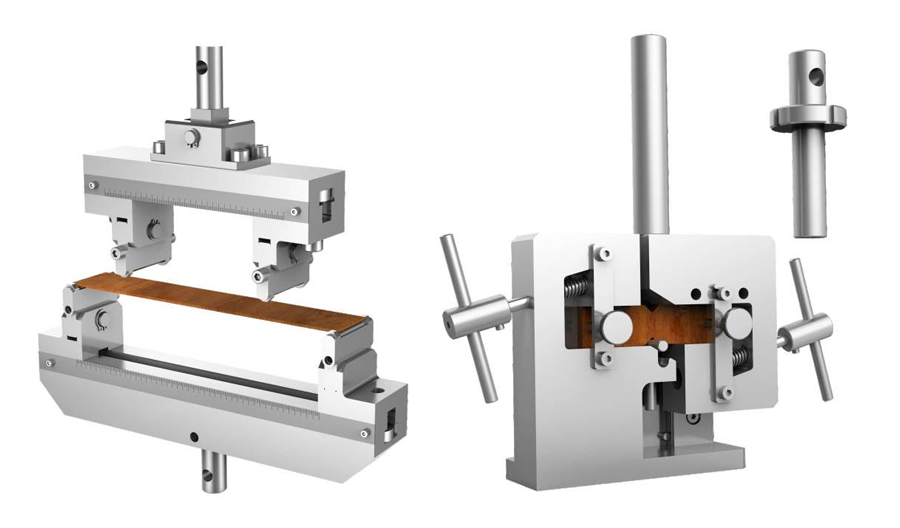

Load Frame Configuration: Dual-column, bench-top and floor-standing electromechanical frame with direct-drive servo transmission

Test Space: Single-space and dual-space options available; extended travel models supported for long specimens or fixtures

Typical Applications: Used in R&D, quality control, and academic environments for testing metals, rubbers, polymers, plastics, foams, composites, and more – including advanced and high-frequency loading scenarios.

Typical Specimens

Designed for high-precision testing of modern materials, the NG-EML Dual Column Bench Top and Floor Standing system supports a wide range of specimen types, including:

- Metals, high-strength steels, and high-temperature alloys

- Rubber, elastomers, and flexible plastics

- Engineering plastics, polymers, and composite materials

- Biodegradable plastics and flexible electronics

- Foams, films, and soft materials

- Materials used in aerospace and research environments

- Samples requiring high-accuracy modulus, yield, and tensile strength determination

NG-EML - Dual Column Bench Top and Floor Standing - Universal Testing Machine (20kN-50kN) Features

- Ultimate User-Friendliness: GenTest™ universal test software features a modern, intuitive interface with icon-based navigation and touchscreen compatibility. It includes a broad library of preloaded ASTM, ISO, GB/T, and EN methods, a step-by-step workflow, real-time feedback, and simplified operation with ergonomic layout and screen orientation support.

- Advanced Accuracy and Reliability: Delivers Accuracy Class 0.5 across 0.2–100% FS for 500 N–50 kN; 0.4–100% FS for 10 N–250 N. Uses preload ball screws, dual-column FEM-optimized frame, and servo belt transmission. ±0.2% speed and position accuracy with compliance to GB/T 228, ISO 6892-1, ASTM E8, ASTM E21.

- Certified Performance: Fully compliant with GB/T 16825.1, ISO 7500, and ASTM E4. Includes a high-resolution optical encoder and TEDS-enabled load cells for plug-and-play setup, self-calibration, and 1/600,000 FS resolution.

- Extended Test Compatibility: Compatible with ASTM D412, ASTM D638, ASTM D790, ISO 178, ISO 527, ISO 604, ISO 37, ISO 1184, and more. Supports testing of metals, polymers, composites, rubbers, biodegradable plastics, and flexible electronics.

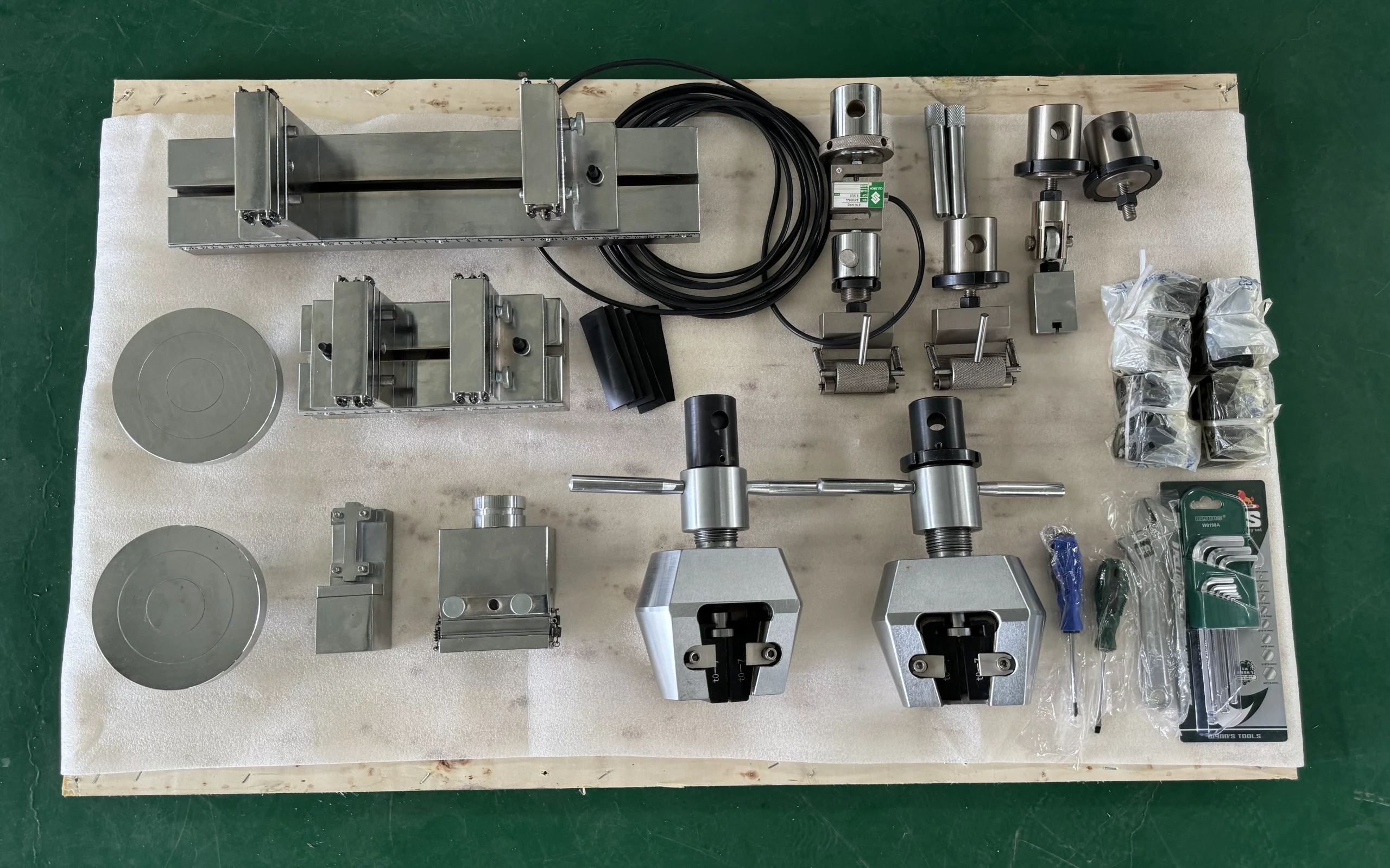

- Stocked Consumables and Spares: Grips, load cells, fixtures, and accessories are stocked and NIST-traceable where applicable. Modular pneumatic and pressure control options available.

- Robust Support: Includes NextGen’s Lifetime Product Support Advantage with calibration, firmware updates, technical support, and optional long-term maintenance. Pull-out controller and easy-access covers improve serviceability.

- Safety Built-In: Integrates overload protection (103%), mechanical limiters, and real-time collision detection. Optional full shield with interlock logic. All safety features are embedded to ensure safe, interruption-free operation.

Control System

The NG-EML system incorporates a high-performance digital control unit designed for precise test execution, seamless communication, and enhanced system integration.

- Alternative Connectivity – Ethernet (TCP/IP)

In addition to USB, the controller supports Ethernet-based communication using a dedicated high-speed logic chip with full TCP/IP protocol stack support. This allows for high-throughput, low-latency data transmission in distributed testing environments or where remote control and network integration are required. - Sampling and Acquisition Performance

The control system offers 1200 Hz closed-loop sampling, enabling precise synchronization of force, displacement, and extensometer inputs. Six-channel analog acquisition with 24-bit resolution allows highly accurate signal capture for real-time feedback and test control. - Integrated Hardware Protection

Embedded firmware ensures autonomous monitoring of voltage, current, overload, motor temperature, and crosshead limits. Emergency stop logic is implemented both in software and hardware layers. - Handheld Remote Console (Standard)

Includes a 3.5-inch full-color touch screen, ergonomic silicone keypad, and fine-adjustment rotary dial. Features include test start/stop, grip control, crosshead positioning, return-to-origin function, and overload prevention. It can operate in dual mode—connected directly to the controller or through the PC interface—offering full control redundancy for lab flexibility.

Optimized Structural Rigidity

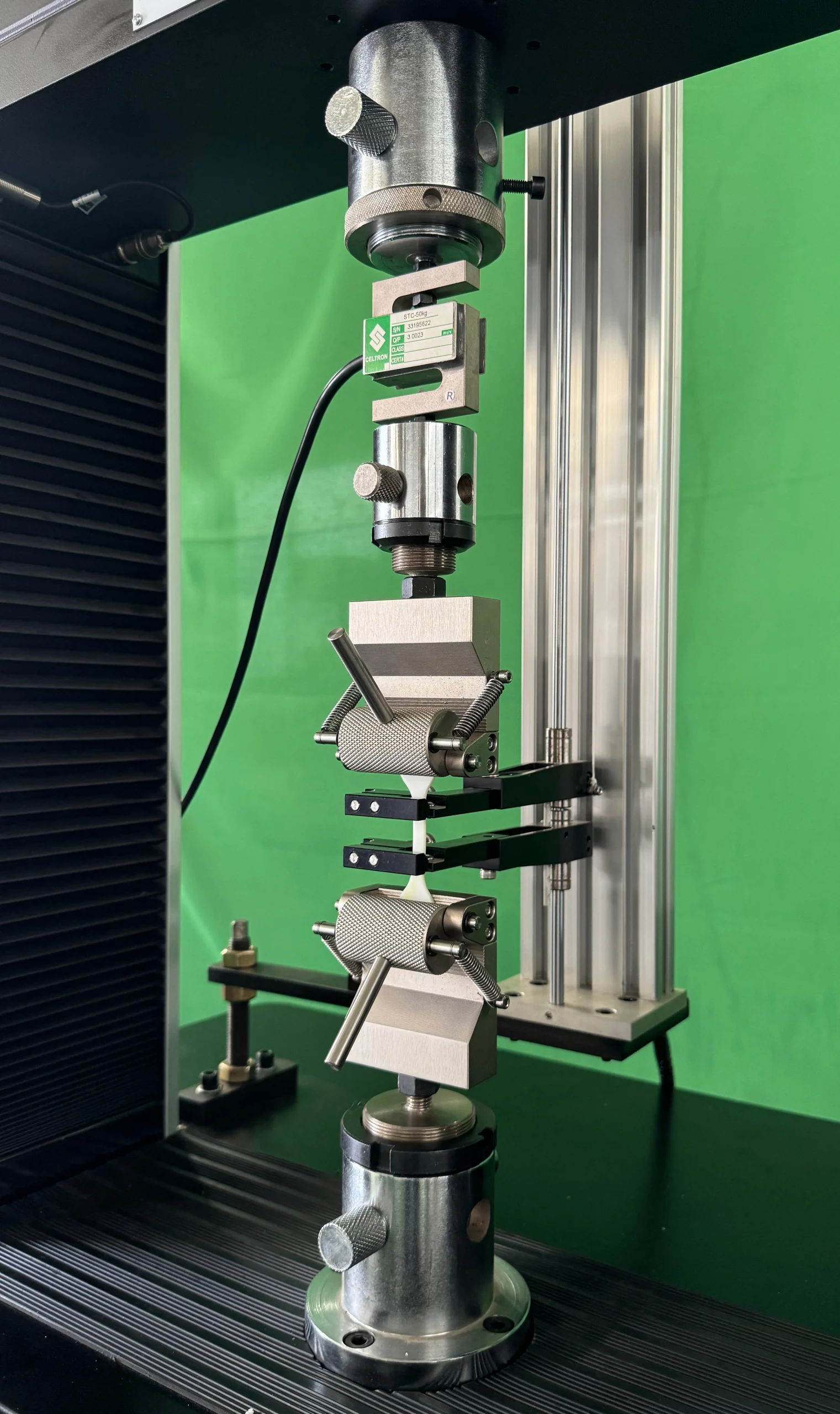

NG-EML Dual Column Bench Top and Floor Standing – Universal Testing Machine features a frame engineered for superior mechanical stiffness and durability. Utilizing a high-rigidity dual-rail structure and an FEA-optimized crosshead design, the system minimizes deflection and backlash, ensuring exceptional accuracy during critical measurements such as modulus determination, yield strength, and failure loads.

- The testing frame integrates preloaded precision ball screws, dual linear motion guide rails, and reinforced column supports to significantly reduce mechanical play.

- All interfaces — load cell, ball screw, motor couplings, and crosshead contact points — are engineered for zero-clearance under load, enhancing measurement consistency in both static and dynamic tests.

- The rigid design ensures long-term alignment stability, even during high-cycle or repetitive test applications.

High-Speed, Direct-Drive Actuation

The NG-EML Dual Column Bench Top and Floor Standing – Universal Testing Machine is equipped with a next-generation direct-drive servo transmission system that delivers exceptional speed, acceleration, and responsiveness.

- The system eliminates traditional gear reducers by employing a high-rigidity synchronous belt and servo motor assembly, which significantly improves mechanical efficiency and reduces transmission backlash.

- Maximum crosshead movement speed reaches 2400 mm/min, significantly reducing testing cycle durations and increasing throughput.

- High-speed drive enables better responsiveness for low-speed creep, stress relaxation, and modulus ramp tests, while still allowing ultra-slow control for precision measurement scenarios.

- Enhanced acceleration profiles improve system adaptability in multi-stage or high-speed ramp testing procedures.

Intelligent Safety and Control Architecture

The NG-EML Dual Column Bench Top and Floor Standing – Universal Testing Machine incorporates an advanced safety and intelligence layer that protects both operator and equipment while optimizing system responsiveness and usability.

- Real-Time Collision Prevention: The system constantly monitors real-time force feedback and movement data. If an abnormal force spike is detected (e.g., specimen fracture or obstruction), crosshead motion is automatically halted to prevent load cell overload or mechanical damage.

- Overload Protection Logic: The system enforces an immediate stop at 103% of rated capacity. This hardware-level safeguard ensures long-term integrity of sensitive components.

- Dual-Layer Position Limit Protection: Built-in software and mechanical end-stop switches ensure safe operation boundaries. Both user-defined digital limits and physical stroke protectors are implemented.

- Emergency Stop Circuitry: Integrated emergency stop buttons allow the operator to immediately interrupt any movement.

- Sensor Range Enforcement: All input channels (force, displacement, extensometer) include range-checking logic to prevent overrange conditions and maintain data validity.

- Handheld Controller Safety: The remote control unit includes grip lockout, overload prevention, and a return-to-origin function that prevents accidental mispositioning.

These features make the system both safe for daily use in production environments and smart enough for complex, precision-driven test workflows.

Streamlined Operation and Maintenance

The NG-EML Dual Column Bench Top and Floor Standing – Universal Testing Machine is designed for intuitive use and efficient daily operation, reducing setup time, operator training, and maintenance complexity.

- User-Centered Software Workflow: GenTest software presents a clean, icon-driven interface. Built-in templates for ASTM, ISO, GB/T, and EN standards allow rapid setup, while drag-and-drop test design and real-time graphical outputs simplify routine and advanced testing alike.

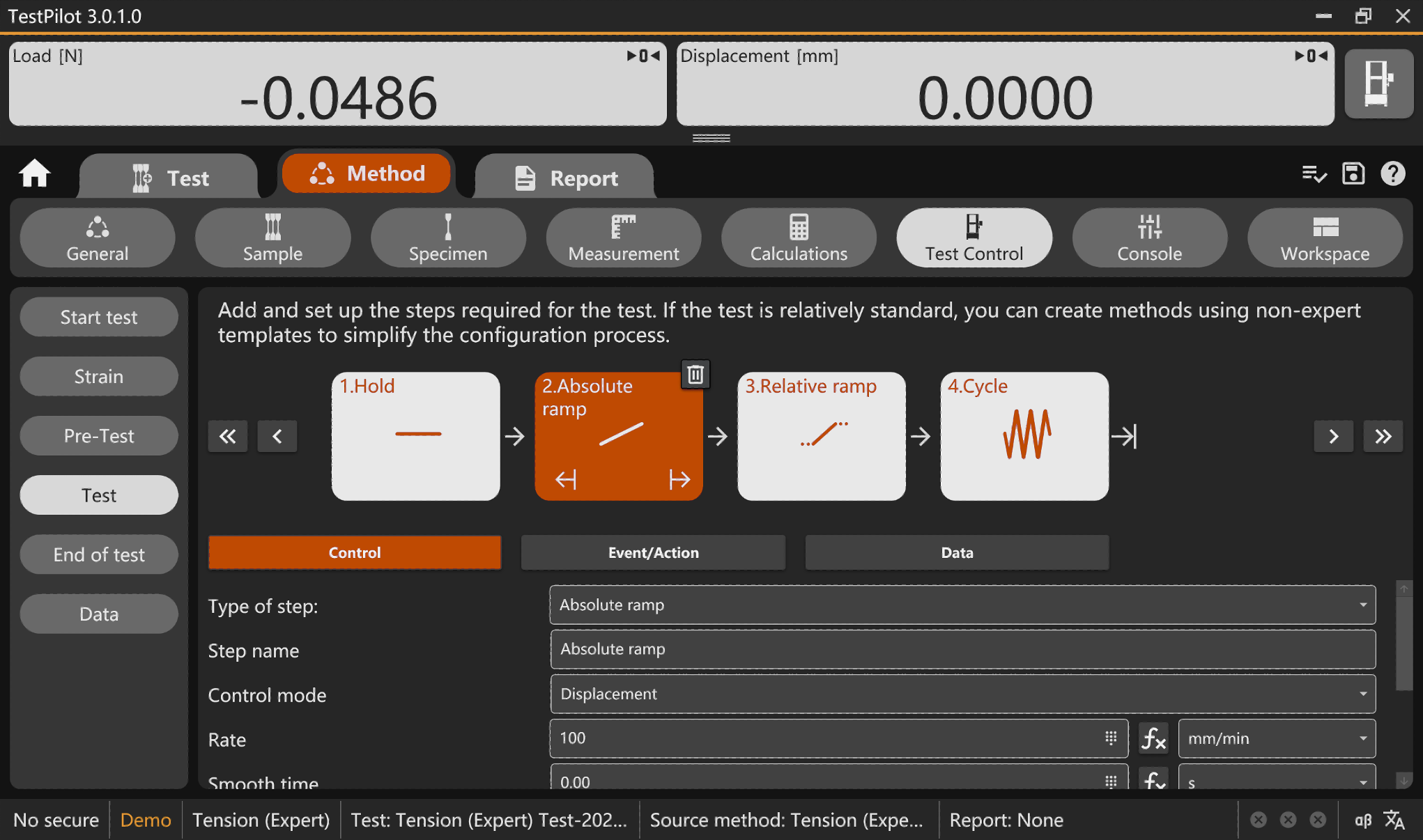

- Step-by-Step Configuration: Operators can build test sequences with guided steps, reducing the risk of errors and ensuring repeatability across users and labs.

- Instant Report Generation: One-click data export, automatic calculation of results (modulus, yield, tensile strength, etc.), and batch processing functions streamline documentation and compliance.

- Accessible Maintenance Architecture: The controller module is slide-mounted and accessible for service without disassembling the frame. Protective covers can be quickly opened for belt, motor, or sensor inspection.

- Dual Control Modes: The handheld remote console and optional touch-screen PC interface allow local or PC-based operation with full synchronization, offering flexibility for both training and production use.

These design principles make the NG-EML system simple to operate and maintain, while still offering the flexibility and performance required by demanding testing environments.

Mechanical and Electronic Architecture

The NG-EML Dual Column Bench Top and Floor Standing – Universal Testing Machine is engineered with a precision mechanical structure and high-performance control electronics to ensure stability, repeatability, and accuracy across all test scenarios.

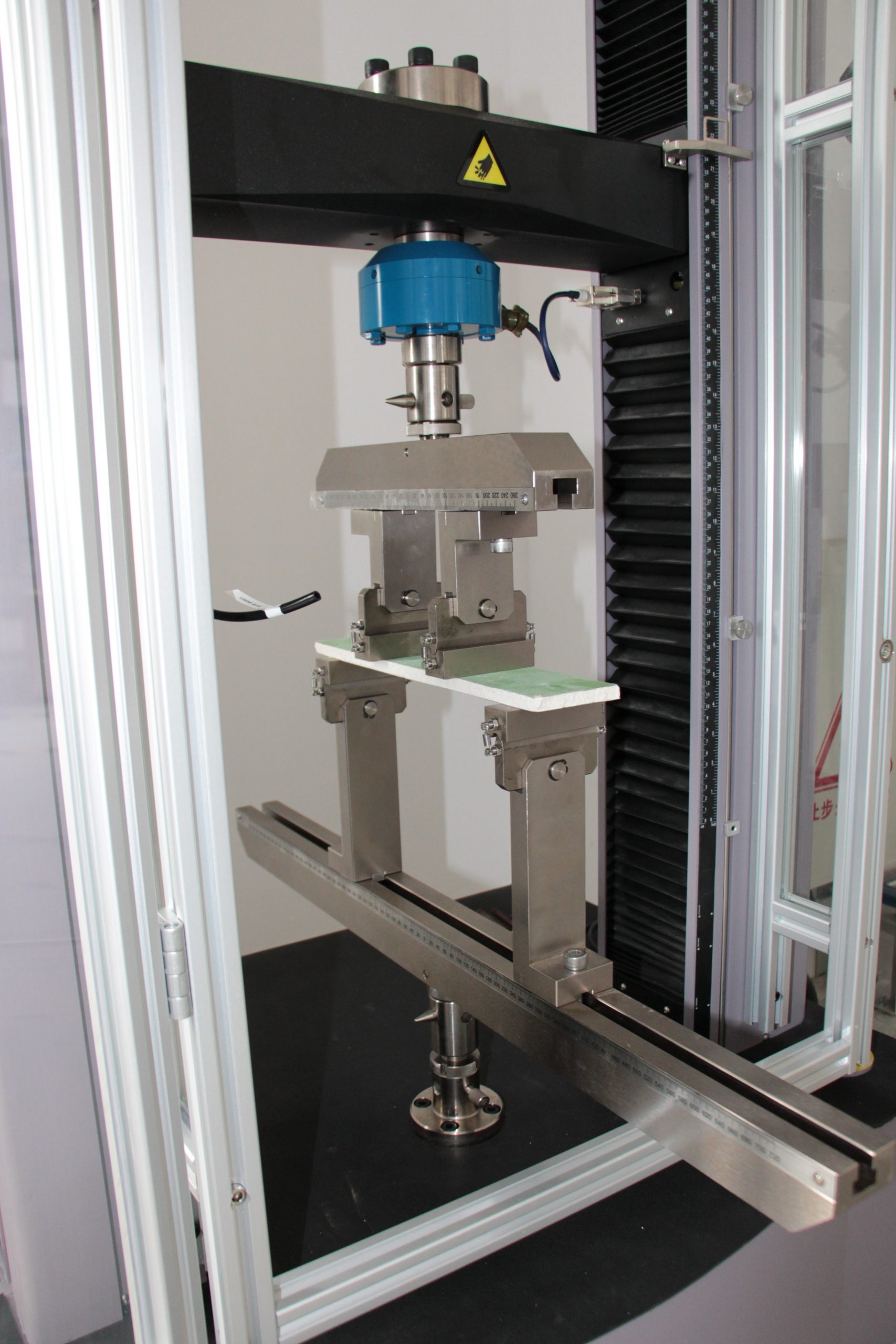

Precision Load Frame

- High-Stiffness Linear Guide System: Dual linear guide rails with integrated self-lubrication significantly enhance lateral stiffness and ensure straight, low-friction crosshead travel. This design minimizes off-axis motion and maintains precise axial alignment, which is essential for reducing measurement error in displacement- and strain-sensitive tests.

- Low-Noise Synchronous Belt Drive: The direct-drive system employs a high-performance synchronous belt optimized for high speed and low vibration. It operates maintenance-free and ensures smooth power transmission between the servo motor and the actuator assembly.

- Integrated Optical Encoder: A high-resolution photoelectric encoder is embedded within the servo system to capture real-time position feedback of the crosshead, supporting micro-displacement measurements with 0.0133 μm resolution.

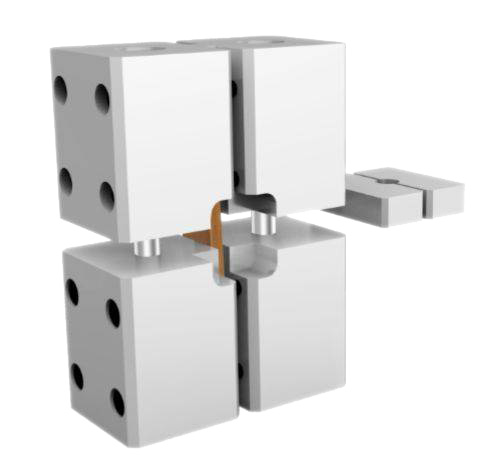

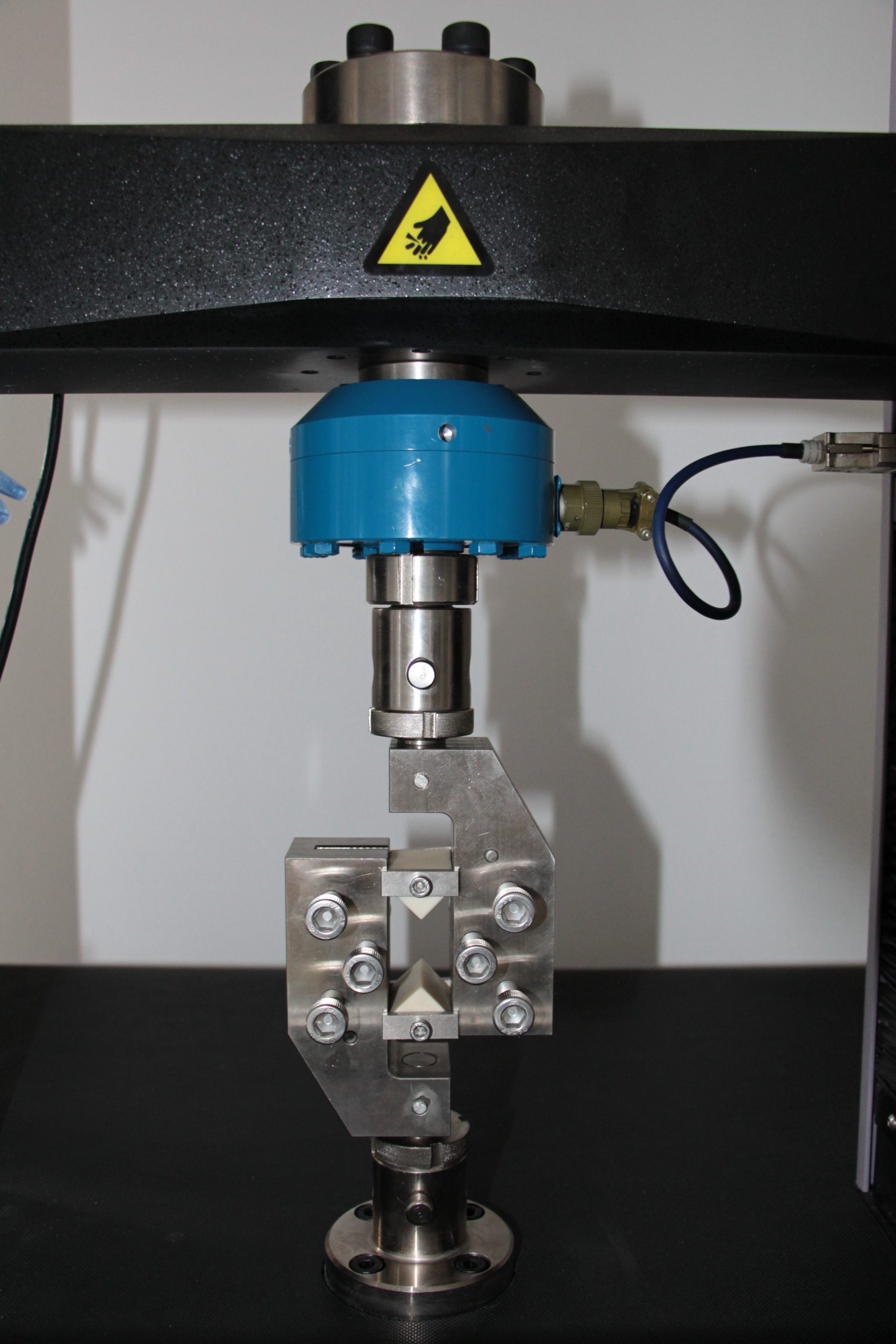

Load Cell Assembly

- High-Precision Load Cells: Each system includes a factory-calibrated load cell with high stiffness, minimal signal drift, and linearity across the entire rated force range.

- Overload and Lateral Force Protection: Built-in safety logic and structural reinforcement protect the sensor against shock loading, side forces, and improper specimen failure.

- Bidirectional Testing: The load cells support both tensile and compression tests without requiring reconfiguration.

- TEDS Auto-Recognition: All load cells are equipped with IEEE 1451.4-compliant TEDS chips, enabling plug-and-play recognition and eliminating manual setup.

- Self-Calibration Ready: The system supports internal load cell verification procedures to maintain measurement accuracy over time.

- Wide Operating Temperature Range: Rated from −55 °C to +90 °C, suitable for standard and environmental chamber-based testing.

Closed-Loop Controller

- Adaptive Feedback Control: The controller features a next-generation closed-loop PID algorithm, optimized for the upgraded direct-drive mechanics. This enables rapid system response under varying material behavior and loading profiles.

- Smooth Transition Profiles: Intelligent speed ramps and control smoothing algorithms ensure consistent performance across high-speed and low-speed regimes. This is critical for metal testing at both ambient and elevated temperatures.

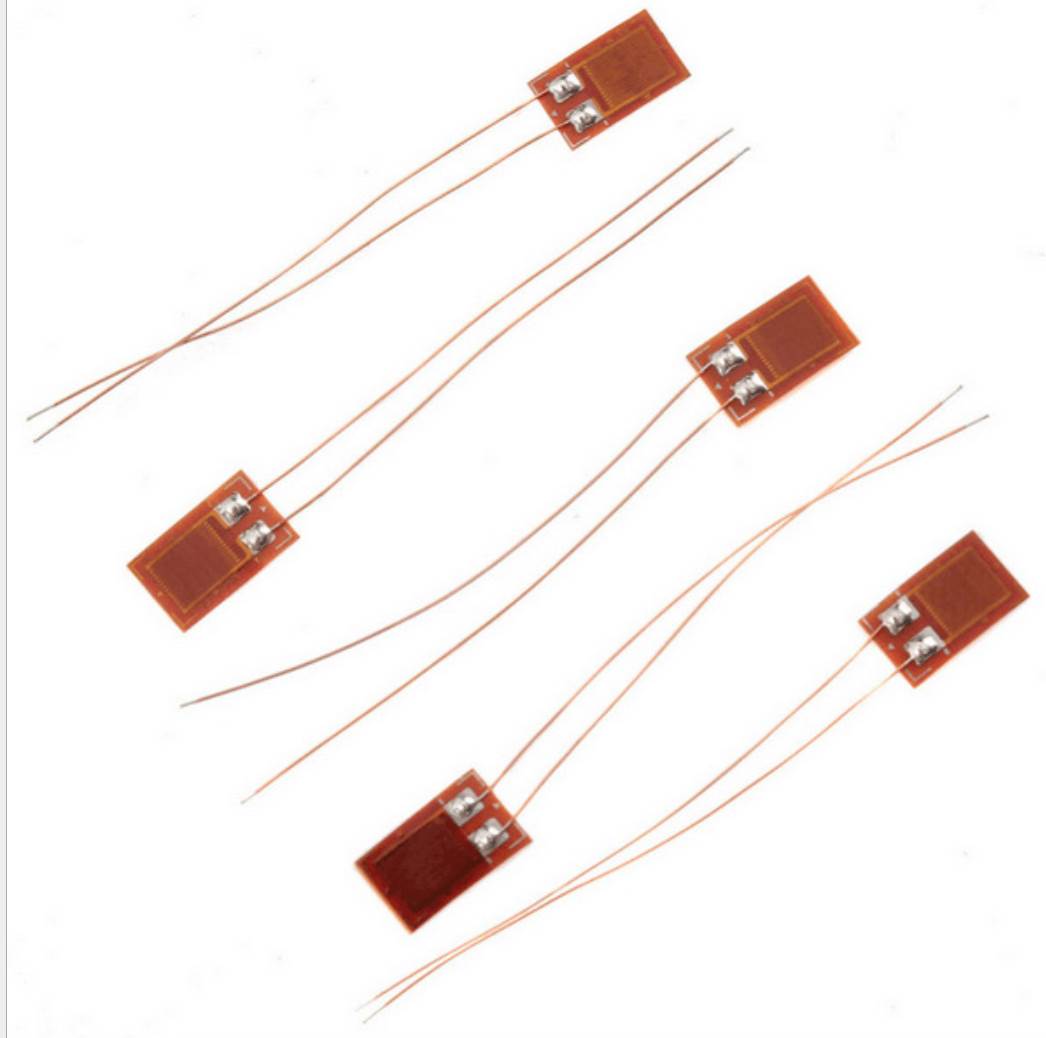

- Multi-Channel Acquisition: Six synchronized analog channels and multiple digital inputs allow simultaneous integration of extensometers, temperature sensors, strain gauges, and load signals with millisecond-level accuracy.

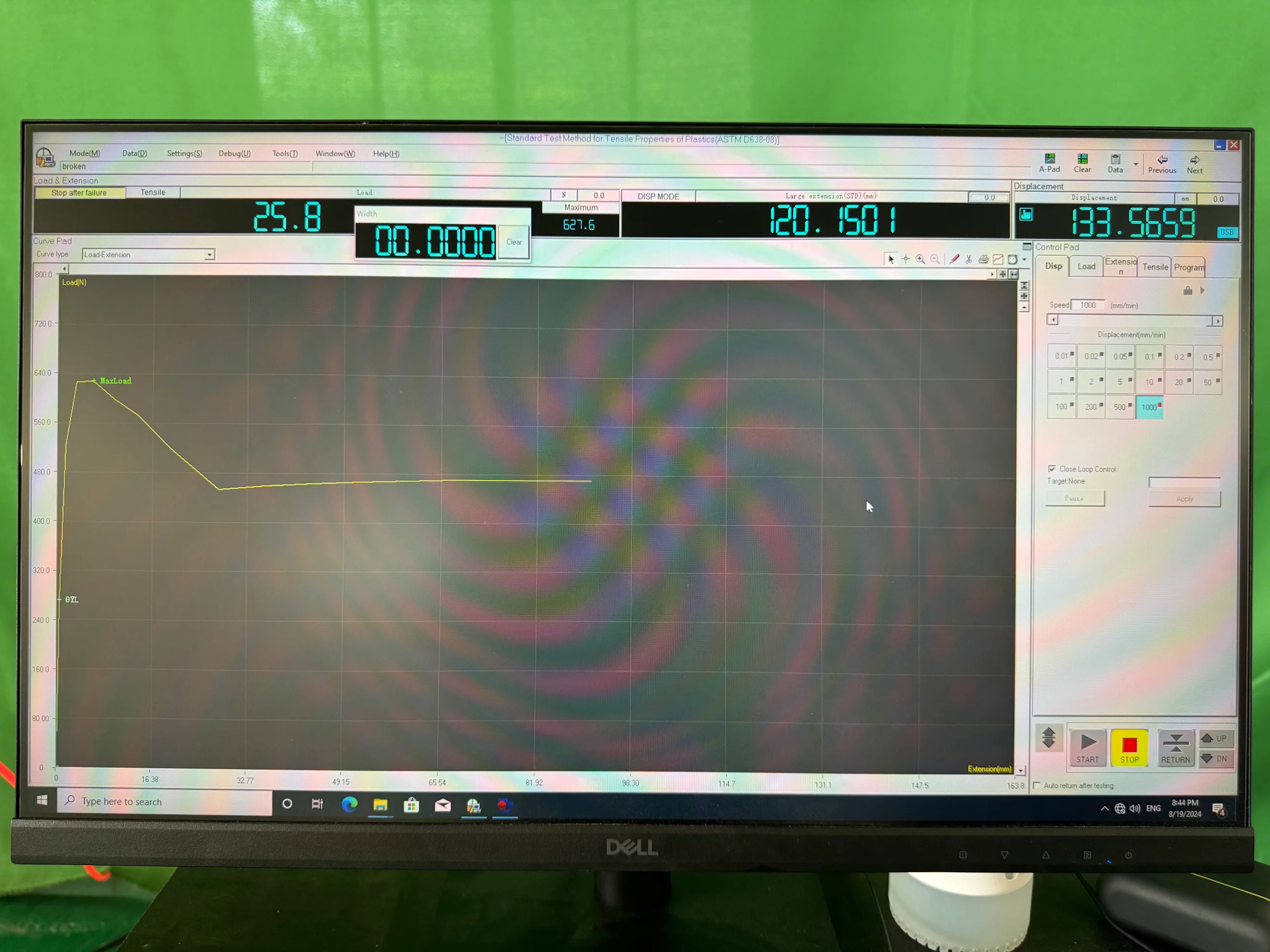

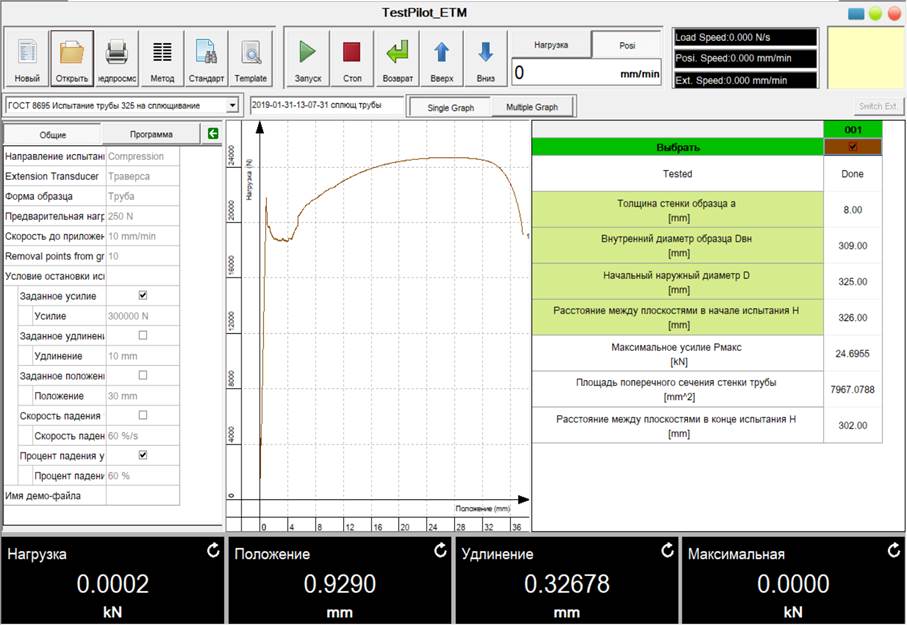

Live Data Visualization and Graphing

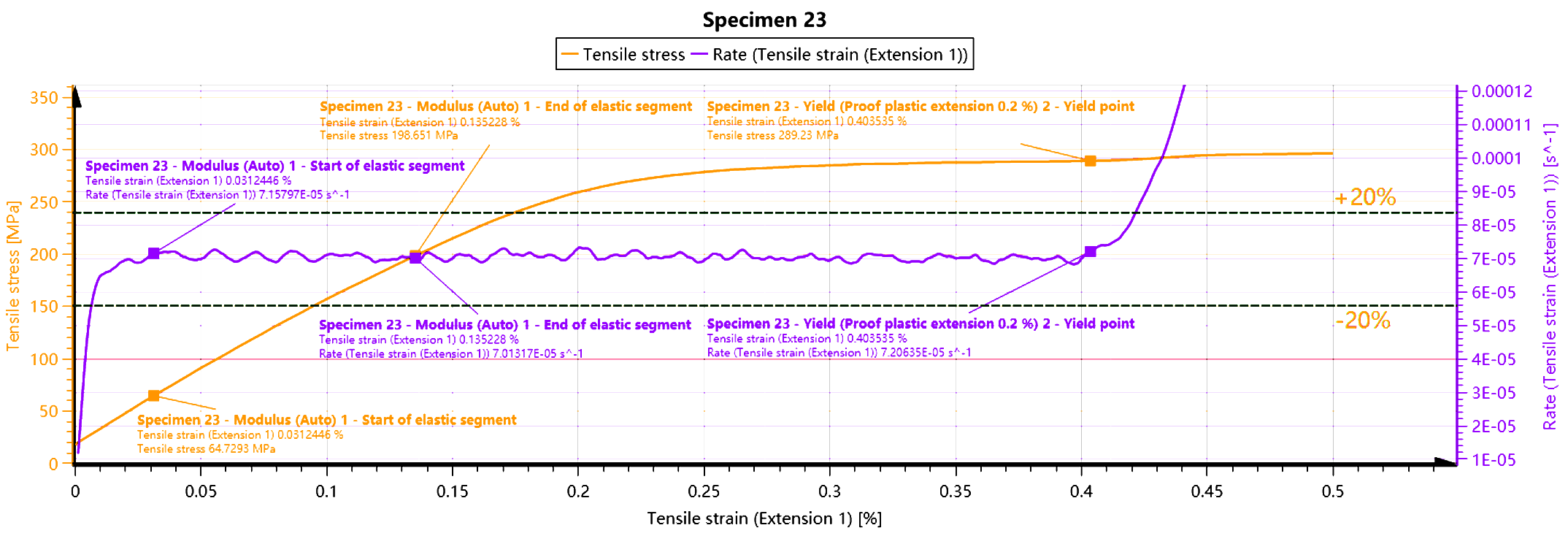

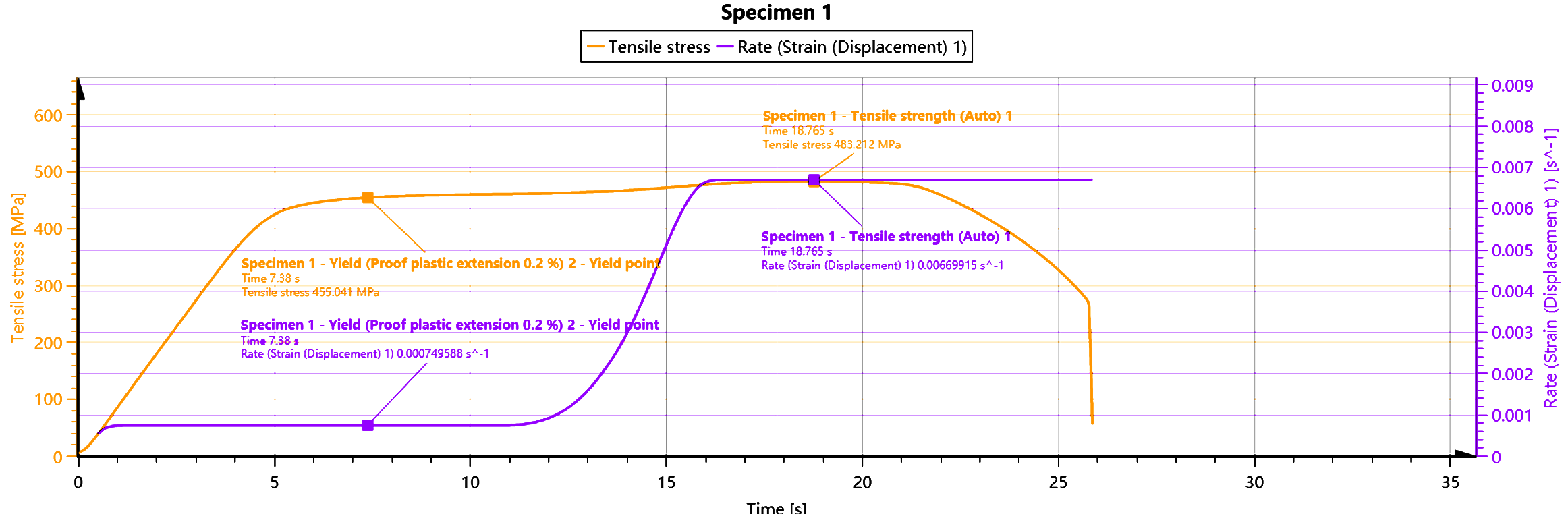

- Real-Time Graphing: During each test, the system displays synchronized force-displacement, stress-strain, and time-based curves in real time. Graphs are updated dynamically with every acquisition cycle (1200 Hz).

- Customizable Chart Layouts: Operators can define custom chart views, zoom windows, axis scaling, and data overlays for advanced comparative analysis.

- Zoom-In Tools: Operators can manually explore key points such as break locations, yield regions, and modulus segments during or after the test using interactive chart controls.

- Multiple Curve Overlays: Batch testing and comparison of multiple sample curves on a single graph allow performance consistency analysis and outlier detection.

- Export Formats: Charts and raw data can be exported in multiple formats including CSV, Excel, PDF, and graphical image (PNG, SVG).

Integrated Control Interfaces

The NG-EML Dual Column Bench Top and Floor Standing – Universal Testing Machine is engineered to support multiple control and interaction modes, providing operators with ergonomic, efficient, and flexible access to all machine functions. Whether in production, R&D, or training environments, these interfaces streamline test execution, setup, and safety control.

Handheld Remote Controller – Included as Standard

This compact, magnetically mountable remote handset includes a fully integrated 3.5-inch full-color touchscreen display for direct user interaction with test status and parameter control.

- Ergonomic Interface: Features silicone-coated buttons and a fine-resolution rotary wheel, which allows precise manual positioning of the crosshead. Operators can jog the crosshead, issue return-to-origin commands, or fine-tune alignment prior to clamping specimens.

- Real-Time Feedback: Live force, displacement, and system state are displayed on-screen. The user receives continuous updates, reducing the need to shift attention between the handset and PC.

-

Core Control Functions:

- Start / Stop test

- Return to home position

- Manual jog of crosshead (up/down)

- Grip open/close control (if pneumatic system installed)

- Specimen protection logic – prevents excessive preload during setup

-

Flexible Communication Modes: Can function either:

- In direct mode, communicating with the controller via embedded logic

- In PC-synchronized mode, acting as a secondary user input device for software-guided workflows

Its magnetic backplate enables quick placement on the load frame or workstation surface, maintaining accessibility throughout test preparation and operation.

Optional Industrial Touchscreen PC

An optional all-in-one touchscreen computer can be mounted directly on the load frame, enabling standalone test execution without requiring an external desktop or laptop.

- GenTest™ Software Ready: The integrated industrial PC is preloaded with the full version of GenTest™ software. It provides access to all standard test method libraries, custom sequence creation, live graphing, real-time analytics, and report generation tools.

- Intuitive Touch Interface: Multi-touch screen supports tap, drag, pinch-to-zoom, and gesture control. Graphs, test results, and settings are interactively accessible on-screen, minimizing the learning curve for new users.

-

Industrial-Grade Build: The PC unit features:

- Shock-absorbing housing

- Sealed surface for dust and moisture resistance

- Vibration isolation mounts (optional)

- Port Expansion: Offers multiple USB ports for data export, printer connection, barcode scanning, or peripheral automation.

This setup is ideal for laboratory benches with limited space, production lines requiring test autonomy, or educational facilities seeking simplified workstation design.

Optional Workbench

The optional ergonomic workbench is designed to enhance operator convenience during test preparation and execution. It provides a stable surface for instrument handling and organized storage of accessories such as grips and fixtures. With compact dimensions of 793 × 658 × 675 mm (L × D × H), it integrates seamlessly into laboratory environments and supports efficient workflow.

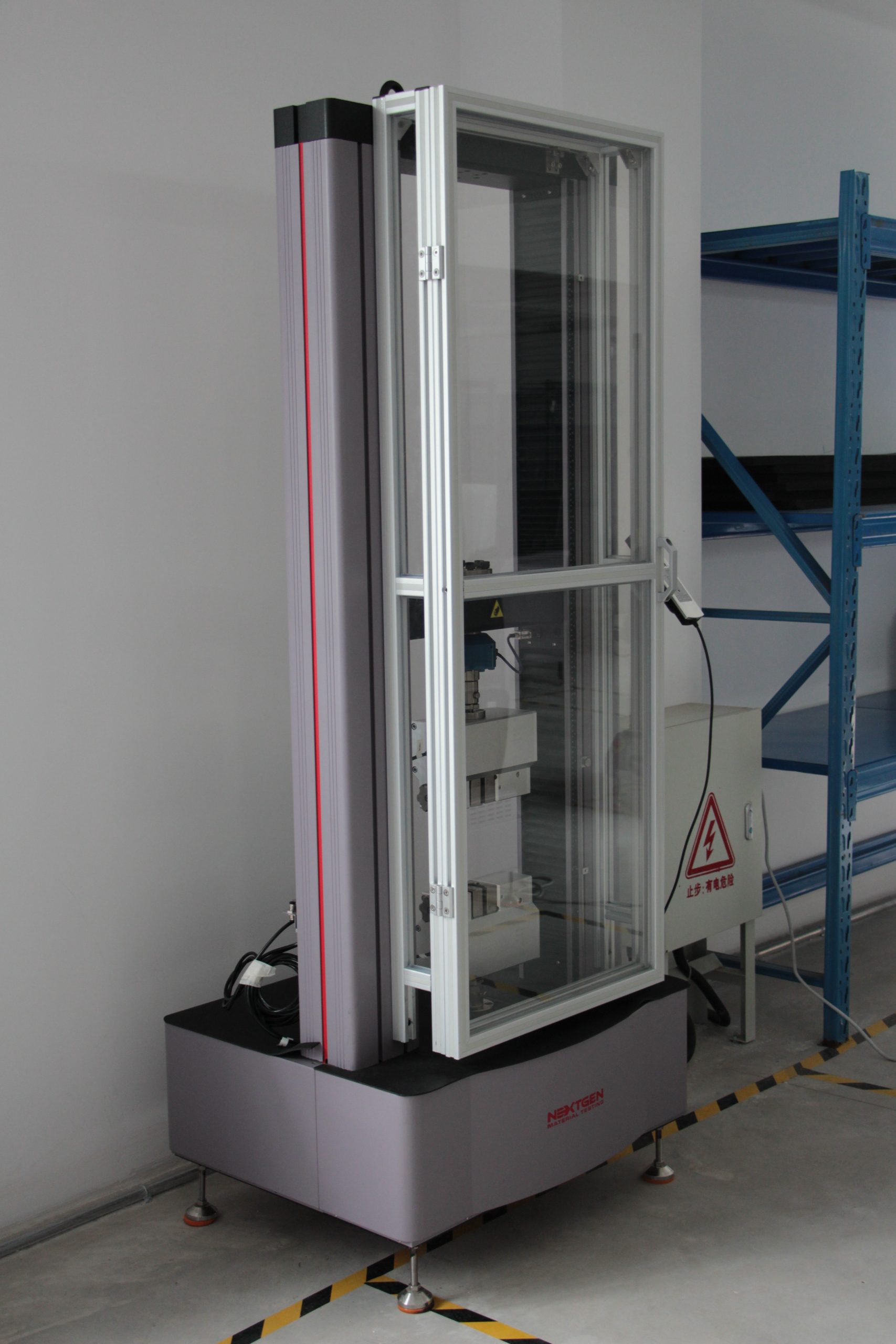

Optional Protection Shield

The optional protection shield features a fully enclosed structural design with an aluminum alloy reinforcement frame and high-impact polycarbonate panels. This safety enclosure is engineered in accordance with international mechanical safety standards to ensure maximum protection during critical testing operations.

Equipped with an integrated door locking mechanism and software-linked interlock system, the shield restricts system movement when the door is open. This design minimizes the risk of injury and enhances occupational safety in high-throughput or high-force test scenarios.

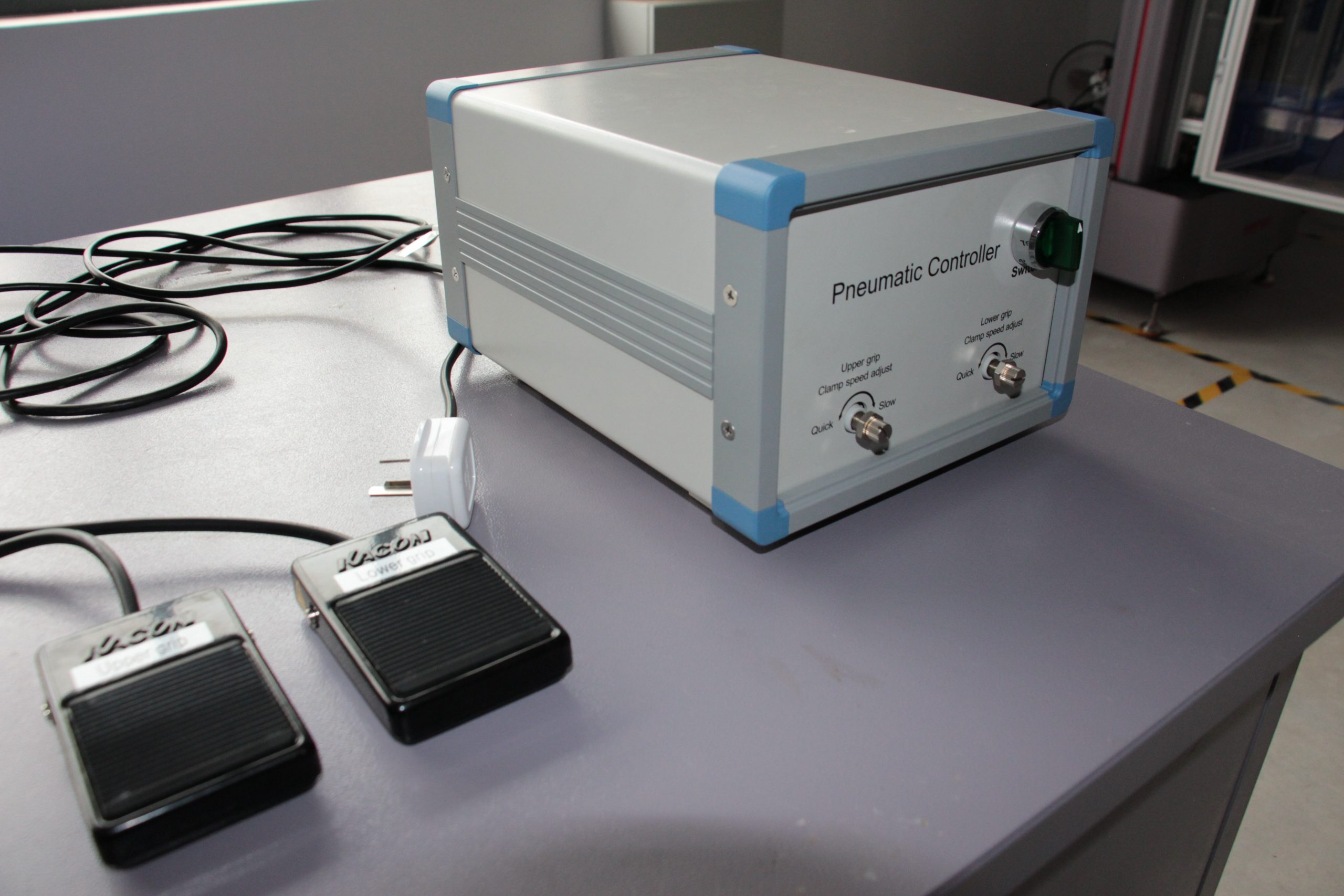

Optional Pneumatic Grip Control Module

For applications requiring pneumatic grips, the system supports an optional digital pneumatic grip pressure control unit, allowing for programmable clamping force and improved specimen protection.

- Pressure Control and Regulation: Users can set and adjust air pressure via a digital interface to match the material’s clamping requirements. Accurate pressure prevents both under-clamping (slippage) and over-clamping (material deformation).

- Dual Gripping Channels: Independently control opening and closing of upper and lower pneumatic grips for high-precision clamping sequences.

-

Integrated Safety Mechanism:

- Grip actuation is disabled unless the test space is clear and the system is in a safe state

- Pre-pressure locking and relief mechanisms help maintain grip force during test start

- Compact Design: The module can be rack-mounted near the testing system or installed directly on the machine frame for easy access. Quick-connect fittings allow fast changeover of grip types.

- Visual Display: Real-time pressure feedback and grip status indicators support operator awareness and reduce the risk of setup error.

This accessory is especially useful for thin films, sheet materials, wires, and flexible samples that require gentle yet secure holding during tensile or cyclic loading.

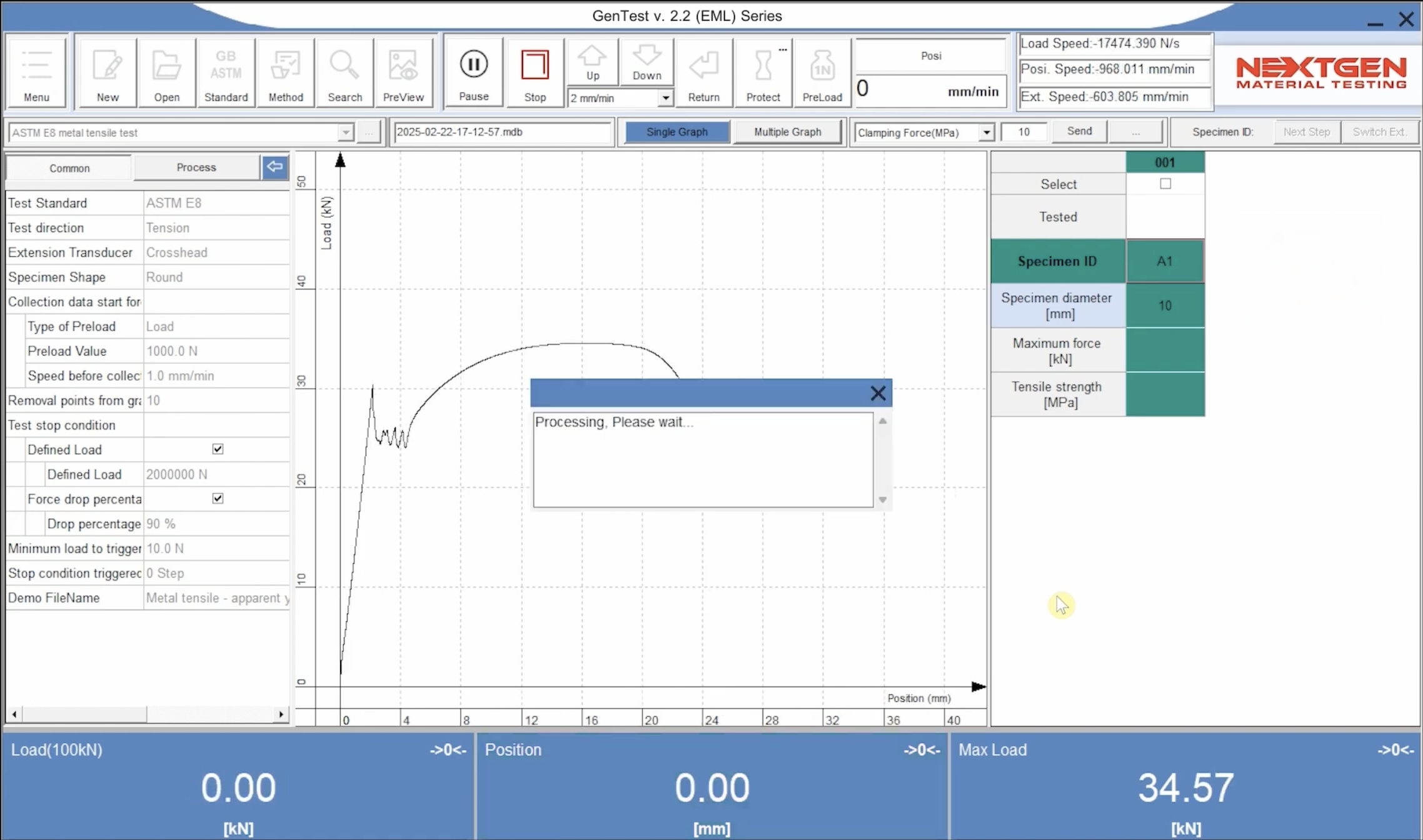

NEXT GEN™ Universal Testing Software

The newly updated testing software features a streamlined and intuitive layout, offering a logical arrangement of functions, consistent interface design, and clearly structured navigation. It supports both horizontal and vertical screen orientations, with automatic resolution scaling based on the display settings of the host computer.

A broad set of preloaded testing protocols is included, covering widely used standards such as GB/T, ASTM, ISO, and EN. These methods are organized into modular test groups based on application type, allowing users to efficiently select appropriate configurations for different industries and materials. In addition to standard methods, the software enables full customization of test procedures and standards to accommodate unique testing scenarios.

An integrated modular accessory management system links accessory configurations directly with the test workflow, allowing seamless interaction between the software and connected components. The platform supports a wide range of external devices, including video extensometers, temperature controllers, analog gauges, fully automatic extensometers, thermal chambers, pneumatic grip controllers, and strain measurement sensors, ensuring maximum adaptability across complex test setups.

- Interface Design: Employs a simplified, flat UI conforming to modern design standards. Optimized font display enhances readability and aesthetic coherence, improving the operator experience significantly.

- Layout and Touch Optimization: Supports both horizontal and vertical display layouts; a numeric keypad is integrated for streamlined touch-based input under operational constraints.

- Demonstration Mode: Enables simulation of tests, allowing familiarization with the software interface without physical specimen interaction.

- Recalculation: Post-test recalculation allows users to modify parameters and reprocess results efficiently.

- Test Standards: Preloaded with built-in test methods compliant with GB/T, ASTM, ISO, and EN standards, organized modularly for streamlined selection.

- Method List: Intuitive display and keyword filtering of test procedures facilitate rapid method identification and selection.

- Quick Test Method: Optimized for tensile and compression tests with minimal configuration steps.

- Data Export: One-click raw data export streamlines post-test processing.

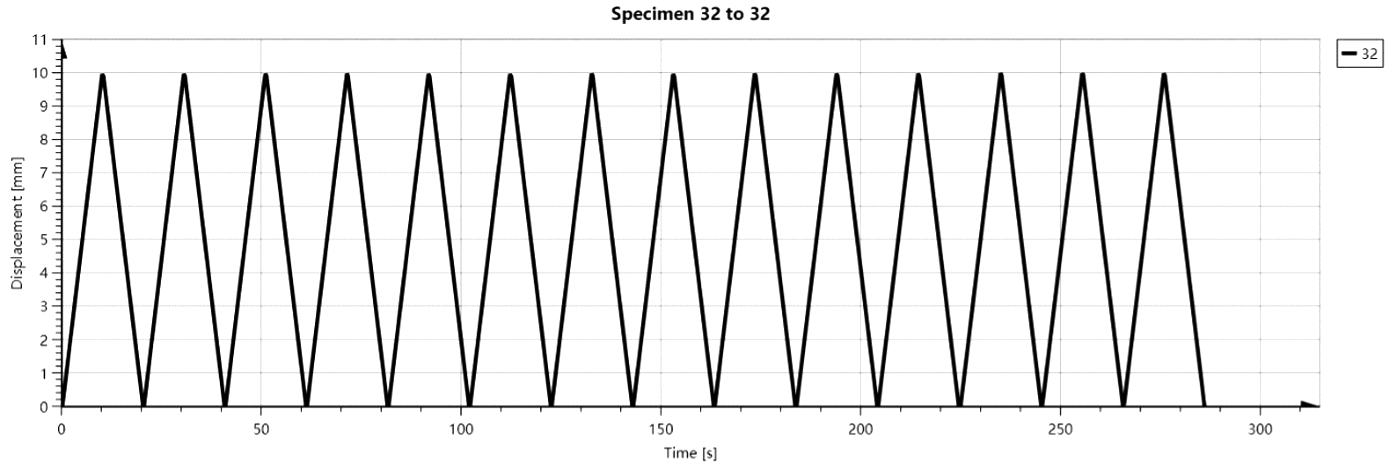

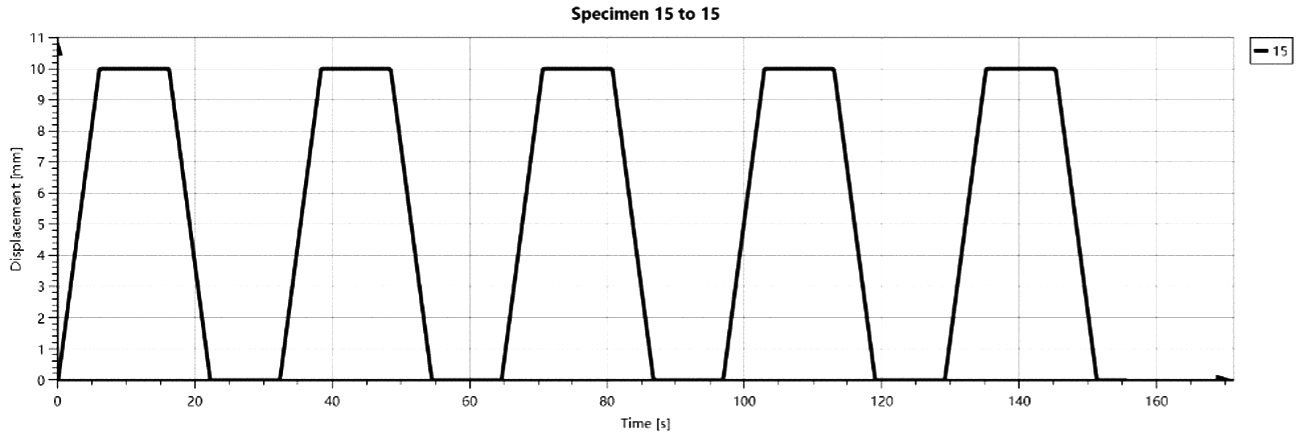

- Test Progress Visualization: Real-time tracking of test steps, cycles, control modes, and duration provides operational transparency.

- Test Graph: Multi-mode interaction with graphs (e.g., touch, keyboard, zoom, and axis panning). Advanced plotting options support complex data visualization needs.

- Function Key Customization: Allows tailored UI controls for specific test methods, maximizing testing efficiency.

- Test Log Recording: Records comprehensive metadata including parameter inputs, system states, and abnormal events for traceability.

- Pre-test Parameter Verification: Enforces parameter validation prior to execution to eliminate procedural errors and reduce waste.

- Sample Protection Mechanism: Prevents premature damage by controlling the clamping sequence and forces.

- Real-Time Data Display: Supports up to 12 configurable channels with customizable layout, units, time formats, and refresh intervals.

- Multifunction Operation Panel: Consolidates manual control functions for connected accessories and core equipment.

- Basic Templates: Pre-configured test method templates support rapid onboarding and expert-level customization.

- Unit System: Includes metric and imperial units; conversion is automatic per selected method or test item.

- Expression Generator: Allows construction of advanced test expressions using logic or variable inputs.

- Measurement Function: Supports multi-channel data collection and live result synthesis.

- Calculation Function: Provides a suite of pre-programmed algorithms for dynamic and static calculations.

- Rounding Function: Permits configurable rounding logic in processed data to ensure result uniformity.

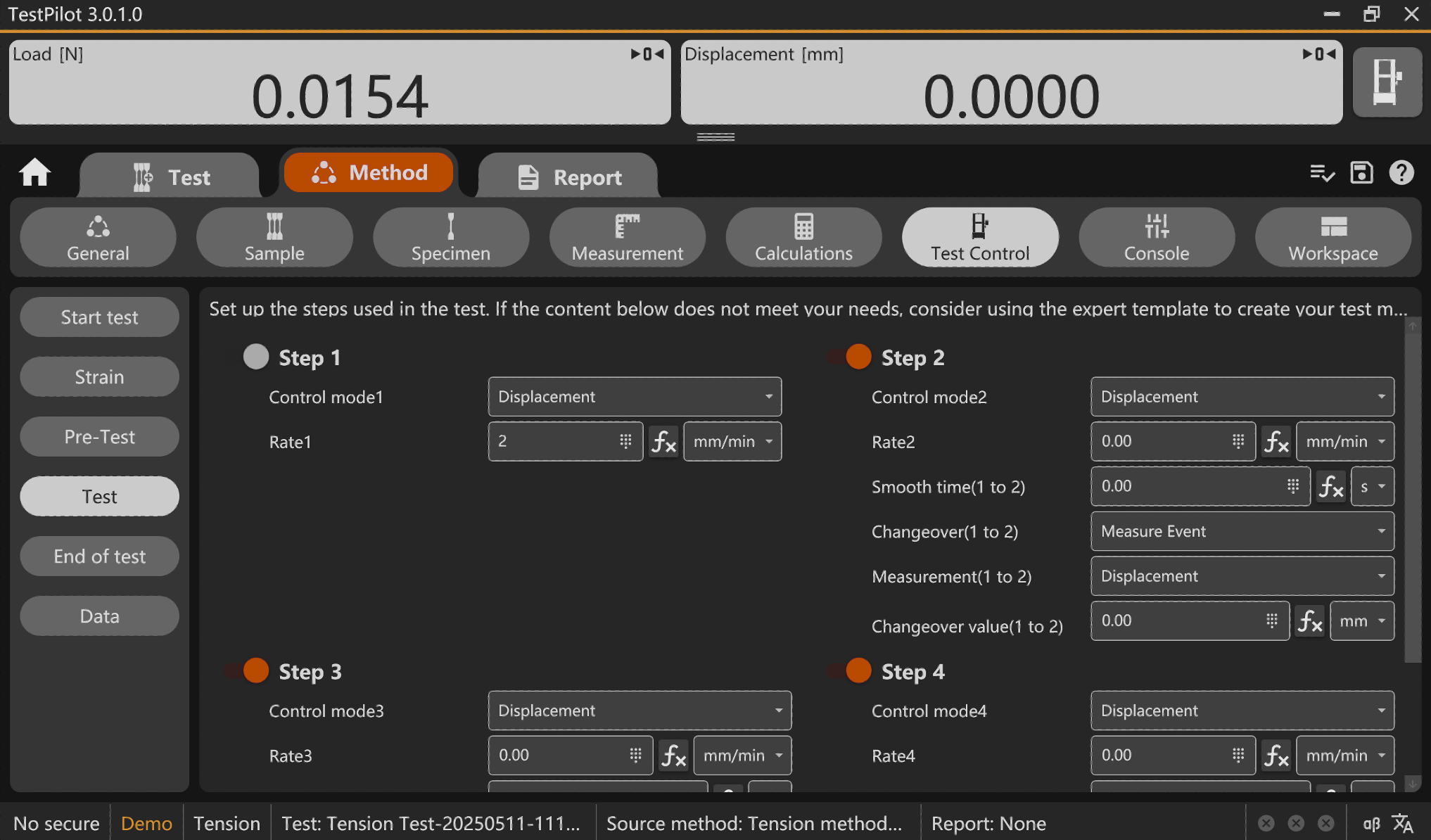

- Test Control: Supports step-based sequencing (ramp, hold, waveform) with customizable trigger events and acquisition strategies.

- Voice Broadcasting Function: Configurable voice prompts guide users through critical testing stages and events.

- Accessory Connection: Broad compatibility with extensometers, chambers, and other peripheral testing hardware.

- Accessory Action Control: Granular control of peripheral device behavior across the test sequence timeline.

- Data Acquisition Strategy: Customizable interval settings prevent data loss during rapid measurement changes.

- Automatic Fixture Pressure Setting: Pressure automatically adjusts based on force thresholds to prevent sample damage.

- Test Report: Full customization of report content and export format, including watermarking and formatting templates.

- Multi-language Switching: Real-time language changes without system reboot enhance international usability.

- Data Analysis: Enables inter-test and inter-batch statistical comparisons for deeper analytical insight.

- Maintenance Reminder: Intelligent system tracking prompts timely servicing to optimize hardware lifespan.

- Permission Configuration Management: Tiered access rights improve operational control and accountability.

- Safety Performance: Covers multi-dimensional safety metrics including electrical, overload, and thermal protections with real-time monitoring.

Technical Specifications

| Model | NG-EML Dual Column Bench Top and Floor Standing – Universal Testing Machine |

|---|---|

| Capacity, kN | 50/30/25/20/10/5 |

| Frame type | Desktop |

| Test space | Single space |

| Maximum speed, mm/min | 900 |

| Minimum speed, mm/min | 0.00005 |

| Maximum return speed, mm/min | 1500 |

| Position resolution, µm | 0.01 |

| Crosshead travel (H), mm | 1000 |

| Test width (W), mm | 420 |

| Dimension (AxBxC), mm | 770x640x1700 |

| Equipped with touch screen (A1), mm | 1350 |

| Frame stiffness, kN/mm | 180 |

| Weight, kg | 370 (single space), 420 (dual space) |

| Power supply | 1.5 kW |

| Voltage | 1-phase AC220V±10%, 50Hz/60Hz |

| Common parameters | |

|---|---|

| Accuracy | Class 0.5 |

| Force range | 500N–10kN 0.2%–100%FS 10N–250N 0.4%–100%FS |

| Calibration standard | GB/T 16825.1, or ISO 7500, class 0.5, ASTM E4 |

| Speed accuracy | ±0.2% of set speed |

| Position accuracy | ±0.2% of set position |

| Force resolution | 1/600000FS |

| Extension resolution | 1/600000FS |

| Strain accuracy | Better than GB/T 228, ISO 6892-1, ASTM E8, ASTM E21 |

| Safety protection | Overload protection (103% of rated force), position limit, over-voltage protection |

| Single channel data sampling frequency | 1200Hz |

| Control frequency | 1200Hz |

| Conditions | |

| Working temperature | +5 ~ +40°C |

| Storage temperature | −25 ~ +55°C |

| Humidity | 20°C, +10% ~ 90%, non-condensing |

| Highest altitude | 2000 meters |

| Motor | AC servo motor |

| Ball screw | Pre-loaded |

| Position measurement | Optical encoder |

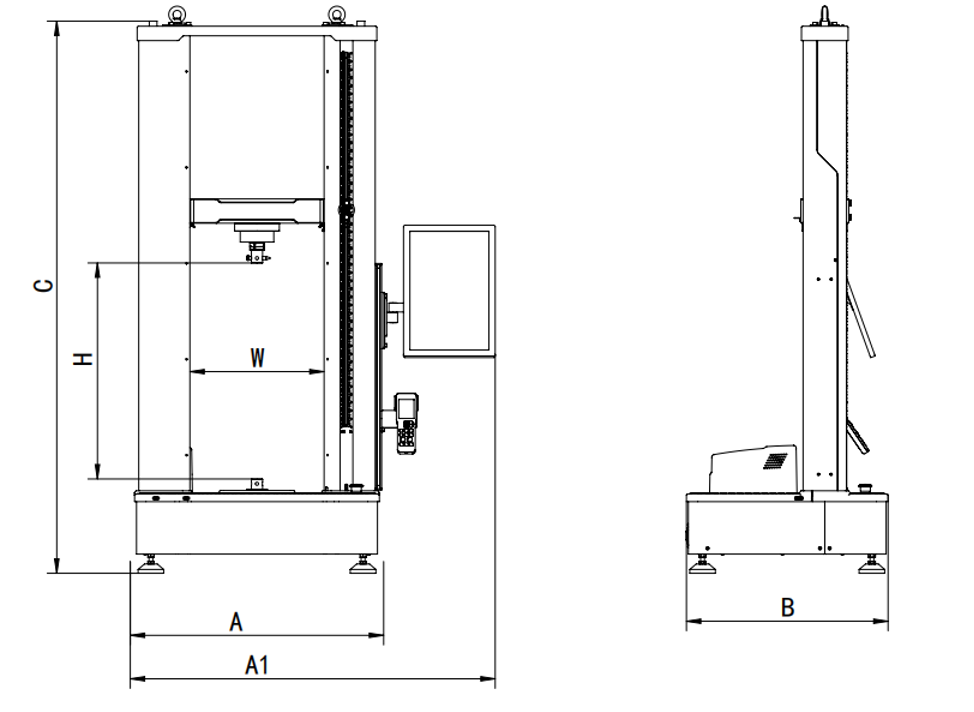

Dimensions

| Frame | Dimension (mm) | Crosshead travel (mm) | Test width (mm) | Equipped with touch screen (mm) |

|---|---|---|---|---|

| A×B×C | H | W | A1 | |

| Standard (single space) | 770×640×1700 | 1000 | 420 | 1350 |

| Standard (dual space) | 770×640×1760 | 900 | ||

| Extend 300mm (single space) | 770×640×2000 | 1300 | ||

| Extend 300mm (dual space) | 770×640×2060 | 1200 | ||

| Extend 600mm (single space) | 770×640×2300 | 1600 | ||

| Extend 600mm (dual space) | 770×640×2360 | 1500 |

FAQs

Dynamometers serve various purposes, including the verification of testing equipment used to gauge the resistance of materials and goods. Standardized requirements must be met by these machines, especially in relation to the intensity of applied forces. International standards ISO 7500-1 and ISO 7500-2 address metallic materials.

The force measurement system for uniaxial static testing machines in tension/compression of metallic materials is verified and calibrated according to ISO 7500-1. These checks are made using tension and/or compression load cells that have been calibrated and categorized under ISO 376 standards.

The verification of force exerted by uniaxial creep testing equipment under the tension of metallic materials is covered in SO 7500-2. Tension load cells that have been previously calibrated and categorized in accordance with ISO 376 Standard are used to carry out this verification.

Even though the ISO 7500-1 and 2 Standards only apply to metallic materials, they are frequently applied to other materials when a specific suitable standard has not yet been published.

NextGen’s Universal Tensile Testing Machine – Class C complies with ISO 7500, Class 1 & Class 2 calibration standards.

Click here to request a personal quote from our team.

Metals are used for various needs in many different production sectors as well as in homes in the form of household items. The physical and mechanical qualities of metals, such as ductility, hardness, malleability, and strength, make them very useful. Metals are frequently used for applications with a high demand for durable and robust materials. Everyone knows that metals are the hardest materials and are frequently utilized to withstand common impacts, wear, and scratches.

Manufacturers must ensure that the raw materials they are using for production are of the highest calibre. Using highly standardized and superior testing equipment, the properties of the metals can be ascertained. Numerous tests are carried out to ascertain the metals' quality, including corrosion, corrosion resistance, and hardness testing. These tests provide incredibly accurate results and make determining quality simply.

NextGen’s EML Class C Universal Testing Machine has the following test force capacity parametres: 20kN, 30KN, 50kN.

Click here to request a personal quote from our team.

Metals are used most commonly in important applications, including aerospace, aviation, weight lifting equipment, electrical cables, household goods, and many others due to their unique combination of qualities. These businesses have no tolerance for errors or flaws because these applications are so crucial. Therefore, it is essential to assess the metals' quality before using them for various production-related tasks. Metals are tested to make sure they can withstand difficult working conditions without difficulty.

If a metallic material satisfies the specifications of a desired application, its mechanical qualities must be tested. The most often measured properties when anything is being tested are the elastic limit, yield strength, tensile strength, and compressive strength. Metals are also tested to determine their rigidity, shear strength, bend strength, flexure strength, fatigue strength, and time-dependent behaviours like creep and stress relaxation. The behaviour that a metal material might be anticipated to display during loading and over the course of its application is accurately represented by these numbers.

NextGen’s EML Class C Universal Testing Machine load frame configuration parameters are: Dual column, Floor Model, Electromechanical.

Click here to request a personal quote from our team.

The methods used to test other materials, including plastics or composites, are frequently quite similar to those used to test metals. Metals are subjected to flexure, bend, shear, and torsion testing, although the tension, compression, and fatigue tests are the most frequently used. The metal sample is subjected to a load along one of its axes during tension and compression testing, pulling the material apart or pushing it together. Although they can be stopped at any point, these tests are typically carried out until the sample fails or ruptures.

To pass shear and torsion tests, the sample must undergo opposing loads at each end that act perpendicular to the sample's axis. A torsion test twists the ends of the sample, so it fails in a turning motion, whereas a shear test pulls the ends, so it fails in a sliding motion.

NextGen’s EML Class C Universal Testing Machine Test Space: Single or Dual Testing Zones.

Crosshead travel 45.3" (115cm)

Customizations available.

Test with

16.5" (42cm)

Customizations available.

Click here to request a personal quote from our team.

The EML Class C Series meets the requirements of routine and standardized testing while offering the user outstanding quality at the most competitive price.

NextGen’s EML Class C Universal Testing Machine Features:

- Complete selection of sturdy, compact dual column load frame

- High-speed, low-vibration electromechanical drive

- Precision, pre-loaded ball screws

- Linear motion guides for superior alignment

- Versatile, easy-to-use software with pre-programmed industry standards library (ASTM, ISO, DIN, EN, BS, and more)

- High-resolution, digital closed loop controls (integrated into load frame)

- Automatic limit checking of crosshead position, overload, over temperature, over voltage, etc.

- Complete selection of grips, fixtures, environmental systems and extensometers

- Durable test space protection

Click here to request a personal quote from our team.

Metals must undergo mechanical testing to determine how well they function under rigorous conditions and whether they meet national or international standards.

The guarantee that a metal or alloy will be acceptable for a product's intended application or fits industry criteria is necessary for foundries, fabricators, manufacturers, metal stocks, importers, and welding inspectors.

When necessary, calibration at the same discrete force levels must be performed, first with increasing force levels and subsequently with decreasing force levels, to ascertain the relative reversibility error v. In this situation, a force-proving instrument calibrated for descending forces in line with ISO 376 must be used for the calibration. To calculate the reversibility error, only one series of measurements with decreasing force levels is necessary.

A hardness test evaluates a metal or alloy's resistance to permanent indentation, and the depth or size of the indentation is measured to get a hardness value. We employ the Brinell, Vickers, and Rockwell procedures, among another hardness testing.

NextGen’s EML Class C Universal Testing Machine test force accuracy is ±0.5% of reading.

Click here to request a personal quote from our team.

Calibration under ISO 7500 must be done for all force ranges and force indicators. Where employed, any auxiliary devices that have the potential to interfere with the force-measuring system must undergo verification.

Each force-measuring system on a testing machine should be treated as a distinct testing machine if the equipment includes several force-measuring systems. For double-piston hydraulic machines, the same technique must be performed. With the following exception: employ known masses if the force to be verified is below the lower limit of the smallest capacity force-proving device used in the calibration method. The calibration must be performed using force-proving instruments.

Each force-measuring system on a testing machine should be treated as a distinct testing machine if the equipment includes several force-measuring systems. For double-piston hydraulic machines, the same technique must be performed. With the following exception: employ known masses if the force to be verified is below the lower limit of the smallest capacity force-proving device used in the calibration method. The calibration must be performed using force-proving instruments.

NextGen’s EML Class C Universal Testing Machine complies with ISO 7500 Calibration Standard.

Click here to request a personal quote from our team.

Tensile testing is used to identify flow curves under tensile load and material characteristics. On a universal testing machine, the specimen is drawn to fracture while being formed in quasi-static conditions. A load cell is used to quantify force during the forming process, and a video extensometer is used to measure the change in specimen length without physical touch. From there, it is possible to calculate both the engineering stress-strain diagram and the real stress-strain diagram. Determine typical metrics, including yield strength, tensile strength, and uniform elongation, using the technical stress-strain diagram. As an alternative, measuring local strains using an optical 3D measurement device is possible.

High-frequency pulses are necessary for metal testing because they can deliver a focused beam of energy, but these frequencies are inappropriate for use with heterogeneous materials due to the significant attenuation that these materials experience when the pulses pass through them.

NextGen’s EML Class C Universal Testing Machine force range is 0.4 - 100%FS.

Click here to request a personal quote from our team.

Metal testing specimens can essentially have any shape. Typical shapes include dog bones, dumbbells, rods, bars, cylinders, cubes, bricks, tubes, and dumbbells. The microstructure of test samples composed of metal and those made of other materials differ from one another. Metals can go through procedures that change their microscopic makeup, including heating, quenching, annealing, and others. The metal's properties, such as its strength, hardness, and ductility, are changed specifically by changing the grain size, grain orientation, and dislocations.

NextGen’s EML Class C Universal Testing Machine typical specimens:

- Small components

- Reinforced plastics

- Metals

- Wire

- Composites

- Elastomers

- Wood products

- Textiles

- Biomaterials

- Paper products

- Adhesives

- Foam

- Consumer products

Click here to request a personal quote from our team.

- Both controller software and professional test software are operating independently. Controller software processes calibration and can define transducer information such as connection number definition and calibration data.

- Windows 7 to latest OS version compatible, 32bit and 64bit

- It is simple to define software access for various levels of operators, such as a lab manager, an operator, and others, using user authorization management.

- Real-time display of transducer value, such as crosshead, load cell, and extensometer

- Displaying many graphs, switching between them in real time, and plotting force, location, extensometer, stress, strain, time, etc.

- To assist you rapidly and effectively meet the criteria of international test standards like ASTM, ISO, DIN, EN, BS, and more, pre-packaged test methods are available.

- Simple programming of testing standards and testing procedures using intuitive expression

- Testing report customization

- Young's modulus, proof stress, yield stress, stress strain, tensile strength, elongation at break, compressive strength, and bending strength are examples of common test results that analysis can produce.

Click here to request a personal quote from our team.

The two column Class C testing systems are appropriate for testing applications requiring load ranges between 20kN and 50kN, such as tension, compression, flexure, and other tests. They are typically used for quality control and production testing.

Impact testing is used to determine a material's ability to absorb energy when forcibly shattered. Impact testing, which gauges the metal's "toughness," sometimes employs the Charpy or Izod techniques.

The behaviour of the metal when it is being pulled is studied via tensile testing, also known as tension testing. Yield strength, proof strength, and ultimate tensile strength can all be determined using tensile testing. A variety of testing equipment from Intertek can test up to 1000kN.

Hardness testing evaluates how well a metal or alloy resists permanent indentation, and the size or depth of the indentation is quantified to get a hardness value. There are various hardness tests, and we employ the Brinell, Vickers, and Rockwell techniques.

NextGen’s EML Class C Universal Testing Machine Force Resolution is 1/500,000FS.

Click here to request a personal quote from our team.

NextGen’s 500 digital controller offers high speed and closed-loop control of load, displacement and extension.

- High dependability, four-layer PCB architecture, and resistance

- Connector with locking capability, constructed for sturdiness and longevity, with a clean, sensible interface that is simple to plug and unplug.

- 6 channel 24-bit AD measurement channel

- Up to 1200Hz sampling frequency

- Up to 1200Hz closed loop control frequency

- 20-bit resolution digital input

- With a maximum signal collection frequency of 4MHZ, three channels of high-speed digital acquisition are employed to gather orthogonal pulse signals from devices such as photoelectric encoders and grating rulers.

- Higher sampling frequencies are supported, and the transmission rate is significantly boosted to support the Ethernet/USB interface mode. To implement a sophisticated TCP/IP protocol cluster, the Ethernet interface uses a specialized high-performance Ethernet interface chip and hardware logic gate circuit, which offers several benefits like high reliability and good security.

- Transducer self-identification system (TEDS) functionality, online software configuration of interface features, and more logical system architecture

- It has three closed-loop control functions (force, extension, and displacement) that enable all-digital three closed loop force, extension, and displacement control. Each control loop can smoothly transition between various modes and control rings by automatically switching between them.

- Perfect limit protection, overload protection, emergency stop and other safety protection functions

Click here to request a personal quote from our team.

Strong advice Self-lubricating columns improve lateral stiffness and guarantee linear crosshead motion. This leads to accurate crosshead alignment, which lowers measurement data variability and improves overall accuracy.

Heavy strength bearings and pre-loaded ball screws ensure extended life, zero backlashes, and linear low force and through zero performance. As a result, measurements are precise and reproducible, accurately reflecting specimen features as opposed to load frame flaws.

Lead screw covers that are fully shielded have a longer lifespan and higher operator protection.

Column covers are made of lightweight aluminum with chamfered corners to make access to the test area easier. T-slots are pre-installed for quick, easy installation of testing accessories and placement.

Click here to request a personal quote from our team.

The EML Class C Series provides the user with outstanding quality at the most competitive price and satisfies the needs of standardized and routine testing. For testing applications requiring load ranges between 20kN and 50kN, such as tension, compression, flexure, and other tests, dual-column Class C testing systems are suitable. Normally, they are involved in production testing and quality control.

A wide variety of accessories are available to suit test needs in practically every application and industry, including textiles, metals, composites, elastomers, components, biomedical, automotive, and aerospace.

- Tension grip

- Peel/tear fixture

- Compression fixture

- Flexure fixture

- Film COF test fixture

- S type load cells: 10N-5kN

- Long travel extensometer

- Clip-on extensometer

- Environmental chamber

- T-slot table

- Others

Click here to request a personal quote from our team.

Here are the technical specifications table of NG-EML Class C:

|

Model |

NG-EML Class C |

|

Capacity |

20kN – 50kN |

|

Calibration standard |

ISO 7500, Class 1 / Class 0.5 |

|

Force range |

0.4 - 100%FS |

|

Force accuracy |

±0.5% of reading |

|

Force resolution |

1/500,000FS |

|

Position accuracy |

±0.50% of reading |

|

Position resolution |

0.06μm |

|

Crosshead speed |

0.001 ~ 500mm/min |

|

Crosshead speed accuracy |

±0.5% of set speed |

|

Crosshead travel |

45.3" (115cm) |

|

Test width |

16.5" (42cm) |

|

Dimension |

30.5 × 26 × 68.5" |

|

Power requirements |

220V±10% AC, 50/60Hz, 850W |

|

Weight |

881lbs / 400kg |

Click here to request a personal quote from our team.

Tensile is a material's capacity to be stretched or dragged out to the point where cracks or strains become visible. Tensile strength, which refers to the resistance to breaking under impacts or stresses, is a different, more popular phrase.

You must ensure that any metal components you use in your products or projects are secure, trustworthy, and up to strict regulatory standards. Our metal testing machines assist you in identifying and evaluating the qualities of your metal components to establish their integrity, dependability, and safety.

Tensile testing or tensile strength tests are crucial in the manufacturing of sheet metal because they can be used to determine how reproducible a given product will be. This is particularly helpful for the mass manufacture of metal products because each item needs to have roughly the same tensile strength readings. Even if a single sheet of a metal coil is manufactured in the same facility, material qualities will still vary, affecting the part's quality and scrap rate.

NextGen’s EML Class C Universal Testing Machine position accuracy is ±0.50% of reading.

Click here to request a personal quote from our team.

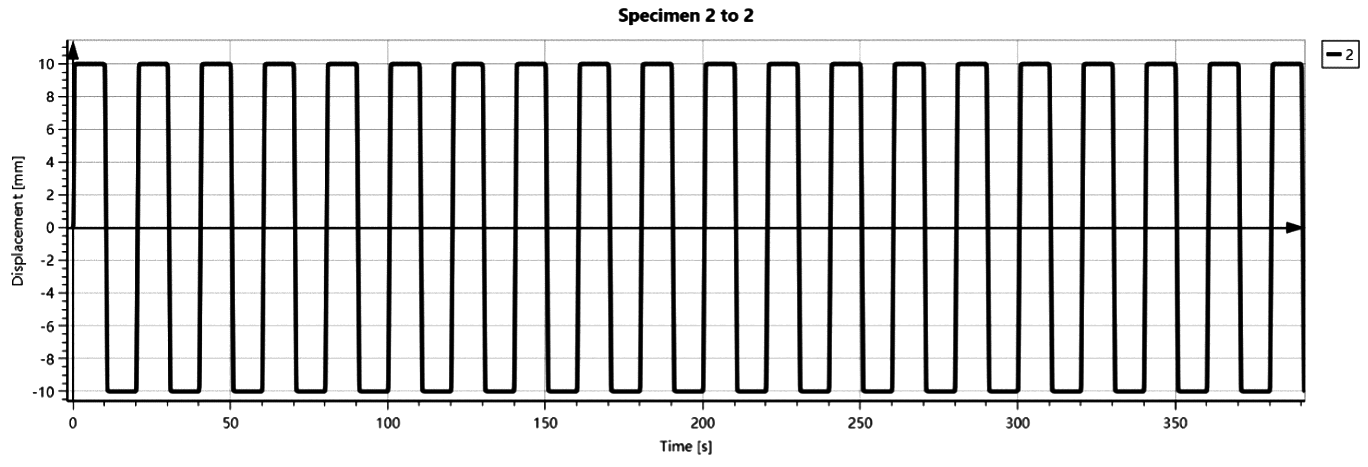

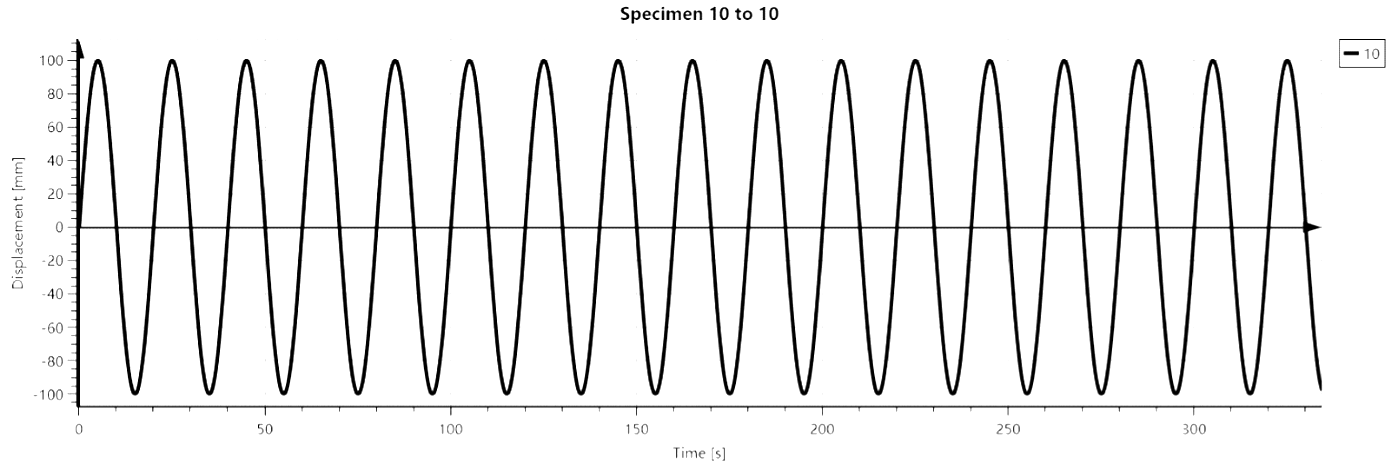

In contrast to tensile strength tests, where a specimen is put through one full execution, fatigue tests are conducted with a cyclical load that continuously increases the material's stress. To measure tension or compression this test is carried out at a specific frequency or using alternating load testing.

In fatigue testing, material failure occurs when the damage appears on the specimen after being repeatedly stressed. Understanding why metal components that have been in service for a while may suddenly fail requires this kind of testing. Frequently, this failure happens not as a result of a single overload but rather a prolonged pattern of recurrent stress.

High-cycle testing and low-cycle testing are two further subcategories of fatigue testing methodologies. The high cycle fatigue strength and the finite life fatigue strength are calculated for the high cycle test. Examples of these two types in usage are turbine blades and stationary power generators that experience disc strain from continuous use.

NextGen’s EML Class C Universal Testing Machine position resolution is: 0.06μm.

Click here to request a personal quote from our team.

The majority of 1.5-millimetre-thick sheets of mild steel or low-carbon steel will most likely have a Rockwell B hardness rating. Simply said, the Rockwell hardness scale measures a material's resistance to permanent deformation and penetration by other materials. This is typically done for some forms of steel, such as tool and cutting steel designed to be more durable than the norm.

As previously established, mild steel has a Rockwell B hardness rating that ranges from the mid-to high-seventies. The indenter, anvil, and specimen are the three primary parts of this kind of testing.

A reference depth is created for the measurement by pressing the minor load against the specimen. Around 10 kg/cm2 of force is applied for Rockwell B.

An additional load is forced onto the sheet metal's surface in order to obtain deeper penetration. It is taken away, then a light load is put back on.

By calculating the difference between the depth of the material and the reference depth, the Rockwell B hardness rating is determined.

NextGen’s EML Class C Universal Testing Machine crosshead speed is 0.001 ~ 500mm/min.

Click here to request a personal quote from our team.

The tensile test is frequently used as an acceptance test for the specification of materials as well as to provide fundamental design information on the strength of materials. It is done to figure out the elastic modulus, % elongation, yield strength, and ultimate tensile strength. A specimen is put through a test in which a continuously rising uniaxial tensile force is applied to it while at the same time being watched for elongation. The typical stress-strain curves for two different alloys are shown in the images below. Only by using an extensometer attached to the test specimen when the load is applied will accurate stress-strain curves be produced.

The Rockwell test uses the penetrator's depth of movement under a constant load to determine the hardness of a material. The deformation's elastic component reduces the entire movement. In contrast, the load is divided by the area of the indentation made while pushing the matching indenters into the metal in the Brinell and Vickers/Knoop scales. As a result, while the Brinell and Vickers/Knoop need optical measurements of the diameters or diagonals, the Rockwell number can be read directly from a gauge that is a component of the tester.

NextGen’s EML Class C Universal Testing Machine crosshead speed accuracy is: ±0.5% of set speed.

Click here to request a personal quote from our team.

There are various test methods available when it comes to metal testing. All of the machines have to use specific load cells in order to deliver the most accurate results. While it might be assumed that all indentation hardness tests have the same objective, each has distinct advantages, with some being more suited to particular types of materials and size and shape parts than the others. Forgings and cast irons are the main applications for Brinell. Because of its broad test area, it is possible to acquire an average representative value in a material that has features or phases with wildly dissimilar properties (i.e. graphite, matrix, carbides, etc.). Vickers, Knoop, and Rockwell are utilized in nearly all other applications as well as for case depth calculations and very small, thin parts.

NG EML Class C Universal Testing Machine Load Cell:

- High precision USA made Interface load cell offers high stiffness, high stability, and high linearity

- Over load protection, lateral loading protection

- Bi direction allows tension and compression test

- Self-recognition (TEDS) function

- Regular self-calibration

- Working temperature: 55℃-90℃

Click here to request a personal quote from our team.

The supplied load cells can measure from 0.2%~100% of their specific load cell capacity.

For example, when using a 50kN load cell one can measure 100N~50kN force without a need for an additional (smaller) load cell.

If the operator requires to measure readings lower than 100N, simply purchase an additional, smaller load cell (E.g 10kN) which gets installed under the master load cell (50kN), so the measurement range can extend to 20N-50kN.

NOTE:

Since the force resolution is 1/500000FS, for 10Kn load cell, the resolution is 10*1/500000=0.00002KN.

Contact our qualified consultants or submit quote today to learn more.

Yes, the Class C 50kN tensile testers can be purchased with a furnace add-on. The furnace will allow to bring the temperatures of the tested tensile specimen up to your desired temperature ranged, depending on your temperature requirements.

NextGen offers a full scope of furnaces and cooling chamber to meet your tensile testing needs. Contact us to learn more today.

Related Products

NG-EML Single Column Bench Top - Universal Testing Machine (50N-5kN)

The single column Class A testing systems are suited for tension, compression, flexure and other testing applications where specimens require less than 5 kN (1124.04 lbf) and where lab space is limited. The system is equipped with 1/500,000 Force Resolution the system is capable to providing +/-1% down to 0.2N.

NG-EML Dual Column Bench Top - Universal Testing Machine (10N-20kN)

The dual column Class B testing systems are suited for tension, compression, flexure and other testing applications where load range requirements are between 10N to 20kN (2.24 - 4496.18 lbf). This bench top model offer a user-friendly compact solution for your universal testing needs.

NG-EML Floor Standing - Universal Testing Machine (50kN-600kN)

The NG-EML Floor Standing - Universal Testing (Machine 50kN-600kN) are suited for tension, compression, flexure and other testing applications where load range requirements are between 50kN to 600kN (11240.44 - 134885.36 lbf). This heavy duty system offers ±0.5% reading accuracy as well as position accuracy down to 0.021μm.

GenTest Data Acquisition Software - Advanced Universal Testing Machine Software

Upgrade to GenTest, the latest data acquisition software for universal testing machines. Ensure precise, repeatable material testing with an intuitive interface, powerful analysis tools, and full compliance with ASTM, ISO, DIN, and more.