Stronger

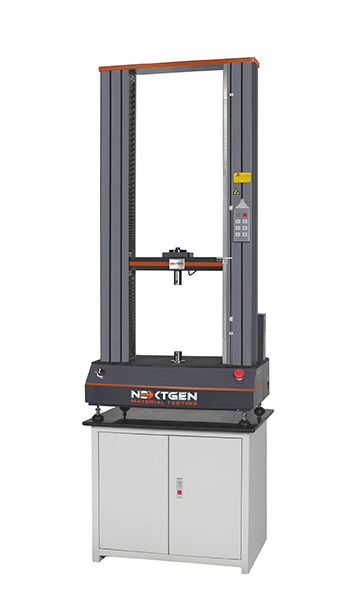

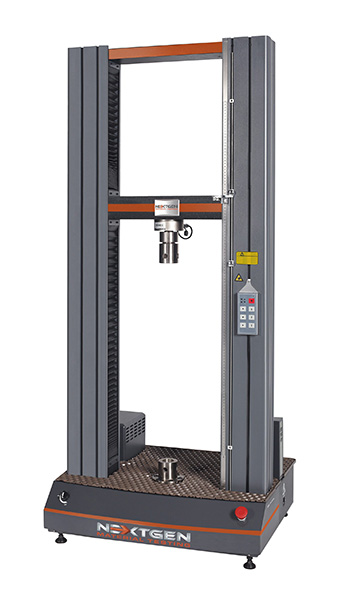

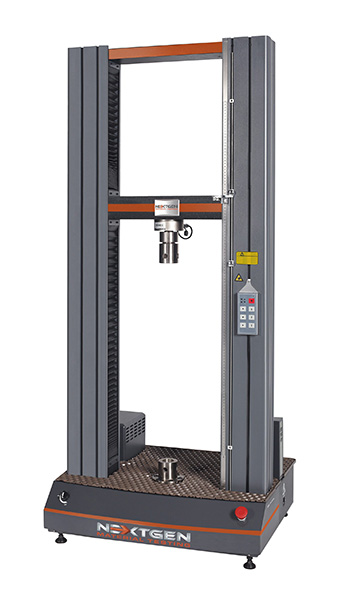

Engineered for maximum stiffness and durability, the NG-EML frames and crossheads are optimized using finite element analysis. Key components (ball screws, nuts, bearings, sensors) are precision-fitted with preload designs to eliminate clearances, dramatically increasing overall rigidity. This guarantees excellent accuracy even when testing cutting-edge materials like ultra-high-strength metals, rubbers, plastics, and thin films. Single-column models include an additional linear guide, and dual-column models use extra guide pillars, further boosting structural stiffness.

- High Measurement Accuracy: Ensures precise determination of material properties such as elastic modulus, yield strength, and tensile strength.

- Superior Stability & Repeatability: Delivers consistent, reliable results with minimal variability – crucial for aerospace, automotive, and research applications.

- Wide Material Versatility: Capable of testing a broad range of materials, from soft elastomers and plastics to high-strength alloys and composites, all on one machine.

- Low Vibration: The robust frame design minimizes vibrations (especially after specimen breakage), improving result fidelity and extending machine life.

Faster

The NG-EML series employs a servo direct-drive transmission with a high-rigidity synchronous belt in place of a traditional gear reducer. This modern drive system significantly improves speed, responsiveness, and efficiency:

- Higher Test & Return Speeds: Ultra-fast crosshead movement (both under load and at return) shortens test cycles and boosts throughput.

- Faster Acceleration: The responsive servo drive enables rapid adjustments to test conditions, meeting demanding high-speed testing requirements.

- Stability & Reliability: A direct belt drive minimizes mechanical backlash and vibration, ensuring smooth operation and highly consistent, accurate data acquisition.

- Improved Precision: Eliminating the gearbox removes energy losses and mechanical play, resulting in finer control and more reliable data – especially important for precise material research on metals, composites, polymers, etc.

- Energy Efficiency: The high-efficiency servo drive reduces power consumption compared to traditional transmissions. This energy-saving design is ideal for high-strength and high-frequency testing (e.g. manufacturing QC or fatigue tests), delivering performance while conserving power.

- Advanced Applications Ready: The optimized drive and control system support the testing of emerging advanced materials (e.g. ultra-high-strength alloys, flexible electronics, biodegradable plastics). This provides a robust foundation for R&D and quality assurance in modern industries. The upgraded system not only enhances core performance but also aligns with global trends in energy efficiency and intelligent manufacturing, making it a future-ready solution for material testing labs.

Safer

Operator safety and equipment protection are built into the NG-EML series:

- Collision Mitigation: A sensitive load monitoring function detects rapid force changes and automatically halts the crosshead if a preset force threshold is exceeded. This prevents damage to the load cell and specimens in the event of an unexpected collision or break.

- Protective Enclosure: An optional fully enclosed transparent safety shield with an interlock is available, providing 360° protection. If the door is opened, the system will automatically stop for the operator’s safety.

- Overload Prevention: The software allows users to set overload limits (e.g. 103% of the rated load cell capacity) so that the machine will stop before exceeding safe load, protecting the load cell from overloading.

- Mechanical Limits: Physical limit switches are installed to prevent over-travel of the crosshead, adding an extra layer of safety and equipment protection.

Smarter

Intelligent visual indicators and feedback make the NG-EML series “smarter” and more user-friendly:

- Status Indication Lights: Each machine features a set of four primary indicator lights compliant with IEC 60073 color standards. Different machine states and modes are signaled via distinct colors, giving operators immediate visual feedback of the machine status at a glance (e.g. ready, running, paused, fault condition).

Simpler

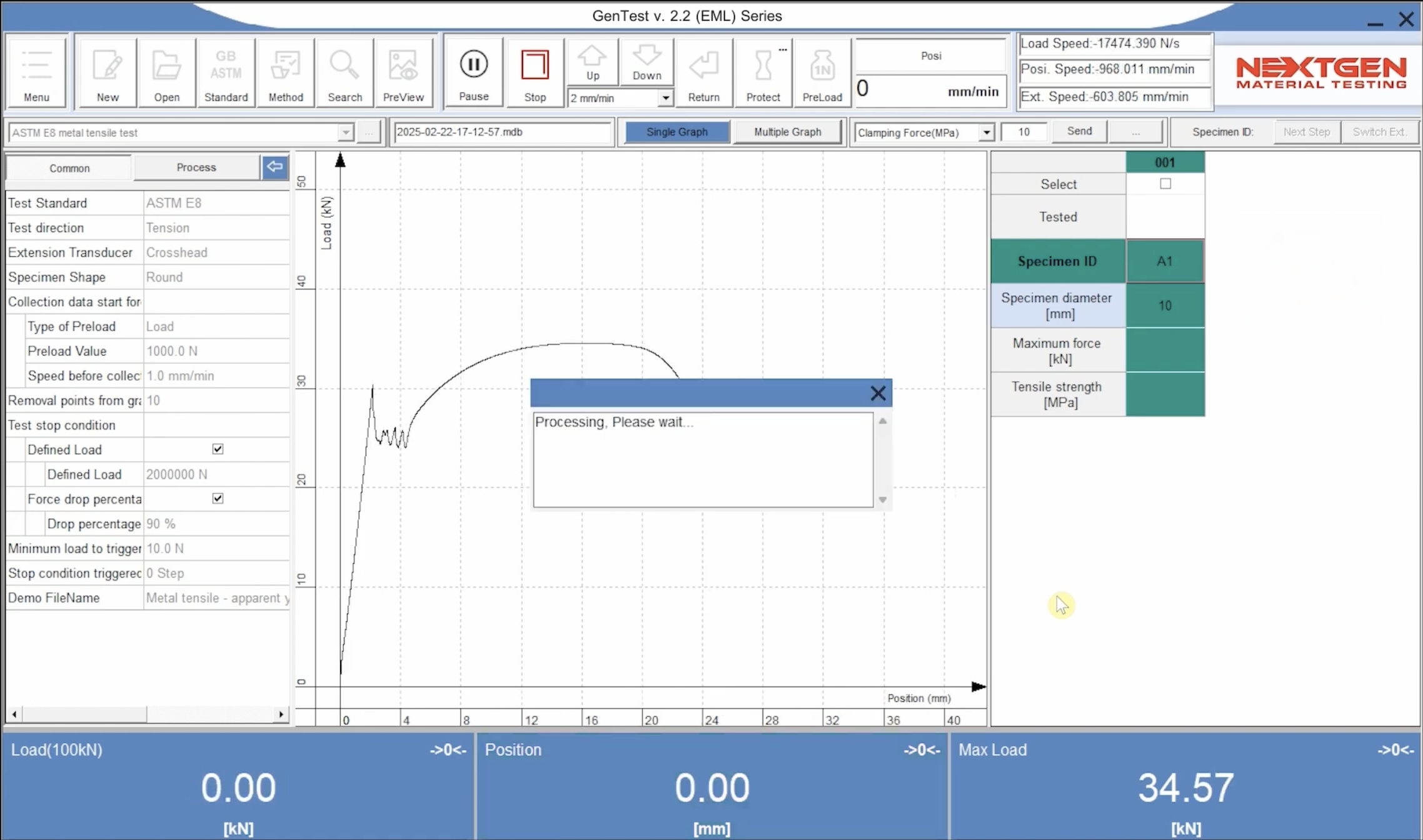

Ease of use is a core design goal. The series comes with TestPilot universal testing software, which has an intuitive, icon-driven interface that simplifies operator training and test setup. This smart design improves efficiency and minimizes errors:

- Quick Test Mode: Start a basic test with minimal setup – simply use the crosshead controls and get automatic calculations of peak force and displacement. Ideal for quick checks and routine tests.

- Pre-Loaded Standard Methods: A large library of pre-configured test methods for the most common ASTM, ISO, EN (and GB/T) standards is included. Each method is tailored to specific specimen types and compatible accessories, so users can run standard-compliant tests without extensive programming.

- Guided Test Process: The software’s step-by-step workflow makes configuring a complete test sequence straightforward and error-free. Even complex test procedures can be set up by following the guided prompts, reducing the chance of mistakes.

- Integrated Touchscreen Control: An optional integrated touch-screen panel PC running the TestPilot software can be mounted on the machine. This allows operators to control the machine and monitor tests directly on a built-in display, streamlining the operation and eliminating the need to move between a separate PC and the machine.

Easier

Maintenance and serviceability have been improved to make the system easier to use over the long term. The controller module is designed for quick access – it can be easily pulled out for maintenance, greatly improving service efficiency. An improved enclosure and cover design make all components more accessible, simplifying repairs and routine checks.

In addition, the machine’s fundamental components are engineered for user convenience and performance:

- Robust Frame Design: Dual-column frames feature rigid guidance columns with self-lubricating bearings to increase lateral stiffness and ensure perfectly linear crosshead travel. This precise alignment reduces any off-axis loading and improves measurement accuracy. The drive uses a high-speed, low-vibration synchronous belt, which is maintenance-free and provides smooth motion. Crosshead position is tracked by a high-resolution photoelectric encoder built into the servo motor for accurate and repeatable positioning.

- High-Performance Load Cell: Each system is equipped with a high-precision load cell offering excellent stiffness, stability, and linearity. The load cell supports both tension and compression testing (bi-directional) and includes overload and lateral load protection to safeguard it during extreme tests. A built-in TEDS chip (Transducer Electronic Data Sheet) enables automatic sensor recognition and calibration, making setup quicker and eliminating configuration errors. The load cell also performs regular self-calibration to maintain accuracy over time. It operates over a wide temperature range (-55 °C to 90 °C) to accommodate various testing environments.

- Advanced Controller: The controller uses an improved closed-loop control algorithm coupled with the upgraded transmission system to achieve ultra-fast response times and exceptional control accuracy under all test conditions. This allows precise speed control and smooth transitions when switching between different control modes (load control, displacement control, strain control), ensuring stable testing even during complex test sequences (for example, tests that require a switch from load control to strain control at yield point). The system can maintain extremely low strain rates (as slow as 0.00007 s⁻¹) for specialized tests such as high-temperature tensile creep. Additionally, the controller supports advanced loading profiles including custom waveform generation (e.g. sinusoidal or trapezoidal cyclic loading for fatigue and dynamic tests).

Advanced Controller & Data Acquisition Features: The NG-EML controller electronics include high-end features to improve data handling and integration:

- Auto Sensor Recognition (TEDS): Plug-and-play transducer recognition allows the system to automatically identify connected load cells or extensometers and load their calibration data. (Interface parameters can also be configured via software for flexibility.)

- Analog Signal Outputs: Optional BNC analog output ports are available, capable of outputting any two selected transducer signals (±10 V) to an external data acquisition system or oscilloscope for synchronous monitoring.

- High-Speed Communication: Both Ethernet and USB communication interfaces are supported, providing high data transfer rates to accommodate fast data sampling. The Ethernet interface uses a specialized high-performance chipset and hardware logic to efficiently handle TCP/IP protocols with high reliability and security.

- Robust Electronics Design: The controller’s internal electronics are built on a four-layer PCB for superior noise immunity and reliability. All connectors have a locking mechanism, ensuring cables remain securely attached and do not unplug during testing – a durable design for long-term use.

- High Resolution & Sampling Rate: The system features 6 channels of 24-bit A/D conversion for measurement inputs, delivering extremely high resolution on force, strain, and other sensors. It supports data sampling rates up to 1200 Hz per channel and a closed-loop control frequency up to 1200 Hz, enabling precise control even during rapid events. Digital inputs (for encoder or other digital sensors) have 20-bit resolution. Additionally, 3 high-speed digital channels are dedicated for incremental devices (e.g. optical encoders or grating rulers) with input frequencies up to 4 MHz, ensuring accurate capture of high-speed or high-frequency signals.

Handset

Each NG-EML machine includes a Handset V3.0 remote controller for convenient local operation. This ergonomic handset features a 3.5-inch color touch screen and tactile silicone buttons, providing a comfortable grip and intuitive controls. A precision wheel is built in for fine adjustment of the crosshead, enabling extremely small movements or force increments with high accuracy. The handset supports dual-mode communication – it can control the machine directly via a wired connection to the controller, or communicate through the PC software – offering flexible use in various scenarios. A magnetic mount on the handset lets you attach it to the machine frame when not in use, keeping the workspace organized. The handset functionality complements the software, allowing efficient test setup and execution right at the machine.

Handset Key Features:

- 3.5″ touch screen display showing live force, crosshead position, and machine status indicators.

- Precision jog wheel for fine-tuning crosshead movement (enabling very small displacement or force adjustments).

- Buttons for grip control – open/close pneumatic grips (when equipped) directly from the handset.

- Specimen protect function to safely clamp the specimen (automatically limiting force during gripping to prevent sample damage).

- Start/Stop test controls for convenient test initiation or emergency stop without needing to go to the PC.

- Crosshead Up/Down controls for manual positioning.

- “Return to Initial Position” command to send the crosshead back to a preset start position.

- “Set Initial Position” function to remember a defined crosshead position (for example, to mark a gauge length or preload position).

Optional Components and Accessories

To further enhance usability and accommodate different lab needs, the NG-EML series offers several optional components:

- Integrated Touchscreen Panel: A high-definition touchscreen panel PC can be integrated with the machine as an optional control station. This panel comes pre-loaded with TestPilot software and is mounted using an advanced ergonomic arm. It creates a convenient operating “hub” within a 0.5 m radius of the test space (the optimal working envelope), so the operator doesn’t need to move between a separate computer desk and the machine. This integration saves time and improves workflow efficiency.

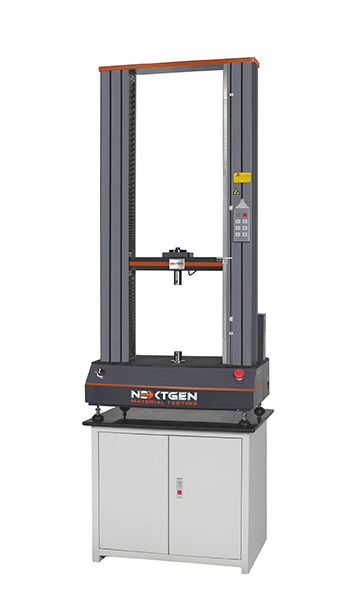

- Ergonomic Workbench: An optional mobile workbench is available for bench-top models. This sturdy bench is designed at an ergonomic height and includes storage space for fixtures and accessories. Its standard dimensions are 793 × 658 × 675 mm (L×D×H). Using the dedicated workbench ensures the machine is securely mounted at a comfortable operating height and keeps the workspace neat and organized.

- Protective Safety Shield: For ultimate safety, a fully enclosed protection shield can be added around the test area. This enclosure has a reinforced aluminum-alloy frame and 5 mm thick impact-resistant polycarbonate viewing windows, providing a clear view of the test. It meets strict mechanical safety standards and includes a safety door interlock switch connected to the system – the software will only allow operation when the door is closed and will automatically stop the test if the door is opened. The safety shield offers comprehensive protection for the operator against debris from specimen failure or other hazards.

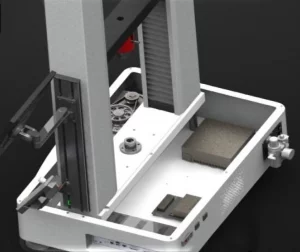

- Pneumatic Grip Controller Module: A compact air pressure control module is available to manage pneumatic grips. This modular unit integrates regulated air pressure supply, flow control, and grip open/close valves in one package that mounts neatly on the machine. It eliminates separate air hoses and regulators, saving space and keeping the lab tidy. The module precisely controls grip pressure to avoid excessive clamping force or specimen slippage during tensile tests, greatly improving test accuracy and reproducibility when using pneumatic grips.

TestPilot Universal Software

Each NG-EML machine is driven by our TestPilot 3.0 universal testing software, which provides a powerful yet user-friendly environment for configuring tests, controlling the machine, and analyzing data. The software features a modern, streamlined interface with a flat design style and optimized typography – giving a clean look and excellent readability. It supports both horizontal and vertical screen orientations and automatically adapts to different monitor resolutions, including touchscreens.

TestPilot comes with an extensive library of pre-installed test methods covering numerous international standards (GB/T, ASTM, ISO, EN, etc.). These methods are organized into application-specific modules (tensile, compression, bending, fatigue, etc.), making it easy to find a relevant standard for your test. Users can also create and save custom test methods and workflows, allowing full flexibility for specialized requirements.

The software includes a modular accessory management system that seamlessly integrates various hardware accessories into the test procedure. You can connect and control devices such as video extensometers, automatic extensometers, strain gauges, temperature chambers (ovens or freezers), humidity chambers, furnaces, pneumatic grip controllers, deflectometers, dial gauges, etc. TestPilot will incorporate their data streams and actions into the test sequence, enabling complex automated test setups through one unified interface.

Key Software Features and Functions:

- Modern UI Design: Simple and flat interface design with a well-organized layout and unified style. The clean design, along with optimized font rendering, provides a high-end look and improves the user’s reading experience.

- Touch-Optimized Layout: Supports adaptive horizontal or vertical screen layouts. For touch-screen use, an on-screen numeric keypad is available to facilitate easy data entry and control via touch.

- Demonstration Mode: Allows users to generate a simulated test file after completing a real test. This enables offline simulation of tests for training or demonstration purposes, without running the machine.

- Post-Test Recalculation: After a test is completed, users can modify certain test parameters (e.g. gauge length, specimen dimensions) and instantly recalculate the results. This eliminates the need to re-run tests just to adjust calculations.

- Built-In Standards Library: A large number of standard test methods are included (covering common ASTM, ISO, EN, GB/T standards), so that tests can be run in compliance with international standards. These methods can be used as-is or as templates for customization.

- Method Management & Search: All test methods and processes are clearly listed. Users can organize methods by category and use keyword filtering to quickly locate the desired method or standard.

- Quick Test Method: For simple tests, a minimalist “Quick Test” configuration is available. This lets users perform a basic tensile or compression test with the fewest possible steps, ideal for quick checks and routine testing.

- Data Export: After a test, raw data can be exported with one click. The software supports exporting data to common formats for further analysis or reporting, making data acquisition convenient.

- Live Test Progress Visualization: As a test runs, each step in the process is highlighted in the software interface. The program displays real-time information such as total elapsed time, the current control mode (e.g. strain control, load control), the set rate, and the number of cycles (if applicable). This gives the operator a clear view of test progress in real time.

- Interactive Graphing: The live graph and plotted results support rich interactions. Users can zoom in/out, pan, and cursor-select regions on the graph via mouse, keyboard, or touch input. Both global and individual axis controls are available. You can add reference lines, enable dual Y-axes for comparing two metrics, switch to logarithmic scales, and even set custom axis boundaries. These tools allow detailed curve analysis and comparison to meet complex data analysis needs.

- Custom Function Keys: The software interface features a configurable function key panel. Depending on the test method, users can set up one-click function buttons (e.g. “zero force”, “extend grips”, etc.) to help control the test efficiently without navigating through menus.

- Comprehensive Test Log: TestPilot automatically records a detailed log of the entire test run. Key step parameters, events, user actions, and any system prompts or warnings are logged with timestamps. This test log allows users to review exactly what happened during the test and is invaluable for troubleshooting or verifying compliance.

- Pre-Test Parameter Check: Before the machine starts loading a specimen, the software runs a thorough validation of all parameters and device statuses. If any setting is out of a reasonable range or any component (like an extensometer or load cell) is not properly tared or configured, the system will alert the user and prevent the test from starting. This prevents wasted samples or machine faults due to incorrect setup.

- Specimen Protection Mechanism: During the specimen mounting and gripping stage, the system can automatically reduce clamping force or release load to avoid damaging the specimen. Users can define custom specimen protection parameters (such as a maximum grip pressure or pre-load) to suit different materials, ensuring delicate samples are not crushed before the test begins.

- Real-Time Data Display: All relevant channels (force, displacement, strain, stress, etc.) can be displayed in real time during the test – up to 12 channels simultaneously. The layout of these data panels is customizable: users can rearrange channels, switch units (SI or Imperial) on the fly, set the number of decimal places, and adjust refresh rates. The currently active control channel is highlighted for clarity. The time channel can be shown in hh:mm:ss format, which is especially useful for long-duration tests. This flexible data display capability allows users to monitor exactly what they need during a test.

- Multi-Function Operation Panel: An on-screen control panel provides one-stop manual control for both the machine and any attached accessories. This panel brings all manual controls (crosshead movement, zeroing, grip control, etc.) into a single interface, so operators can quickly execute manual operations or adjustments without switching contexts.

- Test Templates (Basic & Advanced): To help new users get started, the software includes four basic template wizards that simplify common test process configurations. These templates reduce the setup to only essential inputs. Experienced users can switch to an “expert” template mode, which exposes all configuration options and allows highly customized test sequences, conditional logic, and event actions to be designed from scratch.

- Unit System Flexibility: Both International (Metric) and Imperial unit systems are built in. Users can also customize units for specific needs (for example, using MPa or psi, or non-standard units). The unit system for the entire method and test results can be toggled with one click, instantly converting all values and ensuring convenience for different standards or preferences.

- Expression Builder: A powerful expression generator allows users to create custom formulas and logical expressions using test variables. These expressions can be used for a variety of advanced purposes – defining complex event triggers (e.g. detect when a value drops by X% from its peak), creating user-defined result calculations (such as calculating the Secant Modulus between two strain points), generating virtual measurement channels (combining multiple sensor readings into one), or specifying custom control conditions. This enables automation of sophisticated test logic without the need for external programming.

- Virtual & Extensometer Measurements: All connected accessory channels (e.g. extensometer readings, strain gauge channels) can be logged and used as measurement inputs in the software, contributing to real-time data and graphs. In addition, virtual measurements can be defined via the expression builder, allowing calculated channels (like average strain from two sensors, or stress from load and area inputs) to be recorded in real time. For any measurement that has a meaningful rate (e.g. strain rate or loading rate), the software can provide an associated rate channel if needed.

- Built-in Calculations: Multiple common algorithms for mechanical property calculations are pre-programmed (e.g. finding yield strength by offset method, ultimate tensile strength, Young’s modulus, etc.), with user-adjustable parameters where appropriate. This helps users quickly configure result calculations according to standard definitions without needing to write formulas manually.

- Flexible Rounding Rules: Users can define multiple rounding rules for results (significant figures, decimal places, banker’s rounding, etc.). These rounding settings can be saved and then applied in the result output settings to ensure data is presented exactly as required by specific standards or internal protocols.

- Advanced Test Control Steps: The test sequence editor allows a wide array of step types and control modes. You can program absolute or relative ramps (in load or displacement), hold (dwell) steps, auto-zeroing steps, or even cyclic waveform segments (including sine, square, triangular waves for dynamic loading). The software supports event-driven transitions – for example, you can instruct the test to automatically switch from load control to elongation control when a certain load is reached, or end a hold when a creep rate condition is met. This event-trigger capability, combined with the expression builder, means complex test protocols (like loading to a stress, then holding until strain rate falls below a threshold) can be executed automatically. Additionally, users can set different data acquisition rates for different steps or conditions to ensure no critical data is missed (for instance, using a higher sampling rate during break events).

- Custom Data Acquisition Strategy: You can tailor how data is captured throughout the test. For slow, long-duration holds, a lower sampling frequency can be used to reduce data size, whereas for fast events (like fracture points) the software can temporarily sample at a higher rate. This flexible strategy ensures that sudden changes are recorded in detail without overwhelming data storage for the entire test.

- Voice Prompts: To enhance the user experience, the system supports configurable voice announcements. Voice prompts can be set to play at important moments – for example, a spoken reminder before the test starts (“Please wear eye protection”), an alert to remove an extensometer at the correct time, or a notification when the test is complete. The content of these voice messages is fully customizable.

- Accessory Integration & Control: The software natively integrates with various accessories and allows their actions to be scripted into the test flow. For example, an environmental chamber can be commanded to reach a certain temperature and then signal TestPilot to begin the test. Accessory actions (like turning off a furnace, or activating a strain gauge balance) can be inserted at any point in the test sequence. This tight integration means the entire test (mechanical loading and environmental conditioning) can be automated and synchronized.

- Automatic Grip Pressure Control: When using pneumatic grips, TestPilot can automatically adjust the gripping pressure dynamically during the test. If the measured force exceeds a threshold of the grip capacity, the system will proportionally increase the clamp pressure to prevent the specimen from slipping. This automatic grip control ensures the sample remains secure without manual intervention, even as tensile force increases.

- Custom Report Generation: The software includes a flexible test report generator. Users can design report templates with their company logo, test information, and results in desired formats. Features like adding text watermarks are supported for documentation security. Report templates can be saved as files and reused, streamlining the reporting process. The final test report can include graphs, tables of results, and metadata, and can be exported or printed directly.

- Multi-Language Support: TestPilot supports on-the-fly language switching. With a single click, the entire interface language can be changed (English, Chinese, etc.) without restarting the application. This is extremely useful in multilingual lab environments or for companies with global teams, ensuring a smooth user experience for all operators.

- Data Comparison & Analysis: Powerful data analysis tools allow users to compare results across different tests or even different test methods. You can overlay stress-strain curves from multiple runs, or compare statistical results from multiple batches. This cross-test analysis capability helps in deeply exploring data trends and verifying consistency across tests or materials.

- Maintenance Reminders: The software can be configured with maintenance intervals for the machine (for example, lead screw lubrication, calibration due dates, etc.). Upon startup, it will remind users if a maintenance action is due based on the preset schedule. This helps ensure the equipment is properly maintained, improving longevity and safety.

- User Permissions Management: TestPilot includes role-based access control. Administrators can set up different user roles (e.g. Operator, Engineer, Administrator) with specific permissions. For instance, an Operator may be allowed to run tests but not modify test methods or calibration settings. This prevents accidental or unauthorized changes to critical configurations, ensuring the system remains stable and tests are performed under controlled conditions.

- Comprehensive Safety Interlocks: The software implements numerous safety checks throughout the test process. It provides warnings if a loaded test method has settings that could be unsafe (e.g. an oversized preload or missing limit). Global limits on all measurement channels can be defined (to stop the machine if any reading exceeds a safe value). Pre-loading travel limits and timeouts protect against actuator over-travel or stall conditions. If the safety shield (protective door) is opened during a test, the system can automatically pause or terminate the test. Additionally, features like specimen protection over-travel (stopping if grip separation goes beyond a set range) are in place. Together, these measures offer all-around protection for both the operator and the equipment during testing.