Metal Testing Equipment

NG-EML Test Pilot Series - TestPilot Software

TestPilot is designed to enhance your ability to perform accurate and repeatable mechanical testing of materials, components and finished goods across a full spectrum of applications. It provides the simplicity and ease-of-operation needed for quick and efficient quality assurance and quality control testing, the flexibility to adapt readily to changing requirements, and the sophistication to address unique or complex demands. The software's intuitive operator interface, powerful analysis and reporting, and growing host of test methods make it an excellent foundation for establishing and sustaining a truly global standardized testing methodology. TestPilot software is fully compatible with all NextGen electromechanical universal testing machine NG-ETM Series. This software features a large, growing host of pre-packaged test methods to help you quickly and efficiently meet the requirements of global test standards such as ASTM, ISO, DIN, EN, BS, and more. Selected by an operator at runtime, these methods are crafted to meet the specific test flow, analysis and reporting requirements of industry standards across a range of specimen and test types. Pre-packaged test methods are available in a wide selection of bundled sets, including: Polymers & Plastics, Metals, Construction Materials, Biomedical Products, paper Products, adhesives, foam, textiles and more.

Features

- Versatile, easy-to-use TestPilot software with a large and growing library of standards-compliant test methods (ASTM, ISO, DIN, EN, BS, and more)

- Modular design permits easy upgrading

- Multiple graphs on the same screen & report to observe multiple events at the same time: real time display curves, like displacement-load, stress-strain, displacement-time, load-times, and others.

- Powerful analysis function can calculate typical value and display on the curve, like Fm, ReL, ReH, Rp.

- Measurement unit: Users can select SI, or others, like N, kN, Kgf, lbf, Mpa, and so on, user can define the unit by themselves using formula.

- Customizable report format with full flexibility of adding & removing items in terms of layout, content, graphing to suite the exact test requirement, like company information, statistics, and etc. Test report can export to Excel or Word.

Related Products

NG-EML Single Column Bench Top - Universal Testing Machine (50N-5kN)

The single column Class A testing systems are suited for tension, compression, flexure and other testing applications where specimens require less than 5 kN and where lab space is limited. The system is equipped with 1/500,000 Force Resolution the system is capable to providing +/-1% down to 0.2N.

NG-EML Dual Column Bench Top - Universal Testing Machine (10N-20kN)

The dual column Class B testing systems are suited for tension, compression, flexure and other testing applications where load range requirements are between 10N to 20kN. This bench top model offer a user-friendly compact solution for your universal testing needs.

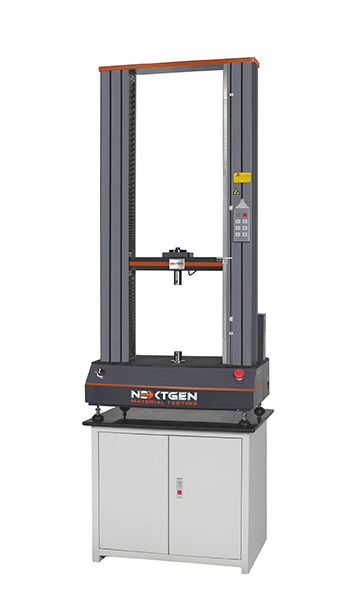

NG-EML - Dual Column Bench Top and Floor Standing - Universal Testing Machine (20kN-50kN)

The dual column Class C testing systems are suited for tension, compression, flexure and other testing applications where load range requirements are between 20kN to 50kN. The advanced load cell system offers ±0.5% accuracy down to 0.4% of capacity.

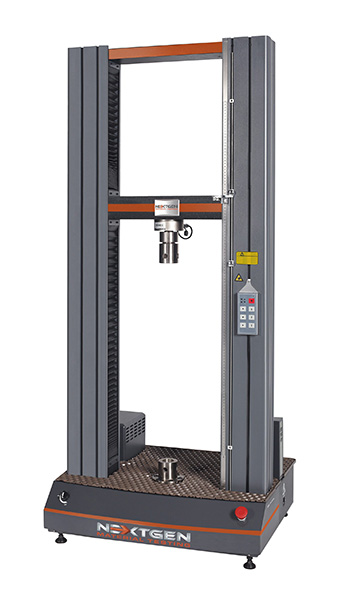

NG-EML Floor Standing - Universal Testing Machine (50kN-600kN)

The NG-EML Floor Standing - Universal Testing Machine (50kN-600kN) are suited for tension, compression, flexure and other testing applications where load range requirements are between 50kN to 600kN. This heavy duty system offers ±0.5% reading accuracy as well as position accuracy down to 0.021μm.